Mechanical Performance of Biodegradable Thermoplastic Polymer-Based Biocomposite Boards from Hemp Shivs and Corn Starch for the Building Industry

Abstract

:1. Introduction

2. Materials and Methods

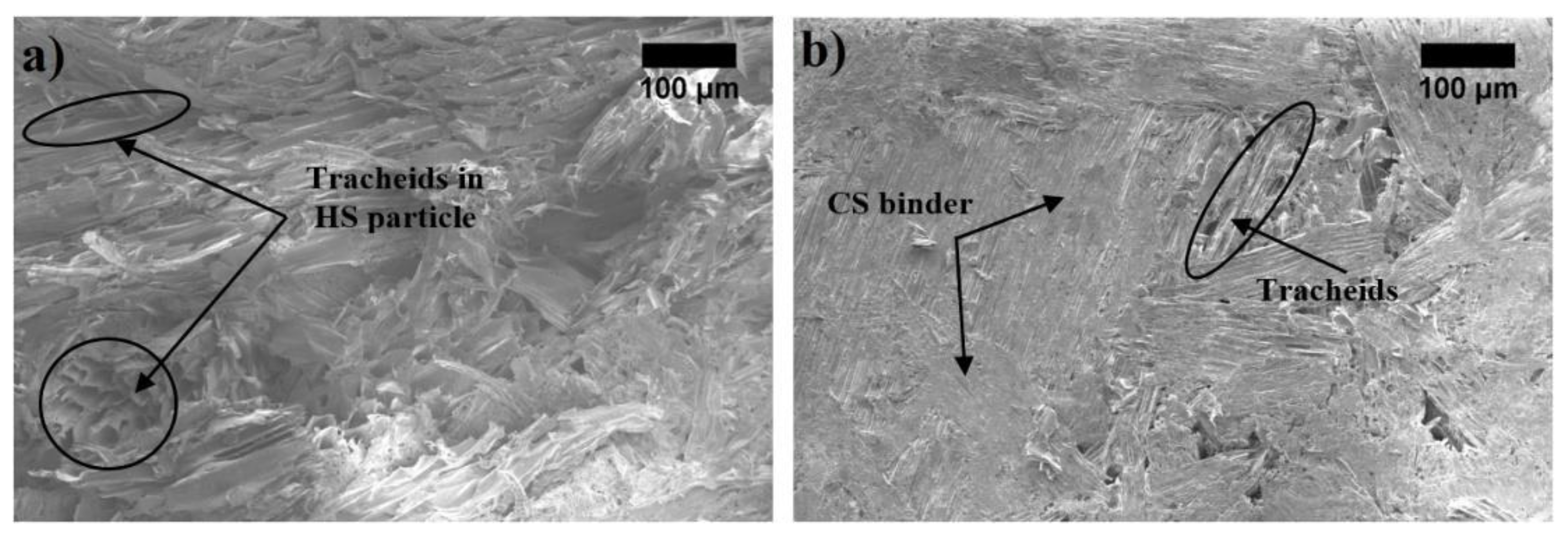

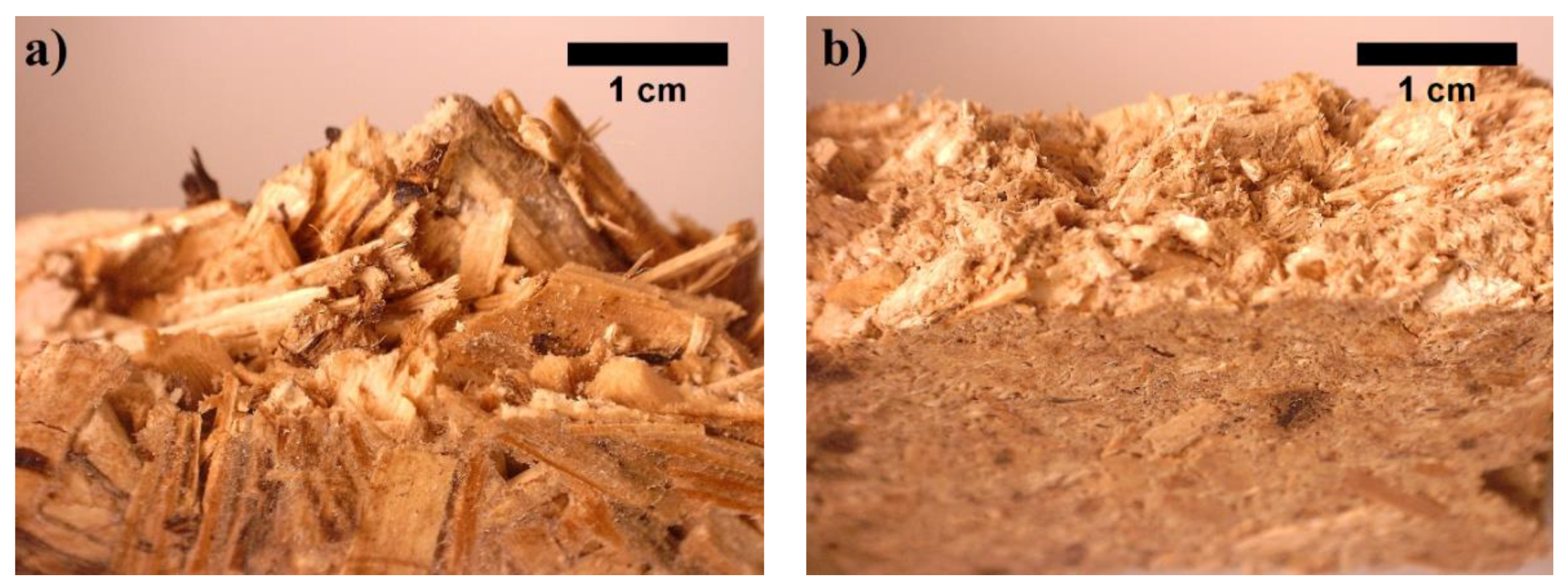

2.1. Raw Materials

2.2. Forming Process

2.3. Tests Methods

3. Results and Discussion

3.1. Compressive Strength of BcB

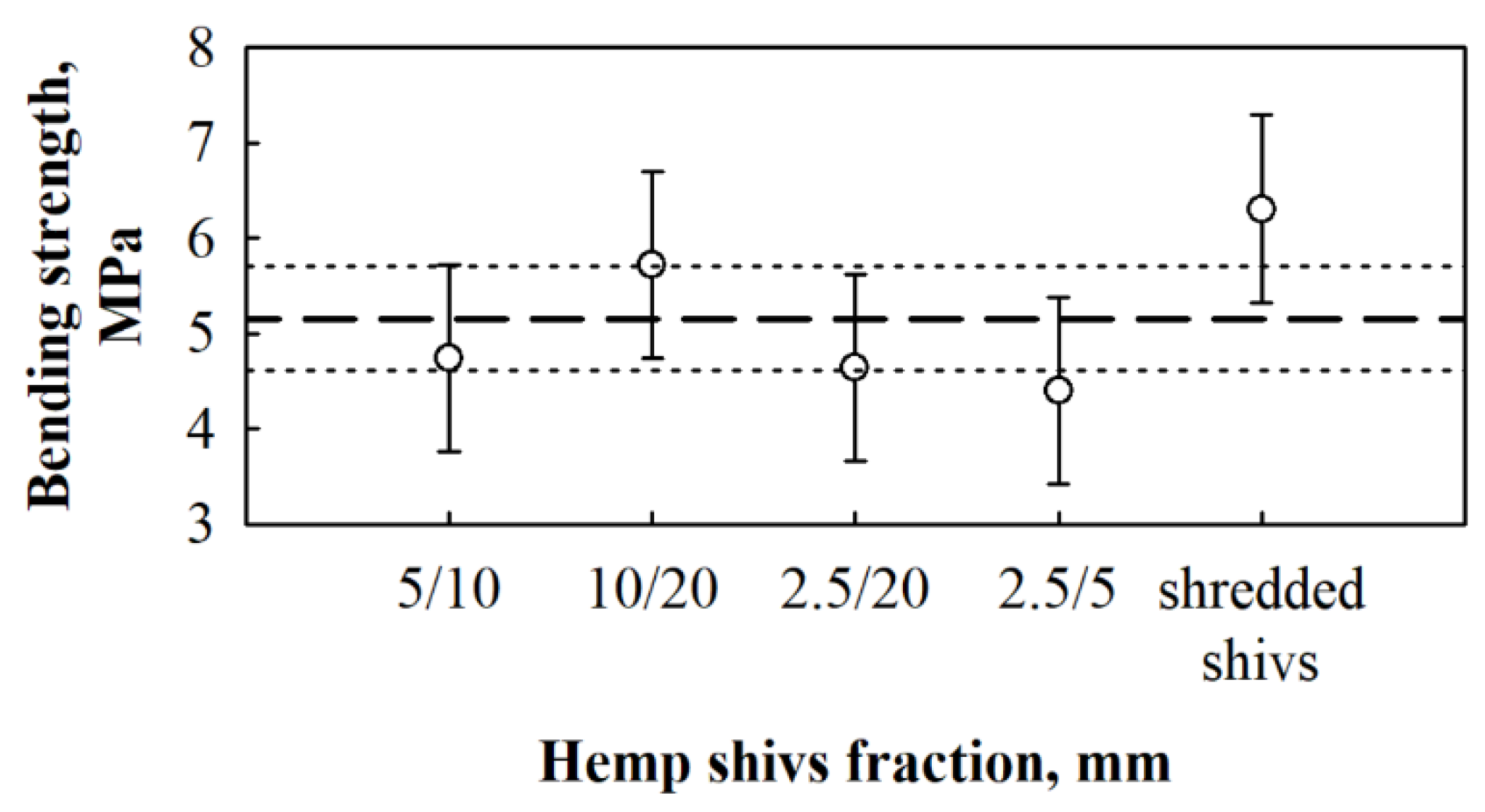

3.2. Bending Strength of BcB

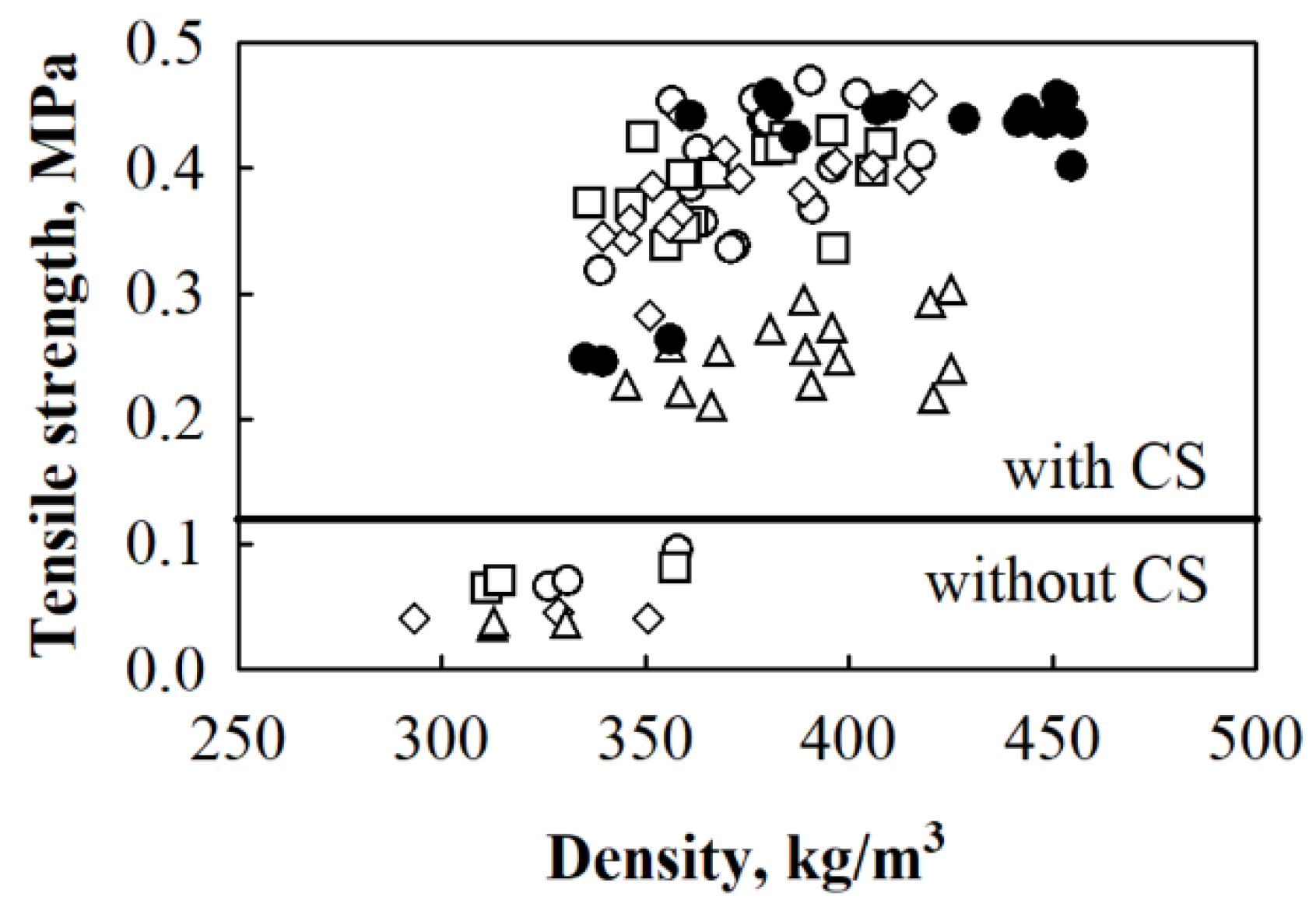

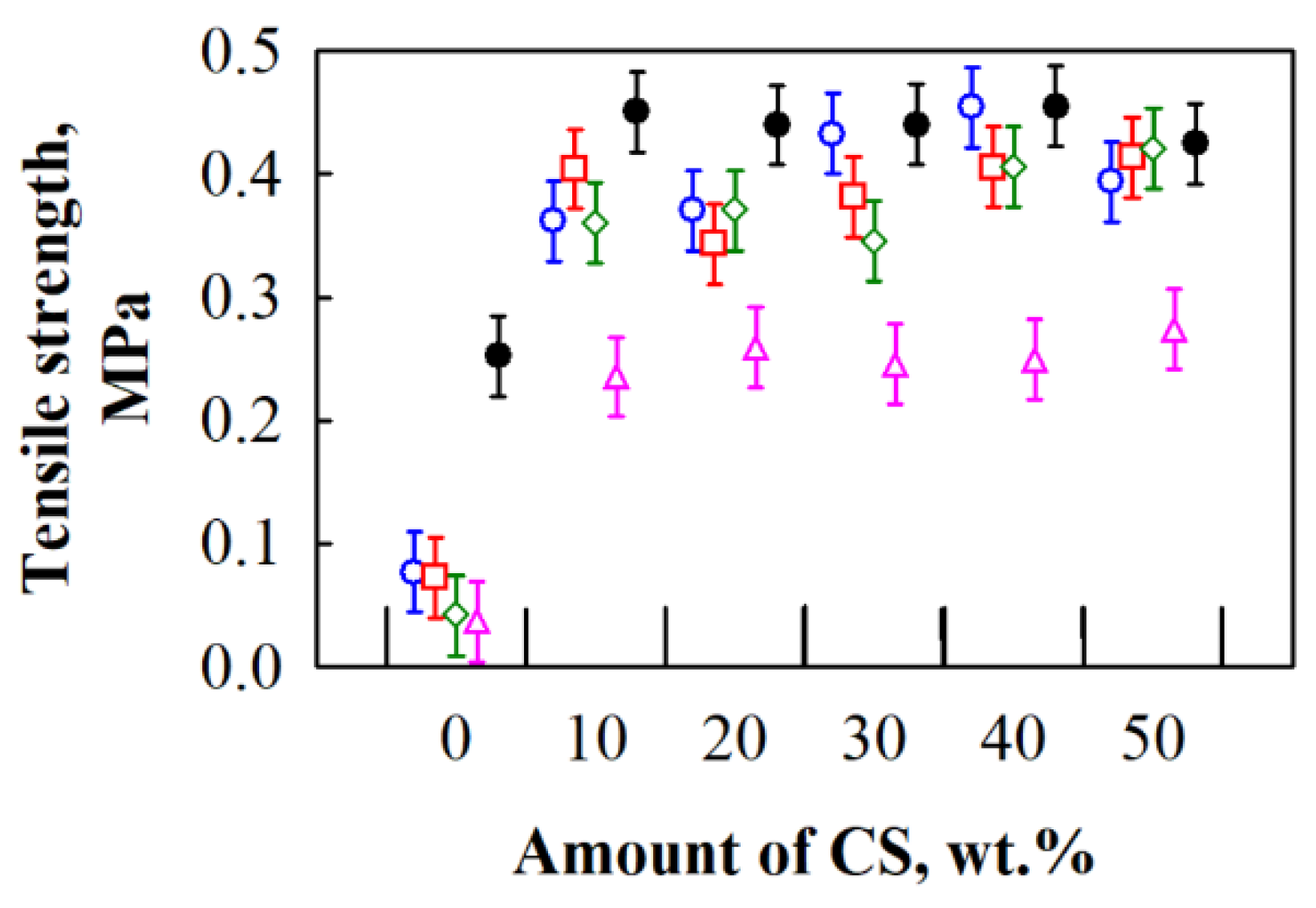

3.3. Tensile Strength of BcB

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ge, S.-B.; Gu, H.-P.; Ma, J.-J.; Yang, H.-Q.; Jiang, S.-C.; Liu, Z.; Peng, W.-X. Potential use of different kinds of carbon in production of decayed wood plastic composite. Arab. J. Chem. 2018, 11, 838–843. [Google Scholar] [CrossRef]

- Dhakal, U.; Berardi, U.; Gorgolewski, M.; Richman, R. Hygrothermal performance of hempcrete for Ontario (Canada) buildings. J. Clean. Prod. 2017, 142, 3655–3664. [Google Scholar] [CrossRef]

- Evrard, A. Bétons de Chanvre—Synthèse des Propriétés Physiques; Association Construire en Chanvre: Lorient, France, 2003; p. 100. [Google Scholar]

- Arnaud, L.; Cerezo, V.; Samri, D. Global approach for the design of building material containing lime and vegetable particles. In Proceedings of the 6th International Symposium on Cement and Concrete, Xi’an, China, 19 September 2006; pp. 1261–1265. [Google Scholar]

- Arnaud, L.; Gourlay, E. Experimental study of parameters influencing mechanical properties of hemp concretes. Constr. Build. Mater. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- Bruijn, P.B.; Jeppsson, K.H.; Sandin, K.; Nilsson, C. Mechanical properties of lime–hemp concrete containing shives and fibres. Biosyst. Eng. 2009, 103, 474–479. [Google Scholar] [CrossRef]

- Williams, J.; Lawrence, M.; Walker, P. The influence of constituents on the properties of the bio-aggregate composite hemp-lime. Constr. Build. Mater. 2018, 159, 9–17. [Google Scholar] [CrossRef]

- Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite materials based on hemp and flax for low-energy buildings. Materials 2017, 10, 510. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Picandet, V.; Carre, P.; Lecompte, T.; Amziane, S.; Baley, C. Effect of compaction on mechanical and thermal properties of hemp concrete. Eur. J. Environ. Civ. Eng. 2010, 14, 545–560. [Google Scholar] [CrossRef]

- Cigasova, J.; Stevulova, N.; Junak, J. Influence of binder nature on properties of ligweight composites based on hemp hurds. Int. J. Mod. Manuf. Technol. 2013, 5, 27–31. [Google Scholar]

- Balčiūnas, G.; Pundienė, I.; Lekūnaitė-Lukošiūnė, L.; Vėjelis, S.; Korjakins, A. Impact of hemp shives aggregate mineralization on physical–mechanical properties and structure of composite with cementitious binding material. Ind. Crops Prod. 2015, 77, 724–734. [Google Scholar] [CrossRef]

- Mikulionienė, S.; Baležentienė, L. Sapropelio biocheminė sudėtis ir efektyvumas penimų kiaulių priesvoriui didinti. Vet. Med. Zoot. 2009, 48, 37–44. [Google Scholar]

- Menzel, K.; Mirzaev, S.Z.; Kaatze, U. Crossover behavior in micellar solutions with lower critical demixing point: Broadband ultrasonic spectrometry of the isobutoxyethanol-water system. Phys. Rev. E 2003, 68, 73–84. [Google Scholar] [CrossRef]

- Capozzi, R.; Picotti, V. Pliocene sequence stratigraphy, climatic trends and sapropel formation in the Northern Apennines (Italy). Palaeogeogr. Palaeocl. 2003, 190, 349–371. [Google Scholar] [CrossRef]

- Balčiūnas, G.; Žvironaitė, J.; Vėjelis, S.; Jagniatinskis, A.; Gaidučis, S. Ecological, thermal and acoustical insulating composite from hemp shives and sapropel binder. Ind. Crops Prod. 2016, 91, 286–294. [Google Scholar] [CrossRef]

- Pleiksnis, S.; Sinka, M.; Sahmenko, G. Experimental justification for sapropel and hemp shives use as a thermal insulation in Latvia. In Proceedings of the 10th International Scientific and Practical Conference, Rezekne, Latvia, 18–20 June 2015; pp. 175–181. [Google Scholar]

- Averous, L. Biodegradable multiphase systems based on plasticized starch: A review. J. Macromol. Sci. Polym. Rev. 2004, 44, 231–274. [Google Scholar] [CrossRef]

- Curvelo, A.A.S.; Carvalho, A.J.F.; Agnelli, J.A.M. Thermoplastic starch–cellulosic fibers composites: Preliminary results. Carbohydr. Polym. 2001, 45, 183–188. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Ashok, A.; Abhijith, R.; Rejeesh, C.R. Material characterization of starch derived bio degradable plastics and its mechanical property estimation. Mater. Today Proc. 2018, 5, 2163–2170. [Google Scholar] [CrossRef]

- Bourdot, A.; Moussa, T.; Gacoin, A.; Maalouf, C.; Vazquez, P.; Thomachot-Schneider, C.; Bliard, C.; Merabtine, A.; Lachi, M.; Douzane, O.; et al. Characterization of hemp-based agro-material: Influence of starch ratio and hemp shive size on physical, mechanical, and hygrothermal properties. Energy Build. 2017, 153, 501–512. [Google Scholar] [CrossRef]

- Sandrine, U.B.; Isabelle, V.; Hoang, M.T.; Chadi, M. Influence of chemical modification on hemp-starch concrete. Constr. Build. Mater. 2015, 81, 208–215. [Google Scholar] [CrossRef]

- EN 622-4—Fibreboards—Specifications—Part 4: Requirements for Softboards; European Standardization Committee: Brussels, Belgium, 2010.

- Sun, Q.; Xi, T.; Li, Y.; Xiong, L. Characterization of corn starch films reinforced with CaCO3 nanoparticles. PLoS ONE 2014, 9, e106727. [Google Scholar] [CrossRef]

- EN 826—Thermal Insulating Products for Building Applications—Determination of Compression Behavior; European Standardization Committee: Brussels, Belgium, 2013.

- EN 310—Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; European Standardization Committee: Brussels, Belgium, 1999.

- EN 319—Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board; European Standardization Committee: Brussels, Belgium, 1999.

- EN 1602—Thermal Insulating Products for Building Applications—Determination of the Apparent Density; European Standardization Committee: Brussels, Belgium, 2013.

- Sokal, R.R.; Rohlf, F.J. Biometry. The principles and Practice of Statistics in Biological Research; W. H. Freeman and Company: New York, NY, USA, 1998; p. 887. [Google Scholar]

- Mazhoud, B.; Collet, F.; Pretot, S.; Lanos, C. Mechanical properties of hemp-clay and hemp stabilized clay composites. Constr. Build. Mater. 2017, 155, 1126–1137. [Google Scholar] [CrossRef]

- Seng, B.; Magniont, C.; Lorente, S. Characterization of a precast hemp concrete. Part I: Physical and thermal properties. J. Build. Eng. 2018, in press. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Schwarzova, I.; Sicakova, A.; Junak, J. Sustainable bio-aggregate-based composites containing hemp hurds and alternative binder. Buildings 2018, 8, 25. [Google Scholar] [CrossRef]

- Santos, E.B.C.; Moreno, C.G.; Barros, J.J.P.; Moura, D.A.; Fim, F.C.; Ries, A.; Wellen, R.R.M.; Silva, L.B. Effect of alkaline and hot water treatments on the structure and morphology of piassava fibers. Mater. Res. 2018, 21, 1–11. [Google Scholar] [CrossRef]

- Moreno, D.D.P.; Saron, C. Low-density polyethylene waste/recycled wood composites. Compos. Struct. 2017, 176, 1152–1157. [Google Scholar] [CrossRef]

- Le, A.T.; Gacoin, A.; Li, A.; Mai, T.H.; Wakil, N.E. Influence of various starch/hemp mixtures on mechanical and acoustical behavior of starch-hemp composite materials. Compos. Part B Eng. 2015, 75, 201–211. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel sustainable hemp-based composites for application in the building industry: Physical, thermal and mechanical characterization. Energy Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Opaliński, I.; Błaszczak, W. Mechanical properties of native maize, wheat and potato starches. Czech J. Food Sci. 2013, 31, 347–354. [Google Scholar] [CrossRef]

- Birnin-Yauri, A.; Abbot, P. Effect of starch composition on the strength of compression moldable starch-wood bio-composite materials. Res. Rev. 2014, 2, 10–13. [Google Scholar]

- Navikaitė, V.; Danilovas, P.P.; Klimavičiūtė, R.; Bendoraitienė, J. Tirpių vandenyje modifikuoto krakmolo jodoforų stabilumas. Chemine Technologija 2013, 1, 34–41. [Google Scholar]

- EN 316—Wood Fibre Boards—Definition, Classification and Symbols; European Standardization Committee: Brussels, Belgium, 2009.

| Raw Materials | HS Fraction, mm | |

|---|---|---|

| HS, g | CS Binder 1, wt.% | |

| 300 | 0; 10; 20; 30; 40; 50 | 5/10; 10/20; 2.5/20; 2.5/5; Shredded HS |

| Reference | Density, kg/m3 | Compressive Stress, MPa | Bending Strength, MPa | Tensile Strength, MPa |

|---|---|---|---|---|

| [21] | 182–188 | 0.57–0.63 | – | 0.080–0.11 |

| [22] | 177–210 | 0.40–0.80 | 0.15–0.25 | – |

| [35] | 164–174 | 0.014–0.080 | 0.030–0.13 | – |

| [36] | 300–600 | 1.2–3.0 | 0.90–6.8 | 0.18–0.49 |

| Current results | 319–408 | 1.8–3.4 | 1.2–6.9 | 0.092–0.42 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kremensas, A.; Kairytė, A.; Vaitkus, S.; Vėjelis, S.; Balčiūnas, G. Mechanical Performance of Biodegradable Thermoplastic Polymer-Based Biocomposite Boards from Hemp Shivs and Corn Starch for the Building Industry. Materials 2019, 12, 845. https://doi.org/10.3390/ma12060845

Kremensas A, Kairytė A, Vaitkus S, Vėjelis S, Balčiūnas G. Mechanical Performance of Biodegradable Thermoplastic Polymer-Based Biocomposite Boards from Hemp Shivs and Corn Starch for the Building Industry. Materials. 2019; 12(6):845. https://doi.org/10.3390/ma12060845

Chicago/Turabian StyleKremensas, Arūnas, Agnė Kairytė, Saulius Vaitkus, Sigitas Vėjelis, and Giedrius Balčiūnas. 2019. "Mechanical Performance of Biodegradable Thermoplastic Polymer-Based Biocomposite Boards from Hemp Shivs and Corn Starch for the Building Industry" Materials 12, no. 6: 845. https://doi.org/10.3390/ma12060845

APA StyleKremensas, A., Kairytė, A., Vaitkus, S., Vėjelis, S., & Balčiūnas, G. (2019). Mechanical Performance of Biodegradable Thermoplastic Polymer-Based Biocomposite Boards from Hemp Shivs and Corn Starch for the Building Industry. Materials, 12(6), 845. https://doi.org/10.3390/ma12060845