Experimental Study on Mechanical Characteristics and Fracture Patterns of Unfrozen/Freezing Saturated Coal and Sandstone

Abstract

1. Introduction

2. Experimental Methodology

2.1. Materials and Sample Preparation

2.2. Experimental Method

3. Results and Discussion

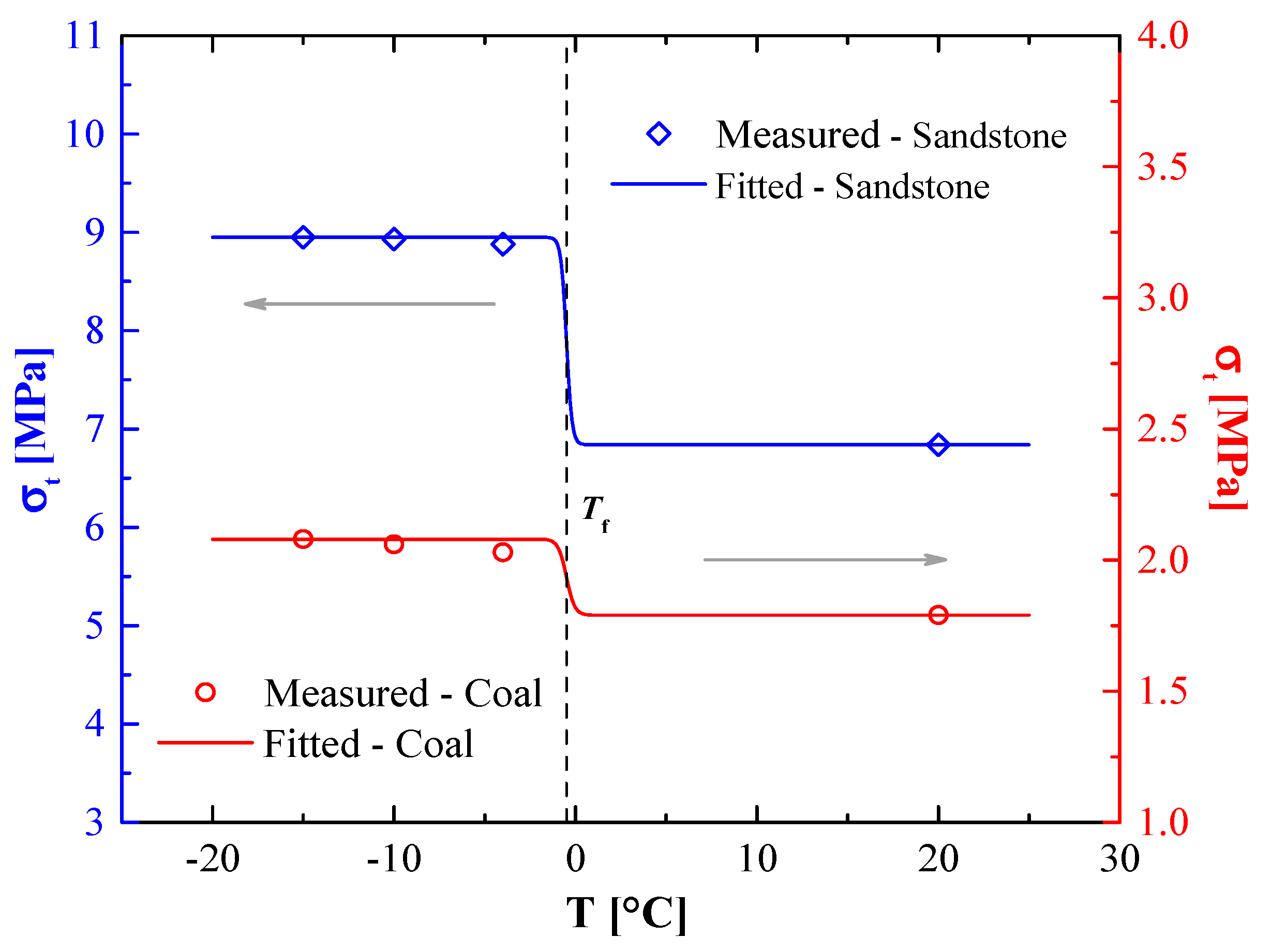

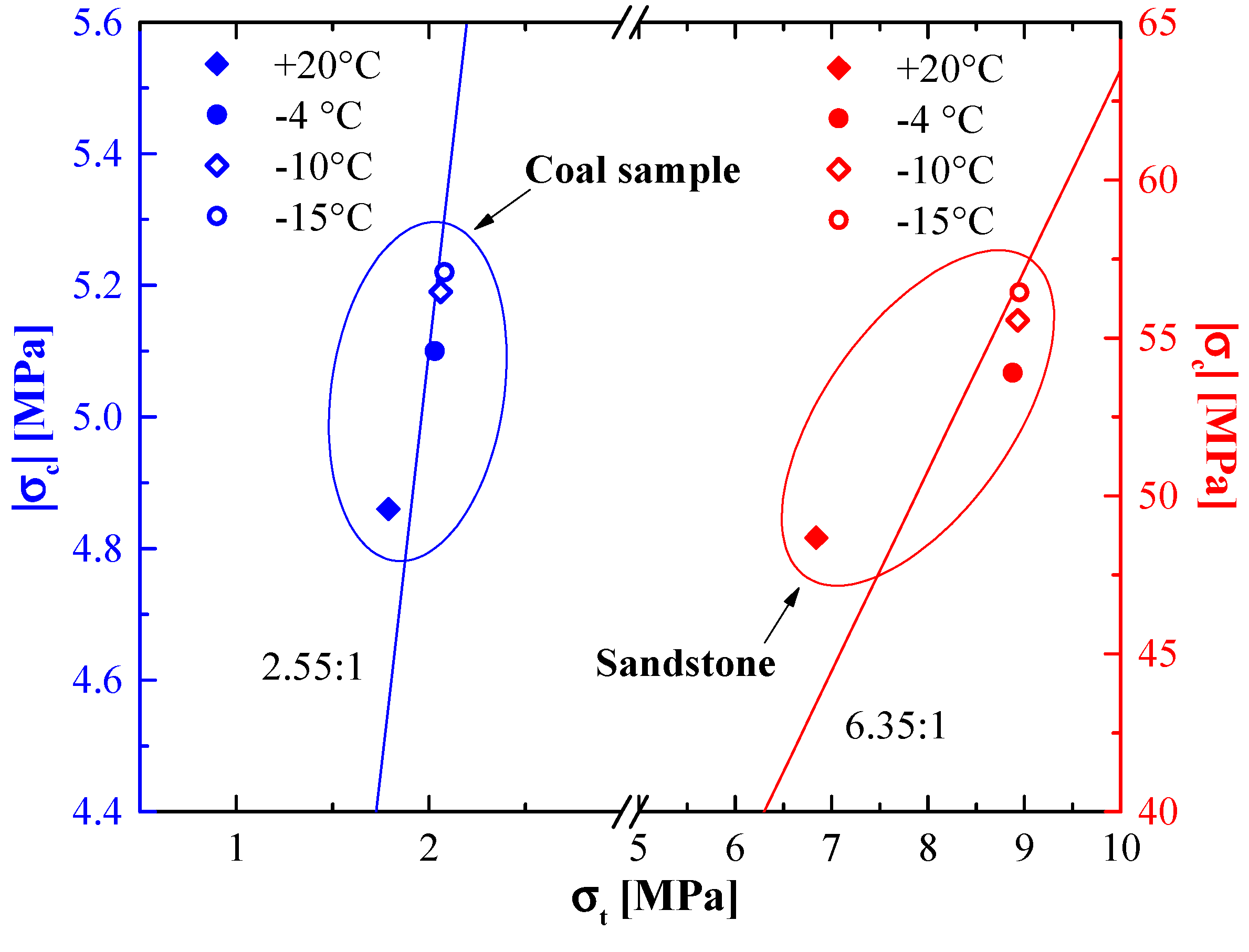

3.1. Brazilian Tensile Strength

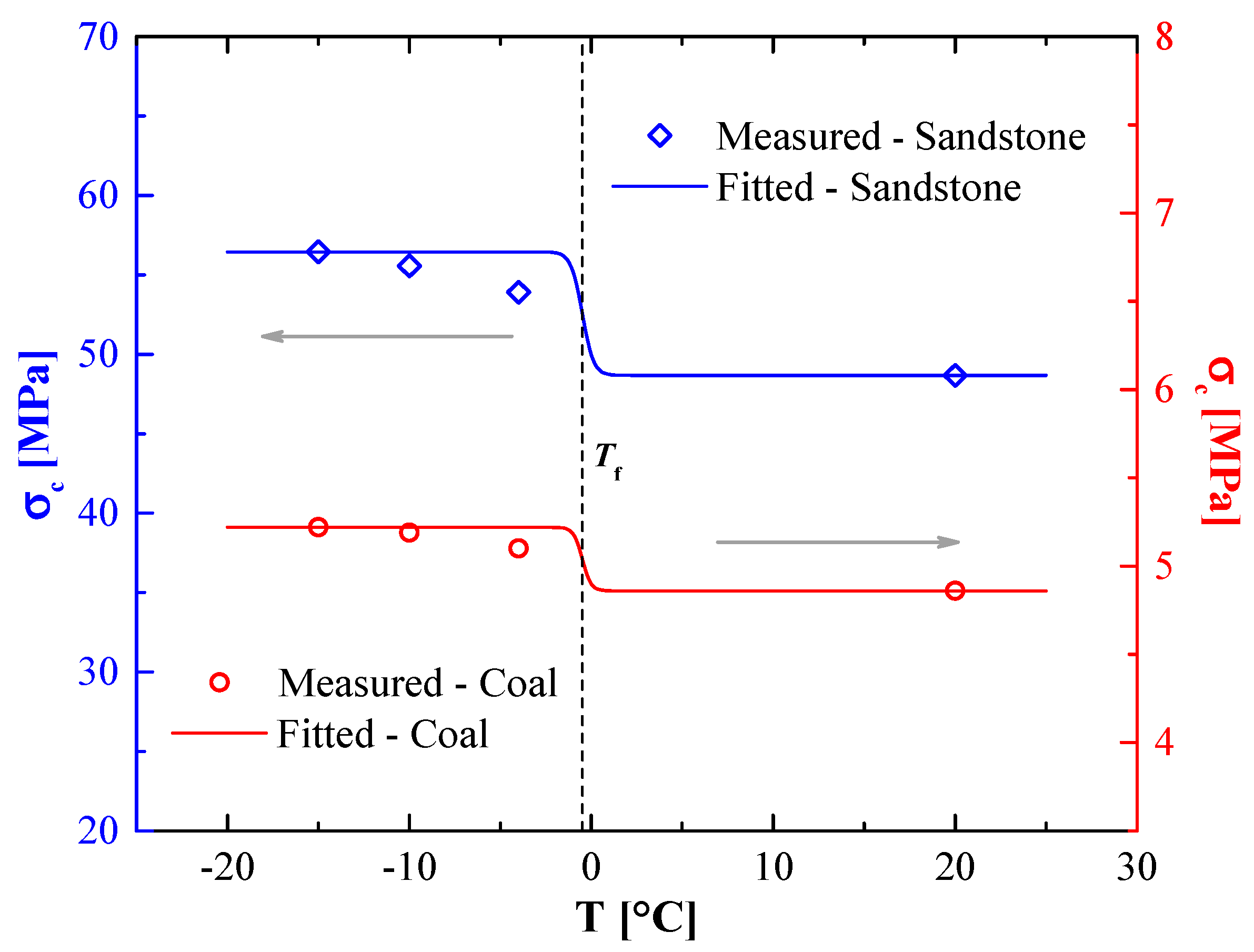

3.2. Uniaxial-Compression Strength

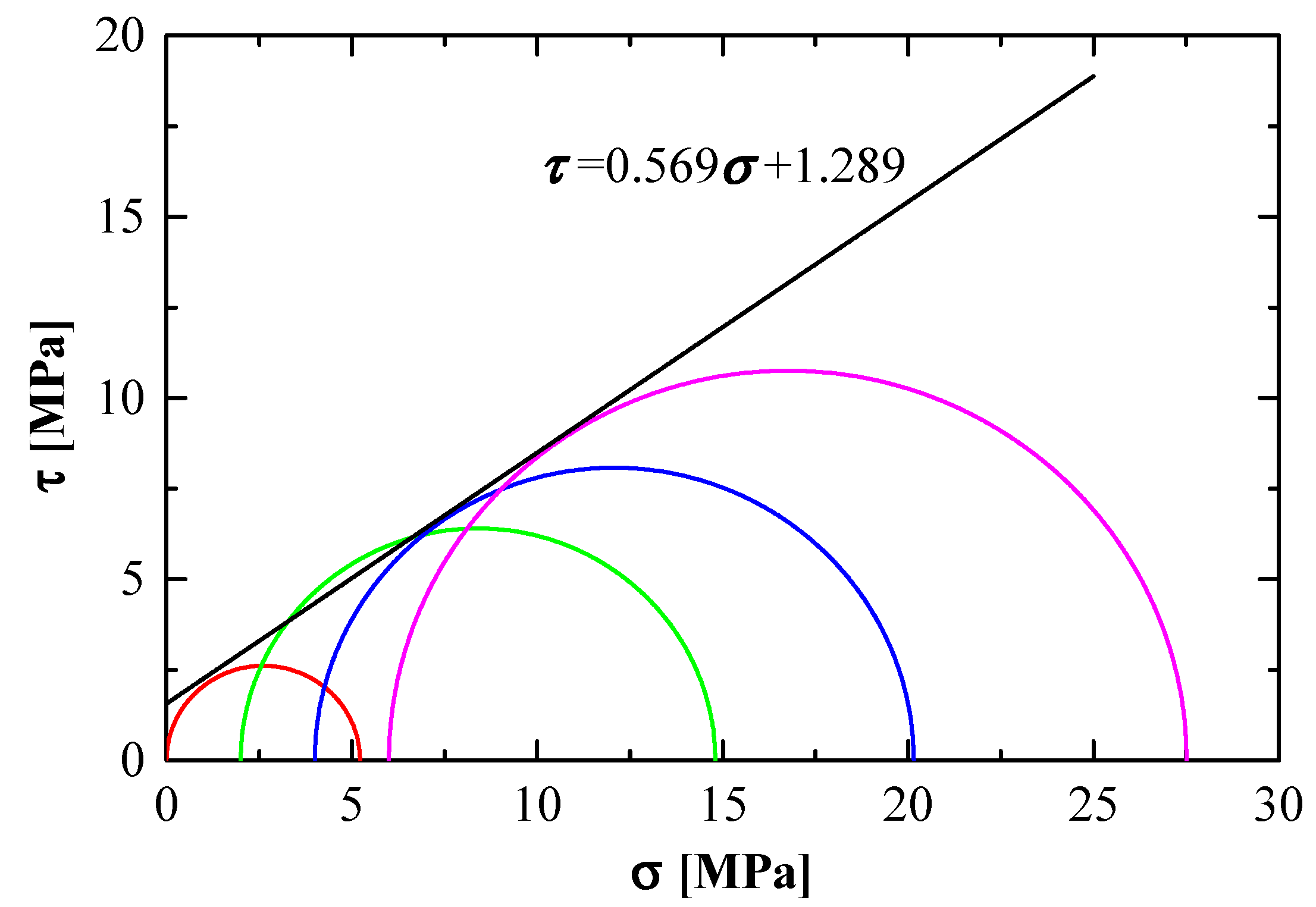

3.3. Triaxial-Compression Strength

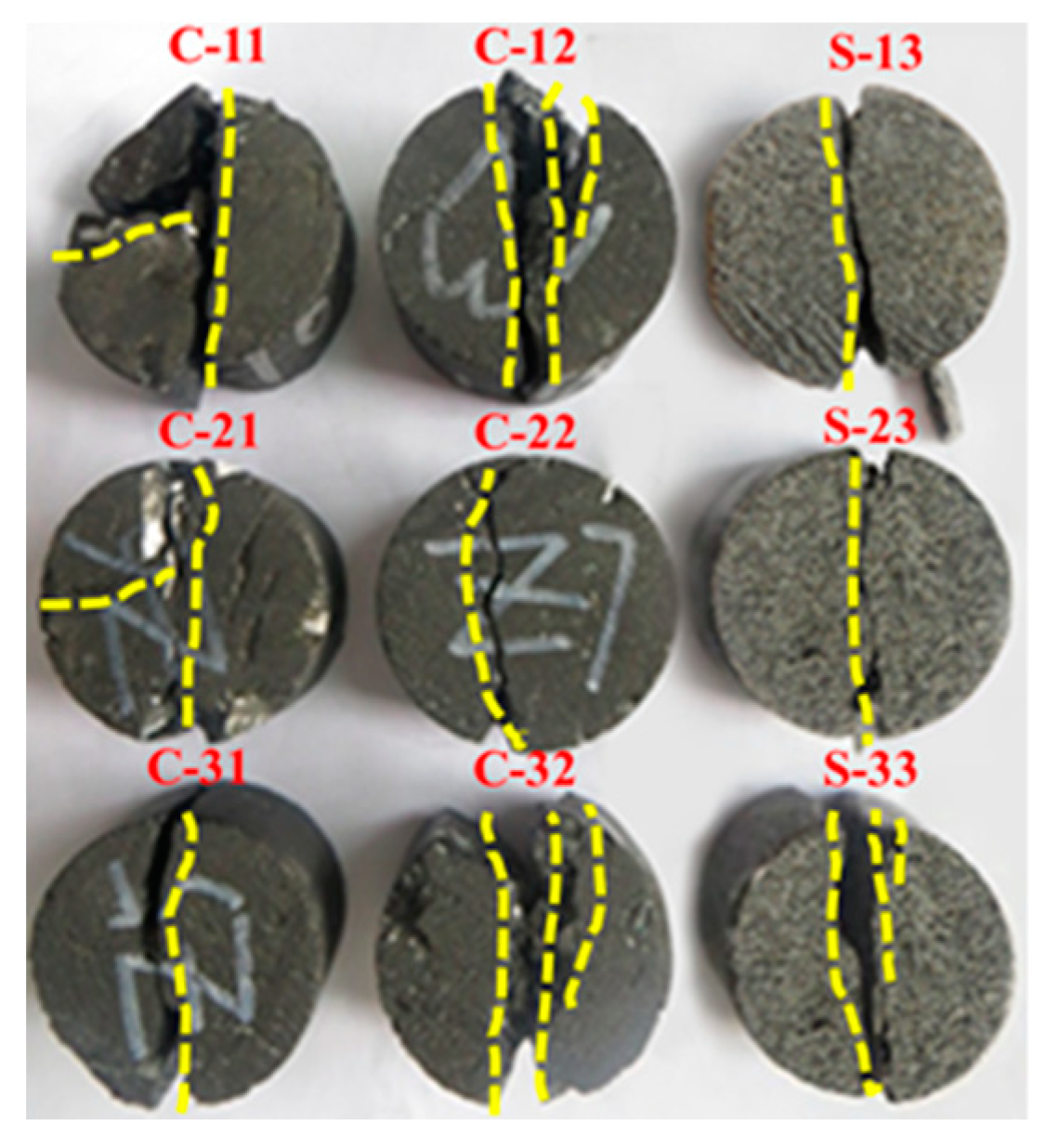

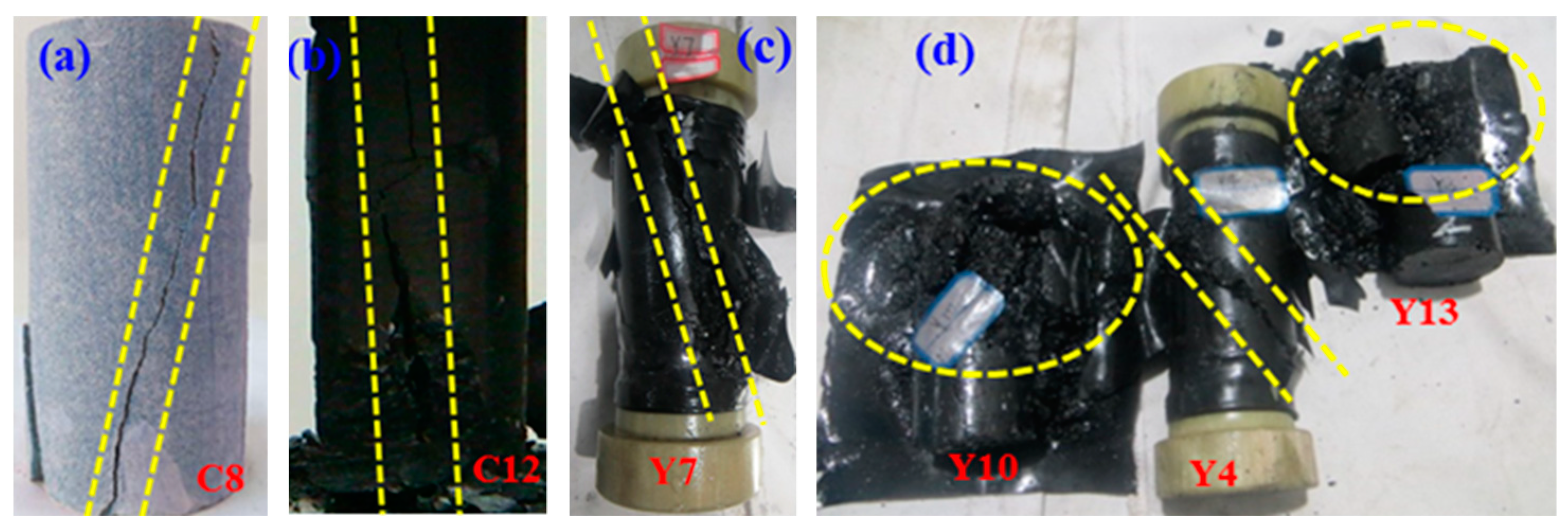

3.4. Failure Modes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Huang, J.H.; Cui, G.X.; Yang, W.H. Mechanics of Frozen Soil for Deep Alluvium—A New Field of Frozen Soil Mechanics. J. Glaciol. Geocryol. 1999, 21, 336–338. [Google Scholar]

- Xu, X.; Wang, Y.; Bai, R.; Fan, C.; Hua, S. Comparative studies on mechanical behavior of frozen natural saline silty sand and frozen desalted silty sand. Cold Reg. Sci. Technol. 2016, 132, 81–88. [Google Scholar] [CrossRef]

- Xu, X.; Wang, Y.; Yin, Z.; Zhang, H. Effect of temperature and strain rate on mechanical characteristics and constitutive model of frozen Helin loess. Cold Reg. Sci. Technol. 2017, 136, 44–51. [Google Scholar] [CrossRef]

- Zhou, Z.; Ma, W.; Zhang, S.; Mu, Y.; Li, G. Effect of freeze-thaw cycles in mechanical behaviors of frozen loess. Cold Reg. Sci. Technol. 2018, 146, 9–18. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.; Taheri, A. Degradation of physical and mechanical properties of sandstone subjected to freeze-thaw cycles and chemical erosion. Cold Reg. Sci. Technol. 2018, 155, 37–46. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.; Taheri, A. Deterioration and strain energy development of sandstones under quasi-static and dynamic loading after freeze-thaw cycles. Cold Reg. Sci. Technol. 2019, 160, 252–264. [Google Scholar] [CrossRef]

- Cheng, G.; Ma, T.; Tang, C.; Liu, H.; Wang, S. A zoning model for coal mining-induced strata movement based on microseismic monitoring. Int. J. Rock Mech. Min. Sci. 2017, 94, 123–138. [Google Scholar] [CrossRef]

- Zhao, H.; Ma, F.; Zhang, Y.; Guo, J. Monitoring and Analysis of the Mining-Induced Ground Movement in the Longshou Mine, China. Rock Mech. Rock Eng. 2013, 46, 207–211. [Google Scholar] [CrossRef]

- Fener, M.; Kahraman, S.; Bilgil, A.; Gunaydin, O. A Comparative Evaluation of Indirect Methods to Estimate the Compressive Strength of Rocks. Rock Mech. Rock Eng. 2005, 38, 329–343. [Google Scholar] [CrossRef]

- Karaman, K.; Kesimal, A.; Ersoy, H. A comparative assessment of indirect methods for estimating the uniaxial compressive and tensile strength of rocks. Arabian J. Geosci. 2015, 8, 2393–2403. [Google Scholar] [CrossRef]

- Mishra, D.A.; Basu, A. Estimation of uniaxial compressive strength of rock materials by index tests using regression analysis and fuzzy inference system. Eng. Geol. 2013, 160, 54–68. [Google Scholar] [CrossRef]

- Yang, G.S.; Xi, J.M.; Wang, Z.J.; Cheng, L.; Li, H.J. Study on rock mechanical properties of frozen wall of main shaft in Hujiahe Coal Mine. J. China Coal Soc. 2010, 35, 565–570. [Google Scholar]

- Basu, A.; Mishra, D.A.; Roychowdhury, K. Rock failure modes under uniaxial compression, Brazilian, and point load tests. Bull. Eng. Geol. Environ. 2013, 72, 457–475. [Google Scholar] [CrossRef]

- Heidari, M.; Khanlari, G.R.; Kaveh, M.T.; Kargarian, S. Predicting the Uniaxial Compressive and Tensile Strengths of Gypsum Rock by Point Load Testing. Rock Mech. Rock Eng. 2012, 45, 265–273. [Google Scholar] [CrossRef]

- Barla, M.; Camusso, M.; Aiassa, S. Analysis of jacking forces during microtunnelling in limestone. Tunn. Undergr. Space Technol. 2006, 21, 668–683. [Google Scholar] [CrossRef]

- Palchik, V.; Hatzor, Y.H. The Influence of Porosity on Tensile and Compressive Strength of Porous Chalks. Rock Mech. Rock Eng. 2004, 37, 331–341. [Google Scholar] [CrossRef]

- Bayram, F. Predicting mechanical strength loss of natural stones after freeze—thaw in cold regions. Cold Reg. Sci. Technol. 2012, 83–84, 98–102. [Google Scholar] [CrossRef]

- Chen, T.C.; Yeung, M.R.; Mori, N. Effect of water saturation on deterioration of welded tuff due to freeze-thaw action. Cold Reg. Sci. Technol. 2004, 38, 127–136. [Google Scholar] [CrossRef]

- Hori, M.; Morihiro, H. Micromechanical analysis on deterioration due to freezing and thawing in porous brittle materials. Int. J. Eng. Sci. 1998, 36, 511–522. [Google Scholar] [CrossRef]

- Jamshidi, A.; Nikudel, M.R.; Khamehchiyan, M. Predicting the long-term durability of building stones against freeze-thaw using a decay function model. Cold Reg. Sci. Technol. 2013, 92, 29–36. [Google Scholar] [CrossRef]

- Mutlutürk, M.; Altindag, R.; Türk, G. A decay function model for the integrity loss of rock when subjected to recurrent cycles of freezing-thawing and heating-cooling. Int. J. Rock Mech. Min. Sci. 2004, 41, 237–244. [Google Scholar] [CrossRef]

- Xu, G.M.; Liu, Q.; Peng, W.; Chang, X. Experimental study on basic mechanical behaviors of rocks under low temperatures. Chin. J. Rock Mech. Eng. 2006, 25, 2502–2508. [Google Scholar]

- Inada, Y.; Yokota, K. Some studies of low temperature rock strength. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1984, 21, 145–153. [Google Scholar] [CrossRef]

- Kodama, J.; Goto, T.; Fujii, Y.; Hagan, P. The effects of water content, temperature and loading rate on strength and failure process of frozen rocks. Int. J. Rock Mech. Min. Sci. 2013, 62, 1–13. [Google Scholar] [CrossRef]

- Shan, R.; Yang, H.; Guo, Z.; Liu, X.; Song, L. Experimental study of strength characters of saturated red sandstone on negative temperature under triaxial compression. Chin. J. Rock Mech. Eng. 2014, 33, 3657–3664. [Google Scholar]

- Liu, X.S.; Tan, Y.L.; Ning, J.G. Mechanical properties and damage constitutive model of coal in coal-rock combined body. Int. J. Rock Mech. Min. Sci. 2018, 110, 140–150. [Google Scholar] [CrossRef]

- Bobet, A.; Einstein, H.H. Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int. J. Rock Mech. Min. Sci. 1998, 35, 863–888. [Google Scholar] [CrossRef]

- Li, L.; Lee, P.K.K.; Tsui, Y.; Tham, L.G.; Tang, C.A. Failure Process of Granite. Int. J. Geomech. 2003, 3, 84–98. [Google Scholar] [CrossRef]

- Tavallali, A.; Vervoort, A. Effect of layer orientation on the failure of layered sandstone under Brazilian test conditions. Int. J. Rock Mech. Min. Sci. 2010, 47, 313–322. [Google Scholar] [CrossRef]

- ASTM (2008), ASTM D4543-08, Standard practices for preparing rock core as cylindrical test specimens and verifying conformance to dimensional and shape tolerances. Available online: https://www.astm.org/Standards/D4543.htm (accessed on 21 March 2019).

- Zhou, Z.W.; Ma, W.; Zhang, S.J.; Du, H.M.; Mu, Y.H.; Li, G.Y. Multiaxial creep of frozen loess. Mech. Mater. 2016, 95, 172–191. [Google Scholar] [CrossRef]

- Zhou, Z.W.; Ma, W.; Zhang, S.J.; Mu, Y.H.; Zhao, S.P.; Li, G.Y. Yield surface evolution for columnar ice. Results Phys. 2016, 6, 851–859. [Google Scholar] [CrossRef]

- Zhou, Z.; Ma, W.; Zhang, S. Damage evolution and recrystallization enhancement of frozen loess. Int. J. Damage Mech. 2018, 27, 1131–1155. [Google Scholar] [CrossRef]

- ASTM (2010), ASTM D7012-10, Standard test method for compressive strength and elastic moduli of intact rock core specimens under varying states of stress and temperatures. Available online: https://www.astm.org/Standards/D7012.htm (accessed on 21 March 2019).

- Michalowski, R.L.; Ming, Z. Frost heave modelling using porosity rate function. Int. J. Numer. Anal. Methods Geomech. 2010, 30, 703–722. [Google Scholar] [CrossRef]

- Peng, W. Tensile strength of frozen loess varying with strain rate and temperature. Chin. J. Geotech. Eng. 1998, 20, 31–33. [Google Scholar]

- Liao, M.; Lai, Y.; Wang, C. A strength criterion for frozen sodium sulfate saline soil. Can. Geotech. J. 2016, 53, 1176–1185. [Google Scholar] [CrossRef]

- Fujii, Y.; Kiyama, T.; Ishijima, Y.; Kodama, J. Examination of a Rock Failure Criterion Based on Circumferential Tensile Strain. Pure Appl. Geophys. 1998, 152, 551–577. [Google Scholar] [CrossRef]

- Yang, G.S.; Lv, X.T. Experimental study on the sandy mudstone mechanical properties of shaft sidewalls under the frozen conditions. J. Min. Saf. Eng. 2012, 29, 492–496. [Google Scholar]

- Bauwens-Crowet, C.; Bauwens, J.C.; Homès, G. The temperature dependence of yield of polycarbonate in uniaxial compression and tensile tests. J. Mater. Sci. 1972, 7, 176–183. [Google Scholar] [CrossRef]

- Nadai, A.; Hodge, P.G. Theory of Flow and Fracture of Solids; McGraw-Hill: New York, NY, USA, 1963; Volume 2, p. 640. [Google Scholar]

- Yamabe, T.; Neaupane, K.M. Determination of some thermo-mechanical properties of Sirahama sandstone under subzero temperature condition. Int. J. Rock Mech. Min. Sci. 2001, 38, 1029–1034. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. Mechanism of brittle fracture of rock: Part I—theory of the fracture process. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1967, 4, 395–406. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stead, D.; Stimpson, B.; Read, R.S. Identifying crack initiation and propagation thresholds in brittle rock. Can. Geotech. J. 1998, 35, 222–233. [Google Scholar] [CrossRef]

- Martin, C.D.; Chandler, N.A. The progressive fracture of Lac du Bonnet granite. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1994, 31, 643–659. [Google Scholar] [CrossRef]

| Rock Specimen | Density (g·cm−3) | Water Content (%) | Effective Porosity (%) | ||||

|---|---|---|---|---|---|---|---|

| Dry | Natural | Saturated | Dry | Natural | Saturated | ||

| Sandstone | 2.6589 | 2.6810 | 2.7273 | 0 | 0.8312 | 2.5725 | 6.8368 |

| Coal sample | 1.4264 | 1.4414 | 1.4766 | 0 | 1.0539 | 3.5253 | 5.0283 |

| Rock Specimen | Parameter | ||||

|---|---|---|---|---|---|

| R2 | |||||

| Sandstone | 6.84 | −6.680 | −0.5 | 2.11 | 0.9984 |

| Coal sample | 1.79 | −4.417 | −0.5 | 0.29 | 0.9469 |

| Rock Specimen | Parameter | ||||

|---|---|---|---|---|---|

| R2 | |||||

| Sandstone | 48.67 | −3.256 | −0.5 | 7.78 | 0.8995 |

| Coal sample | 4.86 | −4.239 | −0.5 | 0.36 | 0.8585 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Li, S.; Zhang, T.; You, Z. Experimental Study on Mechanical Characteristics and Fracture Patterns of Unfrozen/Freezing Saturated Coal and Sandstone. Materials 2019, 12, 992. https://doi.org/10.3390/ma12060992

Wang C, Li S, Zhang T, You Z. Experimental Study on Mechanical Characteristics and Fracture Patterns of Unfrozen/Freezing Saturated Coal and Sandstone. Materials. 2019; 12(6):992. https://doi.org/10.3390/ma12060992

Chicago/Turabian StyleWang, Chong, Shuangyang Li, Tongwei Zhang, and Zhemin You. 2019. "Experimental Study on Mechanical Characteristics and Fracture Patterns of Unfrozen/Freezing Saturated Coal and Sandstone" Materials 12, no. 6: 992. https://doi.org/10.3390/ma12060992

APA StyleWang, C., Li, S., Zhang, T., & You, Z. (2019). Experimental Study on Mechanical Characteristics and Fracture Patterns of Unfrozen/Freezing Saturated Coal and Sandstone. Materials, 12(6), 992. https://doi.org/10.3390/ma12060992