Slurry Erosion–Corrosion Characteristics of As-Built Ti-6Al-4V Manufactured by Selective Laser Melting

Abstract

1. Introduction

2. Experimental Details

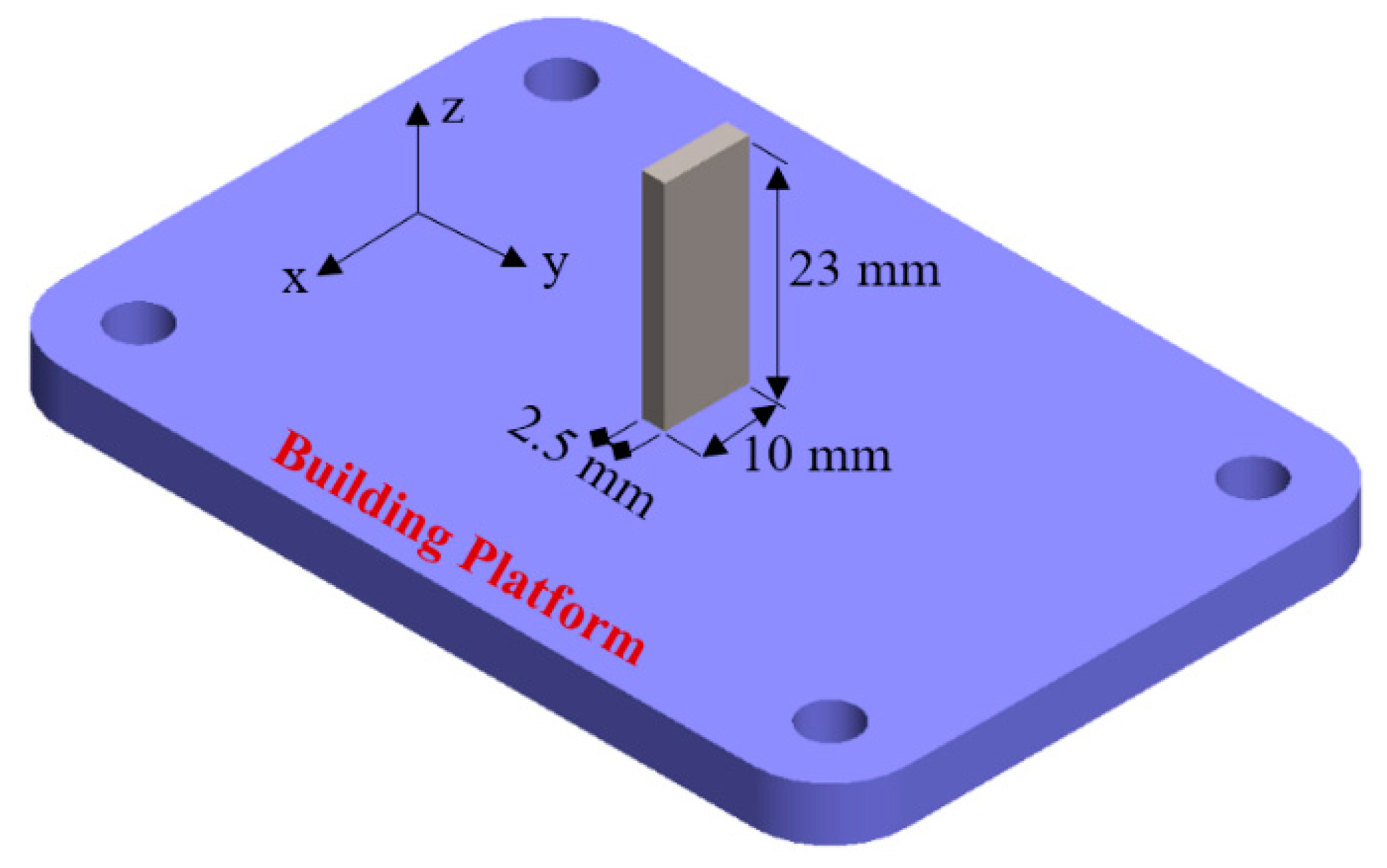

2.1. Material and Sample Preparation

2.2. Microstructure and Microhardness Investigation

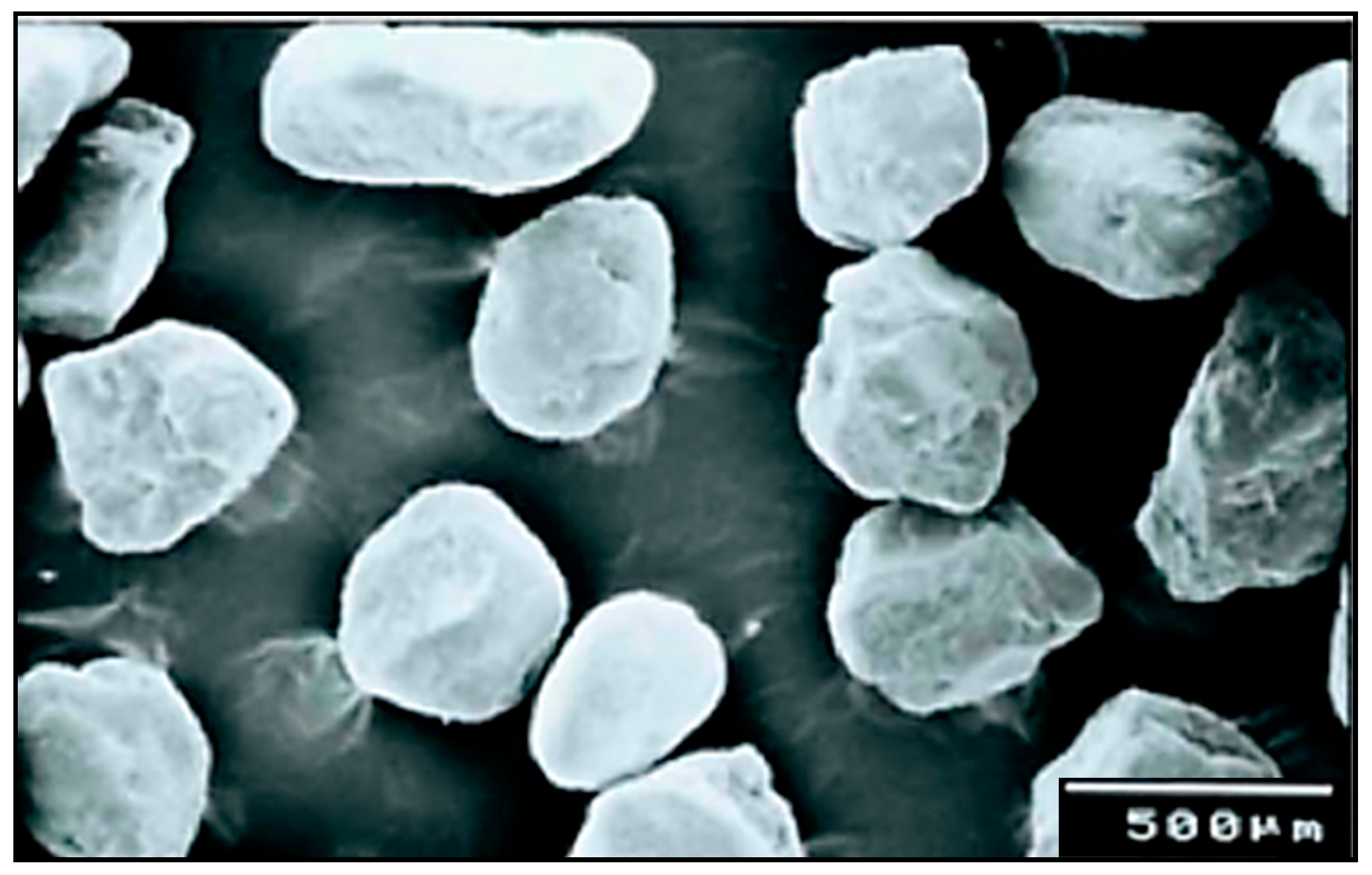

2.3. Erodent

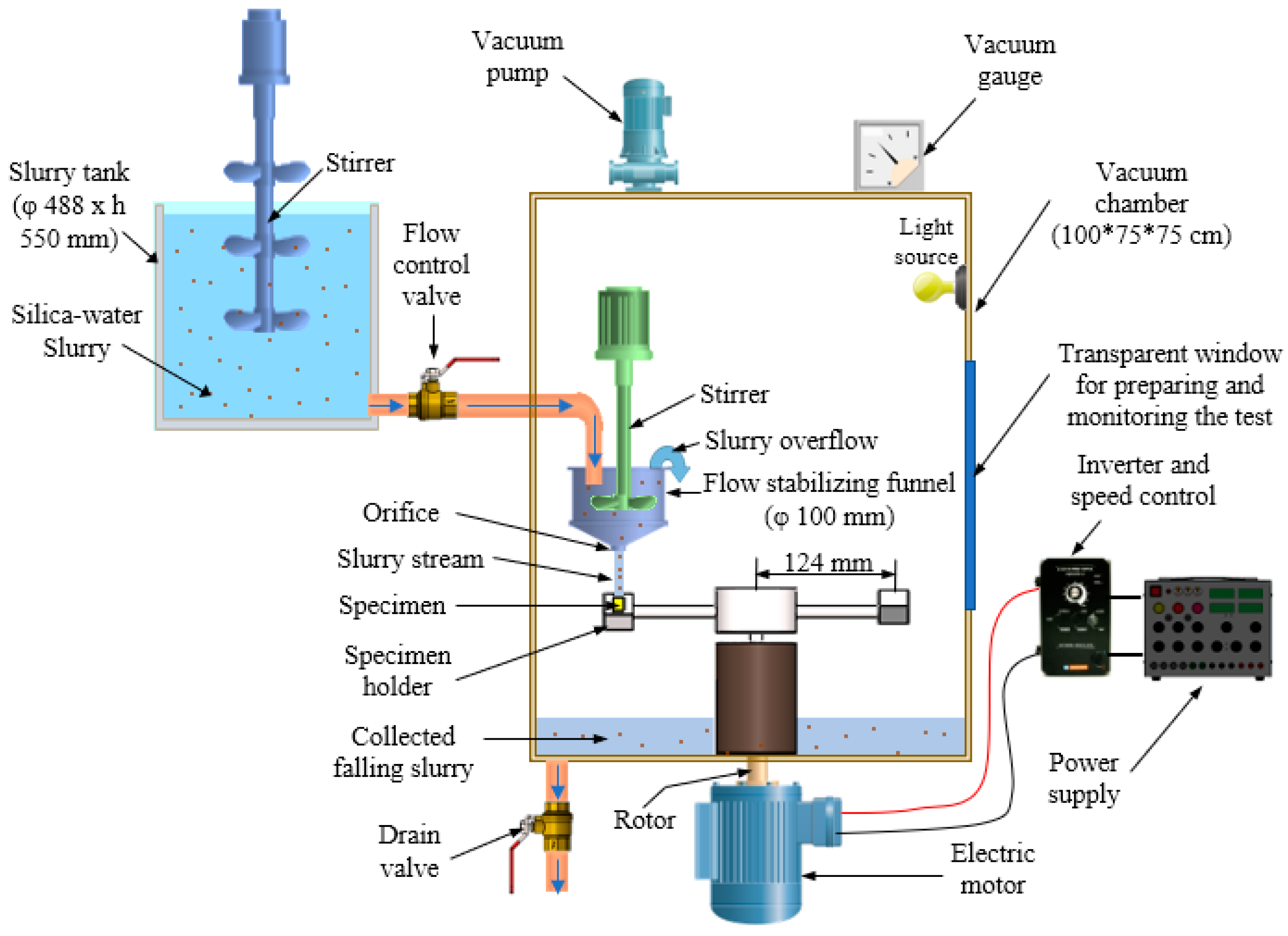

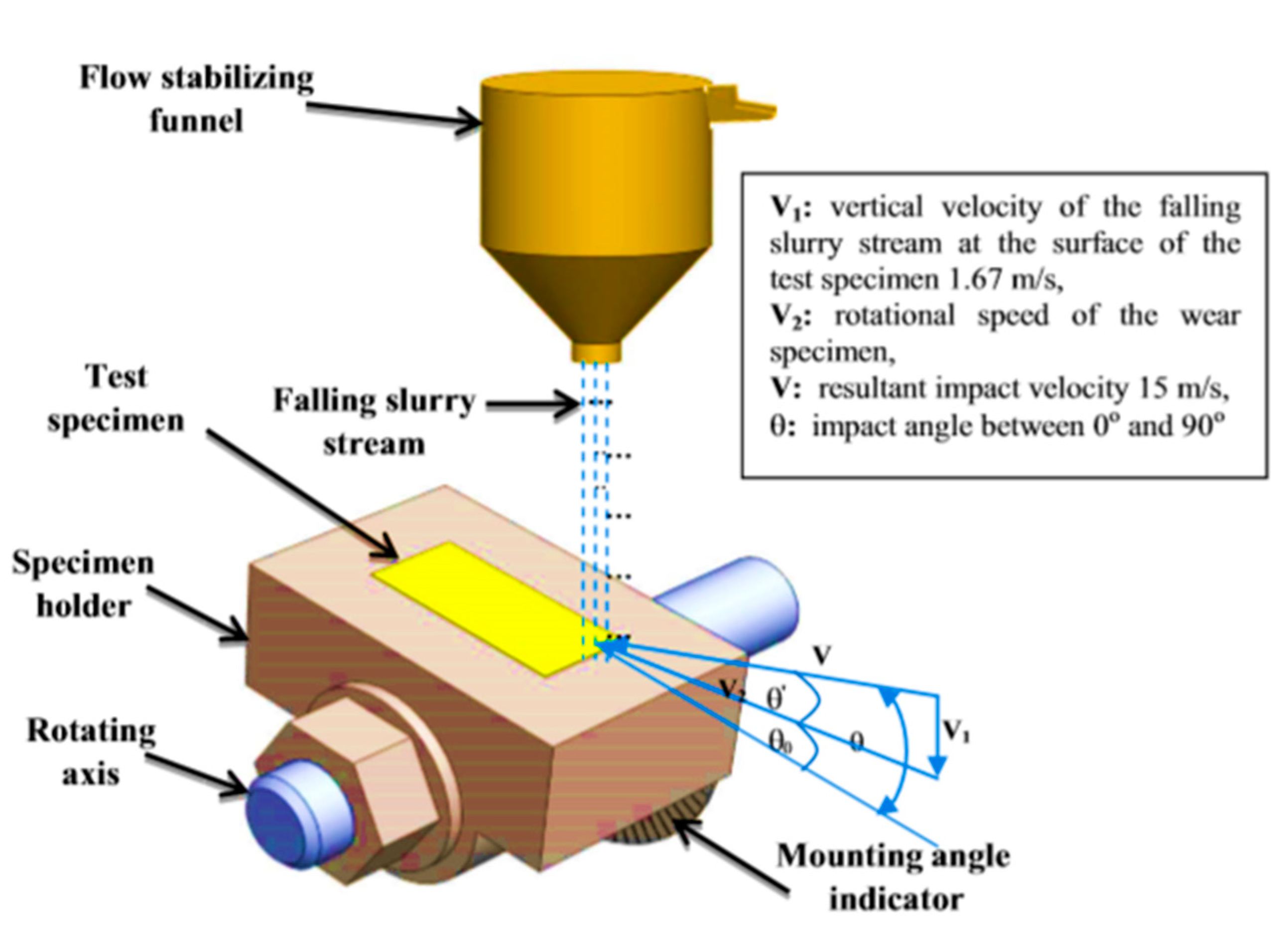

2.4. Slurry Erosion and Erosion–Corrosion Tests Procedure

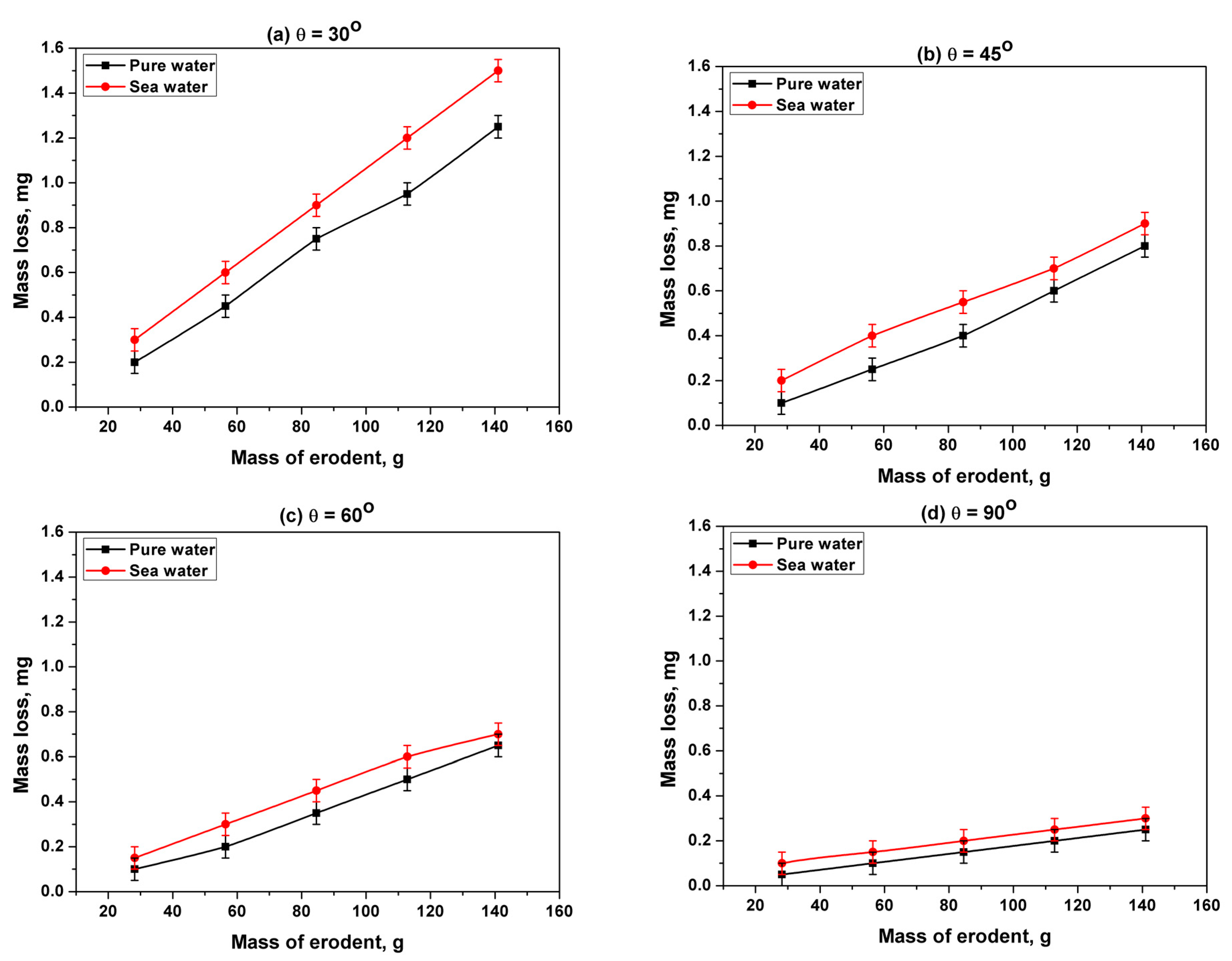

3. Results and Discussion

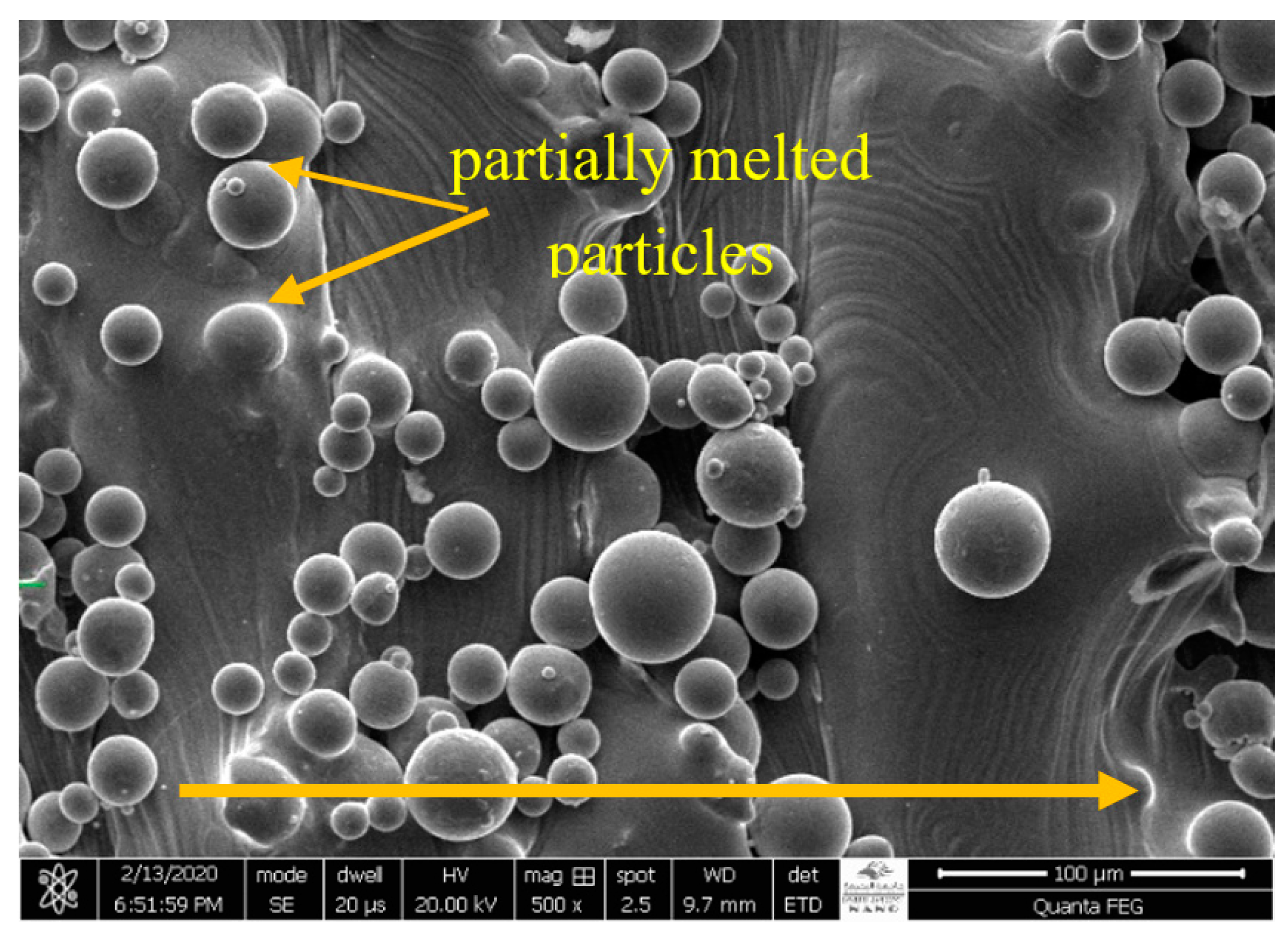

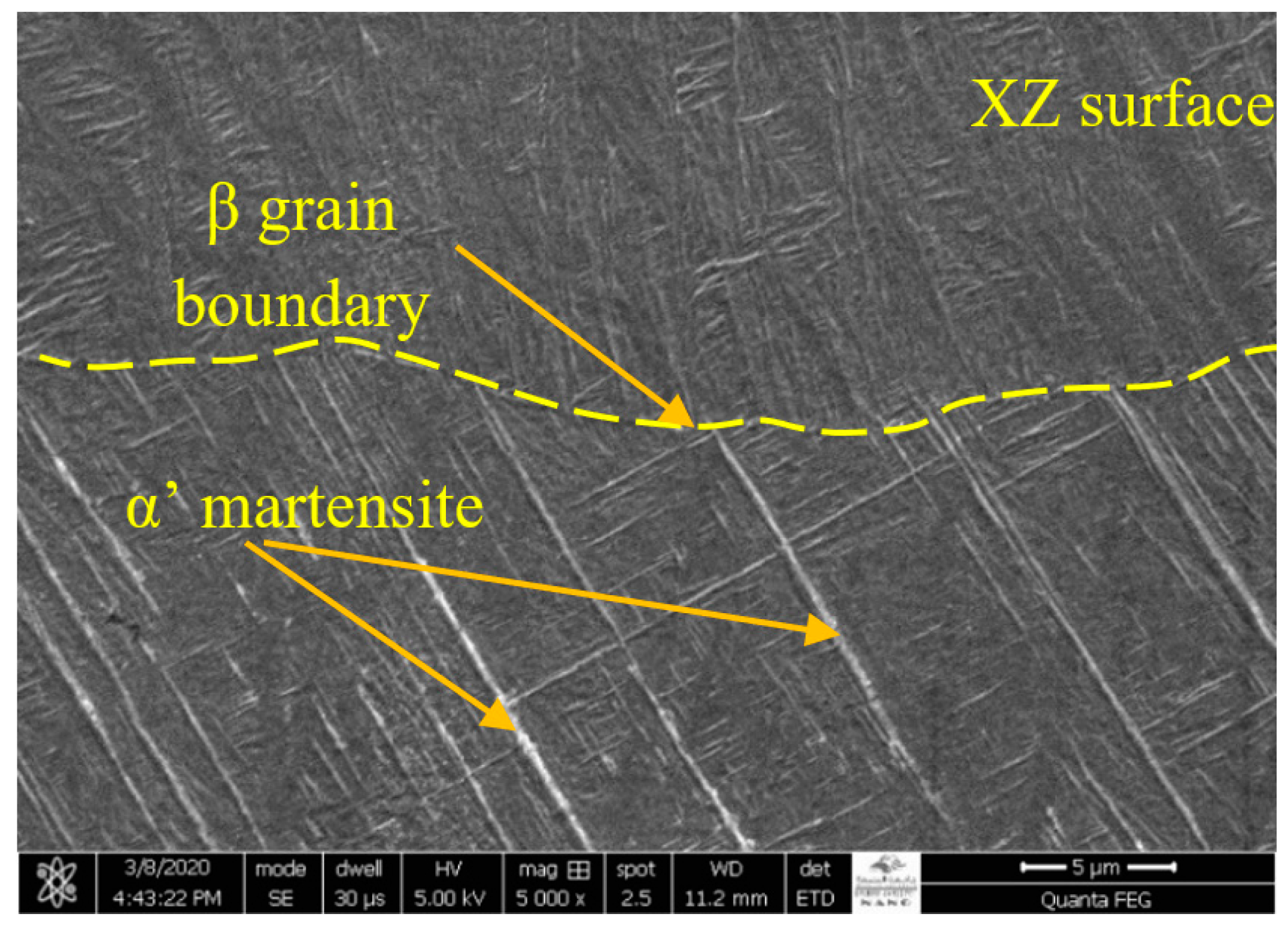

3.1. As-Built Microstructure

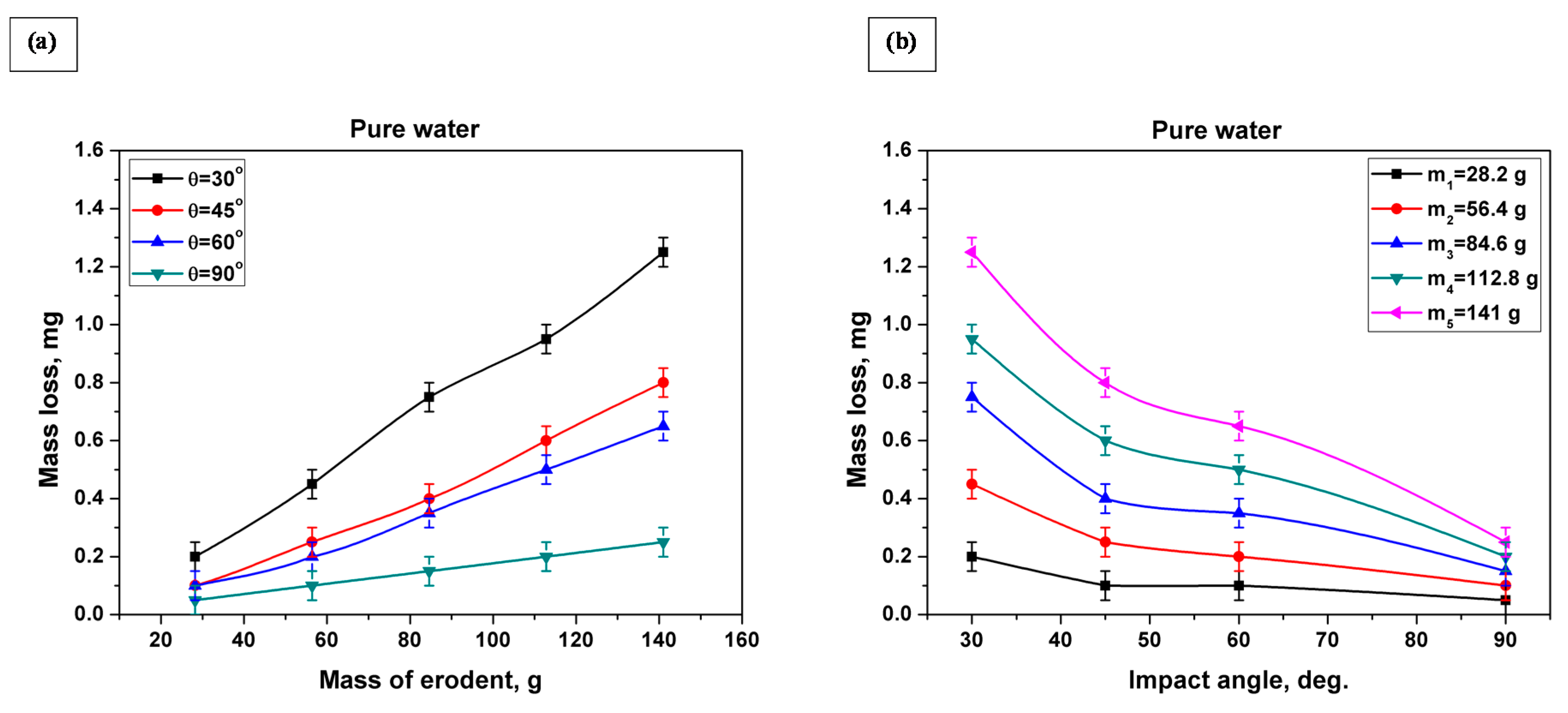

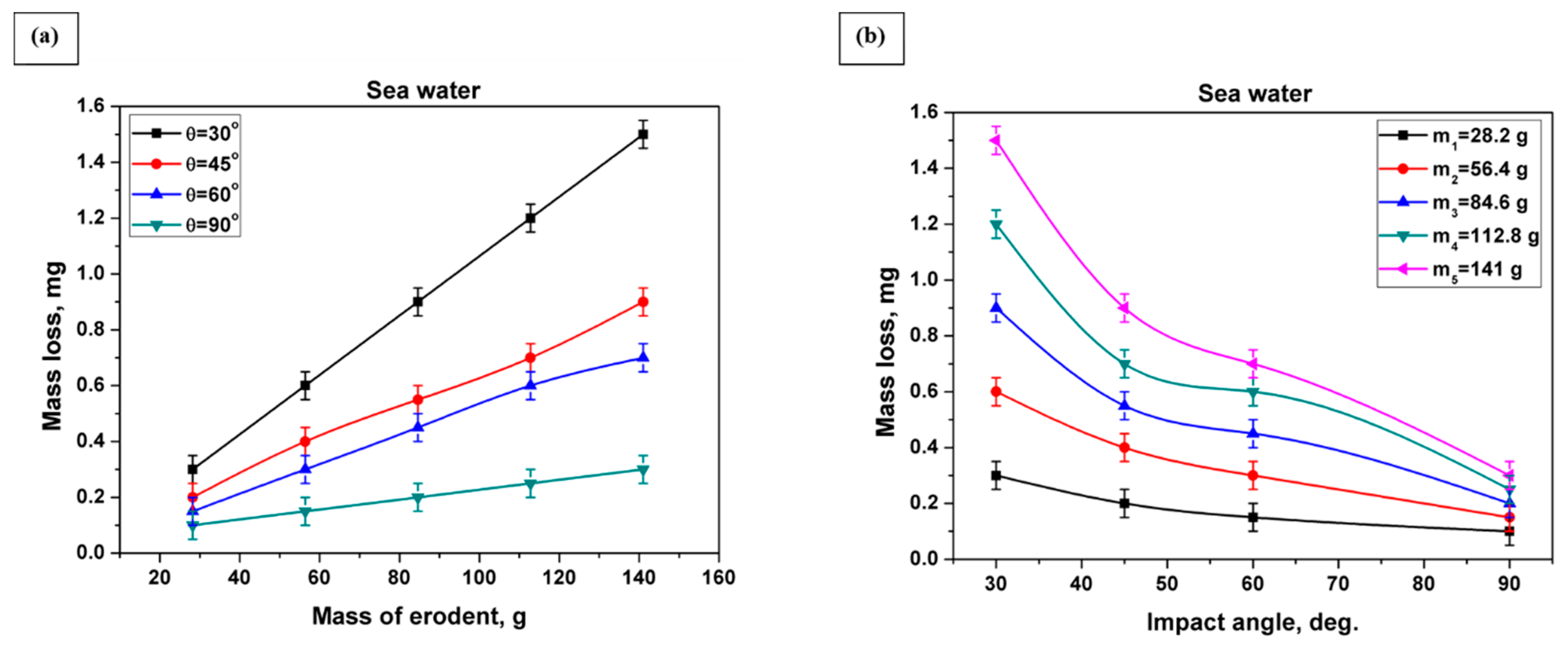

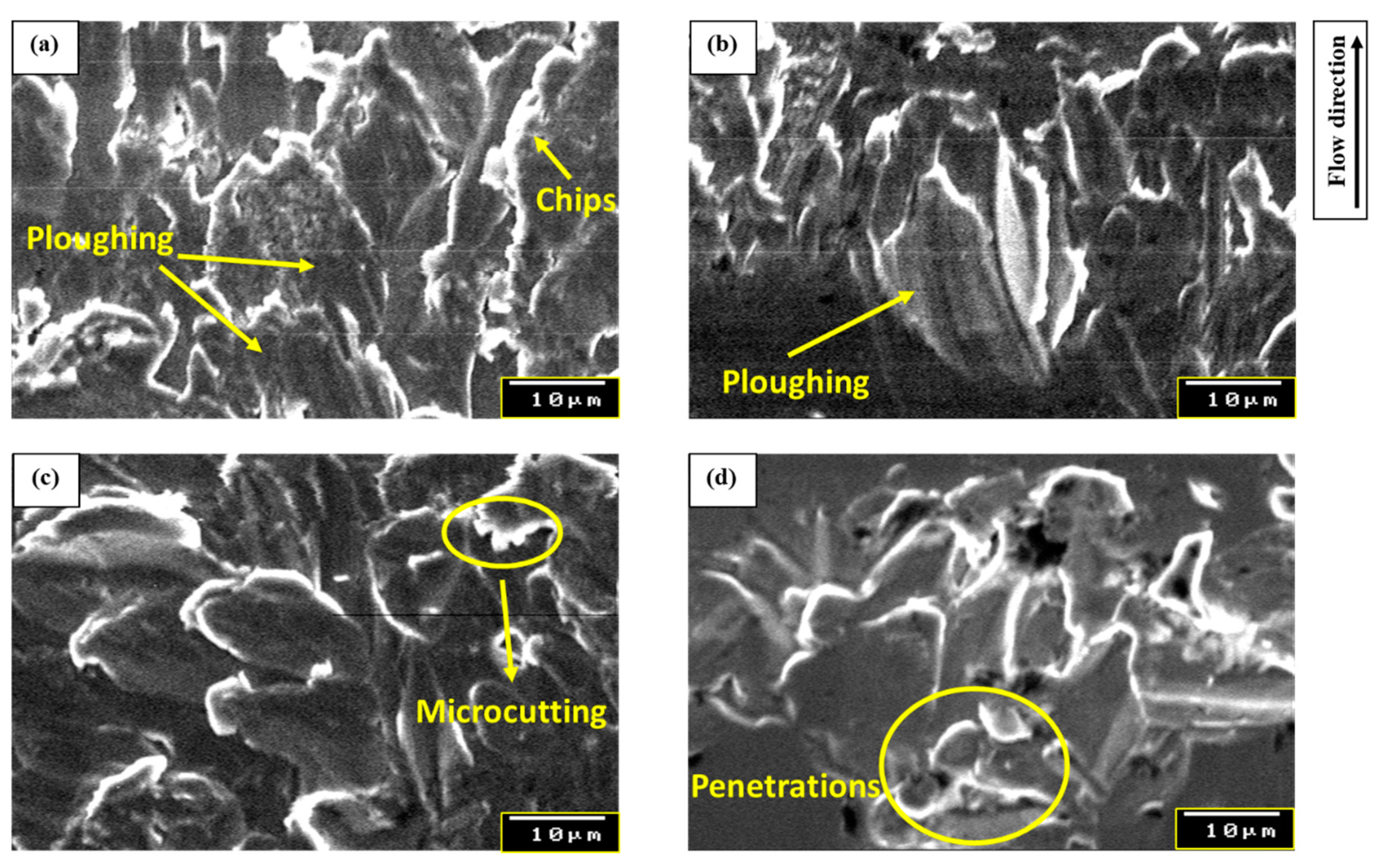

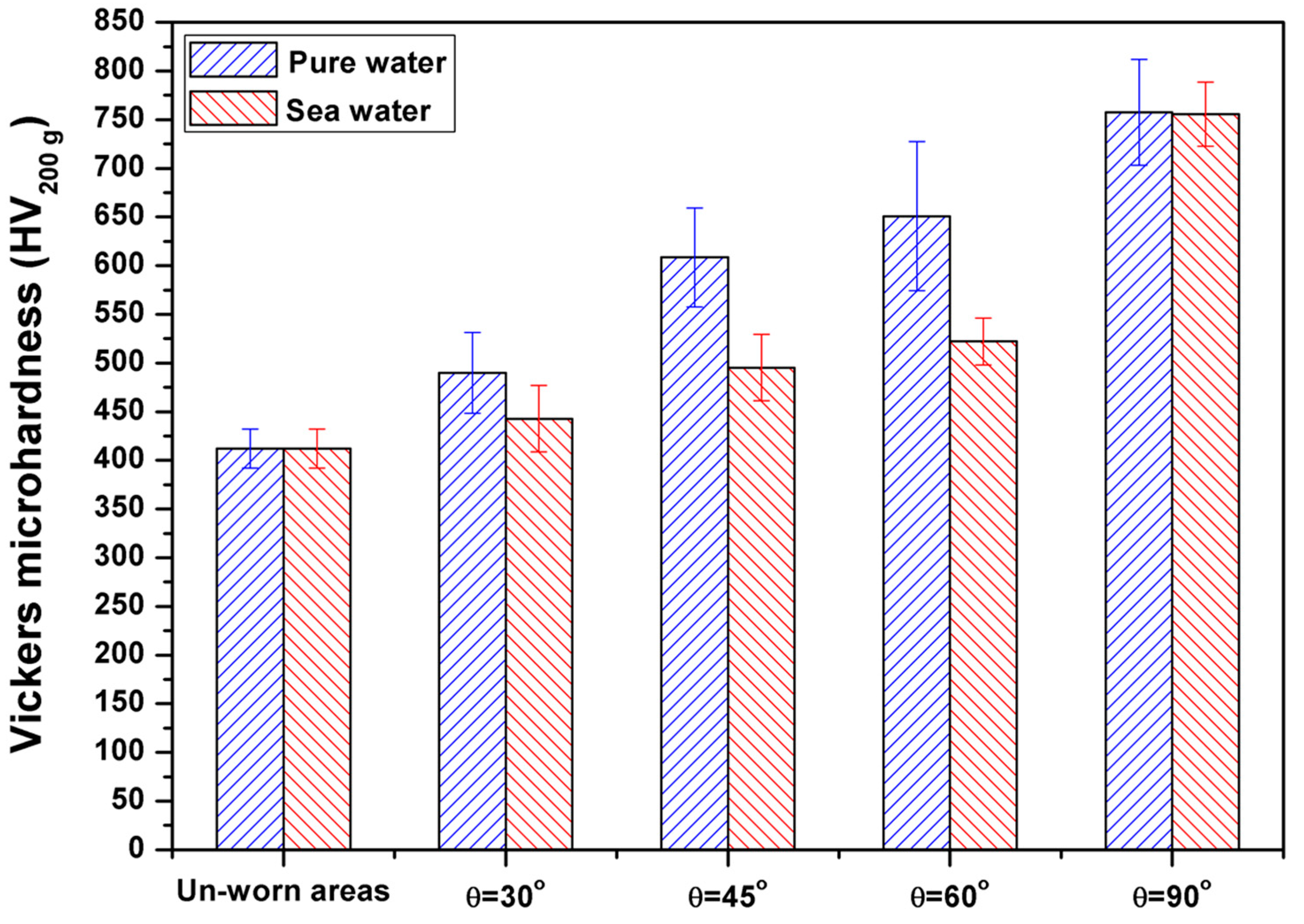

3.2. Eroded Surface Characteristics and Erosion Mechanisms

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Matthew, J.; Donachie, J. Titamium: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2000; ISBN 0871706865. [Google Scholar]

- Chunxiang, C.; Baomin, H.; Lichen, Z.; Shuangjin, L. Titanium alloy production technology, market prospects and industry development Titanium alloy production technology, market prospects and industry development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Gad, S.C. Titanium. In Encyclopedia of Toxicology, 3rd ed.; Wexler, P., Ed.; Academic Press: Cambridge, MA, USA, 2014; pp. 584–585. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Li, Y.; Song, L.; Xie, P.; Cheng, M.; Xiao, H. Enhancing hardness and wear performance of laser additive manufactured Ti6Al4V alloy through achieving ultrafine microstructure. Materials 2020, 13, 1210. [Google Scholar] [CrossRef] [PubMed]

- Tong, J.; Bowen, C.R.; Persson, J.; Plummer, A. Mechanical properties of titanium-based Ti–6Al–4V alloys manufactured by powder bed additive manufacture. Mater. Sci. Technol. 2017, 33, 138–148. [Google Scholar] [CrossRef]

- Li, Y.Q.; Wang, X.D.; Long, C.B.; Sun, Z.P.; Wei, X.L.; Zhou, L.C. Erosion behavior and damage evolution of Ti-6Al-4V aeroengine titanium alloy. IOP Conf. Ser. Mater. Sci. Eng. 2020, 770, 012083. [Google Scholar] [CrossRef]

- Sahoo, R.; Mantry, S.; Sahoo, T.K.; Mishra, S.; Jha, B.B. Influence of Microstructure on High Temperature Solid Particle Erosion Behaviour of Ti–6Al–4V Alloy. Trans. Indian Inst. Met. 2014, 67, 299–304. [Google Scholar] [CrossRef]

- Özen, İ.; Gedikli, H. Solid Particle Erosion on Shield Surface of a Helicopter Rotor Blade Using Computational Fluid Dynamics. J. Aerosp. Eng. 2019, 32, 04018131. [Google Scholar] [CrossRef]

- Rahman, M.H. Design and Analysis of Hybrid Titanium-Composite Hull Structures Under Extreme Wave and Slamming Loads; Florida Atlantic University: Boca Raton, FL, USA, 2013. [Google Scholar]

- Doran, D.; Cather, B. Construction Materials Reference Book, 2nd ed.; Routledge: Abingdon, UK, 2014; ISBN 9780750663762. [Google Scholar]

- Fidan, S.; Avcu, E.; Karakulak, E.; Yamanoglu, R.; Zeren, M.; Sinmazcelik, T. Effect of heat treatment on erosive wear behaviour of Ti6Al4V alloy. Mater. Sci. Technol. 2013, 29, 1088–1094. [Google Scholar] [CrossRef]

- Mann, B.S.; Arya, V.; Maiti, A.K.; Rao, M.U.B.; Joshi, P. Corrosion and erosion performance of HVOF/TiAlN PVD coatings and candidate materials for high pressure gate valve application. Wear 2006, 260, 75–82. [Google Scholar] [CrossRef]

- Lin, N.; Zhou, P.; Wang, Y.; Zou, J.; Ma, Y.; Wang, Z.; Tian, W.; Yao, X.; Tang, B. Thermal Oxidation of Ti6Al4V Alloy with Enhanced Wear and Corrosion Resistance for Oil and Gas Application: Effect of Temperature. Surf. Rev. Lett. 2015, 22, 1–11. [Google Scholar] [CrossRef]

- Mann, B.S.; Arya, V.; Pant, B.K. Enhanced erosion protection of TWAS coated Ti6Al4V Alloy using boride bond coat and subsequent laser treatment. J. Mater. Eng. Perform. 2011, 20, 932–940. [Google Scholar] [CrossRef]

- Krčil, J.; Holec, J.; Horník, J.; Hájková, P.; Čižmárová, E.; Mára, V. The analysis of causes of the damage of a turbine blade made of Ti-6Al-4V alloy. Solid State Phenom. 2017, 270, 189–193. [Google Scholar] [CrossRef]

- Prasanna, N.D.; Siddaraju, C.; Shetty, G.; Ramesh, M.R.; Reddy, M. Studies on the role of HVOF coatings to combat erosion in turbine alloys. Mater. Today Proc. 2018, 5, 3130–3136. [Google Scholar] [CrossRef]

- Agripa, H.; Botef, I. Modern production methods for titanium alloys: A review. In Titanium Alloys—Novel Aspects of Their Manufacturing and Processing; Matyka, M., Ziaja, W., Sieniawski, J., Eds.; IntechOpen: London, UK, 2019; pp. 1–20. [Google Scholar] [CrossRef]

- Boyer, R.R. Processing of Titanium and Titanium Alloys. In Metals Handbook Desk Edition; Davis, R.J., Ed.; ASM International: Almere, The Netherlands, 1998; pp. 1–3. [Google Scholar]

- Chen, K.C.; He, J.L.; Huang, W.H.; Yeh, T.T. Study on the solid-liquid erosion resistance of ion-nitrided metal. Wear 2002, 252, 580–585. [Google Scholar] [CrossRef]

- Ji, X.; Qing, Q.; Ji, C.; Cheng, J.; Zhang, Y. Slurry Erosion Wear Resistance and Impact-Induced Phase Transformation of Titanium Alloys. Tribol. Lett. 2018, 66, 64. [Google Scholar] [CrossRef]

- Dong, H.; Bloyce, A.; Bell, T. Slurry abrasion response of surface engineered Ti6Al4VELI. Tribol. Int. 2000, 32, 517–526. [Google Scholar] [CrossRef]

- Neville, A.; Mcdougall, B.A.B. Erosion– and cavitation–corrosion of titanium and its alloys. Wear 2001, 250, 726–735. [Google Scholar] [CrossRef]

- Wang, Z.X.; Wu, H.R.; Shan, X.L.; Lin, N.M.; He, Z.Y.; Liu, X.P. Microstructure and erosive wear behaviors of Ti6Al4V alloy treated by plasma Ni alloying. Appl. Surf. Sci. 2016, 388, 510–516. [Google Scholar] [CrossRef]

- Yang, J.; Swisher, J.H. Erosion-corrosion behavior and cathodic protection of alloys in seawater-sand slurries. J. Mater. Eng. Perform. 1993, 2, 843–850. [Google Scholar] [CrossRef]

- Lindgren, M.; Perolainen, J. Slurry pot investigation of the influence of erodant characteristics on the erosion resistance of titanium. Wear 2014, 321, 64–69. [Google Scholar] [CrossRef]

- Avcu, E.; Fidan, S.; Yıldıran, Y.; Sınmazçelik, T. Solid particle erosion behaviour of Ti6Al4V alloy. Tribol. Surf. Interfaces 2013, 7, 201–210. [Google Scholar] [CrossRef]

- Zhao, J.-R.; Hung, F.-Y.; Lui, T.-S.; Wu, Y.-L. The Relationship of Fracture Mechanism between High Temperature Tensile Mechanical Properties and Particle Erosion Resistance of Selective Laser Melting Ti-6Al-4V Alloy. Metals 2019, 9, 501. [Google Scholar] [CrossRef]

- Singh, S.; Goyal, D.K.; Kumar, P.; Bansal, A. Laser cladding technique for erosive wear applications: A review. Mater. Res. Express 2020, 7, 012007. [Google Scholar] [CrossRef]

- International Organization for Standardization/ASTM International. Additive Manufacturing—General Principles—Terminology (ISO/ASTM 52900) [Standard]; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Singh, R.; Gupta, A.; Tripathi, O.; Srivastava, S.; Singh, B.; Awasthi, A.; Rajput, S.K.; Sonia, P.; Singhal, P.; Saxena, K.K. Powder bed fusion process in additive manufacturing: An overview. Mater. Today Proc. 2020, 26, 3058–3070. [Google Scholar] [CrossRef]

- Mishurova, T.; Cabeza, S.; Artzt, K.; Haubrich, J.; Klaus, M.; Genzel, C.; Requena, G.; Bruno, G. An assessment of subsurface residual stress analysis in SLM Ti-6Al-4V. Materials 2017, 10, 348. [Google Scholar] [CrossRef]

- Zhang, B.L.; Attar, H. Selective Laser Melting of Titanium Alloys and Titanium Matrix Composites for Biomedical Applications: A Review. Adv. Eng. Mater. 2015, 18, 463–475. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Gussone, J.; Haubrich, J.; Sandlöbes, S.; Da Silva, J.C.; Cloetens, P.; Schell, N.; Requena, G. Inducing stable α + β microstructures during selective laser melting of Ti-6Al-4V using intensified intrinsic heat treatments. Materials 2017, 10, 268. [Google Scholar] [CrossRef]

- Attar, H.; Prashanth, K.G.; Chaubey, A.K.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Mater. Lett. 2015, 142, 38–41. [Google Scholar] [CrossRef]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

- Ji, Y.; Chen, L.; Chen, L.Q. Understanding Microstructure Evolution During Additive Manufacturing of Metallic Alloys Using Phase-Field Modeling, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2018; ISBN 9780128118214. [Google Scholar]

- He, J.; Li, D.; Jiang, W.; Ke, L.; Qin, G.; Ye, Y.; Qin, Q.; Qiu, D. The Martensitic Transformation and Mechanical Properties of Ti6Al4V Prepared via Selective Laser Melting. Materials 2019, 12, 321. [Google Scholar] [CrossRef]

- Tsai, M.; Chen, Y.; Chao, C.; Jang, J.S.C.; Tsai, C.; Su, Y.; Kuo, C. Heat-treatment effects on mechanical properties and microstructure evolution of Ti-6Al-4V alloy fabricated by laser powder bed fusion. J. Alloys Compd. 2020, 816, 152615. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Artzt, K.; Stark, A.; Schell, N.; Siggel, M.; Gussone, J.; Kleinert, J.; Kitsche, W.; Requena, G.; Haubrich, J. Mapping the geometry of Ti-6Al-4V: From martensite decomposition to localized spheroidization during selective laser melting. Scr. Mater. 2020, 182, 48–52. [Google Scholar] [CrossRef]

- Kaschel, F.R.; Celikin, M.; Dowling, D.P. Effects of laser power on geometry, microstructure and mechanical properties of printed Ti-6Al-4V parts. J. Mater. Process. Technol. 2020, 278, 116539. [Google Scholar] [CrossRef]

- Tao, P.; Zhong, J.; Li, H.; Hu, Q.; Gong, S.; Xu, Q. Microstructure, mechanical properties, and constitutive models for Ti–6Al–4V alloy fabricated by selective laser melting (SLM). Metals 2019, 9, 447. [Google Scholar] [CrossRef]

- Agius, D.; Kourousis, K.I.; Wallbrink, C. A review of the as-built SLM Ti-6Al-4V mechanical properties towards achieving fatigue resistant designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef]

- Li, H.; Ramezani, M.; Chen, Z.W. Dry sliding wear performance and behaviour of powder bed fusion processed Ti–6Al–4V alloy. Wear 2019, 440–441, 203103. [Google Scholar] [CrossRef]

- Beese, A.M. Microstructure and Mechanical Properties of AM Builds, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2018; ISBN 9780128118214. [Google Scholar]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K.; Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; et al. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyp. J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Gibson, I.; Goldberg, M.; Littlefair, G. On the role of different annealing heat treatments on mechanical properties and microstructure of selective laser melted and conventional wrought Ti-6Al-4V. Rapid Prototyp. J. 2017, 23, 295–304. [Google Scholar] [CrossRef]

- Fatemi, A.; Molaei, R.; Sharifimehr, S.; Shamsaei, N.; Phan, N. Torsional fatigue behavior of wrought and additive manufactured Ti-6Al-4V by powder bed fusion including surface finish effect. Int. J. Fatigue 2017, 99, 187–201. [Google Scholar] [CrossRef]

- Attar, H.; Bermingham, M.J.; Ehtemam-Haghighi, S.; Dehghan-Manshadi, A.; Kent, D.; Dargusch, M.S. Evaluation of the mechanical and wear properties of titanium produced by three different additive manufacturing methods for biomedical application. Mater. Sci. Eng. A 2019, 760, 339–345. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Abouel-Kasem, A. Particle size effects on slurry erosion of 5117 steels. J. Tribol. 2011, 133, 014502. [Google Scholar] [CrossRef]

- Abouel-Kasem, A.; Abd-elrhman, Y.M.; Emara, K.M.; Ahmed, S.M. Design and Performance of Slurry Erosion Tester. J. Tribol. 2010, 132, 021601. [Google Scholar] [CrossRef]

- Abd-Elrahman, Y.M.; Abouel-Kasem, A.; Ahmed, S.M.; Emara, K.M. Stepwise Erosion as a Method for Investigating the Wear Mechanisms at Different Impact Angles in Slurry Erosion. J. Tribol. 2014, 136, 021608. [Google Scholar] [CrossRef]

- Abdelrhman, Y.; Abouel-Kasem, A.; Emara, K.; Ahmed, S. The effect of boronizing heat treatment on the slurry erosion of AISI 5117. Ind. Lubr. Tribol. 2018, 70, 1176–1186. [Google Scholar] [CrossRef]

- Kaya, G.; Yildiz, F.; Hacisalihoǧlu, A. Characterization of the Structural and Tribological Properties of Medical Ti6Al4V Alloy Produced in Different Production Parameters Using Selective Laser Melting. 3D Print. Addit. Manuf. 2019, 6, 253–261. [Google Scholar] [CrossRef]

- Chen, G.Q.; Jiao, Y.; Tian, T.Y.; Zhang, X.H.; Li, Z.Q.; Zhou, W.L. Effect of wet shot peening on Ti-6Al-4V alloy treated by ceramic beads. Trans. Nonferr. Met. Soc. China 2014, 24, 690–696. [Google Scholar] [CrossRef]

- Abd-Elrhman, Y.M.; Abouel-Kasem, A.; Emara, K.M.; Ahmed, S.M. Effect of Impact Angle on Slurry Erosion Behavior and Mechanisms of Carburized AISI 5117 Steel. J. Tribol. 2013, 136, 011106. [Google Scholar] [CrossRef]

- Saleh, B.; Ahmed, S.M. Slurry erosion-corrosion of carburized AISI 5117 steel. Tribol. Lett. 2013, 51, 135–142. [Google Scholar] [CrossRef]

- Gurrappa, I. Characterization of titanium alloy Ti-6Al-4V for chemical, marine and industrial applications. Mater. Charact. 2003, 51, 131–139. [Google Scholar] [CrossRef]

- Lee, H.; Mall, S.; Allen, W.Y. Fretting fatigue behavior of shot-peened Ti-6Al-4V under seawater environment. Mater. Sci. Eng. A 2006, 420, 72–78. [Google Scholar] [CrossRef]

- Güleryüz, H.; Çimenoǧlu, H. Effect of thermal oxidation on corrosion and corrosion-wear behaviour of a Ti-6Al-4V alloy. Biomaterials 2004, 25, 3325–3333. [Google Scholar] [CrossRef] [PubMed]

- Tamilselvi, S.; Raman, V.; Rajendran, N. Corrosion behaviour of Ti-6Al-7Nb and Ti-6Al-4V ELI alloys in the simulated body fluid solution by electrochemical impedance spectroscopy. Electrochim. Acta 2006, 52, 839–846. [Google Scholar] [CrossRef]

- Sherif, E.-S.M.; Ragab, S.A.; Abdo, H.S. Role of Vanadium Additions on the Corrosion Mitigation of Ti-6Al-xV Alloy in Simulated Body Fluid. Metals 2020, 10, 903. [Google Scholar] [CrossRef]

| Element | Ti | Al | V | C | Fe | O | N | H | Yttrium |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | Balance | 5.50–6.50 | 3.50–4.50 | ≤0.08 | ≤0.25 | ≤0.13 | ≤0.05 | ≤0.012 | ≤0.005 |

| Laser Power (W) | laser Spot Size (μm) | Scanning Velocity (m/s) | Layer Thickness (μm) | Hatch Spacing (mm) | Hatching Strategy | Atmosphere |

|---|---|---|---|---|---|---|

| 200 | 75 | 0.857 | 60 | 0.095 | Meander | Inert atmosphere (Purged with Argon gas) |

| Particle Size Range (µm) | Statistical Parameters | Area, A (µm)2 | Average Dia. (µm) | Width, W, (µm) | Length, L, (µm) | Aspect Ratio = (W/L) | Perimeter, P, (µm) | P2/(4πA) |

|---|---|---|---|---|---|---|---|---|

| 355–500 | Mean Median Std. Dev | 130,512 | 395.66 | 358.12 | 496.53 | 0.734 | 1435.71 | 1.29 |

| 128,716.2 | 396.74 | 356.10 | 481.85 | 0.727 | 1402.37 | 1.23 | ||

| 33,737.24 | 50.35 | 54.62 | 84.61 | 0.126 | 192.53 | 0.213 |

| Impact Angle θ, Deg. | Mass of Erodent mp, (g) | Corresponding Test Time t, (min.) |

|---|---|---|

| 15 | 1.8729 | 4.12 |

| 30 | 1.8729 | 2.06 |

| 45 | 1.8729 | 1.44 |

| 60 | 1.8729 | 1.17 |

| 75 | 1.8729 | 1.04 |

| 90 | 1.8729 | 1.00 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aldahash, S.A.; Abdelaal, O.; Abdelrhman, Y. Slurry Erosion–Corrosion Characteristics of As-Built Ti-6Al-4V Manufactured by Selective Laser Melting. Materials 2020, 13, 3967. https://doi.org/10.3390/ma13183967

Aldahash SA, Abdelaal O, Abdelrhman Y. Slurry Erosion–Corrosion Characteristics of As-Built Ti-6Al-4V Manufactured by Selective Laser Melting. Materials. 2020; 13(18):3967. https://doi.org/10.3390/ma13183967

Chicago/Turabian StyleAldahash, Saleh Ahmed, Osama Abdelaal, and Yasser Abdelrhman. 2020. "Slurry Erosion–Corrosion Characteristics of As-Built Ti-6Al-4V Manufactured by Selective Laser Melting" Materials 13, no. 18: 3967. https://doi.org/10.3390/ma13183967

APA StyleAldahash, S. A., Abdelaal, O., & Abdelrhman, Y. (2020). Slurry Erosion–Corrosion Characteristics of As-Built Ti-6Al-4V Manufactured by Selective Laser Melting. Materials, 13(18), 3967. https://doi.org/10.3390/ma13183967