SiC-IrSi3 for High Oxidation Resistance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

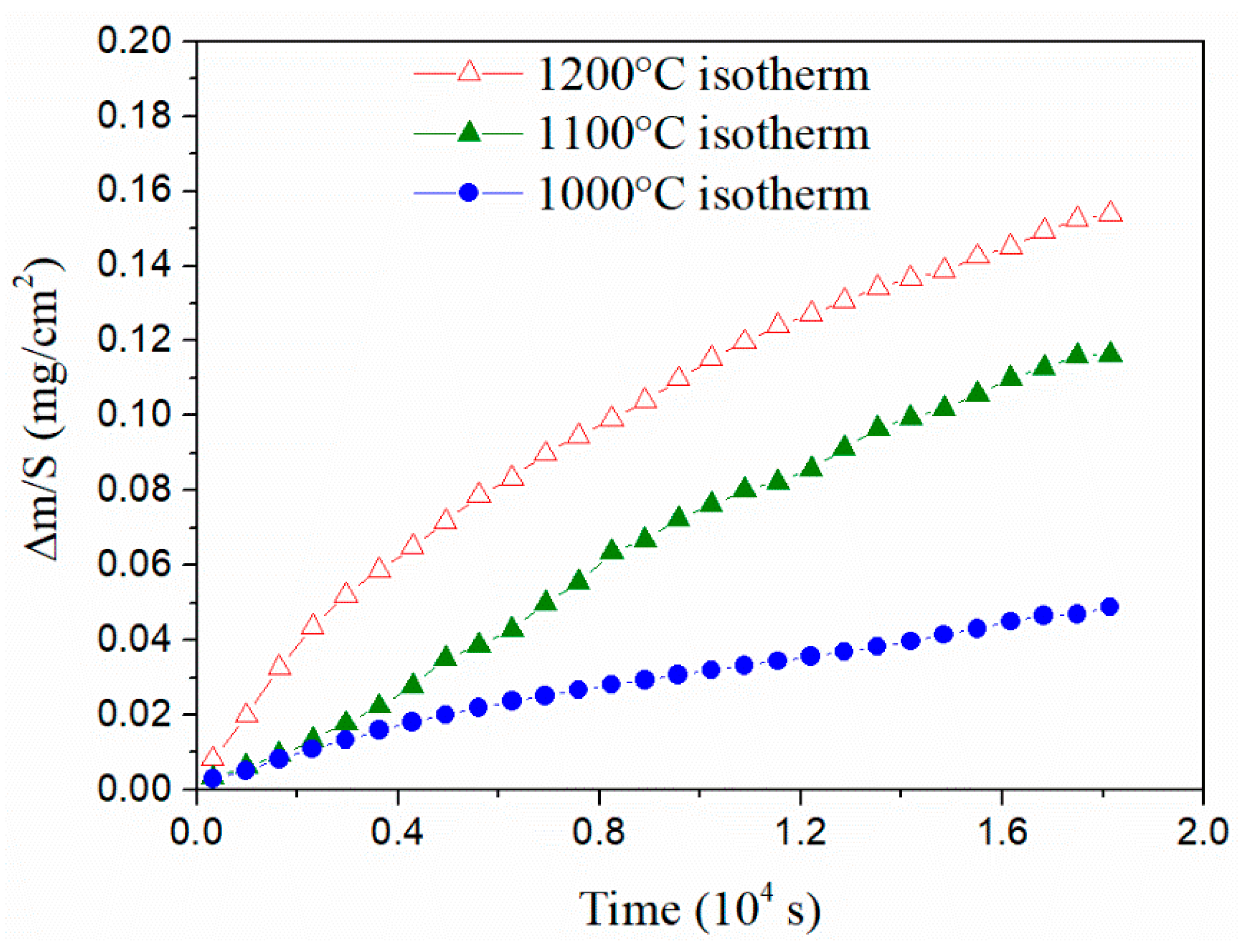

3. Results

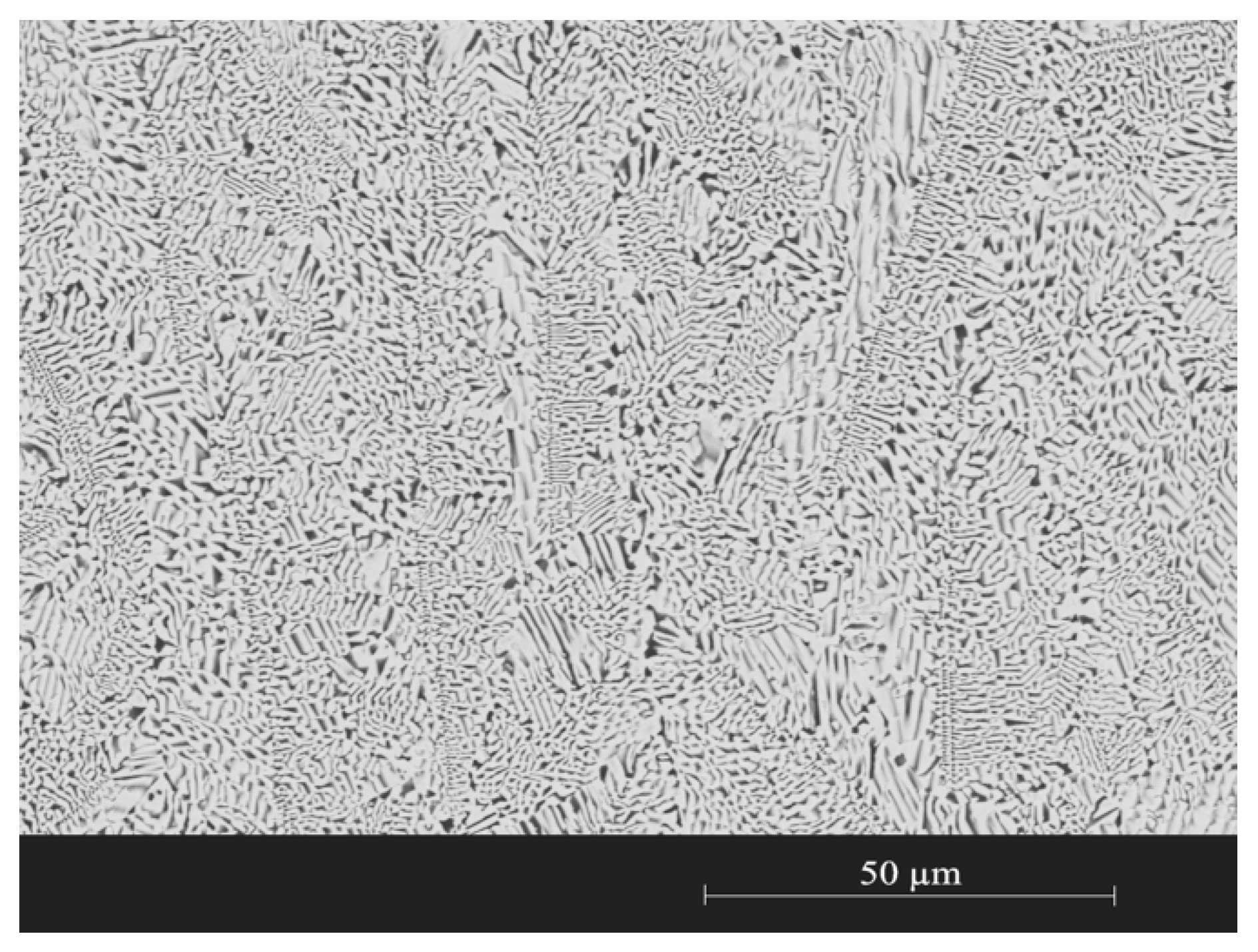

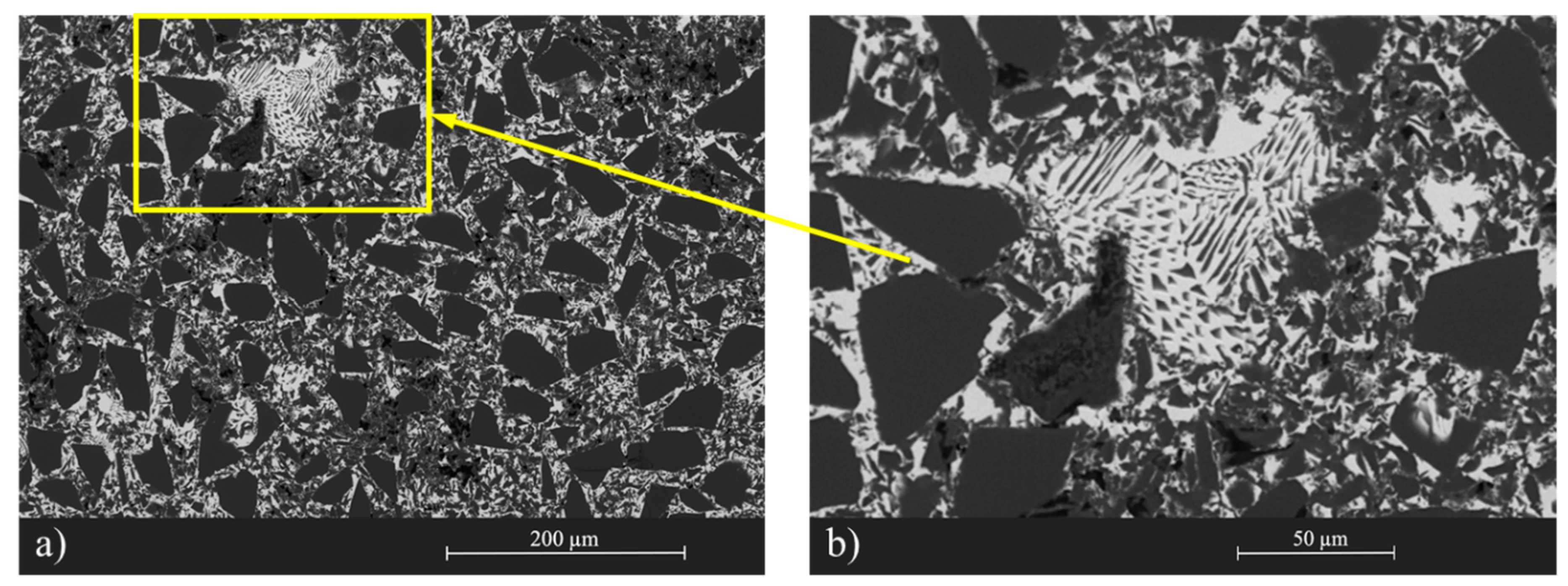

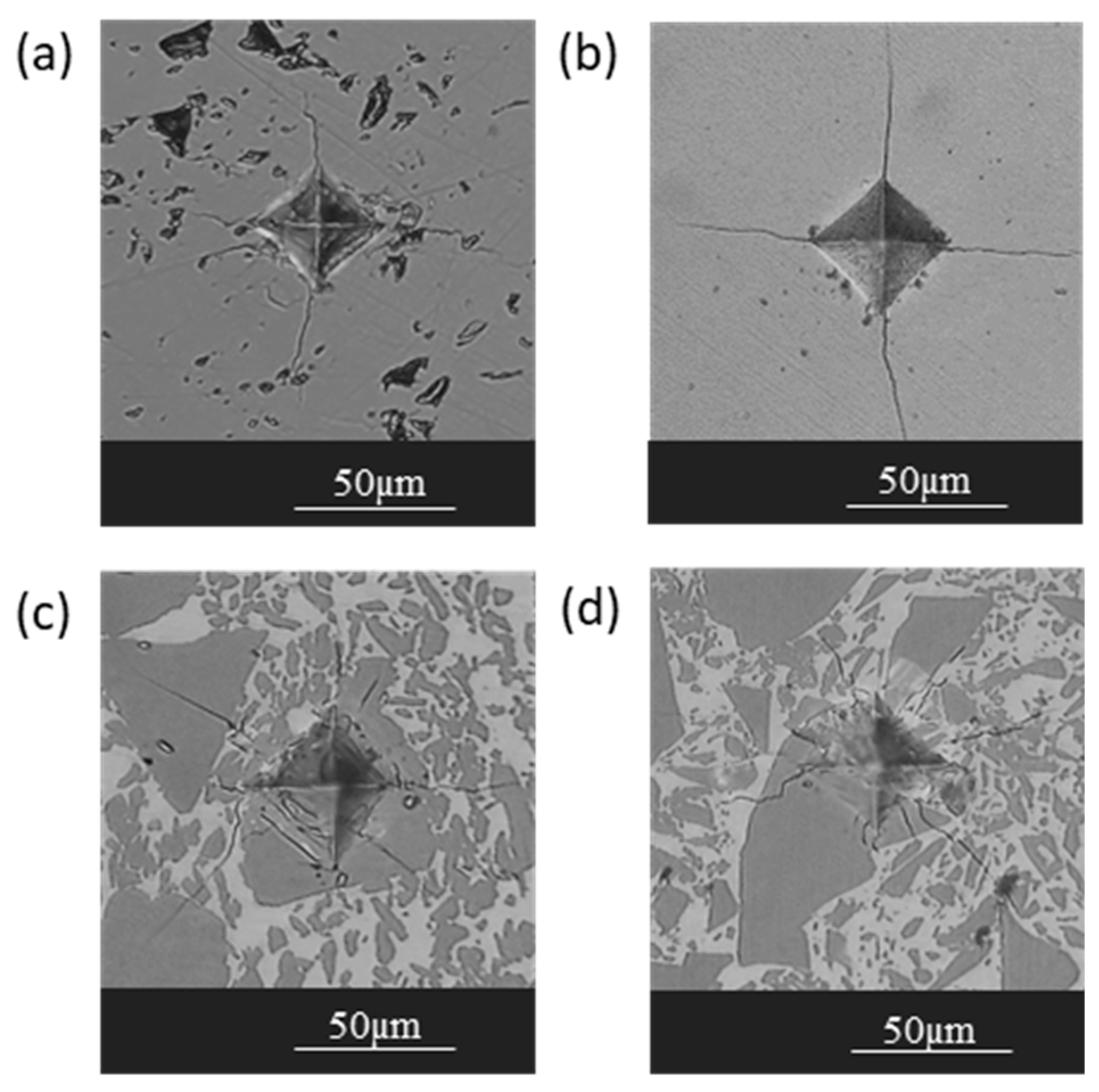

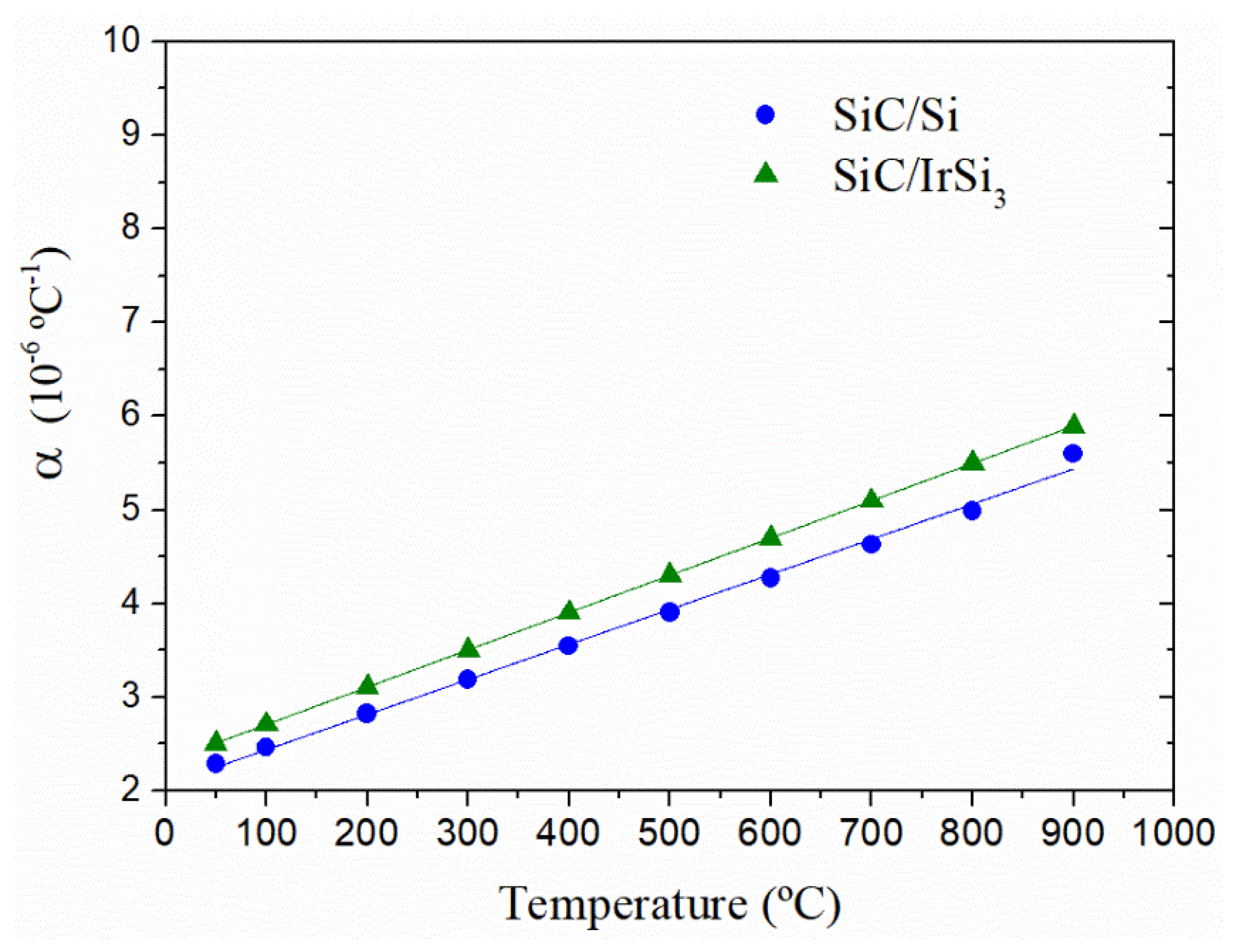

Thermomechanical Properties of SiC-Si and SiC-Si-IrSi3 Materials

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ledoux, M.J.; Pham-Huu, C. Silicon Carbide: A Novel Catalyst Support for Heterogeneous Catalysis. CATTECH 2001, 5, 226–246. [Google Scholar] [CrossRef]

- Piñero, E.; Molina, J.M.; Narciso, J.; García-Cordovilla, C.; Louis, E. The Intrinsic Permeability of packed SiC particles with monomodal and bimodal size distributions. J. Comp. Mater. 2008, 42, 2795–2804. [Google Scholar] [CrossRef]

- Calderon, N.R.; Martinez-escandell, M.; Narciso, J.; Rodriguez-reinoso, F. Manufacture of biomorphic SiC components with homogeneous properties from sawdust by reactive infiltration with liquid silicon. J. Amer. Ceram. Soc. 2010, 93, 1003–1009. [Google Scholar] [CrossRef]

- Low, I.M. Ceramic Matrix Composites: Microstructure, Properties and Applications; Woodhead Publishing: Cambridge, UK, 2006. [Google Scholar]

- Novakovic, R.; Korthaus, B. Advanced Ceramics for Use in Highly Oxidizing and Corrosive Environments: Siliconised Silicon Carbide. Key Eng. Mater. 2001, 201, 141–182. [Google Scholar] [CrossRef]

- Srinivasan, M. Structural Ceramics; Academic Press: London, UK, 1989. [Google Scholar]

- Prochazka, S.; Scanlan, R.M. Effect of Boron and Carbon on sintering of SiC. J. Am. Ceram. Soc. 1975, 58, 72. [Google Scholar] [CrossRef]

- Lange, F.; Gupta, T.K. Sintering of SiC with boron compounds. J. Am. Ceram. Soc. 1976, 59, 537–538. [Google Scholar] [CrossRef]

- Katoh, Y.; Dong, S.M.; Kohyma, A. Thermo-mechanical properties and microstructure of silicon carbide composites fabricated by nano-infiltrated transient eutectoid process. Fusion Eng. Des. 2002, 61, 723–731. [Google Scholar] [CrossRef]

- Yamamoto, T.; Kitaura, H.; Kodera, Y.; Ishii, T.; Ohyanagi, M.; Munir, Z.A. Spark plasma Consolidation of Nanostructured β-SiC by Spark Plasma Sintering. J. Amer. Ceram. Soc. 2004, 87, 1436–1441. [Google Scholar] [CrossRef]

- Ness, J.N.; Page, T.F. Microstructural evolution in reaction-bonded silicon carbide. J. Mater. Sci. 1986, 21, 1377–1397. [Google Scholar] [CrossRef]

- Whitehead, A.J.; Page, T.F. Fabrication and characterization of some novel reaction-bonded silicon carbide materials. J. Mater. Sci. 1992, 27, 839–852. [Google Scholar] [CrossRef]

- Calderon, N.R.; Martinez-Escandell, M.; Narciso, J.; Rodriguez-Reinoso, F. The combined effect of porosity and reactivity of the carbon preforms on the properties of SiC produced by reactive infiltration with liquid Si. Carbon 2009, 47, 2200–2210. [Google Scholar] [CrossRef]

- Calderón, N.R.; Martínez-Escandell, M.; Narciso, J.; Rodríguez-Reinoso, F. The role of carbon biotemplate density in mechanical properties of Biomorphic SiC. J. Eur. Ceram. Soc. 2009, 29, 465–472. [Google Scholar] [CrossRef]

- Caccia, M.; Narciso, J. SiC manufacture via reactive infiltration. In Processing and Properties of Advanced Ceramics and Composites VI: Ceramic Transactions; Singh, J.P., Bansal, N.P., Bhalla, A.S., Mahmoud, M.M., Manjooran, N.J., Singh, G., Lamon, J., Choi, S.R., Pickrell, G., Lu, K., et al., Eds.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Chakrabarti, O.; Kumar-Das, P. High temperature load–deflection behaviour of reaction bonded SiC (RBSC). Ceram. Int. 2001, 27, 559–563. [Google Scholar] [CrossRef]

- Narciso-Romero, F.J.; Arpón-Carballo, R.; Rodríguez-Reinoso, F.; Komatsu, M. Synthesis of a (MoSi2, Mo5Si3)/SiC composite using an in situ solid-state displacement reaction between Mo2C and Si. J. Ceram. Soc. Jpn. 2000, 108, 957–959. [Google Scholar] [CrossRef] [Green Version]

- Arpón, R.; Narciso, J.; Rodríguez-Reinoso, F.; Komatsu, M. Synthesis of mixed disilicides/SiC composites by displacement reaction between metal carbides and silicon. Mater. Sci. Eng. 2004, 380, 62–66. [Google Scholar] [CrossRef]

- Caccia, M.; Amore, S.; Giuranno, D.; Ricci, E.; Narciso, J. Towards optimization of SiC/CoSi2 composite material manufacture via reactive infiltration: Wetting study of Si–Co alloys on carbon materials. J. Eur. Ceram. Soc. 2015, 35, 4099–4106. [Google Scholar] [CrossRef]

- Camarano, A.; Caccia, M.; Narciso, J. Effects of Fe addition on the mechanical and thermo-mechanical properties of SiC/FeSi2/Si composites produced via reactive infiltration. Ceram. Int. 2016, 42, 10726–10733. [Google Scholar] [CrossRef]

- Bougiouri, V.; Voytovych, R.; Rojo-Calderon, N.; Narciso, J.; Eustathopoulos, N. The role of the chemical reaction in the infiltration of porous carbon by NiSi alloys. Scr. Mater. 2006, 54, 1875–1878. [Google Scholar] [CrossRef]

- Calderon, N.R.; Voytovych, R.; Narciso, J.; Eustathopoulos, N. Pressure infiltration versus wetting in AlSi/graphite sysyem. J. Mater. Sci. 2010, 45, 4345–4350. [Google Scholar] [CrossRef]

- Calderon, N.R.; Voytovych, R.; Narciso, J.; Eustathopoulos, N. Wetting dynamics versus interfacial reactivity of AlSi alloys on carbon. J. Mater. Sci. 2010, 45, 2150–2156. [Google Scholar] [CrossRef]

- Caccia, M.; Xiang, C.; Narciso, J.; Gupta, N. Reactive melt infiltration as synthesis route for enhanced SiC/CoSi2 composite materials for advanced armor systems. Ceram. Int. 2018, 44, 13182–13190. [Google Scholar] [CrossRef]

- Criscione, J.M.; Smith, A.W.; Volk, H.F. Protection of graphite from oxidation at 2100 °C. J. AiAA 1966, 4, 1791–1792. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, W.; Cheng, H.; Liu, Y.; Wang, S.; Xue, R. Microstructure and evolution of iridium coating on the C/C composites ablated by oxyacetylene torch. Acta Astronaut. 2010, 66, 682–687. [Google Scholar] [CrossRef]

- Prisbrey, S.T. Oxidation preventative capping layer for deep-ultra-violet and soft x-ray multilayers. U.S. Patent 6,759,141, 6 July 2004. [Google Scholar]

- Camarano, A.; Narciso, J.; Giuranno, D. Solid state reaction between SiC and Ir. J. Eur. Ceram. Soc. 2019, 39, 3959–3970. [Google Scholar] [CrossRef]

- Camarano, A.; Narciso, J.; Giuranno, D. New advanced SiC-based composite materials for use in highly oxidizing environments: Synthesis of SiC/IrSi3. J. Eur. Ceram. Soc. 2019. [Google Scholar] [CrossRef]

- Caccia, M.; Narciso, J. Key Parameters in the Manufacture of SiC-Based Composite Materials by Reactice Infiltration. Materials 2019, 12, 2425. [Google Scholar] [CrossRef] [Green Version]

- Caccia, M.; Narciso, J. On the effects of hot spot formation during MW-assisted synthesis of Cf/SiC composites by reactive melt infiltration: Experimental simulations through high temperature treatments. J. Eur. Cearm. Soc. 2020, 40, 28–35. [Google Scholar] [CrossRef]

- Okamoto, H. Ir-Si (Iridium-Silicon). J. Phase Equilibria Diffus. 2007, 28, 495. [Google Scholar] [CrossRef]

- Giuranno, D.; Delsante, S.; Borzone, G.; Novakovic, R. Effects of Sb addition on the properties of Sn-Ag-Cu/(Cu, Ni) solder systems. J. Alloys Compd. 2016, 689, 918–930. [Google Scholar] [CrossRef]

- Liggieri, L.; Passerone, A. An automatic technique for measuring the surface tension of liquid metals. High Temp. Technol. 1989, 7, 82–86. [Google Scholar] [CrossRef]

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshall, D.B.A. Critical evaluation of indentation techniques for measuring fracture toughness:1, Direct crack Measurements. J. Amer. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Quinn, G.D.; Bradt, R.C. On the Vickers indentation fracture toughness test. J. Amer. Ceram. Soc. 2007, 90, 673–680. [Google Scholar] [CrossRef]

- Sha, J.B.; Yamabe-Mitarai, Y. Phase and microstructural evolution of Ir-Si binary alloys with fcc/silicide structure. Intermetallic 2006, 14, 672–684. [Google Scholar] [CrossRef]

- Petrovic, J.J. MoSi2-Based high temperatures structural silicides. MRS Bull. 1993, 38, 35–41. [Google Scholar] [CrossRef]

- Nekkanti, R.M.; Dimiduk, D.M. Ductile-phase toughening in niobium-niobium silicide powder processed composites. MRS Proc. 1990, 194, 175–182. [Google Scholar] [CrossRef]

- Corman, G.S.; Luthra, K.L. Handbook of Ceramic Composites; Kluwer Academic Publishers: Boston, MA, USA, 2005; pp. 99–115. [Google Scholar]

- Zhu, D.; Gao, M.; Pan, H.; Liu, Y.; Wang, X.; Pan, Y.; Oliveira, F.J.; Vieira, J.M. Reactive infiltration processing of SiC/Fe–Si composites using preforms made of coked rice husks and SiC powder. Ceram. Int. 2013, 39, 3831–3842. [Google Scholar] [CrossRef]

- Kovalčíková, A.; Sedláček, J.; Lenčéš, Z.; Bystrický, R.; Dusza, J.; Šajgalík, P. Oxidation resistance of SiC ceramics prepared by different processing routes. J. Eur. Ceram. Soc. 2016, 36, 3783–3793. [Google Scholar] [CrossRef]

- Deal, B.E.; Grove, A.S. General relationship for the thermal oxidation of silicon. J. Appl. Phys. 1965, 36, 3770–3778. [Google Scholar] [CrossRef] [Green Version]

- d’Heurle, F.M. The Physics and Chemistry of SiO2 and the Si-SiO2 Interface, 1st ed.; Springer: New York, NY, USA, 1988; pp. 85–94. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camarano, A.; Giuranno, D.; Narciso, J. SiC-IrSi3 for High Oxidation Resistance. Materials 2020, 13, 98. https://doi.org/10.3390/ma13010098

Camarano A, Giuranno D, Narciso J. SiC-IrSi3 for High Oxidation Resistance. Materials. 2020; 13(1):98. https://doi.org/10.3390/ma13010098

Chicago/Turabian StyleCamarano, Antonio, Donatella Giuranno, and Javier Narciso. 2020. "SiC-IrSi3 for High Oxidation Resistance" Materials 13, no. 1: 98. https://doi.org/10.3390/ma13010098

APA StyleCamarano, A., Giuranno, D., & Narciso, J. (2020). SiC-IrSi3 for High Oxidation Resistance. Materials, 13(1), 98. https://doi.org/10.3390/ma13010098