Utilization of Banana Fiber-Reinforced Hybrid Composites in the Sports Industry

Abstract

1. Introduction

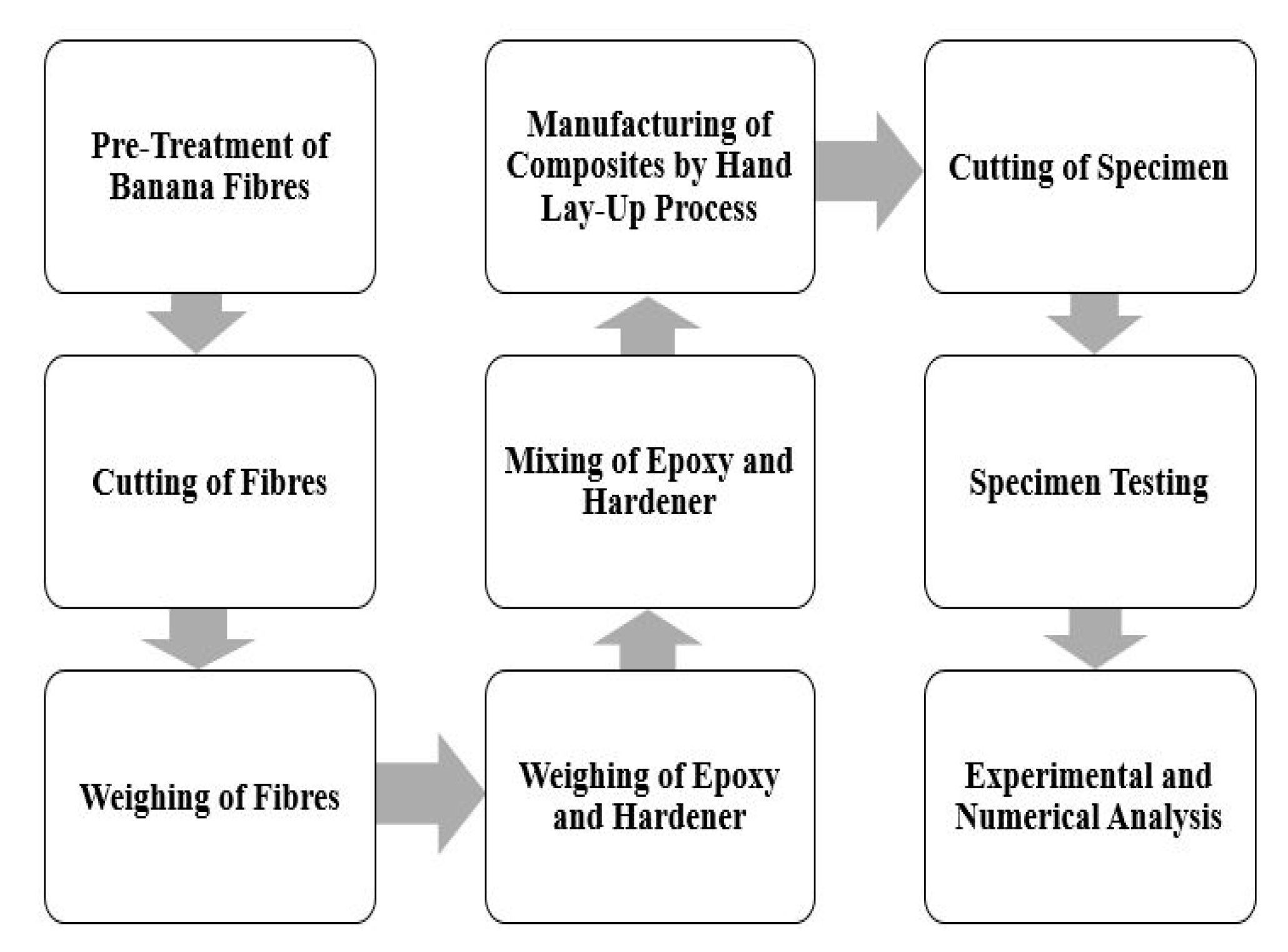

2. Materials and Methods

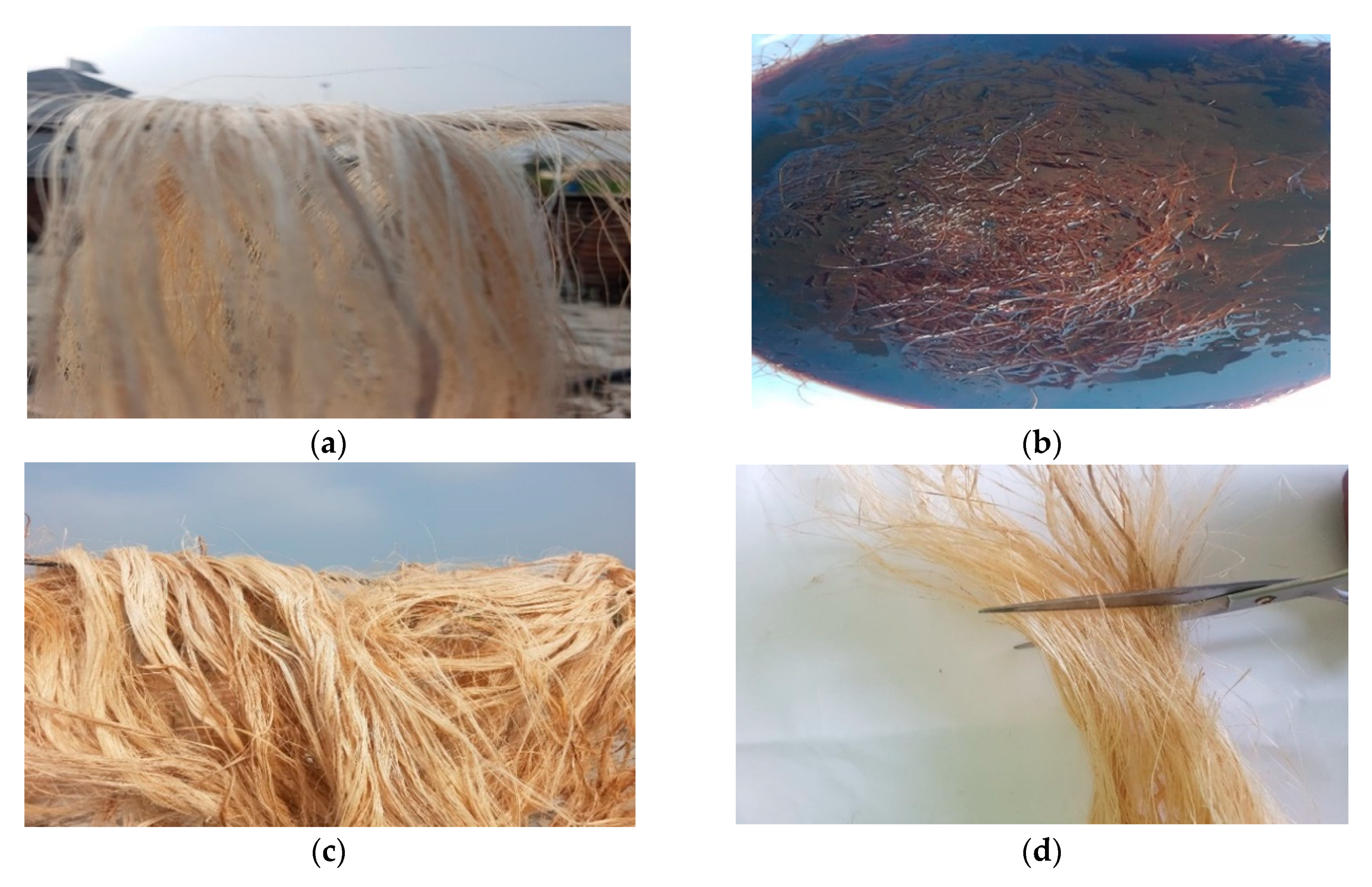

2.1. Materials (Matrix and Reinforcements) and Manufacturing of the Composite

2.2. Mechanical Testing

2.3. Numerical Simulation

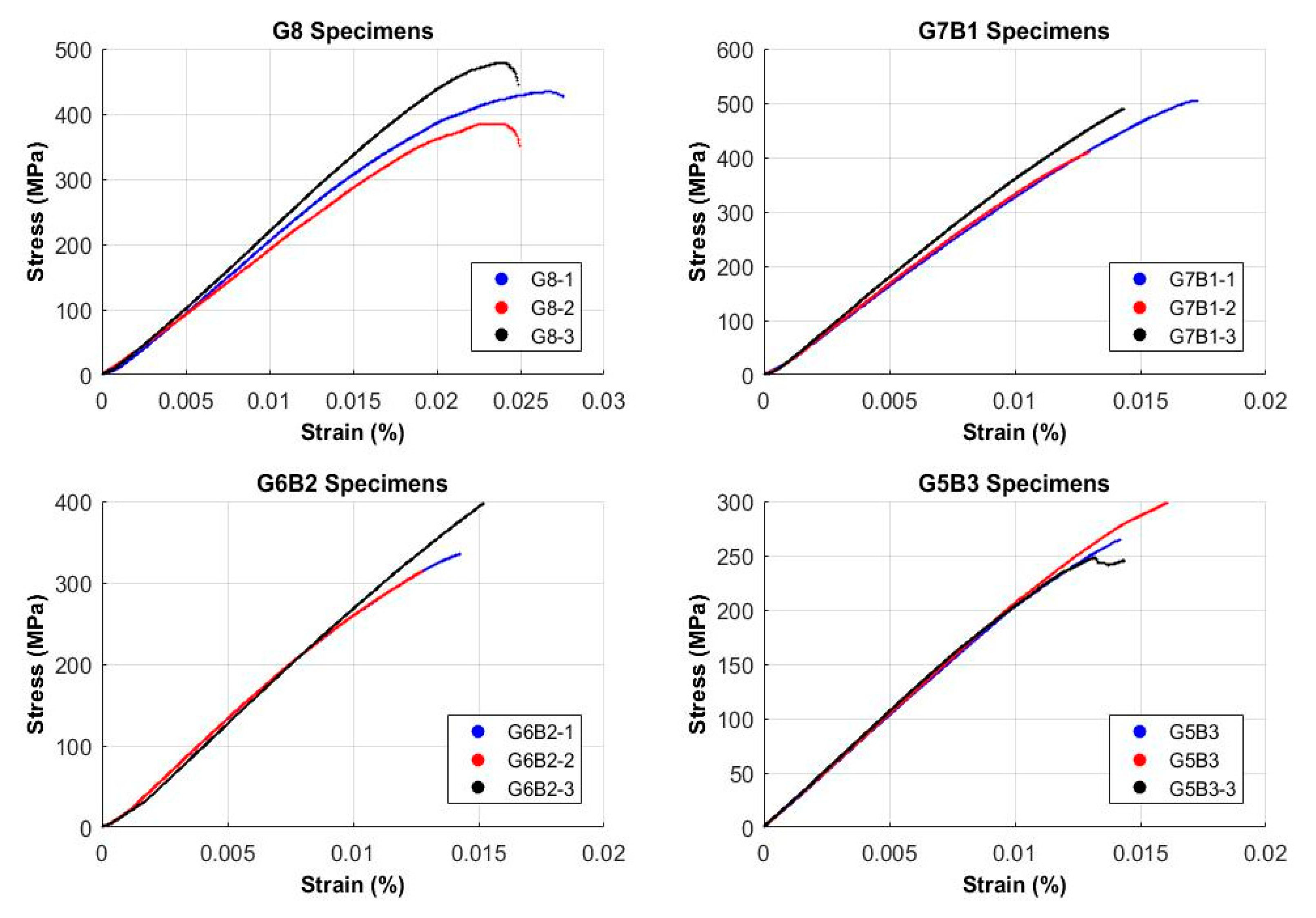

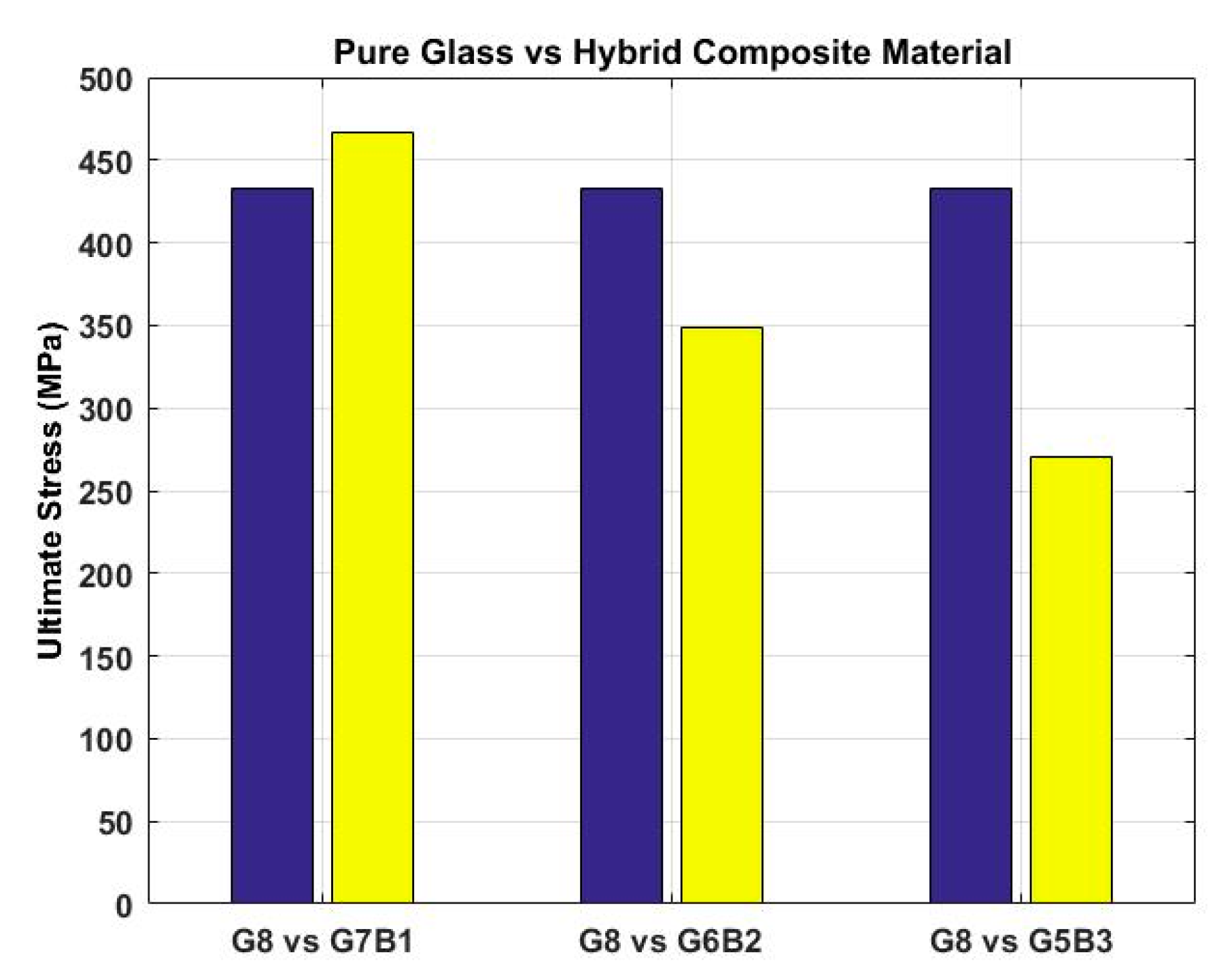

3. Results and Discussion

Flexural Test Results

4. Conclusions & Future Recommendations

Author Contributions

Funding

Acknowledgments

Data Availability

Conflicts of Interest

Abbreviations

| NFRPC | Natural fiber reinforced polymer composites |

| FRPC | Fiber-reinforced polymer composites |

| FEA | Finite Element Analysis |

References

- Torres, G.R. Design of the Supply Chain For A New Field Hockey Company in South America. Ph.D. Thesis, Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 2019. [Google Scholar]

- Matthews, F.L.; Davies, G.A.O.; Hitchings, D.; Soutis, C. Finite Element Modelling of Composite Materials and Structures; Elsevier Science: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Shrivastava, R.; Christy, A.; Telang, A.; Rana, R.S. Effect of Chemical Treatment and Curing Parameters on Mechanical Properties of Natural Fiber Reinforced Polymer Matrix Composites—A Review. J. Eng. Res. Appl. 2015, 5, 70–75. [Google Scholar]

- Mohanty, A.; Wibowo, A.; Misra, M.; Drzal, L. Effect of process engineering on the performance of natural fiber reinforced cellulose acetate biocomposites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 363–370. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- van Voorn, B.; Smit, H.H.; Sinke, R.; de Klerk, B. Natural fibre reinforced sheet moulding compound. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1271–1279. [Google Scholar] [CrossRef]

- Coutinho, F.M.; Costa, T.H. Performance of polypropylene—Wood fiber composites. Polym. Test. 1999, 18, 581–587. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A.; Alavudeen, A.; Thiruchitrambalam, M. Mechanical and water absorption behaviour of banana/sisal reinforced hybrid composites. Mater. Des. 2011, 32, 4017–4021. [Google Scholar] [CrossRef]

- Weed, J.D. Investigation of Interfacial Bonding in Banana Fiber-Reinforced Composites: Ascribing Global Economic Value to Unique Renewable Resources in Developing Countries. Ph.D. Thesis, Baylor University, Waco, TX, USA, 2014. [Google Scholar]

- Jacob, M.; Joseph, S.; Pothan, L.A.; Thomas, S. A study of advances in characterization of interfaces and fiber surfaces in lignocellulosic fiber-reinforced composites. Compos. Interfaces 2005, 12, 95–124. [Google Scholar] [CrossRef]

- Paul, S.A.; Pothan, L.A.; Thomas, S. Advances in the Characterization of Interfaces of Lignocellulosic Fiber Reinforced Composites. Charact. Lignocellul. Mater. 2008, 249–274. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Summerscales, J.; Virk, A.; Hall, W. A review of bast fibres and their composites: Part 3—Modelling. Compos. Part A Appl. Sci. Manuf. 2013, 44, 132–139. [Google Scholar] [CrossRef]

- Singh, J.I.P.; Dhawan, V.; Singh, S.; Jangid, K. Study of Effect of Surface Treatment on Mechanical Properties of Natural Fiber Reinforced Composites. Mater. Today Proc. 2017, 4, 2793–2799. [Google Scholar] [CrossRef]

- Singleton, A.C.N.; Baillie, C.A.; Beaumont, P.W.R.; Peijs, T. On the mechanical properties, deformation and fracture of a natural fibre/recycled polymer composite. Compos. Part B Eng. 2003, 34, 519–526. [Google Scholar] [CrossRef]

- Keller, A. Compounding and mechanical properties of biodegradable hemp fibre composites. Compos. Sci. Technol. 2003, 63, 1307–1316. [Google Scholar] [CrossRef]

- Rana, A.; Mandal, A.; Bandyopadhyay, S. Short jute fiber reinforced polypropylene composites: Effect of compatibiliser, impact modifier and fiber loading. Compos. Sci. Technol. 2003, 63, 801–806. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Olayo, R.; Herrera-Franco, P.J. Effect of fiber surface treatment on the fiber–matrix bond strength of natural fiber reinforced composites. Compos. Part B Eng. 1999, 30, 309–320. [Google Scholar] [CrossRef]

- Dhawan, V.; Singh, S.; Singh, I. Effect of Natural Fillers on Mechanical Properties of GFRP Composites. J. Compos. 2013, 2013, 1–8. [Google Scholar] [CrossRef]

- Fombuena, V.; Bernardi, L.; Fenollar, O.; Boronat, T.; Balart, R. Characterization of green composites from biobased epoxy matrices and bio-fillers derived from seashell wastes. Mater. Des. 2014, 57, 168–174. [Google Scholar] [CrossRef]

- Mishra, S.; Naik, J.; Patil, Y. The compatibilising effect of maleic anhydride on swelling and mechanical properties of plant-fiber-reinforced novolac composites. Compos. Sci. Technol. 2000, 60, 1729–1735. [Google Scholar] [CrossRef]

- Joseph, S.; Sreekala, M.; Oommen, Z.; Koshy, P.; Thomas, S. A comparison of the mechanical properties of phenol formaldehyde composites reinforced with banana fibres and glass fibres. Compos. Sci. Technol. 2002, 62, 1857–1868. [Google Scholar] [CrossRef]

- Pothan, L.A.; Thomas, S.; Groeninckx, G. The role of fibre/matrix interactions on the dynamic mechanical properties of chemically modified banana fibre/polyester composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1260–1269. [Google Scholar] [CrossRef]

- Kiran, C.U.; Reddy, G.R.; Dabade, B.M.; Rajesham, S. Tensile properties of sun hemp, banana and sisal fiber reinforced polyester composites. J. Reinf. Plast. Compos. 2007, 26, 1043–1050. [Google Scholar] [CrossRef]

- Haneefa, A.; Bindu, P.; Aravind, I.; Thomas, S. Studies on tensile and flexural properties of short banana/glass hybrid fiber reinforced polystyrene composites. J. Compos. Mater. 2008, 42, 1471–1489. [Google Scholar] [CrossRef]

- Prasad, V.; Joy, A.; Venkatachalam, G.; Narayanan, S.; Rajakumar, S. Finite Element Analysis of Jute and Banana Fibre Reinforced Hybrid Polymer Matrix Composite and Optimization of Design Parameters Using ANOVA Technique. Procedia Eng. 2014, 97, 1116–1125. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Yogesha, B. Studies on Mechanical Properties of Jute/E-Glass Fiber Reinforced Epoxy Hybrid Composites. J. Miner. Mater. Charact. Eng. 2016, 04, 15–25. [Google Scholar] [CrossRef]

- Jeyanthi, S.; Rani, J.J. Improving mechanical properties by KENAF natural long fiber reinforced composite for automotive structures. J. Appl. Sci. Eng. 2012, 15, 275–280. [Google Scholar]

- Gopinath, A.; Kumar, M.S.; Elayaperumal, A. Experimental investigations on mechanical properties of jute fiber reinforced composites with polyester and epoxy resin matrices. Procedia Eng. 2014, 97, 2052–2063. [Google Scholar] [CrossRef]

- Rodgors, A. Hockey Stick Shaft. U.S. Patent 5,419,553, 18 April 1994. [Google Scholar]

- ASTM D7264. Standard Test Method for flexural Properties of Polymer Matrix Composite Materials. In American Society for Testig and Materials Annual Book of ASTM Standards; ASTM: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division) EPOTEC YD 134 Home Page. Available online: https://www.epotec.info/admin/uploaded/Liquid_epoxy_resin/TDS%20YD%20134.pdf (accessed on 10 September 2019).

- Jamshaid, H.; Mishra, R. A green material from rock: Basalt fiber—A review. J. Text. Inst. 2016, 107, 923–937. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Wang, X. Flexural characteristics of coir fiber reinforced cementitious composites. Fibers Polym. 2006, 7, 286–294. [Google Scholar] [CrossRef]

| Mechanical Properties | EPOTEC YD-134 [33] | Banana Fibers [10] | E-Glass Fibers [34] |

|---|---|---|---|

| Density () | 700 | 1350 | 2550 |

| Tensile Strength (MPa) | – | 392–677 | 3100–3800 |

| Young’s Modulus (GPa) | 3.1 | 27–32 | 72.5–75.5 |

| Shear Modulus (GPa) | 1.25 | 12.5 | 33 |

| Failure Strain (%) | – | 1–3 | 4.70 |

| Poisson’s Ratio | 0.24 | 0.23 | 0.21 |

| Stacking Sequence | Samples | Weight (g) | Description |

|---|---|---|---|

| G8 | G8-1 | 21.96 | 8 layers of E-glass fibers. |

| G8-2 | 21.88 | ||

| G8-3 | 21.93 | ||

| G4B1G3 (G7B1) | G4B1G3-1 | 21.68 | 4 layers of E-glass fibers, 1 layer of banana fibers, and then 3 layers of E-glass fibers. |

| G4B1G3-2 | 21.72 | ||

| G4B1G3-3 | 21.66 | ||

| G3B2G3 (G6B2) | G3B2G3-1 | 19.10 | 3 layers of E-glass fibers, 2 layers of banana fibers, and then 3 layers of E-glass fibers. |

| G3B2G3-2 | 19.07 | ||

| G3B2G3-3 | 19.11 | ||

| G3B3G2 (G5B3) | G3B3G2-1 | 17.31 | 3 layers of E-glass fibers, 3 layers of banana fibers, and then 2 layers of E-glass fibers. |

| G3B3G2-2 | 17.25 | ||

| G3B3G2-3 | 17.29 |

| Stacking Sequence | Thickness (mm) | Total Length (mm) | Average Width (mm) |

|---|---|---|---|

| G8 | 2.82 | 80 | 14.84 |

| G7B1 | 2.85 | 80 | 14.71 |

| G6B2 | 2.93 | 80 | 14.55 |

| G5B3 | 3.08 | 80 | 14.65 |

| Physical Property | Glass/Epoxy Lamina | Banana/Epoxy Lamina |

|---|---|---|

| Density (kg⁄m3) | 2550 | 1350 |

| (MPa) | 13,010 | 7828 |

| (MPa) | 13,010 | 3400 |

| (MPa) | 4953 | 3400 |

| (MPa) | 2850 | 1250 |

| (MPa) | 1795 | 1250 |

| (MPa) | 1795 | 1100 |

| 0.22 | 0.23 | |

| 0.3 | 0.23 | |

| 0.3 | 0.32 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Rashid, A.; Khalid, M.Y.; Imran, R.; Ali, U.; Koc, M. Utilization of Banana Fiber-Reinforced Hybrid Composites in the Sports Industry. Materials 2020, 13, 3167. https://doi.org/10.3390/ma13143167

Al Rashid A, Khalid MY, Imran R, Ali U, Koc M. Utilization of Banana Fiber-Reinforced Hybrid Composites in the Sports Industry. Materials. 2020; 13(14):3167. https://doi.org/10.3390/ma13143167

Chicago/Turabian StyleAl Rashid, Ans, Muhammad Yasir Khalid, Ramsha Imran, Umair Ali, and Muammer Koc. 2020. "Utilization of Banana Fiber-Reinforced Hybrid Composites in the Sports Industry" Materials 13, no. 14: 3167. https://doi.org/10.3390/ma13143167

APA StyleAl Rashid, A., Khalid, M. Y., Imran, R., Ali, U., & Koc, M. (2020). Utilization of Banana Fiber-Reinforced Hybrid Composites in the Sports Industry. Materials, 13(14), 3167. https://doi.org/10.3390/ma13143167