Cu Precipitation Behaviors and Microscopic Mechanical Characteristics of a Novel Ultra-Low Carbon Steel

Abstract

1. Introduction

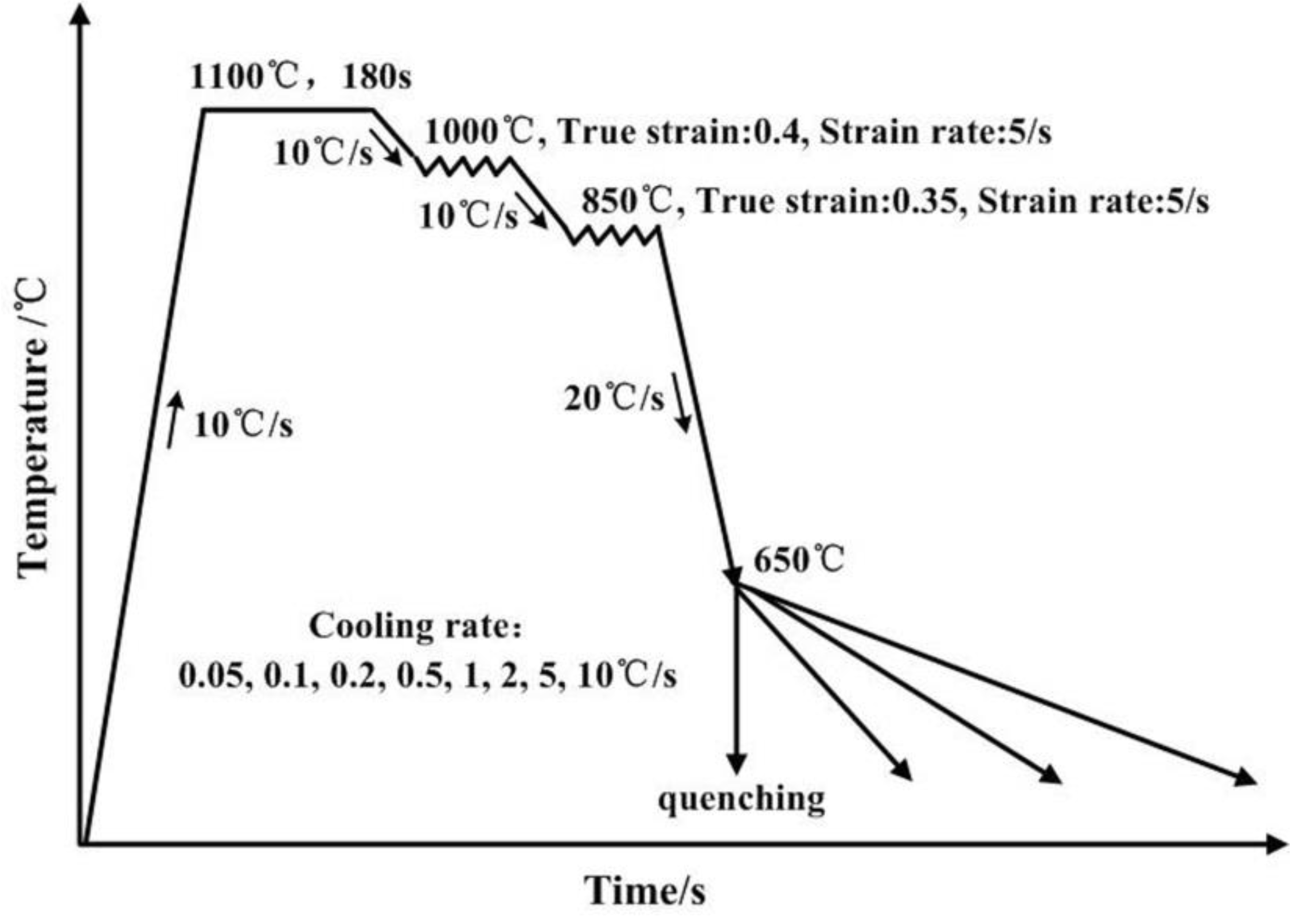

2. Experimental Procedure

3. Results

4. Discussion

4.1. Influence of Processing on Cu Precipitation

4.2. Influence of Processing on Precipitation Strengthening

5. Conclusions

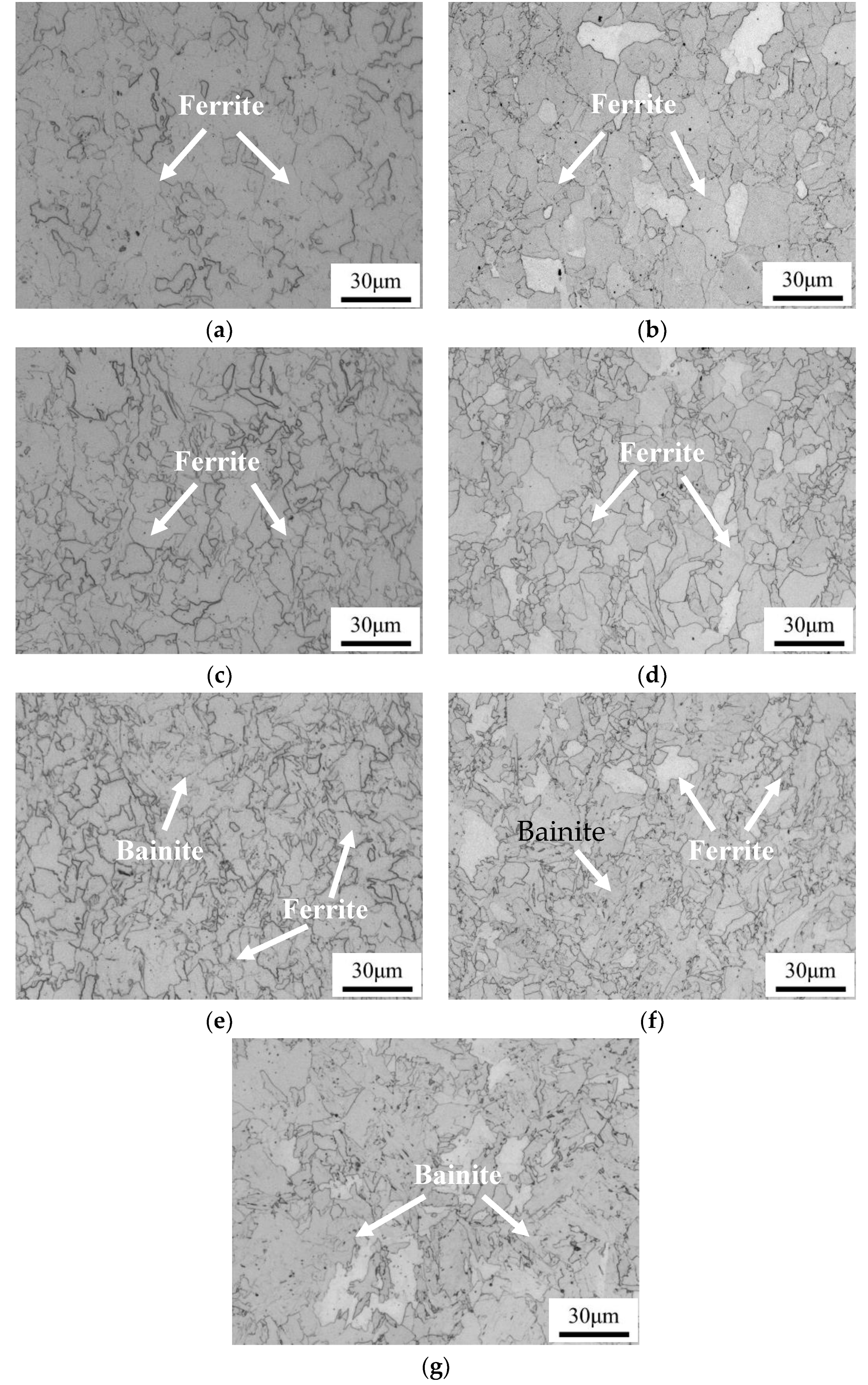

- As the cooling rate increases, the optical microstructure transforms from ferritic structure to ferritic + bainitic structure in the two steels. The addition of Cu can refine the ferritic structure.

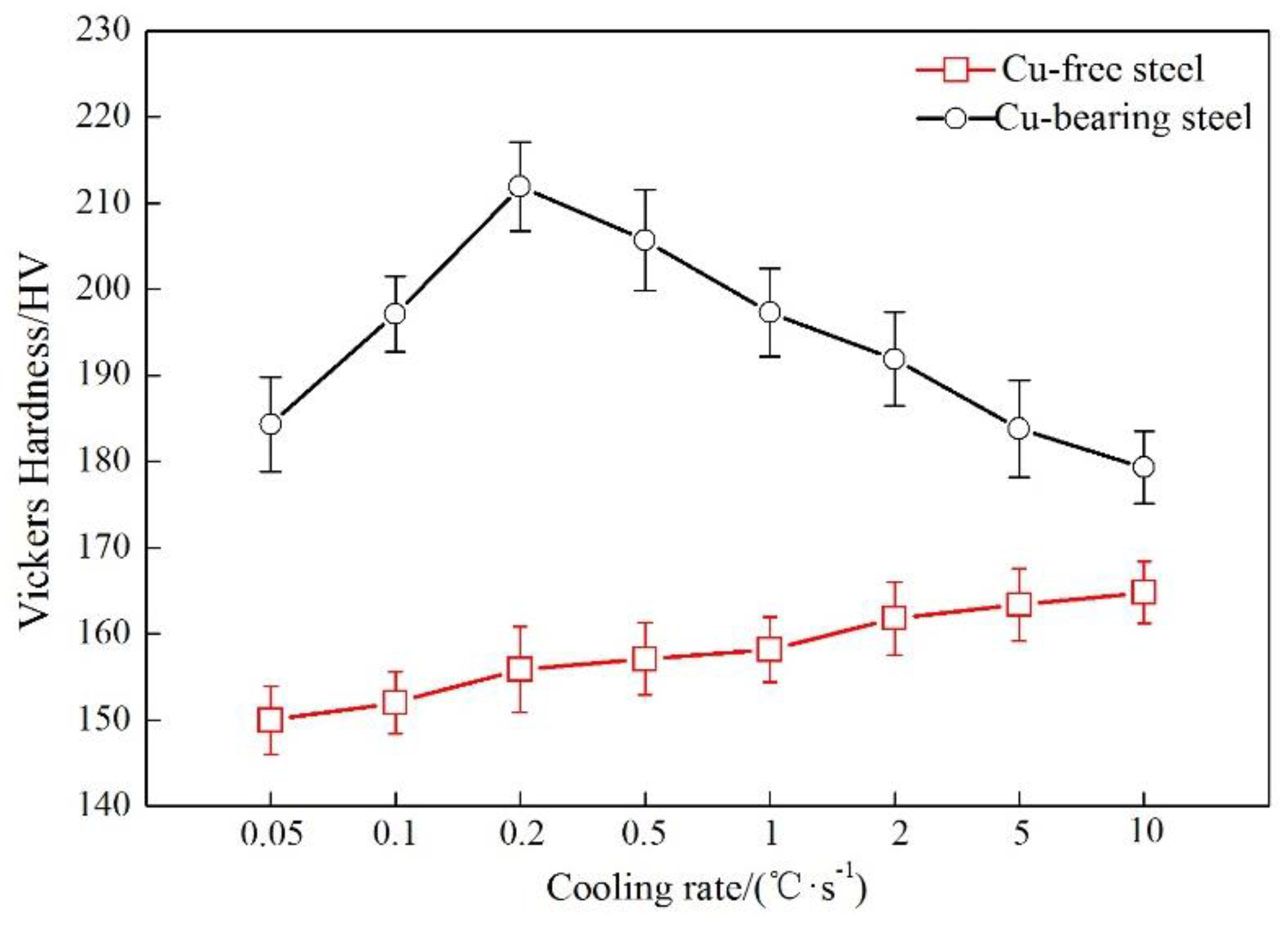

- The Vickers hardness values of Cu-free steel slowly rise with the increase of cooling rate, which can be attributed to the increase of structure strengthening. Due to the Cu precipitation strengthening effect, the Vickers hardness values of Cu-bearing steel are obviously higher than those of Cu-free steel. Cu-bearing steel attains the peak Vickers hardness at the cooling rate of 0.2 °C/s, with the hardness value of 212 HV.

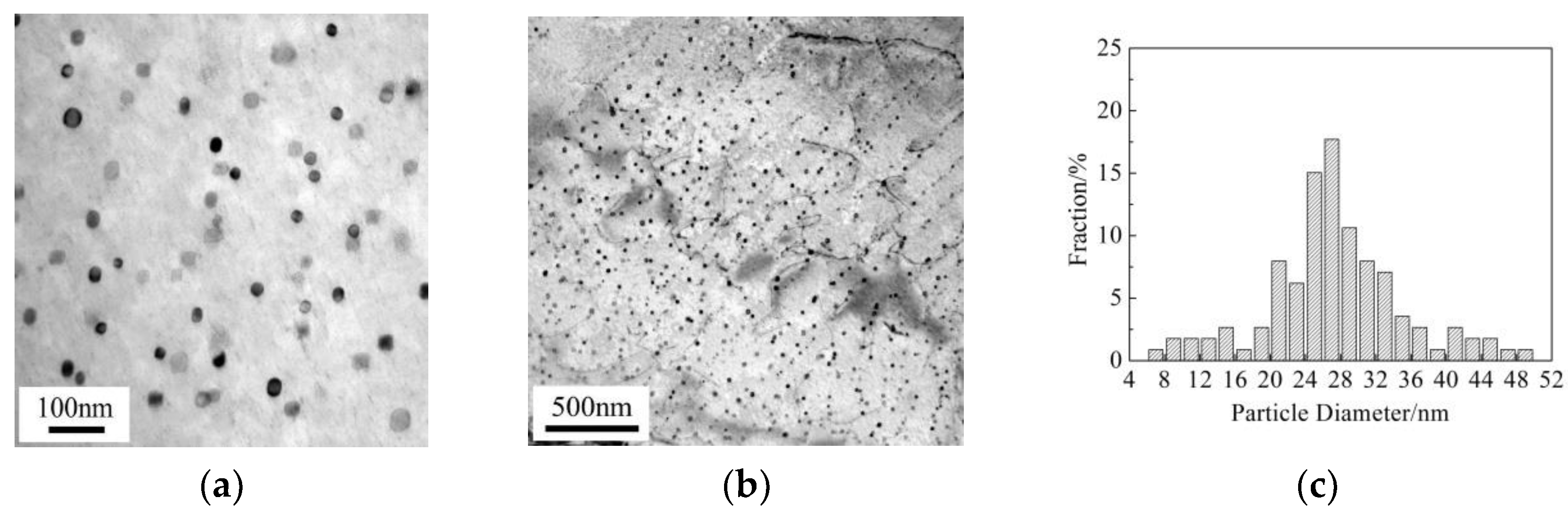

- Dispersive precipitation and interphase precipitation can be observed at a cooling rate below 0.2 °C/s, while interphase precipitation as well as partial dispersive precipitation can be suppressed at faster cooling rate of 5 °C/s. Dispersed Cu precipitates with particle diameter of 26.7 ± 3.6 nm and interphase Cu precipitates of 19.8 ± 3.5 nm can be observed at cooling rate of 0.05 °C/s, while the corresponding values decrease to 16.5 ± 2.6 nm and 7.8 ± 4.4 nm at cooling rate of 0.2 °C/s. The increasing of cooling rate significantly accelerates the formation and coarsening of Cu precipitates.

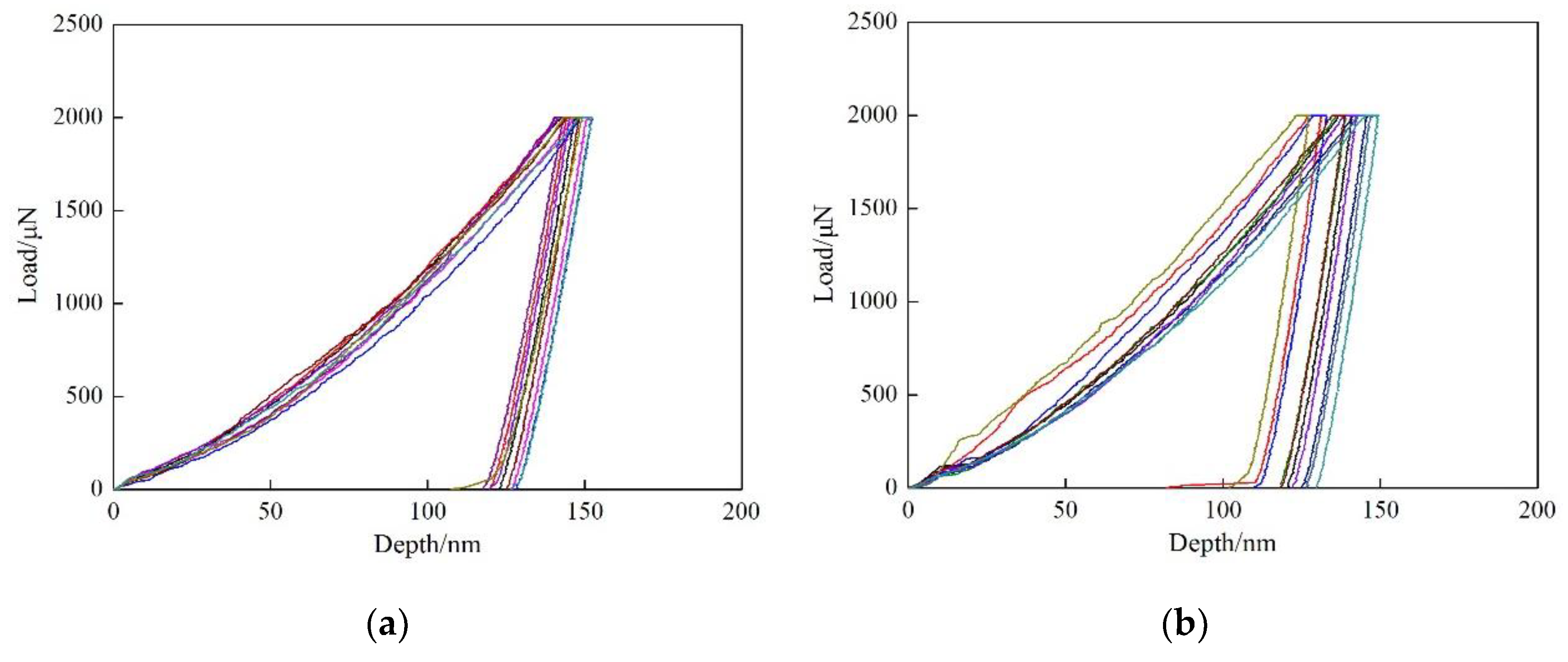

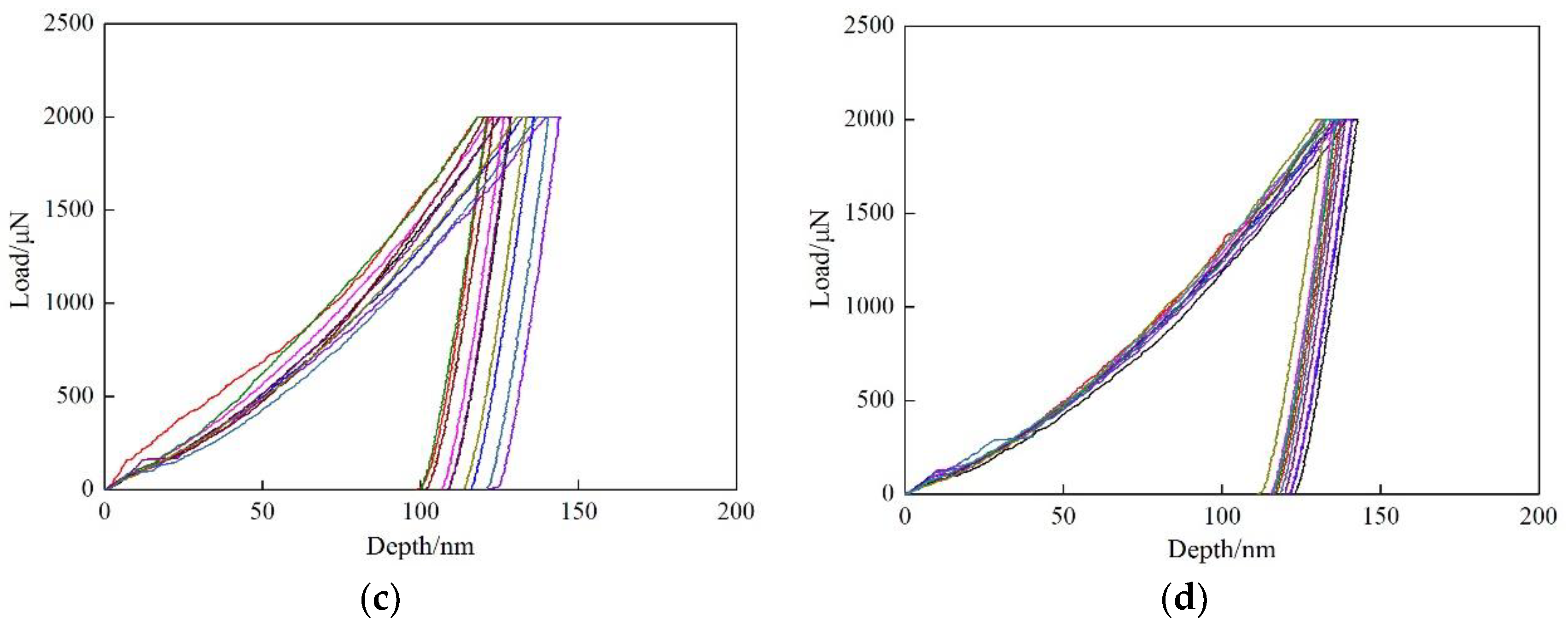

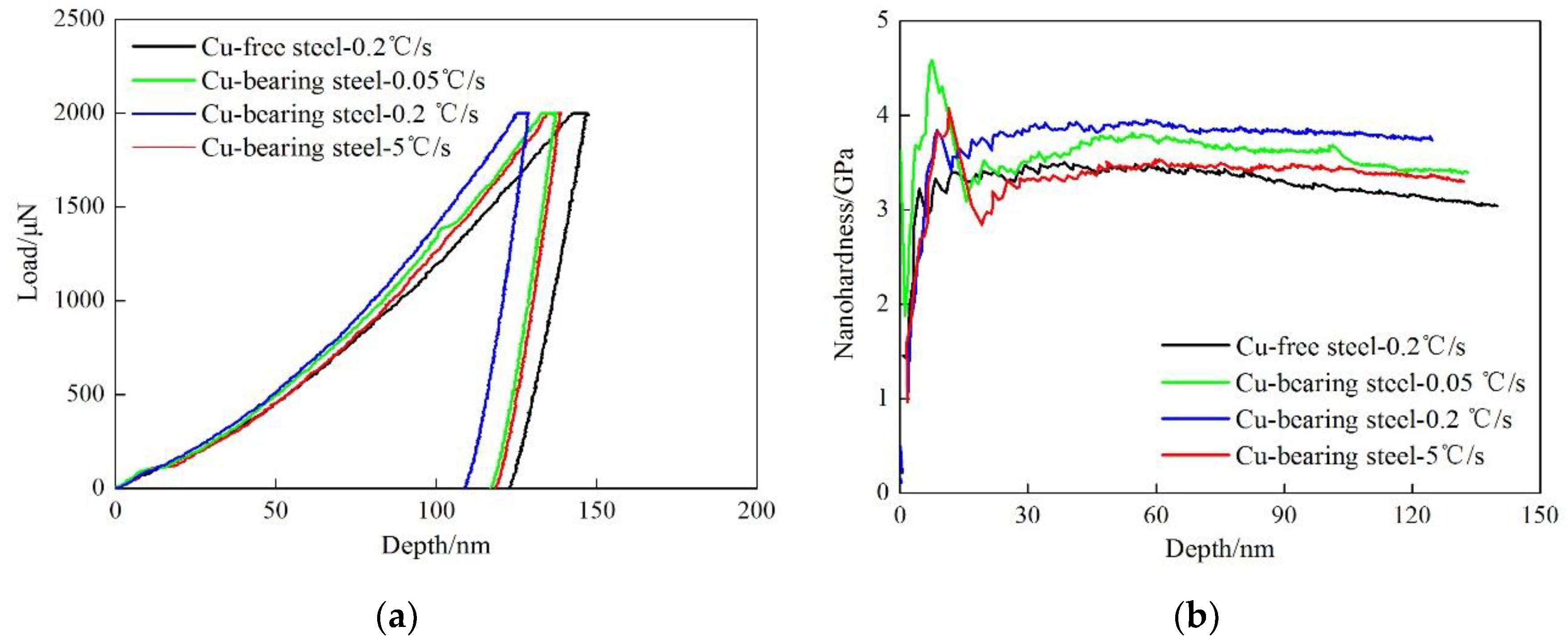

- The indentation depths on different cooling conditions are affected by the nature of Cu precipitation, resulting in the differences in nano-hardness and Young’s Modulus. The nano-hardness and Young’s Modulus of Cu-bearing steel are increased by 0.61 GPa and 55.5 GPa than those of Cu-free steel, respectively, suggesting that the addition of Cu can effectively strengthen the matrix. The experimental results of nano-indentation are in line with Vickers hardness tests.

- The Cu precipitation strengthening effects are estimated using the Russell–Brown model. The precipitation strengthening effects caused by interphase precipitation are obviously higher than those of dispersive precipitation, leading to a wide range of indentation depths. The variation of the calculated values is in line with the variation of nano-hardness, revealing that this model is suitable for calculating the strengthening effects.

Author Contributions

Funding

Conflicts of Interest

References

- Ray, P.K.; Ganguly, R.I.; Panda, A.K. Optimization of mechanical properties of an HSLA-100 steel through control of heat treatment variables. Mater. Sci. Eng. A 2003, 346, 122–131. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Jia, Z.; O’Malley, R.; Jansto, S.J. Precipitation behavior during thin slab thermomechanical processing and isothermal aging of copper-bearing niobium-microalloyed high strength structural steels: The effect on mechanical properties. Mater. Sci. Eng. A 2011, 528, 8772–8780. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Liu, C.T.; Wen, Y.R.; Hirata, A.; Guo, S.; Chen, G.; Chen, M.W.; Chin, B.A. Influence of aging and thermomechanical treatments on the mechanical properties of a nanocluster-strengthened ferritic steel. Metall. Mater. Trans. A 2012, 43, 351–358. [Google Scholar] [CrossRef]

- Dhua, S.K.; Mukerjee, D.; Sarma, D.S. Influence of thermomechanical treatments on the microstructure and mechanical properties of HSLA-100 steel plates. Metall. Mater. Trans. A 2003, 34, 241–253. [Google Scholar] [CrossRef]

- Schnitzer, R.; Schober, M.; Zinner, S.; Leitner, H. Effect of Cu on the evolution of precipitation in an Fe-Cr-Ni-Al-Ti maraging steel. Acta Mater. 2010, 58, 3733–3741. [Google Scholar] [CrossRef]

- Mujahid, M.; Lis, A.K.; Garcia, C.J.; Deardo, A.J. HSLA-100 steels: Influence of aging heat treatment on microstructure and properties. J. Mater. Eng. Perform. 1998, 7, 247–257. [Google Scholar] [CrossRef]

- Dhua, S.K.; Sen, S.K. Effect of direct quenching on the microstructure and mechanical properties of the lean-chemistry HSLA-100 steel plates. Mater. Sci. Eng. A 2011, 528, 6356–6365. [Google Scholar] [CrossRef]

- Hwang, G.C.; Lee, S.; Yoo, J.Y.; Choo, W.Y. Effect of direct quenching on microstructure and mechanical properties of copper-bearing high-strength alloy steels. Mater. Sci. Eng. A 1998, 252, 256–268. [Google Scholar] [CrossRef]

- Kapoor, M.; Isheim, D.; Vaynman, S.; Fine, M.E.; Chung, Y.W. Effects of increased alloying element content on NiAl-type precipitate formation, loading rate sensitivity, and ductility of Cu- and NiAl-precipitation-strengthened ferritic steels. Acta Mater. 2016, 104, 166–171. [Google Scholar] [CrossRef]

- Kapoor, M.; Isheim, D.; Ghosh, G.; Vaynman, S.; Fine, M.E.; Chung, Y.W. Aging characteristics and mechanical properties of 1600 MPa body-centered cubic Cu and B2-NiAl precipitation-strengthened ferritic steel. Acta Mater. 2014, 73, 56–74. [Google Scholar] [CrossRef]

- Wen, Y.R.; Li, Y.P.; Hirata, A.; Zhang, Y.; Fujita, T.; Furuhara, T.; Liu, C.T.; Chiba, A.; Chen, M.W. Synergistic alloying effect on microstructural evolution and mechanical properties of Cu precipitation-strengthened ferritic alloys. Acta Mater. 2013, 61, 7726–7740. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Liu, C.T.; Wang, X.L.; Miller, M.K.; Ma, D.; Chen, G.; Williams, J.R.; Chin, B.A. Effects of proton irradiation on nanocluster precipitation in ferritic steel containing fcc alloying additions. Acta Mater. 2012, 60, 3034–3046. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Miller, M.K.; Liu, C.T. Precipitation mechanism and mechanical properties of an ultra-high strength steel hardened by nanoscale NiAl and Cu particles. Acta Mater. 2015, 97, 58–67. [Google Scholar] [CrossRef]

- Liu, Q.D.; Zhao, S.J. Comparative study on austenite decomposition and Cu precipitation during continuous cooling transformation. Met. Mater. Trans. A 2013, 44, 163–171. [Google Scholar] [CrossRef]

- Thompson, S.W.; Krauss, G. Copper precipitation during continuous cooling and isothermal aging of A710-type steels. Met. Mater. Trans. A 1996, 27, 1573–1588. [Google Scholar] [CrossRef]

- Das, S.; Ghosh, A.; Chatterjee, S.; Rao, P.R. The effect of cooling rate on structure and properties of a HSLA forging. Scr. Mater. 2003, 48, 51–57. [Google Scholar] [CrossRef]

- Ghosh, A.; Das, S.; Chatterjee, S.; Rao, P.R. Effect of cooling rate on structure and properties of an ultra-low carbon HSLA-100 grade steel. Mater. Charact. 2006, 56, 59–65. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Zhang, Z.W.; Miller, M.K.; Ma, W.B.; Liu, C.T. Synergistic effects of Cu and Ni on nanoscale precipitation and mechanical properties of high-strength steels. Acta Mater. 2013, 61, 5996–6005. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Liu, C.T.; Miller, M.K.; Wang, S.L.; Wen, Y.; Fujita, T.; Hirata, A.; Chen, M.W.; Chen, G.; Chin, B.A. A nanoscale co-precipitation approach for property enhancement of Fe-base alloys. Sci. Rep. 2013, 3, 1327. [Google Scholar] [CrossRef]

- Kolli, R.P.; Seidman, D.N. The temporal evolution of the decomposition of a concentrated multicomponent Fe-Cu-based steel. Acta Mater. 2008, 56, 2073–2088. [Google Scholar] [CrossRef]

- Ast, J.; Ghidelli, M.; Durst, K.; Gökene, M.; Sebastiani, M.; Korsunsky, A.M. A review of experimental approaches to fracture toughness evaluation at the micro-scale. Mater. Des. 2019, 173, 107762. [Google Scholar] [CrossRef]

- Ghidelli, M.; Sebastiani, M.; Collet, C.; Guillemet, R. Determination of the elastic moduli and residual stresses of freestanding Au-TiW bilayer thin films by nanoindentation. Mater. Des. 2016, 106, 436–445. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, W.N.; Sun, M.X.; Yi, H.L.; Liu, Z.Y. The blocking effects of interphase precipitation on dislocations’ movement in Ti-bearing micro-alloyed steels. Mater. Lett. 2015, 139, 177–181. [Google Scholar] [CrossRef]

- Zhang, L.J.; Liang, M.Y.; Feng, Z.Q.; Zhang, L.; Cao, W.Q.; Wu, G.L. Nanoindentation characterization of strengthening mechanism in a high strength ferrite/martensite steel. Mater. Sci. Eng. A 2019, 745, 144–148. [Google Scholar] [CrossRef]

- Jin, J.; Wang, W.; Chen, X.C. Microstructure and mechanical properties of Ti + N ion implanted cronidur30 steel. Materials 2019, 12, 427. [Google Scholar] [CrossRef]

- ASTM A751. Standard Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Bhushan, B.; Kulkami, A.V.; Bonin, W.; Wyrobek, J.T. Nanoindentation and picoindentation measurements using a capacitive transducer system in atomic force microscopy. Philos. Mag. A 1996, 74, 1117–1128. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, M.X.; Zhou, Y.L.; Liu, Z.Y.; Wang, G.D. Effect of Mo on nano-precipitation behavior and microscopic mechanical characteristics of ferrite. Steel Res. Int. 2015, 86, 1056–1062. [Google Scholar] [CrossRef]

- Takahashi, J.; Kawakami, K.; Kobayashi, Y. Consideration of particle-strengthening mechanism of copper-precipitation-strengthened steels by atom probe tomography analysis. Mater. Sci. Eng. A 2012, 535, 144–152. [Google Scholar] [CrossRef]

- Karkin, I.N.; Gornostyrev, Y.N.; Karkina, L.E. Atomistic simulation of interaction between Cu precipitates and edge dislocation in BCC Fe crystal. Rev. Adv. Mater. Sci. 2010, 25, 164–167. [Google Scholar]

- Russel, K.C.; Brown, L.M. A dispersion strengthening model based on differing elastic moduli applied to the iron-copper system. Acta Met. 1972, 20, 969–974. [Google Scholar] [CrossRef]

- Kong, H.J.; Xu, C.; Bu, C.C.; Da, C.; Luan, J.H.; Jiao, Z.B.; Chen, G.; Liu, C.T. Hardening mechanisms and impact toughening of a high-strength steel containing low Ni and Cu additions. Acta Mater. 2019, 172, 150–160. [Google Scholar] [CrossRef]

- Deschamps, A.; Militzer, M.; Poole, W.J. Precipitation kinetics strengthening of a Fe-0.8 wt% Cu alloy. ISIJ Int. 2001, 41, 196–205. [Google Scholar] [CrossRef]

| No. | Fe | C | Si | Mn | P | S | Ni | Cr | Cu | Al | N |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu-free | Balance | 0.0065 | 0.21 | 0.68 | 0.010 | 0.004 | 2.53 | 0.48 | - | 0.028 | 0.0050 |

| Cu-bearing | Balance | 0.0050 | 0.20 | 0.70 | 0.010 | 0.004 | 2.49 | 0.47 | 2.01 | 0.030 | 0.0050 |

| Cooling Rate, °C/s | Dispersive Precipitation, MPa | Interphase Precipitation, MPa |

|---|---|---|

| 0.05 | 132.3 | 147.9 |

| 0.2 | 182.3 | 211.8 |

| 5 | 112.4 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Xu, Y.; Xu, T. Cu Precipitation Behaviors and Microscopic Mechanical Characteristics of a Novel Ultra-Low Carbon Steel. Materials 2020, 13, 3571. https://doi.org/10.3390/ma13163571

Sun M, Xu Y, Xu T. Cu Precipitation Behaviors and Microscopic Mechanical Characteristics of a Novel Ultra-Low Carbon Steel. Materials. 2020; 13(16):3571. https://doi.org/10.3390/ma13163571

Chicago/Turabian StyleSun, Mingxue, Yang Xu, and Tiewei Xu. 2020. "Cu Precipitation Behaviors and Microscopic Mechanical Characteristics of a Novel Ultra-Low Carbon Steel" Materials 13, no. 16: 3571. https://doi.org/10.3390/ma13163571

APA StyleSun, M., Xu, Y., & Xu, T. (2020). Cu Precipitation Behaviors and Microscopic Mechanical Characteristics of a Novel Ultra-Low Carbon Steel. Materials, 13(16), 3571. https://doi.org/10.3390/ma13163571