On the Fracture Behavior of a Creep Resistant 10% Cr Steel with High Boron and Low Nitrogen Contents at Low Temperatures

Abstract

1. Introduction

2. Experimental

3. Results

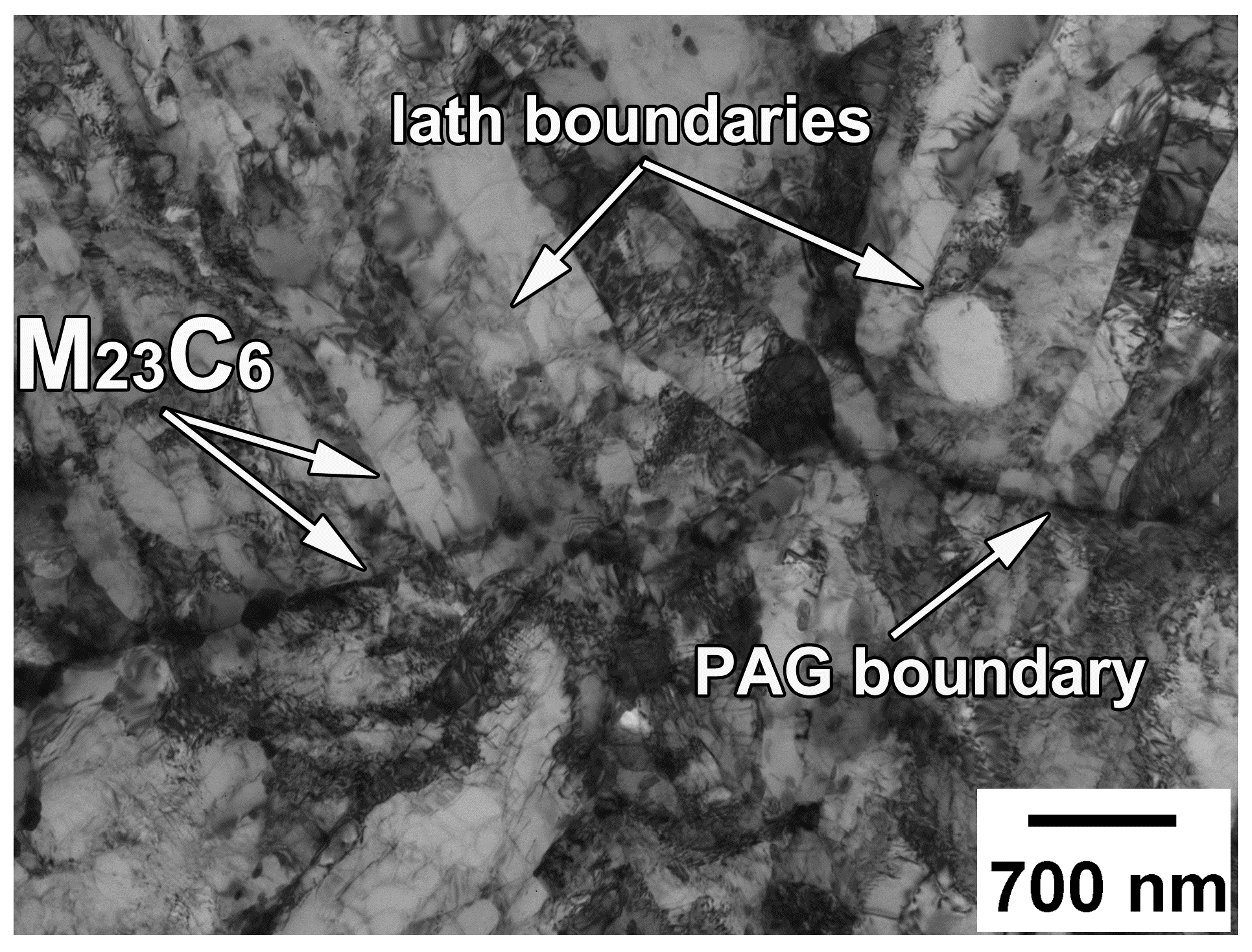

3.1. Microstructure

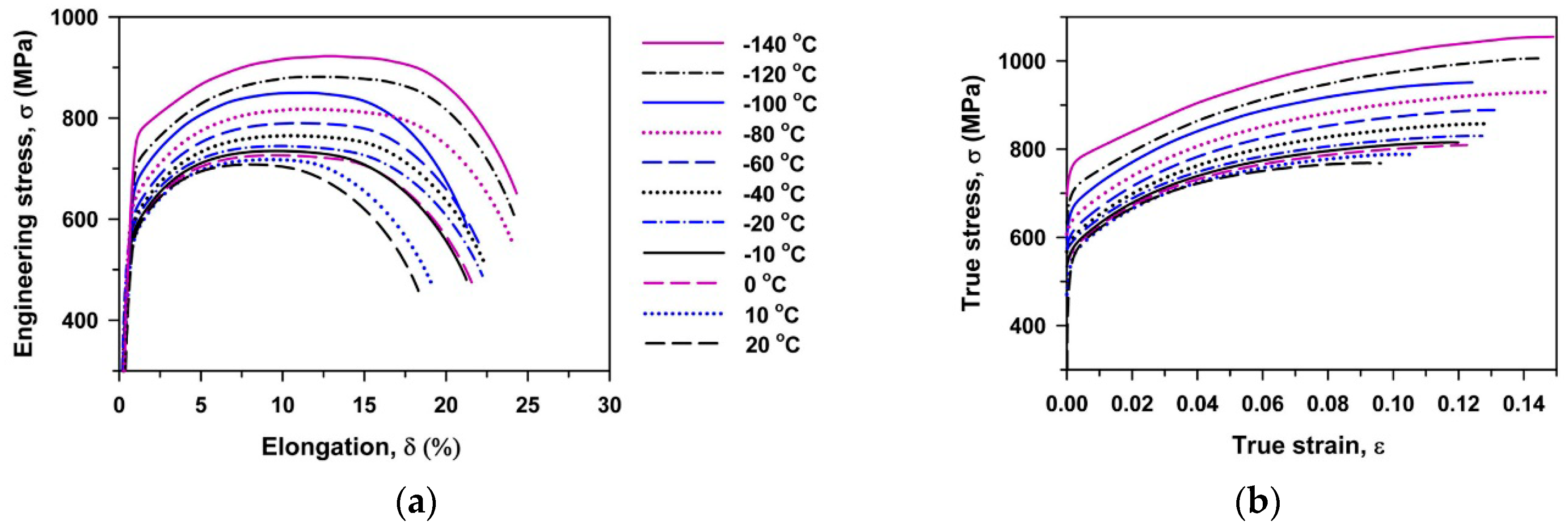

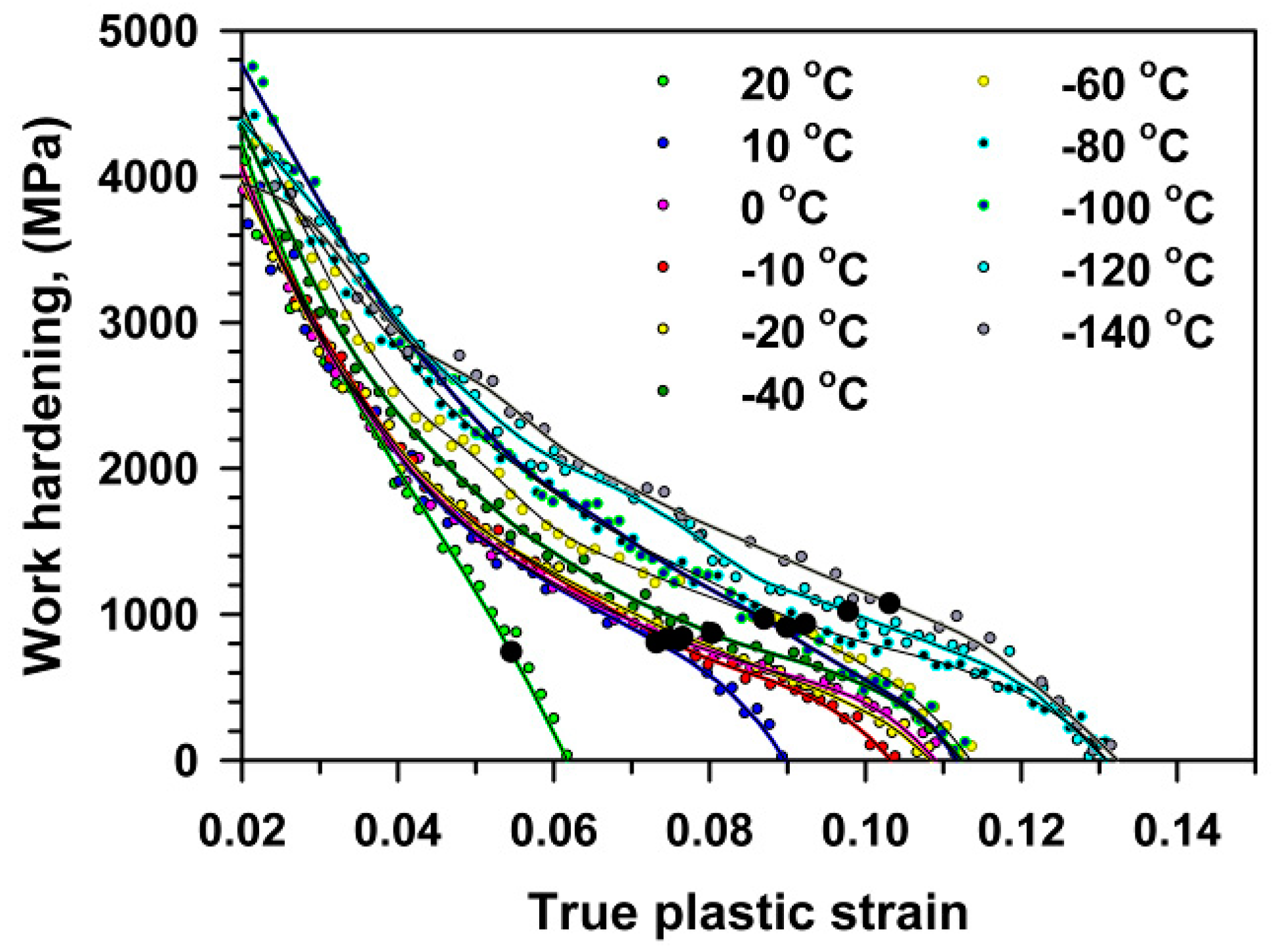

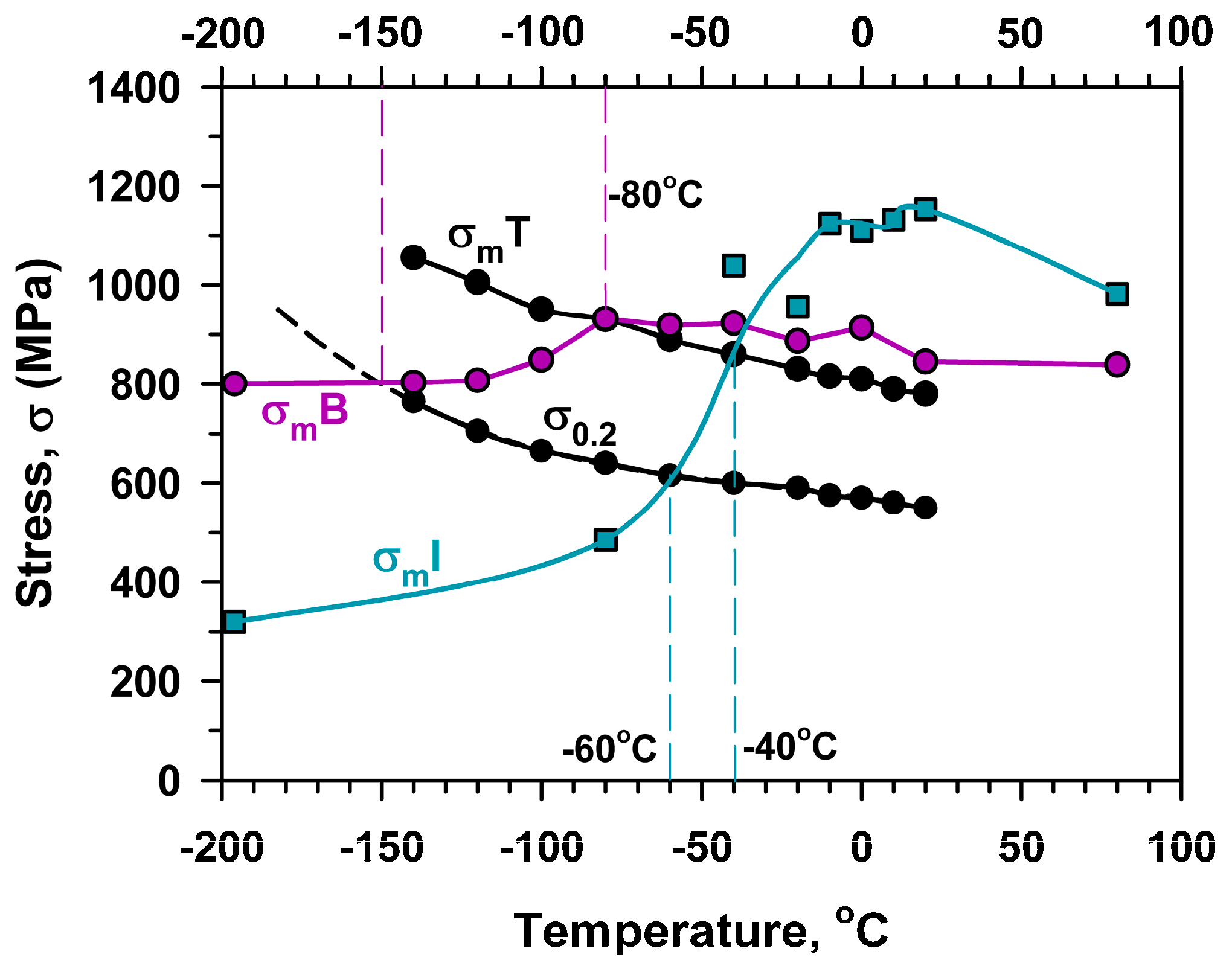

3.2. Tensile Properties

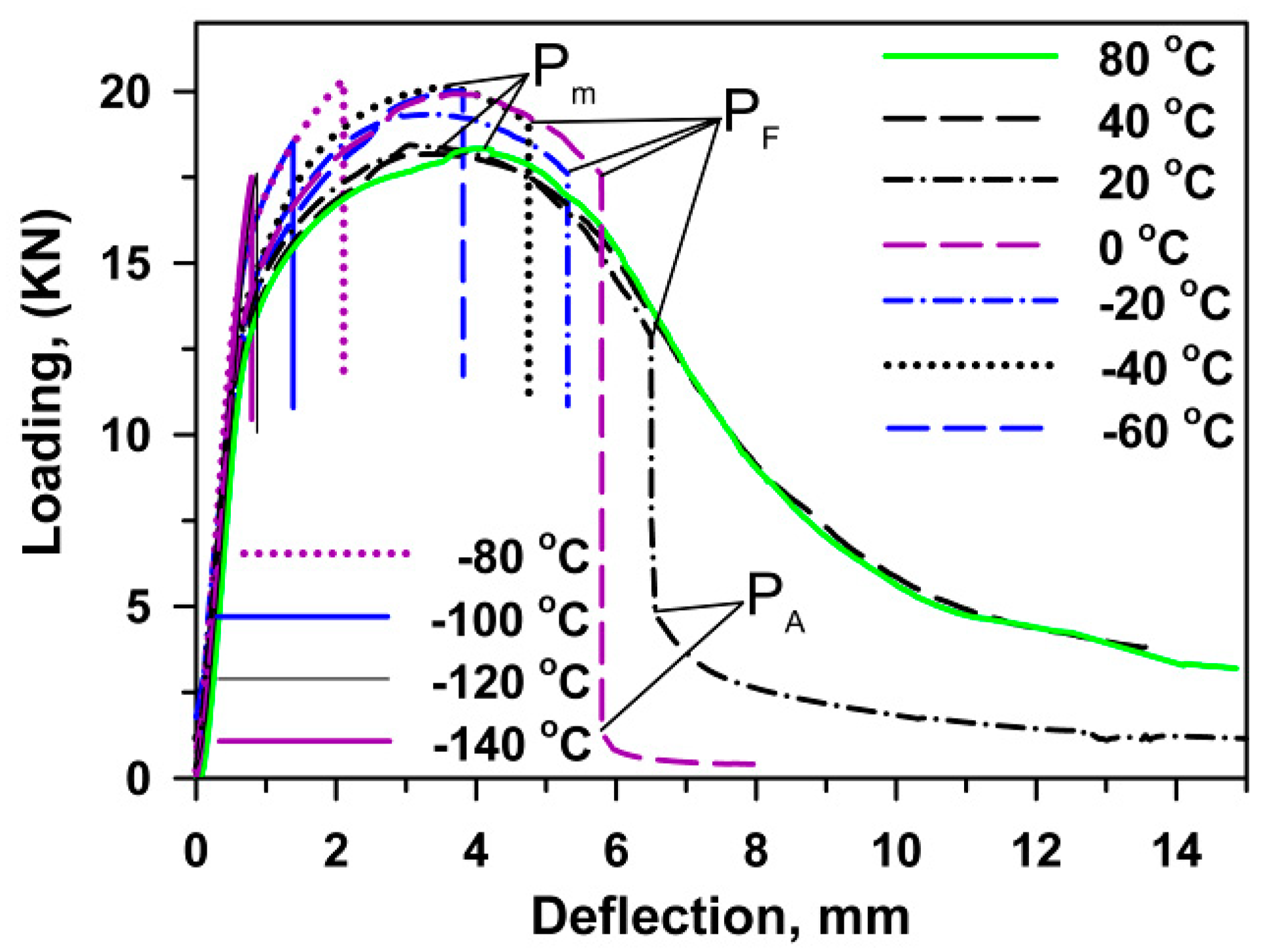

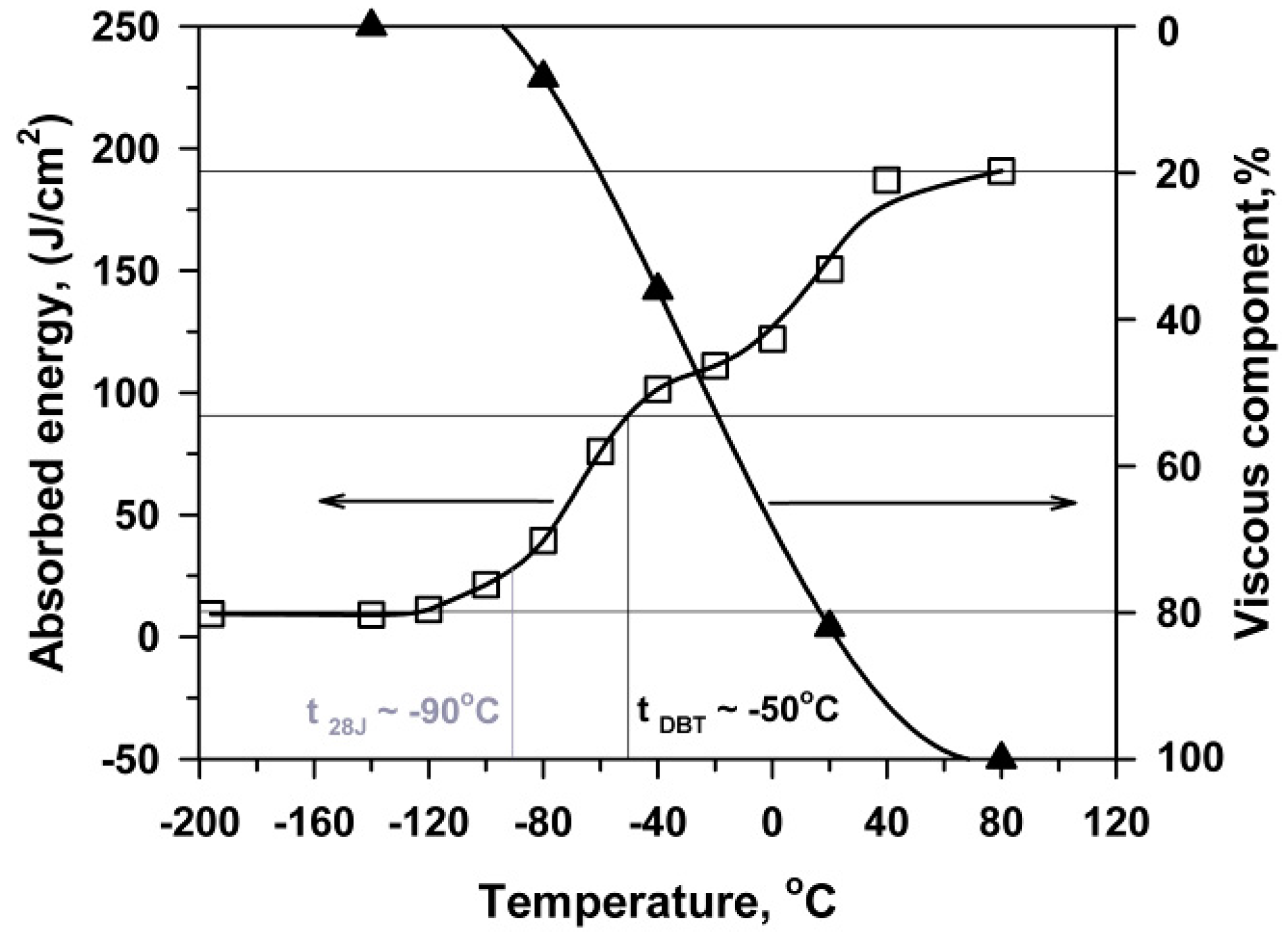

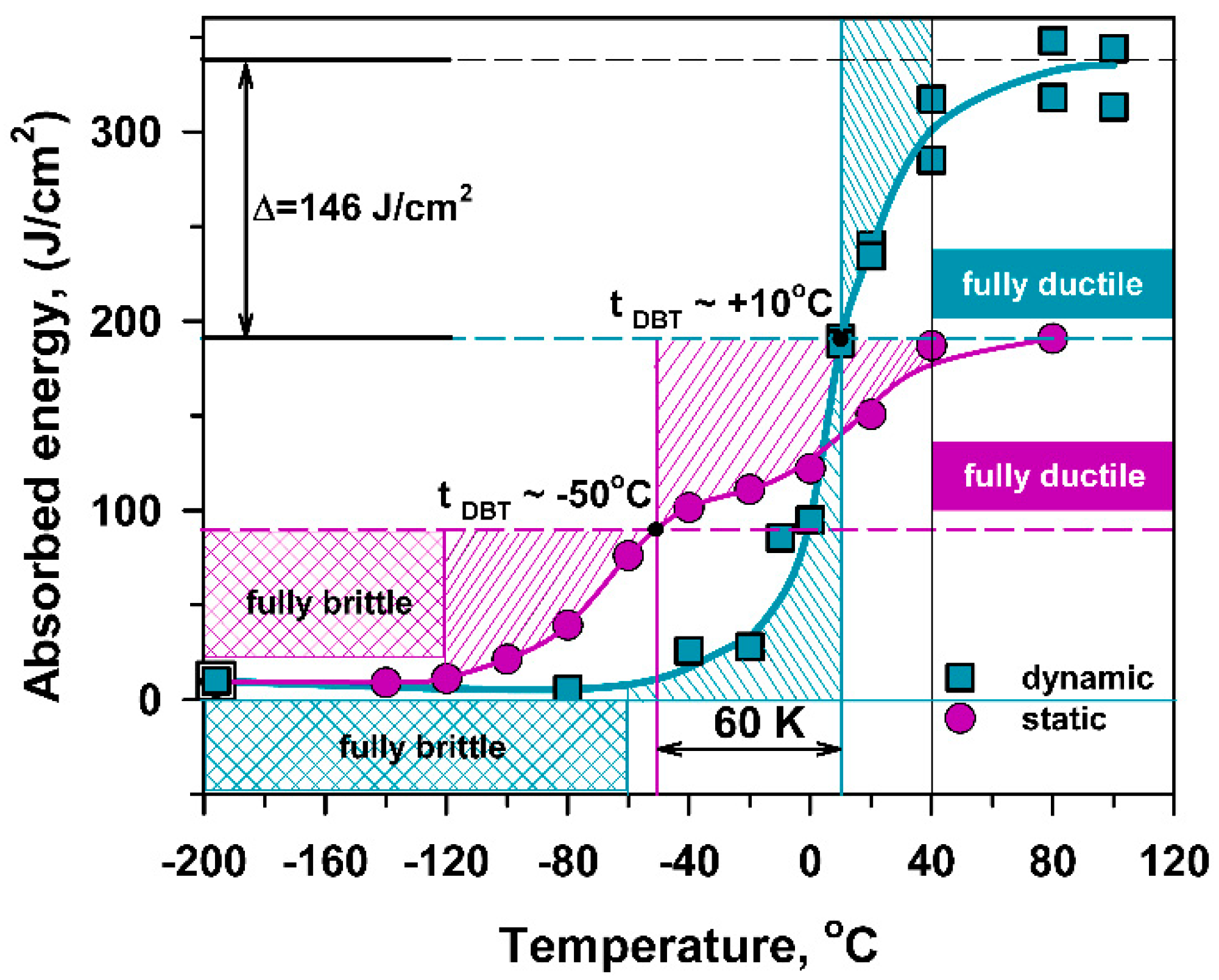

3.3. Fracture Toughness

3.4. Fractography

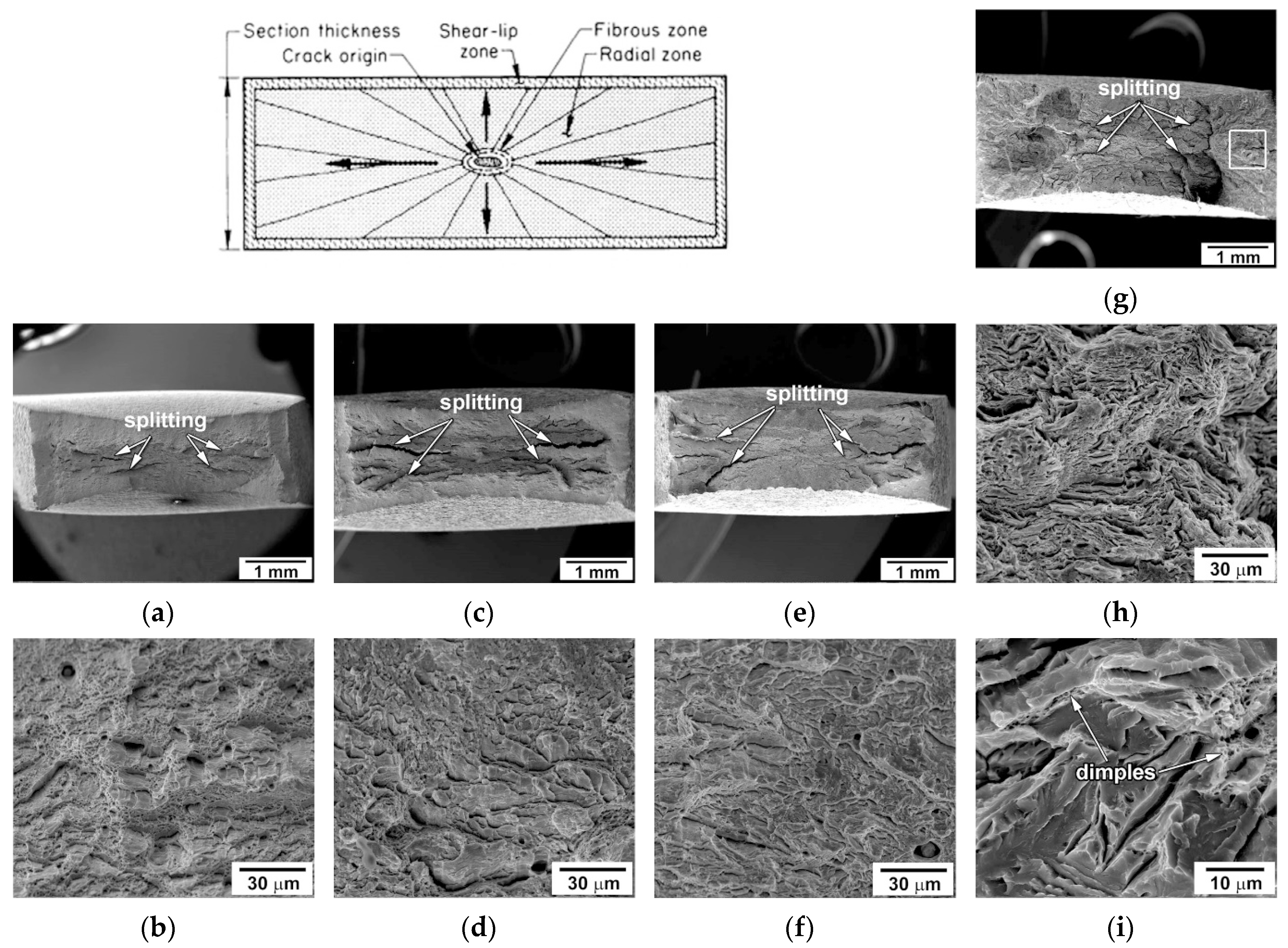

3.4.1. Tension Tests

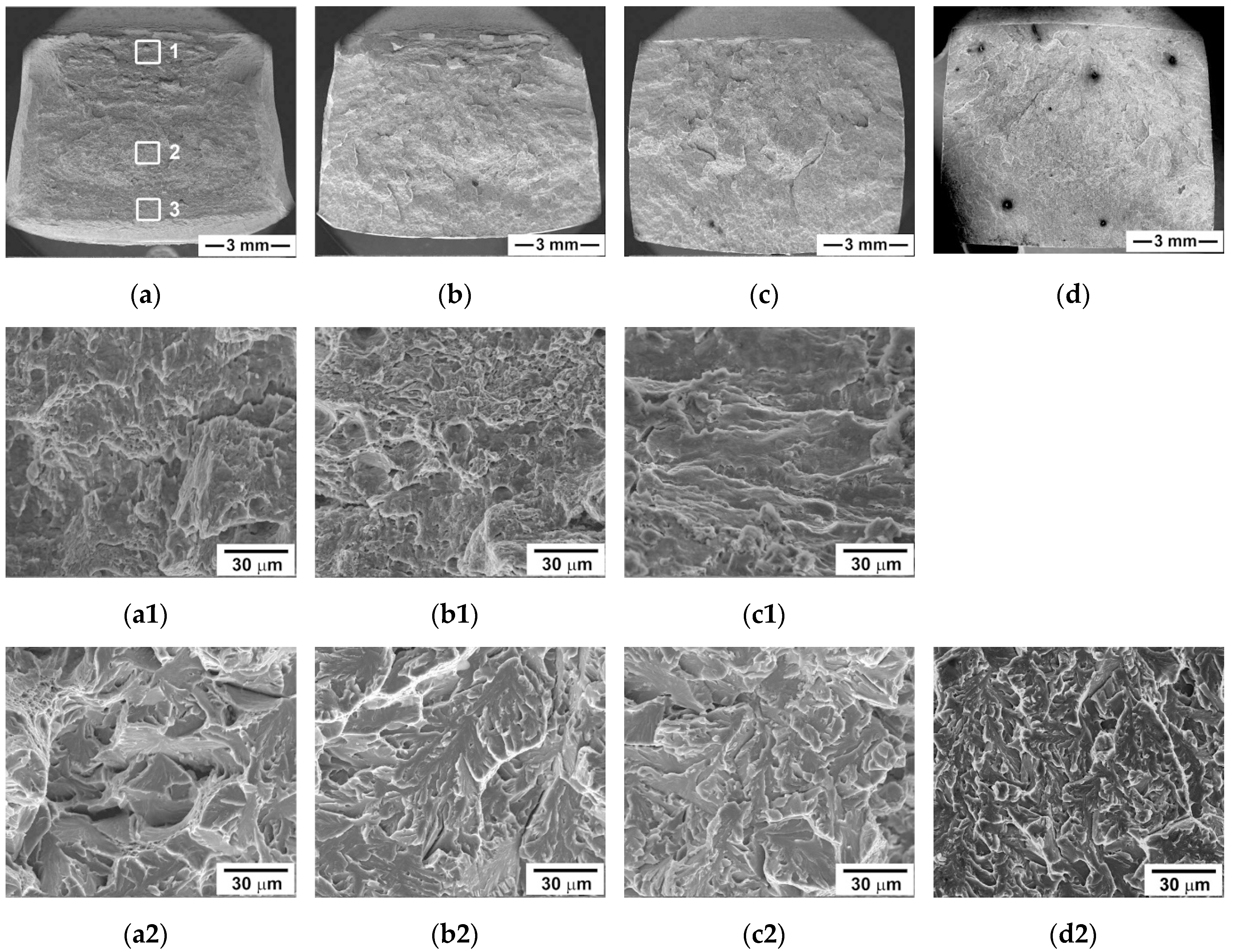

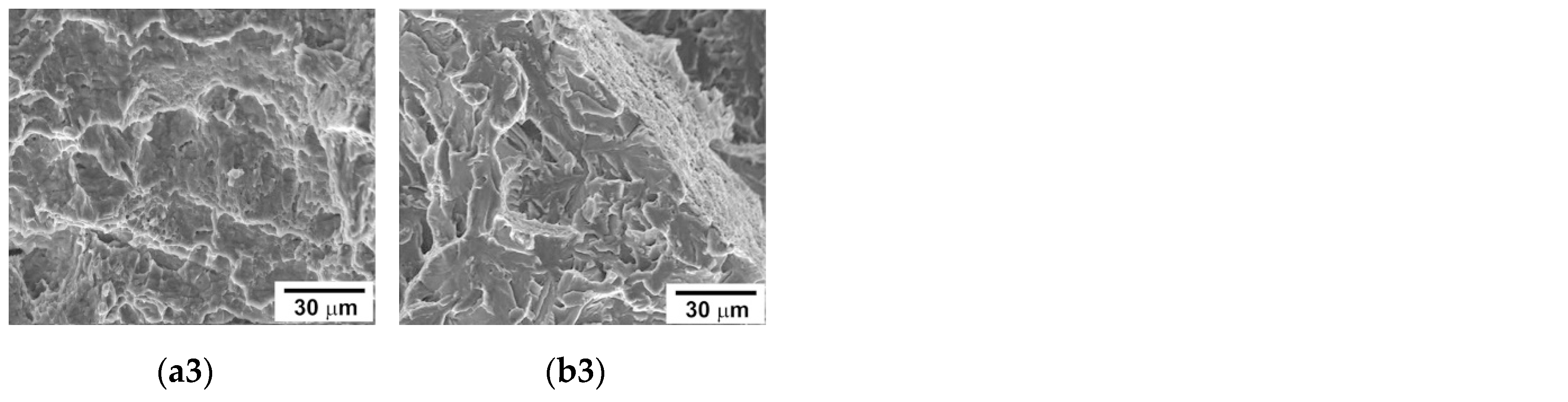

3.4.2. Three-point Bending Tests

4. Discussion

5. Conclusions

- Total elongation and ultimate tensile strength increased from 18% to 24% and from 710 MPa to 925 MPa, respectively, with a decrease in temperature from 20 °C to −140 °C due to an expansion of the strain hardening stage. The formation of crack with critical dimension occurred upon necking accompanied by microcrack nucleation and growth in a ductile manner absorbing high energy. The unstable crack propagation in a brittle manner was observed at −140 °C only.

- A temperature of −50 °C corresponded to the half of the sum of the upper shelf energy and the lower shelf energy, and was considered as a temperature of ductile–brittle transition for three-point bending tests of V-notched specimens. This temperature was lower than the fracture appearance transition temperature by about 30 °C. A rather low 28 J transition temperature, T28J = −90 °C, was attributed to short-range crack propagation in stable manner. The maximal stress during three-point bending and the maximal true stress during tensile tests were almost the same at temperatures above −80 °C. In contrast, the stresses required to fracture initiation for the notched specimens were much lower than the maximal true stresses during tensile tests at T < −80 °C. Therefore, the presence of V-notch scarcely affects the fracture at T ≥ −80 °C, whereas the steel becomes highly susceptible to flaw lower temperatures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abe, F.; Kern, U.T.; Vismanathan, R. Creep-Resistanat Steels; Woodhead Publishing: Cambridge, UK, 2008; ISBN 978-1-84265-129-2. [Google Scholar]

- Kaybyshev, R.O.; Skorobogatykh, V.N.; Shchenkova, I.A. New martensitic steels for fossil power plant: Creep resistance. Phys. Met. Metallogr. 2010, 109, 186–200. [Google Scholar] [CrossRef]

- Fedoseeva, A.; Dudova, N.; Kaibyshev, R. Role of Tungsten in the Tempered Martensite Embrittlement of a Modified 9 Pct Cr Steel. Metall. Mater. Trans. A 2017, 48, 982–998. [Google Scholar] [CrossRef]

- Dudova, N.; Mishnev, R.; Kaibyshev, R. Effect of tempering on microstructure and mechanical properties of boron containing 10% Cr steel. ISIJ Int. 2011, 51, 1912–1918. [Google Scholar] [CrossRef]

- Kipelova, A.Y.; Belyakov, A.N.; Skorobogatykh, V.N.; Shchenkova, I.A.; Kaibyshev, R.O. Tempering-induced structural changes in steel 10Kh9K3V1M1FBR and their effect on the mechanical properties. Met. Sci. Heat Treat. 2010, 52, 100–110. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Dudko, V.; Fedoseeva, A.; Kaibyshev, R. Ductile-brittle transition in a 9% Cr heat-resistant steel. Mater. Sci. Eng. A 2017, 682, 73–84. [Google Scholar] [CrossRef]

- Chatterjee, A.; Chakrabarti, D.; Moitra, A.; Mitra, R.; Bhaduri, A.K. Effect of normalization temperatures on ductile–brittle transition temperature of a modified 9Cr–1Mo steel. Mater. Sci. Eng. A 2014, 618, 219–231. [Google Scholar] [CrossRef]

- Wakai, E.; Okubo, N.; Ando, M.; Yamamoto, T.; Takada, F. Reduction method of DBTT shift due to irradiation for reduced-activation ferritic/martensitic steels. J. Nucl. Mater. 2010, 398, 64–67. [Google Scholar] [CrossRef]

- Chatterjee, A.; Chakrabarti, D.; Moitra, A.; Mitra, R.; Bhaduri, A.K. Effect of deformation temperature on the ductile–brittle transition behavior of a modified 9Cr–1Mo steel. Mater. Sci. Eng. A 2015, 630, 58–70. [Google Scholar] [CrossRef]

- Chatterjee, A.; Moitra, A.; Bhaduri, A.K.; Mitra, R.; Chakrabarti, D. Dynamic fracture behaviour of thermo-mechanically processed modified 9Cr–1Mo steel. Eng. Fract. Mech. 2015, 149, 74–88. [Google Scholar] [CrossRef]

- Sathyanarayanan, S.; Basu, J.; Moitra, A.; Sasikala, G.; Singh, V. Effect of Thermal Aging on Ductile-Brittle Transition Temperature of Modified 9Cr-1Mo Steel Evaluated with Reference Temperature Approach Under Dynamic Loading Condition. Metall. Mater. Trans. A 2013, 44, 2141–2155. [Google Scholar] [CrossRef]

- Hu, X.; Huang, L.; Yan, W.; Wang, W.; Sha, W.; Shan, Y.; Yang, K. Evolution of microstructure and changes of mechanical properties of CLAM steel after long-term aging. Mater. Sci. Eng. A 2013, 586, 253–258. [Google Scholar] [CrossRef]

- Zhong, W.; Wang, W.; Yang, X.; Li, W.; Yan, W.; Sha, W.; Wang, W.; Shan, Y.; Yang, K. Relationship between Laves phase and the impact brittleness of P92 steel reevaluated. Mater. Sci. Eng. A 2015, 639, 252–258. [Google Scholar] [CrossRef]

- Semba, H.; Abe, F. Alloy design and creep strength of advanced 9% Cr USC boiler steels containing high concentration of boron. Energy Mater. 2006, 1, 238–244. [Google Scholar] [CrossRef]

- Tabuchi, M.; Hongo, H.; Abe, F. Creep Strength of Dissimilar Welded Joints Using High B-9Cr Steel for Advanced USC Boiler. Metall. Mater. Trans. A 2014, 45, 5068–5075. [Google Scholar] [CrossRef]

- Liu, Y.; Tsukamoto, S.; Sawada, K.; Tabuchi, M.; Abe, F. Precipitation Behavior in the Heat-Affected Zone of Boron-Added 9Cr-3W-3Co Steel during Post-Weld Heat Treatment and Creep Deformation. Metall. Mater. Trans. A 2015, 46, 1843–1854. [Google Scholar] [CrossRef]

- Mishnev, R.; Dudova, N.; Fedoseeva, A.; Kaibyshev, R. Microstructural aspects of superior creep resistance of a 10% Cr martensitic steel. Mater. Sci. Eng. A 2016, 678, 178–189. [Google Scholar] [CrossRef]

- Sahara, R.; Matsunaga, T.; Hongo, H.; Tabuchi, M. Theoretical Investigation of Stabilizing Mechanism by Boron in Body-Centered Cubic Iron Through (Fe,Cr)23(C,B)6 Precipitates. Metall. Mater. Trans. A 2016, 47, 2487–2497. [Google Scholar] [CrossRef]

- Dudova, N.; Kaibyshev, R. On the Precipitation Sequence in a 10% Cr Steel under Tempering. ISIJ Int. 2011, 51, 826–831. [Google Scholar] [CrossRef]

- Mishnev, R.; Dudova, N.; Dudko, V.; Kaibyshev, R. Impact toughness of a 10% Cr steel with high boron and low nitrogen contents. Mater. Sci. Eng. A 2018, 730, 1–9. [Google Scholar] [CrossRef]

- Jurči, P.; Dománková, M.; Hudáková, M.; Ptačinová, J.; Pašák, M.; Palček, P. Characterization of microstructure and tempering response of conventionally quenched, short- and long-time sub-zero treated PM Vanadis 6 ledeburitic tool steel. Mater. Charact. 2011, 134, 398–415. [Google Scholar] [CrossRef]

- Krauss, G. Steels: Processing, Structure, and Performance; ASM International: Materials Park, OH, USA, 2005. [Google Scholar]

- Antolovich, S.D.; Armstrong, R.W. Plastic strain localization in metals: Origins and consequences. Prog. Mater. Sci. 2014, 59, 1–160. [Google Scholar] [CrossRef]

- Chaouadi, R.; Fabry, A. On the utilization of the instrumented Charpy impact test for characterizing the flow and fracture behavior of reactor pressure vessel steels. In From Charpy to Present Impact Testing; Francois, D., Pineau, A., Eds.; Elsevier Science Ltd. and ESIS: Oxford, UK, 2002. [Google Scholar]

- Kerlins, V. Modes of Fracture. In ASM Handbook, Fractography; Mills, K., Davis, J.R., Destefani, J.D., Dieterich, D., Eds.; ASM International: Materials Park, OH, USA, 1987; Volume 12. [Google Scholar]

- Knott, J.F.; Met, B. Fundamentals of Fracture Mechanics; Butterworths: London, UK, 1973. [Google Scholar]

- Vinogradov, A.; Yasnikov, I.S.; Matsuyama, H.; Uchida, M.; Kaneko, Y.; Estrin, Y. Controlling strength and ductility: Dislocation-based model of necking instability and its verification for ultrafine grain 316L steel. Acta Mater. 2016, 106, 295–303. [Google Scholar] [CrossRef]

- Jobba, M.; Mishra, R.K.; Niewczas, M. Flow stress and work-hardening behaviour of Al–Mg binary alloys. Int. J. Plast. 2015, 65, 43–60. [Google Scholar] [CrossRef]

- ASTM E23-05. Standard test methods for notched bar impact testing of metallic materials. In Annual Book of ASTM Standards, 03.01; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Morris, J.W., Jr. MATERIALS SCIENCE: Stronger, Tougher Steels. Science 2008, 320, 1022–1023. [Google Scholar] [CrossRef]

- Morris, J.W., Jr. On the Ductile-Brittle Transition in Lath Martensitic Steel. ISIJ Int. 2011, 51, 1569–1575. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T. Influence of Warm Tempforming on Microstructure and Mechanical Properties in an Ultrahigh-Strength Medium-Carbon Low-Alloy Steel. Metall. Mater. Trans. A 2013, 44, 560–576. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T. Influence of Carbon Content on Toughening in Ultrafine Elongated Grain Structure Steels. ISIJ Int. 2015, 55, 1135–1144. [Google Scholar] [CrossRef]

| Parameters | Temperature, °C | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 10 | 0 | −10 | −20 | −40 | −60 | −80 | −100 | −120 | −140 | |

| σ0.2, MPa | 550 | 560 | 570 | 575 | 590 | 600 | 615 | 640 | 665 | 705 | 765 |

| UTS, MPa | 710 | 720 | 725 | 735 | 745 | 765 | 790 | 820 | 850 | 880 | 925 |

| σmT, MPa | 780 | 790 | 810 | 815 | 830 | 860 | 890 | 930 | 950 | 1005 | 1055 |

| Elu, % | 7.2 | 8.9 | 9.1 | 7.7 | 9.7 | 8.8 | 10 | 10.8 | 10.5 | 10 | 12.1 |

| Elt, % | 17.7 | 18.5 | 21 | 20.6 | 21.6 | 21.8 | 21.5 | 23.4 | 20.5 | 23.4 | 23.5 |

| Zone | Test Temperature, °C | ||||

|---|---|---|---|---|---|

| 80 | 20 | −40 | −80 | −140 | |

| Initiation and fibrous zones | 4.3 | 2.8 | 1.5 | 0.2 | 0.1 |

| Unstable crack zone | - | 2.9 | 5.5 | 7.7 | 7.9 |

| Shear-lip zone | 3.5 | 3.3 | 0.7 | 0.1 | - |

| Total | 7.8 | 7.9 | 7.7 | 8.0 | 8.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mishnev, R.; Dudova, N.; Kaibyshev, R.; Belyakov, A. On the Fracture Behavior of a Creep Resistant 10% Cr Steel with High Boron and Low Nitrogen Contents at Low Temperatures. Materials 2020, 13, 3. https://doi.org/10.3390/ma13010003

Mishnev R, Dudova N, Kaibyshev R, Belyakov A. On the Fracture Behavior of a Creep Resistant 10% Cr Steel with High Boron and Low Nitrogen Contents at Low Temperatures. Materials. 2020; 13(1):3. https://doi.org/10.3390/ma13010003

Chicago/Turabian StyleMishnev, Roman, Nadezhda Dudova, Rustam Kaibyshev, and Andrey Belyakov. 2020. "On the Fracture Behavior of a Creep Resistant 10% Cr Steel with High Boron and Low Nitrogen Contents at Low Temperatures" Materials 13, no. 1: 3. https://doi.org/10.3390/ma13010003

APA StyleMishnev, R., Dudova, N., Kaibyshev, R., & Belyakov, A. (2020). On the Fracture Behavior of a Creep Resistant 10% Cr Steel with High Boron and Low Nitrogen Contents at Low Temperatures. Materials, 13(1), 3. https://doi.org/10.3390/ma13010003