Incorporation of Alkali-Activated Municipal Solid Waste Incinerator Bottom Ash in Mortar and Concrete: A Critical Review

Abstract

1. Introduction

- (i)

- Agricultural wastes and aquaculture farming ashes: rise husk ash [1,2], palm oil fuel ash [3,4,5,6], corn cob ash [7,8], sugarcane bagasse ash [9], straw ash [7,10], forest biomass bottom ash [11], wood ashes [12,13], other agriculture-farming wastes (e.g., alfalfa steam ash, cotton gin ash, com stalk ash and switch grass ash [7,14,15]), and shell wastes [16,17];

- (ii)

- Industrial waste ashes: FA [18,19,20,21,22,23,24,25,26,27], coal bottom ash [28], industrials slags [3,20,29,30,31,32,33,34], silica fume [35,36,37,38,39,40,41,42], artificial pozzolans (calcined clays [34,43,44,45], ceramic residues [46,47], sedimentary rocks containing clay minerals and burned bauxites [48,49,50]), natural pozzolans (volcanic tuffs/zeolites [51,52], siliceous such as opal and diatomaceous earth [53,54,55,56,57], and volcanic glasses such as volcanic ashes [58,59,60,61,62], pumice and pumicite [63,64,65];

- (iii)

- Municipal solid waste ashes: glass powder [66,67,68,69,70,71,72], sludge ashes [73,74,75,76,77], and municipal solid waste incinerator fly ash [78,79,80,81,82,83,84,85,86], and municipal solid waste incinerator bottom ash [86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109].

2. Methodology

- Bottom ash;

- Concrete;

- Geopolymer;

- Hybrid cements;

- Hydrothermal synthesis;

- Incineration;

- Incinerator bottom ash;

- Inertization;

- Mortar;

- Municipal solid waste;

- Paste;

- Stabilization/solidification.

- Papers explicitly concerning alkali-activated paste, mortar, and/or concrete made with MIBA as the sole precursor or MIBA blended with other supplementary cementitious materials (SCM) or ordinary Portland cement (OPC);

- MIBA must be used as a precursor (binder). Other applications of MIBA e.g., studies on AAM containing MIBA as aggregate were excluded.

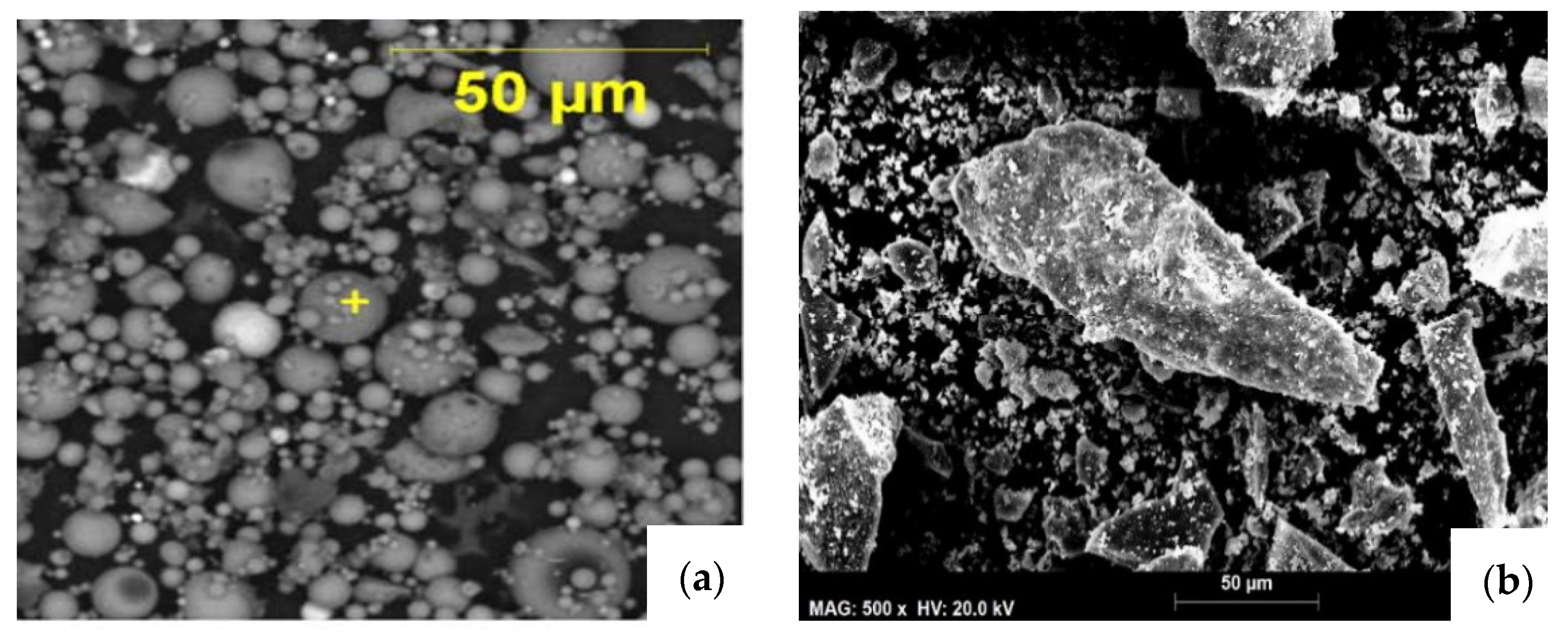

3. Physical and Chemical Characteristics of MIBA

4. Alkali-Activated Materials with MIBA as Sole/Partial Precursor

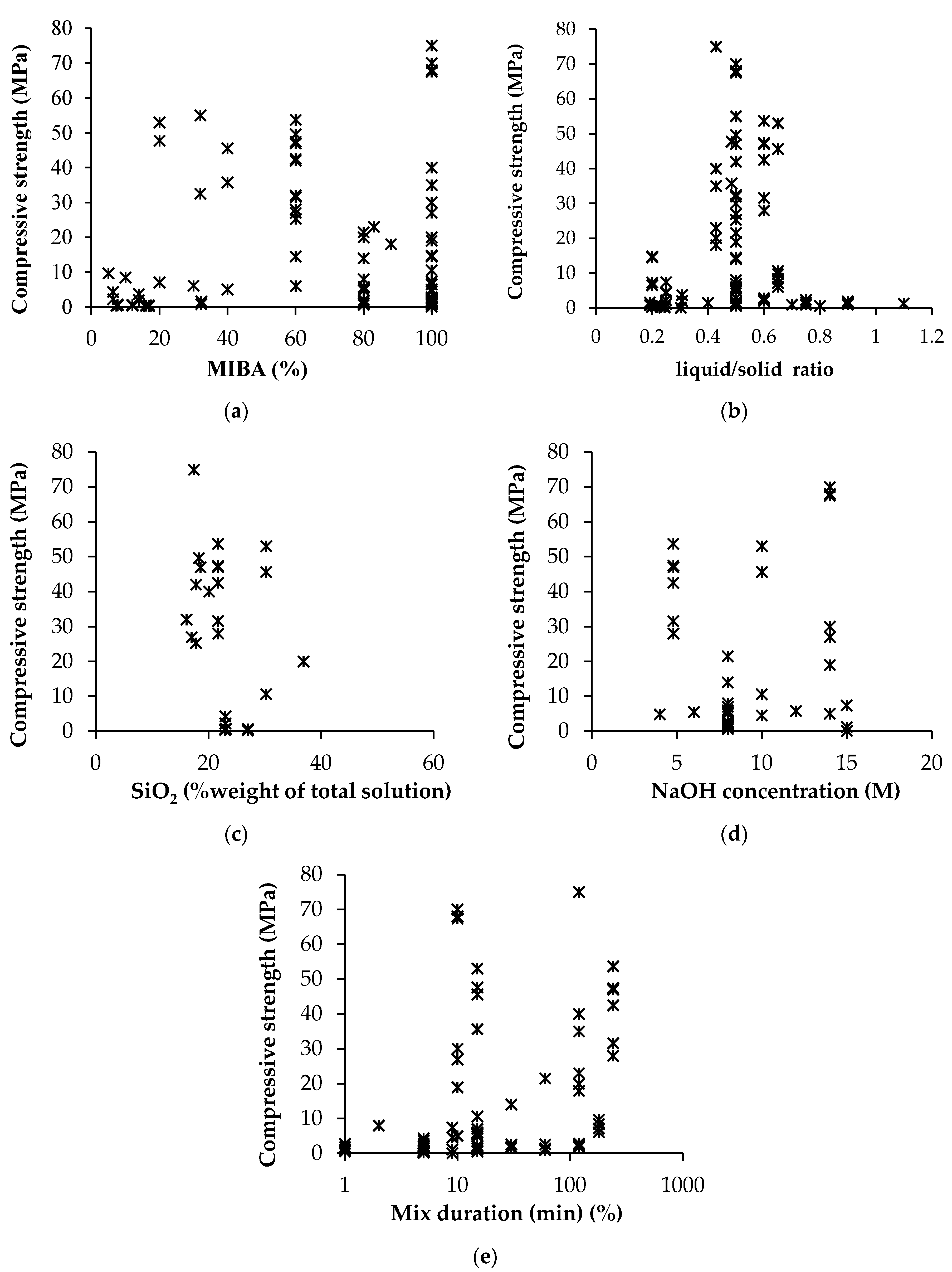

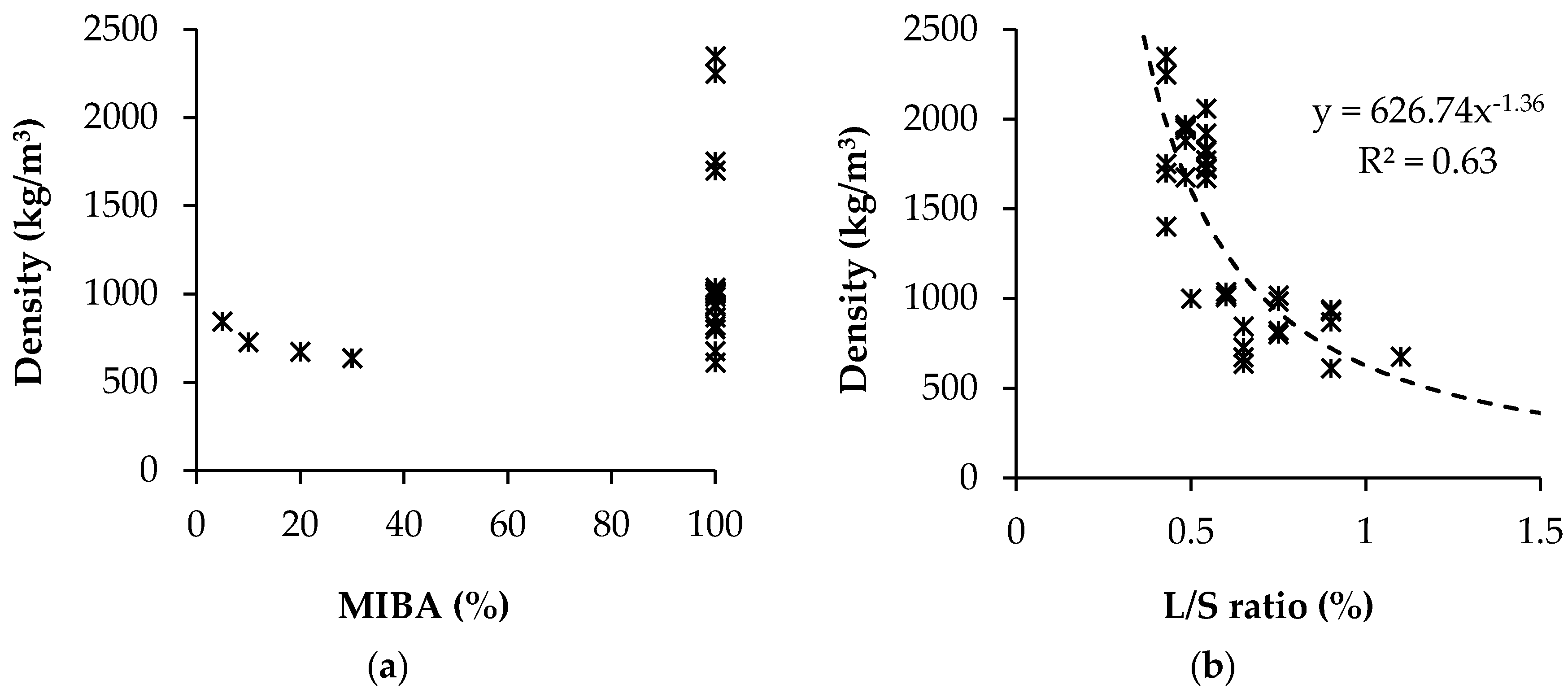

4.1. Fresh, Mechanical and Durability Performance

| Study | Sample | Tests | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mechanical Performance | Toxicity | XRD a | SEM b | FT-IR c | XRF d | Density-Porosity | Conductivity—Heat | Setting Time | pH | Others | ||

| Zhu et al. [134] | Paste | X | - | X | - | X | - | - | - | - | - | NMR e |

| Cristelo et al. [136] | Paste | X | X | X | X | X | - | - | - | - | - | |

| Rożek et al. [89] | Paste | X | X | X | X | X | X | X | - | - | - | Raman spectra |

| Zhu et al. [90] | Paste | X | - | X | - | X | X | X | - | - | - | - |

| Giro-Paloma et al. [91] | Paste | - | X | X | X | X | X | - | - | - | X | TGA f |

| Chen et al. [92] | Paste | X | X | X | X | X | - | X | - | - | - | - |

| Zhu et al. [88] | Paste | X | - | - | - | X | X | X | - | - | - | NMR e |

| Song et al. [94] | Paste | X | - | X | X | - | - | X | - | - | - | Gas production; shrinkage |

| Kim and Kang [95] | Paste | X | - | X | X | - | - | - | - | - | - | - |

| Lancellotti et al. [96] | Paste | - | X | X | X | X | - | - | X | - | - | EDS g |

| Krausova et al. [109] | Paste | - | X | X | X | - | - | X | - | - | X | - |

| Galiano et al. [108] | Paste | X | X | - | - | - | - | - | - | - | X | - |

| Onori et al. [97] | Paste | X | X | - | X | X | - | X | - | - | X | TGA f |

| Qiao et al. [98] | Paste | X | - | X | X | - | X | - | - | X | - | Gas production |

| Qiao et al. [107] | Paste | X | X | X | X | - | - | X | - | X | - | - |

| Huang et al. [99] | Mortar | X | - | X | X | X | - | - | - | - | - | Active silica content; EDS g |

| Huang et al. [100] | Mortar | X | X | X | X | X | - | - | - | - | X | - |

| Huang et al. [137] | Mortar | X | - | X | - | X | - | - | - | - | - | TGA f |

| Liu et al. [101] | Mortar | X | - | X | - | - | - | X | - | - | - | Release of gas |

| Wongsa et al. [102] | Mortar | X | - | X | X | X | - | X | - | - | - | - |

| Garcia-Lodeiro et al. [103] | Mortar | X | X | X | X | - | - | - | - | - | - | - |

| Jing et al. [104] | Mortar | - | X | X | X | - | - | X | - | - | - | - |

| Penilla et al. [105] | Mortar | - | - | X | X | X | - | - | - | - | - | - |

| Huang et al. [135] | Concrete | X | - | X | - | X | - | - | - | - | X | Carbonation |

| Xuan et al. [106] | Concrete | X | - | X | X | X | X | X | X | - | - | EDS g |

4.2. Effect of Alkali Activator Composition

| Studies | Precursor * | Na2SiO3/NaOH Ratio | NaOH Concentration (M) | Silica Modulus (SiO2/Na2O ratio) | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Range | Optimum | Range | Optimum | Range | Optimum | |||

| Görhan and Kürklü [143] | FA | - | - | 3–9 | 6 | 3.0 | - | 12–23 |

| Sukmak et al. [144] | FA | 0.4–2.3 | 0.7 | 10 | - | - | - | 4–14 |

| Somna et al. [145] | FA | - | - | 4.5–16.5 | 14.0- | - | - | 7–23 |

| Ridtirud et al. [146] | FA | 0.33–3.0 | 1.5 | 7.5–12.5 | 7.5 | - | - | 25–45 |

| Guo et al. [147] | FA | - | - | - | - | 1.0–2.0 | 1.5 | 5–63 |

| Law et al. [148] | FA | - | - | 10 | - | 0.75–1.25 | 1.0 | 39–57 |

| He et al. [149] | RHA | - | - | 2–6 | 2 | - | - | 8–15 |

| Nazari et al. [150] | RHA | 2.5 | - | 4–12 | 12 | - | - | 20–30 |

| Songpiriyakij et al. [151] | RHA | 0.5–2.5 | - | 14, 18 | 18 | 0.13–0.27 | 0.13 | 22–56 |

| Detphan and Chindaprasirt [1] | RHA | 1.9–5.5 | 4.0 | - | - | - | - | 15–40 |

| Salih et al. [6] | POFA | 0.5–3.0 | 2.5 | 10 | - | - | - | 7–32 |

| Yusuf et al. [152] | POFA | - | - | 10 | - | 0.92–1.64 | 0.92 | 65–69 |

| Ahmari and Zhang [153] | MS | - | - | 10–15 | 15 | - | - | 4–34 |

| Wongsa et al. [102] | MIBA | 1 | - | 10 | - | - | - | 10.6 |

| Zhu et al. [90] | MIBA | 0.5 | - | 8 | - | - | - | 2.8 |

4.3. Influence of Thermal Curing Regime on the Performance of the MIBA-Based AAM

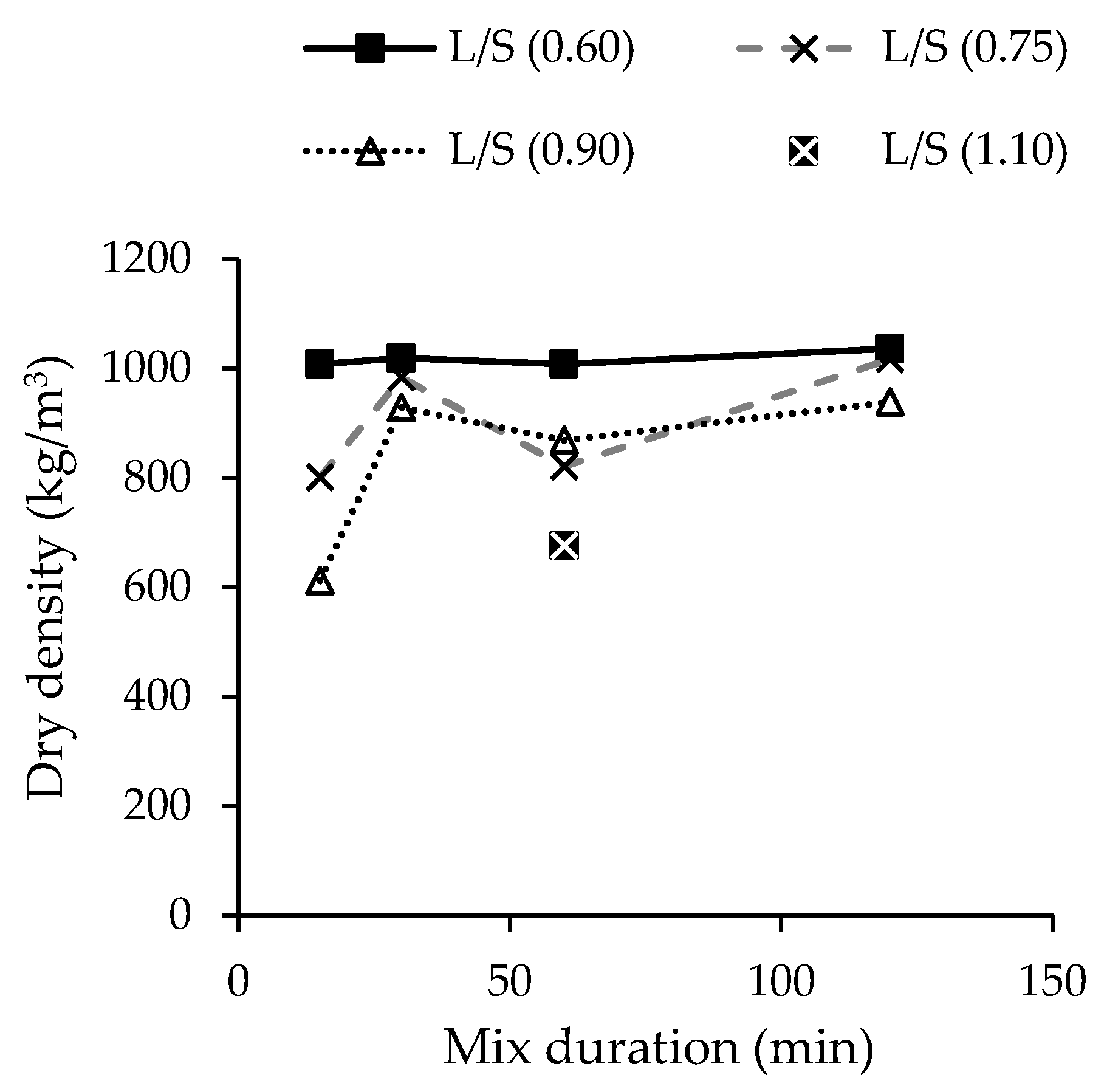

4.4. Performance-Enhacing Treatments

4.4.1. Thermal Treatment

4.4.2. Defoaming Process

4.4.3. Pressing Technique

4.5. Microstructure

4.6. Toxicity

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Detphan, S.; Chindaprasirt, P. Preparation of fly ash and rice husk ash geopolymer. Int. J. Min. Metal. Mater. 2009, 16, 720–726. [Google Scholar]

- Bernal, S.A.; Rodríguez, E.D.; de Gutiérrez, R.M.; Provis, J.L.; Delvasto, S. Activation of metakaolin/slag blends using alkaline solutions based on chemically modified silica fume and rice husk ash. Waste Biomass Valorization 2012, 3, 99–108. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Bashar, I.I. The development of compressive strength of ground granulated blast furnace slag-palm oil fuel ash-fly ash based geopolymer mortar. Mater. Des. 2014, 56, 833–841. [Google Scholar] [CrossRef]

- Zarina, Y.; Al Bakri, A.M.; Kamarudin, H.; Nizar, I.K.; Rafiza, A. Review on the various ash from palm oil waste as geopolymer material. Rev. Adv. Mater. Sci. 2013, 34, 37–43. [Google Scholar]

- Ranjbar, N.; Mehrali, M.; Alengaram, U.J.; Metselaar, H.S.C.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar under elevated temperatures. Constr. Build. Mater. 2014, 65, 114–121. [Google Scholar] [CrossRef]

- Salih, M.A.; Abang Ali, A.A.; Farzadnia, N. Characterization of mechanical and microstructural properties of palm oil fuel ash geopolymer cement paste. Constr. Build. Mater. 2014, 65, 592–603. [Google Scholar] [CrossRef]

- Matalkah, F.; Darsanasiri, A.; Abideen, S.; Balachadra, A.; Soroushian, P. Alkali-Activation of Non-Wood Biomass Ash: Effects of Ash Characteristics on Concrete Performance. Civ. Eng. J. 2017, 3, 365–371. [Google Scholar] [CrossRef]

- Oyebisi, S.; Ede, A.; Olutoge, F.; Ofuyatan, O.M.; Oluwafemi, J. Influence of Alkali Concentrations on the Mechanical Properties of Geopolymer Concrete. Int. J. Civ. Eng. Technol. (IJCIET) 2018, 9, 734–743. [Google Scholar]

- Castaldelli, V.; Akasaki, J.; Melges, J.; Tashima, M.; Soriano, L.; Borrachero, M.; Monzó, J.; Payá, J. Use of slag/sugar cane bagasse ash (SCBA) blends in the production of alkali-activated materials. Materials 2013, 6, 3108–3127. [Google Scholar] [CrossRef]

- Al-Akhras, N.M. Durability of wheat straw ash concrete to alkali-silica reaction. Proc. Inst. Civ. Eng.-Constr. Mater. 2013, 166, 65–70. [Google Scholar] [CrossRef]

- Girón, R.P.; Gil, R.R.; Suárez-Ruiz, I.; Fuente, E.; Ruiz, B. Adsorbents/catalysts from forest biomass fly ash. Influence of alkaline activating agent. Microporous Mesoporous Mater. 2015, 209, 45–53. [Google Scholar] [CrossRef]

- Cheah, C.B.; Samsudin, M.H.; Ramli, M.; Part, W.K.; Tan, L.E. The use of high calcium wood ash in the preparation of Ground Granulated Blast Furnace Slag and Pulverized Fly Ash geopolymers: A complete microstructural and mechanical characterization. J. Clean. Prod. 2017, 156, 114–123. [Google Scholar] [CrossRef]

- Matalkah, F.; Soroushian, P.; Ul Abideen, S.; Peyvandi, A. Use of non-wood biomass combustion ash in development of alkali-activated concrete. Constr. Build. Mater. 2016, 121, 491–500. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; Kirchheim, A.P.; Provis, J.L. Management and valorisation of wastes through use in producing alkali-activated cement materials. J. Chem. Technol. Biotechnol. 2016, 91, 2365–2388. [Google Scholar] [CrossRef]

- Alonso, M.M.; Gascó, C.; Morales, M.M.; Suárez-Navarro, J.A.; Zamorano, M.; Puertas, F. Olive biomass ash as an alternative activator in geopolymer formation: A study of strength, radiology and leaching behaviour. Cem. Concr. Compos. 2019, 104, 103384. [Google Scholar] [CrossRef]

- Monneron-Gyurits, M.; Joussein, E.; Soubrand, M.; Fondanèche, P.; Rossignol, S. Valorization of mussel and oyster shells toward metakaolin-based alkaline activated material. Appl. Clay Sci. 2018, 162, 15–26. [Google Scholar] [CrossRef]

- Djobo, Y.J.N.; Elimbi, A.; Dika Manga, J.; Djon Li Ndjock, I.B. Partial replacement of volcanic ash by bauxite and calcined oyster shell in the synthesis of volcanic ash-based geopolymers. Constr. Build. Mater. 2016, 113, 673–681. [Google Scholar] [CrossRef]

- Singh, N.B.; Middendorf, B. Geopolymers as an alternative to Portland cement: An overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Zhou, W.; Yan, C.; Duan, P.; Liu, Y.; Zhang, Z.; Qiu, X.; Li, D. A comparative study of high-and low-Al2O3 fly ash based-geopolymers: The role of mix proportion factors and curing temperature. Mater. Des. 2016, 95, 63–74. [Google Scholar] [CrossRef]

- Payá, J.; Agrela, F.; Rosales, J.; Morales, M.M.; Borrachero, M.V. 13-Application of alkali-activated industrial waste. In New Trends in Eco-efficient and Recycled Concrete; de Brito, J., Agrela, F., Eds.; Woodhead Publishing: Sawston, Cambridge, UK, 2019; pp. 357–424. [Google Scholar]

- Zhang, Z.; Provis, J.L.; Zou, J.; Reid, A.; Wang, H. Toward an indexing approach to evaluate fly ashes for geopolymer manufacture. Cem. Concr. Res. 2016, 85, 163–173. [Google Scholar] [CrossRef]

- Palomo, A.; Fernández-Jiménez, A. Alkaline activation, procedure for transforming fly ash into new materials. Part I: Applications. In Proceedings of the World of Coal Ash (WOCA) Conference, Denver, CO, USA, 9–12 May 2011; pp. 1–14. [Google Scholar]

- Hajimohammadi, A.; van Deventer, J.S. Characterisation of one-part geopolymer binders made from fly ash. Waste Biomass Valorization 2017, 8, 225–233. [Google Scholar] [CrossRef]

- Choo, H.; Lim, S.; Lee, W.; Lee, C. Compressive strength of one-part alkali activated fly ash using red mud as alkali supplier. Constr. Build. Mater. 2016, 125, 21–28. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.U.A. Comparative deflection hardening behavior of short fiber reinforced geopolymer composites. Constr. Build. Mater. 2014, 70, 54–64. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Optimizing recycled concrete containing high volume of fly ash in terms of the embodied energy and chloride ion resistance. J. Clean. Prod. 2018, 194, 735–750. [Google Scholar] [CrossRef]

- Donatello, S.; Maltseva, O.; Fernandez-Jimenez, A.; Palomo, A. The early age hydration reactions of a hybrid cement containing a very high content of coal bottom ash. J. Am. Ceram. Soc. 2014, 97, 929–937. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; de Moraes Pinheiro, S.M.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Design and properties of 100% waste-based ternary alkali-activated mortars: Blast furnace slag, olive-stone biomass ash and rice husk ash. J. Clean. Prod. 2020, 243, 118568. [Google Scholar] [CrossRef]

- Huseien, G.F.; Tahir, M.M.; Mirza, J.; Ismail, M.; Shah, K.W.; Asaad, M.A. Effects of POFA replaced with FA on durability properties of GBFS included alkali activated mortars. Constr. Build. Mater. 2018, 175, 174–186. [Google Scholar] [CrossRef]

- Li, Z.; Liu, S. Influence of slag as additive on compressive strength of fly ash-based geopolymer. J. Mater. Civ. Eng. 2007, 19, 470–474. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. Mechanical and microstructural properties of heat cured alkali-activated slag mortars. Mater. Des. 2012, 35, 374–383. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Sustainable geopolymer concrete using ground granulated blast furnace slag and rice husk ash: Strength and permeability properties. J. Clean. Prod. 2018, 205, 49–57. [Google Scholar] [CrossRef]

- Sun, Z.; Lin, X.; Vollpracht, A. Pervious concrete made of alkali activated slag and geopolymers. Constr. Build. Mater. 2018, 189, 797–803. [Google Scholar] [CrossRef]

- Assi, L.; Carter, K.; Deaver, E.; Anay, R.; Ziehl, P. Sustainable concrete: Building a greener future. J. Clean. Prod. 2018, 198, 1641–1651. [Google Scholar] [CrossRef]

- Çevik, A.; Alzeebaree, R.; Humur, G.; Niş, A.; Gülşan, M.E. Effect of nano-silica on the chemical durability and mechanical performance of fly ash based geopolymer concrete. Ceram. Int. 2018, 44, 12253–12264. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Zhou, W. Compressive strength and microstructure of fly ash based geopolymer blended with silica fume under thermal cycle. Cem. Concr. Compos. 2017, 78, 108–119. [Google Scholar] [CrossRef]

- Daniel, A.J.; Sivakamasundari, S.; Nishanth, A. Study on Partial Replacement of Silica Fume Based Geopolymer Concrete Beam Behavior under Torsion. Procedia Eng. 2017, 173, 732–739. [Google Scholar] [CrossRef]

- Okoye, F.N.; Durgaprasad, J.; Singh, N.B. Effect of silica fume on the mechanical properties of fly ash based-geopolymer concrete. Ceram. Int. 2016, 42, 3000–3006. [Google Scholar] [CrossRef]

- Assi, L.N.; Deaver, E.; Ziehl, P. Using sucrose for improvement of initial and final setting times of silica fume-based activating solution of fly ash geopolymer concrete. Constr. Build. Mater. 2018, 191, 47–55. [Google Scholar] [CrossRef]

- Okoye, F.N.; Prakash, S.; Singh, N.B. Durability of fly ash based geopolymer concrete in the presence of silica fume. J. Clean. Prod. 2017, 149, 1062–1067. [Google Scholar] [CrossRef]

- Kovtun, M.; Kearsley, E.P.; Shekhovtsova, J. Dry powder alkali-activated slag cements. Adv. Cem. Res. 2015, 27, 447–456. [Google Scholar] [CrossRef]

- Granizo, M.; Blanco-Varela, M.; Palomo, A. Influence of the starting kaolin on alkali-activated materials based on metakaolin. Study of the reaction parameters by isothermal conduction calorimetry. J. Mater. Sci. 2000, 35, 6309–6315. [Google Scholar] [CrossRef]

- Longhi, M.A.; Rodríguez, E.D.; Bernal, S.A.; Provis, J.L.; Kirchheim, A.P. Valorisation of a kaolin mining waste for the production of geopolymers. J. Clean. Prod. 2016, 115, 265–272. [Google Scholar] [CrossRef]

- Duxson, P.; Mallicoat, S.W.; Lukey, G.C.; Kriven, W.M.; van Deventer, J.S. The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloids Surf. Physicochem. Eng. Aspects 2007, 292, 8–20. [Google Scholar] [CrossRef]

- Shoaei, P.; Musaeei, H.R.; Mirlohi, F.; Narimani zamanabadi, S.; Ameri, F.; Bahrami, N. Waste ceramic powder-based geopolymer mortars: Effect of curing temperature and alkaline solution-to-binder ratio. Constr. Build. Mater. 2019, 227, 116686. [Google Scholar] [CrossRef]

- Reig, L.; Tashima, M.; Soriano, L.; Borrachero, M.; Monzó, J.; Payá, J. Alkaline activation of ceramic waste materials. Waste Biomass Valorization 2013, 4, 729–736. [Google Scholar] [CrossRef]

- Dimas, D.D.; Giannopoulou, I.P.; Panias, D. Utilization of alumina red mud for synthesis of inorganic polymeric materials. Miner. Process. Extr. Metall. Rev. 2009, 30, 211–239. [Google Scholar] [CrossRef]

- Gong, C.; Yang, N. Effect of phosphate on the hydration of alkali-activated red mud–slag cementitious material. Cem. Concr. Res. 2000, 30, 1013–1016. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, S. Development of paving blocks from synergistic use of red mud and fly ash using geopolymerization. Constr. Build. Mater. 2013, 38, 865–871. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Kazemian, A.; Sarvari, M.; Ahmadi, B. Use of natural zeolite to produce self-consolidating concrete with low portland cement content and high durability. J. Mater. Civ. Eng. 2013, 25, 589–596. [Google Scholar] [CrossRef]

- Raggiotti, B.B.; Positieri, M.J.; Oshiro, Á. Natural zeolite, a pozzolan for structural concrete. Procedia Struct. Integr. 2018, 11, 36–43. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Li, C.; Monteiro, P.J.M. Green concrete containing diatomaceous earth and limestone: Workability, mechanical properties, and life-cycle assessment. J. Clean. Prod. 2019, 223, 662–679. [Google Scholar] [CrossRef]

- Yılmaz, B.; Ediz, N. The use of raw and calcined diatomite in cement production. Cem. Concr. Compos. 2008, 30, 202–211. [Google Scholar] [CrossRef]

- Vejmelková, E.; Koňáková, D.; Doleželová, M.; Scheinherrová, L.; Svora, P.; Keppert, M.; Reiterman, P.; Černý, R. Effect of calcined Czech claystone on the properties of high performance concrete: Microstructure, strength and durability. Constr. Build. Mater. 2018, 168, 966–974. [Google Scholar] [CrossRef]

- Tagnit-Hamou, A.; Petrov, N.; Luke, K. Properties of concrete containing diatomaceous earth. ACI Mater. J. 2003, 100, 73–78. [Google Scholar]

- Abrão, P.; Cardoso, F.; John, V. Evaluation of Portland pozzolan blended cements containing diatomaceous earth. Cerâmica 2019, 65, 75–86. [Google Scholar]

- Kani, E.N.; Allahverdi, A.; Provis, J.L. Efflorescence control in geopolymer binders based on natural pozzolan. Cem. Concr. Compos. 2012, 34, 25–33. [Google Scholar] [CrossRef]

- Kani, E.N.; Allahverdi, A. Effect of chemical composition on basic engineering properties of inorganic polymeric binder based on natural pozzolan. Ceramics-Silikaty 2009, 53, 195–204. [Google Scholar]

- Lemougna, P.N.; Wang, K.; Tang, Q.; Nzeukou, A.N.; Billong, N.; Melo, U.C.; Cui, X. Review on the use of volcanic ashes for engineering applications. Resour. Conserv. Recy. 2018, 137, 177–190. [Google Scholar] [CrossRef]

- Siddique, R. Properties of concrete made with volcanic ash. Resour. Conserv. Recy. 2012, 66, 40–44. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Lachemi, M. Strength, durability and micro-structural aspects of high performance volcanic ash concrete. Cem. Concr. Res. 2007, 37, 759–766. [Google Scholar] [CrossRef]

- Safari, Z.; Kurda, R.; Al-Hadad, B.; Mahmood, F.; Tapan, M. Mechanical characteristics of pumice-based geopolymer paste. Resour. Conserv. Recy. 2020, 162, 105055. [Google Scholar] [CrossRef]

- Yadollahi, M.M.; Benli, A.; Demirboğa, R. The effects of silica modulus and aging on compressive strength of pumice-based geopolymer composites. Constr. Build. Mater. 2015, 94, 767–774. [Google Scholar] [CrossRef]

- Almalkawi, A.T.; Hamadna, S.; Soroushian, P. One-part alkali activated cement based volcanic pumice. Constr. Build. Mater. 2017, 152, 367–374. [Google Scholar] [CrossRef]

- Kourti, I.; Devaraj, A.R.; Bustos, A.G.; Deegan, D.; Boccaccini, A.R.; Cheeseman, C.R. Geopolymers prepared from DC plasma treated air pollution control (APC) residues glass: Properties and characterisation of the binder phase. J. Hazard. Mater. 2011, 196, 86–92. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Lopez, R.; Ivan Escalante-Garcia, J. Alkali activated composite binders of waste silica soda lime glass and blast furnace slag: Strength as a function of the composition. Constr. Build. Mater. 2016, 119, 119–129. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, C.; Zhang, Z.; Li, N. An overview on the reuse of waste glasses in alkali-activated materials. Resour. Conserv. Recy. 2019, 144, 297–309. [Google Scholar] [CrossRef]

- Tashima, M.; Soriano, L.; Borrachero, M.; Monzó, J.; Cheeseman, C.; Payá, J. Alkali activation of vitreous calcium aluminosilicate derived from glass fiber waste. J. Sustain. Cem.-Based Mater. 2012, 1, 83–93. [Google Scholar] [CrossRef]

- Pascual, A.B.; Tognonvi, M.T.; Tagnit-Hamou, A. Waste glass powder-based alkali-activated mortar. Int. J. Res. Eng. Technol. 2014, 3, 15–19. [Google Scholar]

- Puertas, F.; Torres-Carrasco, M. Use of glass waste as an activator in the preparation of alkali-activated slag. Mechanical strength and paste characterisation. Cem. Concr. Res. 2014, 57, 95–104. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Cherian, C.; Siddiqua, S. Pulp and Paper Mill Fly Ash: A Review. Sustainability 2019, 11, 4394. [Google Scholar] [CrossRef]

- Yang, K.H.; Lo, C.W.; Huang, J.S. Production and properties of foamed reservoir sludge inorganic polymers. Cem. Concr. Compos. 2013, 38, 50–56. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Dick, W. Use of heat-treated water treatment residuals in fly ash-based geopolymers. J. Am. Ceram. Soc. 2010, 93, 272–278. [Google Scholar] [CrossRef]

- Banfill, P.; Frias, M. Rheology and conduction calorimetry of cement modified with calcined paper sludge. Cem. Concr. Res. 2007, 37, 184–190. [Google Scholar] [CrossRef]

- Santa, R.A.A.B.; Bernardin, A.M.; Riella, H.G.; Kuhnen, N.C. Geopolymer synthetized from bottom coal ash and calcined paper sludge. J. Clean. Prod. 2013, 57, 302–307. [Google Scholar] [CrossRef]

- Li, R.; Zhang, B.; Wang, Y.; Zhao, Y.; Li, F. Leaching potential of stabilized fly ash from the incineration of municipal solid waste with a new polymer. J. Environ. Manag. 2019, 232, 286–294. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Shiota, K.; Nakamura, T.; Takaoka, M.; Aminuddin, S.F.; Oshita, K.; Fujimori, T. Stabilization of lead in an alkali-activated municipal solid waste incineration fly ash–Pyrophyllite-based system. J. Environ. Manag. 2017, 201, 327–334. [Google Scholar] [CrossRef]

- Sofi, M.; van Deventer, J.S.J.; Mendis, P.A.; Lukey, G.C. Engineering properties of inorganic polymer concretes (IPCs). Cem. Concr. Res. 2007, 37, 251–257. [Google Scholar] [CrossRef]

- Yakubu, Y.; Zhou, J.; Ping, D.; Shu, Z.; Chen, Y. Effects of pH dynamics on solidification/stabilization of municipal solid waste incineration fly ash. J. Environ. Manag. 2018, 207, 243–248. [Google Scholar] [CrossRef]

- Lach, M.; Mierzwinski, D.; Korniejenko, K.; Mikula, J.; Hebda, M. Geopolymers as a material suitable for immobilization of fly ash from municipal waste incineration plants. J. Air Waste Manag. Assoc. 2018, 68, 1190–1197. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; Hou, H.; Wang, G.; Wan, S.; Zhou, M. Characteristics of the stabilized/solidified municipal solid wastes incineration fly ash and the leaching behavior of Cr and Pb. Front. Environ. Sci. Eng. 2014, 10, 192–200. [Google Scholar] [CrossRef]

- Jin, M.; Zheng, Z.; Sun, Y.; Chen, L.; Jin, Z. Resistance of metakaolin-MSWI fly ash based geopolymer to acid and alkaline environments. J. Non-Cryst. Solids 2016, 450, 116–122. [Google Scholar] [CrossRef]

- Ferone, C.; Colangelo, F.; Messina, F.; Santoro, L.; Cioffi, R. Recycling of Pre-Washed Municipal Solid Waste Incinerator Fly Ash in the Manufacturing of Low Temperature Setting Geopolymer Materials. Materials 2013, 6, 3420–3437. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Emam, M.A. Factors affecting the mechanical properties of alkali activated ground granulated blast furnace slag concrete. Constr. Build. Mater. 2019, 197, 339–355. [Google Scholar] [CrossRef]

- Zhu, W.P.; Chen, X.; Zhao, A.Q.; Struble, L.J.; Yang, E.H. Synthesis of high strength binders from alkali activation of glass materials from municipal solid waste incineration bottom ash. J. Clean. Prod. 2019, 212, 261–269. [Google Scholar] [CrossRef]

- Rożek, P.; Król, M.; Mozgawa, W. Solidification/stabilization of municipal solid waste incineration bottom ash via autoclave treatment: Structural and mechanical properties. Constr. Build. Mater. 2019, 202, 603–613. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, X.; Struble, L.; Yang, E. Characterization of calcium-containing phases in alkali-activated municipal solid waste incineration bottom ash binder through chemical extraction and deconvoluted Fourier transform infrared spectra. J. Clean. Prod. 2018, 192, 782–789. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Maldonado-Alameda, A.; Formosa, J.; Barbieri, L.; Chimenos, J.M.; Lancellotti, I. Geopolymers based on the valorization of municipal solid waste incineration residues. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012125. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Zhu, W.; Yang, E.-H. Incinerator bottom ash (IBA) aerated geopolymer. Constr. Build. Mater. 2016, 112, 1025–1031. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, X.; Struble, L.; Yang, E. Feasibility study of municipal solid waste incinerator bottom ash as geopolymer precursor. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016; pp. 1–10. [Google Scholar]

- Song, Y.; Li, B.; Yang, E.; Liu, Y.; Ding, T. Feasibility study on utilization of municipal solid waste incineration bottom ash as aerating agent for the production of autoclaved aerated concrete. Cem. Concr. Compos. 2015, 56, 51–58. [Google Scholar] [CrossRef]

- Kim, Y.; Kang, S. Characterization of geopolymer made of municipal solid waste incineration ash slag. J. Korean Cryst. Growth Cryst. Technol. 2014, 24, 15–20. [Google Scholar] [CrossRef][Green Version]

- Lancellotti, I.; Ponzoni, C.; Barbieri, L.; Leonelli, C. Alkali activation processes for incinerator residues management. Waste Manag. 2013, 33, 1740–1749. [Google Scholar] [CrossRef] [PubMed]

- Onori, R.; Will, J.; Hoppe, A.; Polettini, A.; Pomi, R.; Boccaccini, A. Bottom ash-based geopolymer materials: Mechanical and environmental properties. In Developments in Strategic Materials and Computational Design II: Ceramic Engineering and Science Proceedings, 1st ed.; Kriven, W.M., Gyekenyesi, A.L., Wang, J., Widjaja, S., Singh, D., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Qiao, X.; Tyrer, M.; Poon, C.; Cheeseman, C. Characterization of alkali-activated thermally treated incinerator bottom ash. Waste Manag. 2008, 28, 1955–1962. [Google Scholar] [CrossRef]

- Huang, G.; Ji, Y.; Li, J.; Zhang, L.; Liu, X.; Liu, B. Effect of activated silica on polymerization mechanism and strength development of MSWI bottom ash alkali-activated mortars. Constr. Build. Mater. 2019, 201, 90–99. [Google Scholar] [CrossRef]

- Huang, G.; Ji, Y.; Zhang, L.; Li, J.; Hou, Z. The influence of curing methods on the strength of MSWI bottom ash-based alkali-activated mortars: The role of leaching of OH- and free alkali. Constr. Build. Mater. 2018, 186, 978–985. [Google Scholar] [CrossRef]

- Liu, Y.; Sidhu, K.; Chen, Z.; Yang, E. Alkali-treated incineration bottom ash as supplementary cementitious materials. Constr. Build. Mater. 2018, 179, 371–378. [Google Scholar] [CrossRef]

- Wongsa, A.; Boonserm, K.; Waisurasingha, C.; Sata, V.; Chindaprasirt, P. Use of municipal solid waste incinerator (MSWI) bottom ash in high calcium fly ash geopolymer matrix. J. Clean. Prod. 2017, 148, 49–59. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Carcelen-Taboada, V.; Fernández-Jiménez, A.; Palomo, A. Manufacture of hybrid cements with fly ash and bottom ash from a municipal solid waste incinerator. Constr. Build. Mater. 2016, 105, 218–226. [Google Scholar] [CrossRef]

- Jing, Z.; Jin, F.; Yamasaki, N.; Ishida, E. Hydrothermal synthesis of a novel tobermorite-based porous material from municipal incineration bottom ash. Ind. Eng. Chem. Res. 2007, 46, 2657–2660. [Google Scholar] [CrossRef]

- Penilla, R.; Bustos, A.; Elizalde, S. Zeolite synthesized by alkaline hydrothermal treatment of bottom ash from combustion of municipal solid wastes. J. Am. Ceram. Soc. 2003, 86, 1527–1533. [Google Scholar] [CrossRef]

- Xuan, D.; Tang, P.; Poon, C. MSWIBA-based cellular alkali-activated concrete incorporating waste glass powder. Cem. Concr. Compos. 2019, 95, 128–136. [Google Scholar] [CrossRef]

- Qiao, X.C.; Tyrer, M.; Poon, C.S.; Cheeseman, C.R. Novel cementitious materials produced from incinerator bottom ash. Resour. Conserv. Recy. 2008, 52, 496–510. [Google Scholar] [CrossRef]

- Galiano, Y.L.; Pereira, C.F.; Vale, J. Stabilization/solidification of a municipal solid waste incineration residue using fly ash-based geopolymers. J. Hazard. Mater. 2011, 185, 373–381. [Google Scholar] [CrossRef]

- Krausova, K.; Cheng, T.W.; Gautron, L.; Dai, Y.S.; Borenstajn, S. Heat treatment on fly and bottom ash based geopolymers: Effect on the immobilization of lead and cadmium. Int. J. Environ. Sci. Dev. 2012, 3, 350–353. [Google Scholar]

- Silva, R.V.; de Brito, J.; Lynn, C.J.; Dhir, R.K. Use of municipal solid waste incineration bottom ashes in alkali-activated materials, ceramics and granular applications: A review. Waste Manag. 2017, 68, 207–220. [Google Scholar] [CrossRef]

- Haukohl, J.; Kristiansen, T. Waste Incineration; World Health Organization-Regional Office for Europe: Copenhagen, Denmark, 1996; 28p. [Google Scholar]

- Dhir, R.K.; De Brito, J.; Lynn, C.J.; Silva, R.V. Sustainable Construction Materials: Municipal Incinerator Bottom Ash; Woodhead Publishing: Duxford, UK, 2018; 458p. [Google Scholar]

- Shen, H.; Forssberg, E. An overview of recovery of metals from slags. Waste Manag. 2003, 23, 933–949. [Google Scholar] [CrossRef]

- Joseph, A.M.; Snellings, R.; Van den Heede, P.; Matthys, S.; De Belie, N. The use of municipal solid waste incineration ash in various building materials: A Belgian point of view. Materials 2018, 11, 141. [Google Scholar] [CrossRef]

- Seleem, H.E.D.H.; Rashad, A.M.; Elsokary, T. Effect of elevated temperature on physico-mechanical properties of blended cement concrete. Constr. Build. Mater. 2011, 25, 1009–1017. [Google Scholar] [CrossRef]

- Dinakar, P.; Babu, K.G.; Santhanam, M. Durability properties of high volume fly ash self compacting concretes. Cem. Concr. Compos. 2008, 30, 880–886. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Bamforth, P.B. Modelling chloride diffusion in concrete: Effect of fly ash and slag. Cem. Concr. Res. 1999, 29, 487–495. [Google Scholar] [CrossRef]

- Richartz, W. Effect of the K2O content and degree of sulfatization on the setting and hardening of cement. Zement-Kalk-Gips 1986, 39, 678–687. [Google Scholar]

- Kosmatka, S.; Kerkhoff, B.C.; Panarese, W. Design and Control of Concrete Mixtures; Creative Media Partners, LLC.: London, UK, 2002; 74p. [Google Scholar]

- Saccani, A.; Sandrolini, F.; Andreola, F.; Barbieri, L.; Corradi, A.; Lancellotti, I. Influence of the pozzolanic fraction obtained from vitrified bottom-ashes from MSWI on the properties of cementitious composites. Mater. Struct. 2005, 38, 367–371. [Google Scholar] [CrossRef]

- Tang, P.; Florea, M.; Spiesz, P.; Brouwers, H. Application of thermally activated municipal solid waste incineration (MSWI) bottom ash fines as binder substitute. Cem. Concr. Compos. 2016, 70, 194–205. [Google Scholar] [CrossRef]

- Bertolini, L.; Carsana, M.; Cassago, D.; Curzio, A.Q.; Collepardi, M. MSWI ashes as mineral additions in concrete. Cem. Concr. Res. 2004, 34, 1899–1906. [Google Scholar] [CrossRef]

- EN 197–1, Cement. Composition, Specifications and Conformity Criteria for Common Cements; Comité Européen de Normalisation (CEN): Brussels, Belgium, 2011; 50p. [Google Scholar]

- RSC TiO2: Uses of titanium dioxide. In Titanium Dioxide Photocatalysis: Uses of Titanium Dioxide; Learn Chemistry-Enhancing Learning and Teaching; Royal Society of Chemistry (RSC): London, UK, 2007; 4p.

- Odler, I.; Schmidt, O. Structure and properties of Portland cement clinker doped with zinc oxide. J. Am. Ceram. Soc. 2006, 63, 13–16. [Google Scholar] [CrossRef]

- Engelsen, C. Effect of Mineralizers in Cement Production- State of the Art; Report NO. SBF BK A07021; SINTEF Building and Infrastructure, COIN–Concrete Innovation Centre: Oslo, Norway, 2007; 25p. [Google Scholar]

- Jackson, J. Portland cement: Classification and manufacture. In Lea’s Chemistry of Cement and Concrete, 4th ed.; Hewlett, P.C., Ed.; Arnold Hodder Headline Group: London, UK, 1998; pp. 25–94. [Google Scholar]

- Sprung, S. Technological Problems in Pyroprocessing Cement Clinker: Cause and Solution, 1st ed.; Beton-Verlag: Düsseldorf, Germany, 1985; 129p. [Google Scholar]

- Bhatty, I. Role of minor elements in cement: Manufacture and use. In International Report of the Portland Cement Association; Portland Cement Association: Skokie, IL, USA, 1995; 40p. [Google Scholar]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Provis, J.L. 4-Activating solution chemistry for geopolymers. In Geopolymers; Provis, J.L., van Deventer, J.S.J., Eds.; Woodhead Publishing: Sawston, Cambridge, UK, 2009; pp. 50–71. [Google Scholar]

- Golek, L. Glass powder and high-calcium fly ash based binders - Long term examinations. J. Clean. Prod. 2019, 220, 493–506. [Google Scholar] [CrossRef]

- Samarakoon, M.H.; Ranjith, P.G.; De Silva, V.R.S. Effect of soda-lime glass powder on alkali-activated binders: Rheology, strength and microstructure characterization. Constr. Build. Mater. 2020, 241, 118013. [Google Scholar] [CrossRef]

- Zhu, W.P.; Chen, X.; Struble, L.J.; Yang, E.H. Quantitative characterization of aluminosilicate gels in alkali-activated incineration bottom ash through sequential chemical extractions and deconvoluted nuclear magnetic resonance spectra. Cem. Concr. Compos. 2019, 99, 175–180. [Google Scholar] [CrossRef]

- Huang, G.; Ji, Y.; Zhang, L.; Li, J.; Hou, Z. Advances in understanding and analyzing the anti-diffusion behavior in complete carbonation zone of MSWI bottom ash-based alkali-activated concrete. Constr. Build. Mater. 2018, 186, 1072–1081. [Google Scholar] [CrossRef]

- Cristelo, N.; Segadaes, L.; Coelho, J.; Chaves, B.; Sousa, N.R.; Lopes, M.D. Recycling municipal solid waste incineration slag and fly ash as precursors in low-range alkaline cements. Waste Manag. 2020, 104, 60–73. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.; Yang, K.; Chen, L.; Lu, Z.; Sun, Y.; Zhang, X.; Feng, Y.; Ji, Y.; Xu, Z. Use of pretreatment to prevent expansion and foaming in high-performance MSWI bottom ash alkali-activated mortars. Constr. Build. Mater. 2020, 245, 118471. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. Alkali Activated Materials-State-of-the-Art Report; RILEM TC 224-AAM; Springer: Dordrecht, The Netherlands, 2014; 388p. [Google Scholar]

- Rowles, M.; O’Connor, B. Chemical optimisation of the compressive strength of aluminosilicate geopolymers synthesised by sodium silicate activation of metakaolinite. J. Mater. Chem. 2003, 13, 1161–1165. [Google Scholar] [CrossRef]

- Lancellotti, I.; Kamseu, E.; Michelazzi, M.; Barbieri, L.; Corradi, A.; Leonelli, C. Chemical stability of geopolymers containing municipal solid waste incinerator fly ash. Waste Manag. 2010, 30, 673–679. [Google Scholar] [CrossRef]

- Part, W.K.; Ramli, M.; Cheah, C.B. An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial by-products. Constr. Build. Mater. 2015, 77, 370–395. [Google Scholar] [CrossRef]

- Maldonado-Alameda, A.; Giro-Paloma, J.; Svobodova-Sedlackova, A.; Formosa, J.; Chimenos, J.M. Municipal solid waste incineration bottom ash as alkali-activated cement precursor depending on particle size. J. Clean. Prod. 2020, 242, 118443. [Google Scholar] [CrossRef]

- Görhan, G.; Kürklü, G. The influence of the NaOH solution on the properties of the fly ash-based geopolymer mortar cured at different temperatures. Compos. Part B Eng. 2014, 58, 371–377. [Google Scholar]

- Sukmak, P.; Horpibulsuk, S.; Shen, S.-L. Strength development in clay–fly ash geopolymer. Constr. Build. Mater. 2013, 40, 566–574. [Google Scholar] [CrossRef]

- Somna, K.; Jaturapitakkul, C.; Kajitvichyanukul, P.; Chindaprasirt, P. NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 2011, 90, 2118–2124. [Google Scholar] [CrossRef]

- Ridtirud, C.; Chindaprasirt, P.; Pimraksa, K. Factors affecting the shrinkage of fly ash geopolymers. Int. J. Miner. Metall. Mater. 2011, 18, 100–104. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Dick, W.A. Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem. Concr. Compos. 2010, 32, 142–147. [Google Scholar] [CrossRef]

- Law, D.W.; Adam, A.A.; Molyneaux, T.K.; Patnaikuni, I.; Wardhono, A. Long term durability properties of class F fly ash geopolymer concrete. Mater. Struct. 2014, 48, 1–11. [Google Scholar] [CrossRef]

- He, J.; Jie, Y.; Zhang, J.; Yu, Y.; Zhang, G. Synthesis and characterization of red mud and rice husk ash-based geopolymer composites. Cem. Concr. Compos. 2013, 37, 108–118. [Google Scholar] [CrossRef]

- Nazari, A.; Bagheri, A.; Riahi, S. Properties of geopolymer with seeded fly ash and rice husk bark ash. Mater. Sci. Eng. A 2011, 528, 7395–7401. [Google Scholar] [CrossRef]

- Songpiriyakij, S.; Kubprasit, T.; Jaturapitakkul, C.; Chindaprasirt, P. Compressive strength and degree of reaction of biomass- and fly ash-based geopolymer. Constr. Build. Mater. 2010, 24, 236–240. [Google Scholar] [CrossRef]

- Yusuf, M.; Johari, M.; Ahmad, Z.; Maslehuddin, M. Impacts of silica modulus on the early strength of alkaline activated ground slag/ultrafine palm oil fuel ash based concrete. Mater. Struct. 2014, 48, 1–9. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Production of eco-friendly bricks from copper mine tailings through geopolymerization. Constr. Build. Mater. 2012, 29, 323–331. [Google Scholar] [CrossRef]

- Coelho, J.; Chaves, B.; Lopes, M.L.; Segadães, L.; Cristelo, N. Stabilizing municipal solid waste incineration residues with alternative binders, 5th. In Proceedings of the International Conference Wastes, Lisbon, Portugal, 4–6 September 2019; pp. 445–450. [Google Scholar]

- Huang, G.; Yang, K.; Sun, Y.; Lu, Z.; Zhang, X.; Zuo, L.; Feng, Y.; Qian, R.; Qi, Y.; Ji, Y.; et al. Influence of NaOH content on the alkali conversion mechanism in MSWI bottom ash alkali-activated mortars. Constr. Build. Mater. 2020, 248, 118582. [Google Scholar] [CrossRef]

- Ascensao, G.; Marchi, M.; Segata, M.; Faleschini, F.; Pontikes, Y. Reaction kinetics and structural analysis of alkali activated Fe-Si-Ca rich materials. J. Clean. Prod. 2020, 246, 119065. [Google Scholar] [CrossRef]

- Zhu, W.P.; Teoh, P.J.; Liu, Y.Q.; Chen, Z.T.; Yang, E.H. Strategic utilization of municipal solid waste incineration bottom ash for the synthesis of lightweight aerated alkali-activated materials. J. Clean. Prod. 2019, 235, 603–612. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers-Inorganic polymeric new materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Biswal, B.K.; Zhu, W.; Yang, E.H. Investigation on Pseudomonas aeruginosa PAO1-driven bioleaching behavior of heavy metals in a novel geopolymer synthesized from municipal solid waste incineration bottom ash. Constr. Build. Mater. 2020, 241, 118005. [Google Scholar] [CrossRef]

- Monich, P.R.; Desideri, D.; Bernardo, E. Low temperature upcycling of vitreous byproduct of the MSW plasma processing into multifunctional porous glass-ceramics. Adv. Appl. Ceram. 2019, 118, 366–371. [Google Scholar] [CrossRef]

- Monich, P.R.; Dogrul, F.; Lucas, H.; Friedrich, B.; Bernardo, E. Strong porous glass-ceramics from alkali activation and sinter-crystallization of vitrified MSWI bottom ash. Detritus 2019, 8, 101–108. [Google Scholar]

- CEU Council Decision of 19 December 2002 establishing criteria and procedures for the acceptance of waste at landfills pursuant to Article 16 of and Annex II to Directive 1999/31/EC. Off. J. Eur. Communities 2003, 11, 27–49.

| Portland Cement | Chemical Composition (%) | ||||||

|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2Oeq | |

| Min-Max | 18.6–24.4 | 2.2–7.3 | 0.2–5.9 | 61.3–68.7 | 0.3–4.5 | 1.7–4.9 | 0.09–1.2 |

| Mean | 21.3 | 4.5 | 3.0 | 63.9 | 2.0 | 2.8 | 0.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurda, R.; Silva, R.V.; de Brito, J. Incorporation of Alkali-Activated Municipal Solid Waste Incinerator Bottom Ash in Mortar and Concrete: A Critical Review. Materials 2020, 13, 3428. https://doi.org/10.3390/ma13153428

Kurda R, Silva RV, de Brito J. Incorporation of Alkali-Activated Municipal Solid Waste Incinerator Bottom Ash in Mortar and Concrete: A Critical Review. Materials. 2020; 13(15):3428. https://doi.org/10.3390/ma13153428

Chicago/Turabian StyleKurda, Rawaz, Rui Vasco Silva, and Jorge de Brito. 2020. "Incorporation of Alkali-Activated Municipal Solid Waste Incinerator Bottom Ash in Mortar and Concrete: A Critical Review" Materials 13, no. 15: 3428. https://doi.org/10.3390/ma13153428

APA StyleKurda, R., Silva, R. V., & de Brito, J. (2020). Incorporation of Alkali-Activated Municipal Solid Waste Incinerator Bottom Ash in Mortar and Concrete: A Critical Review. Materials, 13(15), 3428. https://doi.org/10.3390/ma13153428