Anodic and Mechanical Behavior of Carbon Fiber Reinforced Polymer as a Dual-Functional Material in Chloride-Contaminated Concrete

Abstract

1. Introduction

2. Experimental Program

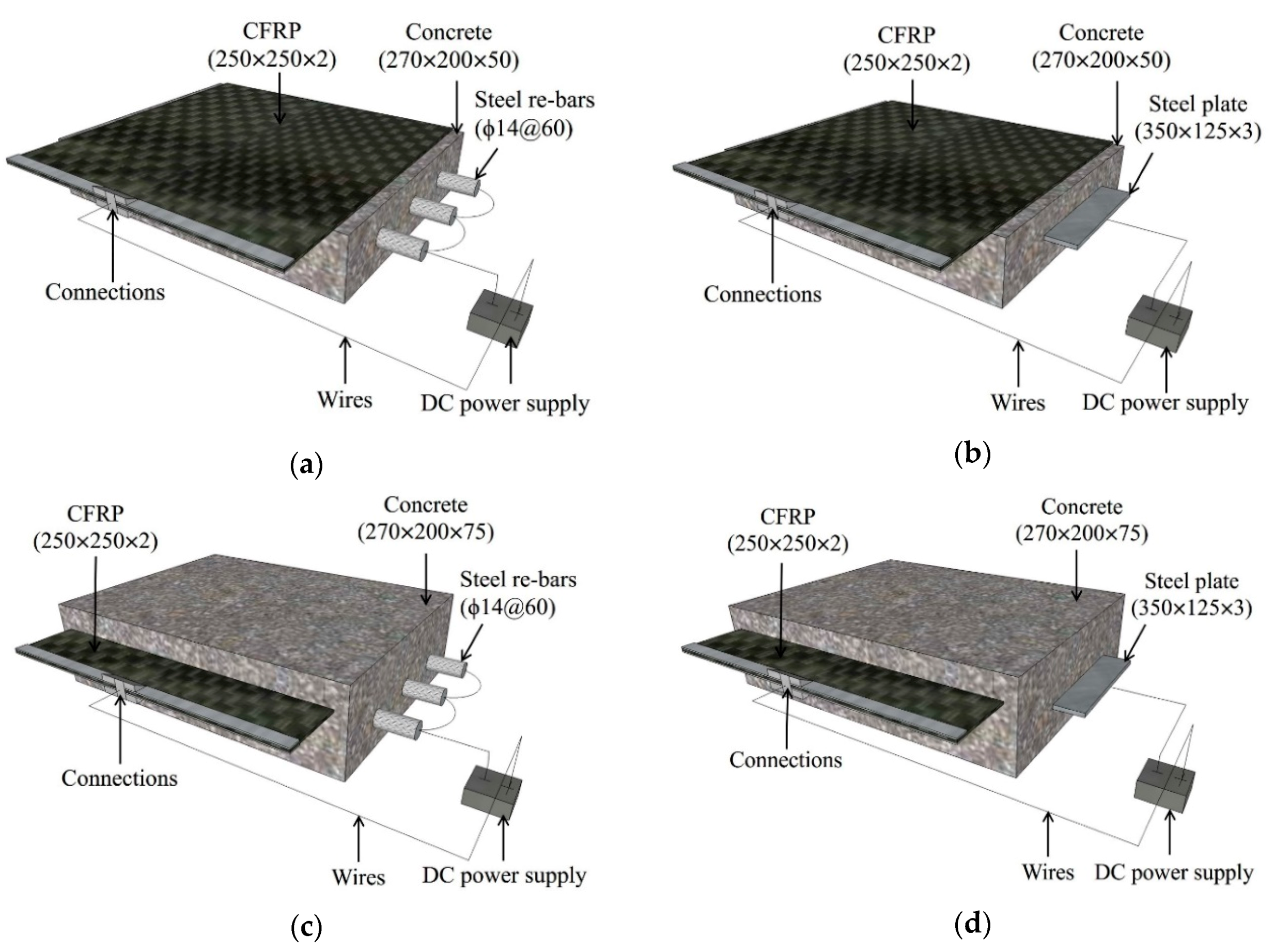

2.1. Test Specimens

2.2. EC Tests Procedure

2.3. Testing Program

3. Results and Discussion

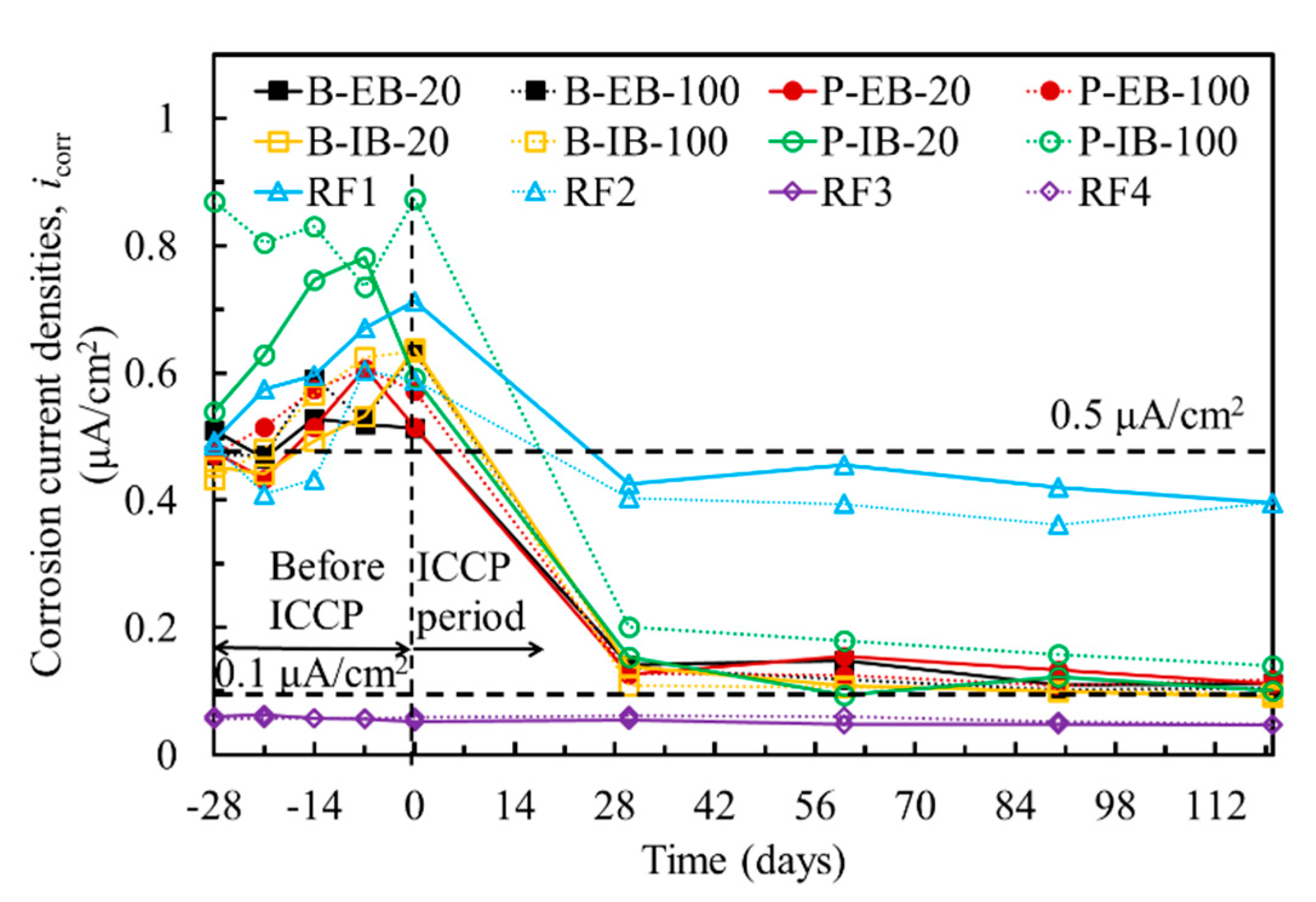

3.1. Corrosion of Steel

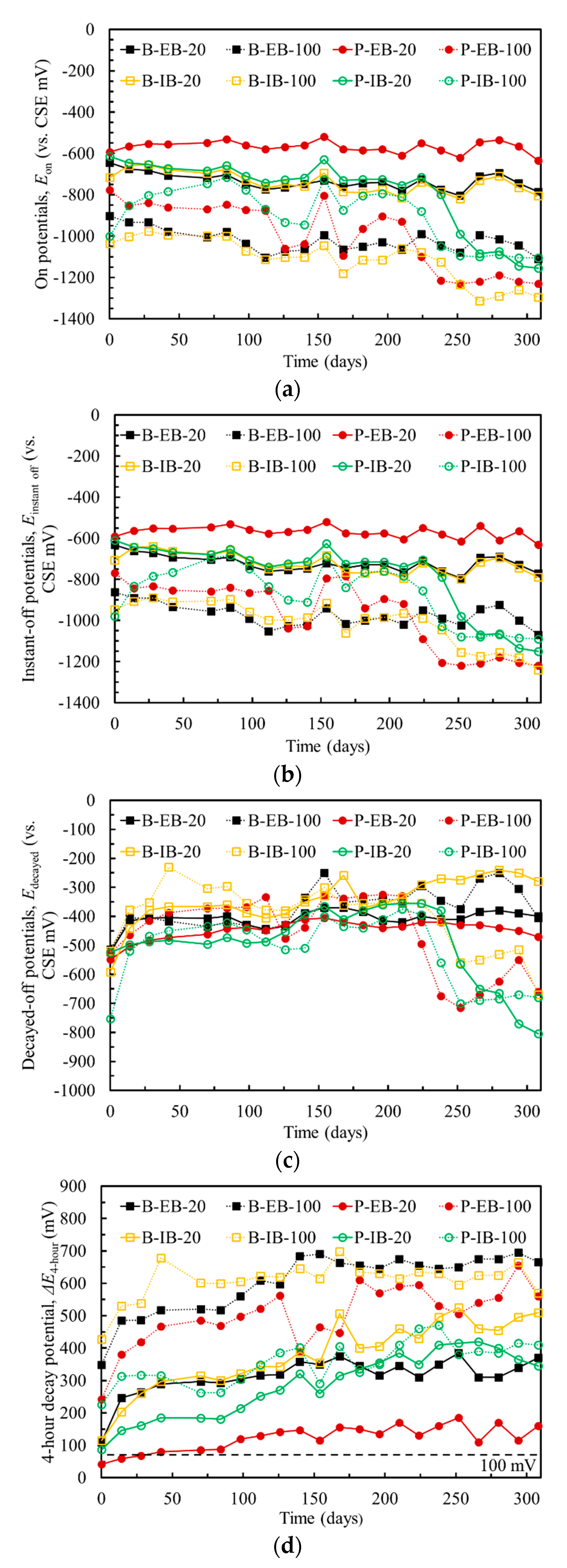

3.2. Cathodic Protection by Using CFRP

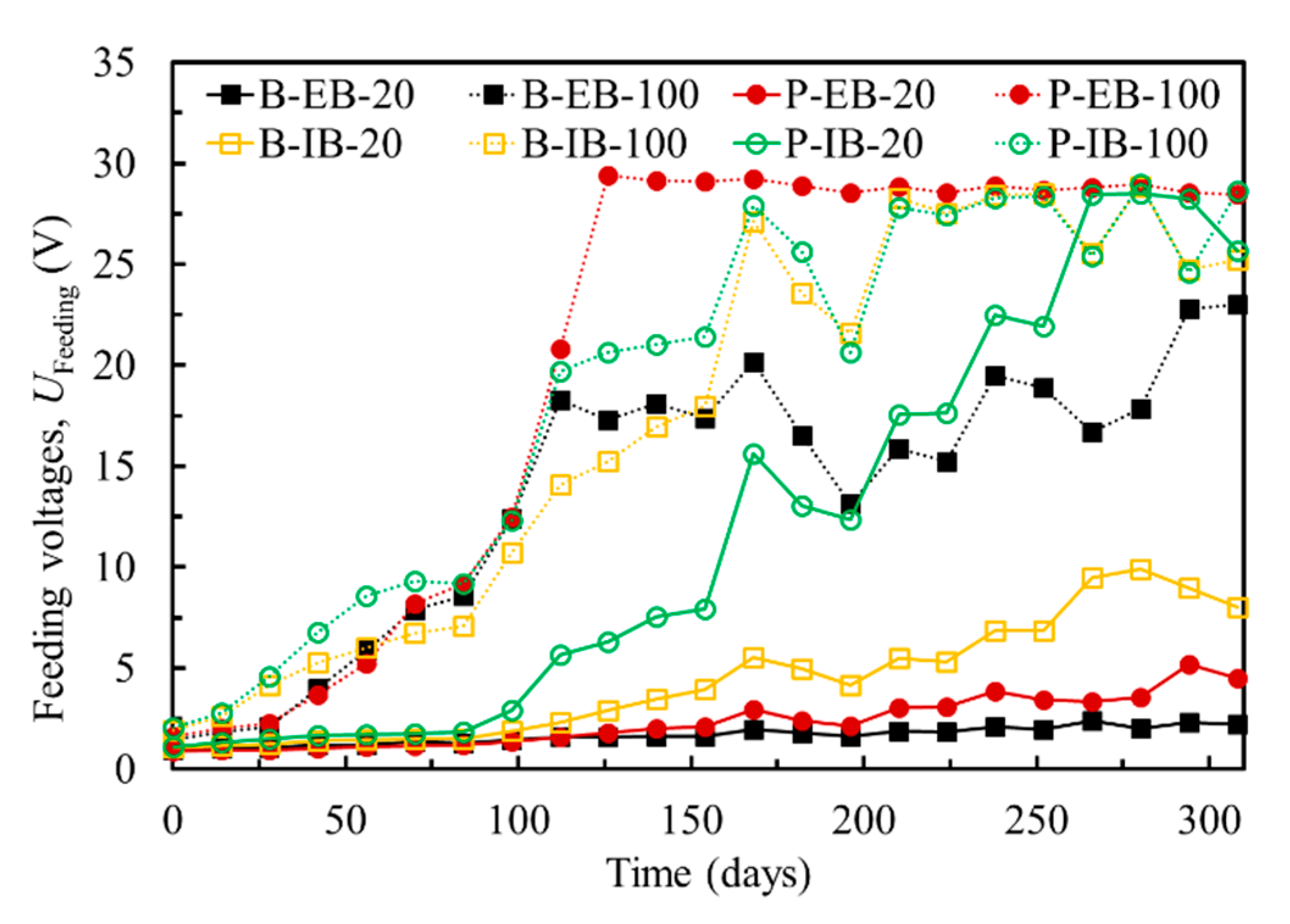

3.3. Degradation Induced by Cathodic Protection

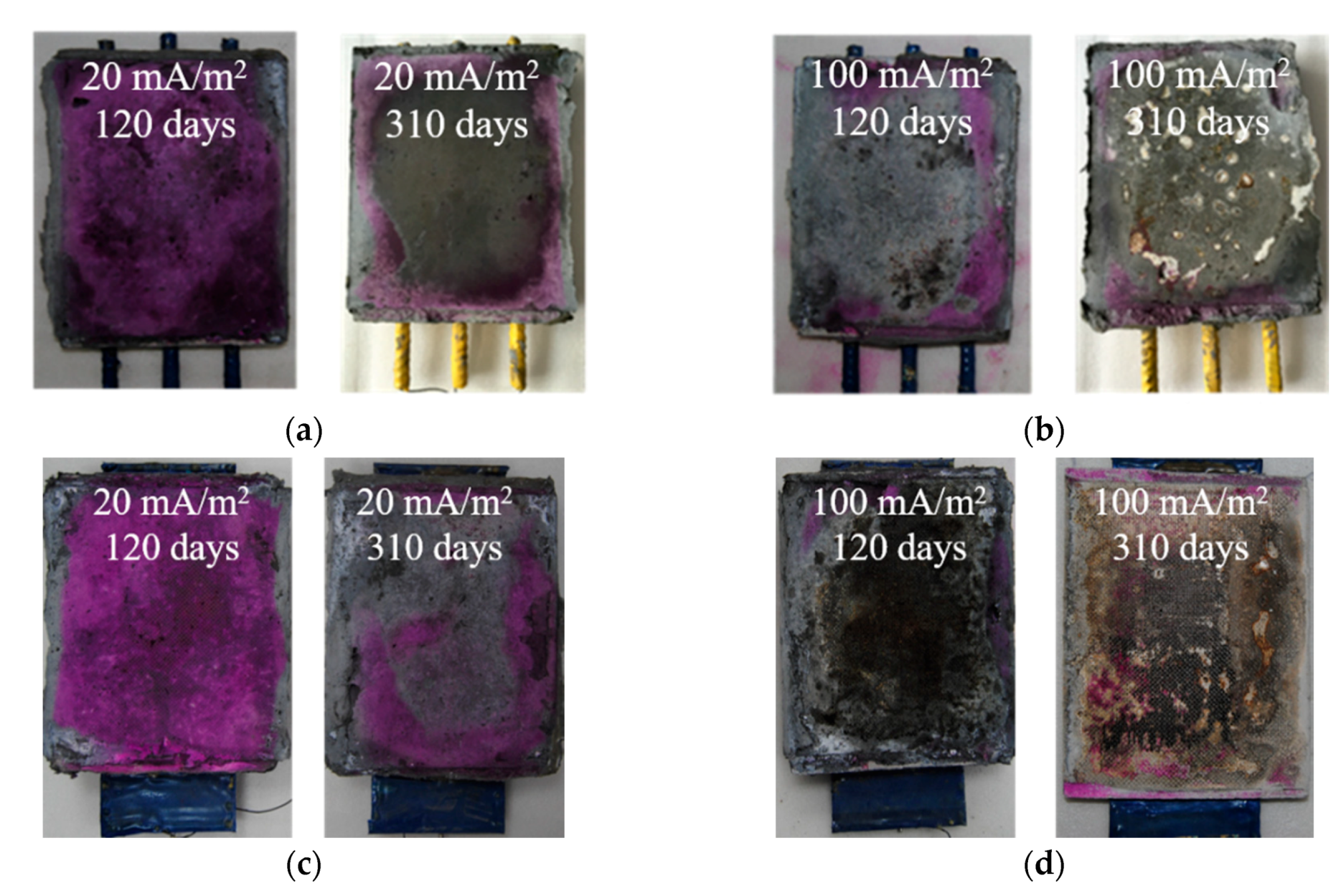

3.3.1. Degradation of Anode Interface

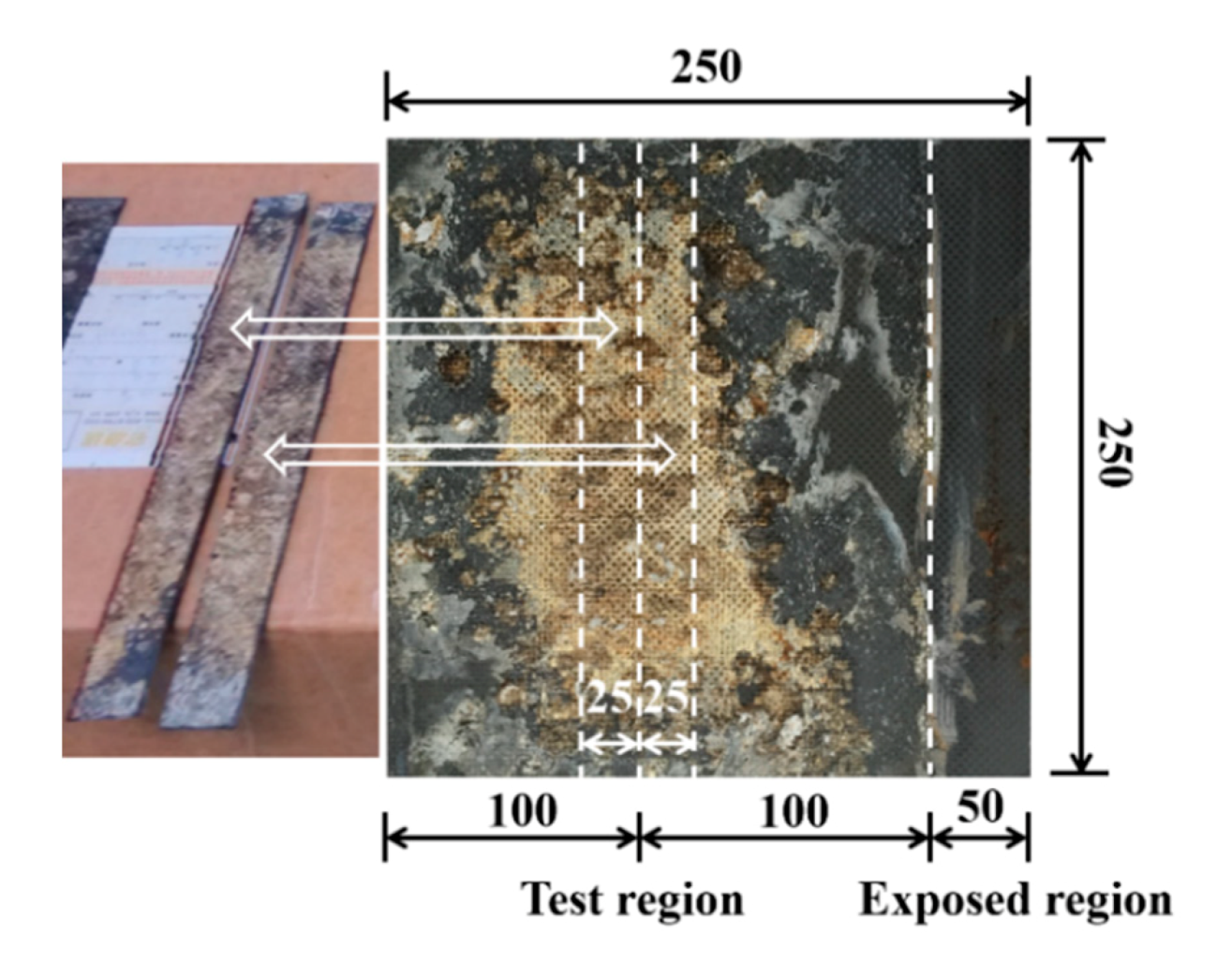

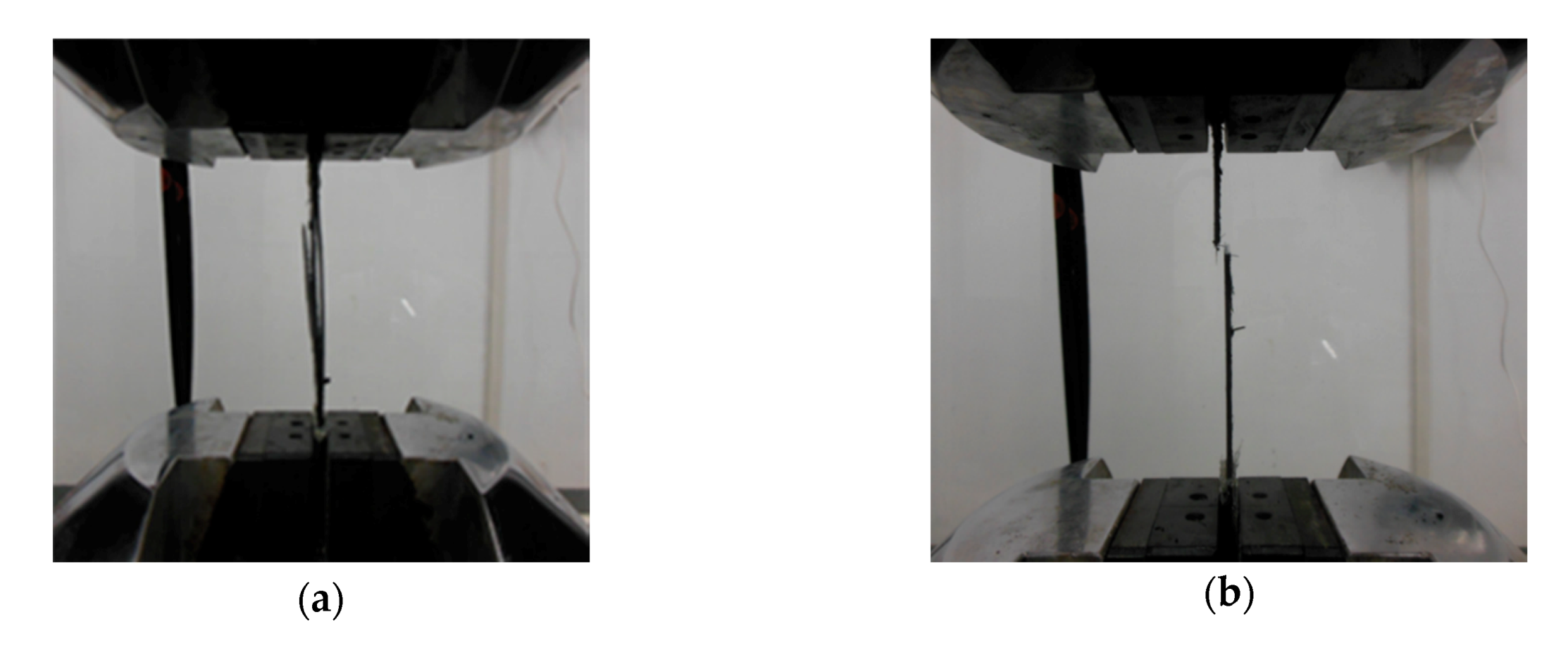

3.3.2. Degradation of CFRP

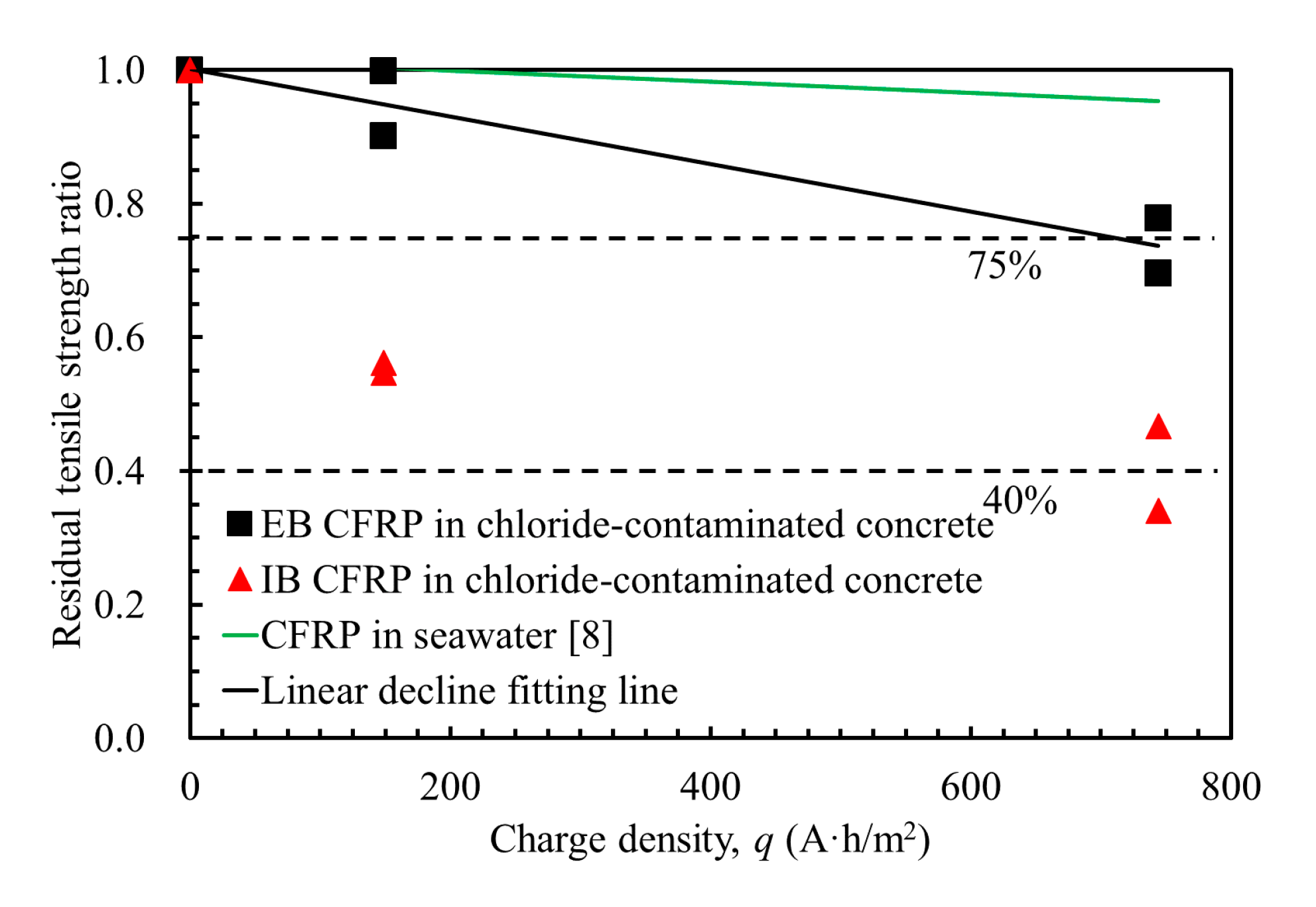

3.4. Prediction of Residual Tensile Strength of CFRP

3.5. Discussion on the Long-Term Performance of CFRP as a Dual-Functional Material in ICCP-SS

4. Conclusions

- (1)

- CFRP can be efficiently used as anode in ICCP which results in the reduction of corrosion of steel reinforcement in chloride-contaminated concrete.

- (2)

- The degradation of anodic behavior of CFRP induced by polarization in ICCP could be presented by the driving voltages.

- (3)

- The residual tensile strength of the CFRP decreased as the charge density increased, but the sufficient residual tensile strength proven that the mechanical behavior of CFRP suffered to polarization in ICCP is acceptable.

- (4)

- To adopt EB CFRP at a current density no greater than 20 mA/m2 is recommended for ICCP-SS intervention in chloride-contaminated concrete.

- (5)

- The service period of CFRP in ICCP-SS system could be longer than 42.5 years under the maximum specified applied current density of cathodic prevention for concrete structures.

Author Contributions

Funding

Conflicts of Interest

References

- Zhu, J.H.; Su, M.N.; Huang, J.Y.; Ueda, T.; Xing, F. The ICCP-SS technique for retrofitting reinforced concrete compressive members subjected to corrosion. Constr. Build. Mater. 2018, 167, 669–679. [Google Scholar] [CrossRef]

- Su, M.N.; Wei, L.L.; Zhu, J.H.; Ueda, T.; Guo, G.P.; Xing, F. Combined impressed current cathodic protection and FRCM strengthening for corrosion-prone concrete structures. J. Compos. Constr. 2019, 23, 04019021. [Google Scholar] [CrossRef]

- Su, M.N.; Wei, L.L.; Zeng, Z.W.; Ueda, T.; Xing, F.; Zhu, J.H. A solution for sea-sand reinforced concrete beams. Constr. Build. Mater. 2019, 204, 586–596. [Google Scholar] [CrossRef]

- Ghahari, S.A.; Ramezanianpour, A.M.; Ramezanianpour, A.A.; Esmaeili, M. An accelerated test method of simultaneous carbonation and chloride ion ingress: Durability of silica fume concrete in severe environments. Adv. Mater. Sci. Eng. 2016, 2016, 12. [Google Scholar] [CrossRef]

- Wang, G.; Wu, Q.; Li, X.Z.; Xu, J.; Xu, Y.; Shi, W.H.; Wang, S.L. Microscopic analysis of steel corrosion products in seawater and sea-sand concrete. Materials 2019, 12, 3330. [Google Scholar] [CrossRef]

- Hong, M.S.; So, Y.S.; Kim, J.G. Optimization of cathodic protection design for pre-insulated pipeline in district heating system using computational simulation. Materials 2019, 12, 1761. [Google Scholar] [CrossRef]

- Sun, H.F.; Wei, L.L.; Zhu, M.C.; Han, N.X.; Zhu, J.H.; Xing, F. Corrosion behavior of carbon fiber reinforced polymer anode in simulated impressed current cathodic protection system with 3% NaCl solution. Constr. Build. Mater. 2016, 112, 538–546. [Google Scholar] [CrossRef]

- Zhu, J.H.; Wei, L.L.; Moahmoud, H.; Redaelli, E.; Xing, F.; Bertolini, L. Investigation on CFRP as dual-functional material in chloride-contaminated solutions. Constr. Build. Mater. 2017, 151, 127–137. [Google Scholar] [CrossRef]

- ASTM D1141. Standard Practice for the Preparation of Substitute Ocean Water; ASTM International: West Conshohocken, PA, USA, 1998.

- BS EN 196-1. Methods of Testing Cement-Part 1: Determination of Strength; British Standard: London, UK, 1995.

- JGJ 206. Technical Code for Application of Sea Sand Concrete; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010.

- ACI 201.2R. Guide to Durable Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2008.

- BS EN 206-1. Specification, Performance, Production and Conformity; British Standard: London, UK, 2000.

- Li, W.Q.; Zhu, J.H.; Chen, P.Y.; Xing, F.; Li, D.W.; Su, M.N. Evaluation of carbon fiber reinforced cementitious matrix as a recyclable strengthening material. J. Clean. Prod. 2019, 217, 234–243. [Google Scholar] [CrossRef]

- Ghahari, S.A.; Ghafari, E.; Assi, L. Pore structure of cementitious material enhanced by graphitic nanomaterial: A critical review. Front. Struct. Civ. Eng. 2018, 12, 137–147. [Google Scholar] [CrossRef]

- NACE TM0150. Evaluation of Coatings Containing Conductive Carbon Additives for Use as an Anode on Atmospherically Exposed Reinforced Concrete; NACE International: Houston, TX, USA, 2018.

- JTS 153-2. Technique Specification for Electrochemical Anticorrosion of Reinforcement Concrete Structures in Harbour and Marine Engineering; Ministry of Transport of the People’s Republic of China: Beijing, China, 2012.

- Hladky, K. Development in Rate of Corrosion Measurements for Reinforced Concrete Structures; NACE International: Houston, TX, USA, 1989. [Google Scholar]

- ASTM C876. Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete; ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D3039/D3039M. Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2008.

- Grantham, M.; Herts, B.; Broomfield, J. The use of linear polarisation corrosion rate measurements in aiding rehabilitation options for the deck slabs of a reinforced concrete underground car park. Constr. Build. Mater. 1997, 11, 215–224. [Google Scholar] [CrossRef]

- NACE SP0290. Impressed Current Cathodic Protection of Reinforcing Steel in Atmospherically Exposed Concrete Structures; NACE International: Houston, TX, USA, 2007.

- BS EN 12696. Cathodic Protection of Steel in Concrete; British Standard: London, UK, 2016.

- Ueda, T.; Dai, J. Interface bond between FRP sheets and concrete substrates: Properties, numerical modeling and roles in member behaviour. Prog. Struct. Eng. Mater. 2005, 7, 27–43. [Google Scholar] [CrossRef]

- Vasseur, L.; Matthys, S.; Taerwe, L. An analytical study on the bond behaviour between an externally bonded FRP and concrete in the case of continuous beams. Mech. Compos. Mater. 2008, 44, 269–278. [Google Scholar] [CrossRef]

- Bilotta, A.; Ceroni, F.; Barros, J.A.; Costa, I.; Palmieri, A.; Szabó, Z.K.; Nigro, E.; Matthys, S.; Balazs, G.L.; Pecce, M. Bond of NSM FRP-strengthened concrete: Round robin test initiative. J. Compos. Constr. 2015, 20, 04015026. [Google Scholar] [CrossRef]

- Chen, P.Y.; Pei, C.; Zhu, J.H.; Su, M.N.; Xing, F. Sustainable recycling of intact carbon fibres from end-of-service-life composites. Green Chem. 2019, 21, 4757–4768. [Google Scholar] [CrossRef]

- Zhu, J.H.; Chen, P.Y.; Su, M.N.; Pei, C.; Xing, F. Recycling of carbon fibre reinforced plastics by electrically driven heterogeneous catalytic degradation of epoxy resin. Green Chem. 2019, 21, 1635–1647. [Google Scholar] [CrossRef]

- Mazzotti, C.; Savoia, M.; Ferracuti, B. A new single-shear set-up for stable debonding of FRP–concrete joints. Constr. Build. Mater. 2009, 23, 1529–1537. [Google Scholar] [CrossRef]

- Serbescu, A.; Guadagnini, M.; Pilakoutas, K. Standardised double-shear test for determining bond of FRP to concrete and corresponding model development. Compos. Part B Eng. 2013, 55, 277–297. [Google Scholar] [CrossRef]

- Chang, J. A study of the bond degradation of rebar due to cathodic protection current. Cem. Concr. Res. 2002, 32, 657–663. [Google Scholar] [CrossRef]

- Cramer, S.; Covino, B., Jr.; Bullard, S.; Holcomb, G.; Russell, J.; Nelson, F.; Laylor, H.; Soltesz, S. Corrosion prevention and remediation strategies for reinforced concrete coastal bridges. Cem. Concr. Comp. 2002, 24, 101–117. [Google Scholar] [CrossRef]

- Anwar, M.S.; Sujitha, B.; Vedalakshmi, R. Light-weight cementitious conductive anode for impressed current cathodic protection of steel reinforced concrete application. Constr. Build. Mater. 2014, 71, 167–180. [Google Scholar] [CrossRef]

- Zhang, E.Q.; Abbas, Z.; Tang, L. Predicting degradation of the anode–concrete interface for impressed current cathodic protection in concrete. Constr. Build. Mater. 2018, 185, 57–68. [Google Scholar] [CrossRef]

- Zhang, E.Q.; Tang, L.; Zack, T. Carbon fiber as anode material for cathodic prevention in cementitious materials. In Proceedings of the International Conference on Durability of Concrete Structures, Shenzhen, China, 30 June–1 July 2016. [Google Scholar]

- Pedeferri, P. Cathodic protection and cathodic prevention. Constr. Build. Mater. 1996, 10, 391–402. [Google Scholar] [CrossRef]

| Cement (kg/m3) | Simulated Seawater (kg/m3) | Standard Quartz Sand Aggregate (kg/m3) |

|---|---|---|

| 594 | 220 | 1188 |

| Square Mesh Size (mm) | Cumulative Sieve Residue (%) |

|---|---|

| 2.00 | 0 |

| 1.60 | 7 ± 5 |

| 1.00 | 33 ± 5 |

| 0.50 | 67 ± 5 |

| 0.16 | 87 ± 5 |

| 0.08 | 99 ± 1 |

| Specimens | Shapes of Embedded Steel | CFRP Bonding Methods | Current Density (mA/m2) | Residual Tensile Strength, fu (MPa) | Residual Tensile Ratio (fu/fu_RF) 1 | Failure Modes |

|---|---|---|---|---|---|---|

| RF1 | Rebar | NA 2 | NA | NA | NA | NA |

| RF2 | Plate | NA | NA | NA | NA | NA |

| RF3 | Rebar | NA | NA | NA | NA | NA |

| RF4 | Plate | NA | NA | NA | NA | NA |

| B-IB-20 | Rebar | Internally | 20 | 530 | 0.55 | Delamination |

| B-IB-100 | Rebar | Internally | 100 | 452 | 0.47 | Delamination |

| P-IB-20 | Plate | Internally | 20 | 544 | 0.56 | Delamination |

| P-IB-100 | Plate | Internally | 100 | 330 | 0.34 | Delamination |

| B-EB-20 | Rebar | Externally | 20 | 872 | 0.90 | Rupture |

| B-EB-100 | Rebar | Externally | 100 | 673 | 0.70 | Rupture |

| P-EB-20 | Plate | Externally | 20 | 967 | 0.99 | Rupture |

| P-EB-100 | Plate | Externally | 100 | 753 | 0.78 | Rupture |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, L.; Zhu, J.-H.; Dong, Z.; Liu, J.; Liu, W.; Su, M.; Xing, F. Anodic and Mechanical Behavior of Carbon Fiber Reinforced Polymer as a Dual-Functional Material in Chloride-Contaminated Concrete. Materials 2020, 13, 222. https://doi.org/10.3390/ma13010222

Wei L, Zhu J-H, Dong Z, Liu J, Liu W, Su M, Xing F. Anodic and Mechanical Behavior of Carbon Fiber Reinforced Polymer as a Dual-Functional Material in Chloride-Contaminated Concrete. Materials. 2020; 13(1):222. https://doi.org/10.3390/ma13010222

Chicago/Turabian StyleWei, Liangliang, Ji-Hua Zhu, Zhijun Dong, Jun Liu, Wei Liu, Meini Su, and Feng Xing. 2020. "Anodic and Mechanical Behavior of Carbon Fiber Reinforced Polymer as a Dual-Functional Material in Chloride-Contaminated Concrete" Materials 13, no. 1: 222. https://doi.org/10.3390/ma13010222

APA StyleWei, L., Zhu, J.-H., Dong, Z., Liu, J., Liu, W., Su, M., & Xing, F. (2020). Anodic and Mechanical Behavior of Carbon Fiber Reinforced Polymer as a Dual-Functional Material in Chloride-Contaminated Concrete. Materials, 13(1), 222. https://doi.org/10.3390/ma13010222