Performance of Short Fiber Interlayered Reinforcement Thermoplastic Resin in Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials for Testing and Research

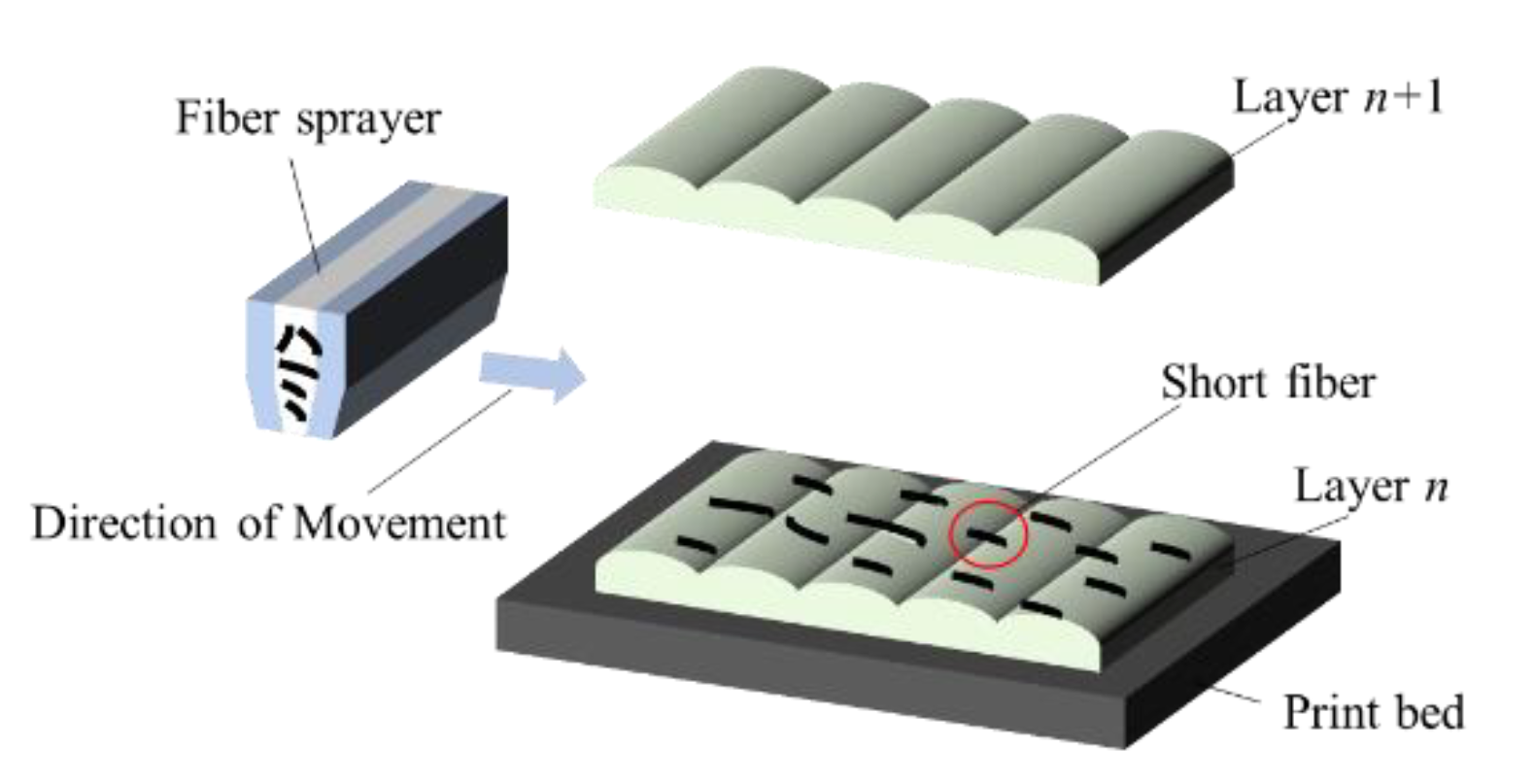

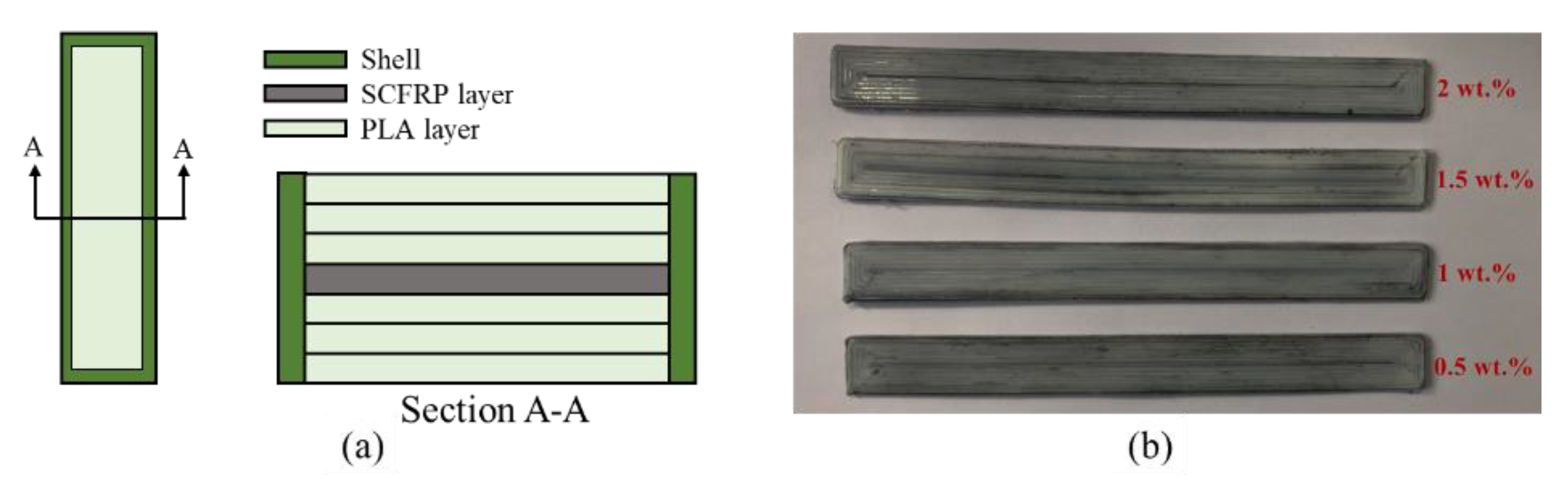

2.2. 3D Printing Equipment with Fiber Placement

2.3. Performance Test and Cross—Section Observation

2.4. Post-Treatment

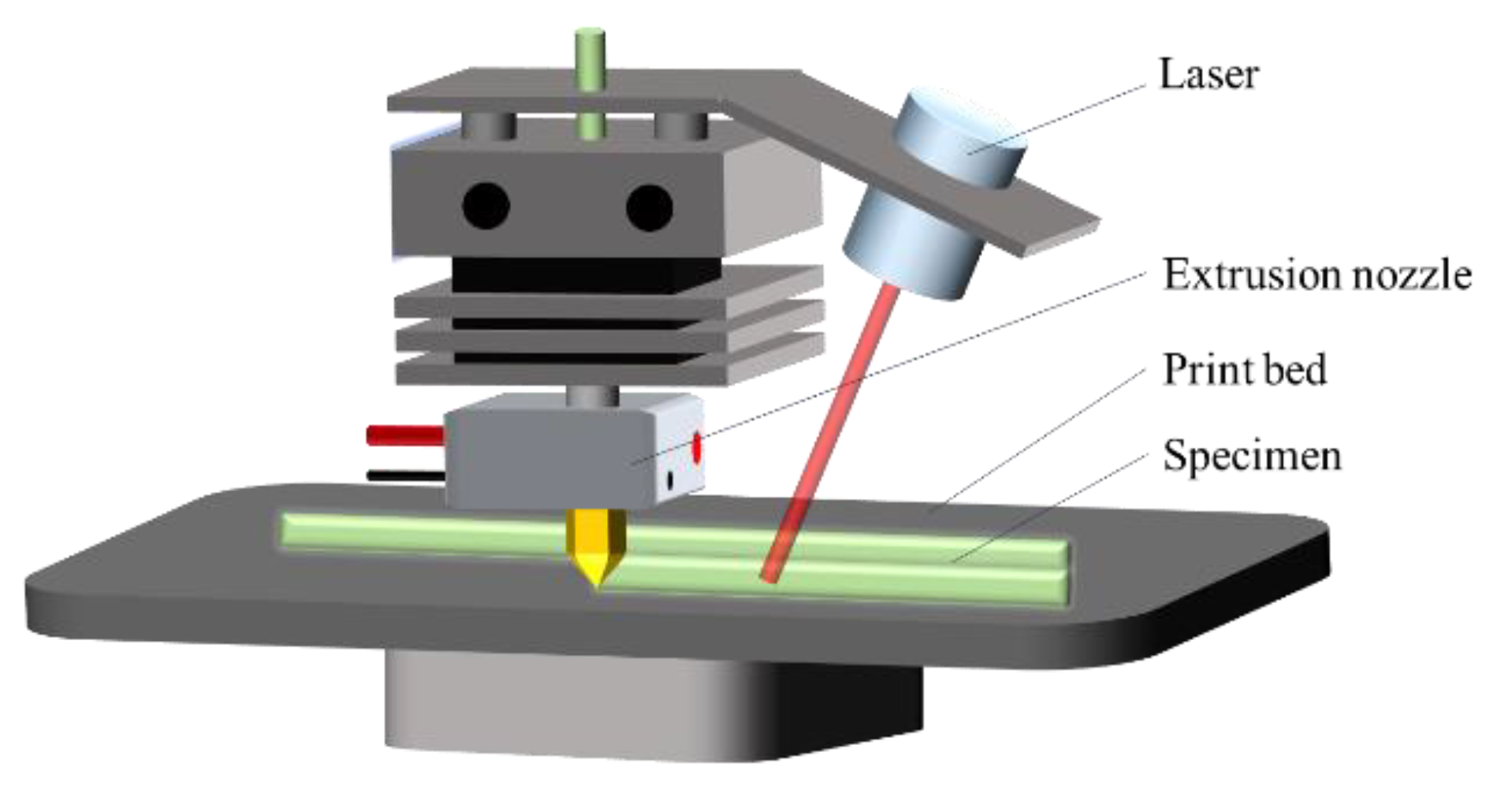

2.5. Laser—Assisted Preheating

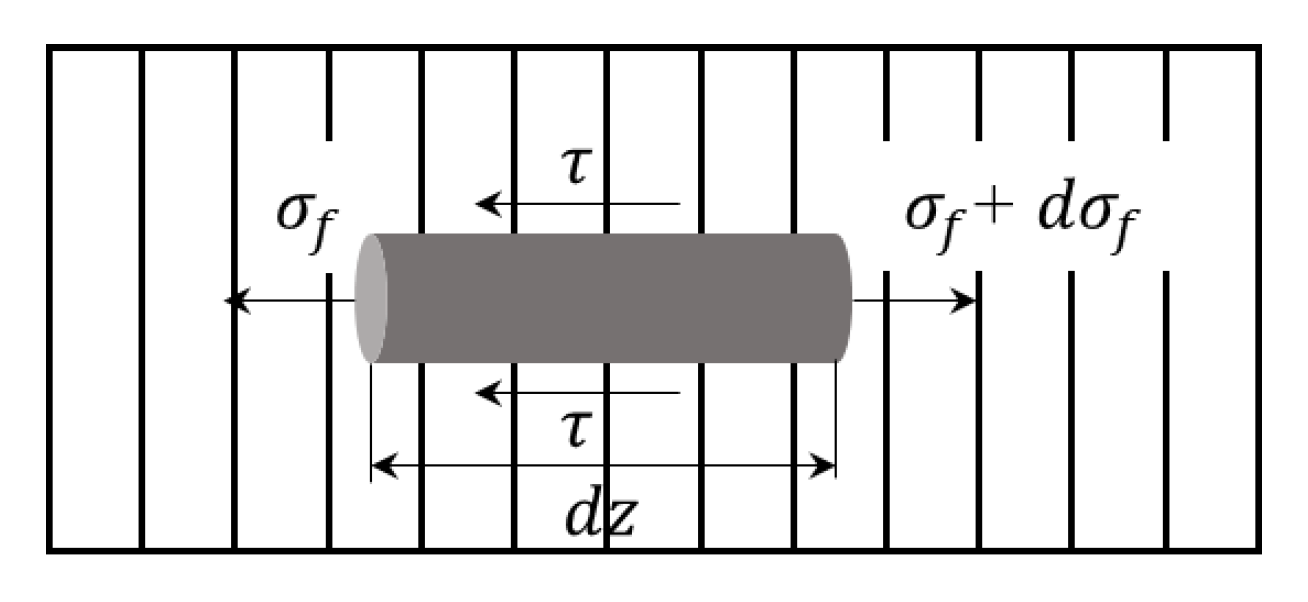

2.6. Short Fibers Reinforcement Mechanism

3. Results and Discussion

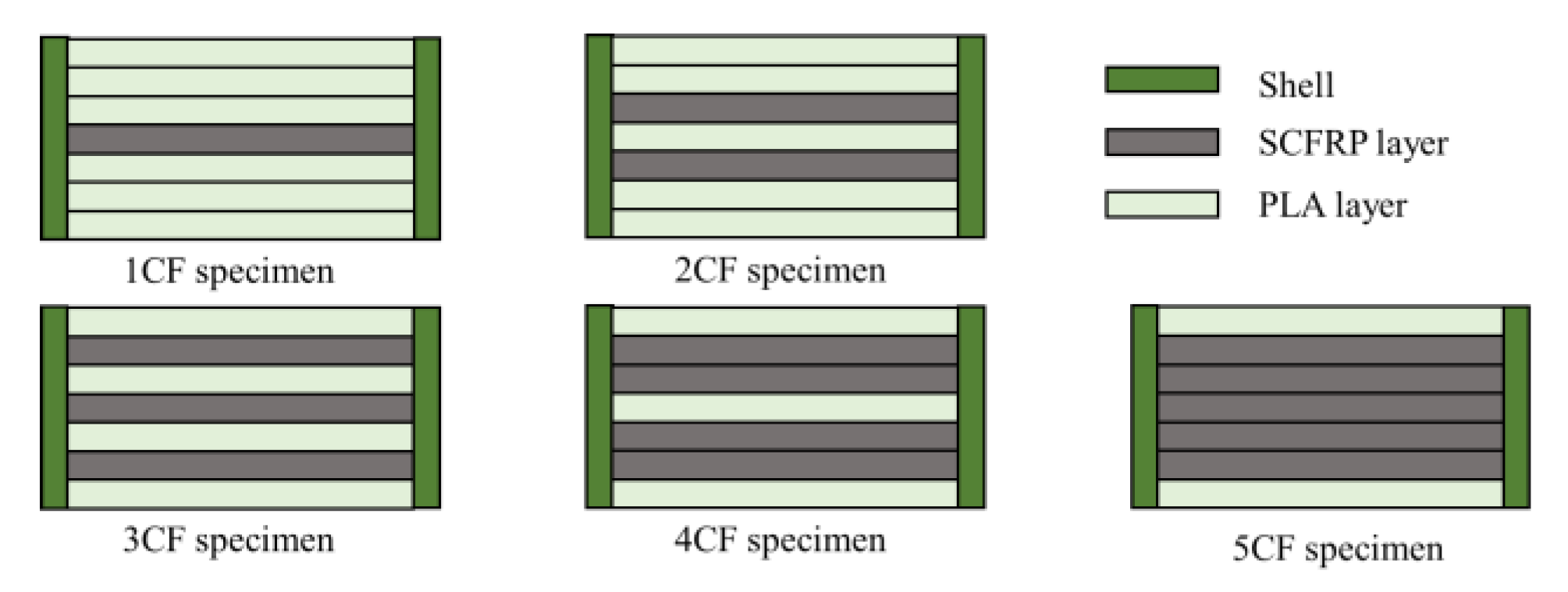

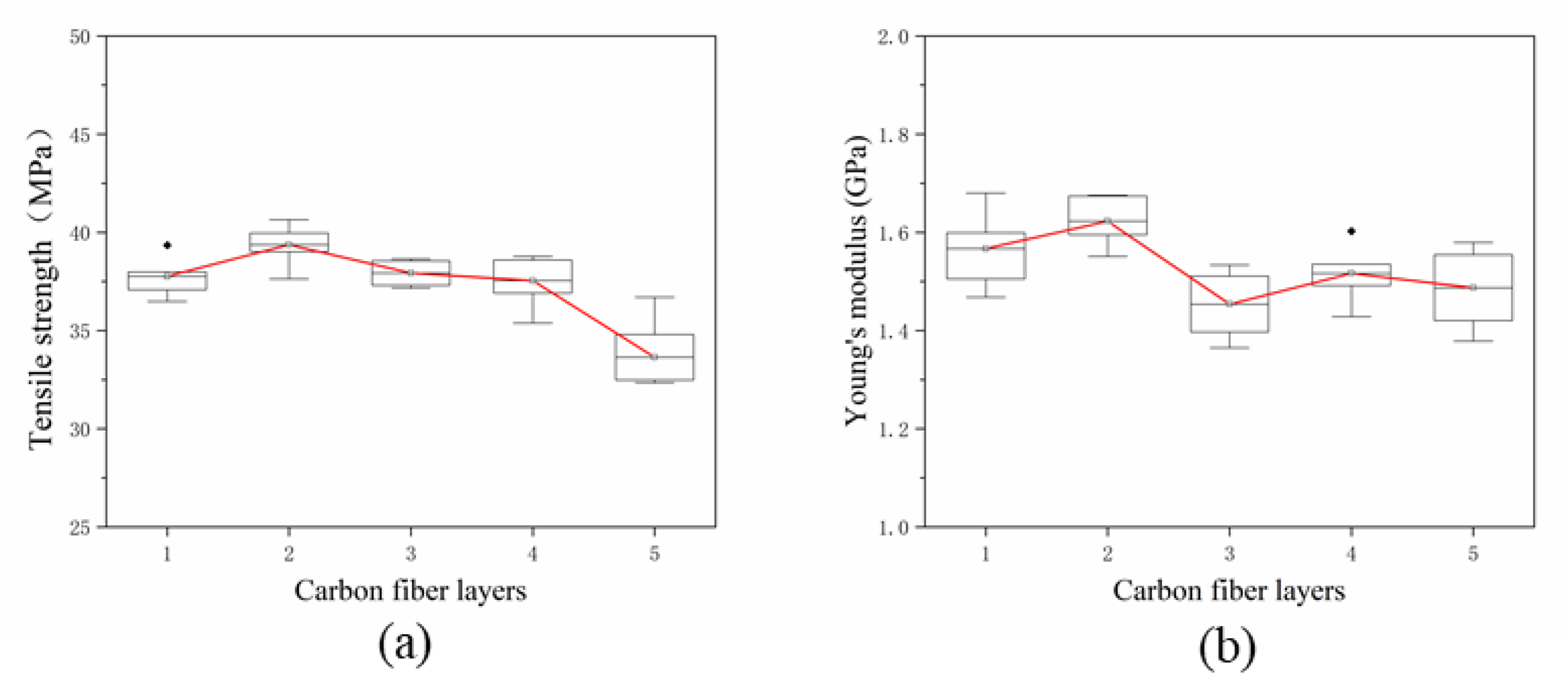

3.1. Effect of Short Fiber Content on Performance of the Additive Manufactured Thermoplastic Resin Parts

3.1.1. Mechanical Properties Test

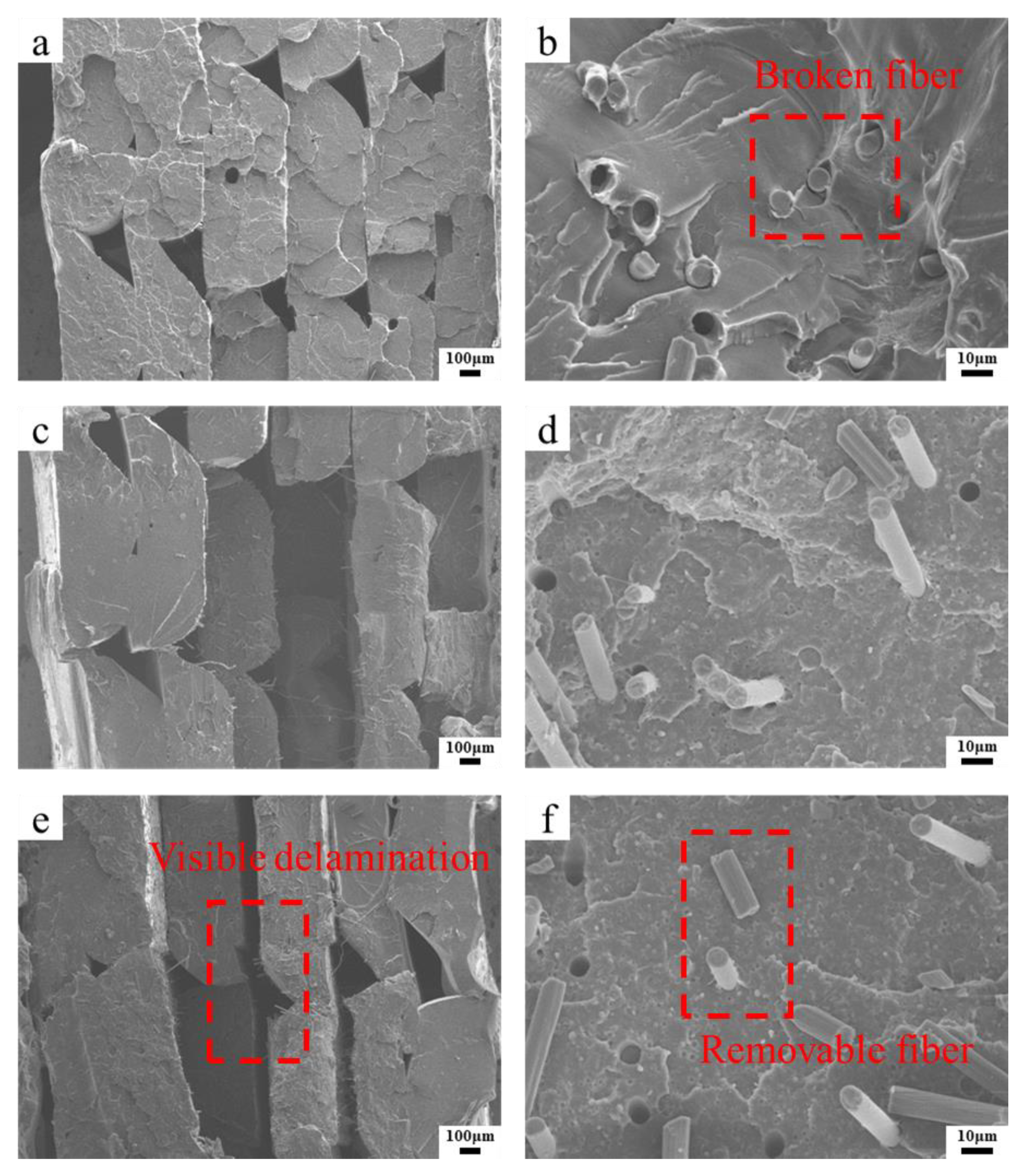

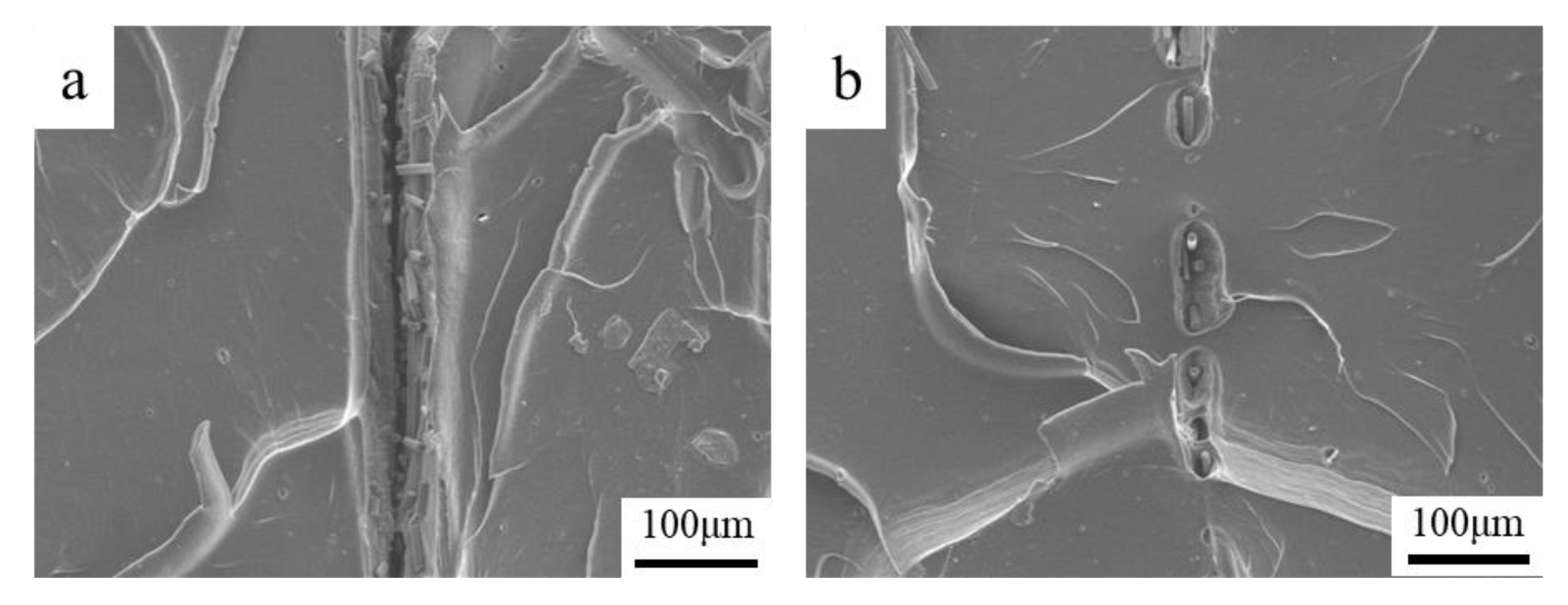

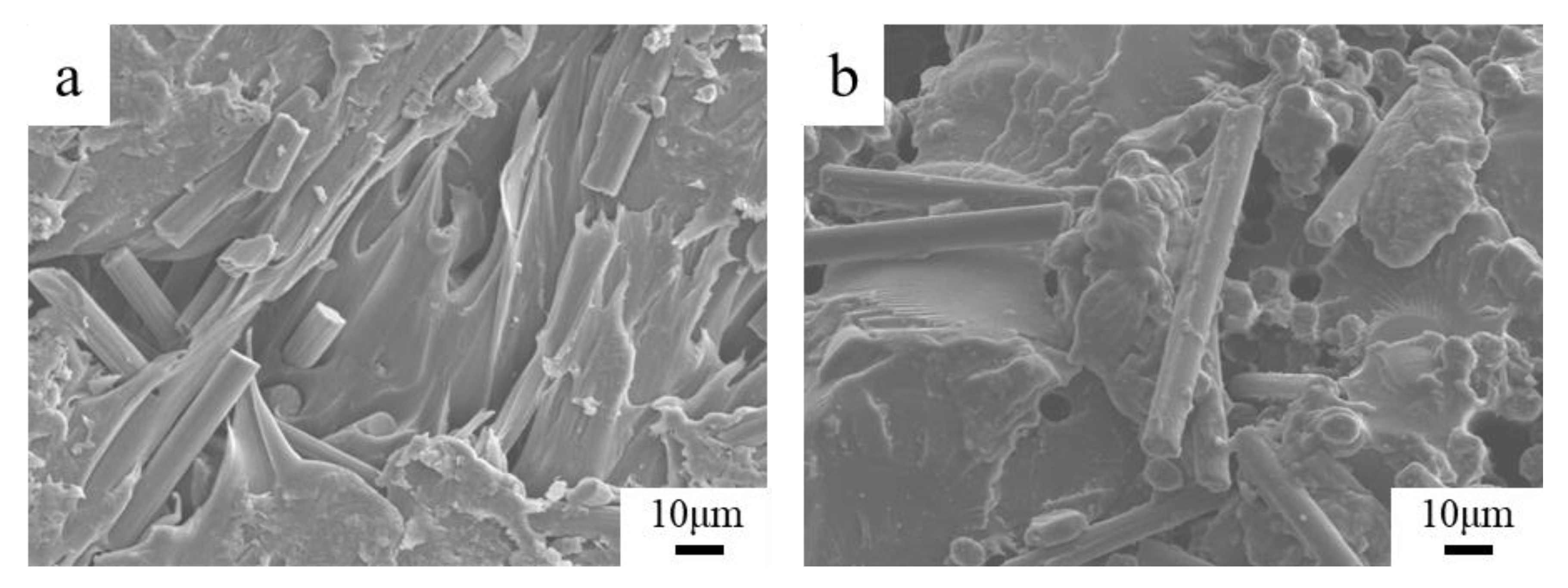

3.1.2. SEM Observation

3.1.3. Discussion

3.2. Effect of Short Fiber Length on Performance

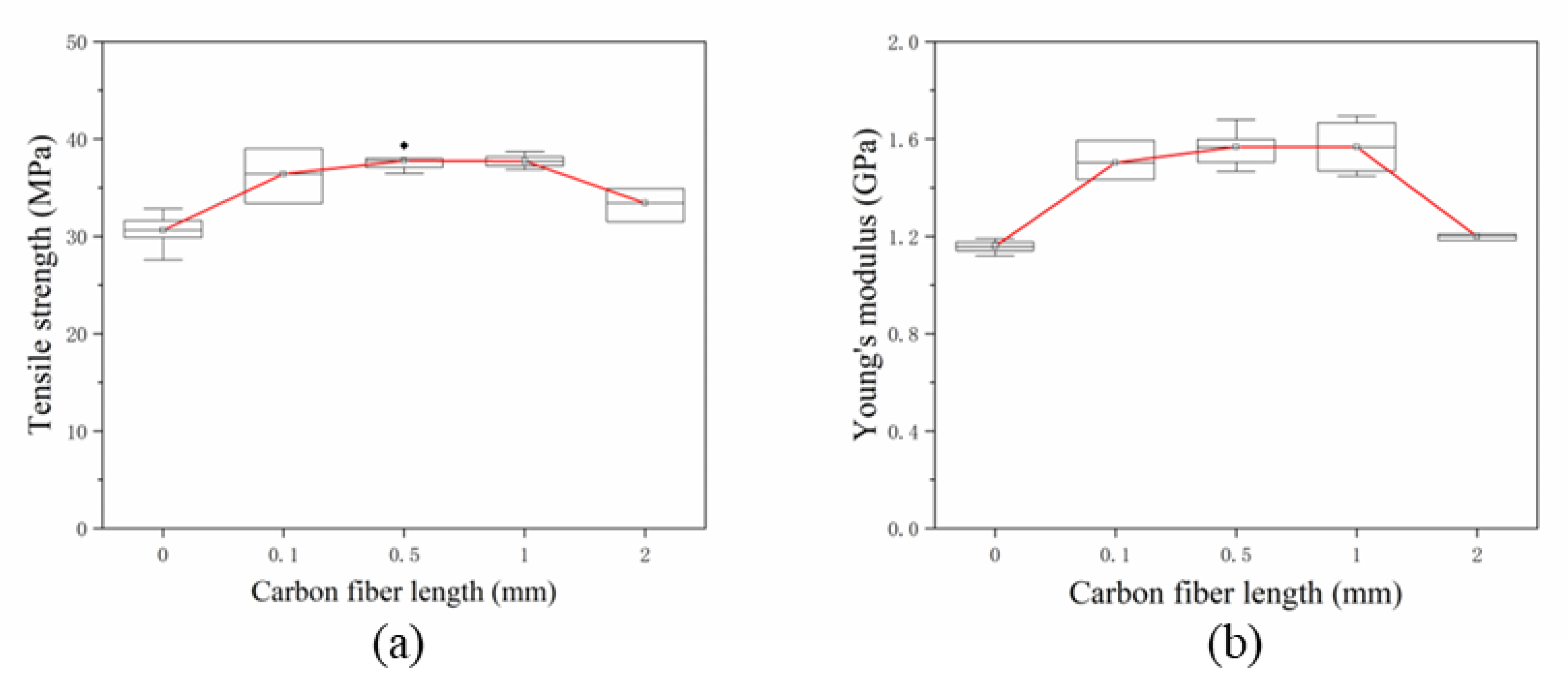

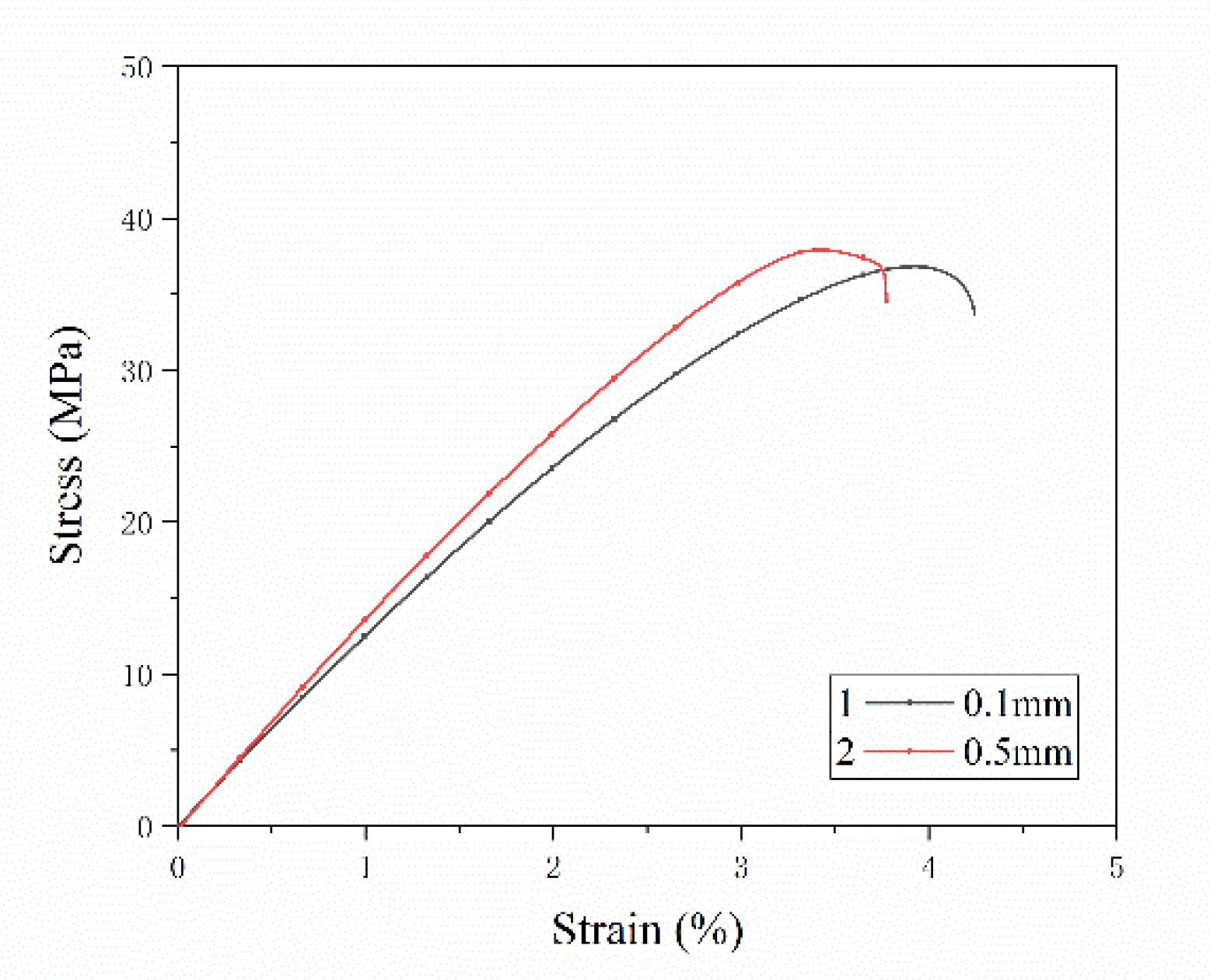

3.2.1. Mechanical Properties Test

3.2.2. Discussion

3.3. Effect of Post-Treatment on Performance

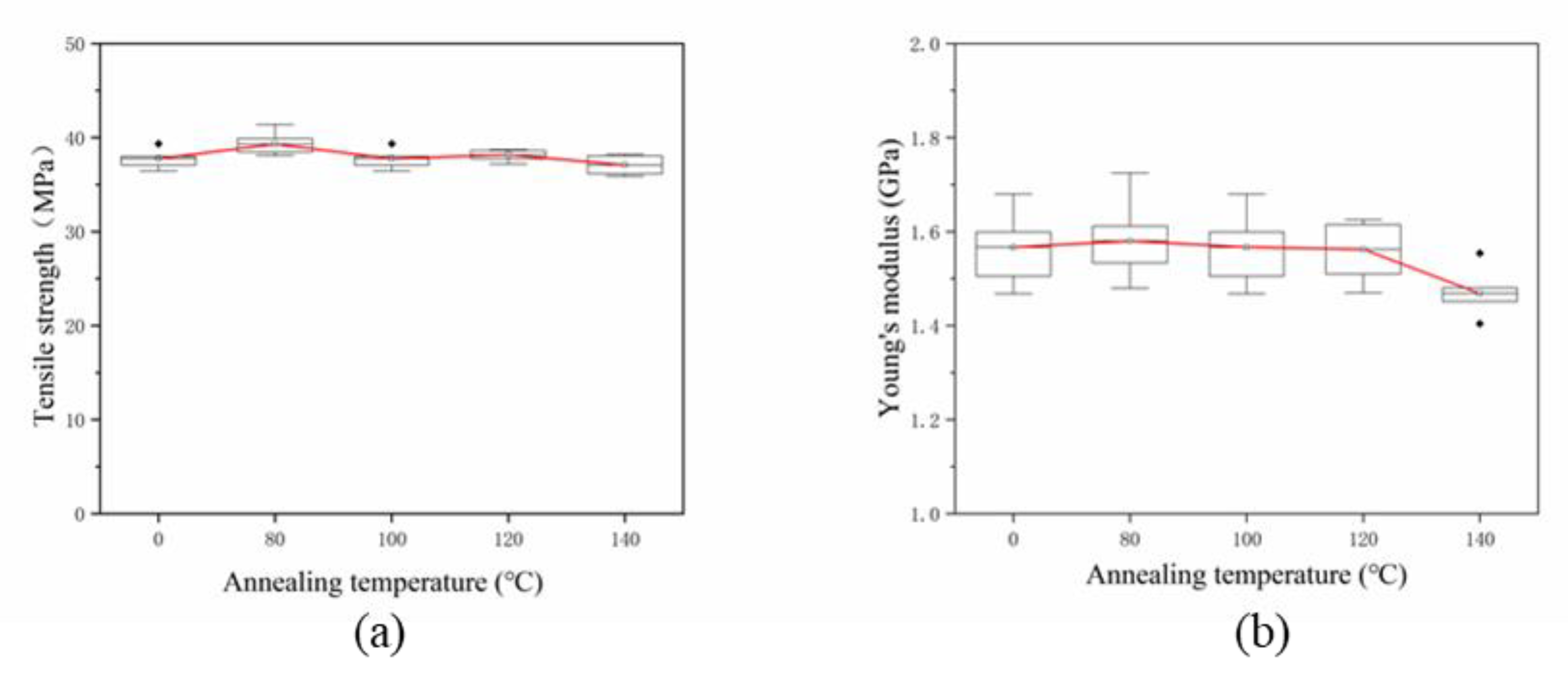

3.3.1. Mechanical Performance Test and SEM Observation

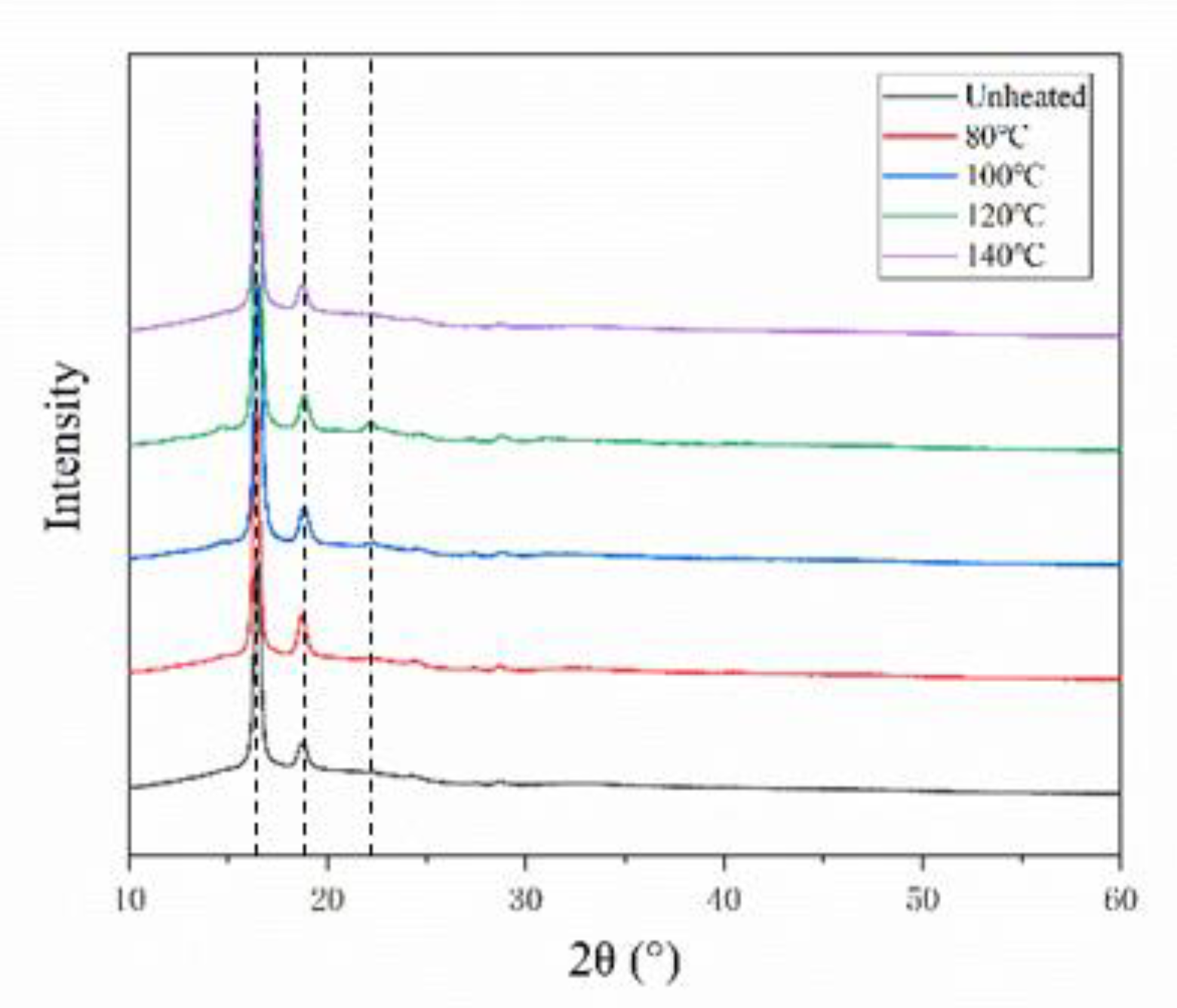

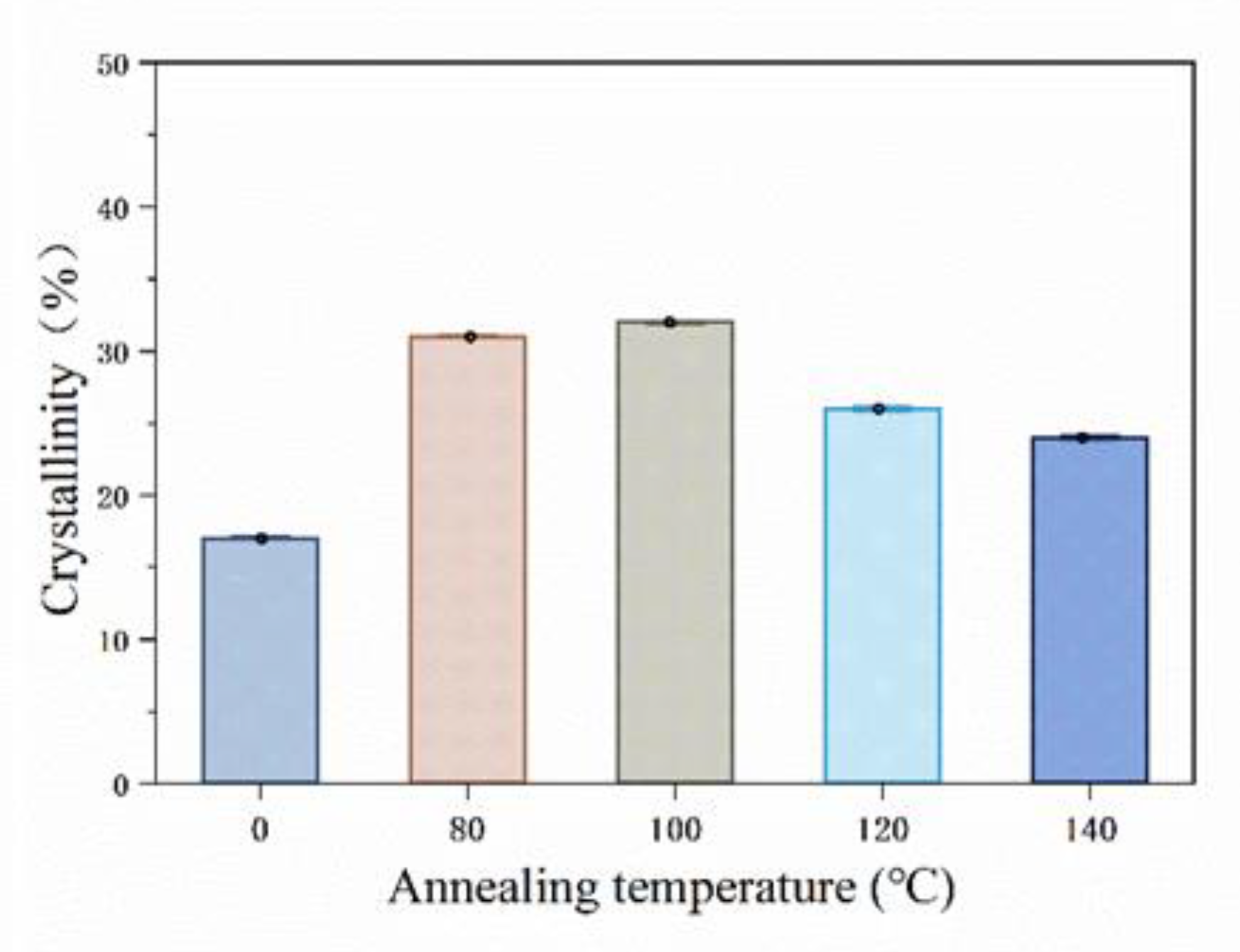

3.3.2. XRD Testing

3.3.3. Discussion

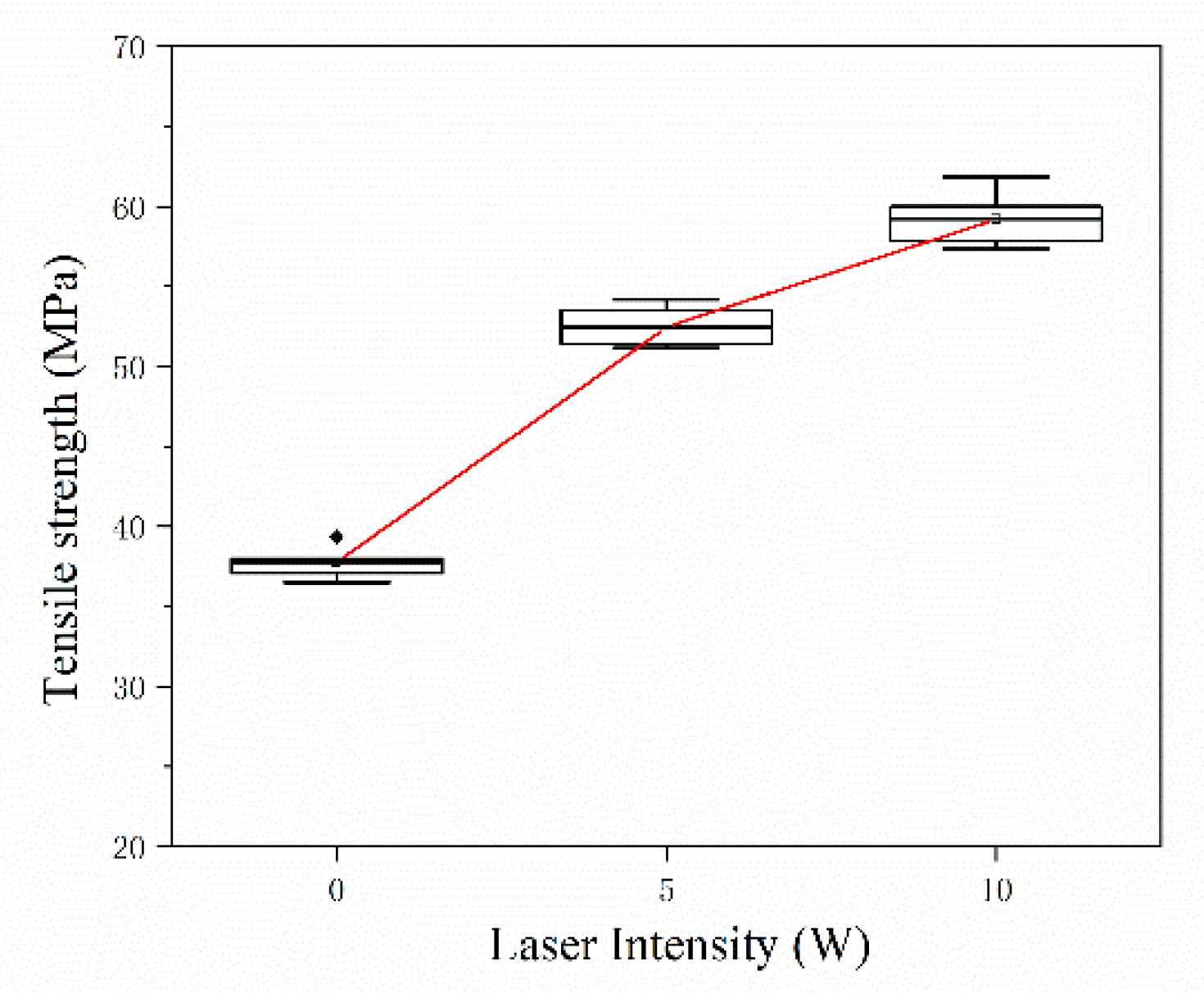

3.4. Effect of Laser-Assisted Preheating on Performance

4. Conclusions

- (a)

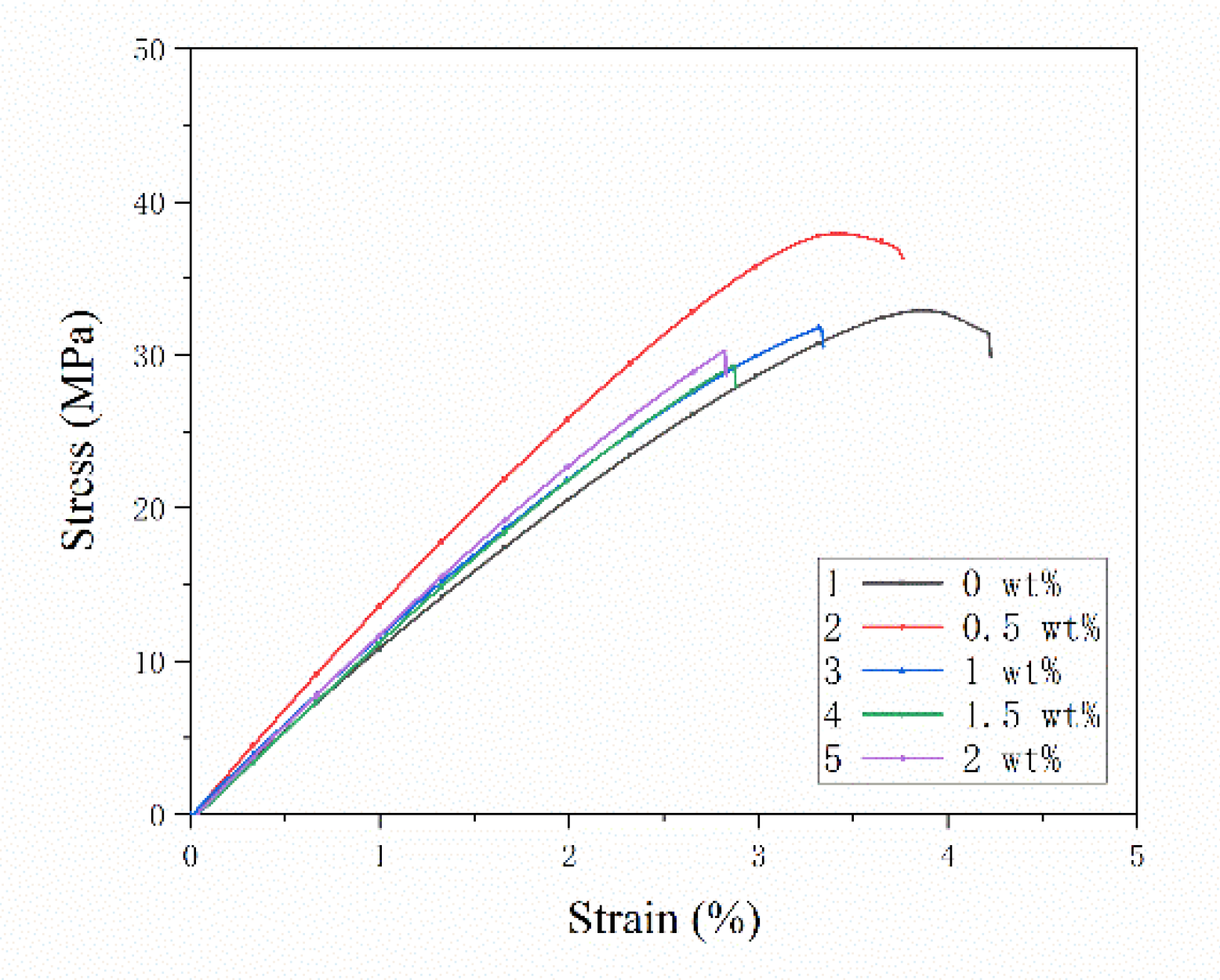

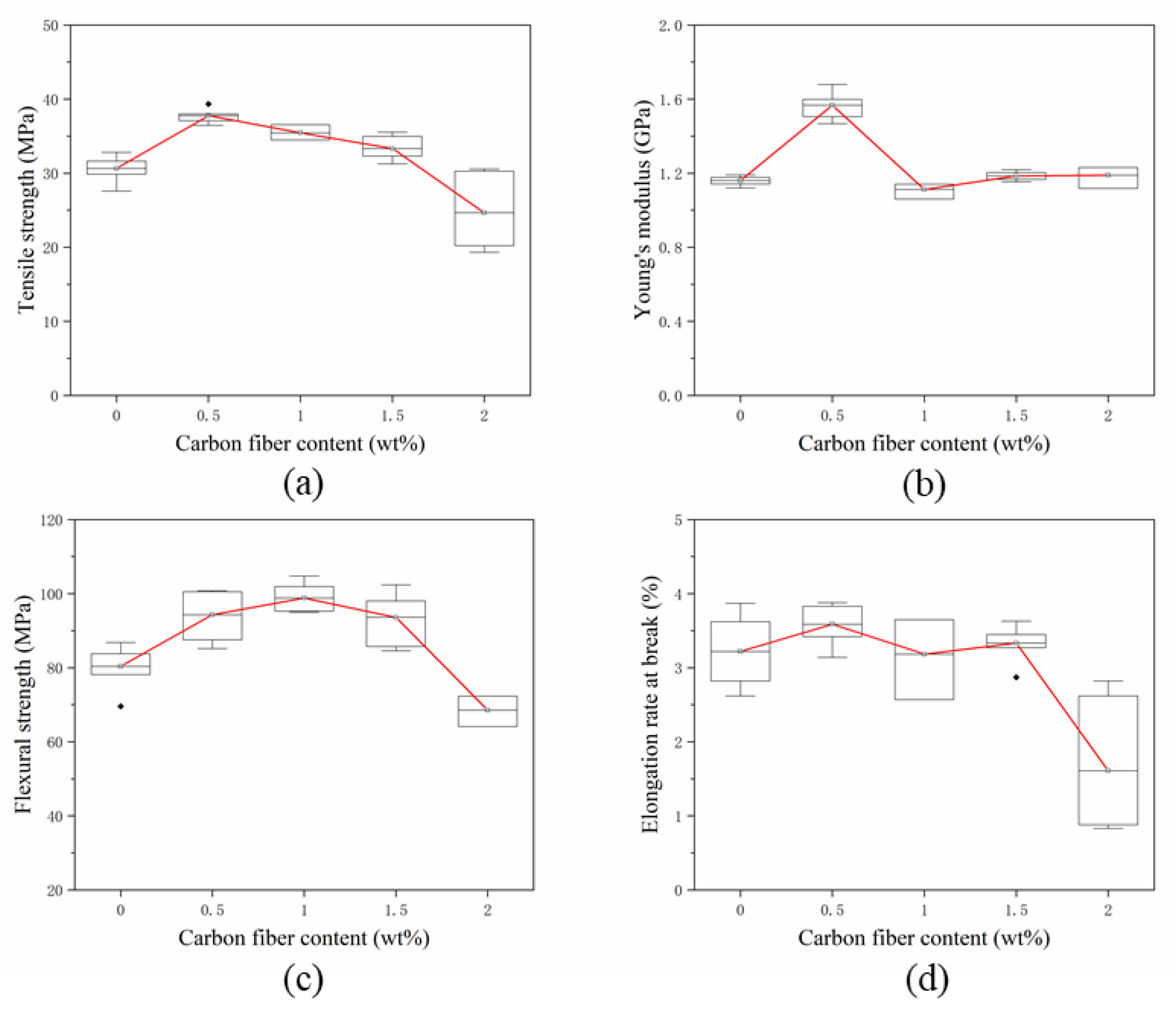

- When the fiber content was 0.5 wt% in a single layer, the tensile strength of the specimen reached 38 MPa, which is about 15% higher than that of the pure resin matrix. When the fiber content continuous to increase SFs the addition of SFs created many voids, resulting in a decrease in the mechanical properties.

- (b)

- When the fiber lengths were 0.5 mm and 1 mm, which are longer than the critical fiber length, the fiber played the main bearing role, and the composite had the best mechanical properties. As the fiber length increased to 2 mm, the fibers were liable to overlap and move, which resulted in a decrease of the bonding quality between interfaces.

- (c)

- Post-treatment was used on the specimens to improve the interfacial bonding quality. When the post-treatment temperature was higher than the glass transition temperature, fusion occurred between the printed layers, and the interface bonding quality was improved. However, the mechanical properties of the printed parts under different post-treatment conditions exhibited no statistically significant differences, and the range of mechanical properties was within 5%.

- (d)

- The method of laser-assisted preheating raised the interlayer temperature to the critical temperature, and then the interpenetrating diffusion of the resin increased, which promoted the impregnation between the fiber and resin. When the laser power was 10 W, the tensile strength of the laser-assisted preheated printed specimen was 59.20 MPa, which is an increase of 56.78% compared to the unheated specimen.

Author Contributions

Funding

Conflicts of Interest

References

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Fused deposition modeling with ABS-graphene nanocomposites. Compos. Part A Appl. Sci. Manuf. 2016, 85, 181–191. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Zhong, W.; Li, F.; Zhang, Z. Short fiber reinforced composites for fused deposition modeling. Mater. Sci. Eng. A 2001, 301, 125–130. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M. Highly oriented carbon fiber-polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J. Compos. Mater. 2017, 51, 451–462. [Google Scholar] [CrossRef]

- Compton, B.G.; Lewis, J.A. 3D-printing of lightweight cellular composites. Adv. Mater. 2014, 26, 5930–5935. [Google Scholar] [CrossRef] [PubMed]

- Karsli, N.G.; Aytac, A. Tensile and thermomechanical properties of short carbon fiber reinforced polyamide 6 composites. Compos. Part B Eng. 2013, 51, 270–275. [Google Scholar] [CrossRef]

- Leon, A.C.D.; Chen, Q.; Palaganas, N.B. High performance polymer nanocomposites for additive manufacturing applications. React. Funct. Polym. 2016, 103, 141–155. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, Q.; Gao, L. Significantly improved electrical and interlaminar mechanical properties of carbon fiber laminated composites by using special carbon nanotube pre-dispersion mixture. Compos. Part A Appl. Sci. Manuf. 2017, 95, 294–303. [Google Scholar] [CrossRef]

- Kang, H.; Shan, Z.; Zang, Y. Progressive damage analysis and strength properties of fiber-bar composites reinforced by three-dimensional weaving under unaxial tension. Compos. Struct. 2016, 141, 264–281. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, Z.; Zhang, F. Performance of 3D-Printed Continuous-Carbon-Fiber-Reinforced Plastics with Pressure. Materials 2020, 13, 471. [Google Scholar] [CrossRef] [PubMed]

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- Justo, J.; Távara, L.; García-Guzmán, L. Characterization of 3D printed long fibre reinforced composites. Compos. Struct. 2017, 185, 537–548. [Google Scholar] [CrossRef]

- Haoqi, Z.; Dongmin, Y.; Yong, S. Performance-driven 3D printing of continuous curved carbon fibre reinforced polymer composites: A preliminary numerical study. Compos. Part B Eng. 2018, 151, 256–264. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Compos. Part B Eng. 2018, 148, 93–103. [Google Scholar] [CrossRef]

- Fu, S.Y.; Lauke, B.; Mäder, E. Tensile properties of short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Serra, T.; Planell, J.A.; Navarro, M. High-resolution PLA-based composite scaffolds via 3-D printing technology. Acta Biomater. 2013, 9, 5521–5530. [Google Scholar] [CrossRef]

- Murphy, C.A.; Collins, M.N. Microcrystalline cellulose reinforced polylactic acid biocomposite filaments for 3D printing. Polym. Compos. 2018, 39, 1311–1320. [Google Scholar] [CrossRef]

- Spoerk, M.; Savandaiah, C.; Arbeiter, F. Optimization of mechanical properties of glass-spheres-filled polypropylene composites for extrusion based additive manufacturing. Polym. Compos. 2017, 638–651. [Google Scholar] [CrossRef]

- Martin, S.; Chethan, S.; Florian, A. Anisotropic properties of oriented short carbon fibre filled polypropylene parts fabricated by extrusion-based additive manufacturing. Compos. Part A Appl. Sci. Manuf. 2018, 113, 95–104. [Google Scholar] [CrossRef]

- Ivey, M.; Melenka, G.W.; Carey, J.P. Characterizing short-fiber-reinforced composites produced using additive manufacturing. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 81–91. [Google Scholar] [CrossRef]

- Zou, G.X.; Jiao, Q.W.; Zhang, X. Crystallization behavior and morphology of poly (lactic acid) with a novel nucleating agent. J. Appl. Polym. Sci. 2015, 132, 41367. [Google Scholar] [CrossRef]

- Kawai, T.; Rahman, N.; Matsuba, G. Crystallization and melting behavior of poly (L-lactic acid). Macromolecules 2007, 40, 9463–9469. [Google Scholar] [CrossRef]

- Coogan, T.J.; Kazmer, D.O. Healing simulation for bond strength prediction of FDM. Rapid Prototyp. J. 2017, 23, 551–561. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Hatch spacing—mm | 1 |

| Layer thickness—mm | 0.5 |

| Printing speed—mm/s | 20 |

| Diameter of nozzle—mm | 1 |

| Temperature of liquefier—°C | 220 |

| Infill density—% | 100 |

| Infill patterns | Concentric |

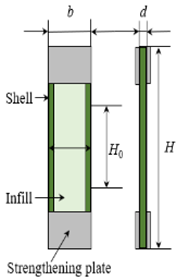

| Specimen Geometry Variable | Value | ISO GB/T 1447–2005–Type Geometry |

|---|---|---|

| Height (H)—mm | 200 |  |

| Width (b)—mm | 18 | |

| Thickness (d)—mm | 3 | |

| Standard distance (H0)—mm | 50 | |

| Number of shells (Ns) | 1 | |

| Number of layers (Nl) | 6 |

| Materials | Annealing Temperature (°C) | Number of Specimens |

|---|---|---|

| PLA + 0.5%CF | 80 | 5 |

| 100 | 5 | |

| 120 | 5 | |

| 140 | 5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, C.; Shan, Z.; Zou, G.; Zhan, L.; Yan, D. Performance of Short Fiber Interlayered Reinforcement Thermoplastic Resin in Additive Manufacturing. Materials 2020, 13, 2868. https://doi.org/10.3390/ma13122868

Fan C, Shan Z, Zou G, Zhan L, Yan D. Performance of Short Fiber Interlayered Reinforcement Thermoplastic Resin in Additive Manufacturing. Materials. 2020; 13(12):2868. https://doi.org/10.3390/ma13122868

Chicago/Turabian StyleFan, Congze, Zhongde Shan, Guisheng Zou, Li Zhan, and Dongdong Yan. 2020. "Performance of Short Fiber Interlayered Reinforcement Thermoplastic Resin in Additive Manufacturing" Materials 13, no. 12: 2868. https://doi.org/10.3390/ma13122868

APA StyleFan, C., Shan, Z., Zou, G., Zhan, L., & Yan, D. (2020). Performance of Short Fiber Interlayered Reinforcement Thermoplastic Resin in Additive Manufacturing. Materials, 13(12), 2868. https://doi.org/10.3390/ma13122868