Effects of Ball Milling Processing Conditions and Alloy Components on the Synthesis of Cu-Nb and Cu-Mo Alloys

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

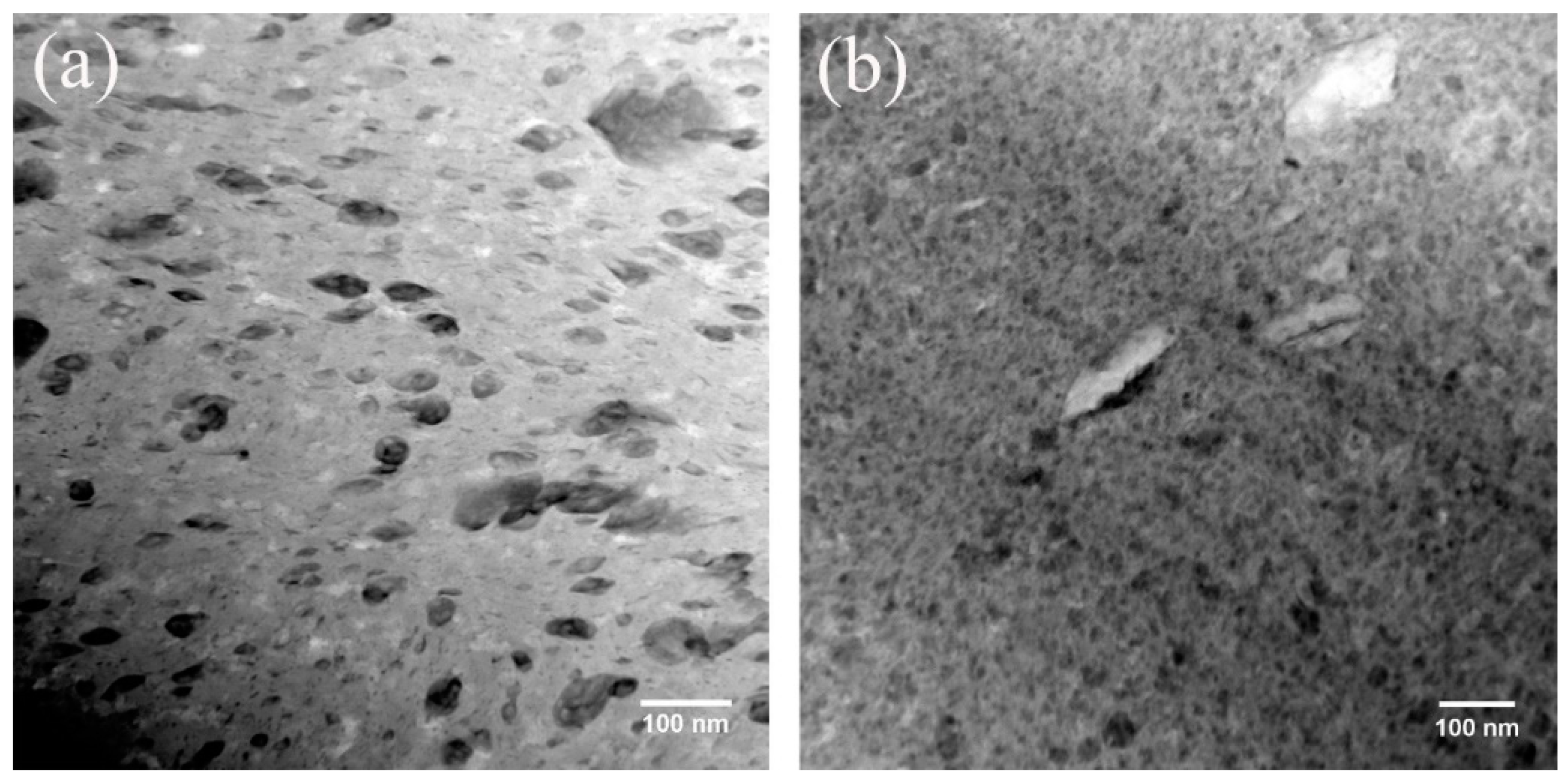

3.1. Optimization of BPR and Ball Size Distribution

3.2. Synthesis of ODS Copper Alloy

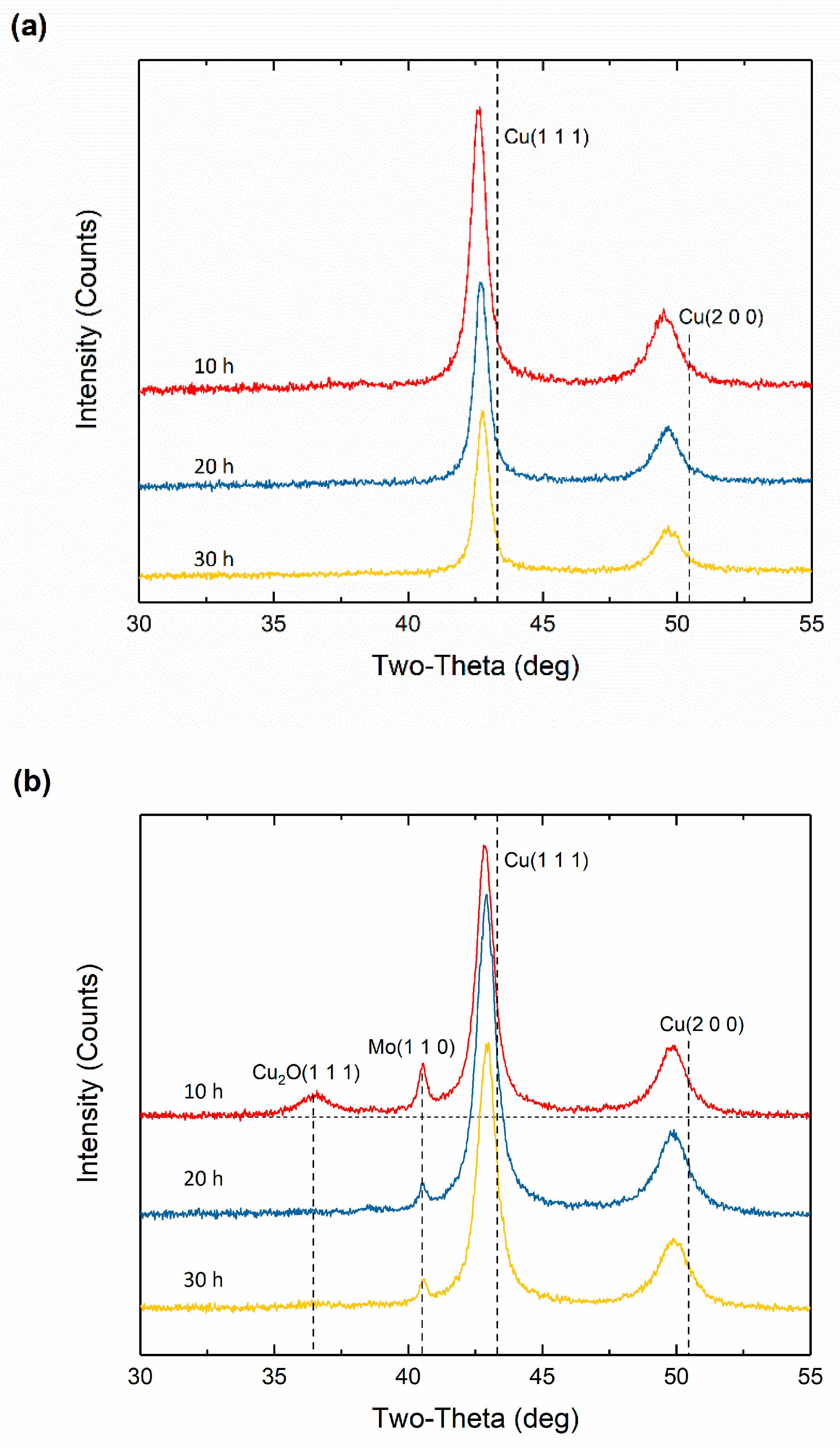

3.2.1. Addition of CuO

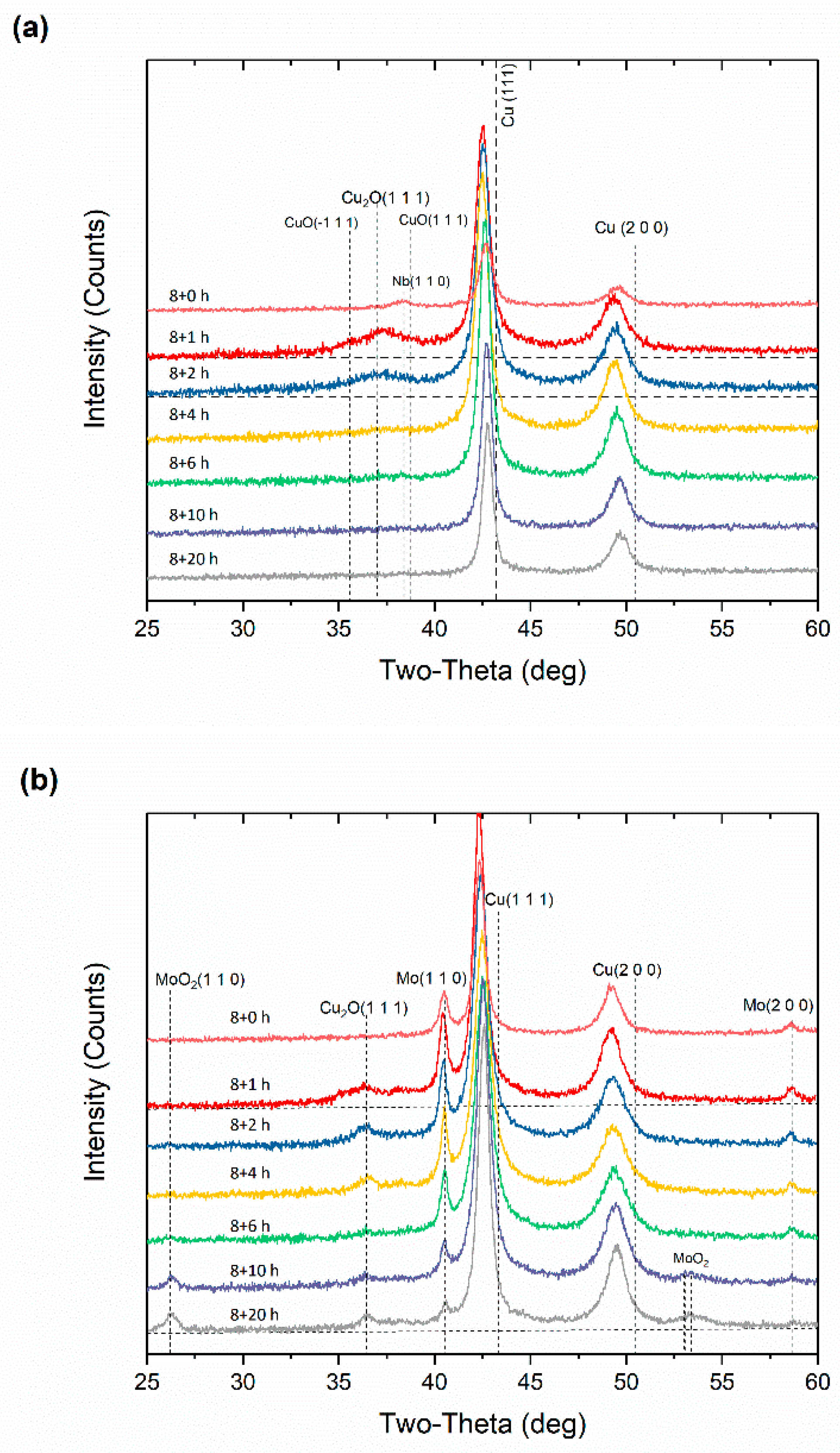

3.2.2. Two-Step Ball Milling

4. Summary and Conclusions

- High powder yields can be obtained by changing the BPR value and ball size distribution.

- No clear dependence of BPR value on powder yield can be found from the experiment results.

- The addition of oxygen can largely reduce the effect of excessive cold welding during ball milling.

- A “two-step” ball milling procedure considerably benefits the oxidation process of Mo and shows its promising potential in the synthesis of immiscible alloys.

- The chemical and mechanical properties of elements play a critical role in the evolution process and morphologies of different alloys during milling.

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Gilman, P.S.; Benjamin, J.S. Mechanical Alloying. Annu. Rev. Mater. Sci. 1983, 13, 279–300. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Benjamin, J.S. Dispersion strengthened superalloys by mechanical alloying. Metall. Trans. 1970, 1, 2943–2951. [Google Scholar] [CrossRef]

- Benjamin, J.S.; Volin, T.E. The mechanism of mechanical alloying. Metall. Trans. 1974, 5, 1929–1934. [Google Scholar] [CrossRef]

- Zhang, D.L. Processing of advanced materials using high-energy mechanical milling. Prog. Mater. Sci. 2004, 49, 537–560. [Google Scholar] [CrossRef]

- Razavi-Tousi, S.S.; Szpunar, J.A. Effect of ball size on steady state of aluminum powder and efficiency of impacts during milling. Powder Technol. 2015, 284, 149–158. [Google Scholar] [CrossRef]

- Canakci, A.; Varol, T.; Ozsahin, S. Analysis of the effect of a new process control agent technique on the mechanical milling process using a neural network model: Measurement and modeling. Meas. J. Int. Meas. Confed. 2013, 46, 1818–1827. [Google Scholar] [CrossRef]

- Hosseini-Gourajoubi, F.; Pourabdoli, M.; Uner, D.; Raygan, S. Effect of process control agents on synthesizing nano-structured 2Mg-9Ni-Y catalyst by mechanical milling and its catalytic effect on desorption capacity of MgH2. Adv. Powder Technol. 2015, 26, 448–453. [Google Scholar] [CrossRef]

- Nouri, A.; Hodgson, P.D.; Wen, C.E. Effect of process control agent on the porous structure and mechanical properties of a biomedical Ti-Sn-Nb alloy produced by powder metallurgy. Acta Biomater. 2010, 6, 1630–1639. [Google Scholar] [CrossRef]

- Gheisari, K.; Javadpour, S. The effect of process control agent on the structure and magnetic properties of nanocrystalline mechanically alloyed Fe-45% Ni powders. J. Magn. Magn. Mater. 2013, 343, 133–137. [Google Scholar] [CrossRef]

- Kurama, H.; Erkuş, Ş.; Gaşan, H. The effect of process control agent usage on the structural properties of MgB2synthesized by high energy ball mill. Ceram. Int. 2017, 43, S391–S396. [Google Scholar] [CrossRef]

- Lee, W.; Kwun, S.I. The effects of process control agents on mechanical alloying mechanisms in the Ti-Al system. J. Alloys Compd. 1996, 240, 193–199. [Google Scholar] [CrossRef]

- Wu, Z.; Liang, Y.; Fu, E.; Du, J.; Wang, P.; Fan, Y.; Zhao, Y. Effect of Ball Milling Parameters on the Refinement of Tungsten Powder. Metals 2018, 8, 281. [Google Scholar] [CrossRef]

- Chauruka, S.R.; Roberts, K.J.; Stitt, H.; Hassanpour, A.; Brydson, R.; Ghadiri, M. Effect of mill type on the size reduction and phase transformation of gamma alumina. Chem. Eng. Sci. 2015, 134, 774–783. [Google Scholar] [CrossRef]

- Beranoagirre, A.; Olvera, D.; López De Lacalle, L.N. Milling of gamma titanium-aluminum alloys. Int. J. Adv. Manuf. Technol. 2012, 62, 83–88. [Google Scholar] [CrossRef]

- Ward, T.S.; Chen, W.; Schoenitz, M.; Dave, R.N.; Dreizin, E.L. A study of mechanical alloying processes using reactive milling and discrete element modeling. Acta Mater. 2005, 53, 2909–2918. [Google Scholar] [CrossRef]

- Qu, S.; Li, X.; Li, Y.; Hu, L.; Wang, E. Manufacturing a TiAl alloy by high-energy ball milling and subsequent reactive sintering. Rare Met. 2006, 25, 21–26. [Google Scholar] [CrossRef]

- Gotor, F.J.; Achimovicova, M.; Real, C.; Balaz, P. Influence of the milling parameters on the mechanical work intensity in planetary mills. Powder Technol. 2013, 233, 1–7. [Google Scholar] [CrossRef]

- Mojarrad, N.R.; Kheirifard, R.; Mousavian, R.T.; Afkham, Y.; Nakisa, S. Filling ratio of vial. J. Therm. Anal. Calorim. 2016, 126, 1097–1103. [Google Scholar] [CrossRef]

- Broseghini, M.; D’Incau, M.; Gelisio, L.; Pugno, N.M.; Scardi, P. Effect of jar shape on high-energy planetary ball milling efficiency: Simulations and experiments. Mater. Des. 2016, 110, 365–374. [Google Scholar] [CrossRef]

- Madavali, B.; Lee, J.-H.; Lee, J.K.; Cho, K.Y.; Challapalli, S.; Hong, S.-J. Effects of atmosphere and milling time on the coarsening of copper powders during mechanical milling. Powder Technol. 2014, 256, 251–256. [Google Scholar] [CrossRef]

- Hegedűs, Z.; Meka, S.R.; Mittemeijer, E.J. In situ consolidation of ball milled metals. J. Alloys Compd. 2017, 695, 721–725. [Google Scholar] [CrossRef]

- Caballero, E.; Cintas, J.; Cuevas, F.; Montes, J.; Ternero, F. Influence of Milling Atmosphere on the Controlled Formation of Ultrafine Dispersoids in Al-Based MMCs. Metals 2016, 6, 224. [Google Scholar] [CrossRef]

- Wang, M.; Averback, R.S.; Bellon, P.; Dillon, S. Chemical mixing and self-organization of Nb precipitates in Cu during severe plastic deformation. Acta Mater. 2014, 62, 276–285. [Google Scholar] [CrossRef]

- Kuziora, P.; Wyszyńska, M.; Polanski, M.; Bystrzycki, J. Why the ball to powder ratio (BPR) is insufficient for describing the mechanical ball milling process. Inter. J. Hydrogen Energy 2014, 39, 9883–9887. [Google Scholar] [CrossRef]

- Padella, F.; Paradiso, E.; Burgio, N.; Magini, M.; Martelli, S.; Guo, W.; Iasonna, A. Mechanical alloying of the Pd-Si system in controlled conditions of energy transfer. J. Less Common Met. 1991, 175, 79–90. [Google Scholar] [CrossRef]

- Guo, W.; Iasonna, A.; Magini, M.; Martelli, S.; Padella, F. Synthesis of amorphous and metastable Ti40Al60 alloys by mechanical alloying of elemental powders. J. Mater. Sci. 1994, 29, 2436–2444. [Google Scholar] [CrossRef]

- Park, Y.H.; Hashimoto, H.; Watanabe, R. Morphological Evolution and Amorphization of Ti/Cu and Ti/Al Powder Mixtures during Vibratory Ball Milling. Mater. Sci. Forum 1992, 88–90, 59–66. [Google Scholar] [CrossRef]

- Tcherdyntsev, V.V.; Kaloshkin, S.D.; Tomilin, I.a.; Shelekhov, E.V.; Serdyukov, V.N. Alloy Formation at Ball Milling of Cu50Cr50 and Fe86.5Cu13.5 Compositions. Mater. Sci. Forum 2001, 360–362, 361–366. [Google Scholar] [CrossRef]

- Takacs, L.; Pardavi-Horvath, M. Nanocomposite formation in the Fe3O4-Zn system by reaction milling. J. Appl. Phys. 1994, 75, 5864–5866. [Google Scholar] [CrossRef]

- Botcharova, E.; Freudenberger, J.; Schultz, L. Mechanical alloying of copper with niobium and molybdenum. J. Mater. Sci. 2004, 39, 5287–5290. [Google Scholar] [CrossRef]

- Linde, R.K. Lattice Parameters of Metastable Silver–Copper Alloys. J. Appl. Phys. 1966, 37, 934. [Google Scholar] [CrossRef]

- Kim, H.S.; Suhr, D.S.; Kim, G.H.; Kum, D.W. Analysis of X-ray diffraction patterns from mechanically alloyed Al-Ti powders. Met. Mater. 1996, 2, 15–21. [Google Scholar] [CrossRef]

| N | D | Ma | BPR | Mb | P |

|---|---|---|---|---|---|

| 1 | 1L | 10 g | 0.8355 | 5.85 g | 58.5% |

| 2 | 1S1M | 5 g | 0.912 | 3.76 g | 75.2% |

| 3 | 2M | 10 g | 0.7073 | 2.83 g | 28.3% |

| 4 | 3M | 15 g | 0.7073 | 0 | 0 |

| 5 | 3M | 10 g | 1.059 | 0 | 0 |

| 6 | 4M | 10 g | 1.41 | 0 | 0 |

| 7 | 7M | 10 g | 2.47 | 4.65 g | 46.5% |

| 8 | 7M | 5 g | 4.95 | 1.55 g | 31% |

| 9 | 1L1M | 10 g | 1.19 | 0 | 0 |

| 10 | 1L2M | 10 g | 1.54 | 5.93 g | 59.3% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, X.; Wang, X.; Chen, S. Effects of Ball Milling Processing Conditions and Alloy Components on the Synthesis of Cu-Nb and Cu-Mo Alloys. Materials 2019, 12, 1224. https://doi.org/10.3390/ma12081224

Shang X, Wang X, Chen S. Effects of Ball Milling Processing Conditions and Alloy Components on the Synthesis of Cu-Nb and Cu-Mo Alloys. Materials. 2019; 12(8):1224. https://doi.org/10.3390/ma12081224

Chicago/Turabian StyleShang, Xuekun, Xitao Wang, and Silian Chen. 2019. "Effects of Ball Milling Processing Conditions and Alloy Components on the Synthesis of Cu-Nb and Cu-Mo Alloys" Materials 12, no. 8: 1224. https://doi.org/10.3390/ma12081224

APA StyleShang, X., Wang, X., & Chen, S. (2019). Effects of Ball Milling Processing Conditions and Alloy Components on the Synthesis of Cu-Nb and Cu-Mo Alloys. Materials, 12(8), 1224. https://doi.org/10.3390/ma12081224