Microstructure, Texture and Mechanical Properties of AZ31 Magnesium Alloy Fabricated by High Strain Rate Biaxial Forging

Abstract

1. Introduction

2. Experimental Procedures

3. Results and Discussion

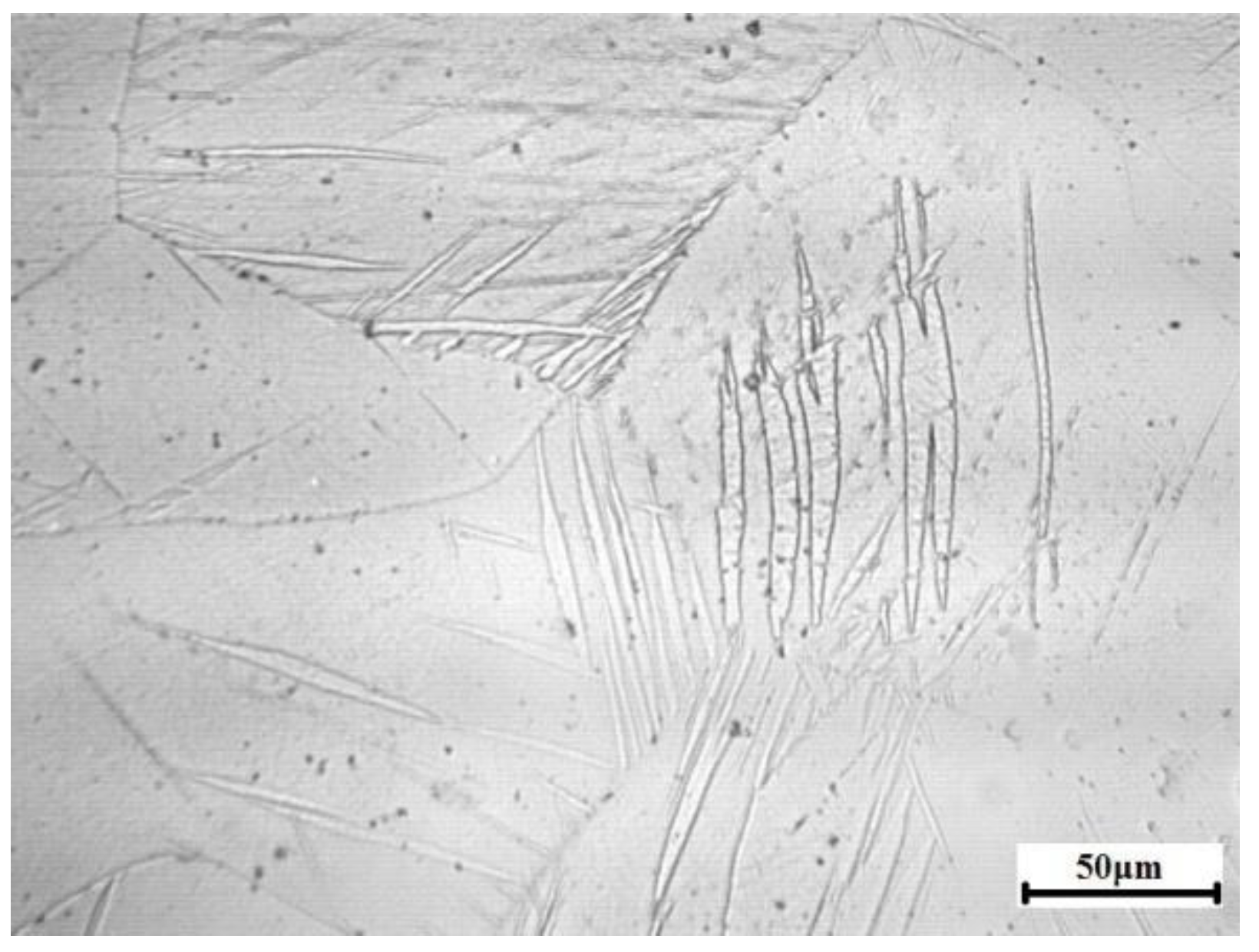

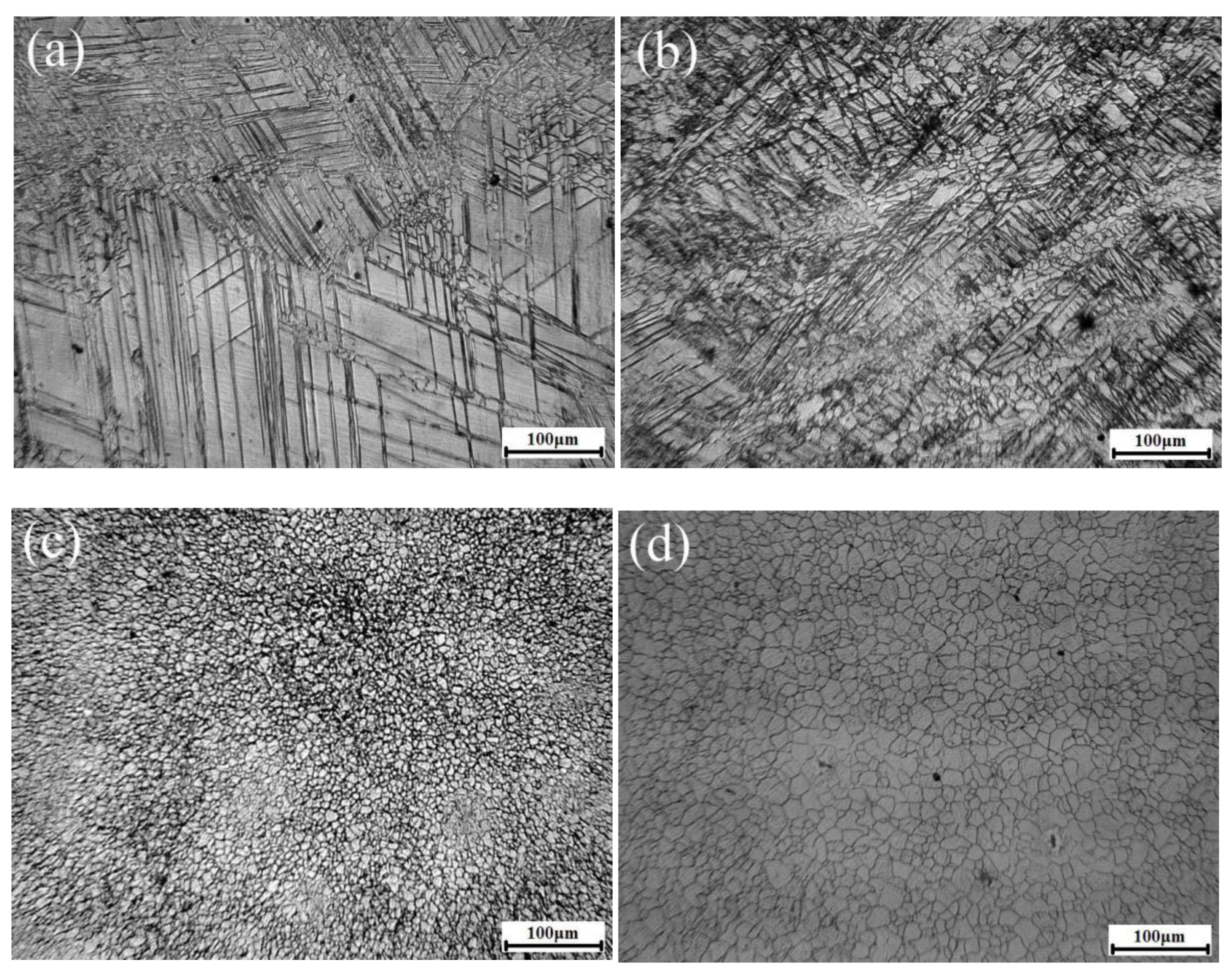

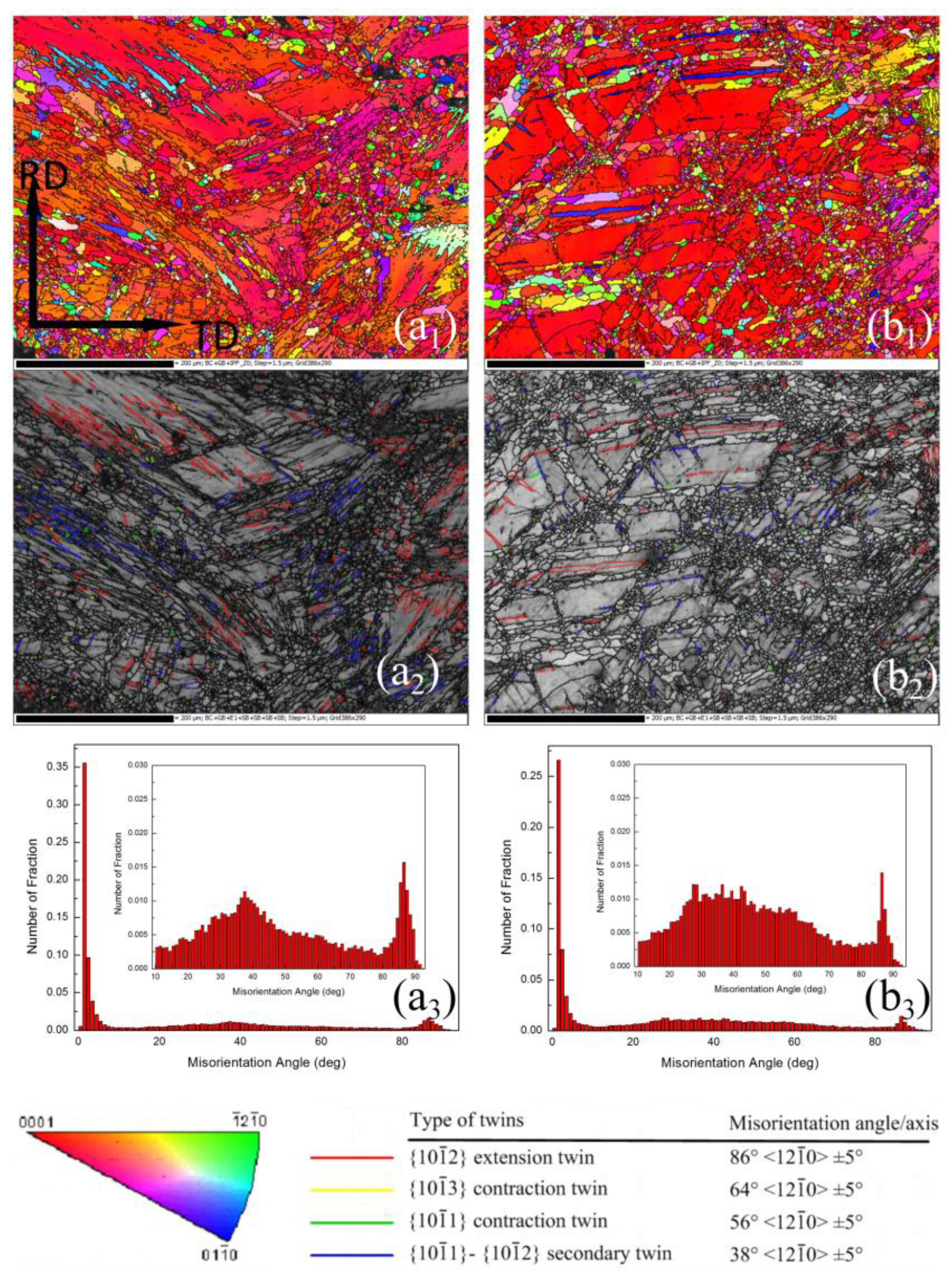

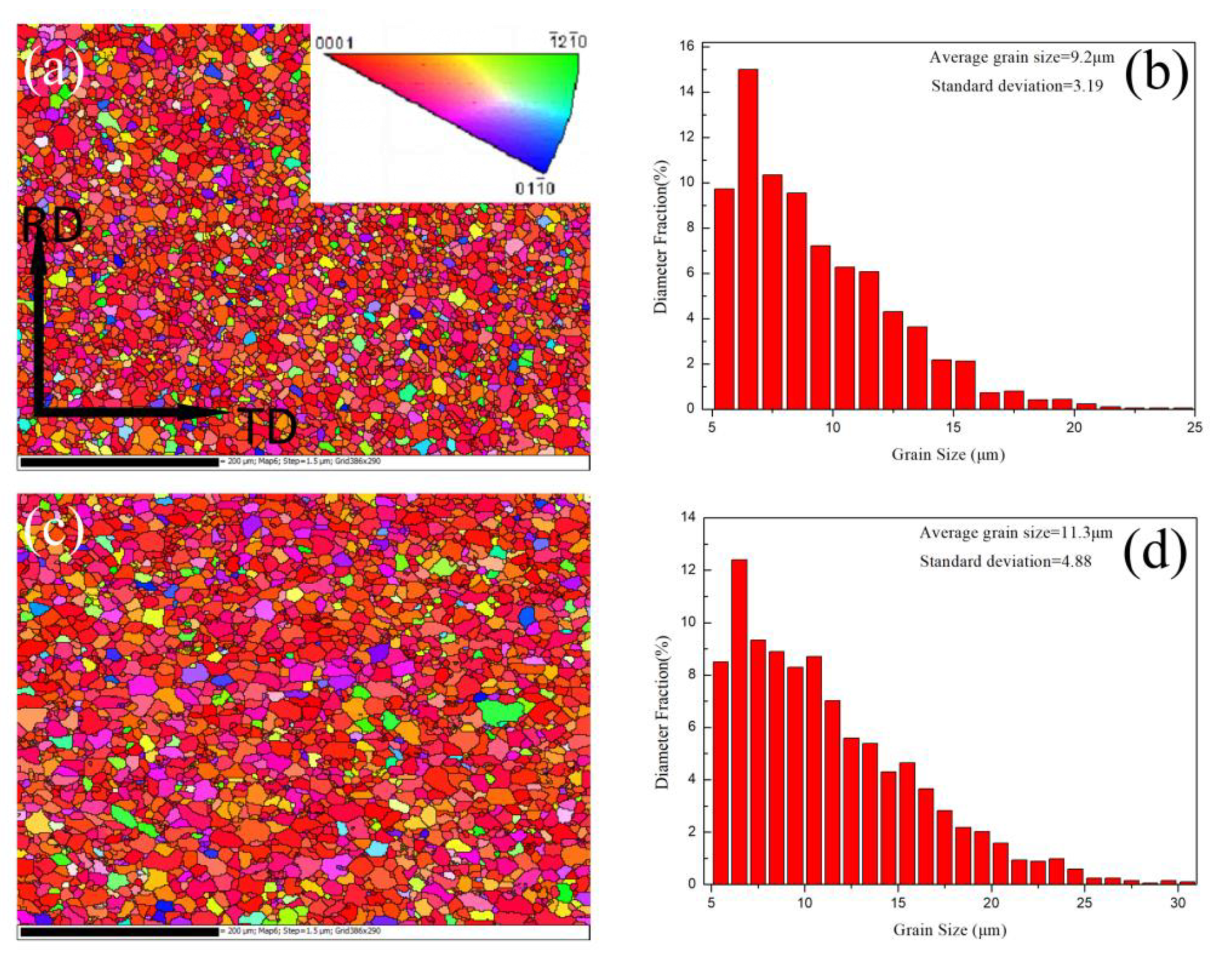

3.1. Microstructure Evolution

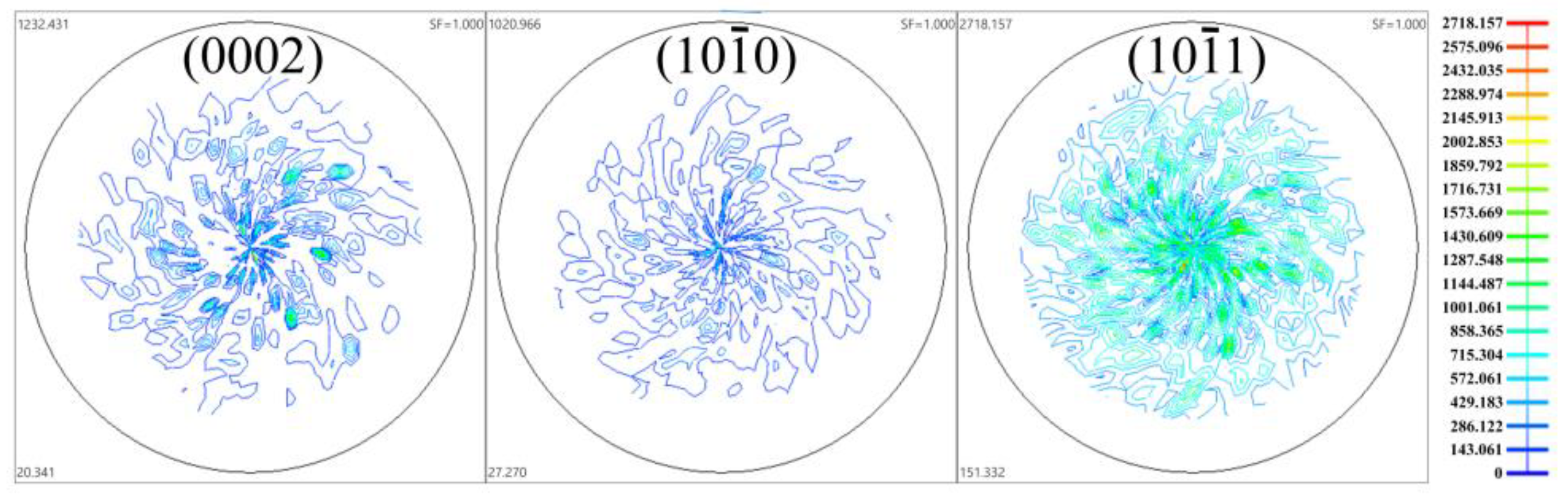

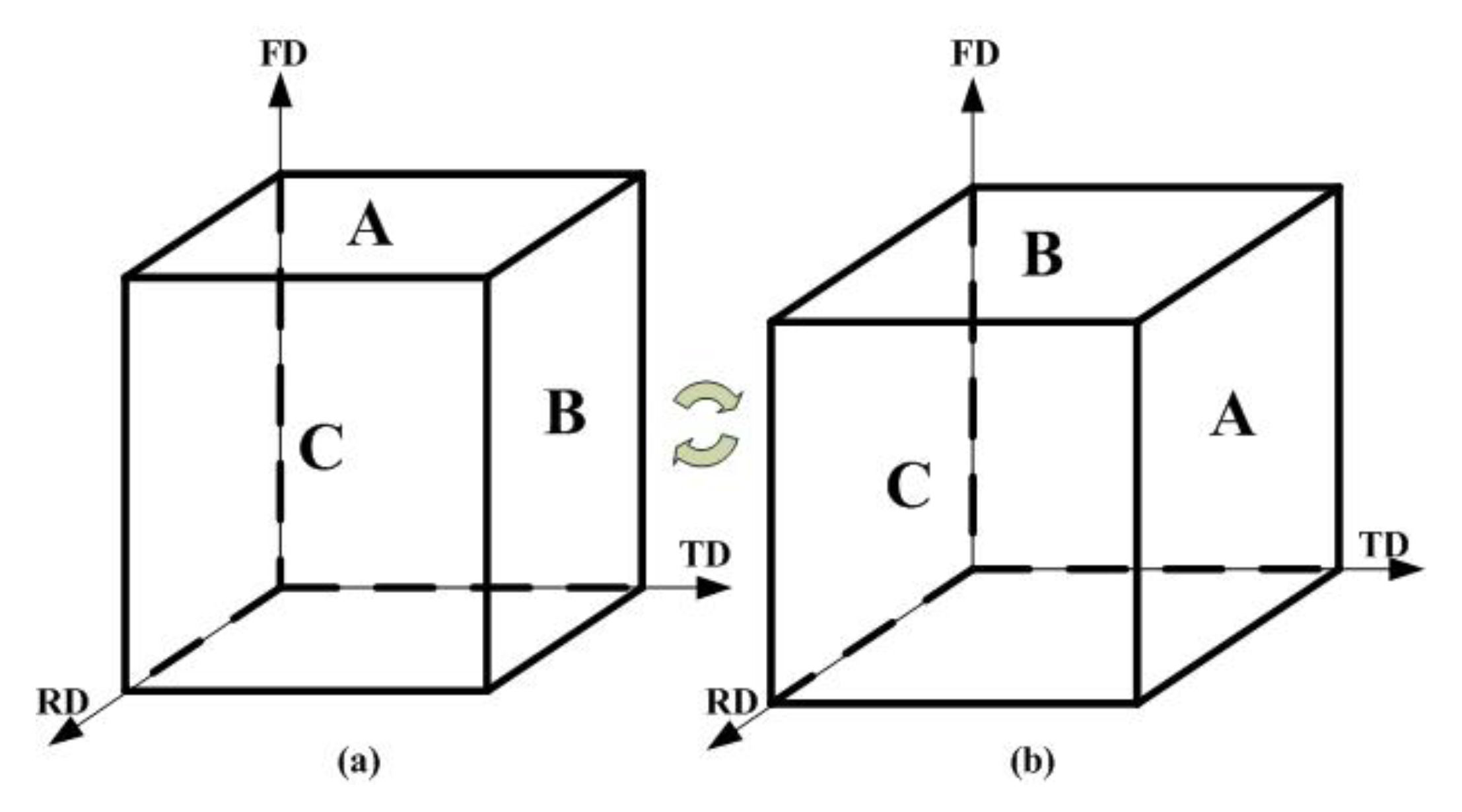

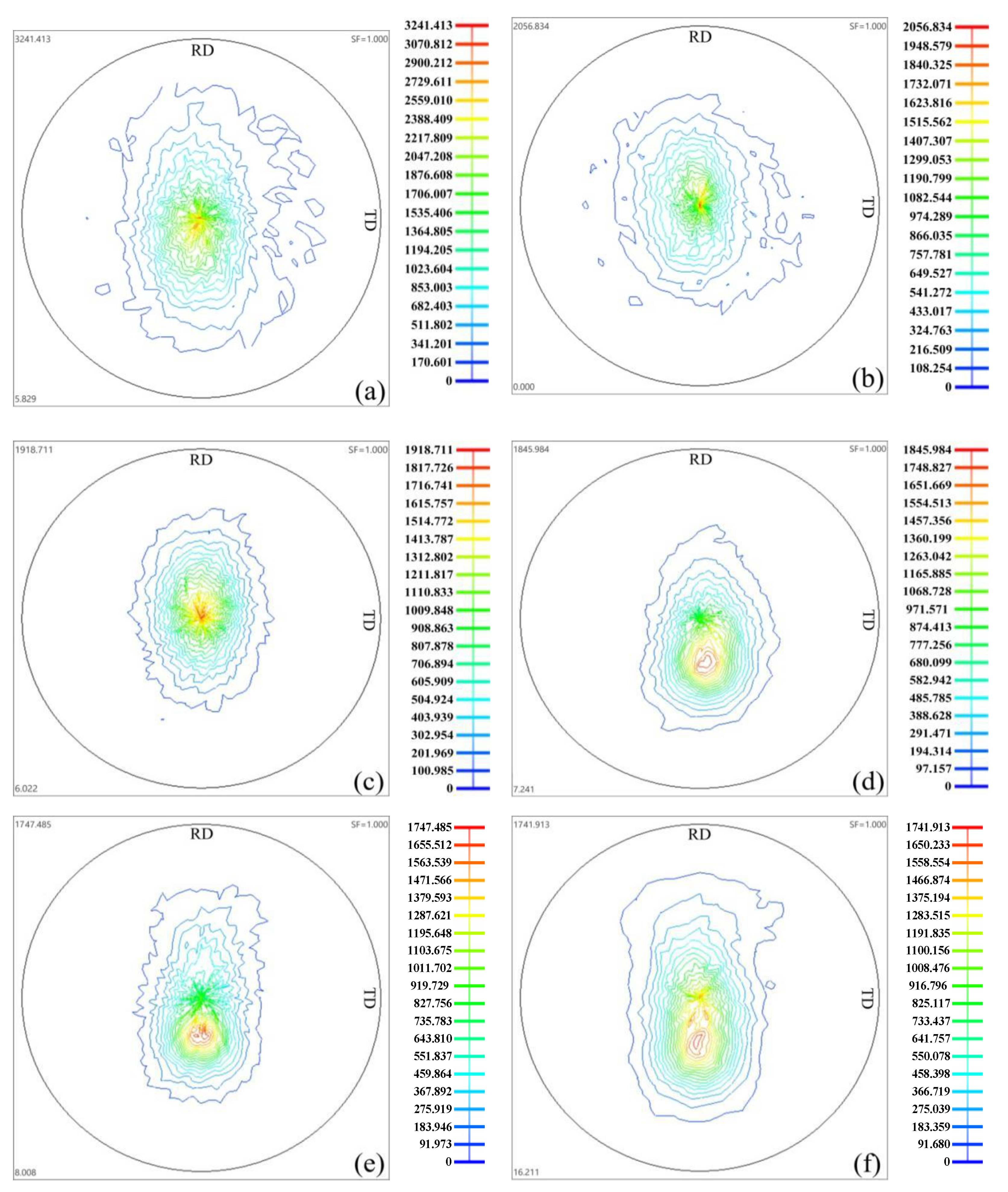

3.2. Texture

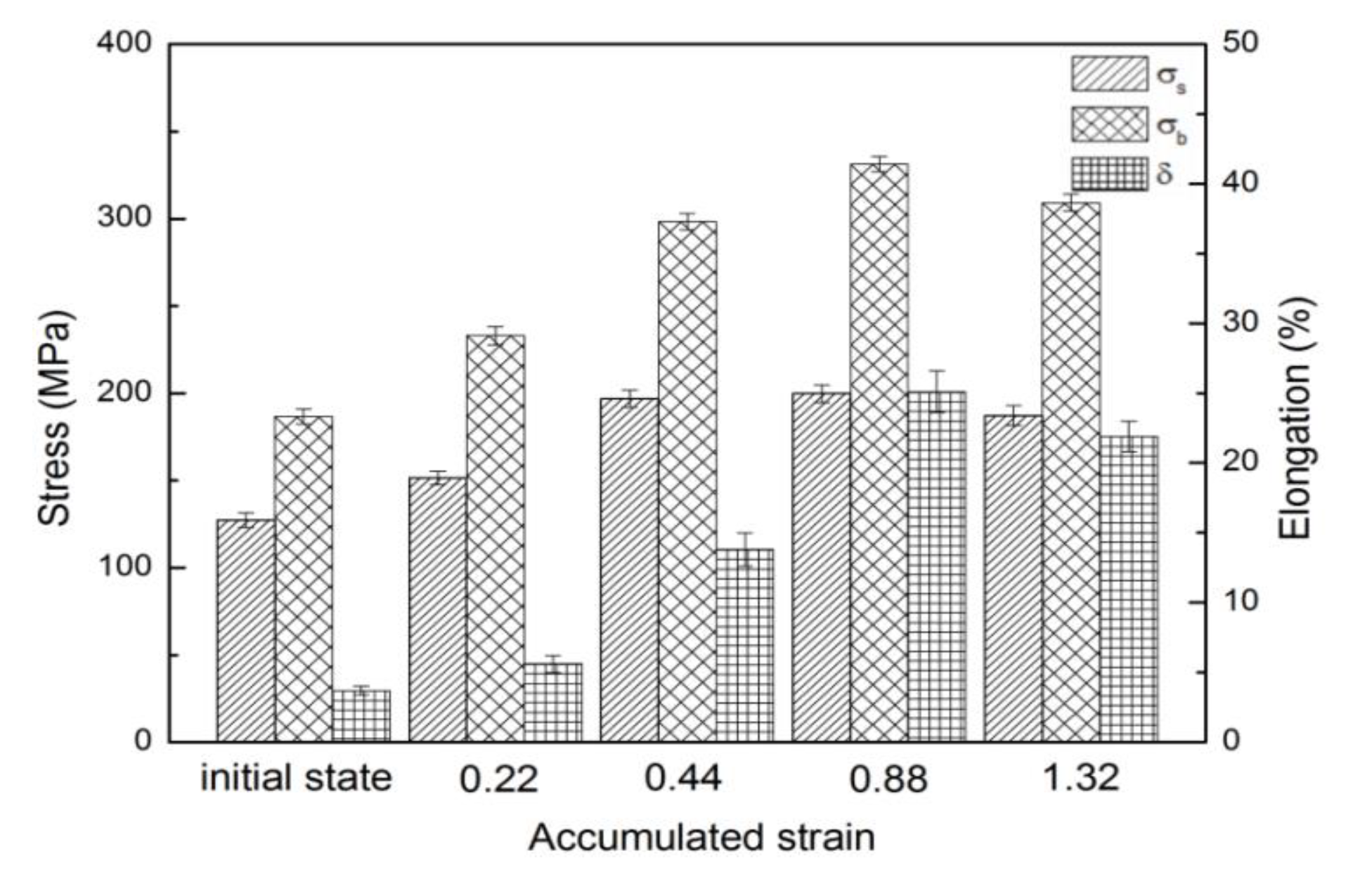

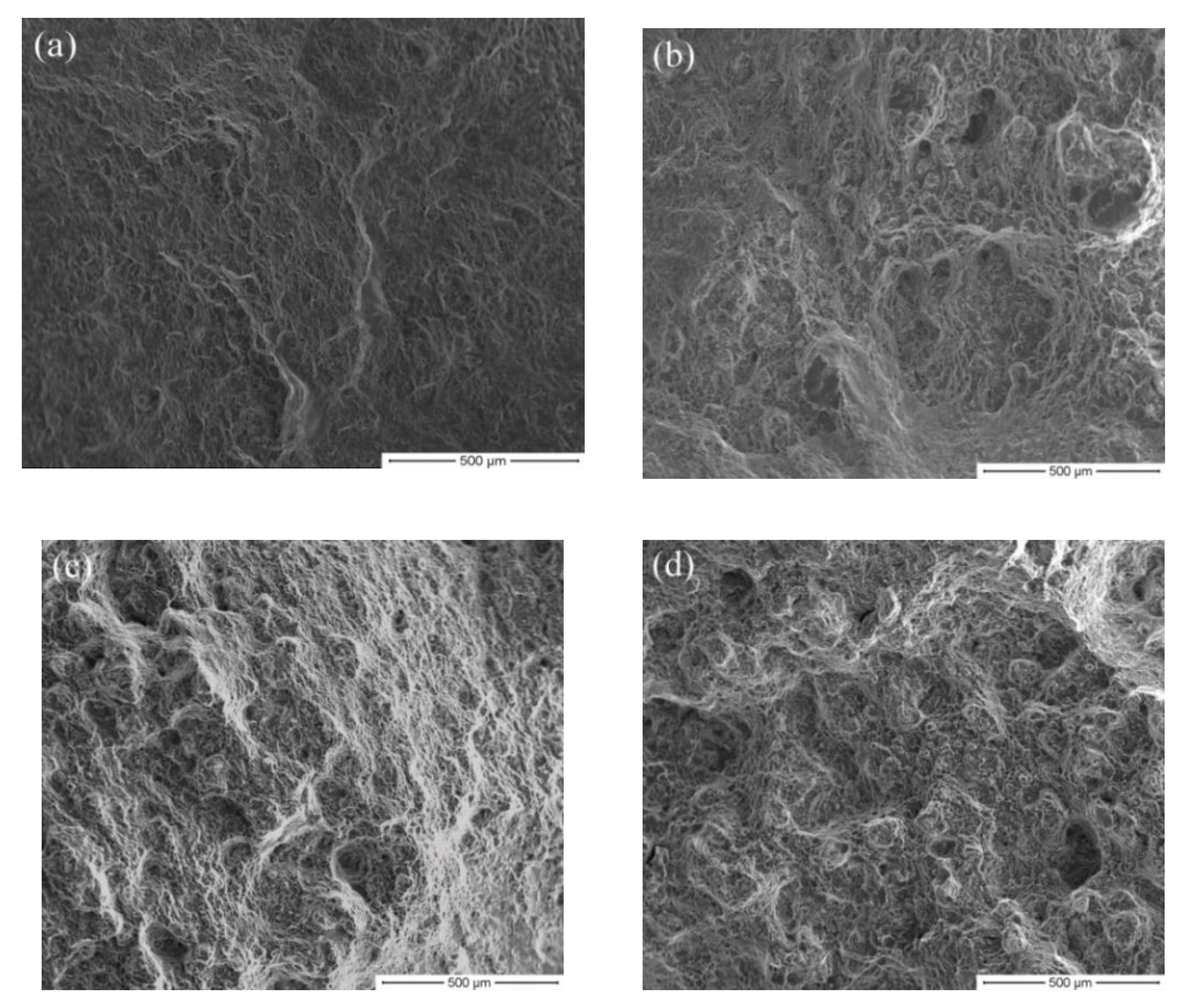

3.3. Mechanical Properties

4. Conclusions

- The microstructure evolution during HSRBF can be divided into two steps, i.e., grain refinement in the early stage and grain growth with further increase of accumulated strain. A homogeneous fine DRX structure with the average grain size of 9.2 μm was obtained as accumulated strain was 0.88, implying that DRX developed at lower strain during HSRBF.

- The formation of high density twins, and subsequently twining induced DRX, leads to the grain refinement, and {102} and {101}-{102} twining are the predominant twinning mechanisms in magnesium alloy forged at high strain rate.

- The main texture in the HSRBFed alloys is a typical hot-rolled texture, and the intensity of the texture decreases with increasing of the accumulated strain. Moreover, the basal pole rotates towards the direction of forging direction (FD) after each pass, and a basal texture with a basal pole inclining at 15–20° form the rolling direction (RD) formed in the full recrystallized HSRBFed alloy.

- The strength and elongation increase with the strain as the accumulated strain is lower than 0.88, but decrease slightly with further forging, and an excellent combination of mechanical property with UTS of 331.2 MPa and elongation of 25.1% was achieved at ΣΔε = 0.88, which resulted from the combined effects of grain refinement and weakened basal texture. Therefore, HSRMF is an efficient way to produce strong and ductile wrought AZ31 alloy.

Author Contributions

Funding

Conflicts of Interest

References

- Papenberg, N.P.; Gneiger, S.; Weißensteiner, I.; Uggowitzer, P.J.; Pogatscher, S. Mg-alloys for forging applications-a review. Materials 2020, 13, 985. [Google Scholar] [CrossRef] [PubMed]

- Kotiba, H. Highly-ductile magnesium alloys: Atomistic-flow mechanism and alloy designing. Materials 2019, 12, 1934. [Google Scholar]

- Zhu, S.Q.; Yan, H.G.; Chen, J.H.; Wu, Y.Z.; Su, B.; Du, Y.G.; Liao, X.Z. Feasibility of high strain-rate rolling of a magnesium alloy across a wide temperature range. Scr. Mater. 2012, 67, 404–407. [Google Scholar] [CrossRef]

- Kahana, E.; Ben-Artzy, A.; Sadot, O.; Shneck, R.Z. Microstructure evolution of AZ31 magnesium alloy after high strain rate expanding rings test. Mater. Sci. Eng. A 2015, 641, 274–280. [Google Scholar] [CrossRef]

- Asgari, H.; Szpunar, J.A.; Odeshi, A.G. Texture evolution and dynamic mechanical behavior of cast AZ magnesium alloy under high strain rate compressive loading. Mater. Sci. Eng. A 2013, 559, 765–772. [Google Scholar] [CrossRef]

- You, J.; Huang, Y.J.; Liu, C.M.; Zhan, H.Y.; Huang, L.X.; Zeng, G. Microstructural study of a Mg-Zn-Zr alloy hot compressed at high strain rate. Materials 2020, 13, 2348. [Google Scholar] [CrossRef]

- Wu, Y.Z.; Yan, H.G.; Chen, J.H.; Zhu, S.Q.; Su, B.; Zeng, P.L. Hot deformation behavior and microstructure evolution of ZK21 alloy. Mater. Sci. Eng. A 2010, 527, 3670–3675. [Google Scholar] [CrossRef]

- Vávra, T.; Minárik, P.; Veselý, J.; Král, R. Excellent superplastic properties achieved in Mg-4Y-3RE alloy in high strain rate regime. Mater. Sci. Eng. A 2020, 784, 139314. [Google Scholar] [CrossRef]

- Khan MD, F.; Panigrahi, S.K. Achieving excellent superplasticity in an ultrafine-grained QE22 alloy at both high strain rate and low-temperature regimes. J. Alloy. Compd. 2018, 747, 71–82. [Google Scholar]

- Dixit, N.; Xie, K.Y.; Hemker, K.J.; Ramesh, K.T. Microstructural evolution of pure magnesium under high strain rate loading. Acta Mater. 2015, 87, 56–67. [Google Scholar] [CrossRef]

- Li, Y.P.; Wu, S.; Bian, H.; Tang, N.; Liu, B.; Koizumi, Y.; Chiba, A. Grain refinement due to complex twin formation in rapid hot forging of magnesium. Scr. Mater. 2013, 68, 171–174. [Google Scholar] [CrossRef]

- Jiang, M.G.; Yan, H.; Chen, R.S. Microstructure, texture and mechanical properties in an as-cast AZ61 Mg alloy during multi-directional impact forging and subsequent heat treatment. Mater. Des. 2015, 87, 891–900. [Google Scholar] [CrossRef]

- Jiang, M.G.; Yan, H.; Chen, R.S. Enhanced mechanical properties due to grain refinement and texture modification in an AZ61 Mg alloy processed by small strain impact forging. Mater. Sci. Eng. A 2015, 621, 204–211. [Google Scholar] [CrossRef]

- Shah, S.S.A.; Wu, D.; Chen, R.S.; Song, G.S. Static recrystallization behavior of multi-directional impact forged Mg-Gd-Y-Zr alloy. J. Alloy. Compd. 2019, 805, 189–197. [Google Scholar] [CrossRef]

- Wu, Y.Z.; Yan, H.G.; Chen, J.H.; Zhu, S.Q.; Su, B.; Zeng, P.L. Microstructure and mechanical properties of ZK60 alloy fabricated by high strain rate multiple forging. Mater. Sci. Technol. 2013, 29, 54–59. [Google Scholar] [CrossRef]

- Wu, Y.Z.; Yan, H.G.; Chen, J.H.; Du, Y.G.; Zhu, S.Q.; Su, B. Microstructure and mechanical properties of ZK21 magnesium alloy fabricated by multiple forging at different strain rates. Mater. Sci. Eng. A 2012, 556, 164–169. [Google Scholar] [CrossRef]

- Wu, Y.; Deng, B.; Ye, T.; Nie, Z.; Liu, X. Fabrication of strong and ductile AZ31 magnesium alloy using high strain rate multiple forging in a wide temperature range. Metals 2020, 10, 729. [Google Scholar] [CrossRef]

- Bodnar, R.L.; Erman, E.; Medei, N.M.; Cappellini, R.R.; Johnson, C.A.; Stuart, D.J. Open-Die Forging, ASM Handbook: Forging and Forging; ASM International: Novelty, OH, USA, 1993. [Google Scholar]

- Zhu, S.Q.; Yan, H.G.; Liao, X.Z.; Moody, S.J.; Sha, G.; Wu, Y.Z.; Ringer, S.P. Mechanisms for enhanced plasticity in magnesium alloys. Acta Mater. 2015, 82, 344–355. [Google Scholar] [CrossRef]

- Salandari-Rabori, A.; Zarei-Hanzaki, A.; Fatemi, S.M.; Ghambari, M.; Moghaddam, M. Microstructure and superior mechanical properties of a multi-axially forged WE magnesium alloy. J. Alloy. Compd. 2017, 693, 406–413. [Google Scholar] [CrossRef]

- Salandari-Rabori, A.; Zarei-Hanzaki, A.; Abedi, H.R.; Lecomte, J.S.; Khatami-hamedani, H. Micro and macro texture evolution during multiaxial forging of a WE43 magnesium alloy. J. Alloy. Compd. 2018, 739, 249–259. [Google Scholar] [CrossRef]

- Guo, Q.; Yan, H.G.; Chen, Z.H.; Zhang, H. Grain refinement in as-cast AZ80 magnesium alloy under large strain deformation. Mater. Des. 2007, 58, 162–167. [Google Scholar]

- Chen, Q.; Shu, D.; Hu, C.; Zhao, Z.; Yuan, B. Grain refinement in an as-cast AZ61 magnesium alloy processed by multiaxial forging under the multi temperature processing procedure. Mater. Sci. Eng. A 2012, 541, 98–104. [Google Scholar] [CrossRef]

- Ishikawa, K.; Watanabe, H.; Mukai, T. High strain rate deformation behavior of an AZ91 magnesium alloy at elevated temperatures. Mater. Lett. 2005, 59, 1511–1515. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Zhu, S.Q.; Ringer, S.P. On the role of twinning and stacking faults on the crystal plasticity and grain refinement in magnesium alloys. Acta Mater. 2018, 144, 365–375. [Google Scholar] [CrossRef]

- Sakai, T.; Utsunomiya, H.; Koh, H.; Minamiguchi, S. Texture of AZ31 magnesium alloy sheet heavily rolled by high speed warm rolling. Mater. Sci. Forum 2007, 539, 3359–3364. [Google Scholar] [CrossRef]

- Tahreen, N.; Chen, D.L.; Nouri, M.; Li, D.Y. Influence of aluminum content on twinning and texture development of cast Mg-Al-Zn alloy during compression. J. Alloy. Compd. 2015, 623, 15–23. [Google Scholar] [CrossRef]

- Wu, J.L.; Jin, L.; Dong, J.; Wang, F.H.; Dong, S. The texture and its optimization in magnesium alloy. J. Mater. Sci. Tech. 2020, 42, 175–189. [Google Scholar] [CrossRef]

- Nie, K.B.; Deng, K.K.; Wang, X.J.; Xu, F.J.; Wu, K.; Zheng, M.Y. Multidirectional forging of AZ91 magnesium alloy and its effects on microstructures and mechanical properties. Mater. Sci. Eng. A 2011, 624, 157–168. [Google Scholar] [CrossRef]

- Pérez-Prado, M.T.; Del Valle, J.A.; Ruan, O.A. Effect of sheet thickness on the microstructural evolution of a Mg AZ61 alloy during large strain hot rolling. Scr. Mater. 2004, 50, 667–671. [Google Scholar] [CrossRef]

- Sagapuram, D.; Efe, M.; Moscoso, W.; Chandrasekar, S.; Trumble, K.P. Controlling texture in magnesium alloy sheet by shear-based deformation processing. Acta Mater. 2013, 61, 6843–6856. [Google Scholar] [CrossRef]

- Biswas, S.; Suwas, S. Evolution of sub-micron grain size and weak texture in magnesium alloy Mg–3Al–0.4Mn by a modified multi-axial forging process. Scr. Mater. 2012, 66, 89–92. [Google Scholar] [CrossRef]

- Martynenko, N.S.; Lukyanova, E.A.; Serebryany, V.N.; Gorshenkov, M.V.; Shchetinin, I.V.; Raab, G.I.; Dobatkin, S.V.; Estrin, Y. Increasing strength and ductility of magnesium alloy WE43 by equal-channel angular pressing. Mater. Sci. Eng. A 2018, 712, 625–629. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Enhancing plastic deformability of Mg and its alloys—A review of traditional and nascent developments. J. Magnes. Alloy. 2017, 5, 460–475. [Google Scholar] [CrossRef]

| Accumulated Strain | σs (MPa) | σb (MPa) | δ (%) |

|---|---|---|---|

| initial state | 127.2 ± 4.1 | 186.6 ± 4.4 | 3.7 ± 0.3 |

| 0.22 | 151.3 ± 3.9 | 233 ± 5.2 | 5.6 ± 0.6 |

| 0.44 | 196.8 ± 4.8 | 298.3 ± 4.7 | 13.8 ± 1.2 |

| 0.88 | 199.7 ± 4.9 | 331.2 ± 4.3 | 25.1 ± 1.5 |

| 1.32 | 187.2 ± 5.8 | 309.1 ± 4.9 | 21.9 ± 1.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Liu, J.; Deng, B.; Ye, T.; Li, Q.; Zhou, X.; Zhang, H. Microstructure, Texture and Mechanical Properties of AZ31 Magnesium Alloy Fabricated by High Strain Rate Biaxial Forging. Materials 2020, 13, 3050. https://doi.org/10.3390/ma13143050

Wu Y, Liu J, Deng B, Ye T, Li Q, Zhou X, Zhang H. Microstructure, Texture and Mechanical Properties of AZ31 Magnesium Alloy Fabricated by High Strain Rate Biaxial Forging. Materials. 2020; 13(14):3050. https://doi.org/10.3390/ma13143050

Chicago/Turabian StyleWu, Yuanzhi, Jizhao Liu, Bin Deng, Tuo Ye, Qingfen Li, Xiaotao Zhou, and Hongji Zhang. 2020. "Microstructure, Texture and Mechanical Properties of AZ31 Magnesium Alloy Fabricated by High Strain Rate Biaxial Forging" Materials 13, no. 14: 3050. https://doi.org/10.3390/ma13143050

APA StyleWu, Y., Liu, J., Deng, B., Ye, T., Li, Q., Zhou, X., & Zhang, H. (2020). Microstructure, Texture and Mechanical Properties of AZ31 Magnesium Alloy Fabricated by High Strain Rate Biaxial Forging. Materials, 13(14), 3050. https://doi.org/10.3390/ma13143050