Cyclic Response of Steel Fiber Reinforced Concrete Slender Beams: An Experimental Study

Abstract

:1. Introduction

1.1. Compression and Tensile Behavior of Steel Fiber Reinforced Concrete (SFRC)

1.2. Reinforced Concrete (RC) Structural Members with Steel Fibers in Shear and/or Flexure

1.3. Cyclic Response of Reinforced Concrete (RC) Structural Members with Steel Fibers

1.4. Research Significance

2. Steel Fiber Reinforced Concrete

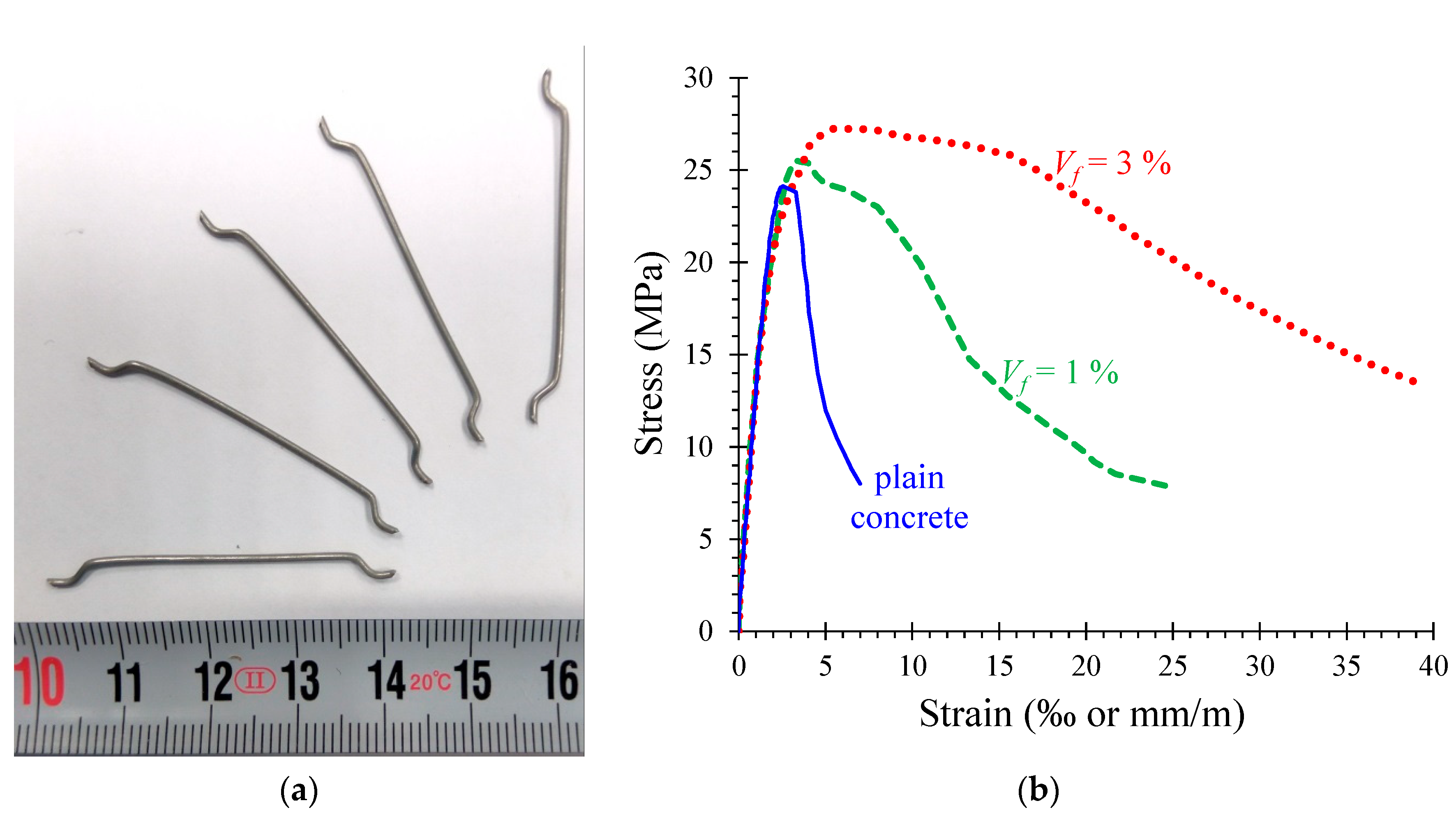

2.1. Materials

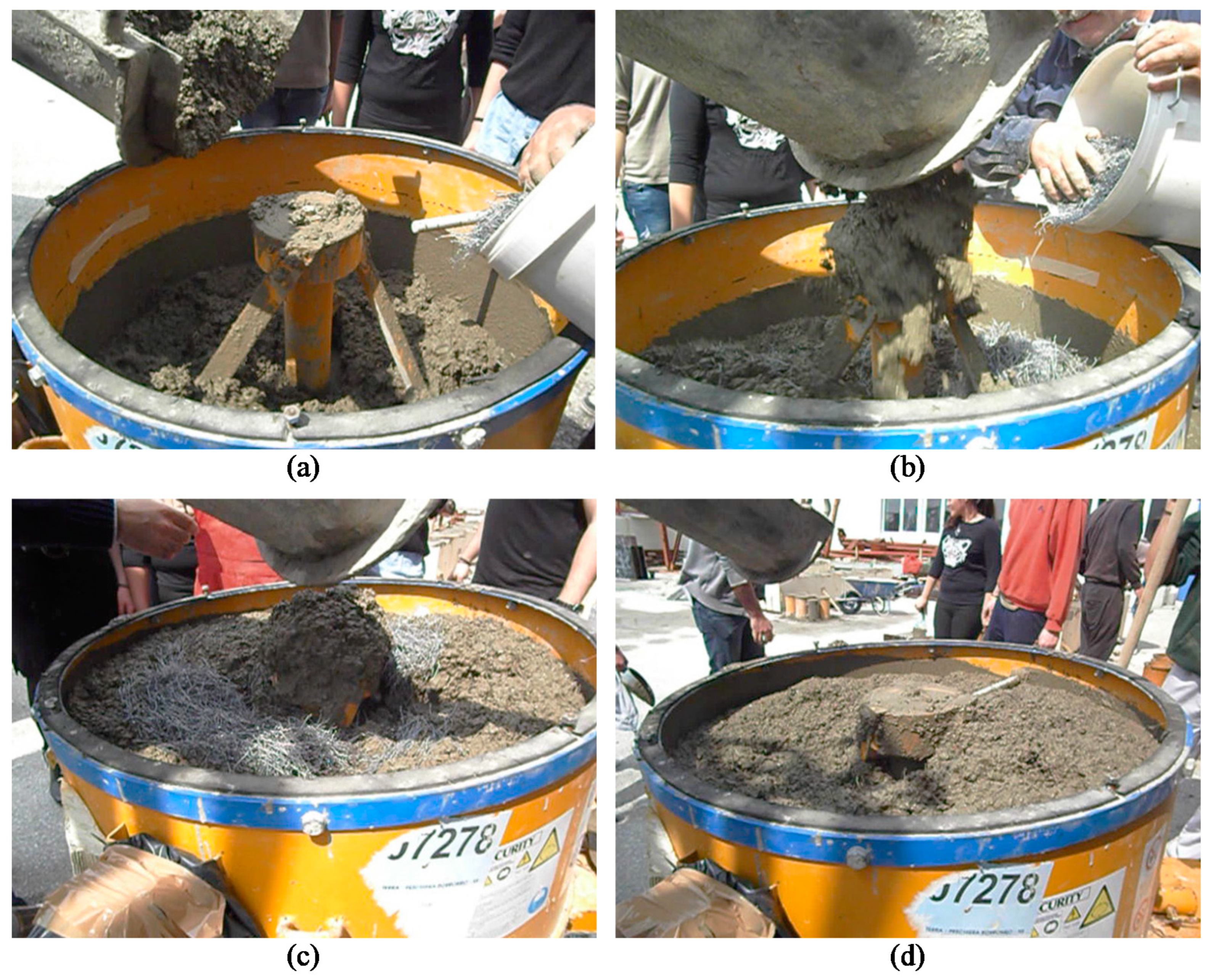

2.2. Mix Preparation

2.3. Compression and Splitting Tests

3. Experimental Program of the Cyclic Tests

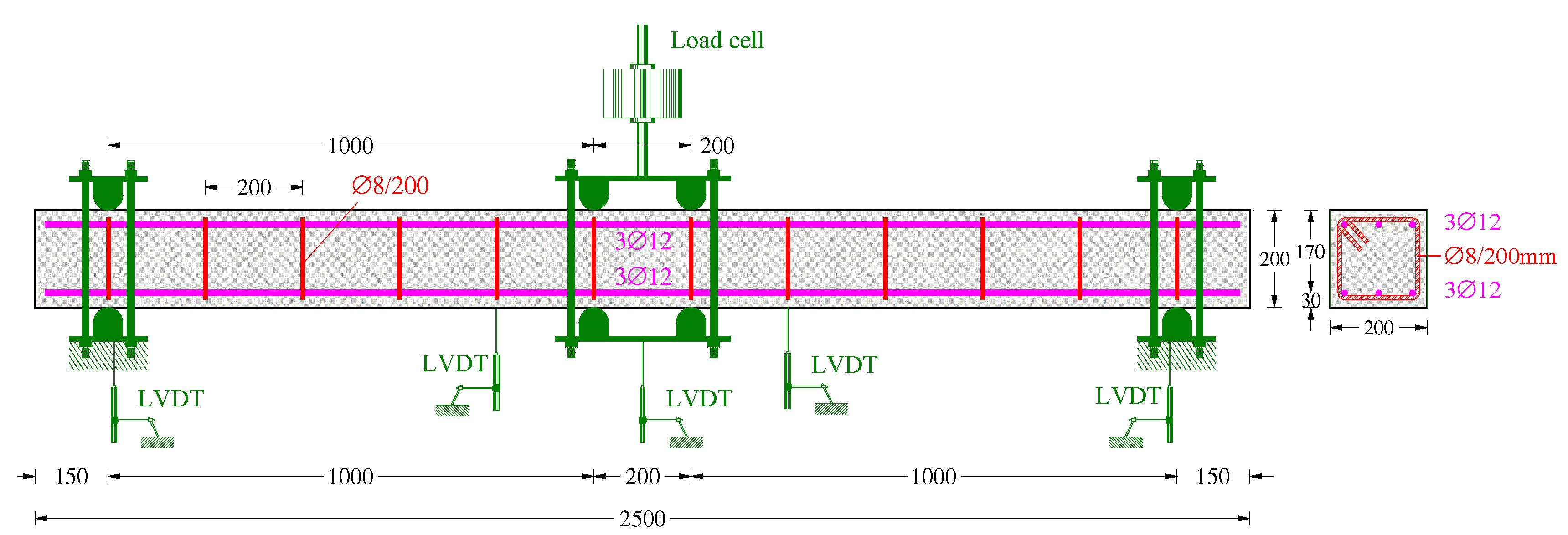

3.1. Specimens’ Characteristics

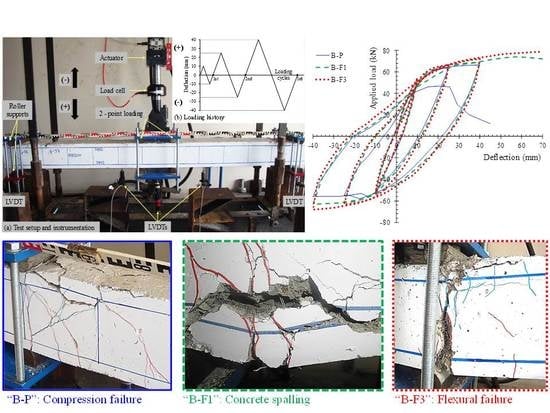

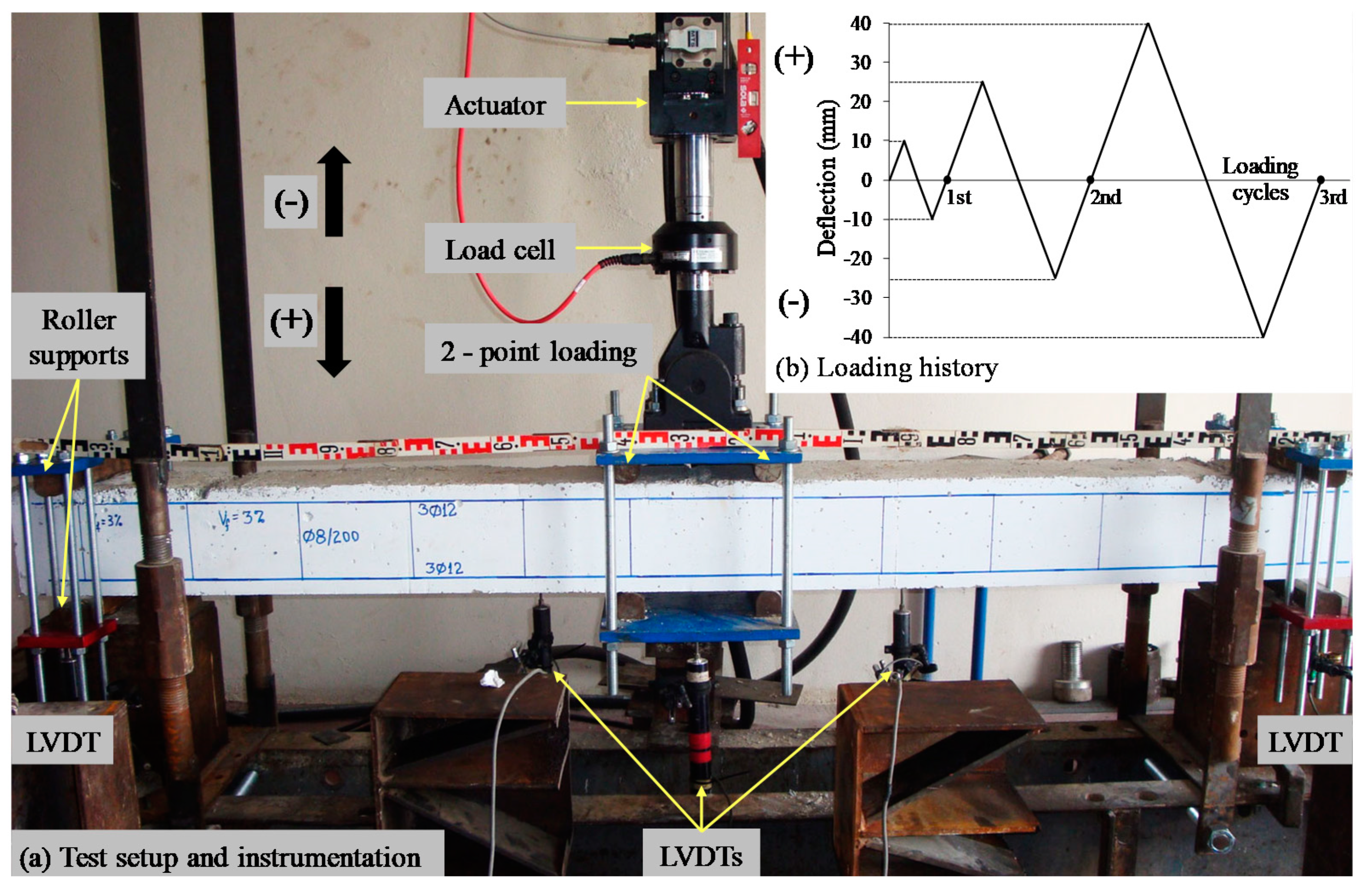

3.2. Experimental Setup and Instrumentation

4. Test Results

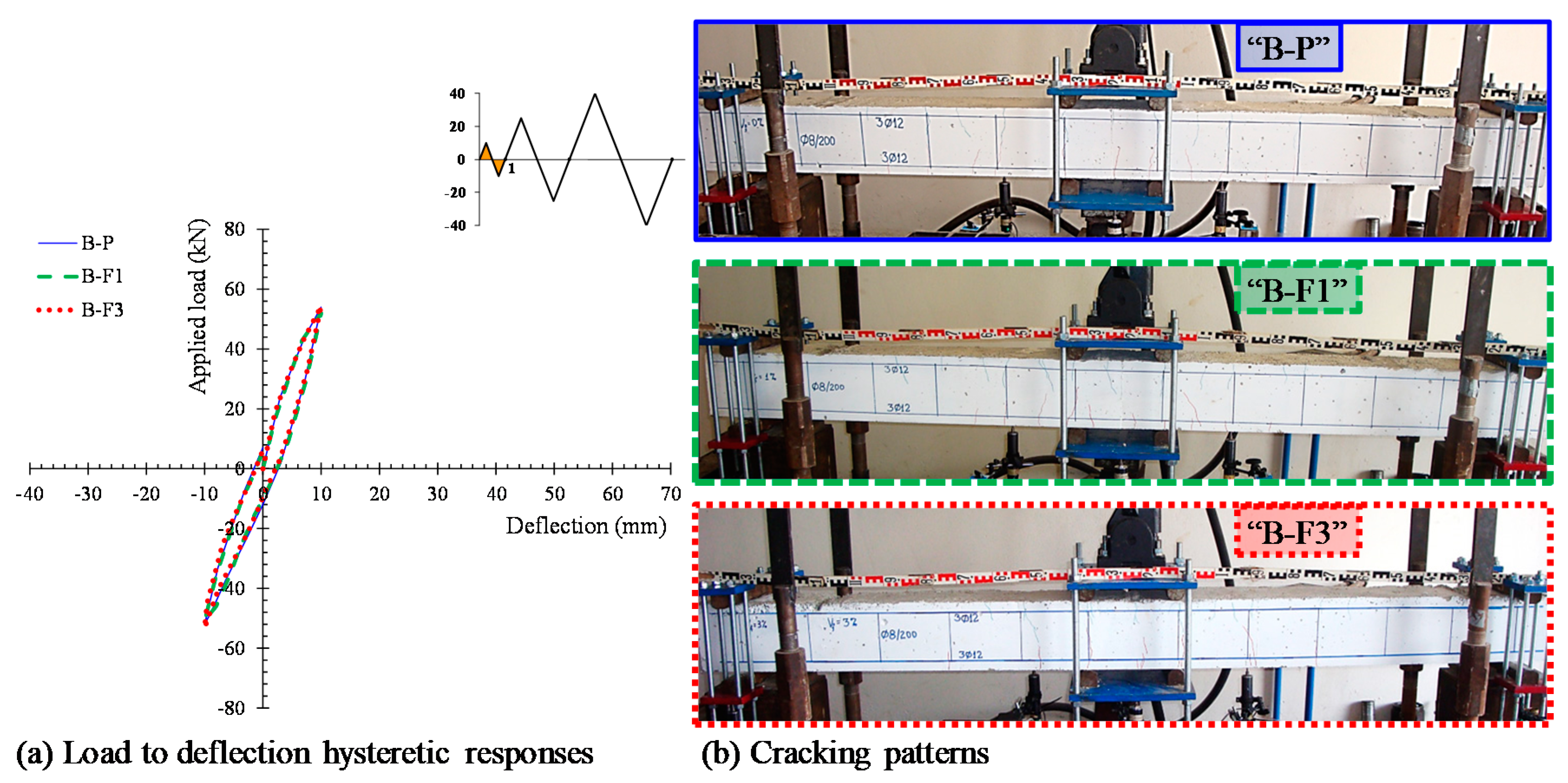

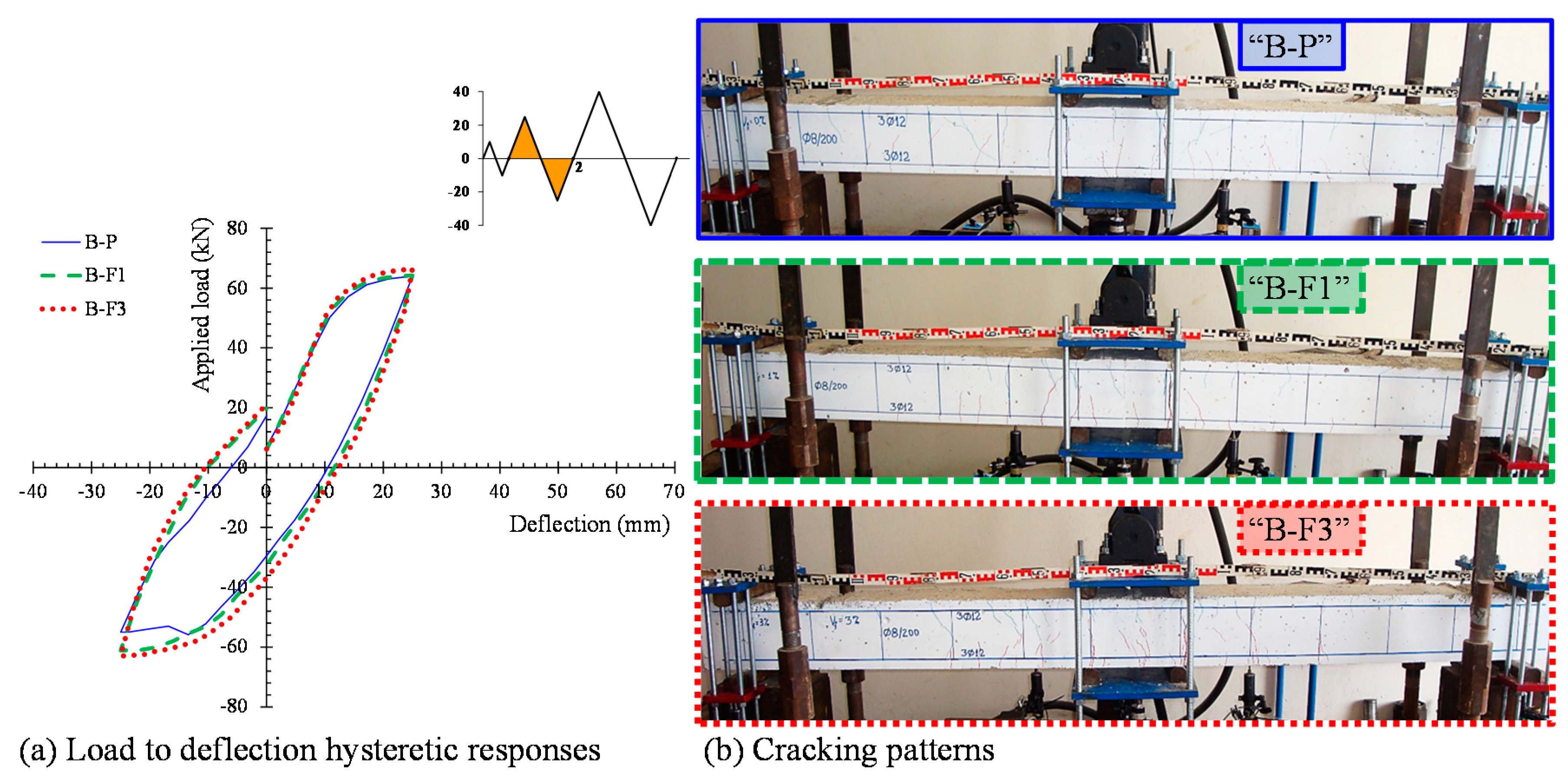

4.1. Beam “B-P”

4.2. Beam “B-F1”

4.3. Beam “B-F3”

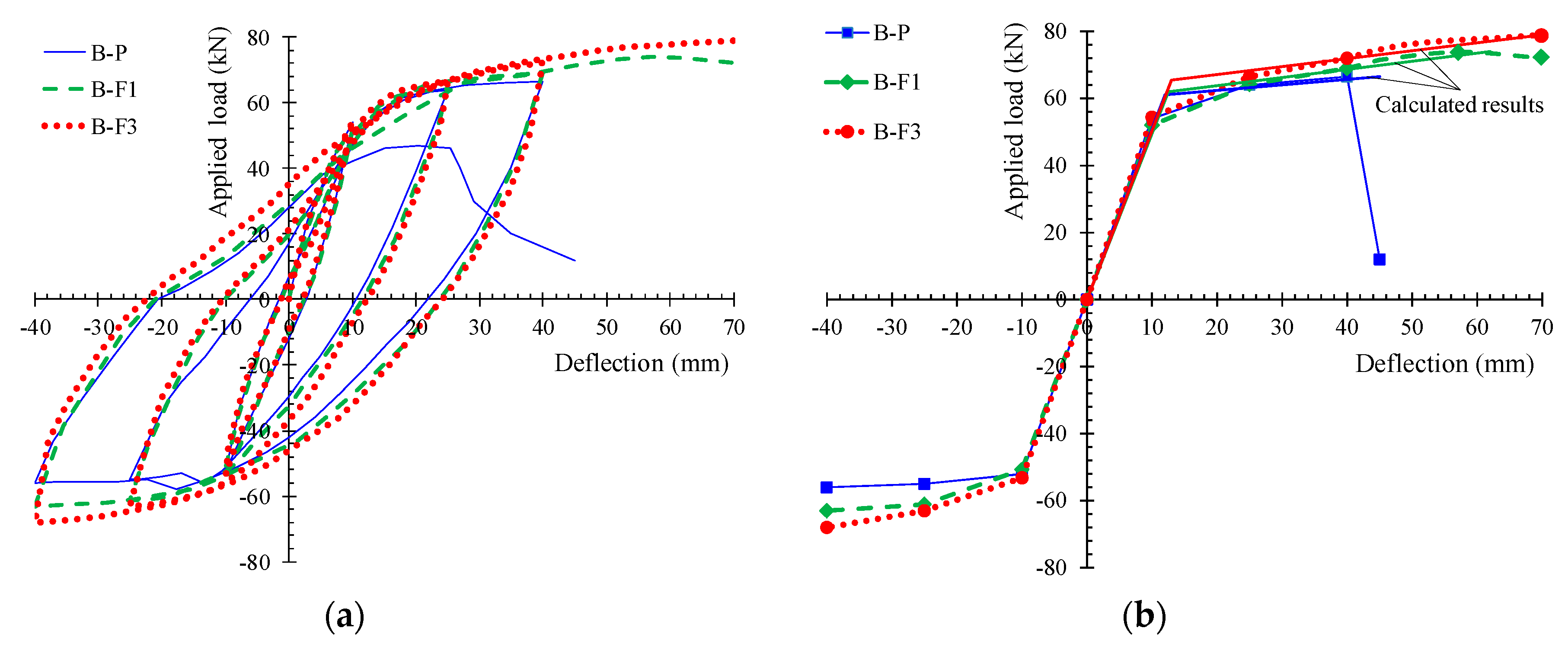

5. Comparisons and Discussion of Test Results

6. Experimental Database and Comparisons

7. Concluding Remarks

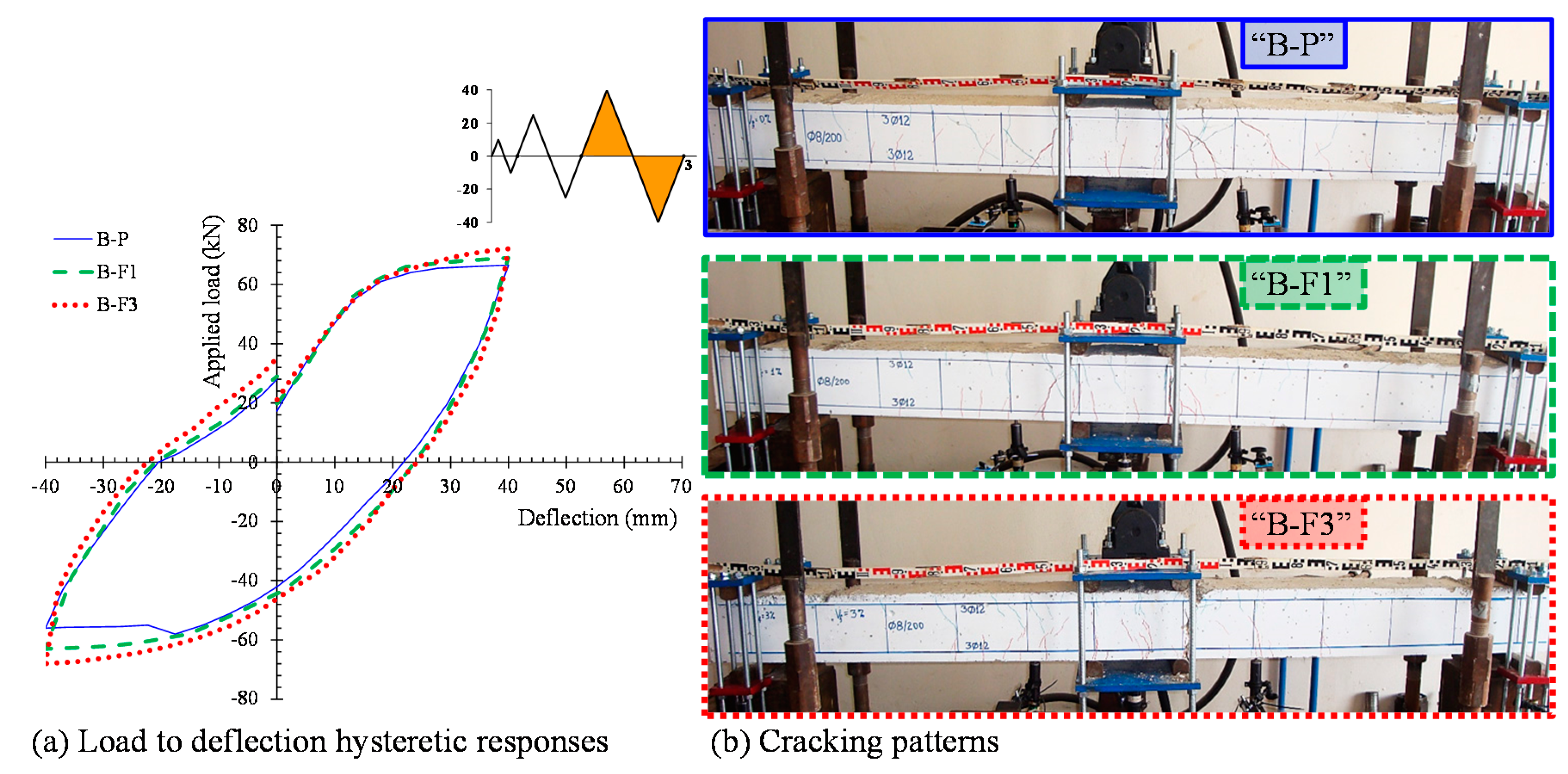

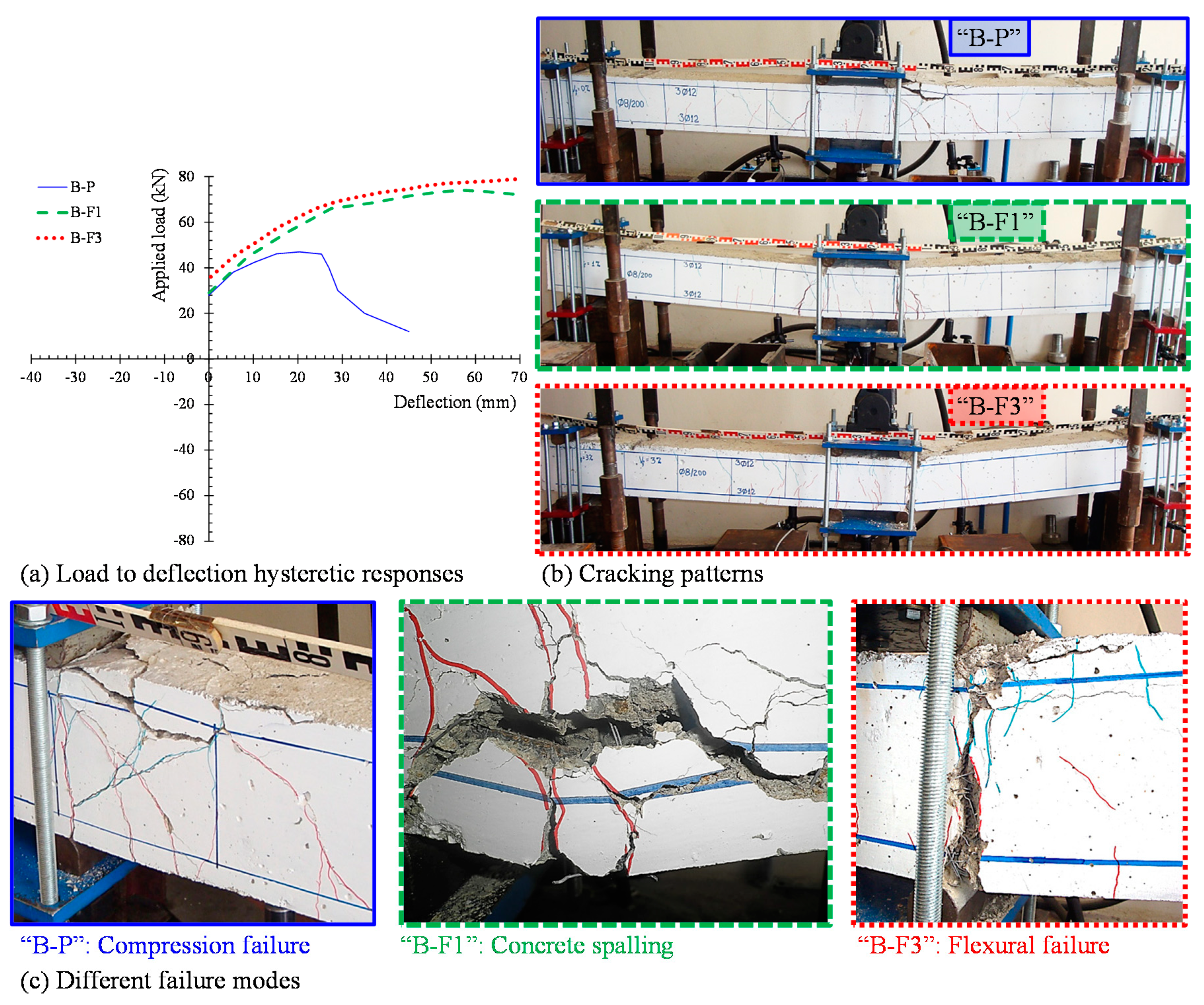

- Based on the hysteretic responses, the cracking, and the failure modes of the tested beams, it can be deduced that the overall performance of the RC beams with steel fibers was improved with respect to the behavior of the reference specimen without fibers, confirming most of the known aspects.

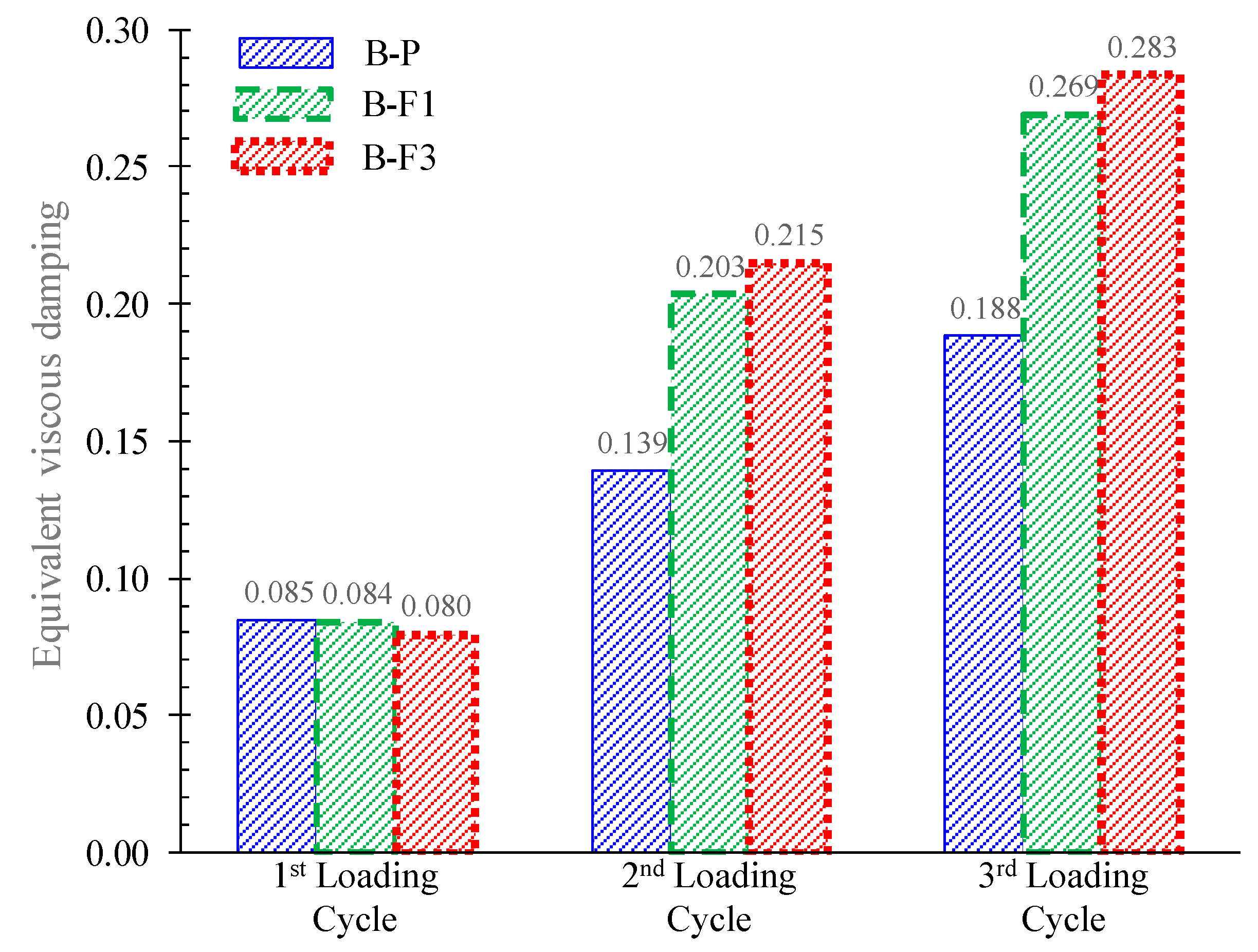

- The non-fibrous reference specimen demonstrated shear diagonal cracking failing in a rather brittle manner, whereas the SFRC beam with 1% steel fibers failed after concrete spalling with satisfactory ductility. Moreover, it is stressed that the SFRC beam with 3% steel fibers exhibited an improved cyclic response, since no inclined cracks of shear nature or concrete spalling were observed along the length of the beam that failed due to flexure with significant ductility.

- The lower amount of the steel fibers seemed to be inefficient to bridge the tensile cracks developed at the level of the longitudinal reinforcing bars due to the degradation of the steel–concrete bond performance and, consequently, SFRC demonstrated concrete spalling. The addition of a higher volume fraction of steel fibers (3%) prevented the propagation of horizontal cracking, resulting in a pronounced flexural failure with enhanced post-peak hysteretic behavior in terms of strength, ductility, cracking performance, absorbed energy capability, and equivalent viscous damping.

- The obtained increase of the first cracking load due to the addition of steel fibers in dosage 1% and 3% was found to be 25% and 47%, respectively. Further, although the increase of the ultimate load during the third cycle of the SFRC beams with 1% and 3% fibers was only 4% and 8%, respectively (downward loading direction), and 13% and 21%, respectively (upward loading direction), compared to the reference beam, the increase of the load-bearing capacity at failure was 61% and 72% for the SFRC beams with 1% and 3% steel fibers, respectively.

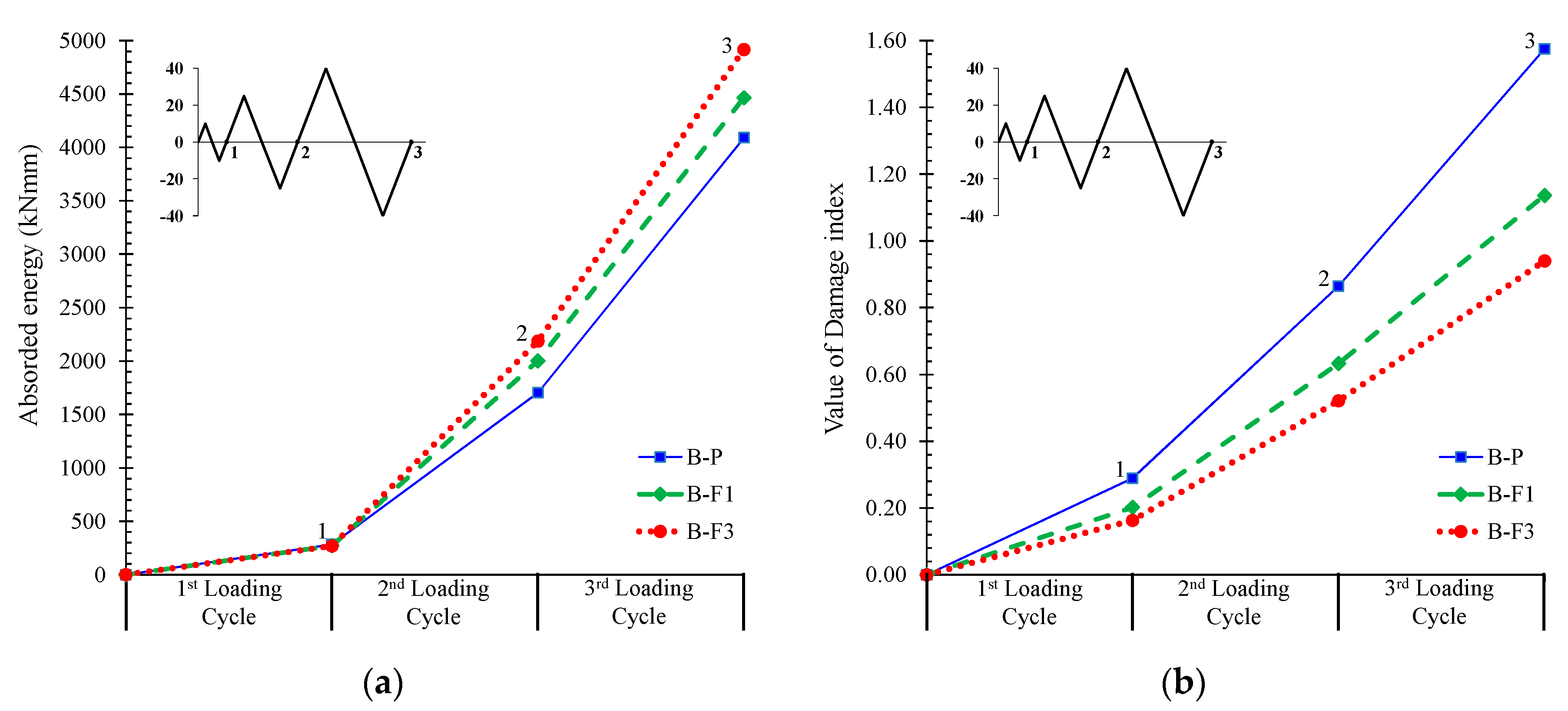

- Based on the calculated values of damage indices, it can be deduced that the fibrous beams presented lower damage index factors than the corresponding non-fibrous reference specimen. Further, the SFRC beam containing 3% steel fibers exhibited a considerable lower damage level regarding the reference specimen even from the first loading cycle.

- A systematic report of an experimental database consisting of 39 beams tested under cyclic loading was also presented in order to clarify the effectiveness of steel fibers and their role on the hysteretic response and the failure mode of RC structural members. Although the amount of the examined specimens was rather limited to derive sound conclusions, it was found that the favorable influence of steel fibers on the overall performance can be achieved by taking extra care to choose the right thickness of concrete cover with a rather high amount of steel fibers (1.5% seems an appropriate lower volume content level of steel fibers).

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wang, R.; Gao, X. Relationship between flowability, entrapped air content and strength of UHPC mixtures containing different dosage of steel fiber. Appl. Sci. 2016, 6, 216. [Google Scholar] [CrossRef]

- Caggiano, A.; Gambarelli, S.; Martinelli, E.; Nisticò, N.; Pepe, M. Experimental characterization of the post-cracking response in hybrid steel/polypropylene fiber-reinforced concrete. Constr. Build. Mater. 2016, 125, 1035–1043. [Google Scholar] [CrossRef]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of hybrid fiber reinforced concrete with recycled and industrial steel fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Simoes, T.; Octavio, C.; Valença, J.; Costa, H.; Dias-da-Costa, D.; Júlio, E. Influence of concrete strength and steel fiber geometry on the fiber/matrix interface. Compos. Part B Eng. 2017, 122, 156–164. [Google Scholar] [CrossRef]

- Smarzewski, P. Effect of curing period on properties of steel and polypropylene fiber reinforced ultra-high performance concrete. Mater. Sci. Eng. 2017, 245. [Google Scholar] [CrossRef]

- Shon, C.-S.; Mukashev, T.; Lee, D.; Zhang, D.; Kim, J.R. Can common reed fiber become an effective construction material? Physical, mechanical, and thermal properties of mortar mixture containing common reed fiber. Sustainability 2019, 11, 903. [Google Scholar] [CrossRef]

- Rizzuti, L.; Bencardino, F. Effects of fiber volume fraction on the compressive and flexural experimental behavior of SFRC. Contemp. Eng. Sci. 2014, 7, 379–390. [Google Scholar] [CrossRef]

- Lee, S.-C.; Oh, J.-H.; Cho, J.-Y. Compressive behavior of fiber-reinforced concrete with end-hooked steel fibers. Materials 2015, 8, 1442–1458. [Google Scholar] [CrossRef]

- Perceka, W.; Liao, W.-C.; Wang, Y.-D. High strength concrete columns under axial compression load: Hybrid confinement efficiency of high strength transverse reinforcement and steel fibers. Materials 2016, 9, 264. [Google Scholar] [CrossRef]

- Song, W.; Yin, J. Hybrid effect evaluation of steel fiber and carbon fiber on the performance of the fiber reinforced concrete. Materials 2016, 9, 704. [Google Scholar] [CrossRef] [PubMed]

- Chalioris, C.E.; Liotoglou, F.A. Tests and simplified behavioral model for steel fibrous concrete under compression. In Advances in Civil Engineering and Building Materials IV; Chang, S.-Y., Al Bahar, S.K., Husain, A.-A.M., Zhao, J., Eds.; CRC Press/Balkema: Leiden, The Netherlands, 2015; pp. 195–199. [Google Scholar]

- Saidani, M.; Saraireh, D.; Gerges, M. Behavior of different types of fiber reinforced concrete without admixture. Eng. Struct. 2016, 113, 328–334. [Google Scholar] [CrossRef]

- Bencardino, F.; Rizzuti, L.; Spadea, G.; Swamy, R.N. Implications of test methodology on post-cracking and fracture behavior of steel fiber reinforced concrete. Compos. Part B Eng. 2013, 46, 31–38. [Google Scholar] [CrossRef]

- Caggiano, A.; Cremona, M.; Faella, C.; Lima, C.; Martinelli, E. Fracture behavior of concrete beams reinforced with mixed long/short steel fibers. Constr. Build. Mater. 2012, 37, 832–840. [Google Scholar] [CrossRef]

- Smarzewski, P.; Barnat-Hunek, D. Fracture properties of plain and steel-polypropylene fiber reinforced high-performance concrete. Mater. Technol. 2015, 49, 563–571. [Google Scholar]

- Simoes, T.; Costa, H.; Dias-da-Costa, D.; Júlio, E. Influence of fibers on the mechanical behavior of fiber reinforced concrete matrixes. Constr. Build. Mater. 2017, 137, 548–556. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N.; Lee, J.-Y.; Yoon, Y.-S. Effect of fiber geometric property on rate dependent flexural behavior of ultra-high-performance cementitious composite. Cem. Concr. Compos. 2018, 86, 57–71. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Karayannis, C.G. Effectiveness of the use of steel fibers on the torsional behavior of flanged concrete beams. Cem. Concr. Compos. 2009, 31, 331–341. [Google Scholar] [CrossRef]

- Lin, W.-T.; Wu, Y.-C.; Cheng, A.; Chao, S.-J.; Hsu, H.-M. Engineering properties and correlation analysis of fiber cementitious materials. Materials 2014, 7, 7423–7435. [Google Scholar] [CrossRef]

- Xue, W.; Chen, J.; Xie, F.; Feng, B. Orientation of steel fibers in magnetically driven concrete and mortar. Materials 2018, 11, 170. [Google Scholar] [CrossRef] [PubMed]

- Choi, M.S.; Kang, S.-T.; Lee, B.Y.; Koh, K.-T.; Ryu, G.-S. Improvement in predicting the post-cracking tensile behavior of ultra-high performance cementitious composites based on fiber orientation distribution. Materials 2016, 9, 829. [Google Scholar] [CrossRef]

- Herrmann, H.; Pastorelli, E.; Kallonen, A.; Suuronen, J.-P. Methods for fiber orientation analysis of X-ray tomography images of steel fiber reinforced concrete (SFRC). J. Mater. Sci. 2016, 51, 3772–3783. [Google Scholar] [CrossRef]

- Trofimov, A.; Mishurova, T.; Lanzoni, L.; Radi, E.; Bruno, G.; Sevostianov, I. Microstructural analysis and mechanical properties of concrete reinforced with polymer short fibers. Int. J. Eng. Sci. 2018, 133, 210–218. [Google Scholar] [CrossRef]

- Eik, M.; Puttonen, J.; Herrmann, H. The effect of approximation accuracy of the orientation distribution function on the elastic properties of short fiber reinforced composites. Compos. Struct. 2016, 148, 12–18. [Google Scholar] [CrossRef]

- Mishurova, T.; Rachmatulin, N.; Fontana, P.; Oesch, T.; Bruno, G.; Radi, E.; Sevostianov, I. Evaluation of the probability density of inhomogeneous fiber orientations by computed tomography and its application to the calculation of the effective properties of a fiber-reinforced composite. Int. J. Eng. Sci. 2018, 122, 14–29. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fiber Reinforced Cementitious Composites: Modern Concrete Technology Series, 2nd ed.; Taylor & Francis: New York, NY, USA, 2007; p. 624. [Google Scholar]

- Olivito, R.S.; Zuccarello, F.A. An experimental study on the tensile strength of steel fiber reinforced concrete. Compos. Part B Eng. 2010, 41, 246–255. [Google Scholar] [CrossRef]

- Karayannis, C.G. Nonlinear analysis and tests of steel-fiber concrete beams in torsion. Struct. Eng. Mech. 2000, 9, 323–338. [Google Scholar] [CrossRef]

- Naaman, A.E. Engineered steel fibers with optimal properties for reinforcement of cement composites. J. Adv. Concr. Technol. 2003, 1, 241–252. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Panagiotopoulos, T.A. Flexural analysis of steel fiber-reinforced concrete members. Comput. Concr. 2018, 22, 11–25. [Google Scholar]

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of strain hardening ultra-high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- Ding, X.; Li, C.; Han, B.; Lu, Y.; Zhao, S. Effects of different deformed steel-fibers on preparation and properties of self-compacting SFRC. Constr. Build. Mater. 2018, 168, 471–481. [Google Scholar] [CrossRef]

- Guerini, V.; Conforti, A.; Plizzari, G.A.; Kawashima, S. Influence of steel and macro-synthetic fibers on concrete properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiao, Y.; Gu, A.; Lu, Z. Dispersion, workability and mechanical properties of different steel-microfiber-reinforced concretes with low fiber content. Sustainability 2018, 10, 2335. [Google Scholar] [CrossRef]

- Caggiano, A.; Xargay, H.; Folino, P.; Martinelli, E. Experimental and numerical characterization of the bond behavior of steel fibers recovered from waste tires embedded in cementitious matrices. Cem. Concr. Compos. 2015, 62, 146–155. [Google Scholar] [CrossRef]

- Montero-Chacón, F.; Cifuentes, H.; Medina, F. Mesoscale characterization of fracture properties of steel fiber-reinforced concrete using a lattice–particle model. Materials 2017, 10, 207. [Google Scholar] [CrossRef]

- Caggiano, A.; Martinelli, E. A unified formulation for simulating the bond behavior of fibers in cementitious materials. Mater. Des. 2012, 42, 204–213. [Google Scholar] [CrossRef]

- Vougioukas, E.; Papadatou, M. A model for the prediction of the tensile strength of fiber-reinforced concrete members, before and after cracking. Fibers 2017, 5, 27. [Google Scholar] [CrossRef]

- Shannag, M.J.; Brincker, R.; Hansen, W. Pullout behavior of steel fibers from cement-based composites. Cem. Concr. Res. 1997, 27, 925–936. [Google Scholar] [CrossRef]

- Karayannis, C.G. Analysis and experimental study for steel fiber pullout from cementitious matrices. Adv. Compos. Lett. 2000, 9, 243–256. [Google Scholar] [CrossRef]

- Georgiadi-Stefanidi, K.; Mistakidis, E.; Pantousa, D.; Zygomalas, M. Numerical modeling of the pull-out of hooked steel fibers from high-strength cementitious matrix, supplemented by experimental results. Constr. Build. Mater. 2010, 24, 2489–2506. [Google Scholar] [CrossRef]

- Kaklauskas, G.; Gribniak, V.; Bacinskas, D. Inverse technique for deformational analysis of concrete beams with ordinary reinforcement and steel fibers. Procedia Eng. 2011, 14, 1439–1446. [Google Scholar] [CrossRef]

- Gribniak, V.; Kaklauskas, G.; Kwan, H.; Bacinskas, D.; Ulbinas, D. Deriving stress–strain relationships for steel fiber concrete in tension from tests of beams with ordinary reinforcement. Eng. Struct. 2012, 42, 387–395. [Google Scholar] [CrossRef]

- Kim, D.J.; Kang, S.H.; Ahn, T.-H. Mechanical characterization of high-performance steel-fiber reinforced cement composites with self-healing effect. Materials 2014, 7, 508–526. [Google Scholar] [CrossRef] [PubMed]

- Nishiwaki, T.; Kwon, S.; Homma, D.; Yamada, M.; Mihashi, H. Self-healing capability of fiber-reinforced cementitious composites for recovery of watertightness and mechanical properties. Materials 2014, 7, 2141–2154. [Google Scholar] [CrossRef]

- Tsonos, A.G. Steel fiber high-strength reinforced concrete: A new solution for earthquake strengthening of old R/C structures. WIT Trans. Built Environ. 2009, 104, 153–164. [Google Scholar]

- Chalioris, C.E.; Karayannis, C.G. Experimental investigation of RC beams with rectangular spiral reinforcement in torsion. Eng. Struct. 2013, 56, 286–297. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Bantilas, K.E. Shear strength of reinforced concrete beam-column joints with crossed inclined bars. Eng. Struct. 2017, 140, 241–255. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Kosmidou, P.-M.K.; Papadopoulos, N.A. Investigation of a new strengthening technique for RC deep beams using carbon FRP ropes as transverse reinforcements. Fibers 2018, 6, 52. [Google Scholar] [CrossRef]

- Canbolat, B.A.; Parra-Montesinos, G.J.; Wight, J.K. Experimental study on the seismic behavior of high-performance fiber-reinforced cement composite coupling beams. ACI Struct. J. 2005, 102, 159–166. [Google Scholar]

- Abbas, A.A.; Mohsin, S.M.S.; Cotsovos, D.M. Seismic response of steel fiber reinforced concrete beam-column joints. Eng. Struct. 2014, 59, 261–283. [Google Scholar] [CrossRef]

- Ma, K.; Qi, T.; Liu, H.; Wang, H. Shear behavior of hybrid fiber reinforced concrete deep beams. Materials 2018, 11, 2023. [Google Scholar] [CrossRef]

- Furlan, S., Jr.; Bento de Hanai, J. Shear behavior of fiber reinforced concrete beams. Cem. Concr. Compos. 1997, 19, 359–366. [Google Scholar] [CrossRef]

- Cucchiara, C.; Mendola, L.; Papia, M. Effectiveness of stirrups and steel fibers as shear reinforcement. Cem. Concr. Compos. 2004, 26, 777–786. [Google Scholar] [CrossRef]

- Juárez, C.; Valdez, P.; Durán, A.; Sobolev, K. The diagonal tension behavior of fiber reinforced concrete beams. Cem. Concr. Compos. 2007, 29, 402–408. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Sfiri, E.F. Shear performance of steel fibrous concrete beams. Procedia Eng. 2011, 14, 2064–2068. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Shin, H.-O.; Yoo, D.-Y.; Yoon, Y.-S. Structural response of steel-fiber-reinforced concrete beams under various loading rates. Eng. Struct. 2018, 156, 271–283. [Google Scholar] [CrossRef]

- Smarzewski, P. Hybrid fibers as shear reinforcement in high-performance concrete beams with and without openings. Appl. Sci. 2018, 8, 2070. [Google Scholar] [CrossRef]

- Smarzewski, P. Analysis of failure mechanics in hybrid fiber-reinforced high-performance concrete deep beams with and without openings. Materials 2019, 12, 101. [Google Scholar] [CrossRef]

- Zhao, J.; Liang, J.; Chu, L.; Shen, F. Experimental study on shear behavior of steel fiber reinforced concrete beams with high-strength reinforcement. Materials 2018, 11, 1682. [Google Scholar] [CrossRef] [PubMed]

- Chalioris, C.E. Analytical approach for the evaluation of minimum fiber factor required for steel fibrous concrete beams under combined shear and flexure. Constr. Build. Mater. 2013, 43, 317–336. [Google Scholar] [CrossRef]

- Kim, K.S.; Lee, D.H.; Hwang, J.H.; Kuchma, D.A. Shear behavior model for steel fiber-reinforced concrete members without transverse reinforcements. Compos. Part B Eng. 2012, 43, 2324–2334. [Google Scholar] [CrossRef]

- Zhang, F.; Ding, Y.; Xu, J.; Zhang, Y.; Zhu, W.; Shi, Y. Shear strength prediction for steel fiber reinforced concrete beams without stirrups. Eng. Struct. 2016, 127, 101–116. [Google Scholar] [CrossRef]

- Lee, D.H.; Han, S.-J.; Kim, K.S.; LaFave, J.M. Shear capacity of steel fiber-reinforced concrete beams. Struct. Concr. 2017, 18, 278–291. [Google Scholar] [CrossRef]

- Colajanni, P.; Recupero, A.; Spinella, N. Generalization of shear truss model to the case of SFRC beams with stirrups. Comput. Concr. 2012, 9, 227–244. [Google Scholar] [CrossRef]

- Hwang, J.-H.; Lee, D.H.; Ju, H.; Kim, K.S.; Seo, S.-Y.; Kang, J.-W. Shear behavior models of steel fiber reinforced concrete beams modifying softened truss model approaches. Materials 2013, 6, 4847–4867. [Google Scholar] [CrossRef]

- Bafghi, M.A.B.; Amini, F.; Nikoo, H.S.; Sarkardeh, H. Effect of steel fiber and different environments on flexural behavior of reinforced concrete beams. Appl. Sci. 2017, 7, 1011. [Google Scholar] [CrossRef]

- Kotsovos, G.; Zeris, C.; Kotsovos, M. The effect of steel fibers on the earthquake-resistant design of reinforced concrete structures. Mater. Struct. 2007, 40, 175–188. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Le, T.T.; Lampropoulos, A.P. Flexural performance of fiber reinforced concrete made with steel and synthetic fibers. Constr. Build. Mater. 2012, 36, 704–710. [Google Scholar] [CrossRef]

- Barros, J.A.; Figueiras, J.A. Flexural behavior of SFRC: Testing and modeling. ASCE J. Mater. Civ. Eng. 1999, 11, 331–339. [Google Scholar] [CrossRef]

- Campione, G.; Mangiavillano, M.L. Fibrous reinforced concrete beams in flexure: Experimental investigation, analytical modelling and design considerations. Eng. Struct. 2008, 30, 2970–2980. [Google Scholar] [CrossRef]

- Li, C.; Geng, H.; Deng, C.; Li, B.; Zhao, S. Experimental investigation on columns of steel fiber reinforced concrete with recycled aggregates under large eccentric compression load. Materials 2019, 12, 445. [Google Scholar] [CrossRef]

- Gribniak, V.; Arnautov, A.K.; Norkus, A.; Tamulenas, V.; Gudonis, E.; Sokolov, A. Experimental investigation of the capacity of steel fibers to ensure the structural integrity of reinforced concrete specimens coated with CFRP sheets. Mech. Compos. Mater. 2016, 52, 401–410. [Google Scholar] [CrossRef]

- Gribniak, V.; Arnautov, A.K.; Norkus, A.; Kliukas, R.; Tamulenas, V.; Gudonis, E.; Sokolov, A.V. Steel fibers: Effective way to prevent failure of the concrete bonded with FRP sheets. Adv. Mater. Sci. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Gribniak, V.; Tamulenas, V.; Ng, P.-L.; Arnautov, A.K.; Gudonis, E.; Misiunaite, I. Mechanical behavior of steel fiber-reinforced concrete beams bonded with external carbon fiber sheets. Materials 2017, 10, 666. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-Y.; Shin, H.-O.; Min, K.-H.; Yoon, Y.-S. Flexural assessment of blast-damaged RC beams retrofitted with CFRP sheet and steel fiber. Int. J. Polym. Sci. 2018, 2018, 2036436. [Google Scholar] [CrossRef]

- Kotsovos, M.D.; Baka, A.; Vougioukas, E. Earthquake-resistant design of reinforced concrete structures: Shortcomings of current methods. ACI Struct. J. 2003, 100, 11–18. [Google Scholar]

- Hameed, R.; Duprat, F.; Turatsinze, A.; Sellier, A.; Siddiqi, Z.A. Behavior of reinforced fibrous concrete beams under reversed cyclic loading. Pak. J. Eng. Appl. Sci. 2011, 9, 1–12. [Google Scholar]

- Lepage, A.; Tavallali, H.; Pujol, S.; Rautenberg, J.M. High-performance steel bars and fibers as concrete reinforcement for seismic-resistant frames. Adv. Civ. Eng. 2012, 2012, 450981. [Google Scholar] [CrossRef]

- Daniel, L.; Loukili, A. Behavior of high-strength fiber-reinforced concrete beams under cyclic loading. ACI Struct. J. 2002, 99, 248–256. [Google Scholar]

- Harajli, M.H.; Gharzeddine, O. Effect of steel fibers on bond performance of steel bars in NSC and HSC under load reversals. J. Mater. Civ. Eng. 2007, 19, 864–873. [Google Scholar] [CrossRef]

- Parra-Montesinos, G.J.; Chompreda, P. Deformation capacity and shear strength of fiber-reinforced cement composite flexural members subjected to displacement reversals. ASCE J. Struct. Eng. 2007, 133, 421–431. [Google Scholar] [CrossRef]

- Chalioris, C.E. Steel fibrous RC beams subjected to cyclic deformations under predominant shear. Eng. Struct. 2013, 49, 104–118. [Google Scholar] [CrossRef]

- Tavallali, H.; Lepage, A.; Rautenberg, J.M.; Pujol, S. Concrete beams reinforced with high-strength steel subjected to displacement reversals. ACI Struct. J. 2014, 111, 1037–1048. [Google Scholar] [CrossRef]

- Tsonos, A.-D.G. Ultra-high-performance fiber reinforced concrete: An innovative solution for strengthening old R/C structures and for improving the FRP strengthening method. WIT Trans. Eng. Sci. 2009, 64, 273–284. [Google Scholar]

- Park, Y.-J.; Ang, A.H.-S. Mechanistic seismic damage model for reinforced concrete. ASCE J. Struct. Eng. 1985, 111, 722–739. [Google Scholar] [CrossRef]

- Popov, E.P. Bond and anchorage of reinforcing bars under cyclic loading. ACI Struct. J. 1984, 81, 340–349. [Google Scholar]

- Meskenas, A.; Kaklauskas, G.; Daniunas, A.; Bacinskas, D.; Jakubovskis, R.; Gribniak, V.; Gelazius, V. Determination of the stress-crack opening relationship of SFRC by an inverse analysis. Mech. Compos. Mater. 2014, 49, 685–690. [Google Scholar] [CrossRef]

- Gribniak, V.; Kaklauskas, G.; Torres, L.; Daniunas, A.; Timinskas, E.; Gudonis, E. Comparative analysis of deformations and tension-stiffening in concrete beams reinforced with GFRP or steel bars and fibers. Compos. Part B Eng. 2013, 50, 158–170. [Google Scholar] [CrossRef]

| Concrete Mixture | Cylinder Compressive Strength, fc | Splitting Tensile Strength, fct,spl |

|---|---|---|

| (MPa) | (MPa) | |

| Plain concrete | 24.13 (0.67) | 2.62 (0.30) |

| SFRC with Vf = 1% | 25.51 (0.71) | 3.32 (0.59) |

| SFRC with Vf = 3% | 27.25 (1.05) | 4.96 (0.69) |

| Cycle | Maximum Deflection (mm) | B-P | B-F1 | B-F3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Load | Energy | Damage | Load | Energy | Damage | Load | Energy | Damage | ||

| (kN) | (kNmm) | Index | (kN) | (kNmm) | Index | (kN) | (kNmm) | Index | ||

| 1st | +10 | 54.0 | 282.5 | 0.29 | 52.0 | 271.4 | 0.20 | 54.4 | 269.1 | 0.16 |

| −10 | −52.0 | −50.7 | −53.2 | |||||||

| 2nd | +25 | 64.0 | 1704.5 | 0.86 | 64.2 | 2002.2 | 0.63 | 66.5 | 2186.6 | 0.52 |

| −25 | −55.0 | −61.1 | −63.0 | |||||||

| 3rd | +40 | 66.5 | 4091.1 | 1.58 | 69.0 | 4465.3 | 1.14 | 72.0 | 4915.9 | 0.94 |

| −40 | −56.0 | −63.0 | −68.0 | |||||||

| Cracking load: | 24.0 kN | 30.0 kN | 35.2 kN | |||||||

| Failure mode: | Concrete crushing | Concrete spalling | Flexural failure | |||||||

| Beam Codified Name | Geometrical and Mechanical Characteristics | Reinforcements | Experimental Results | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| b/h | d | c | L | a/d | fc1 | ρsl | ρst | Lf | Df | Vf | Pmax | dPmax | ΔPmax | Failure | |

| (mm/mm) | (mm) | (mm) | (mm) | (MPa) | (%) | (%) | (mm) | (mm) | (%) | (kN) | (mm) | Mode 2 | |||

| Present study | |||||||||||||||

| B-P | 200/200 | 170 | 16 | 2200 | 5.9 | 24 | 1.00 | 0.25 | - | - | - | 67 | 40 | - | CC |

| B-F1 | 200/200 | 170 | 16 | 2200 | 5.9 | 26 | 1.00 | 0.25 | 44 | 1.00 | 1.0 | 74 | 57 | 11% | CS |

| B-F3 | 200/200 | 170 | 16 | 2200 | 5.9 | 27 | 1.00 | 0.25 | 44 | 1.00 | 3.0 | 79 | 70 | 19% | Fl |

| Daniel and Loukili [81] | |||||||||||||||

| L-ref | 150/300 | 270 | 16 | 2400 | 4.1 | 97 | 0.55 | 0.34 | - | - | - | 59 | 9.2 | - | Fl |

| L-30 | 150/300 | 270 | 16 | 2400 | 4.1 | 110 | 0.55 | 0.34 | 30 | 0.38 | 1.0 | 86 | 9.9 | 47% | Fl |

| L-60 | 150/300 | 270 | 16 | 2400 | 4.1 | 116 | 0.55 | 0.34 | 60 | 0.75 | 1.0 | 93 | 9.9 | 59% | Fl |

| M-ref | 150/300 | 270 | 14 | 2400 | 4.1 | 95 | 0.97 | 0.34 | - | - | - | 89 | 10.3 | - | Fl |

| M-30 | 150/300 | 270 | 14 | 2400 | 4.1 | 112 | 0.97 | 0.34 | 30 | 0.38 | 1.0 | 116 | 11.0 | 30% | Fl |

| M-60 | 150/300 | 270 | 14 | 2400 | 4.1 | 117 | 0.97 | 0.34 | 60 | 0.75 | 1.0 | 124 | 12.1 | 40% | Fl |

| H-ref | 150/300 | 270 | 12 | 2400 | 4.1 | 94 | 1.52 | 0.34 | - | - | - | 151 | 15.1 | - | Fl |

| H-30 | 150/300 | 270 | 12 | 2400 | 4.1 | 114 | 1.52 | 0.34 | 30 | 0.38 | 1.0 | 159 | 13.7 | 5% | Fl |

| H-60 | 150/300 | 270 | 12 | 2400 | 4.1 | 117 | 1.52 | 0.34 | 60 | 0.75 | 1.0 | 179 | 15.0 | 18% | Fl |

| Harajli and Gharzeddine [82] | |||||||||||||||

| NB20F0.0 | 240/300 | 250 | 40 | 2000 | 2.8 | 43 | 1.05 | 0.65 | - | - | - | 176 | 5.8 | - | CS |

| NB20F0.5 | 240/300 | 250 | 40 | 2000 | 2.8 | 1.05 | 0.65 | 30 | 0.50 | 0.5 | 220 | 7.0 | 25% | CS | |

| NB20F1.0 | 240/300 | 250 | 40 | 2000 | 2.8 | 1.05 | 0.65 | 30 | 0.50 | 1.0 | 227 | 12.5 | 29% | Fl | |

| NB20F1.5 | 240/300 | 250 | 40 | 2000 | 2.8 | 1.05 | 0.65 | 30 | 0.50 | 1.5 | 228 | 15.0 | 30% | Fl | |

| NB25F0.0 | 240/300 | 253 | 35 | 2000 | 2.8 | 43 | 1.62 | 0.65 | - | - | - | 217 | 5.5 | - | CS |

| NB25F0.5 | 240/300 | 253 | 35 | 2000 | 2.8 | 1.62 | 0.65 | 30 | 0.50 | 0.5 | 242 | 6.0 | 12% | CS | |

| NB25F1.0 | 240/300 | 253 | 35 | 2000 | 2.8 | 1.62 | 0.65 | 30 | 0.50 | 1.0 | 302 | 7.5 | 39% | CS | |

| NB20F1.5 | 240/300 | 253 | 35 | 2000 | 2.8 | 1.62 | 0.65 | 30 | 0.50 | 1.5 | 255 | 7.0 | 18% | CS | |

| HSC25F0.0 | 240/300 | 253 | 35 | 2000 | 2.8 | 68 | 1.62 | 0.65 | - | - | - | 244 | 5.5 | - | CS |

| HSC25F0.5 | 240/300 | 253 | 35 | 2000 | 2.8 | 1.62 | 0.65 | 30 | 0.50 | 0.5 | 310 | 7.0 | 27% | CS | |

| HSC25F1.0 | 240/300 | 253 | 35 | 2000 | 2.8 | 1.62 | 0.65 | 30 | 0.50 | 1.0 | 342 | 7.0 | 40% | CS | |

| HSC20F1.5 | 240/300 | 253 | 35 | 2000 | 2.8 | 1.62 | 0.65 | 30 | 0.50 | 1.5 | 372 | 9.0 | 52% | CS | |

| Campione and Mangiavillano [72] | |||||||||||||||

| Beam I | 150/150 | 133 | 5 | 550 | 2.1 | 31 | 1.13 | 0.75 | - | - | - | 95 | 6.0 | - | Sh |

| Beam II | 150/150 | 133 | 5 | 550 | 2.1 | 35 | 1.13 | 0.75 | 30 | 0.50 | 1.0 | 120 | 9.5 | 26% | CS |

| Beam III | 150/150 | 123 | 15 | 550 | 2.2 | 31 | 1.23 | 0.75 | - | - | - | 105 | 4.0 | - | Sh |

| Beam IV | 150/150 | 123 | 15 | 550 | 2.2 | 35 | 1.23 | 0.75 | 30 | 0.50 | 1.0 | 126 | 9.5 | 20% | Fl |

| Beam V | 150/150 | 113 | 25 | 550 | 2.4 | 31 | 1.33 | 0.75 | - | - | - | 112 | 9.5 | - | Fl |

| Beam VI | 150/150 | 113 | 25 | 550 | 2.4 | 35 | 1.33 | 0.75 | 30 | 0.50 | 1.0 | 100 | 9.5 | –11% | Fl |

| Hameed et al. [79] | |||||||||||||||

| Beam-cont | 150/200 | 176 | 15 | 1000 | 2.8 | 41–45 | 0.21 | 0.38 | - | - | - | 24 | 8.0 | - | CS |

| Beam-DF40 | 150/200 | 176 | 15 | 1000 | 2.8 | 41–45 | 0.21 | 0.38 | 30 | 0.50 | 0.5 | 29 | 8.0 | 19% | Fl |

| Tavallali [85] | |||||||||||||||

| CC4-X | 406/254 | 203 | 31 | 914 | 3.0 | 41 | 1.84 | 0.69 | - | - | - | 245 | 24.4 | - | CC |

| UC4-X | 406/254 | 203 | 33 | 914 | 3.0 | 43 | 1.24 | 0.69 | - | - | - | 236 | 16.0 | - | CC |

| UC4-F | 406/254 | 203 | 33 | 914 | 3.0 | 44 | 1.24 | 0.69 | 30 | 0.38 | 1.5 | 285 | 18.3 | 21% | Fl |

| UC2-F | 406/254 | 203 | 33 | 914 | 3.0 | 44 | 1.24 | 0.34 | 30 | 0.38 | 1.5 | 271 | 24.4 | 15% | Fl |

| CC2-F | 406/254 | 203 | 31 | 914 | 3.0 | 40 | 1.84 | 0.34 | 30 | 0.38 | 1.5 | 255 | 29.3 | 4% | Fl |

| CC4-X$ | 406/254 | 203 | 31 | 914 | 3.0 | 43 | 1.84 | 0.69 | - | - | - | 220 | 18.3 | - | CC |

| UC2-F$ | 406/254 | 203 | 33 | 914 | 3.0 | 43 | 1.24 | 0.34 | 30 | 0.38 | 1.5 | 267 | 17.1 | 13% | Fl |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chalioris, C.E.; Kosmidou, P.-M.K.; Karayannis, C.G. Cyclic Response of Steel Fiber Reinforced Concrete Slender Beams: An Experimental Study. Materials 2019, 12, 1398. https://doi.org/10.3390/ma12091398

Chalioris CE, Kosmidou P-MK, Karayannis CG. Cyclic Response of Steel Fiber Reinforced Concrete Slender Beams: An Experimental Study. Materials. 2019; 12(9):1398. https://doi.org/10.3390/ma12091398

Chicago/Turabian StyleChalioris, Constantin E., Parthena-Maria K. Kosmidou, and Chris G. Karayannis. 2019. "Cyclic Response of Steel Fiber Reinforced Concrete Slender Beams: An Experimental Study" Materials 12, no. 9: 1398. https://doi.org/10.3390/ma12091398

APA StyleChalioris, C. E., Kosmidou, P.-M. K., & Karayannis, C. G. (2019). Cyclic Response of Steel Fiber Reinforced Concrete Slender Beams: An Experimental Study. Materials, 12(9), 1398. https://doi.org/10.3390/ma12091398