Crack-Assisted Charge Injection into Solvent-Free Liquid Organic Semiconductors via Local Electric Field Enhancement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

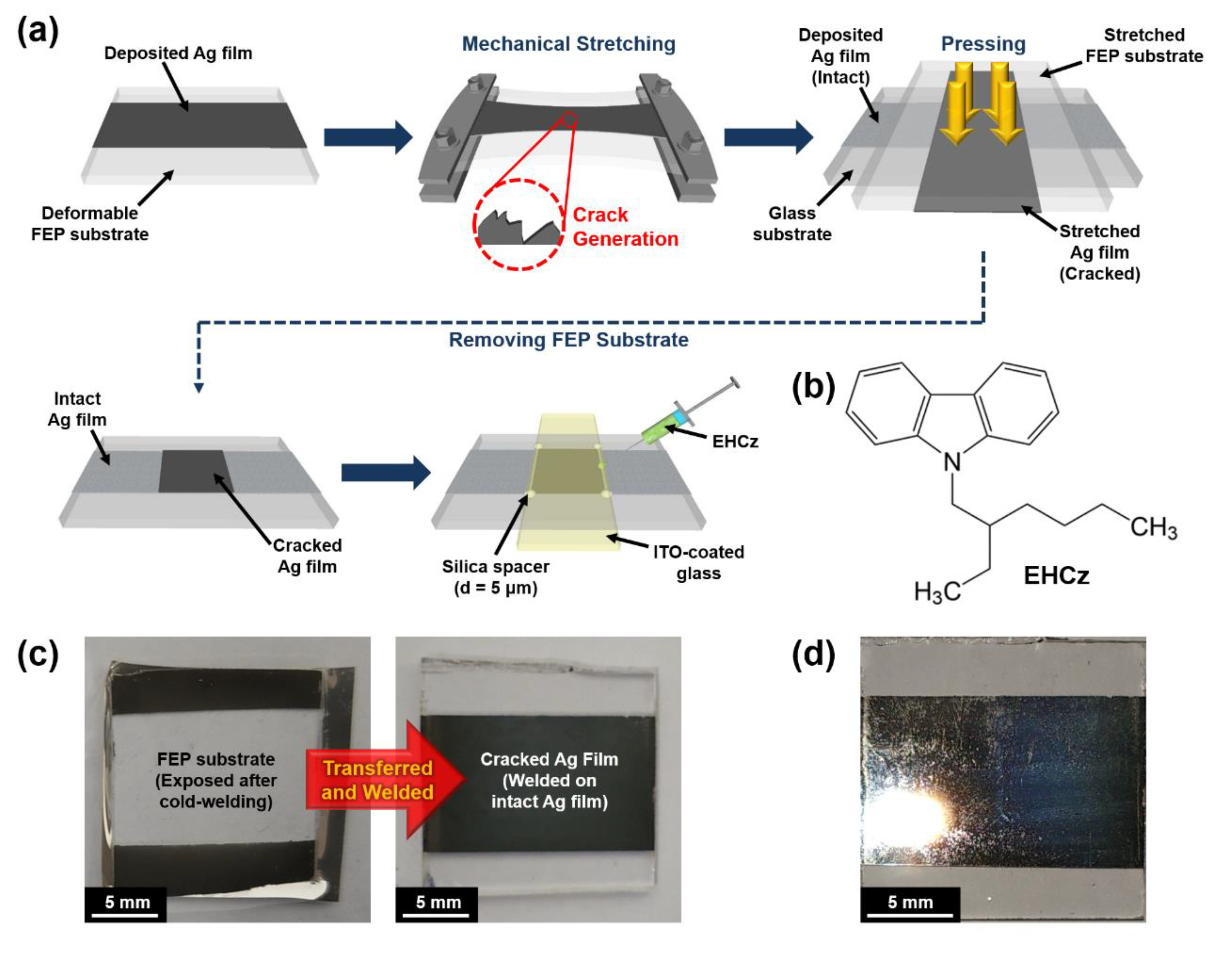

2.2. Device Fabrication

2.3. Measurements

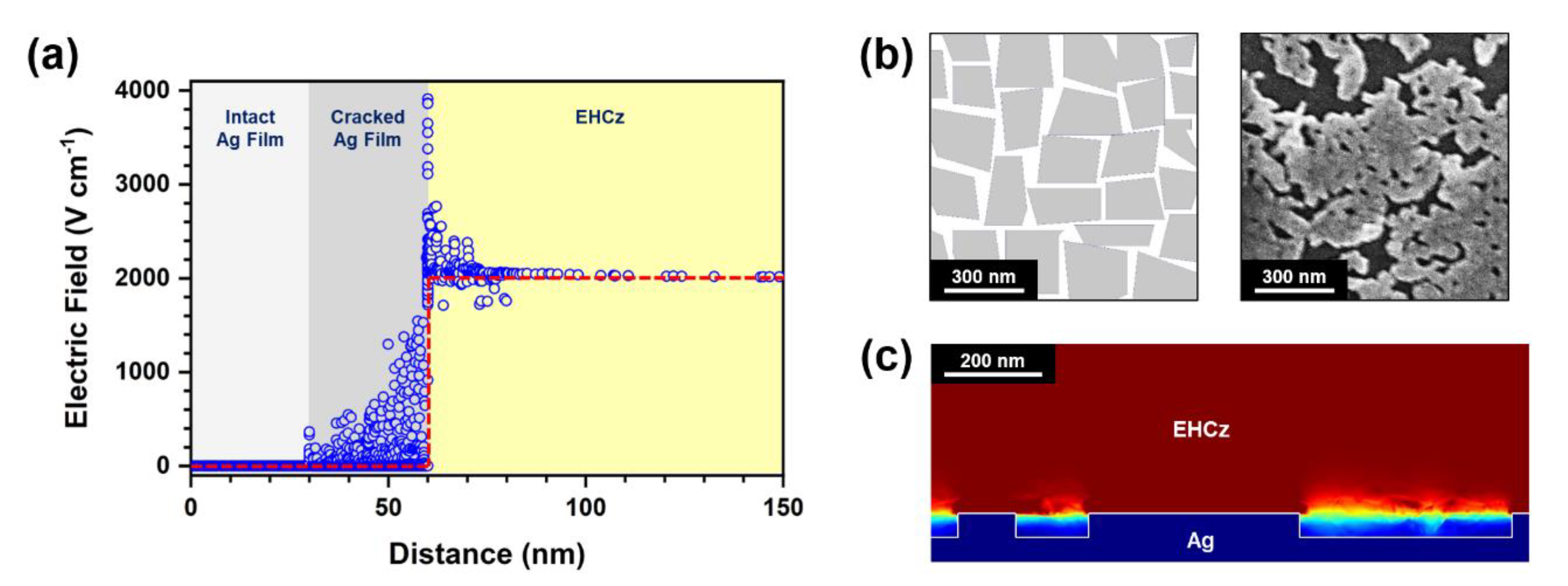

2.4. Field Intensity Calculation

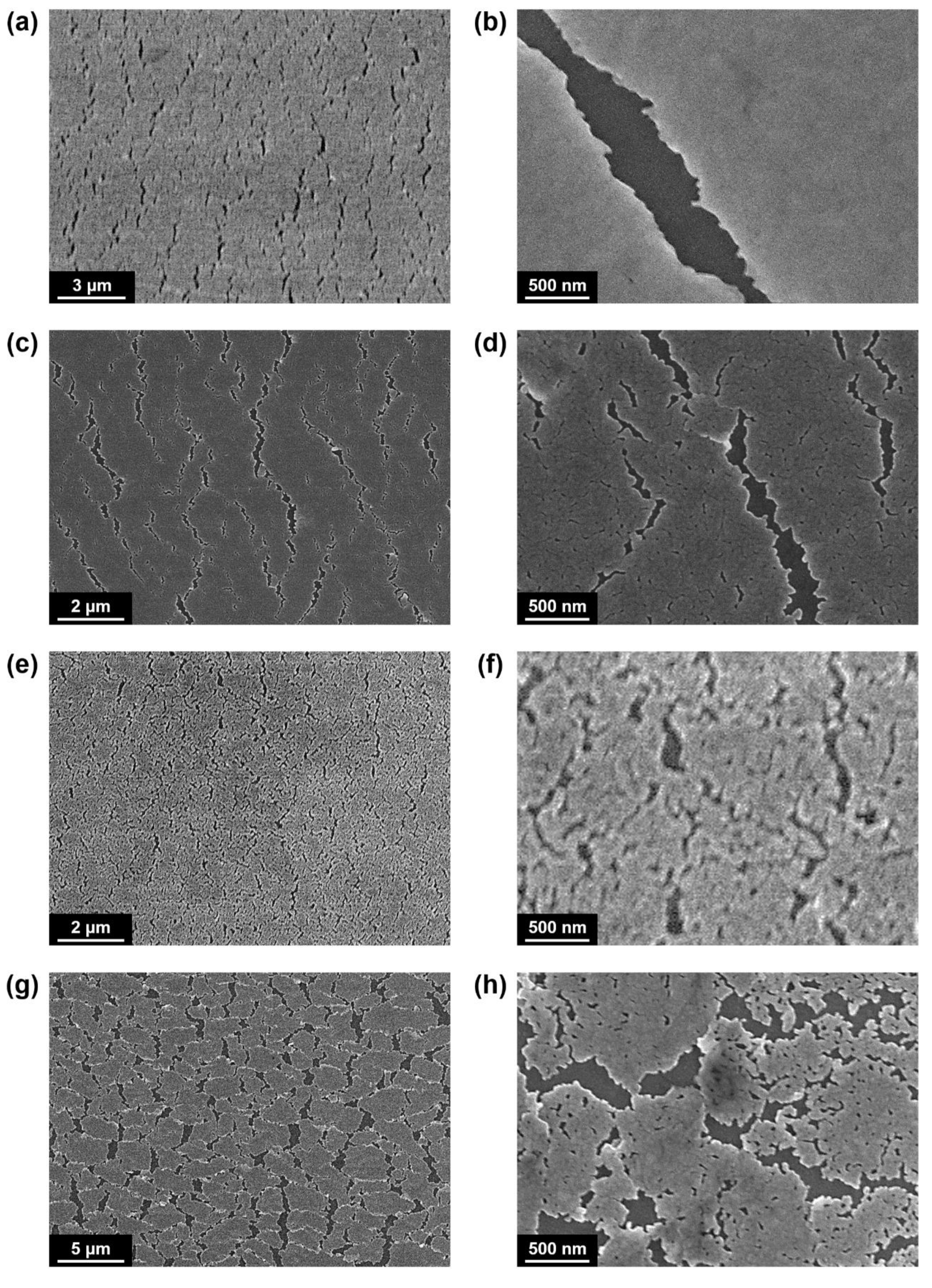

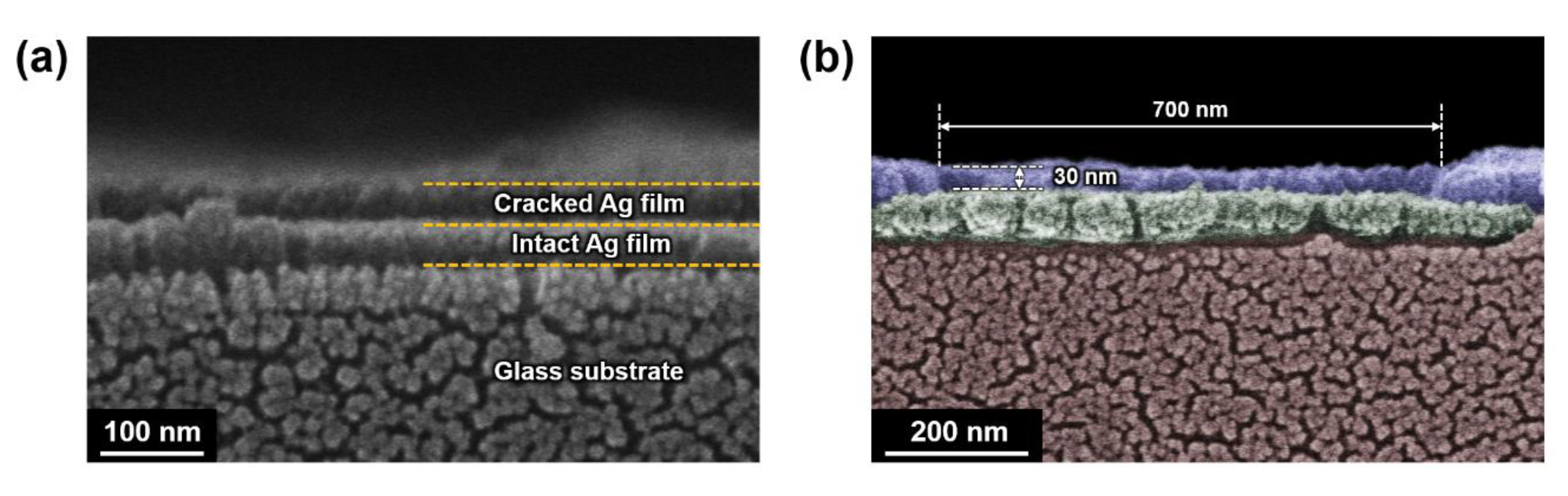

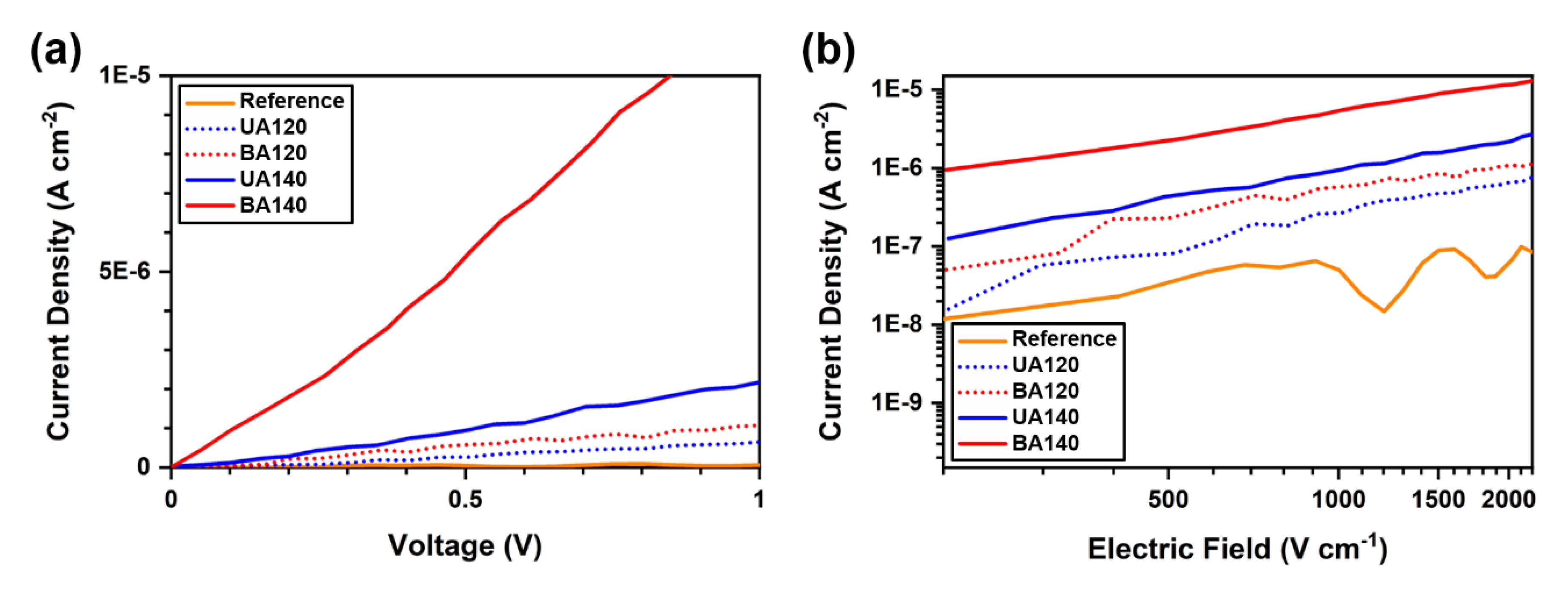

3. Results

4. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Ribierre, J.-C.; Aoyama, T.; Muto, T.; Imase, Y.; Wada, T. Charge transport properties in liquid carbazole. Org. Electron. 2008, 9, 396–400. [Google Scholar] [CrossRef]

- Schmidt, H.; Hawkins, A.R. The photonic integration of non-solid media using optofluidics. Nat. Photon. 2011, 5, 598–604. [Google Scholar] [CrossRef]

- Kamino, B.A.; Bender, T.P.; Klenkler, R.A. Hole mobility of a liquid organic semiconductor. J. Phys. Chem. Lett. 2012, 3, 1002–1006. [Google Scholar] [CrossRef]

- Babu, S.S.; Aimi, J.; Ozawa, H.; Shirahata, N.; Saeki, A.; Seki, S.; Ajayaghosh, A.; Möhwald, H.; Nakanishi, T. Solvent-free luminescent organic liquids. Angew. Chem. Int. Ed. Engl. 2012, 51, 3391–3395. [Google Scholar] [CrossRef]

- Choi, E.Y.; Mager, L.; Cham, T.T.; Dorkenoo, K.D.; Fort, A.; Wu, J.W.; Barsella, A.; Ribierre, J.-C. Solvent-free fluidic organic dye lasers. Opt. Express 2013, 21, 11368–11375. [Google Scholar] [CrossRef]

- Kim, J.-H.; Inoue, M.; Zhao, L.; Komino, T.; Seo, S.; Ribierre, J.-C.; Adachi, C. Tunable and flexible solvent-free liquid organic distributed feedback lasers. Appl. Phys. Lett. 2015, 106, 053302. [Google Scholar] [CrossRef]

- Ribierre, J.C.; Zhao, L.; Inoue, M.; Schwartz, P.O.; Kim, J.H.; Yoshida, K.; Sandanayaka, A.S.; Nakanotani, H.; Mager, L.; Mery, S.; et al. Low threshold amplified spontaneous emission and ambipolar charge transport in non-volatile liquid fluorene derivatives. Chem. Commun. 2016, 52, 3103–3106. [Google Scholar] [CrossRef] [PubMed]

- Sandanayaka, A.S.D.; Zhao, L.; Pitrat, D.; Mulatier, J.-C.; Matsushima, T.; Andraud, C.; Kim, J.-H.; Ribierre, J.-C.; Adachi, C. Improvement of the quasi-continuous-wave lasing properties in organic semiconductor lasers using oxygen as triplet quencher. Appl. Phys. Lett. 2016, 108, 223301. [Google Scholar] [CrossRef]

- Snaith, H.J.; Zakeeruddin, S.M.; Wang, Q.; Péchy, P.; Grätzel, M. Dye-sensitized solar cells incorporating a liquid hole-transporting material. Nano Lett. 2006, 6, 2000–2003. [Google Scholar] [CrossRef]

- Ribierre, J.-C.; Aoyama, T.; Kobayashi, T.; Sassa, T.; Muto, T.; Wada, T. Influence of the liquid carbazole concentration on charge trapping in C60 sensitized photorefractive polymers. J. Appl. Phys. 2007, 102, 033106. [Google Scholar] [CrossRef]

- Xu, D.; Adachi, C. Organic light-emitting diode with liquid emitting layer. Appl. Phys. Lett. 2009, 95, 053304. [Google Scholar] [CrossRef]

- Ribierre, J.-C.; Aoyama, T.; Muto, T.; André, P. Hybrid organic–inorganic liquid bistable memory devices. Org. Electron. 2011, 12, 1800–1805. [Google Scholar] [CrossRef]

- Hirata, S.; Kubota, K.; Jung, H.H.; Hirata, O.; Goushi, K.; Yahiro, M.; Adachi, C. Improvement of electroluminescence performance of organic light-emitting diodes with a liquid-emitting layer by introduction of electrolyte and a hole-blocking layer. Adv. Mater. 2011, 23, 889–893. [Google Scholar] [CrossRef]

- Kubota, K.; Hirata, S.; Shibano, Y.; Hirata, O.; Yahiro, M.; Adachi, C. Liquid carbazole substituted with a poly(ethylene oxide) group and its application for liquid organic light-emitting diodes. Chem. Lett. 2012, 41, 934–936. [Google Scholar] [CrossRef]

- Shim, C.-H.; Hirata, S.; Oshima, J.; Edura, T.; Hattori, R.; Adachi, C. Uniform and refreshable liquid electroluminescent device with a back side reservoir. Appl. Phys. Lett. 2012, 101, 113302. [Google Scholar] [CrossRef]

- Kasahara, T.; Matsunami, S.; Edura, T.; Oshima, J.; Adachi, C.; Shoji, S.; Mizuno, J. Fabrication and performance evaluation of microfluidic organic light emitting diode. Sensor. Actuat. A Phys. 2013, 195, 219–223. [Google Scholar] [CrossRef]

- Plint, T.G.; Kamino, B.A.; Bender, T.P. Charge carrier mobility of siliconized liquid triarylamine organic semiconductors by time-of-flight spectroscopy. J. Phys. Chem. C 2015, 4, 1676–1682. [Google Scholar] [CrossRef]

- Coropceanu, V.; Cornil, J.; da Silva Filho, D.A.; Olivier, Y.; Silbey, R.; Brédas, J.-L. Charge transport in organic semiconductors. Chem. Rev. 2007, 107, 926–952. [Google Scholar] [CrossRef]

- Forrest, S.R. Ultrathin organic films grown by organic molecular beam deposition and related techniques. Chem. Rev. 1997, 97, 1793–1896. [Google Scholar] [CrossRef]

- Ishii, H.; Sugiyama, K.; Ito, E.; Seki, K. Energy level alignment and interfacial electronic structures at organic/metal and organic/organic interfaces. Adv. Mater. 1999, 11, 605–625. [Google Scholar] [CrossRef]

- Hooks, D.E.; Fritz, T.; Ward, M.D. Epitaxy and molecular organization on solid substrates. Adv. Mater. 2001, 13, 227–241. [Google Scholar] [CrossRef]

- Zhu, X.-Y. Electronic structure and electron dynamics at molecule-metal interfaces: Implications for molecule-based electronics. Surf. Sci. Rep. 2004, 56, 1–83. [Google Scholar] [CrossRef]

- Yamane, H.; Kanai, K.; Ouchi, Y.; Ueno, N.; Seki, K. Impact of interface geometric structure on organic–metal interface energetics and subsequent films electronic structure. J. Electron Spectrosc. Relat. Phenom. 2009, 174, 28–34. [Google Scholar] [CrossRef]

- Ma, H.; Yip, H.-L.; Huang, F.; Jen, A.K.-Y. Interface engineering for organic electronics. Adv. Funct. Mater. 2010, 20, 1371–1388. [Google Scholar] [CrossRef]

- Kim, J.-H. Interfacial phenomena between conjugated organic molecules and noble metals. Korean J. Chem. Eng. 2017, 34, 1281–1293. [Google Scholar] [CrossRef]

- Jain, S.; Geens, W.; Mehra, A.; Kumar, V.; Aernouts, T.; Poortmans, J.; Mertens, R.; Willander, M. Injection-and space charge limited-currents in doped conducting organic materials. J. Appl. Phys. 2001, 89, 3804–3810. [Google Scholar] [CrossRef]

- Hosseini, A.; Wong, M.H.; Shen, Y.; Malliaras, G.G. Charge injection in doped organic semiconductors. J. Appl. Phys. 2005, 97, 023705. [Google Scholar] [CrossRef]

- Matsushima, T.; Kinoshita, Y.; Murata, H. Formation of ohmic hole injection by inserting an ultrathin layer of molybdenum trioxide between indium tin oxide and organic hole-transporting layers. Appl. Phys. Lett. 2007, 91, 253504. [Google Scholar] [CrossRef]

- Kim, J.; Khang, D.-Y.; Kim, J.-H.; Lee, H.H. The surface engineering of top electrode in inverted polymer bulk-heterojunction solar cells. Appl. Phys. Lett. 2008, 92, 133307. [Google Scholar] [CrossRef]

- Kim, J.-H.; Huh, S.-Y.; Kim, T.-i.; Lee, H.H. Thin pentacene interlayer for polymer bulk-heterojunction solar cell. Appl. Phys. Lett. 2008, 93, 143305. [Google Scholar] [CrossRef]

- Lee, J.-H.; Leem, D.-S.; Kim, H.-J.; Kim, J.-J. Effectiveness of p-dopants in an organic hole transporting material. Appl. Phys. Lett. 2009, 94, 123306. [Google Scholar] [CrossRef]

- Shan, M.; Jiang, H.; Guan, Y.; Sun, D.; Wang, Y.; Hua, J.; Wang, J. Enhanced hole injection in organic light-emitting diodes utilizing a copper iodide-doped hole injection layer. RSC Adv. 2017, 7, 13584–13589. [Google Scholar] [CrossRef]

- Arkhipov, V.; Emelianova, E.; Tak, Y.; Bässler, H. Charge injection into light-emitting diodes: Theory and experiment. J. Appl. Phys. 1998, 84, 848–856. [Google Scholar] [CrossRef]

- Mahapatro, A.K.; Ghosh, S. Schottky energy barrier and charge injection in metal/copper–phthalocyanine/metal structures. Appl. Phys. Lett. 2002, 80, 4840–4842. [Google Scholar] [CrossRef]

- Fowler, R.H.; Nordheim, L. Electron emission in intense electric fields. Proc. R. Soc. A 1928, 119, 173–181. [Google Scholar]

- De Heer, W.A.; Chatelain, A.; Ugarte, D. A carbon nanotube field-emission electron source. Science 1995, 270, 1179–1180. [Google Scholar] [CrossRef]

- Fujii, S.; Honda, S.-i.; Machida, H.; Kawai, H.; Ishida, K.; Katayama, M.; Furuta, H.; Hirao, T.; Oura, K. Efficient field emission from an individual aligned carbon nanotube bundle enhanced by edge effect. Appl. Phys. Lett. 2007, 90, 153108. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Yeow, J.T. Nanotube field electron emission: Principles, development, and applications. Nanotechnology 2015, 26, 242001. [Google Scholar] [CrossRef]

- Ye, T.; Suo, Z.; Evans, A. Thin film cracking and the roles of substrate and interface. Int. J. Solids Struct. 1992, 29, 2639–2648. [Google Scholar] [CrossRef]

- Li, T.; Suo, Z. Deformability of thin metal films on elastomer substrates. Int. J. Solids Struct. 2006, 43, 2351–2363. [Google Scholar] [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.-Y.; Kim, T.-i.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef] [PubMed]

- Park, B.; Kim, J.; Kang, D.; Jeong, C.; Kim, K.S.; Kim, J.U.; Yoo, P.J.; Kim, T.-i. Dramatically enhanced mechanosensitivity and signal-to-noise ratio of nanoscale crack-based sensors: Effect of crack depth. Adv. Mat. 2016, 28, 8130–8137. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Choi, H.; Kim, T.; Hong, I.; Roh, Y.; Park, J.; Seo, S.; Han, S.; Koh, J.-s.; Kang, D. FEP encapsulated crack-based sensor for measurement in moisture-laden environment. Materials 2019, 12, 1516. [Google Scholar] [CrossRef] [PubMed]

- Bay, N. Cold pressure welding—The mechanisms governing bonding. J. Eng. Ind. 1979, 101, 121–127. [Google Scholar] [CrossRef]

- Kim, C.; Burrows, P.E.; Forrest, S.R. Micropatterning of organic electronic devices by cold-welding. Science 2000, 288, 831–833. [Google Scholar] [CrossRef]

- Kim, C.; Shtein, M.; Forrest, S.R. Nanolithography based on patterned metal transfer and its application to organic electronic devices. Appl. Phys. Lett. 2002, 80, 4051–4053. [Google Scholar] [CrossRef]

- Asare, J.; Adeniji, S.; Oyewole, O.; Agyei-Tuffour, B.; Du, J.; Arthur, E.; Fashina, A.; Zebaze Kana, M.; Soboyejo, W. Cold welding of organic light emitting diode: Interfacial and contact models. AIP Adv. 2016, 6, 065125. [Google Scholar] [CrossRef]

- Varo, P.L.; Tejada, J.J.; Villanueva, J.L.; Carceller, J.; Deen, M. Modeling the transition from ohmic to space charge limited current in organic semiconductors. Org. Electron. 2012, 13, 1700–1709. [Google Scholar] [CrossRef]

- Wetzelaer, G.; Blom, P.W. Ohmic current in organic metal-insulator-metal diodes revisited. Phys. Rev. B 2014, 89, 241201. [Google Scholar] [CrossRef]

- Liu, B.G.; Liaw, D.-J.; Lee, W.-Y.; Ling, Q.-D.; Zhu, C.-X.; Chan, D.S.-H.; Kang, E.-T.; Neoh, K.-G. Tristable electrical conductivity switching in a polyfluorene-diphenylpyridine copolymer with pendant carbazole groups. Phil. Trans. R. Soc. A 2009, 367, 4203–4214. [Google Scholar] [CrossRef]

- Havare, A.K. Effect of the interface improved by self-assembled aromatic organic semiconductor molecules on performance of OLED. ECS J. Solid State Sci. Technol. 2020, 9, 041007. [Google Scholar] [CrossRef]

- Noine, K.; Pu, Y.-J.; Nakayama, K.-i.; Kido, J. Bifluorene compounds containing carbazole and/or diphenylamine groups and their bipolar charge transport properties in organic light emitting devices. Org. Electron. 2010, 11, 717–723. [Google Scholar] [CrossRef]

| Sample Name | Stretching Ratio (X-Axis) | Stretching Ratio (Y-Axis) |

|---|---|---|

| Reference | 0% | 0% |

| UA120 | 20% | 0% |

| UA140 | 40% | 0% |

| BA120 | 20% | 20% |

| BA140 | 40% | 40% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.-H.; Park, M.-J.; Kim, J.-H. Crack-Assisted Charge Injection into Solvent-Free Liquid Organic Semiconductors via Local Electric Field Enhancement. Materials 2020, 13, 3349. https://doi.org/10.3390/ma13153349

Kim K-H, Park M-J, Kim J-H. Crack-Assisted Charge Injection into Solvent-Free Liquid Organic Semiconductors via Local Electric Field Enhancement. Materials. 2020; 13(15):3349. https://doi.org/10.3390/ma13153349

Chicago/Turabian StyleKim, Kyoung-Hwan, Myung-June Park, and Ju-Hyung Kim. 2020. "Crack-Assisted Charge Injection into Solvent-Free Liquid Organic Semiconductors via Local Electric Field Enhancement" Materials 13, no. 15: 3349. https://doi.org/10.3390/ma13153349

APA StyleKim, K.-H., Park, M.-J., & Kim, J.-H. (2020). Crack-Assisted Charge Injection into Solvent-Free Liquid Organic Semiconductors via Local Electric Field Enhancement. Materials, 13(15), 3349. https://doi.org/10.3390/ma13153349