Greener Nanocomposite Polyurethane Foam Based on Sustainable Polyol and Natural Fillers: Investigation of Chemico-Physical and Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Foams Nanocomposite Preparations, PUs

3. Characterizations

3.1. Wide and Small Angle X-ray Scattering (WAXS/SAXS)

3.2. Infrared Spectroscopy (FTIR)

3.3. Polarized Optical Microscopy (POM)

3.4. Scanning Electron Microscopy (SEM)

3.5. Thermal Properties (Thermo-Gravimetric Analysis-TGA, Differential Scanning Calorimetric-DSC and Thermal Conductivity)

3.6. Mechanical Properties

4. Results and Discussion

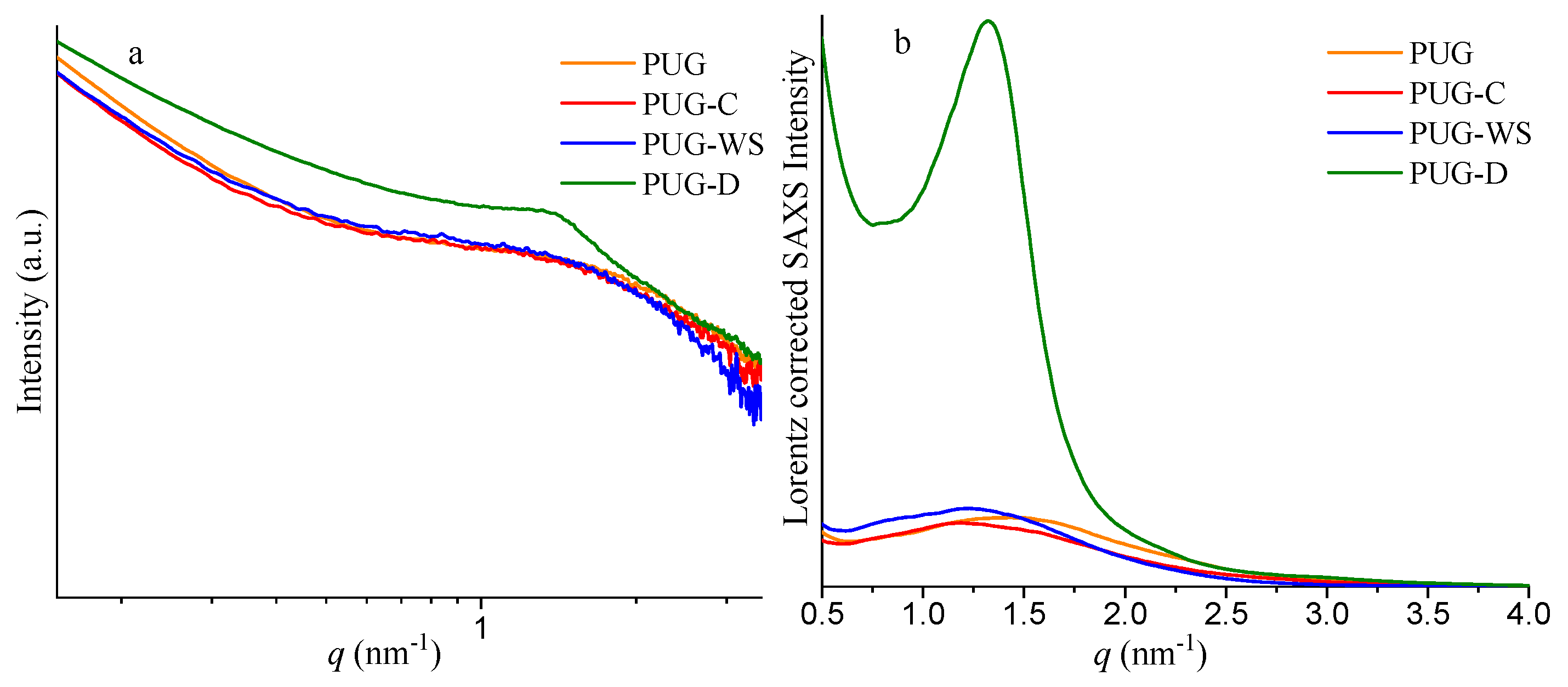

4.1. Wide and Small Angle X-ray Scattering (WAXS/SAXS) and Optical Polarized Microscopy (POM)

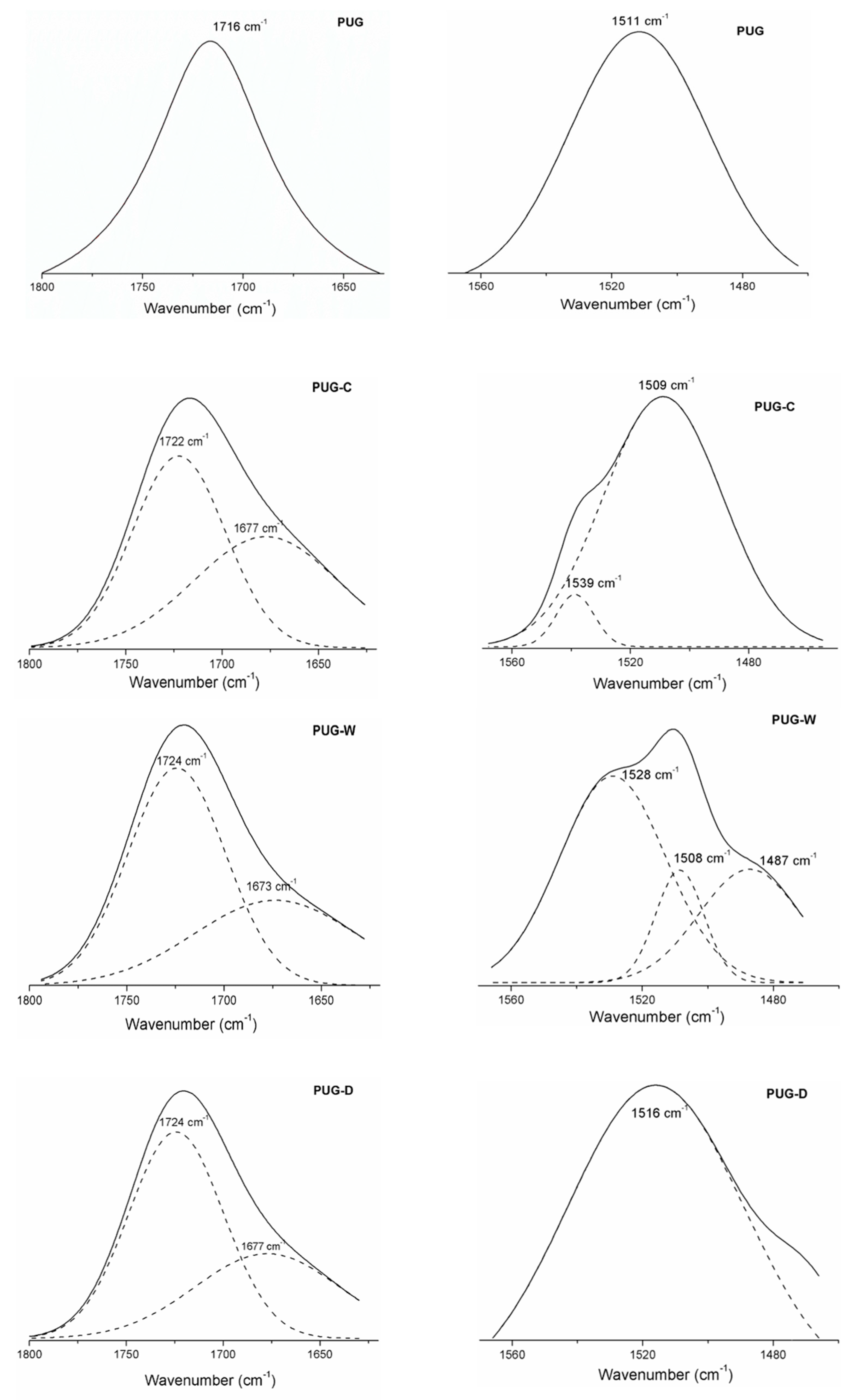

4.2. Infrared Spectroscopy (FTIR)

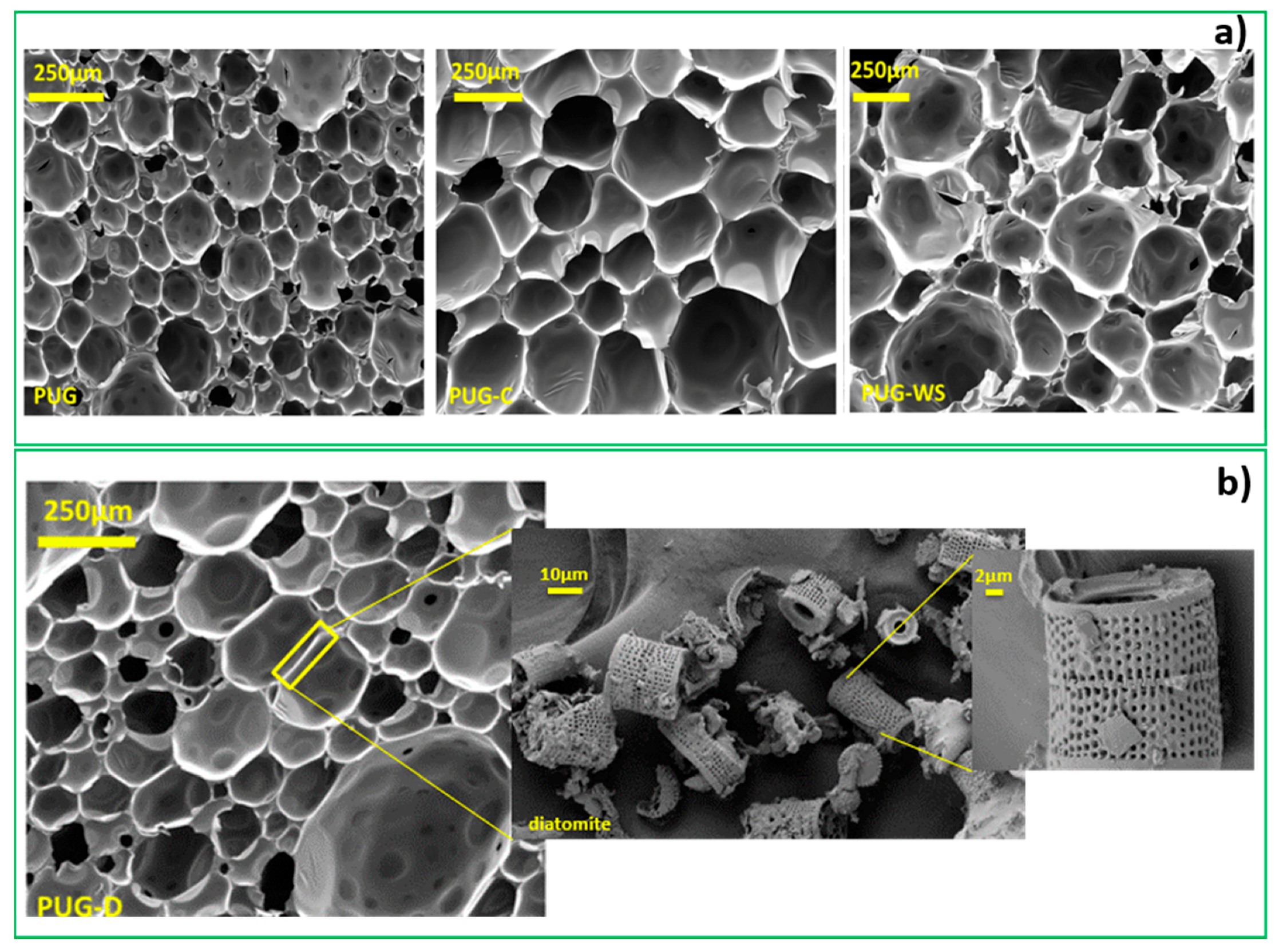

4.3. Scanning Electron Microscopy (SEM)

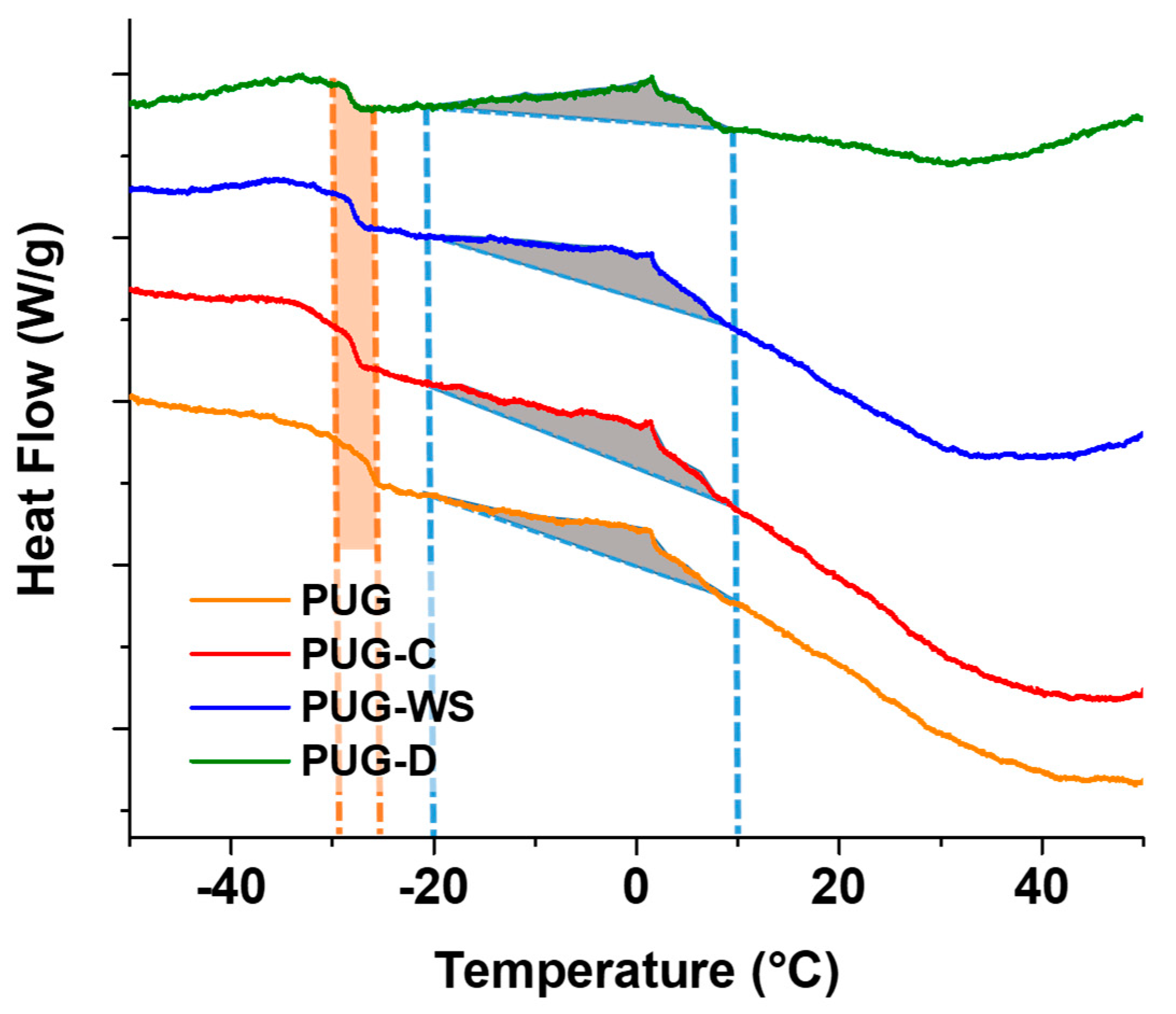

4.4. Thermal Properties (Thermo-Gravimetric Analysis-TGA, Differential Scanning Calorimetric-DSC and Thermal Conductivity)

- λ is the apparent thermal conductivity of the insulation material,

- λs is the thermal conduction through the solid structure of the pore walls,

- λg is the conduction through the gas-filled inside the pores,

- λr is the heat radiation through the cell walls,

- λc is the convention within the cells, that is negligible.

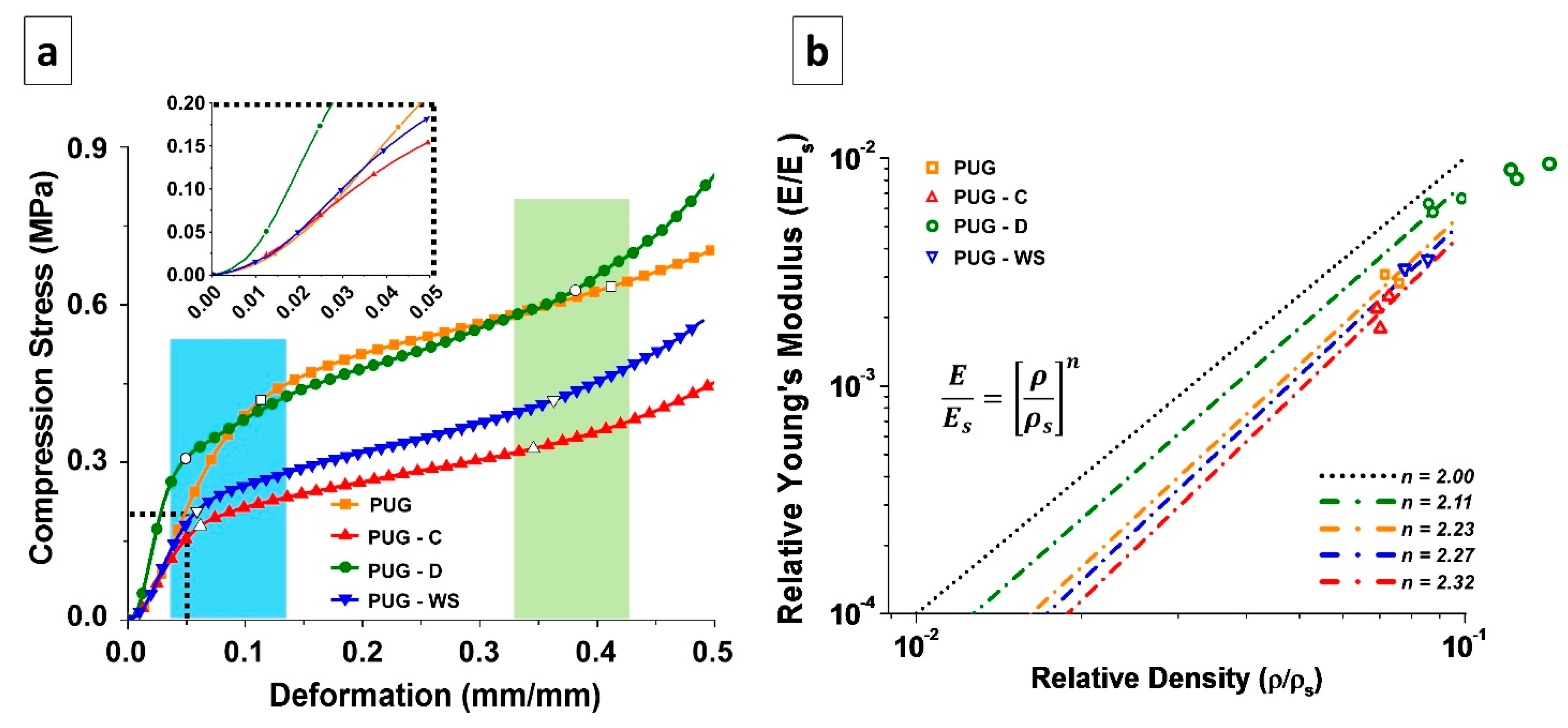

4.5. Mechanical Properties

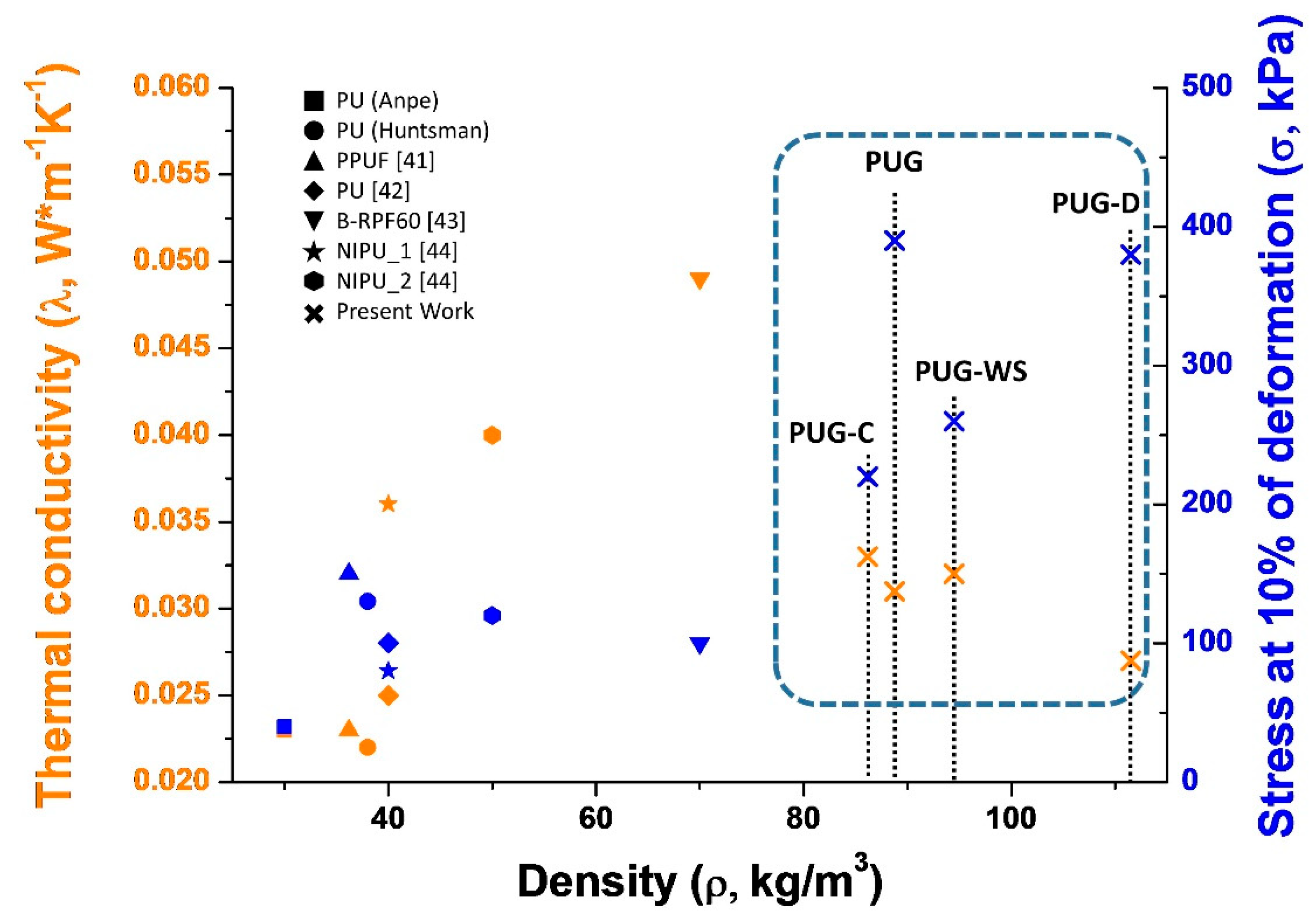

4.6. Comparison of Some Key Parameters of Selected Rigid Polyurethane Foams

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anastas, P.T.; Warner, J.C. Green Chemistry, Theory and Practice; Oxford University Press: New York, NY, USA, 1998. [Google Scholar]

- Benessere, V.; Cucciolito, M.E.; De Santis, A.; Di Serio, M.; Esposito, R.; Melchiorre, M.; Nugnes, F.; Paduano, L.; Ruffo, F. A Sustainable Process for the Production of Varnishes Based on Pelargonic Acid Esters. J. Am. Oil Chem. Soc. 2019, 96, 443–451. [Google Scholar] [CrossRef]

- Zheng, J.-L.; Zhu, Y.-H.; Zhu, M.-Q.; Sun, G.-T.; Sun, R.-C. Life-cycle assessment and techno-economic analysis of the utilization of bio-oil components for the production of three chemicals. Green Chem. 2018, 20, 3287–3301. [Google Scholar] [CrossRef]

- Cherubini, F.; Stromman, A.H. Chemicals from lignocellulosic biomass: Opportunities, perspectives, and potential of biorefinery systems. Biofuel Bioprod. Biorefin. 2011, 5, 548–561. [Google Scholar] [CrossRef]

- Cheng, H.N.; Gross, R.A.; Smith, P.B. Green Polymer Chemistry: New Products, Processes, and Applications; ACS Simposium Series; American Chemical Society: Washington, DC, USA, 2018; Volume 1310. [Google Scholar]

- Atabani, A.E.; Silitonga, A.S.; Badruddin, I.A.; Mahlia, T.M.I.; Masjuki, H.H.; Mekhilef, S. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew. Sustain. Energy Rev. 2012, 16, 2070–2093. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Džunuzović, J.V.; Stefanović, I.S.; Džunuzović, E.S.; Dapčević, A.; Šešlija, S.I.; Balanč, B.D.; Lama, G.C. Polyurethane networks based on polycaprolactone and hyperbranched polyester: Structural, thermal and mechanical investigation. Prog. Org. Coat. 2019, 137, 105305–105316. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Daver, F.; Ivanova, E.P.; Adhikari, B. Bio-based routes to synthesize cyclic carbonates and polyamines precursors of non–isocyanate polyurethanes: A review. Eur. Polym. J. 2019, 118, 668–684. [Google Scholar] [CrossRef]

- Stanzione, M.; Russo, V.; Oliviero, M.; Verdolotti, L.; Sorrentino, A.; Di Serio, M.; Tesser, R.; Iannace, S.; Lavorgna, M. Synthesis and characterization of sustainable polyurethane foams based on polyhydroxyls with different terminal groups. Polymer 2018, 149, 134–145. [Google Scholar] [CrossRef]

- Verdolotti, L.; Di Maio, E.; Lavorgna, M.; Iannace, S. Hydration-induced reinforcement of rigid polyurethane-cement foams: Mechanical and functional properties. J. Mater. Sci. 2012, 47, 6948–6957. [Google Scholar] [CrossRef]

- Verdolotti, L.; Lavorgna, M.; Lamanna, R.; Di Maio, E.; Iannace, S. Polyurethane-silica hybrid foam by sol-gel approach: Chemical and functional properties. Polymer 2015, 56, 20–28. [Google Scholar] [CrossRef]

- Suresh, K.I. Rigid Polyurethane Foams from Cardanol: Synthesis, Structural Characterization, and Evaluation of Polyol and Foam Properties. ACS Sustain. Chem. Eng. 2013, 1, 232–242. [Google Scholar] [CrossRef]

- Surech, K.I.; Kishanprasad, A.S. Synthesis, Structure, and Properties of Novel Polyols from Cardanol and Developed Polyurethanes. Ind. Eng. Chem. Res. 2005, 44, 4504–4512. [Google Scholar] [CrossRef]

- Białkowska, A.; Mucha, K.; Bakar, M.; Przybylek, M. Effect of hard segments content on the properties, structure and biodegradation of non-isocyanate polyurethane. Polym Compos. 2018, 26, 423–430. [Google Scholar] [CrossRef]

- Cornille, A.; Auvergne, R.; Figovsky, O.; Boutevin, B.; Caillol, S. A perspective approach to sustainable routes for non-isocyanate polyurethanes. Eur. Polym. J. 2017, 87, 535–552. [Google Scholar] [CrossRef]

- Carrè, C.; Ecochard, Y.; Caillol, S.; Averous, L. From the Synthesis of Biobased Cyclic Carbonate to Polyhydroxyurethanes: A Promising Route towards Renewable Non-Isocyanate Polyurethanes. ChemSusChem 2019, 12, 3410–3430. [Google Scholar]

- Queirós, C.S.G.P.; Cardoso, S.; Lourenço, A.; Ferreira, J.; Miranda, I.; Lourenço, M.J.V.; Pereira, H. Characterization of walnut, almond, and pine nut shells regarding chemical composition and extract composition. Biomass Convers. Biorefin. 2019, 1–14. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.-P.; Bohn, A. Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- Sun, X.W.; Zhang, Y.X.; Losic, D. Diatom silica, an emerging biomaterial for energy conversion and storage. J. Mater. Chem. A 2017, 19, 8847–8859. [Google Scholar] [CrossRef]

- Plyushch, A.; Zhai, T.; Xia, H.; Santillo, C.; Verdolotti, L.; Lavorgna, M.; Kuzhir, P. Ultra-light reduced graphene oxide based aerogel/foam absorber of microwave radiation. Materials 2019, 12, 213. [Google Scholar] [CrossRef]

- Lirer, S.; Flora, A.; Evangelista, A.; Verdolotti, L.; Lavorgna, M.; Iannace, S. Permeation grouting of a fine-grained pyroclastic soil. Ground Improv. 2006, 10, 135–145. [Google Scholar] [CrossRef]

- Laity, P.R.; Taylor, J.E.; Wong, S.S.; Khunkamchoo, P.; Norris, K.; Cable, M.; Andrews, G.T.; Johnson, A.F.; Cameron, R.E. A 2-dimensional small-angle X-ray scattering study of the microphase-separated morphology exhibited by thermoplastic polyurethanes and its response to deformation. Polymer 2004, 45, 5215–5232. [Google Scholar] [CrossRef]

- Neff, R.; Adedeji, A.; Macosko, C.W.; Ryan, A.J. Urea hard segment morphology in flexible polyurethane foam. J. Polym. Sci. Polym. Phys. 1998, 36, 573–581. [Google Scholar] [CrossRef]

- Koberstein, J.T.; Stein, R.S. Small-angle X-ray scattering studies of microdomain structure in segmented polyurethane elastomers. J. Polym. Sci. Polym. Phys. 1983, 21, 1439–1472. [Google Scholar] [CrossRef]

- Elwell, M.J.; Mortimer, S.; Ryan, A.J. A Synchrotron SAXS Study of Structure Development Kinetics during the Reactive Processing of Flexible Polyurethane Foam. Macromolecules 1994, 27, 5428–5439. [Google Scholar] [CrossRef]

- Ping, P.; Wang, W.; Chen, X.; Jing, X. The Influence of Hard-Segments on Two-Phase Structure and Shape Memory Properties of PCL-Based Segmented Polyurethanes. J. Polym. Sci. Polym. Phys. 2007, 45, 557–570. [Google Scholar] [CrossRef]

- Russo, P.; Lavorgna, M.; Piscitelli, F.; Acierno, D.; Di Maio, L. Thermoplastic polyurethane films reinforced with carbon nanotubes: The effect of processing on the structure and mechanical properties. Eur. Polym. J. 2013, 49, 379–388. [Google Scholar] [CrossRef]

- Zhan, Y.H.; Patel, R.; Lavorgna, M.; Piscitelli, F.; Khan, A.; Xia, H.S.; Benkreira, H.; Coates, P. Processing of polyurethane/carbon nanotubes composites using novel minimixer. Plast. Rubber Compos. 2010, 39, 400–410. [Google Scholar] [CrossRef]

- Manjula Dhevi, D.; Anand Prabu, A.; Kim, K.J. Hyperbranched polyester as a crosslinker in polyurethane formation: Real-time monitoring using in situ FTIR. Polym. Bull. 2016, 73, 2867–2888. [Google Scholar] [CrossRef]

- Das, S.; Yilgor, I.; Yilgor, E.; Wilkes, G.L. Probing the urea hard domain connectivity in segmented, non-chain extended polyureas using hydrogen-bond screening agents. Polymer 2008, 49, 174–179. [Google Scholar] [CrossRef]

- Huang, X.; De Hoop, C.F.; Xie, J.; Wu, Q.; Boldor, D.; Qi, J. High bio-content polyurethane (PU) foam made from bio-polyol and cellulose nanocrystals (CNCs) via microwave liquefaction. Mater. Des. 2018, 138, 11–20. [Google Scholar] [CrossRef]

- Capasso, I.; Liguori, B.; Verdolotti, L.; Caputo, D.; Lavorgna, M.; Tervoort, E.; Studart, A.R. Process strategy to fabricate a hierarchical porosity gradient in diatomite-based foams by 3D printing. Sci. Rep. 2020. [Google Scholar] [CrossRef]

- Verdolotti, L.; Oliviero, M.; Lavorgna, M.; Iannace, S.; Camino, G.; Vollaro, P.; Frache, A. On revealing the effect of alkaline lignin and ammonium polyphosphate additives on fire retardant properties of sustainable zein-based composites. Polym. Degrad. Stab. 2016, 134, 115–125. [Google Scholar] [CrossRef]

- Oliviero, M.; Rizvi, R.; Verdolotti, L.; Iannace, S.; Naguib, H.E.; Di Maio, E.; Neitzert, H.C.; Landi, G. Dielectric Properties of Sustainable Nanocomposites based on Zein Protein and Lignin as biodegradable insulators. Adv. Funct. Mater. 2017, 27, 1–9. [Google Scholar] [CrossRef]

- Piscitelli, F.; Buonocore, G.G.; Lavorgna, M.; Verdolotti, L.; Pricl, S.; Gentile, G.; Mascia, L. Peculiarities in the structure—Properties relationship of epoxy-silica hybrids with highly organic siloxane domains. Polymer 2015, 63, 222–229. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids—Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 2001; ISBN 0-521-49911-9. [Google Scholar]

- Ashby, M.F.; Mehl Medalist, R.F. The mechanical properties of cellular solids. Metall. Meter. Trans. A 1983, 14, 1755–1769. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F.; Schajer, G.S.; Robertson, C.I. The mechanics of two-dimensional cellular materials. Proc. R. Soc. Lond. A Math. Phys. Sci. 1982, 382, 25–42. [Google Scholar] [CrossRef]

- Michałowski, S.; Mosiewicki, M.A.; Kurańska, M.; Aranguren, M.I.; Prociak, A. Polyurethane composites synthesized using natural oil-based polyols and sisal fibers. J. Renew. Mater. 2018, 6, 426–437. [Google Scholar] [CrossRef]

- Emre, A.; Murat, E.; Erdem, U.M.; Kaya, M. Rigid polyurethane foams with halogen-free flame retardants: Thermal insulation, mechanical, and flame retardant properties. J. Appl. Polym. Sci. 2020, 137, 316–329. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, M.; Uram, K.; Lewandowski, K.; Prociak, A.; Michałowski, S. Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym. Test. 2019, 76, 90–100. [Google Scholar] [CrossRef]

- Li, B.; Zhou, M.; Huo, W.; Cai, D.; Qin, P.; Cao, H.; Tan, T. Fractionation and oxypropylation of corn-stover lignin for the production of biobased rigid polyurethane foam. Ind. Crops Prod. 2020, 143, 111887. [Google Scholar] [CrossRef]

- Pizzi, A. Tannin-Based Biofoams-A Review. J. Renew. Mater. 2019, 7, 477–492. [Google Scholar] [CrossRef]

| Sample | Polyol [wt%] | MDI [wt%] | CH3COOK [wt%] | Niax L6164 [wt%]* | Niax PM40 [wt%]* | H2O [wt%]* | Powder [wt%]* | Amount of Bio-Based Components [wt%] |

|---|---|---|---|---|---|---|---|---|

| PUG | 50 | 48 | 0.25 | 0.50 | 0.25 | 0.50 | / | 51.01 |

| PUG-C | 48 | 45 | 0.24 | 0.48 | 0.24 | 0.48 | 5 | 53.37 |

| PUG-WS | 48 | 45 | 0.24 | 0.48 | 0.24 | 0.48 | 5 | 53.37 |

| PUG-D | 48 | 45 | 0.24 | 0.48 | 0.24 | 0.48 | 5 | 53.37 |

| Sample | qmax (nm−1) | L (nm) | Q |

|---|---|---|---|

| PUG | 1.42 | 4.42 | 0.022 |

| PUG-C | 1.18 | 5.32 | 0.018 |

| PUG-WS | 1.22 | 5.15 | 0.020 |

| PUG-D | 1.32 | 4.76 | 0.102 |

| Assignment | Groups Assignment | Wavenumber [cm−1] | |||

|---|---|---|---|---|---|

| PUG | PUG-C | PUG-W | PUG-D | ||

| υas C-N and δ N-H | Urethane linkages | 1511 | 1509 | 1508 | 1516 |

| υas C-N and δ N-H | Urea linkages | - | 1539 | 1528 | - |

| Aromatic ring vibration | Urethane structure | 1594 | 1594 | 1595 | 1593 |

| υs C=O | Urea bidentate | 1611 | 1611 | 1611 | 1602 |

| υs C=O | f-C=O urea | - | 1677 | 1673 | 1677 |

| υs C=O | H-C=O urethane | 1716 | - | - | - |

| υs C=O | f-C=O urethane | - | 1722 | 1724 | 1724 |

| Sample | Degradation Temperature [°C] | Weight Residues T [wt%] | λ [W/mK] | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Tmax1 | Tmax2 | Tmax3 | Tchar | Tmax1 | Tmax2 | Tmax3 | Tchar | ||

| PUG | 222 | 311 | 406 | 800 | 5.38 | 24.75 | 15.89 | 18.8 | 0.031 |

| PUG-C | 222 | 317 | 451 | 800 | 5.6 | 37.8 | 43.5 | 17.1 | 0.033 |

| PUG-W | 222 | 316 | 451 | 800 | 7 | 30 | 42 | 21 | 0.032 |

| PU-D | 270 | 310 | 440 | 800 | 13 | 24.6 | 40 | 22.4 | 0.027 |

| Sample | Tg [°C] | Tcc [°C] | ΔH [J/g] |

|---|---|---|---|

| PUG | −26.25 | 1.34 | 1.364 |

| PUG-C | −27.78 | 1.39 | 1.821 |

| PUG-WS | −27.54 | 1.48 | 1.934 |

| PUG-D | −28.35 | 1.53 | 1.614 |

| Sample | Young’s Modulus (E) [MPa] | Density (ρ) [kg/m3] | Cell Wall Density (ρs) [kg/m3] | Stress at 10% deformation (σ10) [MPa] | Plateau Modulus (Epl) [MPa] |

|---|---|---|---|---|---|

| PUG | 4.730 ± 0.29 | 88.75 ± 2.66 | 1200 | 0.39 ± 0.02 | 0.621 ± 0.028 |

| PUG-C | 3.431 ± 0.547 | 86.17 ± 2.08 | 1212 | 0.22 ± 0.04 | 0.446 ± 0.036 |

| PUG-WS | 5.501 ± 0.360 | 94.48 ± 4.69 | 1150 | 0.26 ± 0.04 | 0.587 ± 0.059 |

| PUG-D | 9.996 ± 0.690 | 111.53 ± 8.66 | 1229 | 0.38 ± 0.02 | 0.753 ± 0.004 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Luca Bossa, F.; Santillo, C.; Verdolotti, L.; Campaner, P.; Minigher, A.; Boggioni, L.; Losio, S.; Coccia, F.; Iannace, S.; Lama, G.C. Greener Nanocomposite Polyurethane Foam Based on Sustainable Polyol and Natural Fillers: Investigation of Chemico-Physical and Mechanical Properties. Materials 2020, 13, 211. https://doi.org/10.3390/ma13010211

De Luca Bossa F, Santillo C, Verdolotti L, Campaner P, Minigher A, Boggioni L, Losio S, Coccia F, Iannace S, Lama GC. Greener Nanocomposite Polyurethane Foam Based on Sustainable Polyol and Natural Fillers: Investigation of Chemico-Physical and Mechanical Properties. Materials. 2020; 13(1):211. https://doi.org/10.3390/ma13010211

Chicago/Turabian StyleDe Luca Bossa, Ferdinando, Chiara Santillo, Letizia Verdolotti, Pietro Campaner, Andrea Minigher, Laura Boggioni, Simona Losio, Francesca Coccia, Salvatore Iannace, and Giuseppe C. Lama. 2020. "Greener Nanocomposite Polyurethane Foam Based on Sustainable Polyol and Natural Fillers: Investigation of Chemico-Physical and Mechanical Properties" Materials 13, no. 1: 211. https://doi.org/10.3390/ma13010211

APA StyleDe Luca Bossa, F., Santillo, C., Verdolotti, L., Campaner, P., Minigher, A., Boggioni, L., Losio, S., Coccia, F., Iannace, S., & Lama, G. C. (2020). Greener Nanocomposite Polyurethane Foam Based on Sustainable Polyol and Natural Fillers: Investigation of Chemico-Physical and Mechanical Properties. Materials, 13(1), 211. https://doi.org/10.3390/ma13010211