Ultrasonic Cavitation Erosion Behavior of AlCoCrxCuFe High Entropy Alloy Coatings Synthesized by Laser Cladding

Abstract

1. Introduction

2. Materials and Methods

2.1. Coatings Preparation

2.2. Microstructural Characterization

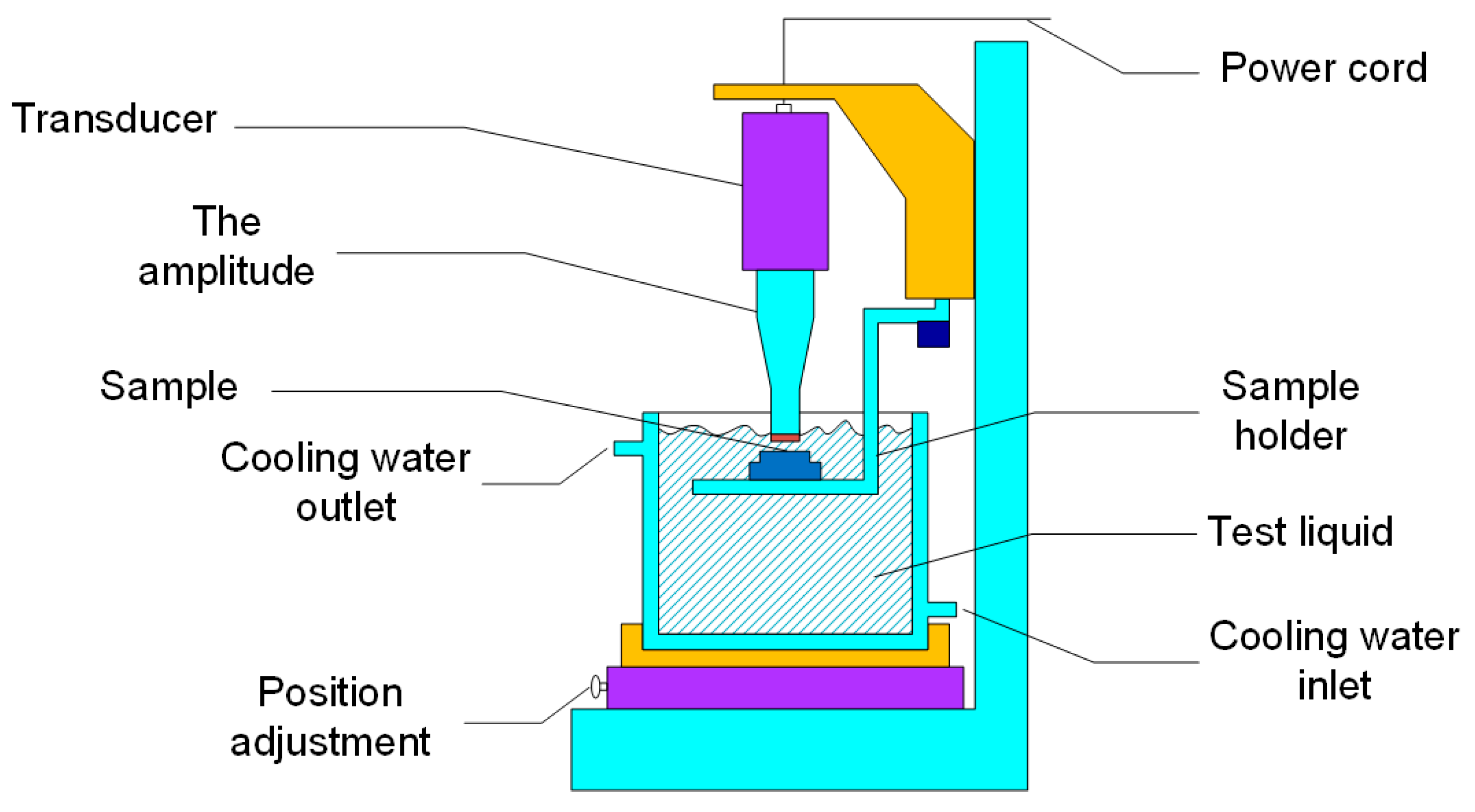

2.3. Cavitation Erosion Test

3. Results

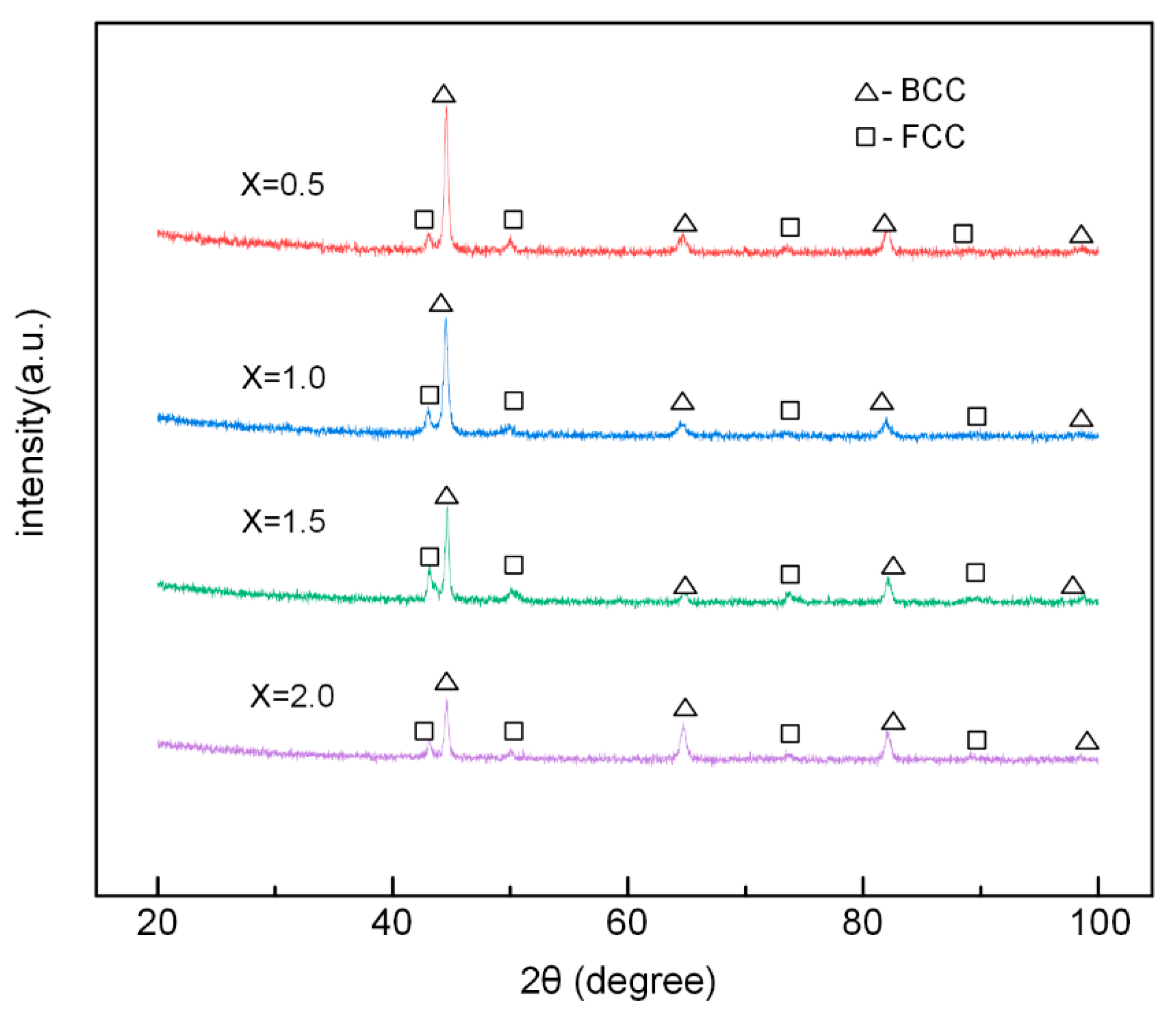

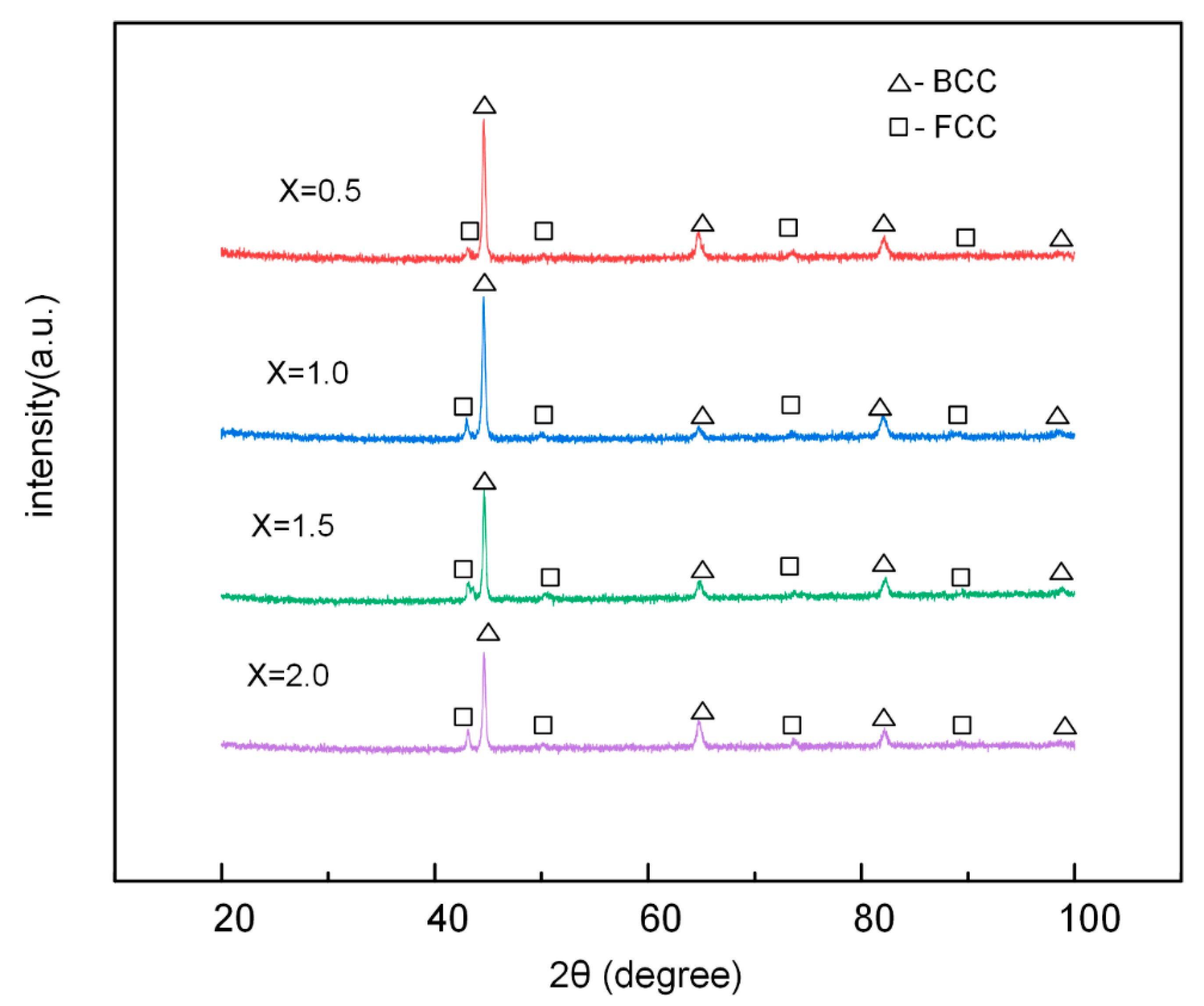

3.1. Phase Formation

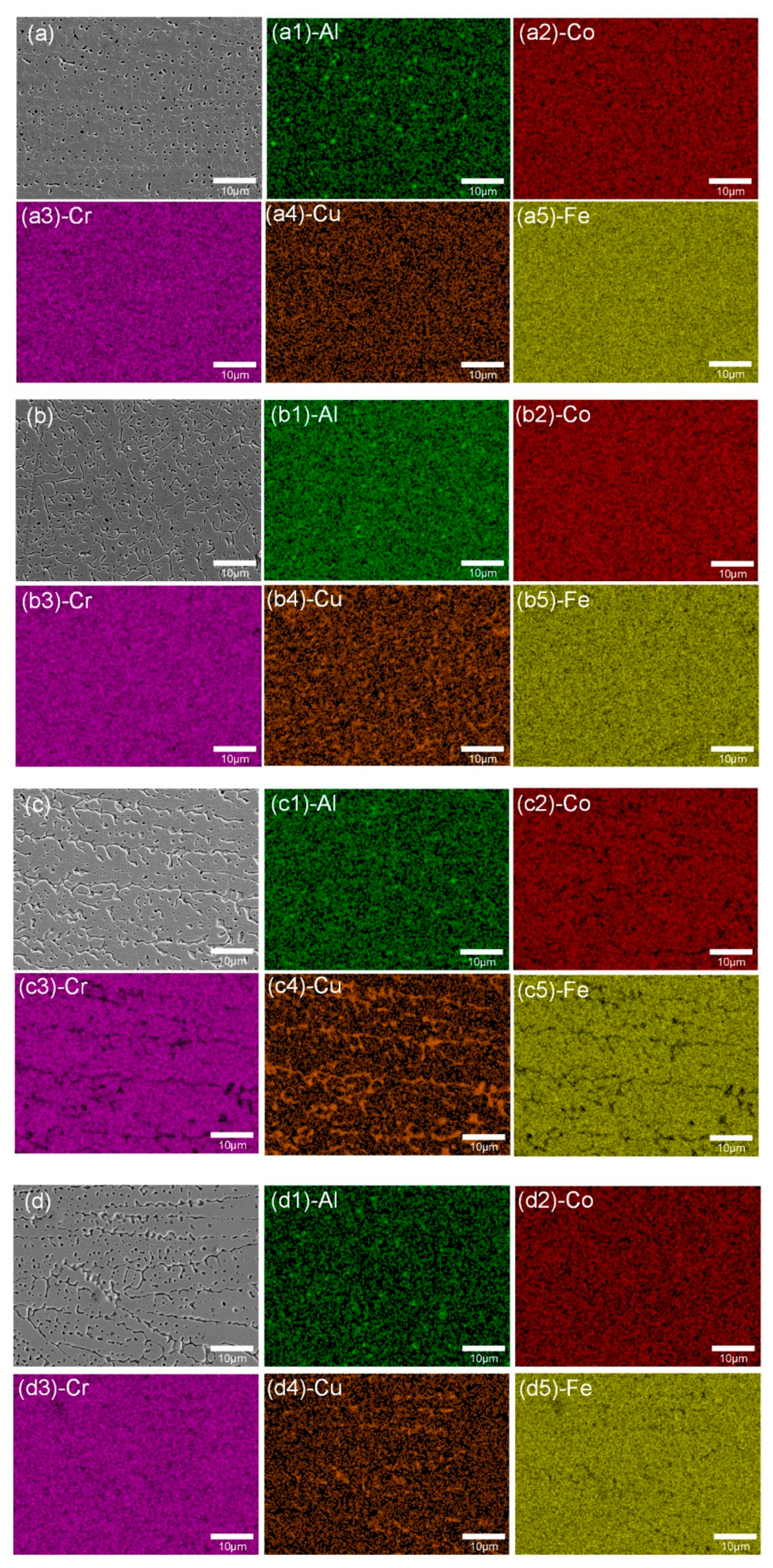

3.2. Microstructure Characterization

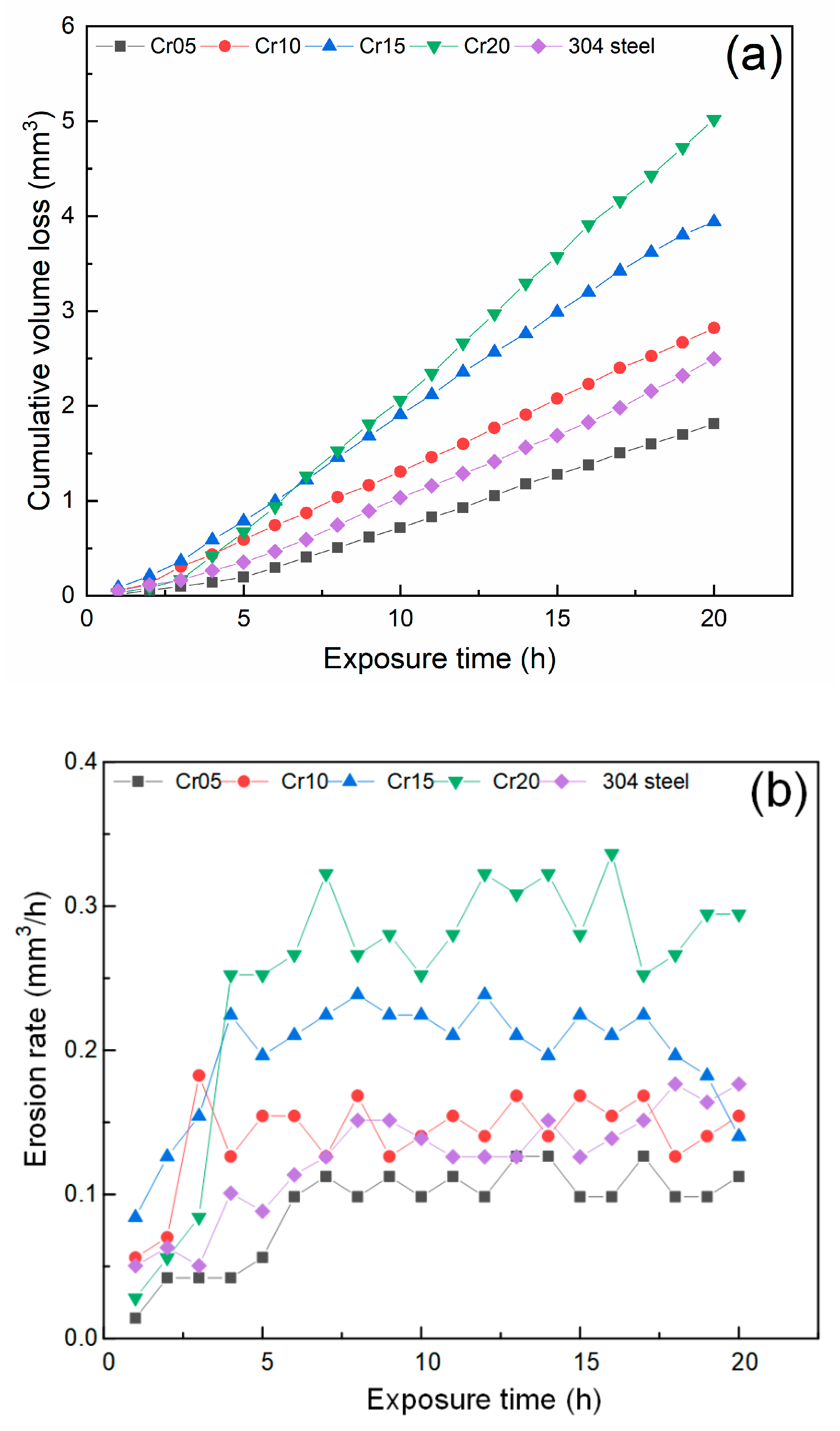

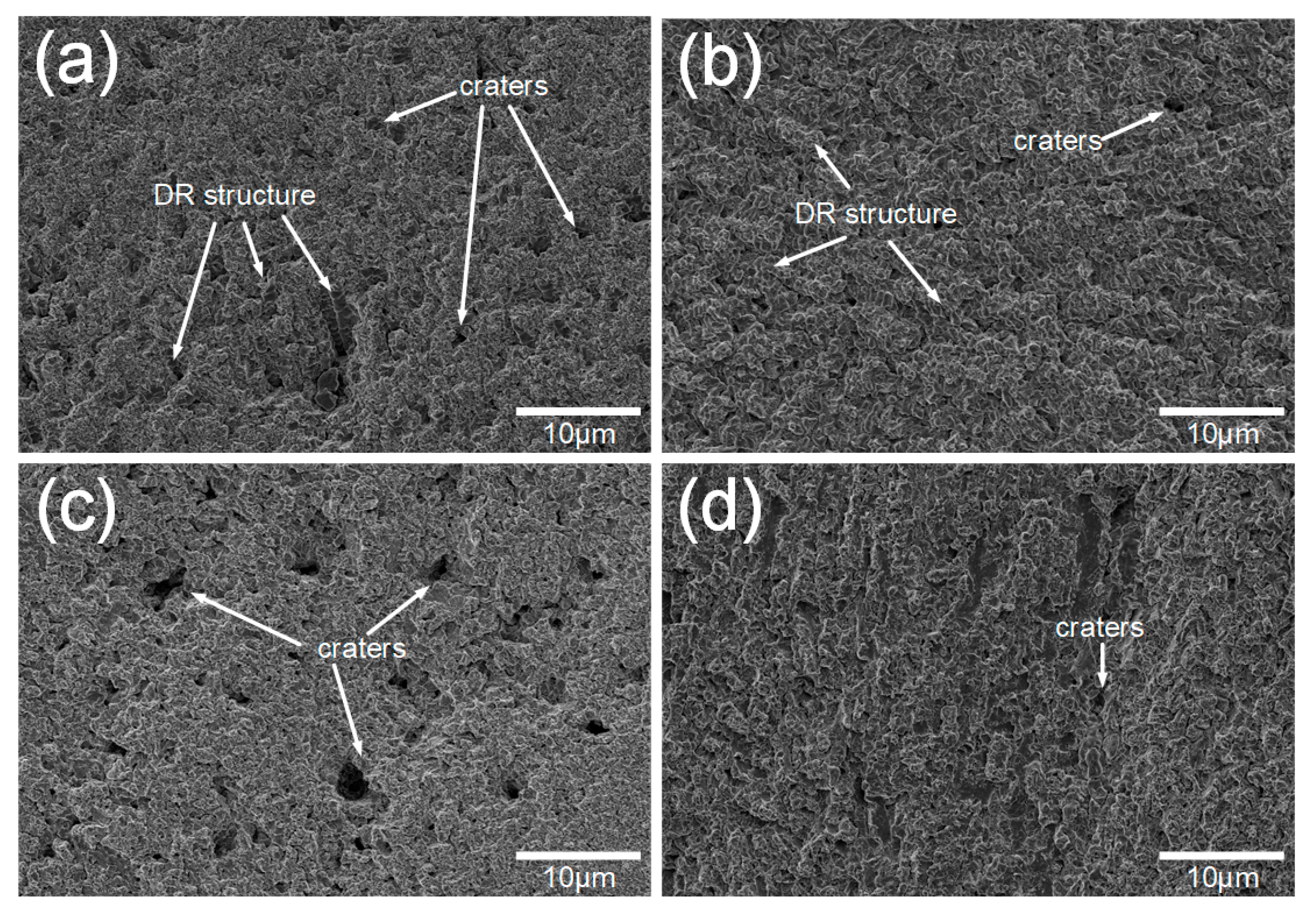

3.3. Cavitation Erosion Performance and Mechanism

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Luo, X.; Ji, B.; Tsujimoto, Y. A review of cavitation in hydraulic machinery. J. Hydrodyn. 2016, 28, 335–358. [Google Scholar] [CrossRef]

- Sreedhar, B.K.; Albert, S.K.; Pandit, A.B. Cavitation damage: Theory and measurements-A review. Wear 2017, 372, 177–196. [Google Scholar] [CrossRef]

- Szkodo, M. Mathematical description and evaluation of cavitation erosion resistance of materials. J. Mater. Process. Technol. 2005, 164, 1631–1636. [Google Scholar] [CrossRef]

- Escaler, X.; Egusquiza, E.; Farhat, M.; Avellan, F.; Coussirat, N. Detection of cavitation in hydraulic turbines. Mech. Syst. Signal Process. 2006, 20, 983–1007. [Google Scholar] [CrossRef]

- Chiu, K.Y.; Cheng, F.T.; Man, H.C. Laser cladding of austenitic stainless steel using NiTi strips for resisting cavitation erosion. Mater. Sci. Eng. A 2005, 402, 126–134. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, D.; Mishra, S.K.; Tiwari, S.K. Laser cladding of Stellite 6 on stainless steel to enhance solid particle erosion and cavitation resistance. Surf. Coat. Technol. 2014, 251, 87–97. [Google Scholar] [CrossRef]

- Taillon, G.; Pougoum, F.; Lavigne, S.; Ton-That, L.; Schulz, R.; Bousser, E.; Savoie, S.; Martinu, L.; Klemberg-Sapieha, J.E. Cavitation erosion mechanisms in stainless steels and in composite metal-ceramic HVOF coatings. Wear 2016, 364, 201–210. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.; Kang, N.; Darut, G.; Poirier, T.; Stella, J.; Liao, H.; Planche, M.P. Cavitation erosion of plasma-sprayed CoMoCrSi coatings. Tribol. Int. 2016, 102, 429–435. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Gao, M.C.; Yeh, J.W.; Liaw, P.K.; Zhang, Y. High-Entropy Alloys; Springer International Publishing: Cham, Germany, 2016. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Zhang, Y.; Wang, Y.L.; Chen, G.L. Solid solution alloys of Al Co Cr Fe Ni Ti x with excellent room-temperature mechanical properties. Appl. Phys. Lett. 2007, 90, 181904. [Google Scholar] [CrossRef]

- Tang, Z.; Huang, L.; He, W.; Liaw, P.K. Alloying and processing effects on the aqueous corrosion behavior of high-entropy alloys. Entropy 2014, 16, 895–911. [Google Scholar] [CrossRef]

- Laktionova, M.A.; Tabchnikova, E.D.; Tang, Z.; Liaw, P.K. Mechanical properties of the high-entropy alloy Ag0. 5CoCrCuFeNi at temperatures of 4.2–300 K. Low Temp. Phys. 2013, 39, 630–632. [Google Scholar] [CrossRef]

- Gorr, B.; Azim, M.; Christ, H.J.; Mueller, T.; Schliephake, D.; Heilmaier, M. Phase equilibria, microstructure, and high temperature oxidation resistance of novel refractory high-entropy alloys. J. Alloy Compd. 2015, 624, 270–278. [Google Scholar] [CrossRef]

- Hemphill, M.A.; Yuan, T.; Wang, G.Y.; Yeh, J.W.; Tsai, C.W.; Chuang, A.; Liaw, P.K. Fatigue behavior of Al0. 5CoCrCuFeNi high entropy alloys. Acta Mater. 2012, 60, 5723–5734. [Google Scholar] [CrossRef]

- Zhang, H.X.; Dai, J.J.; Sun, C.X.; Li, S.Y. Microstructure and wear resistance of TiAlNiSiV high-entropy laser cladding coating on Ti-6Al-4V. J. Mater. Process. Technol. 2020, 116671. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chang, S.Y.; Hong, Y.D.; Chen, S.K.; Lin, S.J. Anomalous decrease in X-ray diffraction intensities of Cu–Ni–Al–Co–Cr–Fe–Si alloy systems with multi-principal elements. Mater. Chem. Phys. 2007, 103, 41–46. [Google Scholar] [CrossRef]

- Jien-Wei, Y. Recent progress in high entropy alloys. Ann. Chim. Sci. Mat. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Kao, Y.F.; Chen, T.J.; Chen, S.K.; Yeh, J.W. Microstructure and mechanical property of as-cast,-homogenized, and-deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. J. Alloy Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Wu, C.L.; Zhang, S.; Zhang, C.H.; Zhang, H.; Dong, S.Y. Phase evolution and cavitation erosion-corrosion behavior of FeCoCrAlNiTix high entropy alloy coatings on SS304 stainless steel by laser surface alloying. J. Alloy Compd. 2017, 698, 761–770. [Google Scholar] [CrossRef]

- Nair, R.B.; Arora, H.S.; Mukherjee, S.; Singh, S.; Singh, H.; Grewal, H.S. Exceptionally high cavitation erosion and corrosion resistance of a high entropy alloy. Ultrason. Sonochem. 2018, 41, 252–260. [Google Scholar] [CrossRef] [PubMed]

- Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; ASTM G32-16; ASTM International: West Conshohocken, PA, USA, 2016.

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Praveen, S.; Murty, B.S.; Kottada, R.S. Alloying behavior in multi-component AlCoCrCuFe and NiCoCrCuFe high entropy alloys. Mater. Sci. Eng. A 2012, 534, 83–89. [Google Scholar] [CrossRef]

- Fang, S.; Xiao, X.; Xia, L.; Li, W.; Dong, Y. Relationship between the widths of supercooled liquid regions and bond parameters of Mg-based bulk metallic glasses. J. Non-Cryst. Solids 2003, 321, 120–125. [Google Scholar] [CrossRef]

- Dong, Y.; Lu, Y.; Jiang, L.; Wang, T.; Li, T. Effects of electro-negativity on the stability of topologically close-packed phase in high entropy alloys. Intermetallics 2014, 52, 105–109. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Guo, S.; Ng, C.; Lu, J.; Liu, C.T. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J. Appl. Phys. 2011, 109, 103505. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, Z.P.; Ma, S.G.; Liaw, P.K.; Tang, Z.; Cheng, Y.Q.; Gao, M.C. Guidelines in predicting phase formation of high-entropy alloys. Mrs Commun. 2014, 4, 57–62. [Google Scholar] [CrossRef]

- Sheng, G.; Liu, C.T. Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci. Mater. Int. 2011, 21, 433–446. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Zeng, X. A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition. Mater. Sci. Eng. A 2017, 685, 265–273. [Google Scholar] [CrossRef]

- Munitz, A.; Venkert, A.; Landau, P.; Kaufman, M.J.; Abbaschian, R. Microstructure and phase selection in supercooled copper alloys exhibiting metastable liquid miscibility gaps. J. Mater. Sci. 2012, 47, 7955–7970. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Okulov, I.V.; Wendrock, H.; Bönisch, M.; Volegov, A.S.; Calin, M.; Eckert, J.; Dargusch, M.S. Nanoindentation and wear properties of Ti and Ti-TiB composite materials produced by selective laser melting. Mater. Sci. Eng. A 2017, 688, 20–26. [Google Scholar] [CrossRef]

- Heuer, C.J.; Cardoso, R.P.; Brunatto, S.F. Cavitation erosion resistance enhancement of martensitic stainless steel via low-temperature plasma carburizing. Wear 2019, 428, 162–166. [Google Scholar] [CrossRef]

- Beake, B.D.; Vishnyakov, V.M.; Harris, A.J. Relationship between mechanical properties of thin nitride-based films and their behaviour in nano-scratch tests. Tribol. Int. 2011, 44, 468–475. [Google Scholar] [CrossRef]

- Oláh, N.; Fogarassy, Z.; Sulyok, A.; Szívós, J.; Csanádi, T.; Balázsi, K. Ceramic TiC/a: C protective nanocomposite coatings: Structure and composition versus mechanical properties and tribology. Ceram. Int. 2016, 42, 12215–12220. [Google Scholar] [CrossRef]

- Gangireddy, S.; Gwalani, B.; Soni, V.; Banerjee, R.; Mishra, R.S. Contrasting mechanical behavior in precipitation hardenable AlXCoCrFeNi high entropy alloy microstructures: Single phase FCC vs. dual phase FCC-BCC. Mater. Sci. Eng. A 2019, 739, 158–166. [Google Scholar] [CrossRef]

- Liu, S.F.; Wu, Y.; Wang, H.T.; He, J.Y.; Liu, J.B.; Chen, C.X.; Liu, X.J.; Wang, H.; Lu, Z.P. Stacking fault energy of face-centered-cubic high entropy alloys. Intermetallics 2018, 93, 269–273. [Google Scholar] [CrossRef]

- Sreedhar, B.K.; Albert, S.K.; Pandit, A.B. Improving cavitation erosion resistance of austenitic stainless steel in liquid sodium by hardfacing–comparison of Ni and Co based deposits. Wear 2015, 342, 92–99. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- McNamara, W.B.; Didenko, Y.T.; Suslick, K.S. Sonoluminescence temperatures during multi-bubble cavitation. Nature 1999, 401, 772–775. [Google Scholar] [CrossRef]

- Mu, S.; Pei, Z.; Liu, X.; Stocks, G.M. Electronic transport and phonon properties of maximally disordered alloys: From binaries to high-entropy alloys. J. Mater. Res. 2018, 33, 2857–2880. [Google Scholar] [CrossRef]

| C | Si | Cr | Mn | Ni | P | S | Fe |

|---|---|---|---|---|---|---|---|

| 0.08 | 1.0 | 19.0 | 2.0 | 11.0 | 0.035 | 0.03 | bal. |

| Laser Power | Powder Feeding Speed | Scanning Speed | Spot Diameter | Shielding Gas and Its Flow Rate | Overlapping Ratio |

|---|---|---|---|---|---|

| 1400 w | 20 g/min | 350 mm/min | 4 mm | Ar 3.5 NL/min | 50% |

| HECs | Ω | |||||

|---|---|---|---|---|---|---|

| Cr05 | 13.14 | −2.86 | 5.23% | 0.118683 | 7.55 | 5.82 |

| Cr10 | 13.38 | −2.56 | 4.98% | 0.118423 | 7.40 | 6.93 |

| Cr15 | 13.25 | −2.31 | 4.78% | 0.118199 | 7.27 | 7.88 |

| Cr20 | 12.97 | −2.11 | 4.60% | 0.118005 | 7.16 | 8.69 |

| AL | Co | Cr | Fe | Cu | |

|---|---|---|---|---|---|

| Al | - | −19 | −10 | −11 | −1 |

| Co | - | - | −4 | −1 | 6 |

| Cr | - | - | - | −1 | 12 |

| Fe | - | - | - | - | 13 |

| Cu | - | - | - | - | - |

| Al | Co | Cr | Fe | Cu | |

|---|---|---|---|---|---|

| Electronegativity | 1.61 | 1.88 | 1.66 | 1.83 | 1.9 |

| Atomic Radius (nm) | 0.143 | 0.125 | 0.128 | 0.127 | 0.128 |

| VEC | 3 | 9 | 6 | 8 | 11 |

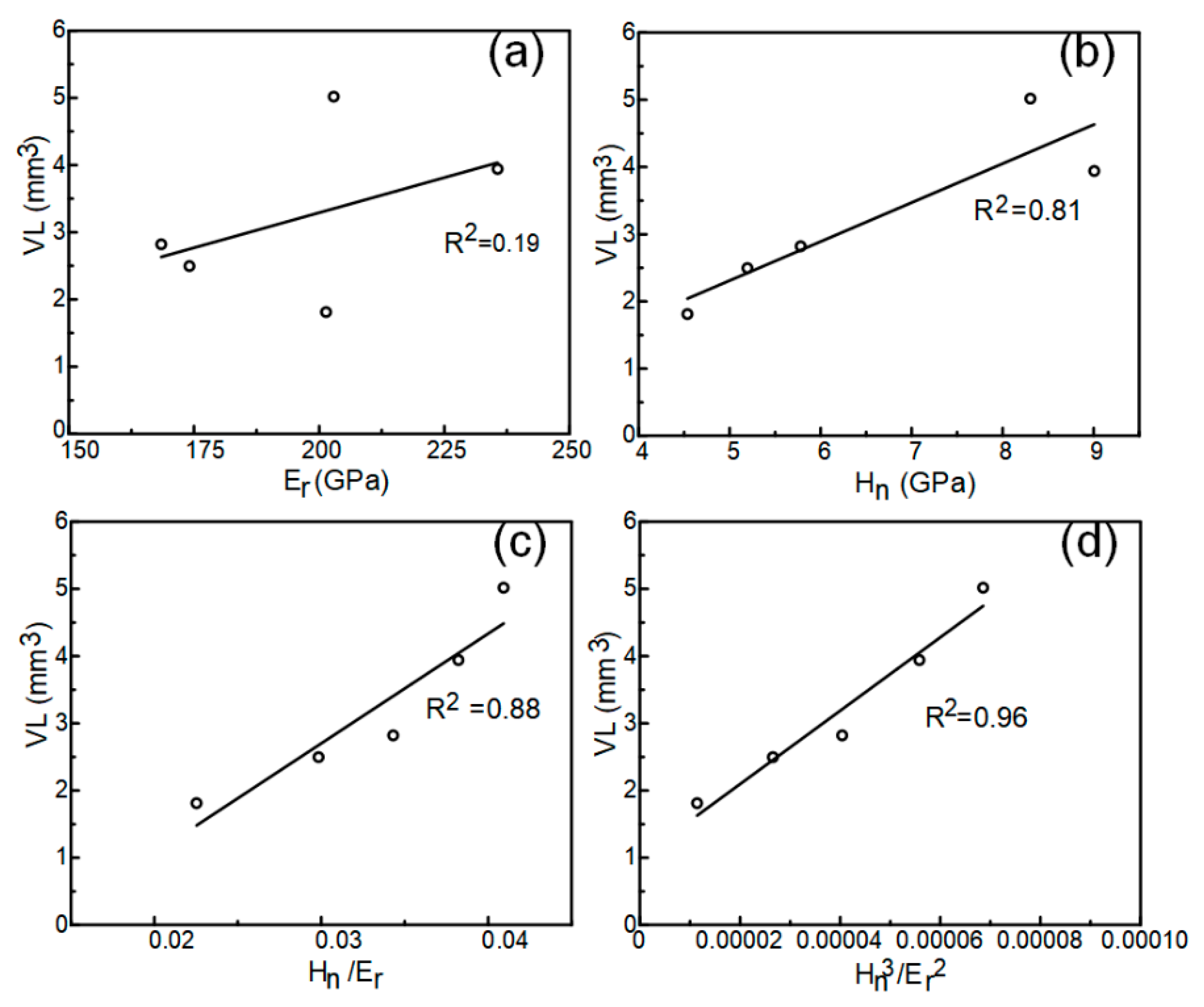

| HEC | ||||

|---|---|---|---|---|

| AISI 304 | 174.1 ± 9.6 | 5.19 ± 0.14 | 0.0298 | 0.00002658 |

| Cr05 | 201.4 ± 6.4 | 4.54 ± 0.21 | 0.0225 | 0.00001143 |

| Cr10 | 168.4 ± 6.1 | 5.78 ± 0.13 | 0.0343 | 0.00004040 |

| Cr15 | 235.6 ± 12.7 | 9.01 ± 0.44 | 0.0382 | 0.00005582 |

| Cr20 | 202.8 ± 8.5 | 8.30 ± 0.17 | 0.0409 | 0.00006856 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, D.; Liang, G.; Fan, S.; Li, S. Ultrasonic Cavitation Erosion Behavior of AlCoCrxCuFe High Entropy Alloy Coatings Synthesized by Laser Cladding. Materials 2020, 13, 4067. https://doi.org/10.3390/ma13184067

Yin D, Liang G, Fan S, Li S. Ultrasonic Cavitation Erosion Behavior of AlCoCrxCuFe High Entropy Alloy Coatings Synthesized by Laser Cladding. Materials. 2020; 13(18):4067. https://doi.org/10.3390/ma13184067

Chicago/Turabian StyleYin, Danqing, Guangbing Liang, Shuai Fan, and Shanxin Li. 2020. "Ultrasonic Cavitation Erosion Behavior of AlCoCrxCuFe High Entropy Alloy Coatings Synthesized by Laser Cladding" Materials 13, no. 18: 4067. https://doi.org/10.3390/ma13184067

APA StyleYin, D., Liang, G., Fan, S., & Li, S. (2020). Ultrasonic Cavitation Erosion Behavior of AlCoCrxCuFe High Entropy Alloy Coatings Synthesized by Laser Cladding. Materials, 13(18), 4067. https://doi.org/10.3390/ma13184067