Statistical Analysis and Preliminary Study on the Mix Proportion Design of Self-Compacting Steel Fiber Reinforced Concrete

Abstract

1. Introduction

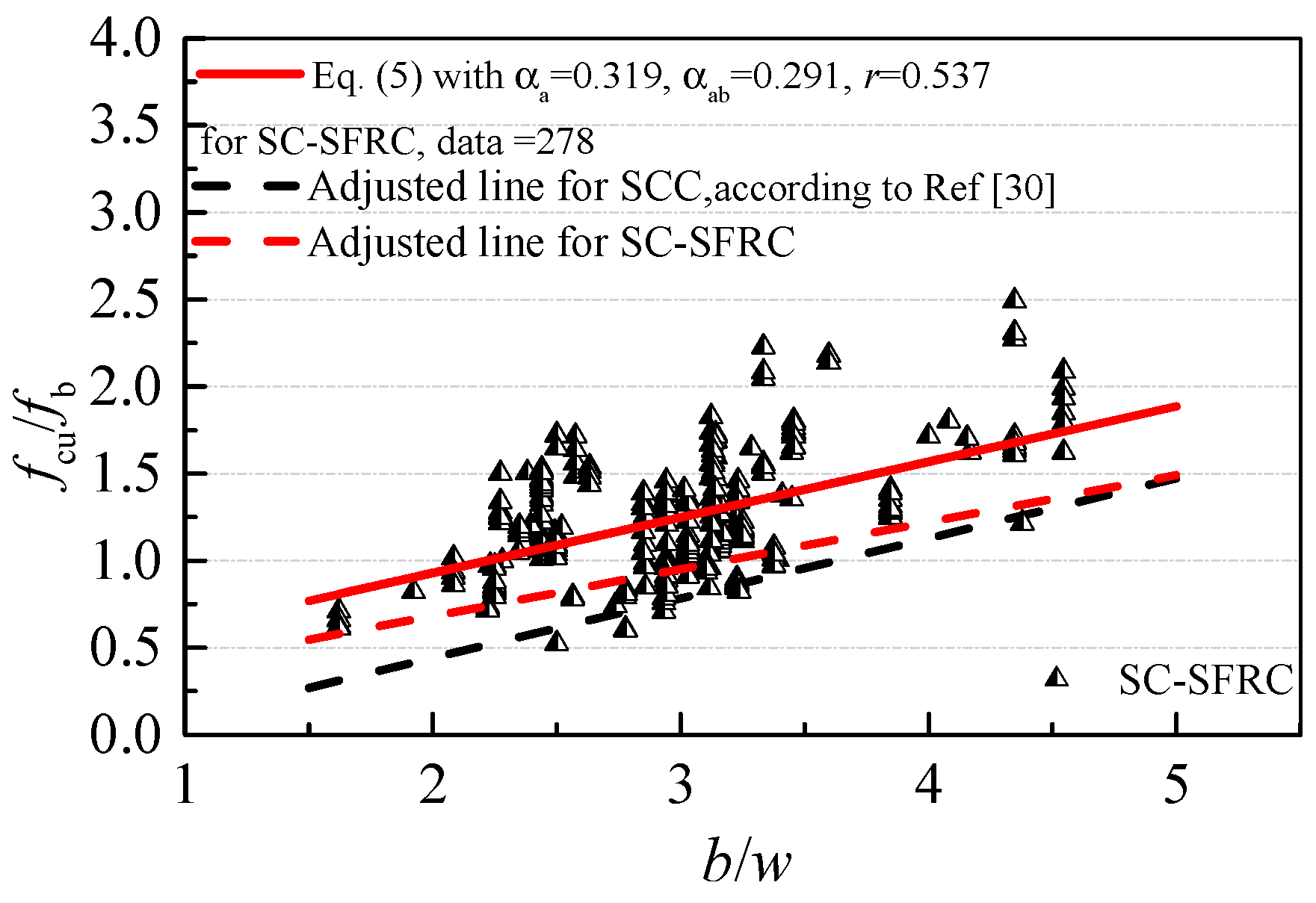

2. Statistical Analysis for Mix Proportion of SC-SFRC

2.1. Experimental Database

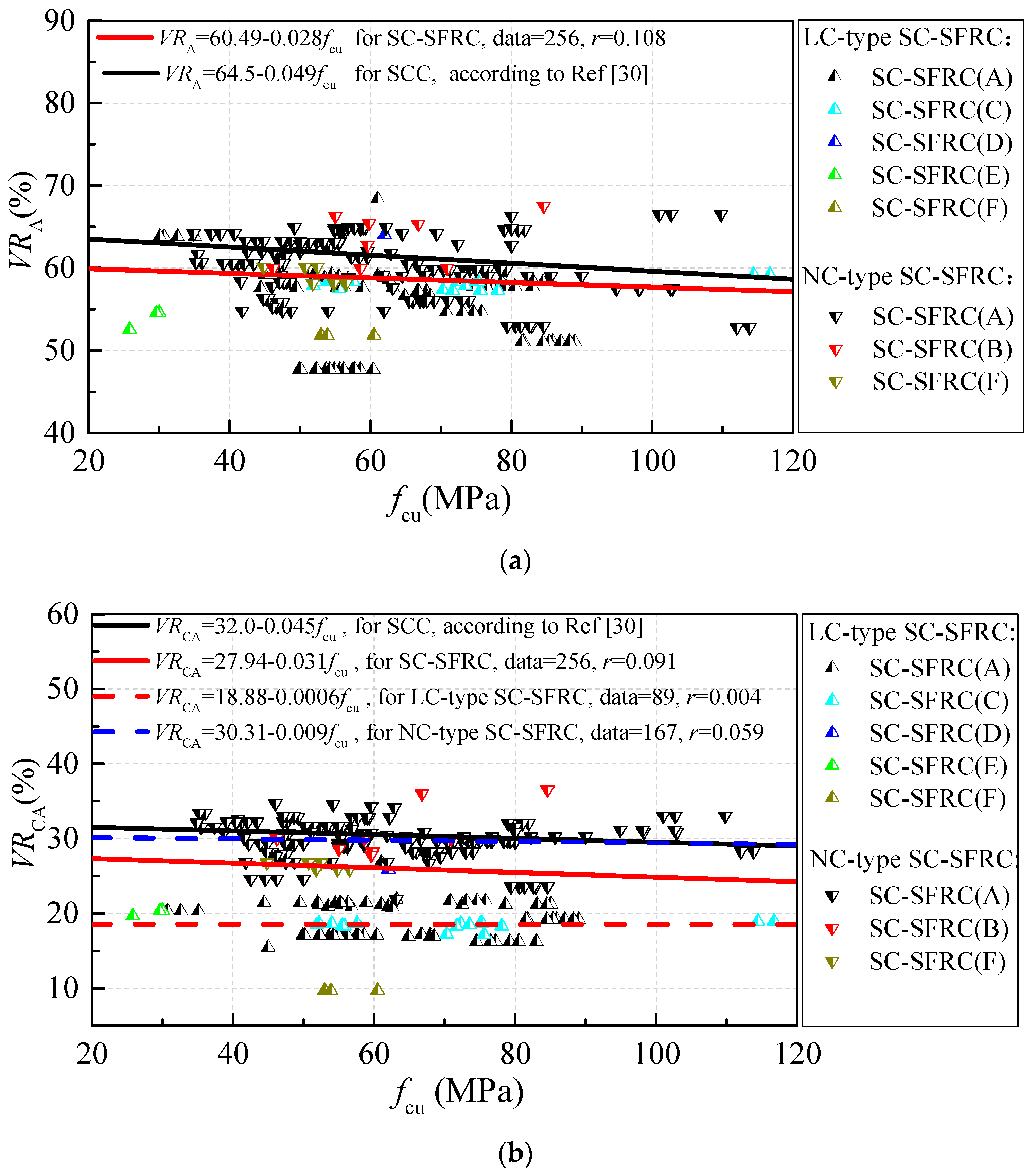

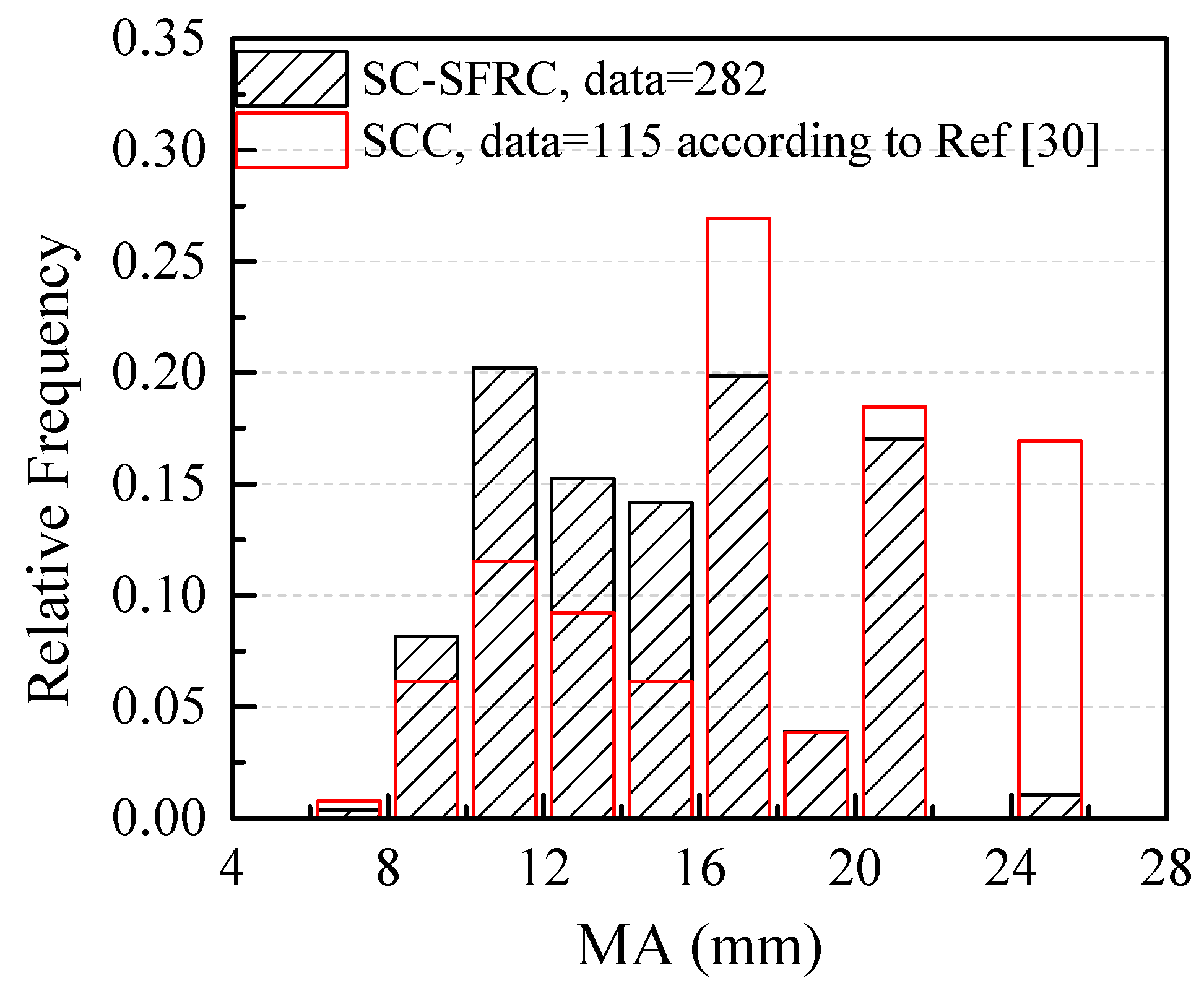

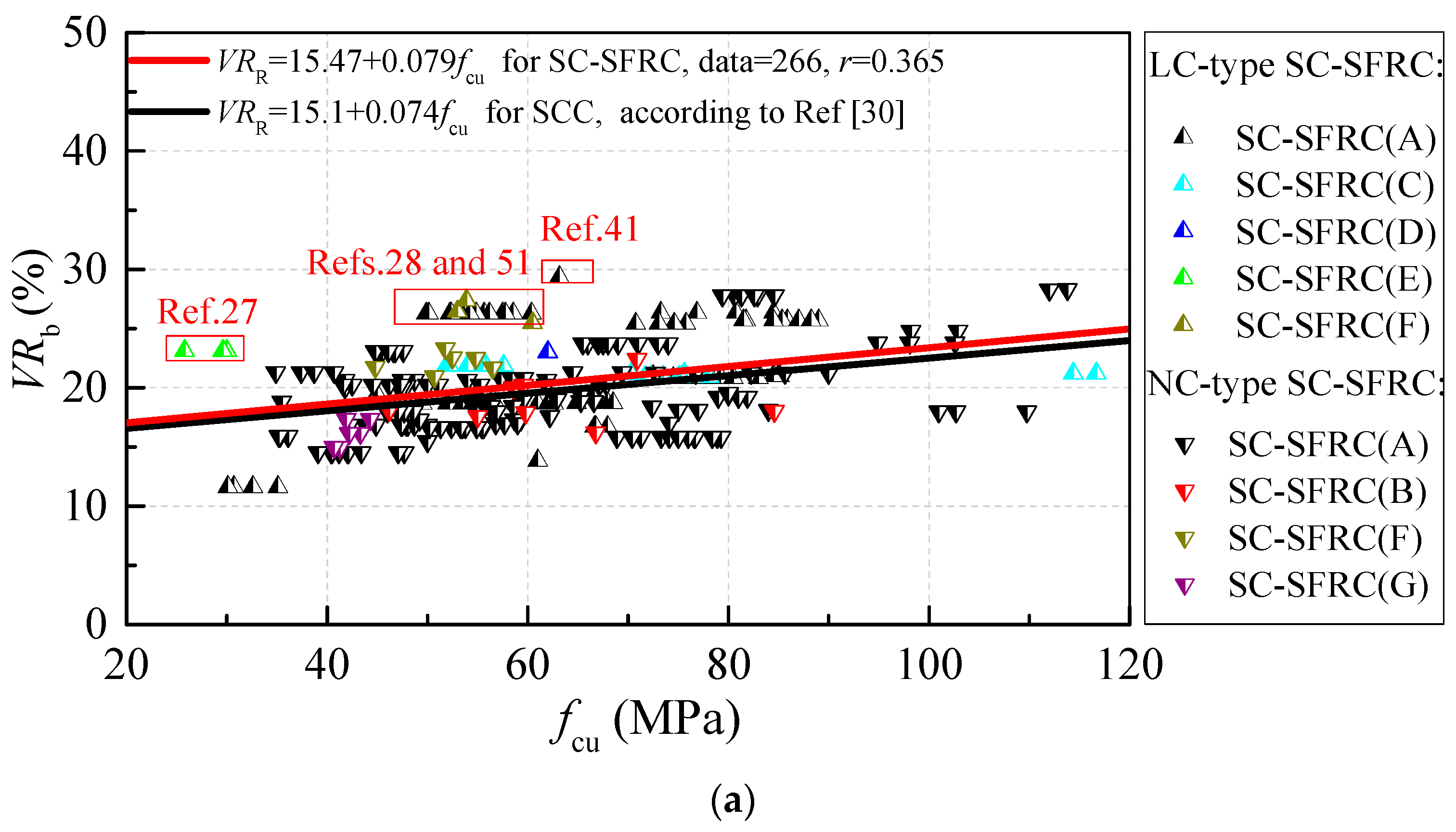

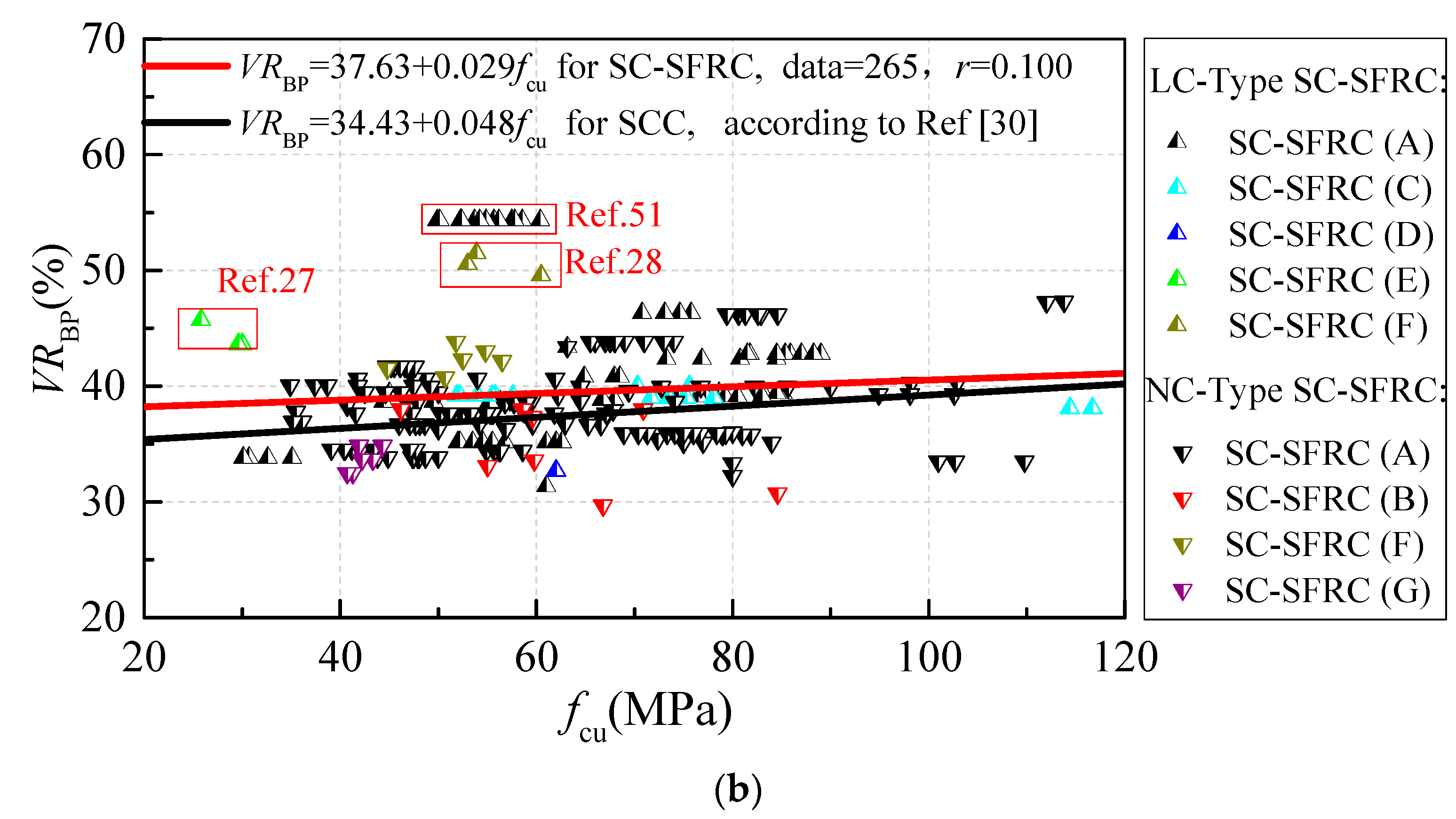

2.2. Aggregates

2.3. Binder and Binder Paste

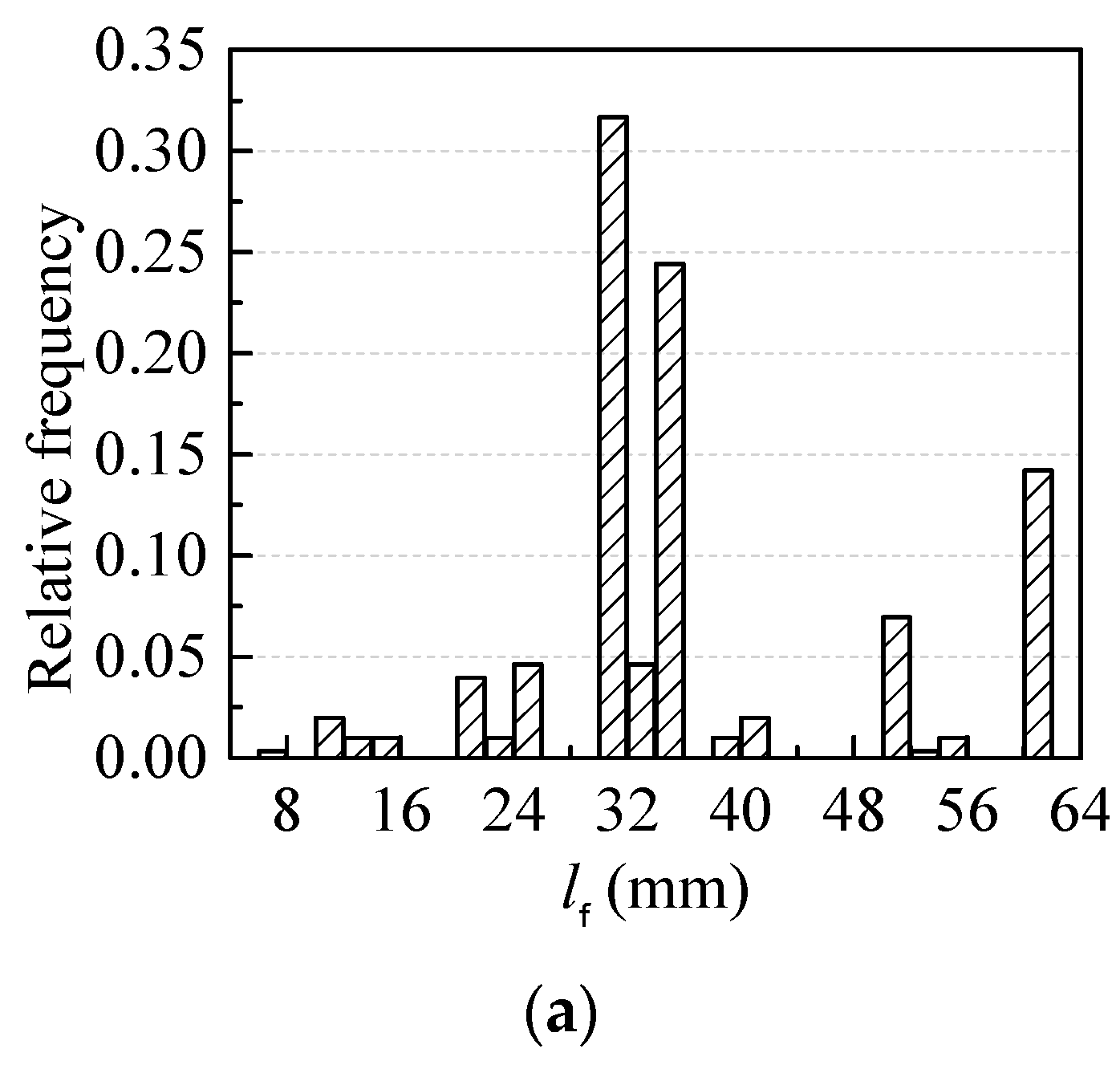

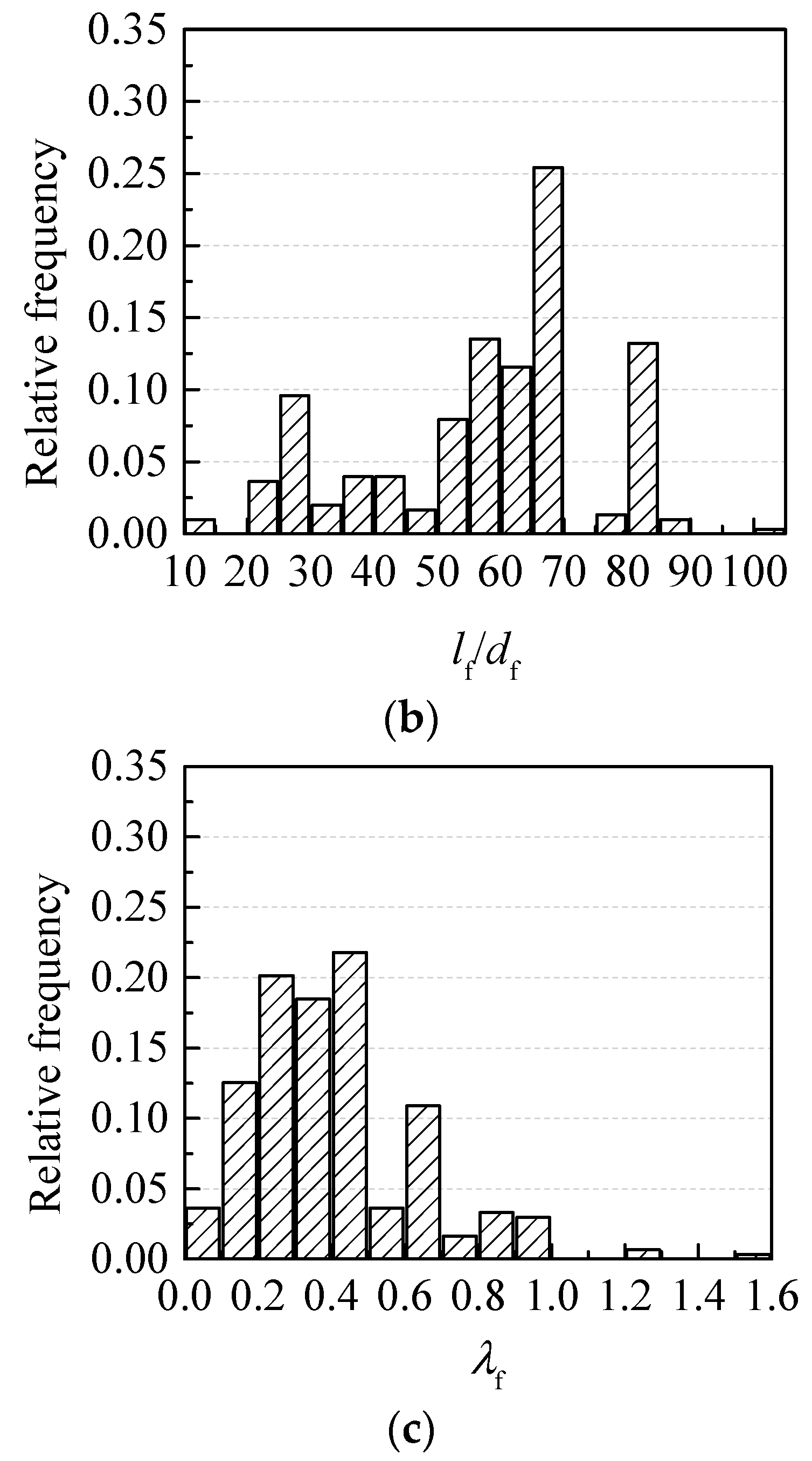

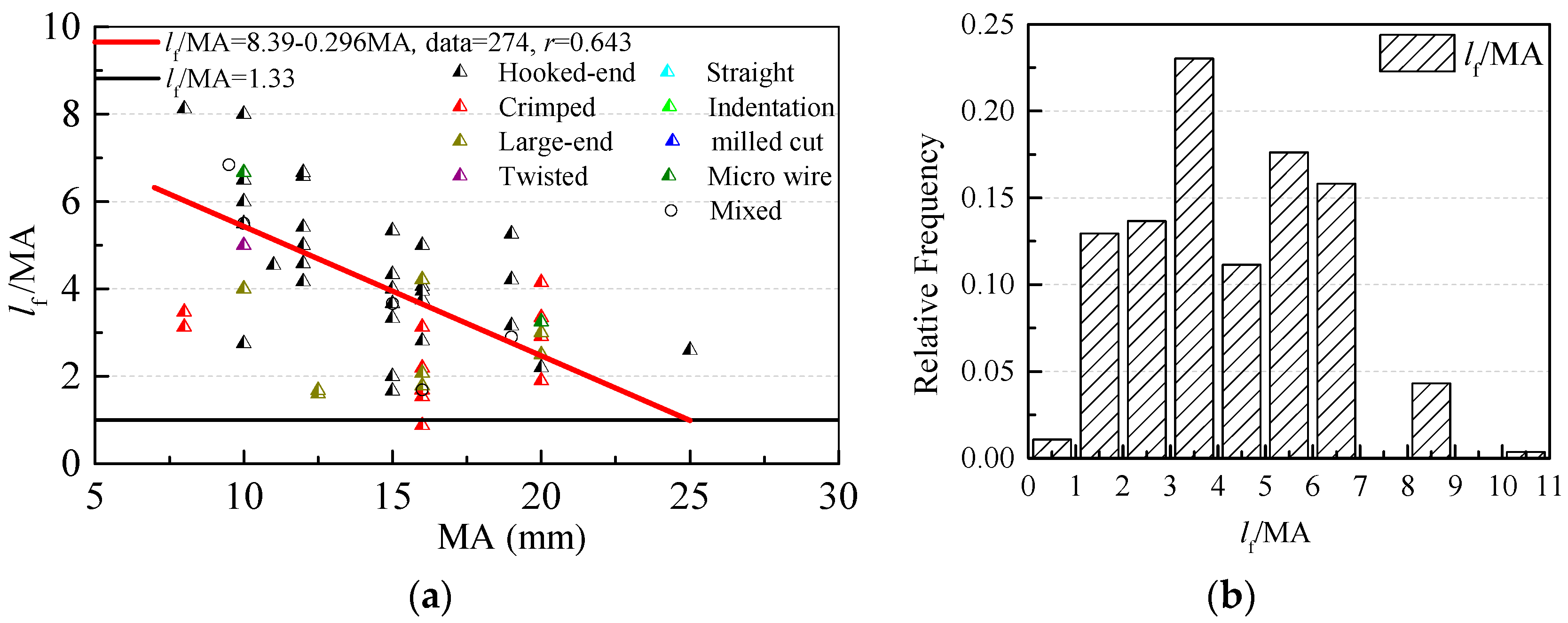

2.4. Steel Fiber

3. Calculation Model of Water-to-Binder Ratio for SC-SFRC

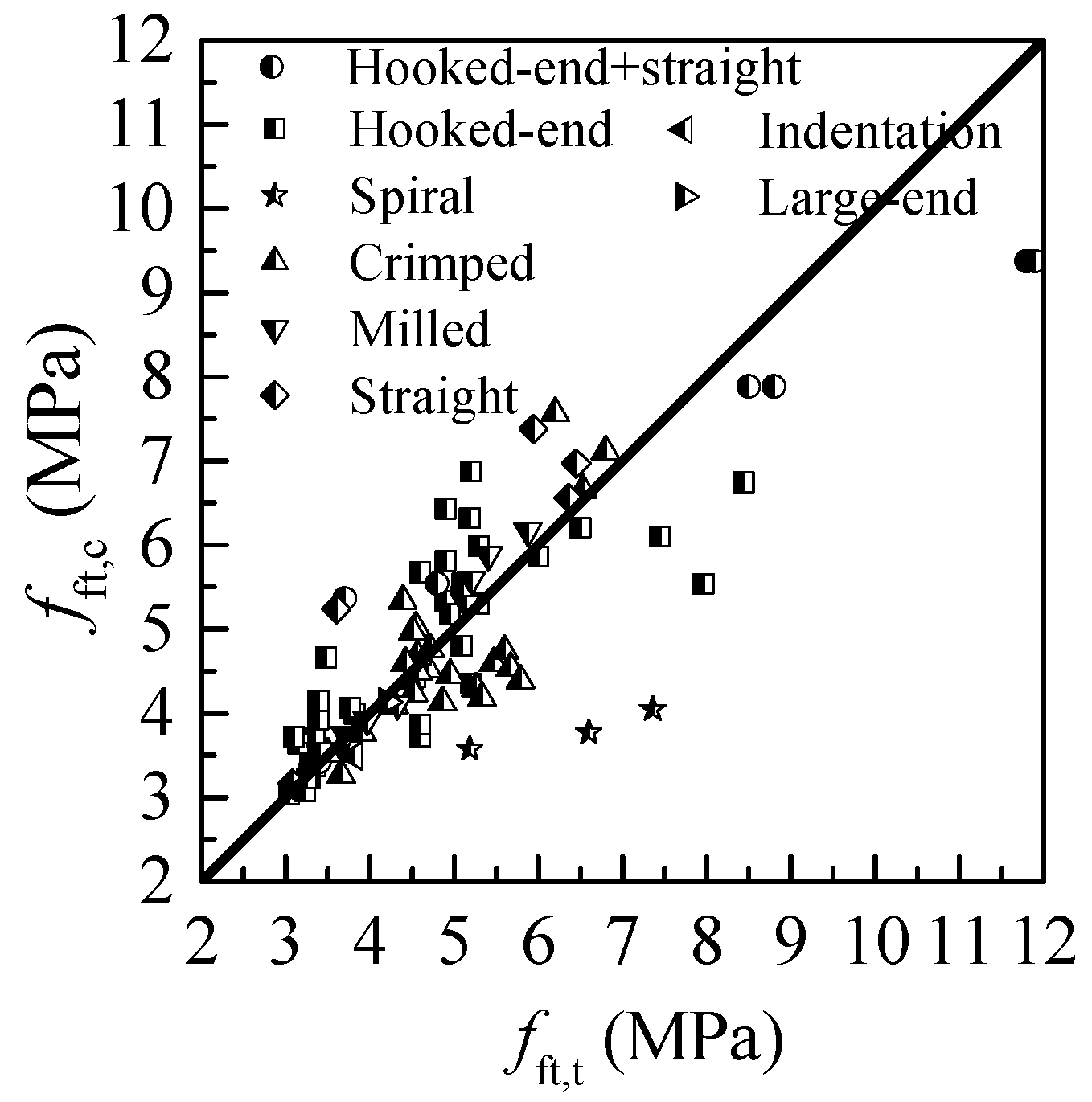

4. Designed Tensile Strength of SC-SFRC

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Ref. no | Cement Type | N | w/b | w/c | MA (mm) | βs (%) | Steel Fiber | fcu (MPa) | fft (MPa) | SF (mm) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | lf (mm) | lf/df | ρf (%) | ||||||||||

| [2] | CEM III 42.5N + CEM I 52.5R or/and CEM III 52.5A | 16 | 0.30 | 0.47 | 16 | 68 | Hooked-end | 60 | 80 | 0.77 | 54 | 6.3 | – |

| 0.30 | 0.47 | 16 | 68 | Hooked-end | 30 | 80 | 0.77 | 58 | 6.6 | – | |||

| 0.30 | 0.47 | 16 | 68 | Hooked-end | 40 | 65 | 1.28 | 52 | 6.6 | – | |||

| 0.30 | 0.47 | 16 | 68 | Hooked-end | 30 | 45 | 1.79 | 56 | 7.6 | – | |||

| 0.32 | 0.46 | 8 | 70 | Hooked-end | 30 | 80 | 0.51 | 70 | 7.6 | – | |||

| 0.32 | 0.46 | 8 | 70 | Hooked-end | 20 | 65 | 0.77 | 76 | 7.4 | – | |||

| 0.31 | 0.44 | 16 | 68 | Hooked-end | 60 | 80 | 0.77 | 75 | 8.7 | – | |||

| 0.31 | 0.44 | 16 | 68 | Hooked-end | 30 | 80 | 0.77 | 72 | 8.1 | – | |||

| 0.31 | 0.44 | 16 | 68 | Hooked-end | 40 | 65 | 1.28 | 74 | 8.9 | – | |||

| 0.31 | 0.44 | 16 | 68 | Hooked-end | 30 | 45 | 1.79 | 78 | 9.8 | – | |||

| 0.31 | 0.44 | 16 | 68 | Hooked-end | 60 | 80 | 0.77 | 75 | 8.1 | – | |||

| 0.31 | 0.44 | 16 | 68 | Hooked-end | 30 | 45 | 1.79 | 72 | 9.6 | – | |||

| 0.28 | 0.38 | 16 | 68 | Hooked-end | 60 | 80 | 0.77 | 117 | 12.4 | – | |||

| 0.30 | 0.47 | 16 | 68 | Hooked-end | 30 | 45 | 0.77 | 52 | 5.6 | – | |||

| 0.30 | 0.47 | 16 | 68 | Hooked-end | 30 | 45 | 1.54 | 56 | 7.3 | – | |||

| 0.28 | 0.38 | 16 | 68 | Hooked-end | 30 | 80 | 0.77 | 114 | 11.6 | – | |||

| [9] | CEM II 42.5 | 9 | 0.34 | 0.49 | 15 | 50–52 | Hooked-end | 25 | 25 | 0.35–1.0 | 42–46 | 3.0–3.3 | 653–693 |

| Hooked-end | 30 | 30 | 0.35–1.0 | 43–48 | 3.2–3.4 | 625–655 | |||||||

| Hooked-end | 50 | 50 | 0.35–1.0 | 40–45 | 3.3–3.4 | 594–638 | |||||||

| [10] | ASTM Type III | 3 | 0.30 | 0.43 | 19 | 49–50 | Hooked-end | 60 | 80 | 0.5 | 100–110 | 7.5–8.4 | 700–785 |

| [12] | P.O 42.5 | 6 | 0.31–0.34 | 0.61–0.67 | 20 | 50–57 | Straight | 30 | 60 | 0.3–1 | 35–69 | 2.5–5.3 | 665–680 |

| [13] | P.II 52.5 | 7 | 0.32–0.36 | 0.46–0.57 | 16 | 46–47 | Crimped | 25 | 50 | 0.38–0.89 | 75–84 | – | 445–665 |

| [14] | P.O.42.5R | 3 | 0.22 | 0.31 | 20 | 46 | straight | 10 | 62.5 | 0.3–0.9 | 98–103 | – | 570–655 |

| [15] | OPC #53 | 9 | 0.31 | 0.48 | 16 | 45–48 | - | 13 | 14 | 0.5–1.5 | 45–48 | 4.5–4.7 | 650–685 |

| - | 23 | 25 | 0.5–1.5 | 46–48 | 4.6–4.7 | 590–655 | |||||||

| - | 32 | 35 | 0.5–1.5 | 45–47 | 4.4–4.5 | 565–605 | |||||||

| [16] | CEM II | 4 | 0.31 | 0.40 | 15 | – | Hooked-end | 30 | 60 | 0.2–0.8 | 55–59 | 4.9–5.3 | 580–690 |

| [17] | CEM I | 5 | 0.23 | 0.27 | 10 | – | screw-type | 25 | 50 | 0.08–0.51 | 112–120 | 5.2–7.4 | 700–730 |

| 0.22 | 0.31 | 10 | 45 | Straight | 10 | 67 | 0.31–0.61 | 98–103 | – | 630–655 | |||

| [18] | P.O.42.5 | 3 | 0.30 | 0.38 | 20 | 48–49 | dumbbell-shaped | 20 | 50 | 0.6–0.8 | 79–82 | – | 635–680 |

| [19] | P.O.42.5 | 1 | 0.32 | 0.45 | 20 | 49 | Hooked-end | 35 | 65 | 0.26 | 72 | 5.3 | 720 |

| [22] | Type I PC | 5 | 0.25–0.32 | 0.42–0.62 | 19 | 44–56 | Hooked-end | 30 | 60 | 0.51–1.02 | 55–85 | – | 395–645 |

| 0.32 | 0.57 | 19 | 54 | Hooked-end | 50 | 100 | 0.51 | 60 | – | 620 | |||

| [23] | OPC #53 | 3 | 0.23–0.36 | 0.37–0.58 | 20 | 52 | Hooked-end | 35 | 65 | 0.5–0.75 | 46–71 | 4.9–6.5 | 610–660 |

| [26] | CEM I 42.5R | 1 | 0.15 | 0.27 | 12 | 59 | Hooked-end | 60 | 80 | 0.38 | 62 | – | 720 |

| [27] | ASTM Type I | 3 | 0.40 | 0.904 | 19 | 60 | Hooked-end | 30 | 55 | 0.77 | 26 | 3.1 | 660 |

| 0.36 | 0.82 | 19 | – | Hooked-end&straight | – | – | 0.77 | 30 | 3.4 | 630 | |||

| 0.36 | 0.82 | 19 | 60 | Straight | 6 | 37.5 | 0.77 | 30 | 3.1 | 700 | |||

| [28] | P.O 42.5 | 9 | 0.33 | 0.41–0.55 | 20 | 53–76 | Hooked-end | 35 | 65 | 0.6–1.2 | 45–61 | 3.7–6.4 | 650–700 |

| [29] | CEM I42.5 N | 6 | 0.34–0.39 | 0.5 | 16 | 61 | Hooked-end&straight | 30 | 60 | 0.4–0.7 | 41–44 | – | 500–600 |

| [31] | CEM II 42.5 | 7 | 0.40–0.44 | 0.44–048 | 8 | 49 | Hooked-end | 35 | 65 | 0.64 | 49–62 | 2.9–5.1 | 450–850 |

| [32] | CEM I42.5 R | 4 | 0.21 | 0.39 | 13 | 59 | Hooked-end | 33 | 60 | 0.77 | 75–85 | – | 680–720 |

| [33] | P.O 42.5 | 3 | 0.34 | 0.5 | 20 | 44 | Crimped | 15 | 40 | 0.5–1.25 | 54–63 | – | 650–685 |

| [34] | CEM I 52.5R | 2 | 0.36 | 0.47 | 18 | 55 | Hooked-end | 50 | 50 | 0.45 | – | – | 540 |

| Hooked-end | 30 | 79 | 0.45 | – | – | 590 | |||||||

| [35] | P.O 42.5 | 9 | 0.31–0.37 | 0.39–0.48 | 20 | 48 | Hooked-end | 35 | 44 | 0.2–0.6 | 35–60 | – | 610–705 |

| [36] | P.O 42.5 | 7 | 0.35 | 0.50 | 10 | 49–50 | Hooked-end | 60 | 80 | 0.26–0.76 | 49–62 | – | 650–710 |

| 0.33–0.35 | 0.46–0.50 | 10 | 48–50 | Hooked-end | 35 | 65 | 0.32–0.64 | 42–67 | – | 650–760 | |||

| [37] | CEM I 42.5R | 12 | 0.41 | 0.41 | 8 | 47–49 | Crimped | 35 | 28 | 0.5–1.5 | 69–77 | – | 740–805 |

| Crimped | 50 | 25 | 0.5–1.5 | 75–79 | – | 720–795 | |||||||

| [38] | P.C 32.5R | 7 | 0.45 | 0.56 | 10 | 45 | Hooked-end | 35 | 65 | 0.25–0.51 | 35–36 | – | 420–580 |

| P.O 42.5R | 0.35 | 0.5 | 10 | 51 | Hooked-end | 35 | 65 | 0.32–0.64 | 42–48 | – | 730–760 | ||

| P.II 52.5R | 0.33 | 0.46 | 10 | 50 | Hooked-end | 35 | 65 | 0.32–0.64 | 65–67 | – | 650–700 | ||

| [39] | – | 5 | 0.22–0.41 | 0.25–0.41 | 10 | 51–63 | Hooked-end | 30 | 55 | 0.51–0.64 | 80 | – | 560–830 |

| [40] | – | 1 | 0.41 | 0.41 | 11 | 60 | Hooked-end | 50 | 50 | 0.64 | 61 | – | 570 |

| [41] | CEM 42.5 R | 1 | 0.34 | 0.34 | – | – | Hooked-end | 33 | 60 | 0.8 | 63 | – | 670 |

| [42] | CEM II/A-L 42.5 R | 1 | 0.34 | 0.40 | 10 | – | Straight | 11 | 27.5 | 0.65 | 45 | – | 650 |

| [43] | ASTM Type I | 3 | 0.32 | 0.71 | 10 | 48 | Hooked-end | 30 | 60 | 0.5–1.5 | 55–67 | – | 550–670 |

| [44] | P.O 42.5 | 11 | 0.34 | 0.49 | 20 | 46–49 | Mill-cut | 32 | 40 | 0.3-1.2 | 40–45 | 5.2–6.2 | 650–685 |

| [45] | OPC # 53 | 9 | 0.35 | 0.35 | 20 | 41 | Straight | 50 | – | – | 41–42 | 3.5–4.3 | – |

| Hooked-end | 50 | – | – | 43–44 | 4.0–4.3 | – | |||||||

| Crimped | 50 | – | – | 44–48 | 4.0–4.5 | – | |||||||

| [46] | CEM I 52.5R | 12 | 0.26 | 0.26 | 10 | – | Double Hook-end | 60 | 65 | 0.25–1.0 | 66–74 | – | 730–810 |

| Double Hook-end | 60 | 65 | 0.25–1.0 | 66–71 | – | 765–830 | |||||||

| Single hooked-end | 60 | 65 | 0.25-1.0 | 67–73 | – | 740–810 | |||||||

| [47] | CEM I 42.5R | 6 | 0.43 | 0.43 | 15 | 70 | Hooked-end | 30 | 45 | 0.5 | 68 | – | 740 |

| straight | 6 | 37.5 | 0.5 | 67 | – | 760 | |||||||

| mixed | 0.5 | 67 | – | 750 | |||||||||

| 0.85 | 15 | 70 | Hooked-end | 30 | 45 | 0.5 | 68 | – | 710 | ||||

| straight | 6 | 37.5 | 0.5 | 65 | – | 720 | |||||||

| mixed | 0.5 | 69 | – | 700 | |||||||||

| [48] | CPIII 40 | 4 | 0.32 | 0.5 | 9.5 | – | Hooked-end | 35 | 65 | 1.0–1.5 | – | – | – |

| Hooked-end and straight | 35/12 | 65/67 | 1.0–1.5 | – | – | – | |||||||

| [49] | SLC | 1 | 0.52 | 1.3 | 10 | – | Hooked-end | 60 | 80 | 0.38 | 50 | 4.5 | 670 |

| [50] | CEM1 42.5R | 2 | 0.24 | 0.45 | 12 | – | Hooked-end | 60 | 80 | 0.38–0.57 | 84–89 | – | 700 |

| [51] | ASTM type I | 22 | 0.41 | 0.77 | 12 | 65 | Hooked-end | 30 | 80 | 0.5–1.5 | 50–59 | – | 570–650 |

| Hooked-end | 30 | 55 | 0.5–1.5 | 50–58 | – | 585–635 | |||||||

| 4DHooked-end | 60 | 65 | 0.5–1.5 | 55–60 | – | 535–635 | |||||||

| 5DHooked-end | 60 | 65 | 0.75–1.5 | 52–54 | – | 505–555 | |||||||

| 0.29 | 0.36 | 12 | 63 | Hooked-end | 30 | 80 | 0.5–1.5 | 82–87 | – | 570–720 | |||

| 4DHooked-end | 60 | 65 | 0.75–1.5 | 88–89 | – | 595–750 | |||||||

| 5DHooked-end | 60 | 65 | 0.75–1.5 | 82–85 | – | 685–720 | |||||||

| [52] | ASTM Type I | 18 | 0.32 | 0.46 | 15 | 48.6 | Hooked-end | 30 | 55 | 0.26–0.77 | 73–90 | – | 600–750 |

| 48.6 | Hooked-end | 60 | 80 | 0.26–0.77 | 65–86 | – | 530–720 | ||||||

| 63.2 | Hooked-end | 30 | 55 | 0.26–0.77 | 79–85 | – | 640–755 | ||||||

| 63.2 | Hooked-end | 60 | 80 | 0.26–0.77 | 73–85 | – | 600–750 | ||||||

| 71.5 | Hooked-end | 30 | 55 | 0.26–0.77 | 77–83 | – | 680–765 | ||||||

| 71.5 | Hooked-end | 60 | 80 | 0.26–0.77 | 75–81 | – | 660–760 | ||||||

| [53] | ASTM Type II | 8 | 0.48 | 0.48 | 12.5 | 60 | Milled-cut | 20.6 | 20 | 0.4–1.5 | 43–50 | 3.4–4.3 | 640–750 |

| 0.38 | 0.42 | 12.5 | 60 | Milled-cut | 20.6 | 20 | 0.4–1.6 | 71–76 | 5.1–5.9 | 730–780 | |||

| [54] | CEM II/B 42.5N | 13 | 0.4 | 0.4 | 20 | 50 | Crimped | 35 | 58 | 0.3–1.2 | 48–53 | 4.3–5.6 | 650–800 |

| Crimped | 40 | 67 | 0.3–1 | 51–53 | 4.9–5.7 | 650–795 | |||||||

| Crimped | 50 | 83 | 0.3–1 | 52–53 | 5.3–5.8 | 630–750 | |||||||

| [55] | Type II PC | 6 | 0.23 | 0.37 | 10 | 52–53 | Crimped | 25 | 50 | 0.5–1.0 | 100–106 | 6.2–6.8 | 720–770 |

| straight | – | – | 0.5–1.0 | 99–103 | 5.9–6.4 | 730–780 | |||||||

| [56] | Type II PC | 4 | 0.62 | 0.62 | 6 | 69 | Hooked-end | 35 | 65 | 0.19–0.77 | 29–33 | – | 580–770 |

| [57] | CEM I 42.5R | 9 | 0.44 | 0.44 | 16 | 46 | Straight and crimped mixed | 6/35 | 32/27 | 1–2 | 39–48 | – | 700–790 |

| [58] | High Strength PC | 9 | 0.32 | 0.5 | 13.2 | 64–65 | Hooked-end | 35 | 65 | 0.5–1 | 52–63 | 3.2–5.2 | 570–675 |

| [59] | ASTM Type I | 5 | 0.35 | 0.4 | 19 | 63 | Hooked-end and straight mixed | 35/6 | 55/37.5 | 0.77 | 44–59 | 3.6–5.1 | 615–695 |

| [60] | P.O 42.5 | 6 | 0.31–0.32 | 0.44–0.46 | 16 | 53–57 | Crimped | 38.8 | 33.2 | 0.5–1.5 | 46–57 | 3.5–3.9 | 690–740 |

| Indentation | 32.3 | 28.5 | 1 | 49 | 3.8 | 715 | |||||||

| Hooked-end | 50.7 | 63.3 | 1 | 48 | 3.8 | 660 | |||||||

| Large-end | 52.2 | 67.4 | 1 | 47 | 4.2 | 665 | |||||||

| [61] | CEM II/A-LL 42.5R | 1 | 0.29 | 0.44 | 12 | 54 | Hooked-end | 50 | 63 | 0.51 | 68 | – | 720 |

References

- Athiyamaan, V.; Ganesh, G.M. Statistical and detailed analysis on fiber reinforced self-compacting concrete containing admixtures-A state of art of review. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 032037. [Google Scholar] [CrossRef]

- Grunewald, S. Performance Based Design of Self-Compacting Steel Fiber Reinforced Concrete. Ph.D. Thesis, Delft University of Technology, Holland, The Netherlands, 2004. [Google Scholar]

- Larrard, F.D. Concrete Mixture Proportioning: A Scientific Approach; Spon Press: London, UK, 1999; pp. 77–169. [Google Scholar]

- Grünewald, S.; Walraven, J.C. Parameter-study on the influence of steel fibers and coarse aggregate content on the fresh properties of self-compacting concrete. Cem. Concr. Res. 2001, 31, 1793–1798. [Google Scholar] [CrossRef]

- Martinie, L.; Rossi, P.; Roussel, N. Rheology of fiber reinforced cementitious materials: classification and prediction. Cem. Concr. Res. 2010, 40, 226–234. [Google Scholar] [CrossRef]

- Ghzai, F.K.; Rand, S.A.J. New method for proportioning self-consolidating concrete based on compressive strength requirements. ACI Mater. J. 2010, 107, 490–497. [Google Scholar]

- Barros, J.; Pereira, E.; Santos, S. Lightweight panels of steel fiber-reinforced self-compacting concrete. J. Mater. Civ. Eng. 2007, 19, 295–304. [Google Scholar] [CrossRef]

- Ponikiewski, T. The rheological properties of fresh steel fibre reinforced self-compacting concrete. In Proceedings of the 8th International Symposium on Brittle Matrix Composites, Warsaw, Poland, 23–25 October 2006; Woodhead Publishing Limited: Cambridge, UK, 2006; pp. 451–458. [Google Scholar]

- Haddadou, N.; Chaid, R.; Ghernouti, Y. Experimental study on steel fibre reinforced self-compacting concrete incorporating high volume of marble powder. Rev. Française Génie Civ. 2015, 19, 48–64. [Google Scholar] [CrossRef]

- Dhonde, H.B.; Mo, Y.L.; Hsu, T.T.C.; Vogel, J. Fresh and hardened properties of self-consolidating fiber-reinforced concrete. ACI Mater. J. 2007, 104, 491–500. [Google Scholar]

- Vijaykumar, H.; Shamu, S. A critical study on the influence of steel fiber on performance of fresh and hard self-compacting concrete. J. Struct. Eng. (India) 2015, 42, 237–245. [Google Scholar]

- Li, Y.H. Study of Mix Design and Mechanical Properties of Fiber Reinforced Self-Compacting Concrete. Master’s Thesis, Fuzhou University, Fuzhou, China, 2006. (In Chinese). [Google Scholar]

- Huang, K.J.; Li, G.F.; Wang, Y.G.; Wei, Y. Properties of high strength self-compacting steel fiber reinforced concrete used in bridge steel-mixes union section. J. Wuhan Univ. Technol. 2013, 35, 107–111, 116. (In Chinese) [Google Scholar]

- Wang, C.; Lin, H.B.; Yang, C.H.; Ye, J.X.; Bai, G. Preparation technology of fiber toughened self-compacting high-strength concrete. J. Civ. Archit. Environ. Eng. 2013, 35, 129–134. (In Chinese) [Google Scholar]

- Rao, B.K.; Ravindra, V. Steel fiber reinforced self-compacting concrete incorporating class F fly ash. Int. J. Eng. Sci. Technol. 2010, 2, 4936–4943. [Google Scholar]

- Gencel, O.; Brostow, W.; Datashvili, T.; Thedford, M. Workability and mechanical performance of steel fiber-reinforced self-compacting concrete with fly ash. Compos. Interfaces 2011, 18, 169–184. [Google Scholar] [CrossRef]

- Ei-Dibe, A.S. Mechanical, durability and microstructural characteristics of ultra-high-strength self-compacting concrete incorporating steel fibers. Mater. Des. 2009, 30, 4286–4292. [Google Scholar]

- Gao, H.; Li, B.X.; Cui, G.; Zha, J. Mix proportion design and experimental study on CF55 self-compacting concrete reinforced by steel fiber. Concrete 2008, 8, 82–83, 107. (In Chinese) [Google Scholar]

- Yu, C.H.; Liu, J.Y.; Xiao, X. Mixture ratio design and application of C60 self-compacting concrete reinforced by steel fiber. Concrete 2007, 7, 74–78. (In Chinese) [Google Scholar]

- Chen, R.L. Mix Proportion and Mechanical Properties of Fiber Reinforced Self-Compacting Concrete. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2015. (In Chinese). [Google Scholar]

- Fernandes, P.A.L.; Veludo, J.; Almeida, N.; Baptista, J.; Rodrigues, H. Study of a self‑compacting fiber‑reinforced concrete to be applied in the precast industry. Innov. Infrast. Solut. 2018, 3, 28. [Google Scholar] [CrossRef]

- Tsai, C.T.; Li, L.S.; Chang, C.C.; Hwang, C.L. Durability design and application of steel fiber reinforced concrete in Taiwan. Arab. J. Sci. Eng. 2009, 34, 57–79. [Google Scholar]

- Basheerudeen, A.; Anandan, S. Simplified mix design procedures for steel fibre reinforced self-compacting concrete. Eng. J. 2015, 19, 22–24. [Google Scholar] [CrossRef]

- Yu, A.B.; Standish, N.; McLean, A. Porosity calculation of binary mixtures of non-spherical particles. J. Am. Ceram. Soc. 1993, 76, 2813–2816. [Google Scholar] [CrossRef]

- Ferrara, L.; Park, Y.D.; Shah, S.P. A method for mix-design of fiber-reinforced self-compacting concrete. Cem. Concr. Res. 2007, 37, 957–971. [Google Scholar] [CrossRef]

- Pereira, E.N.B.; Barros, J.A.O.; Camões, A. Steel fiber-reinforced self-compacting concrete: Experimental research and numerical simulation. J. Struct. Eng. 2008, 134, 1310–1321. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yaman, I.O. Hybrid fiber reinforced self-compacting concrete with a high-volume coarse fly ash. Constr. Build. Mater. 2007, 21, 150–156. [Google Scholar] [CrossRef]

- Cai, H.S. Testing Research on Mix Proportion and Mechanical Performance of Steel Fiber Reinforced Self-Compacting Concrete. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2006. (In Chinese). [Google Scholar]

- Anastasiou, E.K.; Papayianni, I.; Papachristoforou, M. Behavior of self-compacting concrete containing ladle furnace slag and steel fiber reinforcement. Mater. Des. 2014, 59, 454–460. [Google Scholar] [CrossRef]

- Zhao, M.L.; Ding, X.X.; Li, J.; Law, D. Numerical analysis of mix proportion of self-compacting concrete compared to ordinary concrete. Key Eng. Mater. 2018, 789, 69–75. [Google Scholar] [CrossRef]

- Ferrara, L.; Bamonte, P.; Caverzan, A.; Musa, A.; Sanal, I. A comprehensive methodology to test the performance of steel fibre reinforced self-compacting concrete. Constr. Build. Mater. 2012, 37, 406–424. [Google Scholar] [CrossRef]

- Mazaheripour, H.; Barros, J.A.O.; Sena-Cruz, J.M.; Pepe, M.; Martinelli, E. Experimental study on bond performance of GFRP bars in self-compacting steel fiber reinforced concrete. Compos. Struct. 2013, 95, 202–212. [Google Scholar] [CrossRef]

- Zhang, C.X. Research of Steel Fiber Self-Compacting Concrete. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2010. (In Chinese). [Google Scholar]

- Torrijos, M.C.; Barragán, B.E.; Zerbino, R.L. Placing conditions, mesostructural characteristics and post-cracking response of fibre reinforced self-compacting concretes. Constr. Build. Mater. 2010, 24, 1078–1085. [Google Scholar] [CrossRef]

- Zhao, Y.R.; Hao, S.; Gao, M.B.; Fan, X.Q.; Shi, J.N. Research of steel fiber self-compacting concrete workability and compressive strength. Constr. Technol. 2017, 46, 61–64. (In Chinese) [Google Scholar]

- Ding, Y.N.; Liu, Y.J.; Liu, S.G.; Liu, H.K. Study on shear resistance of steel fiber reinforced self-compacting concrete beams. Shuili Xuebao 2011, 42, 461–468. (In Chinese) [Google Scholar]

- Ponikiewski, T.; Katzer, J. X-ray computed tomography of fibre reinforced self-compacting concrete as a tool of assessing its flexural behaviour. Mater. Struct. 2016, 49, 1–10. [Google Scholar] [CrossRef]

- Liu, H.K. Influence of Steel Fiber on the Flexural and Shear Behavior of High Performance Self-Consolidating Concrete Elements. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2012. (In Chinese). [Google Scholar]

- Deeb, R.; Ghanbari, A.; Karihaloo, B.L. Development of self-compacting high and ultra high performance concretes with and without steel fibres. Cem. Concr. Compos. 2012, 34, 185–190. [Google Scholar] [CrossRef]

- Orbe, A.; Cuadrado, J.; Losada, R.; Rojí, E. Framework for the design and analysis of steel fiber reinforced self-compacting concrete structures. Constr. Build. Mater. 2012, 35, 676–686. [Google Scholar] [CrossRef]

- Abrishambaf, A.; Barros, J.A.O.; Cunha, V.M.C.F. Relation between fibre distribution and post-cracking behaviour in steel fibre reinforced self-compacting concrete panels. Cem. Concr. Res. 2013, 51, 57–66. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Durable fiber reinforced self-compacting concrete. Cem. Concr. Res. 2004, 34, 249–254. [Google Scholar] [CrossRef]

- Miao, B.Q.; Chern, J.C.; Yang, C.A. Influences of fiber content on properties of self-compacting steel fiber reinforced concrete. J. Chin. Inst. Eng. 2003, 26, 523–530. [Google Scholar] [CrossRef]

- Cai, Y. Study on the Preparation and Properties of Steel Fiber Self-Compacting Concrete. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2018. (In Chinese). [Google Scholar]

- Patel, Y.; Pasha, N.; Azam, D.S.K.M. Effect of different types of steel fibers on strength parameters of self compacting concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 14727–14736. [Google Scholar]

- Okeh, C.; Begg, D.; Barnett, S.; Nanos, N. Discrete hooked-end steel fibre shape and geometry on material properties of self-compacting concrete under bending stress. In Proceedings of the International Concrete Conference 2016 on Environment, Efficiency and Economic Challenges for Concrete, Dundee, UK, 4–6 July 2016. [Google Scholar]

- Yalçınkaya, Ç.; Yazıcı, H. The effect of high volume GGBFs replacement on mechanical performance of self-compacting steel fiber reinforced concrete. In Proceedings of the 9th International Congress on Advances in Civil Engineering, Trabzon, Turkey, 27–30 September 2010; pp. 1–10. [Google Scholar]

- Rambo, D.A.S.; Silva, F.D.A.; Filho, R.D.T. Mechanical behavior of hybrid steel-fiber self-consolidating concrete: materials and structural aspects. Mater. Des. 2014, 54, 32–42. [Google Scholar] [CrossRef]

- Aslani, F.; Bastami, M. Relationship between deflection and crack mouth opening displacement of self-compacting concrete beams with and without fibers. Mech. Adv. Mater. Struct. 2015, 22, 956–967. [Google Scholar] [CrossRef]

- Cunha, V.M.C.F.; Barros, J.A.O.; Sena-Cruz, J.M. An integrated approach for modelling the tensile behaviour of steel fibre reinforced self-compacting concrete. Cem. Concr. Res. 2011, 41, 64–76. [Google Scholar] [CrossRef]

- Tameemi, W. Correlations between Compressive, Flexural and Tensile Behavior of Self-Consolidating Fiber Reinforced Concrete. Master’s Thesis, University of Kansas, Lawrence, KS, USA, 2015. [Google Scholar]

- Yardimci, M.Y.; Baradan, B.; Taşdemir, M.A. Effect of fine to coarse aggregate ratio on the rheology and fracture energy of steel fibre reinforced self-compacting concretes. Sadhana 2014, 39, 1447–1469. [Google Scholar] [CrossRef]

- Khaloo, A.; Raisi, E.M.; Hosseini, P.; Tahsiri, H. Mechanical performance of self-compacting concrete reinforced with steel fibers. Constr. Build. Mater. 2014, 51, 179–186. [Google Scholar] [CrossRef]

- Irkia, I.; Debieba, F.; Kadrib, E.H.; Boukendakdji, O.; Bentchikou, M.; Soualhi, H. Effect of the length and the volume fraction of wavy steel fibers on the behavior of self-compacting concrete. J. Adhes. Sci. Technol. 2016, 31, 735–748. [Google Scholar] [CrossRef]

- Ghanbarpour, S. The effect of type and volume fraction (VF) of steel fiber on the mechanical properties of self-compacting concrete. J. Eng. Des. Technol. 2010, 8, 247–256. [Google Scholar] [CrossRef]

- Poveda, E.; Ruiz, G.; Cifuentes, H.; Yu, R.C.; Zhang, X. Influence of the fiber content on the compressive low-cycle fatigue behavior of self-compacting SFRC. Int. J. Fatigue 2017, 101, 9–17. [Google Scholar] [CrossRef]

- Pajak, M.; Ponikiewski, T. Experimental investigation on hybrid steel fibers reinforced self compacting concrete under flexure. Procedia Eng. 2017, 193, 218–225. [Google Scholar] [CrossRef]

- Silva, M.A.D.; Pepe, M.; Pfeil, M.S.; Toledo Filho, R.D. Rheological and mechanical behavior of high strength steel fiber-river gravel self-compacting concrete. Constr. Build. Mater. 2017, 150, 606–618. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yurtseven, A.; Yaman, I.O. Workability of hybrid fiber reinforced self-compacting concrete. Build. Environ. 2005, 40, 1672–1677. [Google Scholar] [CrossRef]

- Ding, X.X.; Li, C.Y.; Han, B.; Lu, Y.Z.; Zhao, S.B. Effects of different deformed steel-fibers on preparation and fundamental properties of self-compacting SFRC. Constr. Build. Mater. 2018, 168, 471–481. [Google Scholar] [CrossRef]

- Conforti, A.; Plizzari, G.A.; Zerbino, R. Vibrated and self-compacting fibre reinforced concrete: experimental investigation on the fibre orientation. IOP Conf. Ser. Mater. Sci. Eng. 2017, 246. [Google Scholar] [CrossRef]

- Boel, V.; Craeye, B.; Desnerck, P.; Van Der Vurst, F.; De Schutter, G. Influence of specimen shape and dimensions on the compressive strength of self compacting concrete. In Proceedings of the 7th International RILEM Symposium on Self-Compacting Concrete, Paris, France, 2–4 September 2013; pp. 596–605. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Steel Fiber Reinforced Concrete; JG/T 472-2015; Standards Press of China: Beijing, China, 2015. (In Chinese) [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Specification for Mix Proportion Design of Ordinary Concrete; JGJ/T55-2011; China Architecture & Building Press: Beijing, China, 2011. (In Chinese) [Google Scholar]

- Ding, X.X.; Lu, Y.Z.; Han, B.; Zhao, M.S.; Chen, M.H.; Zhao, S.B. Influence coefficient of fly-ash for determination of binder strength in mix proportion design of concrete. In Proceedings of the International Conference on Architectural Engineering and New Materials, Guangzhou, China, 30–31 January 2015; pp. 115–123. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Application of Self-Compacting Concrete; JGJ/T 283-2012; China Architecture & Building Press: Beijing, China, 2012. (In Chinese) [Google Scholar]

- Vilanova, A.; Fernandez-Gomez, J.; Landsberger, G.A. Evaluation of the mechanical properties of self compacting concrete using current estimating models: Estimating the modulus of elasticity, tensile strength and modulus of rupture of self compacting concrete. Constr. Build. Mater. 2011, 25, 3417–3426. [Google Scholar] [CrossRef]

- Craeye, B.; Itterbeeck, P.V.; Desnerck, P.; Boel, V. Schutter, G.D. Modulus of elasticity and tensile strength of self-compacting concrete: survey of experimental data and structural design codes. Cem. Concr. Compos. 2014, 54, 53–61. [Google Scholar] [CrossRef]

- Domone, P.L. A review of the hardened mechanical properties of self-compacting concrete. Cem. Concr. Compos. 2007, 29, 1–12. [Google Scholar] [CrossRef]

- Li, X.K.; Huo, H.Y.; Zhang, L.; Zhao, S.B. Experimental study on mechanical properties of concrete reinforce by hybrid steel fiber. J. Henan Univ. 2017, 1, 101–107. (In Chinese) [Google Scholar]

| Index | Minimum Value | Maximum Value | |

|---|---|---|---|

| Water-to-binder ratio (w/b) | 0.15 | 0.52 | |

| Water-cement ratio (w/c) | 0.25 | 1.30 | |

| Coarse aggregate | Maximum particle size (MA) (mm) | 8 | 25 |

| Apparent density (kg/m3) | 2600 | 3170 | |

| Fine aggregate | Maximum particle size (MA) (mm) | 2 | 5 |

| Fineness modulus | 1.9 | 3.5 | |

| Apparent density (kg/m3) | 2590 | 2720 | |

| Sand ratio by mass βs (%) | 41 | 76 | |

| Cement density (kg/m3) | 3090 | 3170 | |

| Steel fiber | Length lf (mm) | 6 | 60 |

| Aspect ratio lf/df | 15 | 120 | |

| Volume fraction ρf (%) | 0.08 | 1.79 | |

| Slump flow (SF) (mm) | 500 | 830 | |

| The cubic compressive strength (fcu) (MPa) | 20 | 120 | |

| The splitting tensile strength (fft) (MPa) | 3.0 | 12.4 | |

| Percentage of Fly-Ash | 0 | 10 | 20 | 30 | 40 | 50 |

|---|---|---|---|---|---|---|

| Fly-ash of class I or superfine fly-ash; Fly-ash of class II with w/b ≤ 0.35 | 1 | 1.00–1.05 | 0.95–1.00 | 0.85–0.90 | 0.75–0.80 | 0.65–0.70 |

| Fly-ash of class II with w/b > 0.35 | 1 | 0.90–0.95 | 0.80–0.85 | 0.70–0.75 | 0.60–0.65 | - |

| Fiber Type | Number of Tests Data | Mean Ratio of fft,c/ fft,t | Standard Deviation | Coefficient of Variation |

|---|---|---|---|---|

| Hooked-end | 38 | 1.042 | 0.154 | 0.148 |

| crimped | 25 | 0.962 | 0.124 | 0.128 |

| Milled | 8 | 1.030 | 0.045 | 0.044 |

| Straight | 5 | 1.167 | 0.183 | 0.157 |

| Spiral | 3 | 0.603 | 0.075 | 0.124 |

| Indentation | 1 | 0.916 | – | – |

| Large-end | 1 | 0.984 | – | – |

| Hooked-end & straight | 8 | 1.011 | 0.219 | 0.216 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, X.; Zhao, M.; Zhou, S.; Fu, Y.; Li, C. Statistical Analysis and Preliminary Study on the Mix Proportion Design of Self-Compacting Steel Fiber Reinforced Concrete. Materials 2019, 12, 637. https://doi.org/10.3390/ma12040637

Ding X, Zhao M, Zhou S, Fu Y, Li C. Statistical Analysis and Preliminary Study on the Mix Proportion Design of Self-Compacting Steel Fiber Reinforced Concrete. Materials. 2019; 12(4):637. https://doi.org/10.3390/ma12040637

Chicago/Turabian StyleDing, Xinxin, Minglei Zhao, Siyi Zhou, Yan Fu, and Changyong Li. 2019. "Statistical Analysis and Preliminary Study on the Mix Proportion Design of Self-Compacting Steel Fiber Reinforced Concrete" Materials 12, no. 4: 637. https://doi.org/10.3390/ma12040637

APA StyleDing, X., Zhao, M., Zhou, S., Fu, Y., & Li, C. (2019). Statistical Analysis and Preliminary Study on the Mix Proportion Design of Self-Compacting Steel Fiber Reinforced Concrete. Materials, 12(4), 637. https://doi.org/10.3390/ma12040637