Mechanical Property and Structure of Polypropylene/Aluminum Alloy Hybrid Prepared via Ultrasound-Assisted Hot-Pressing Technology

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Sample Preparation

2.3. Orthogonal Experiment Design

2.4. Tensile Shear Strength Test

2.5. Surface Morphology Observation

3. Results and Discussion

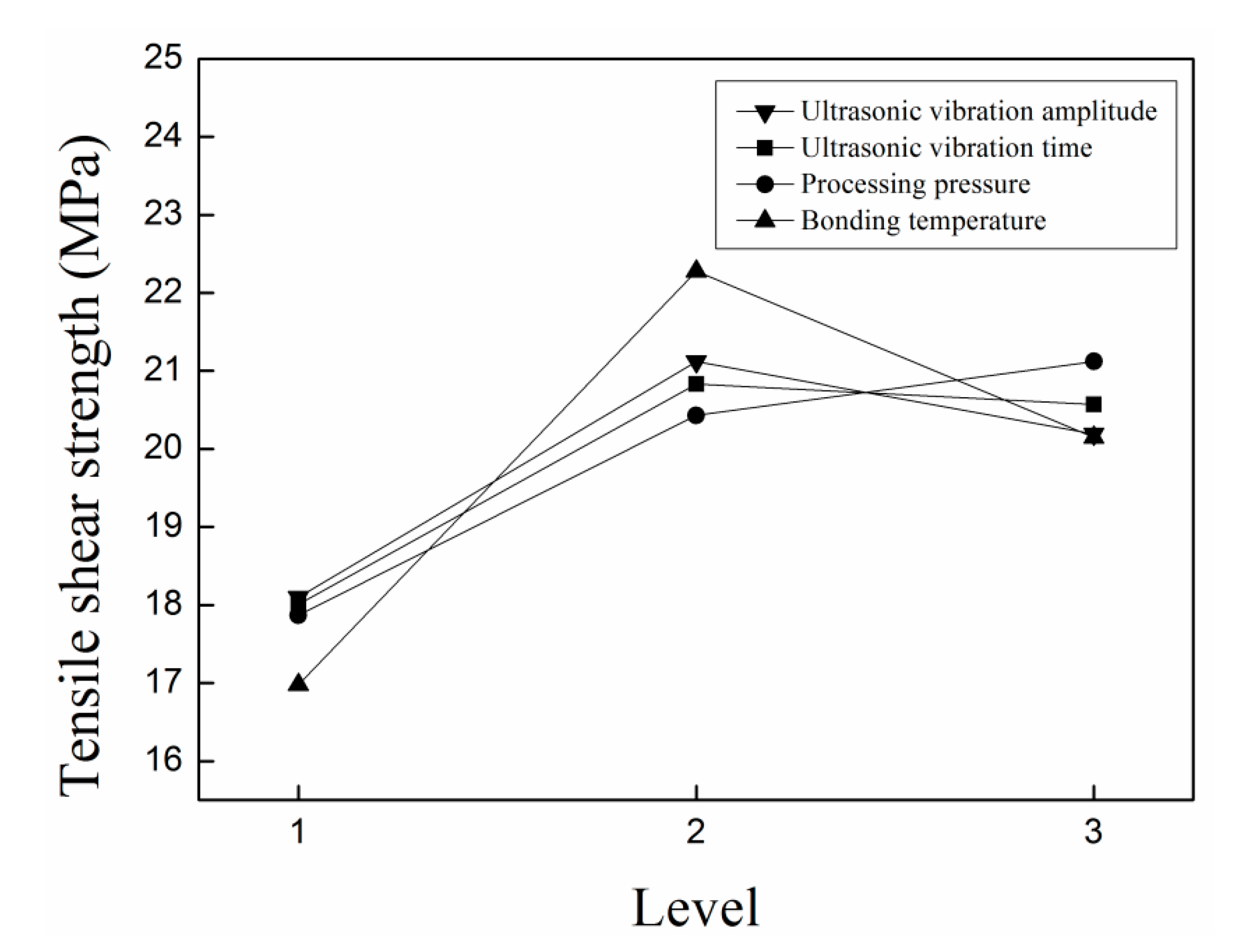

3.1. Tensile Shear Behavior of the Polypropylene/Aluminum Alloy Hybrid Prepared by UAHPT

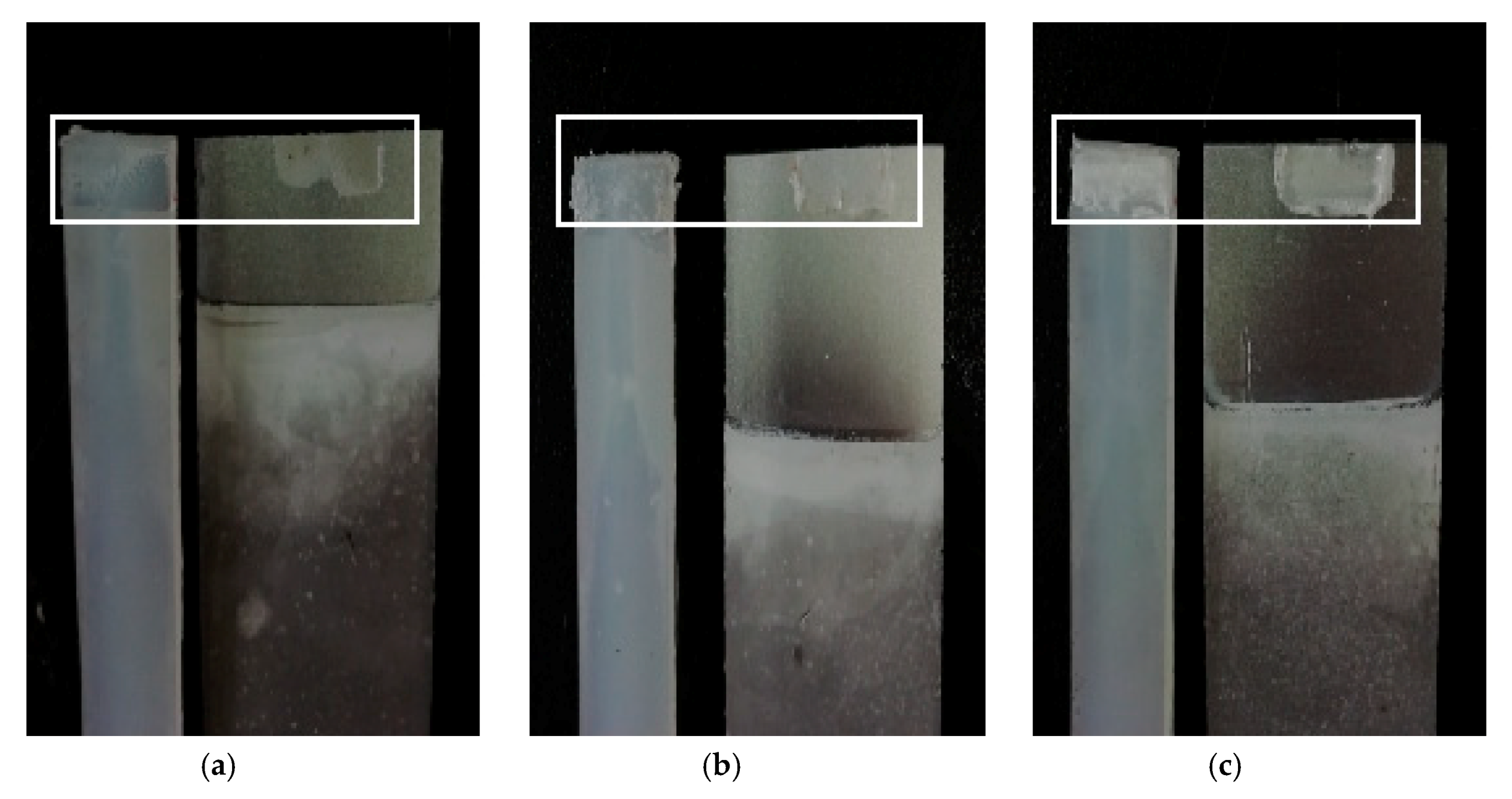

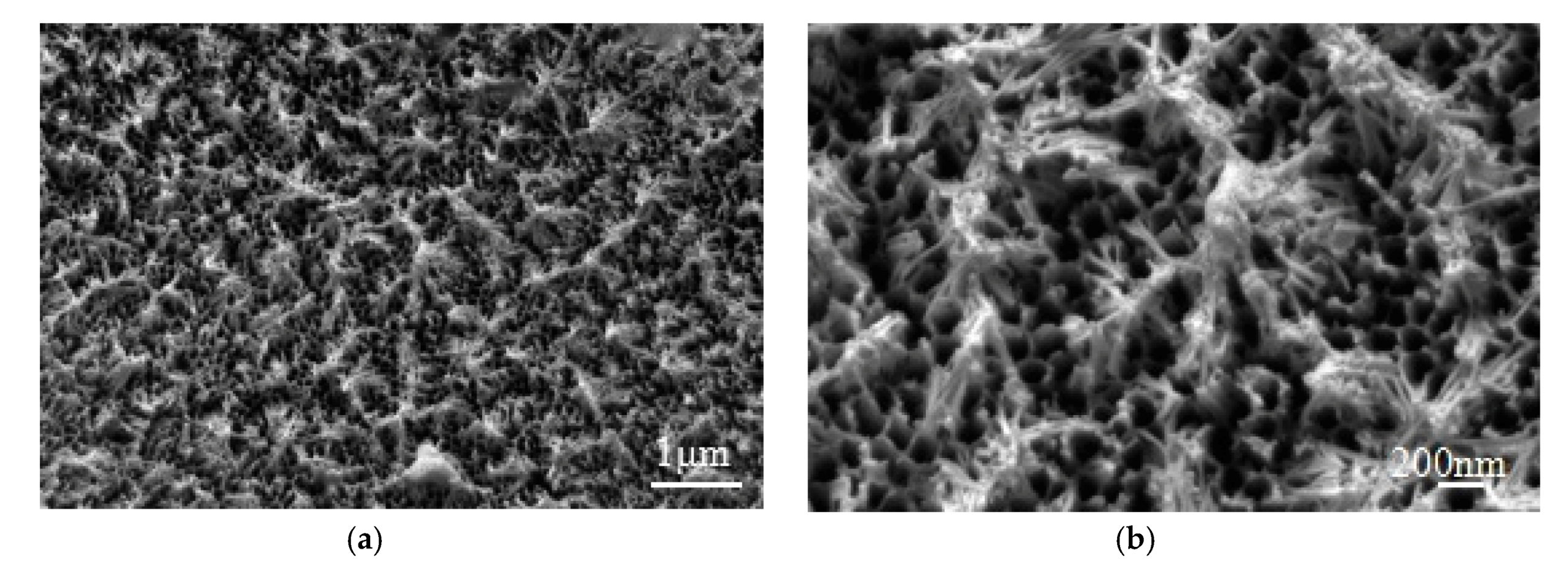

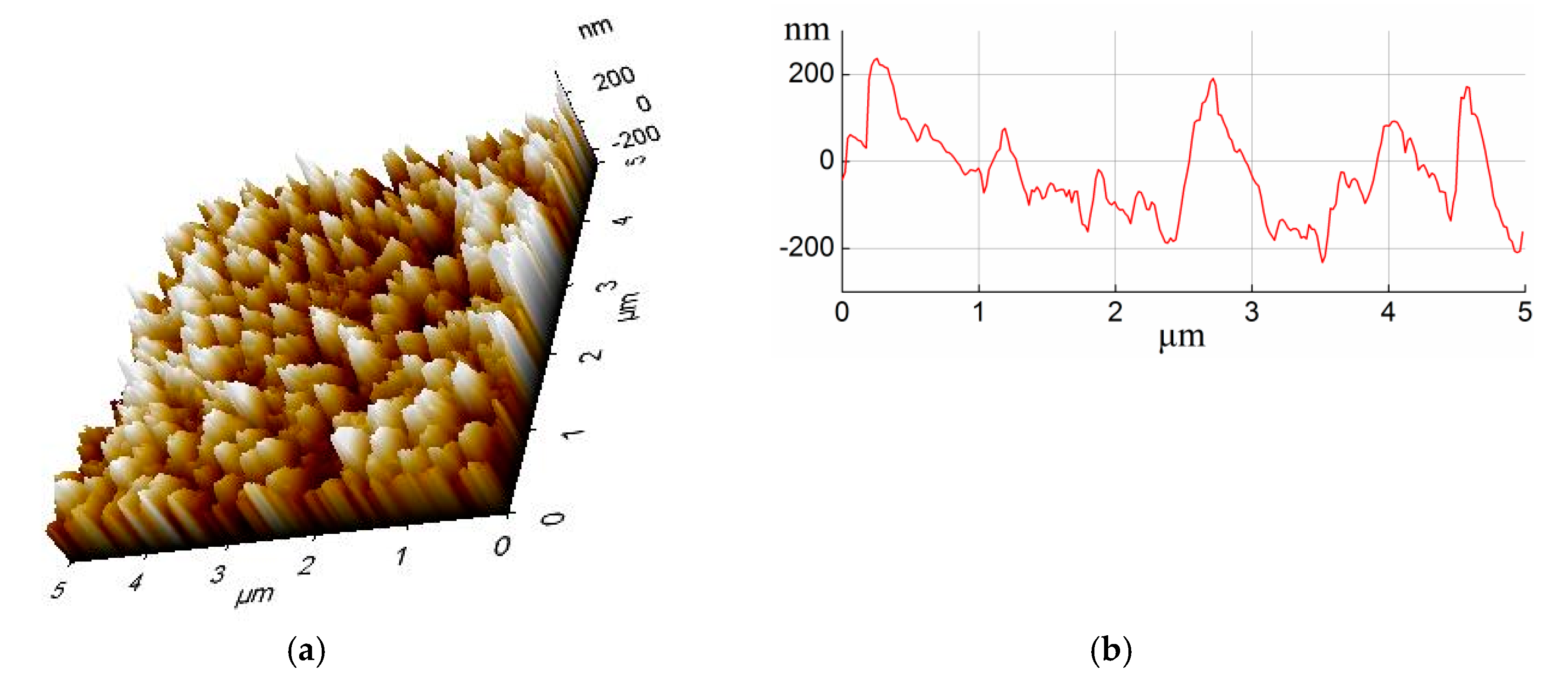

3.2. Surface Characterization

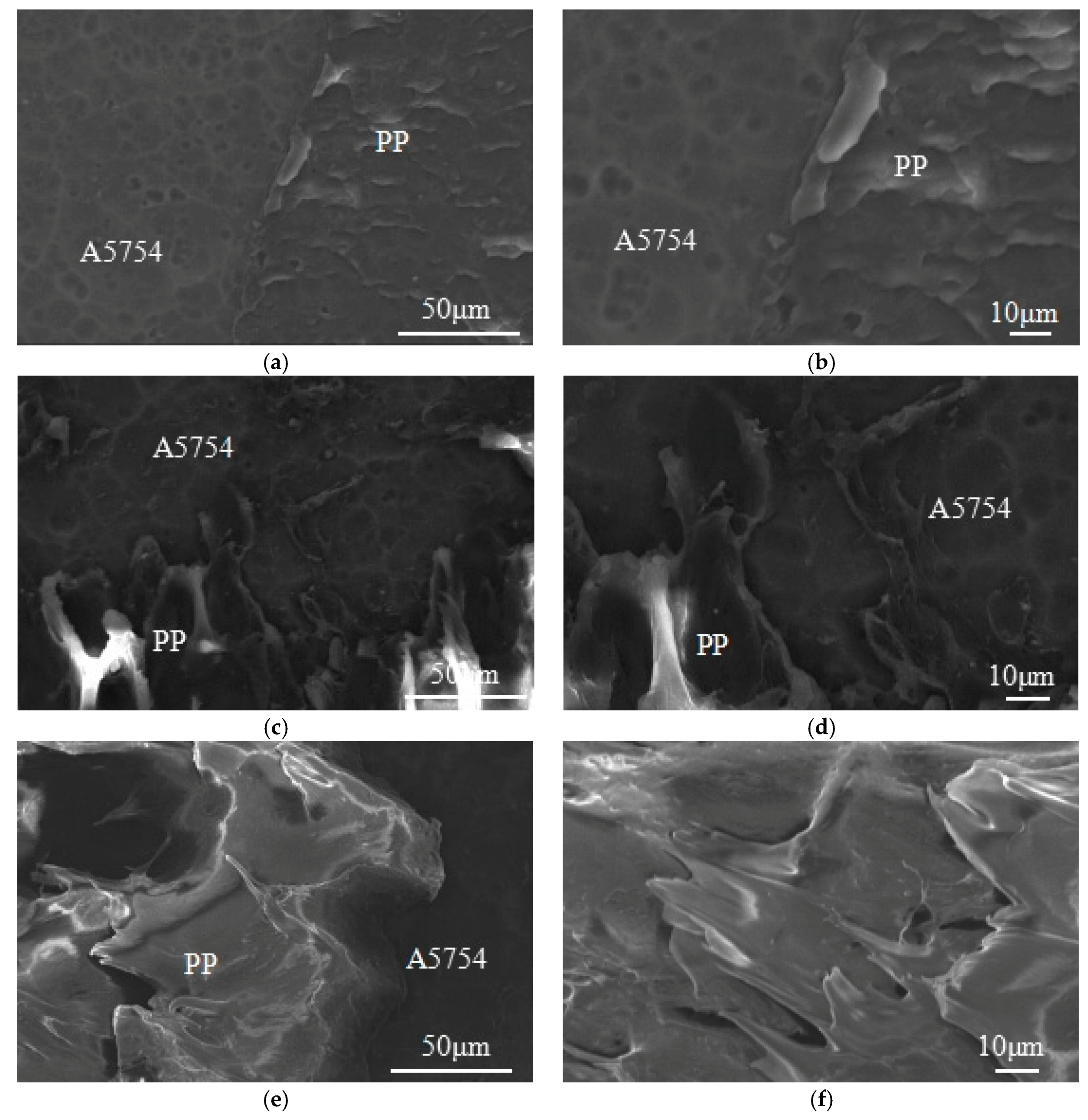

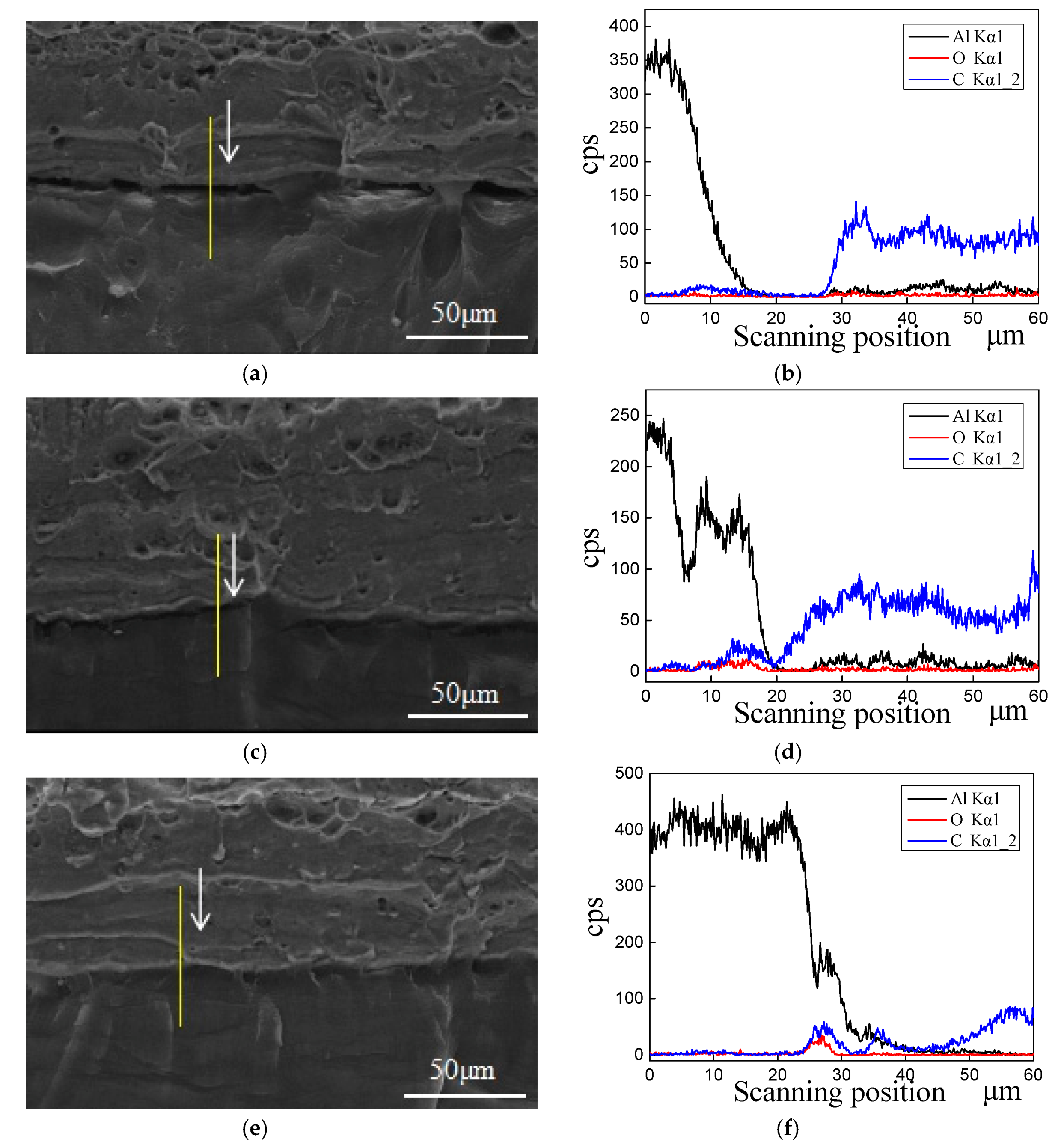

3.3. Microstructure Characteristics at Joint Interface

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Venkatesh, V.; Akhil, G.; Liang, G.; Rangarajan, V. Finite Element Based Physical Chemical Modeling of Corrosion in Magnesium Alloys. Metals 2017, 7, 83. [Google Scholar] [CrossRef]

- Ramani, K.; Tagle, J. Process-induced effects in thin-film bonding of PEKEKK in metal-polymer joints. Polym. Compos. 1996, 17, 879–885. [Google Scholar] [CrossRef]

- Grujicic, M.; Sellappan, V.; Omar, M.A.; Seyr, N.; Obieglo, A.; Erdmann, M.; Holzleitner, J. An overview of the polymer-to-metal direct-adhesion hybrid technologies for load-bearing automotive components. J. Mater. Process. Tech. 2008, 197, 363–373. [Google Scholar] [CrossRef]

- Arkhurst, B.M.; Lee, M.; Kim, J.H. Effect of resin matrix on the strength of an AZ31 Mg alloy-CFRP joint made by the hot metal pressing technique. Compos. Struct. 2018, 201, 303–314. [Google Scholar] [CrossRef]

- Arkhurst, B.M.; Kim, J.H.; Lee, M. Hot metal pressing joining of carbon fiber reinforced plastic to AZ31 Mg alloy and the effect of the oxide surface layer on joint strength. Appl. Surf. Sci. 2019, 477, 241–256. [Google Scholar] [CrossRef]

- Zhou, P.; Wu, X.; Pan, Y.; Tao, Y.; Wu, G.; Huang, Z. Mechanical properties of carbon fibre-reinforced polymer/magnesium alloy hybrid laminates. Mater. Res. Express. 2018, 5, 1–14. [Google Scholar] [CrossRef]

- Fabrin, P.A.; Hoikkanen, M.E.; Vuorinen, J.E. Adhesion of thermoplastic elastomer on surface treated aluminum by injection molding. Polym. Eng. Sci. 2007, 47, 1187–1191. [Google Scholar] [CrossRef]

- Izadi, O.; Silani, M.; Mosaddegh, P.; Farzin, M. Warpage and bending behavior of polymer-metal hybrids: Experimental and numerical simulations. Int. J. Adv. Manuf. Technol. 2018, 98, 873–885. [Google Scholar] [CrossRef]

- Jiao, J.; Wang, Q.; Wang, F.; Zan, S.; Zhang, W. Numerical and experimental investigation on joining CFRTP and stainless steel using fiber lasers. J. Mater. Process. Technol. 2017, 240, 362–369. [Google Scholar] [CrossRef]

- Liu, F.C.; Dong, P.; Lu, W.; Sun, K. On formation of Al-O-C bonds at aluminum/polyamide joint interface. Appl. Surf. Sci. 2019, 466, 202–209. [Google Scholar] [CrossRef]

- Honkanen, M.; Hoikkanen, M.; Vippola, M.; Vuorinen, J.; Lepistö, T.; Jussila, P.; Ali-Löytty, H.; Lampimäki, M.; Valden, M. Characterization of silane layers on modified stainless steel surfaces and related stainless steel-plastic hybrids. Appl. Surf. Sci. 2011, 257, 9335–9346. [Google Scholar] [CrossRef]

- Pan, L.; Ali, A.; Wang, Y.; Zheng, Z.; Lv, Y. Characterization of effects of heat treated anodized film on the properties of hygrothermally aged AA5083-based fiber-metal laminates. Compos. Struct. 2017, 167, 112–122. [Google Scholar] [CrossRef]

- Yeh, R.Y.; Hsu, R.Q. Improving the adhesion of plastic/metal direct bonding by injection moulding using surface modifications. Adv. Mater. Process. Technol. 2016, 78, 21–30. [Google Scholar] [CrossRef]

- Byskov-Nielsen, J.; Boll, J.V.; Holm, A.H.; Højsholt, R.; Balling, P. Ultra-high-strength micro-mechanical interlocking by injection molding into laser-structured surfaces. Int. J. Adhes. Adhes. 2010, 30, 485–488. [Google Scholar] [CrossRef]

- Li, X.; Gong, N.; Yang, C.; Zeng, S.; Fu, S.; Zhang, K. Aluminum/polypropylene composites produced through injection molding. J. Mater. Process. Technol. 2018, 225, 635–643. [Google Scholar] [CrossRef]

- Chen, J.; Du, K.; Chen, X.; Li, Y.; Huang, J.; Wu, Y.; Yang, C.; Xia, X. Influence of surface microstructure on bonding strength of modified Polypropylene/Aluminum alloy direct adhesion. Appl. Surf. Sci. 2019, 489, 392–402. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, J.; Chen, X.; Li, C.; Li, Y.; Yang, C.; Xia, T. Study on integrally molded PA6/304 stainless steel by micro-nano pressing technology. J. Adhes. Sci. Technol. 2019, 33, 511–522. [Google Scholar] [CrossRef]

- Kimiaki, N.; Shoichiro, Y.; Atsuki, T. Direct joining of carbon-fiber-reinforced plastic to an aluminum alloy using friction lap joining. Compos. Part B 2015, 73, 82–88. [Google Scholar] [CrossRef]

- Chen, M.A.; Li, H.Z.; Zhang, X.M. Improvement of shear strength of aluminum-polypropylene lap joints by grafting maleic anhydride onto polypropylene. Int. J. Adhes. Adhes. 2017, 27, 175–187. [Google Scholar] [CrossRef]

| Density (g/cm3) | Melt Index (g/10 min) | Vicat Softening Point (°C) | Shrinking Percentage (%) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 0.91 | 13 | 120 | 1.5–20 | 33 |

| Injection Pressure (MPa) | Holding Pressure (MPa) | Holding Time (s) | Cooling Time (s) | Screw Speed (rpm) |

|---|---|---|---|---|

| 40 | 30 | 6 | 20 | 40 |

| Level | Factors | |||

|---|---|---|---|---|

| Ultrasonic Vibration Amplitude (%) | Ultrasonic Vibration Time (s) | Processing Pressure (MPa) | Bonding Temperature (°C) | |

| 1 | 10 | 2 | 0.1 | 165 |

| 2 | 10 | 5 | 0.3 | 175 |

| 3 | 10 | 10 | 0.6 | 185 |

| 4 | 50 | 2 | 0.3 | 185 |

| 5 | 50 | 5 | 0.6 | 165 |

| 6 | 50 | 10 | 0.1 | 175 |

| 7 | 100 | 2 | 0.6 | 175 |

| 8 | 100 | 5 | 0.1 | 185 |

| 9 | 100 | 10 | 0.3 | 165 |

| Specimens | Tensile Shear Strength (MPa) |

|---|---|

| 1 | 11.55 |

| 2 | 22.23 |

| 3 | 20.53 |

| 4 | 20.29 |

| 5 | 20.64 |

| 6 | 22.43 |

| 7 | 22.18 |

| 8 | 19.62 |

| 9 | 18.76 |

| Level | Factors | |||

|---|---|---|---|---|

| Ultrasonic Vibration Amplitude (%) | Ultrasonic Vibration Time (s) | Processing Pressure (MPa) | Bonding Temperature (°C) | |

| K1 | 18.10 | 18.01 | 17.87 | 16.98 |

| K2 | 21.12 | 20.83 | 20.43 | 22.28 |

| K3 | 20.19 | 20.57 | 21.12 | 20.15 |

| R | 3.02 | 2.82 | 3.25 | 5.30 |

| Ultrasonic Vibration Amplitude (%) | Ultrasonic Vibration Time (s) | Processing Pressure (MPa) | Bonding Temperature (°C) | Hot-Pressing Time (s) |

|---|---|---|---|---|

| 50 | 5 | 0.6 | 175 | 15 |

| Aluminum Alloy Sample | Rpv (nm) | Rq (nm) | Ra (nm) | Rz (nm) |

|---|---|---|---|---|

| 445.94 ± 0.11 | 107.76 ± 0.24 | 89.95 ± 0.16 | 388.94 ± 0.42 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, K.; Huang, J.; Chen, J.; Li, Y.; Yang, C.; Xia, X. Mechanical Property and Structure of Polypropylene/Aluminum Alloy Hybrid Prepared via Ultrasound-Assisted Hot-Pressing Technology. Materials 2020, 13, 236. https://doi.org/10.3390/ma13010236

Du K, Huang J, Chen J, Li Y, Yang C, Xia X. Mechanical Property and Structure of Polypropylene/Aluminum Alloy Hybrid Prepared via Ultrasound-Assisted Hot-Pressing Technology. Materials. 2020; 13(1):236. https://doi.org/10.3390/ma13010236

Chicago/Turabian StyleDu, Kunpeng, Jin Huang, Jing Chen, Youbing Li, Chaolong Yang, and Xiaochao Xia. 2020. "Mechanical Property and Structure of Polypropylene/Aluminum Alloy Hybrid Prepared via Ultrasound-Assisted Hot-Pressing Technology" Materials 13, no. 1: 236. https://doi.org/10.3390/ma13010236

APA StyleDu, K., Huang, J., Chen, J., Li, Y., Yang, C., & Xia, X. (2020). Mechanical Property and Structure of Polypropylene/Aluminum Alloy Hybrid Prepared via Ultrasound-Assisted Hot-Pressing Technology. Materials, 13(1), 236. https://doi.org/10.3390/ma13010236