Damage Evolution of RC Beams Under Simultaneous Reinforcement Corrosion and Sustained Load

Abstract

1. Introduction

2. Experimental Program

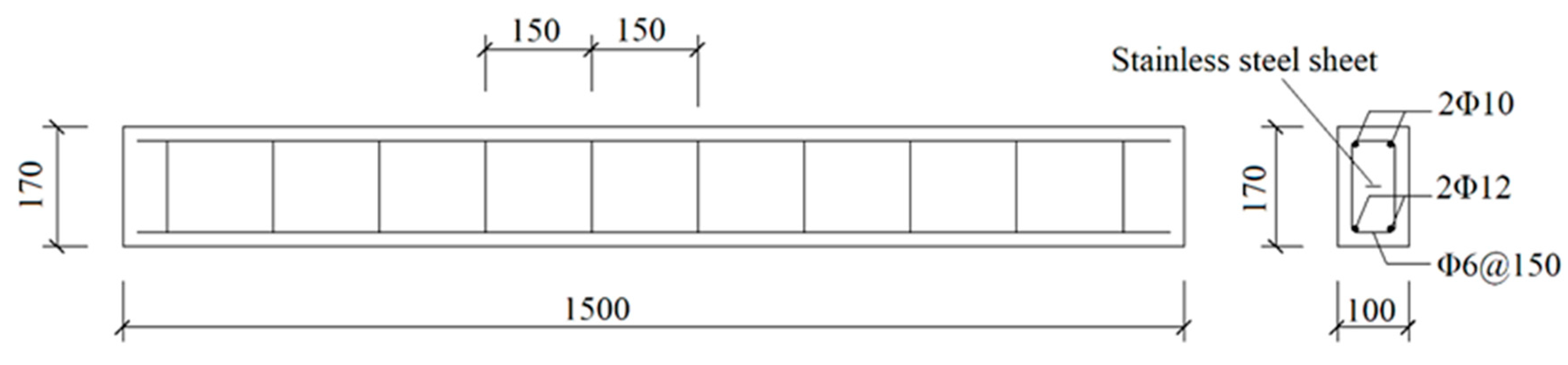

2.1. Specimens

2.2. Accelerated Corrosion Test

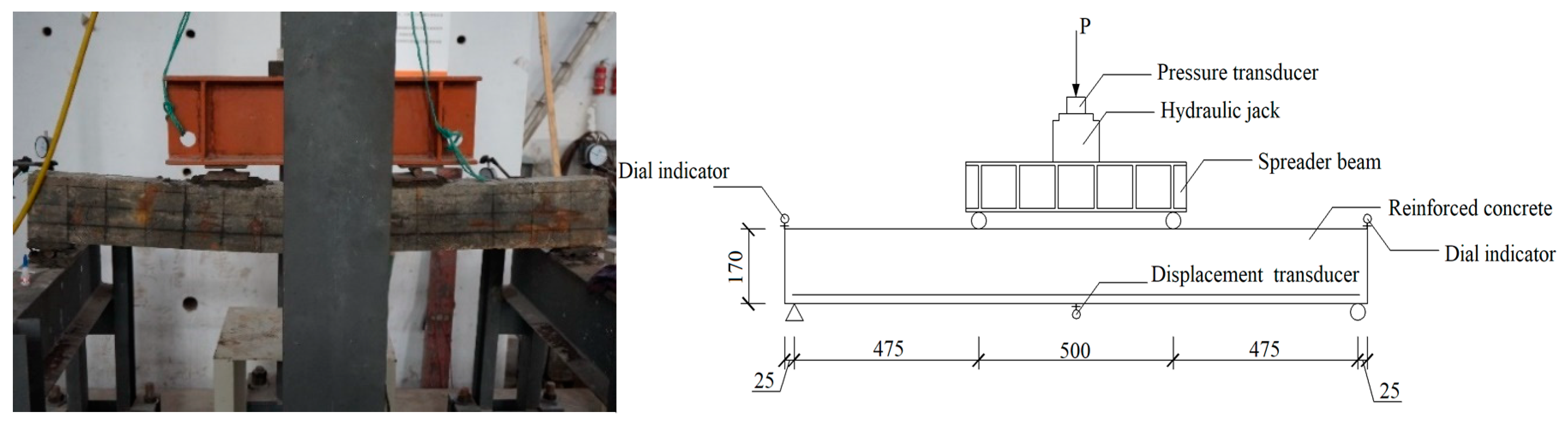

2.3. Loading Scheme

3. Experimental Results and Discussion

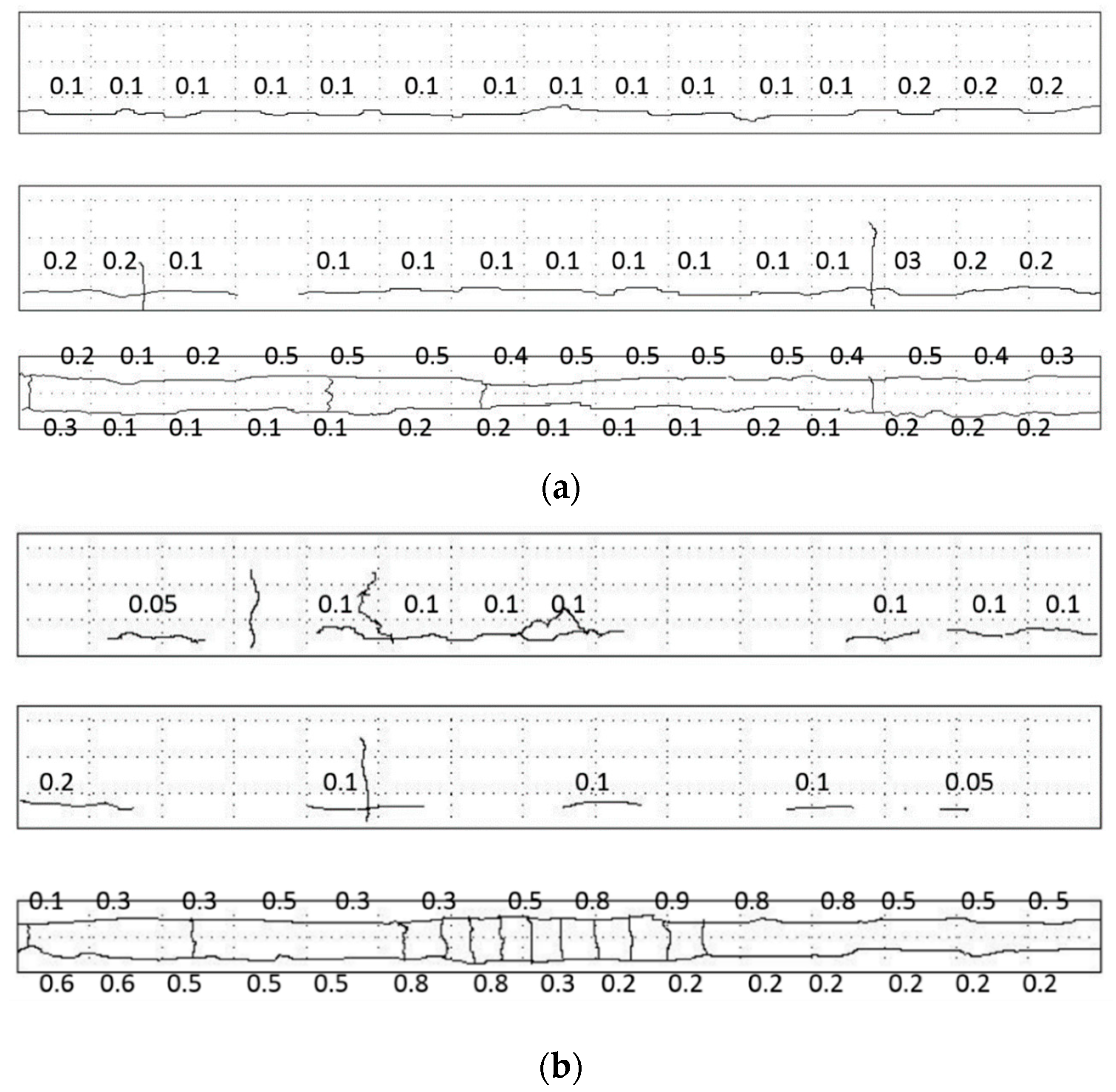

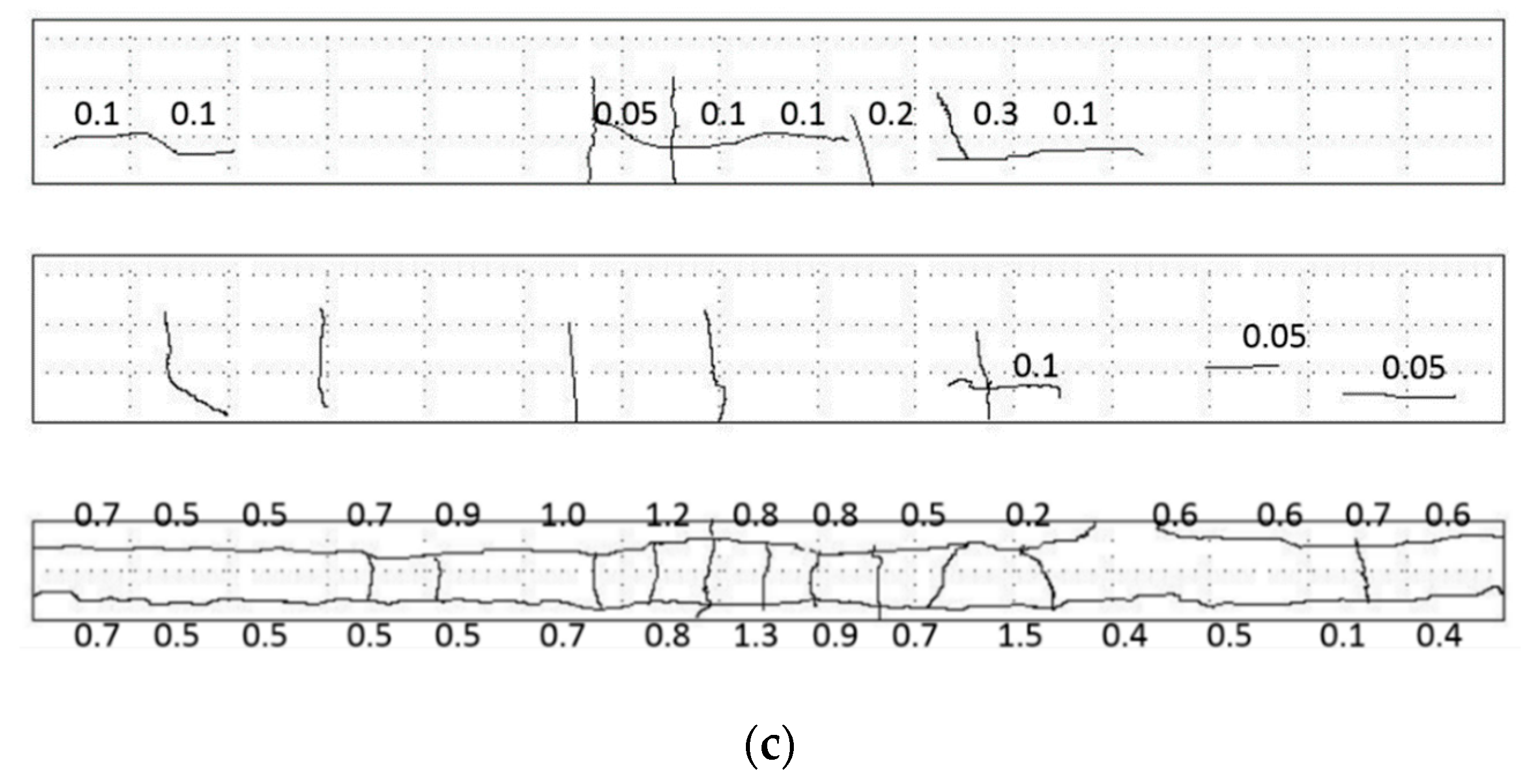

3.1. Cracking Behavior of RC Corroded Beams

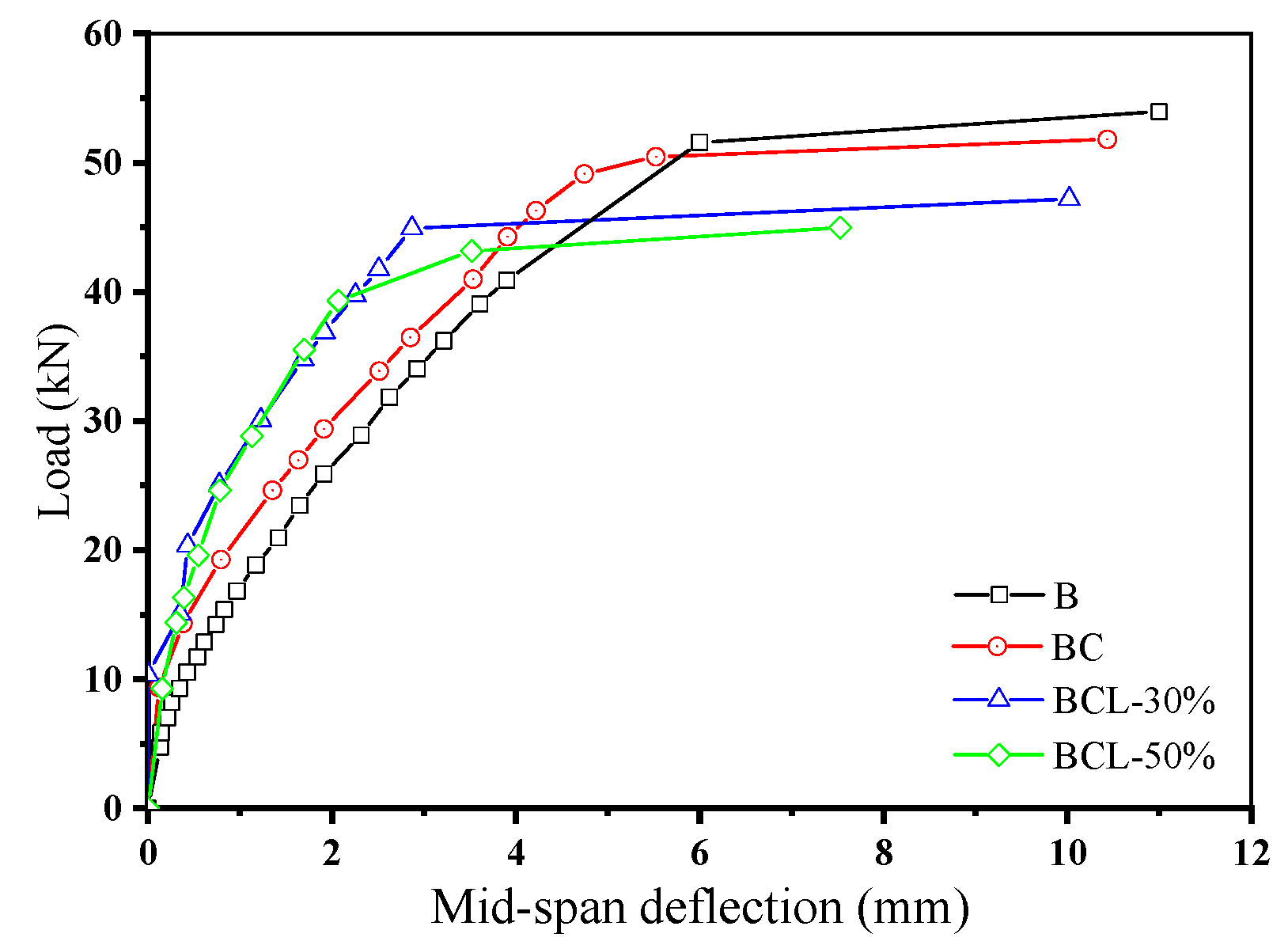

3.2. Loading Capacities of the Corroded RC Beams

4. Simulation Results and Discussion

4.1. Concrete Plastic Damage Model

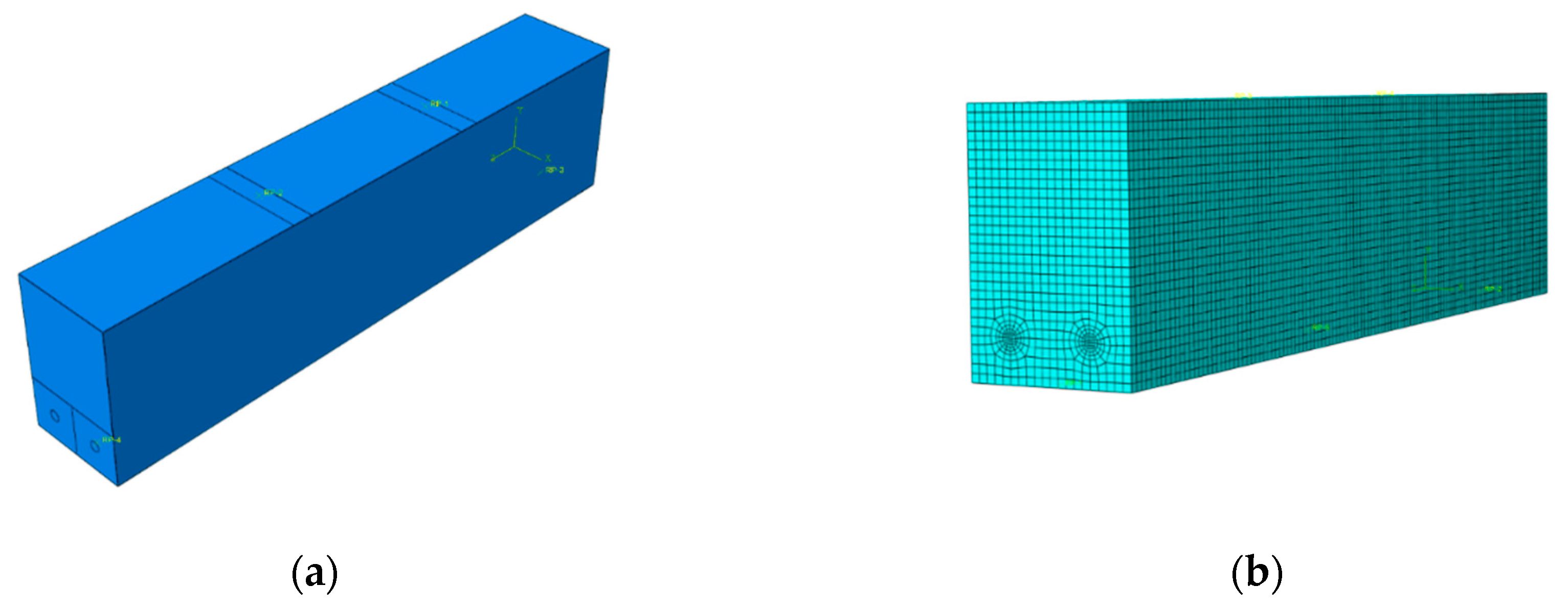

4.2. Finite Element Model of RC Beams

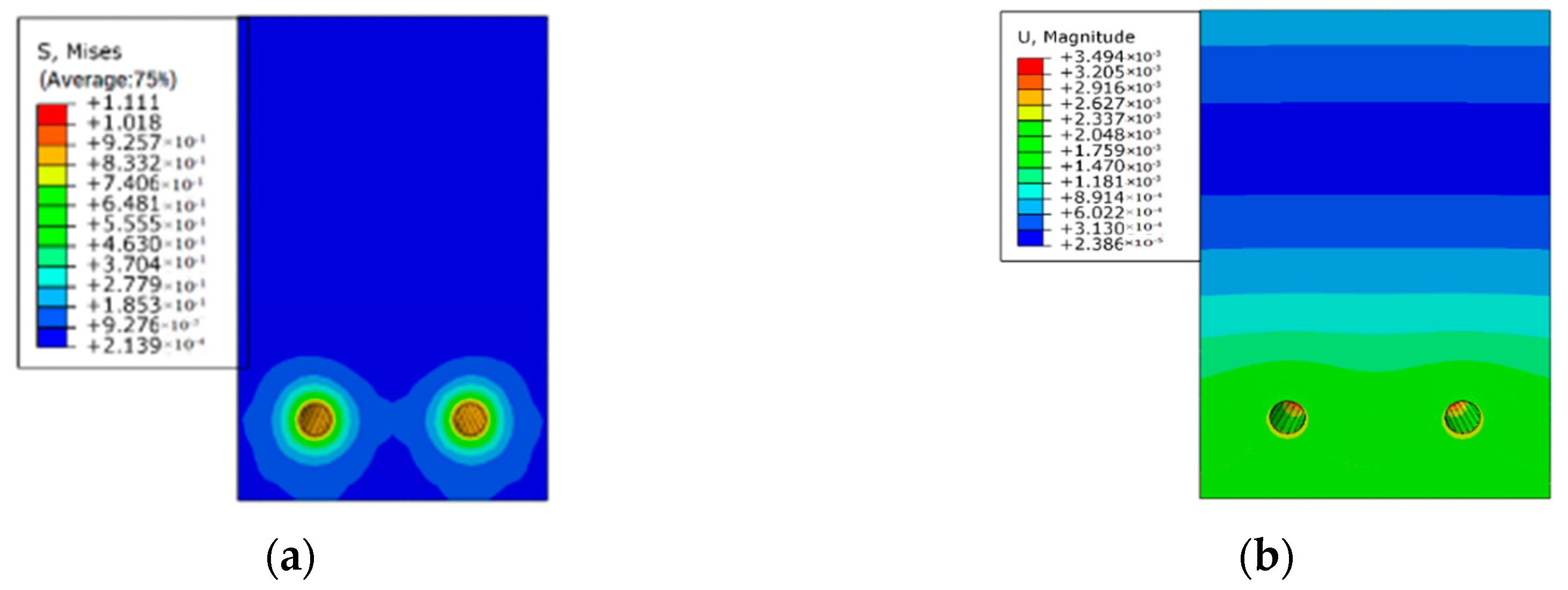

4.3. Application of Sustained Load and Reinforcement Corrosion

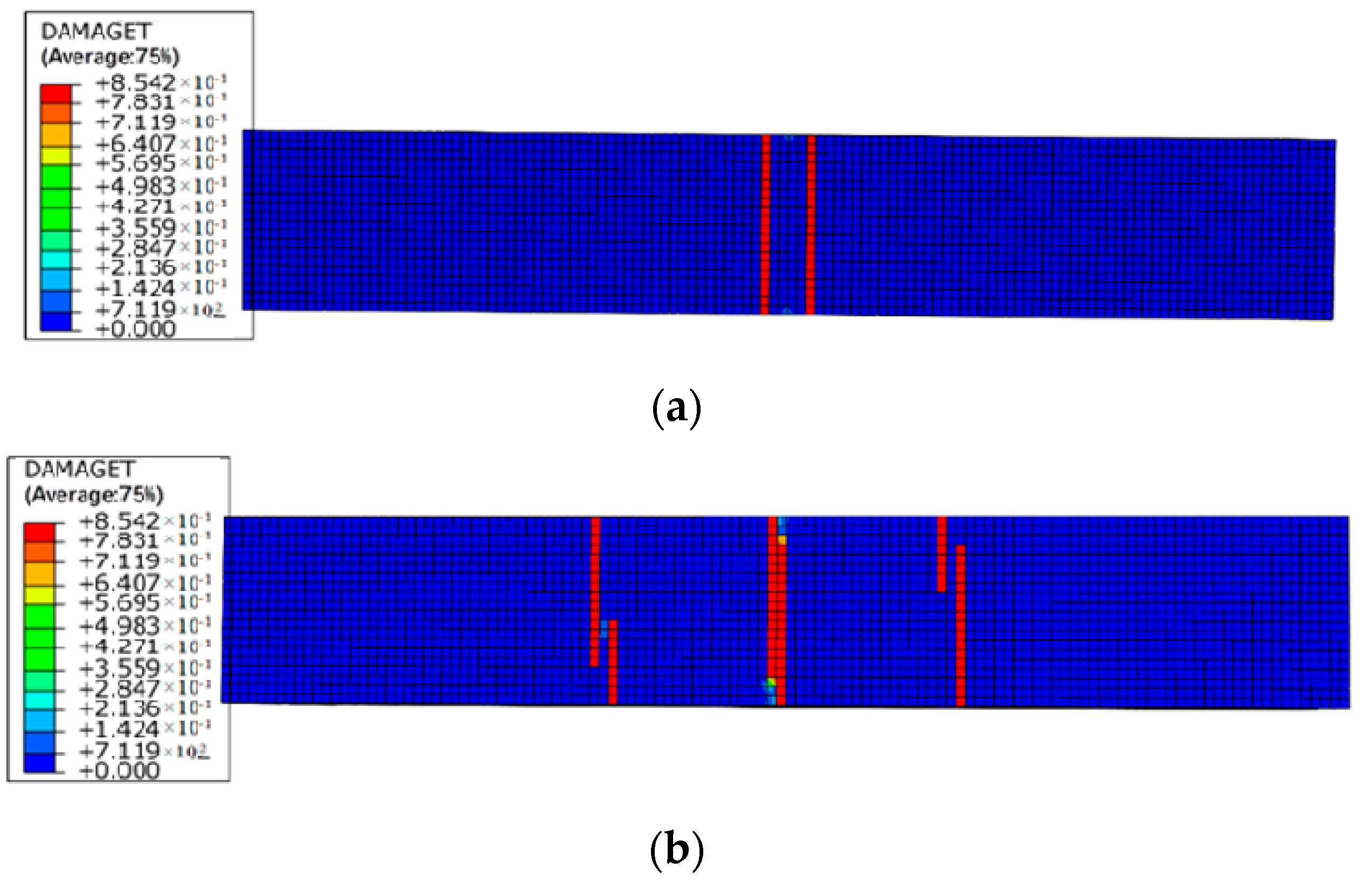

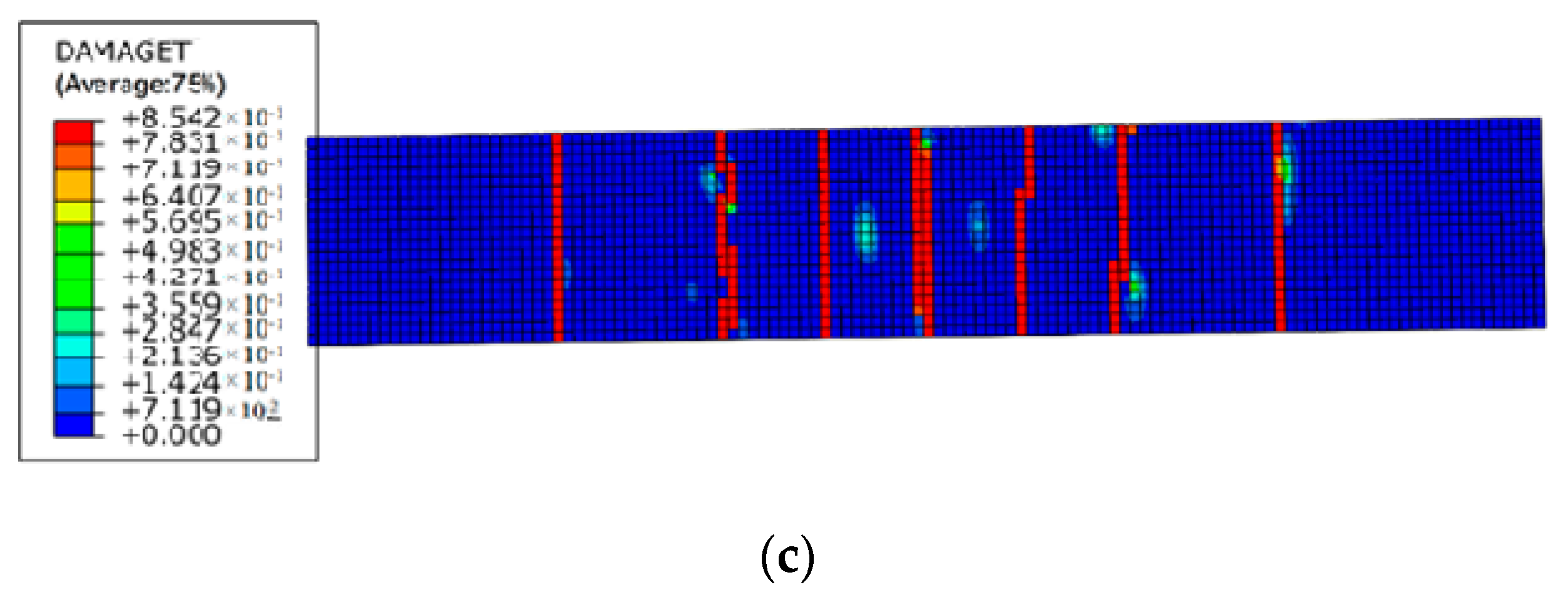

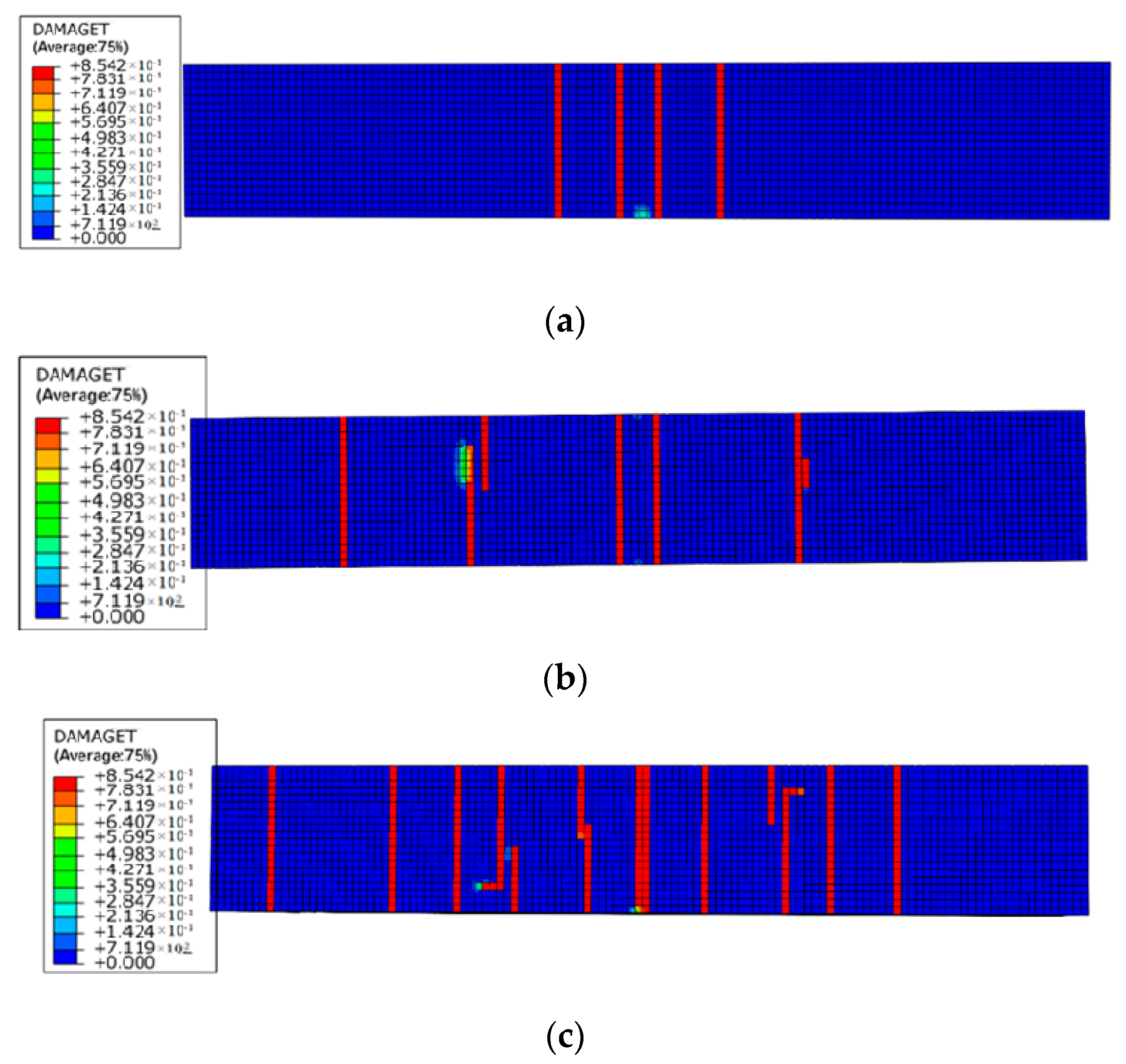

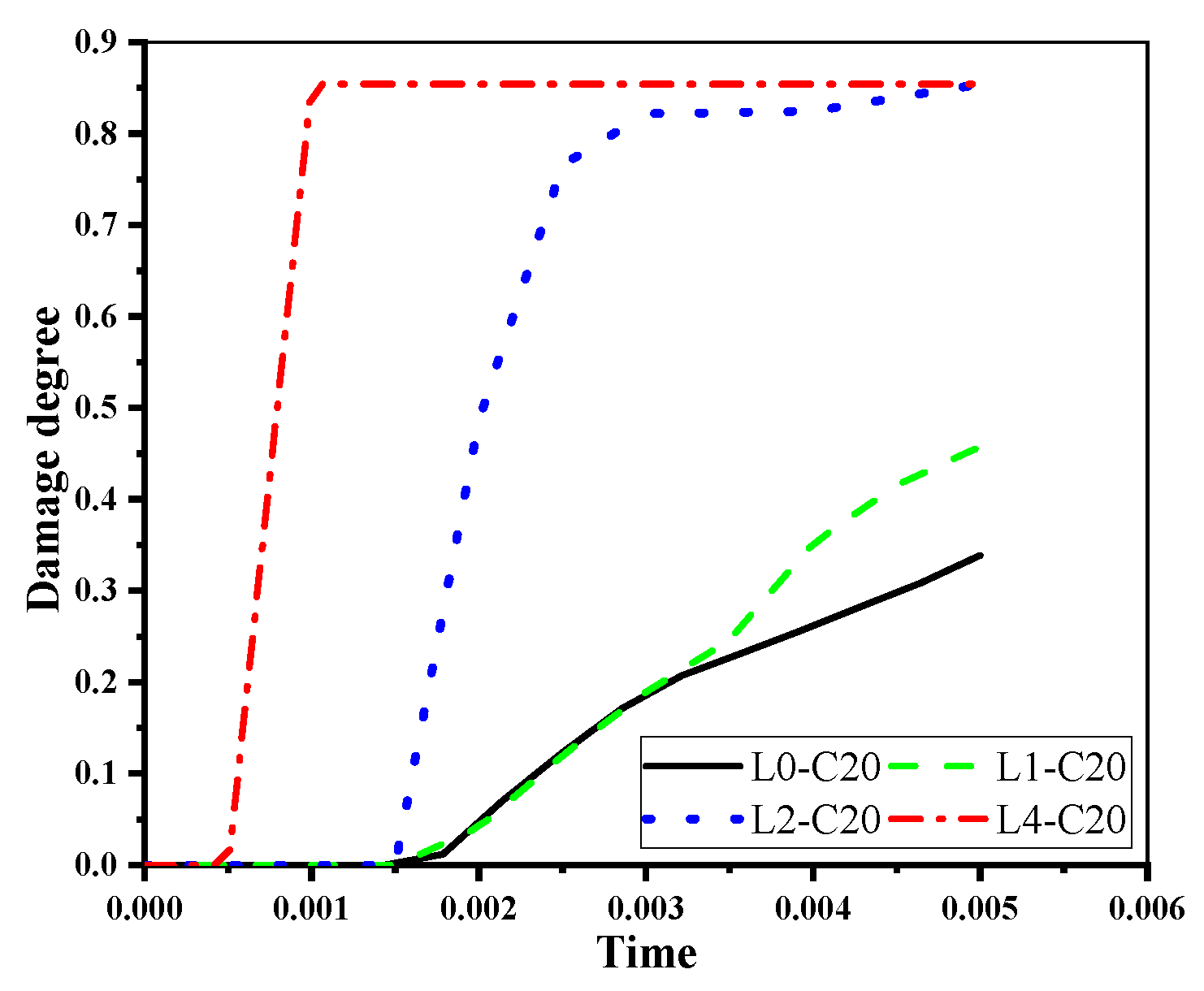

4.4. Damage Evolution of RC Beams under Reinforcement Corrosion and Sustained Load

5. Conclusions

- Reinforcement corrosion, coupled with sustained load, changes the cracking behavior of RC beams. Increasing the sustained load reduces the number of cracks on the side of the beam but increases the number and width of cracks on the bottom of the beam. The crack width in the corroded beam under 50% of designed load is 67% higher than that under 30% of designed load.

- Reinforcement corrosion, coupled with sustained load, decreases the residual loading capacities of RC beams, but increases their initial stiffness. Comparing to the control beam, the loading capacity of the corroded beams subjected to 0, 30%, and 50% of designed load is decreased by 3.9%, 12.5%, and 19.2%, respectively.

- Stresses caused by the corrosion expansion of reinforcement are successfully simulated by the temperature filed method. With the influence of concrete cover, concrete stresses at both the sides and the bottom of the beam are higher than that above the reinforcement. This is consistent with the actual corrosion expansion of reinforcements in the RC beams.

- Parametrical studies indicate that coupling reinforcement corrosion with sustained load significantly increases the damage level in the beams. Increasing sustained loading intensifies the concrete damage around the reinforcement, particularly for the concrete below the reinforcements. Further increases in the sustained load aggregates the concrete damage until concrete cracking.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tang, S.W.; Yao, Y.; Andrade, C.; Li, Z.J. Recent durability studies on concrete structure. Cem. Concr. Res. 2015, 78, 143–154. [Google Scholar] [CrossRef]

- Zhao, Y.; Jin, W. Steel Corrosion-Induced Concrete Cracking Model; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Zhang, R.; Castel, A.; François, R. Concrete cover cracking with reinforcement corrosion of RC beam during chloride-induced corrosion process. Cem. Concr. Res. 2010, 40, 415–425. [Google Scholar] [CrossRef]

- Khan, I.; François, R.; Castel, A. Prediction of reinforcement corrosion using corrosion induced cracks width in corroded reinforced concrete beams. Cem. Concr. Res. 2014, 56, 84–96. [Google Scholar] [CrossRef]

- Rodriguez, J.; Ortega, L.M.; Casal, J.; Diez, J.M. Corrosion of reinforcement and service life of concrete structures. In Proceedings of the 7th International Conference on Durability of Building Materials and Components, Stockholm, UK, 19–23 May 1996. [Google Scholar]

- Vidal, T.; Castel, A.; François, R. Analyzing crack width to predict corrosion in reinforced concrete. Cem. Concr. Res. 2004, 34, 165–174. [Google Scholar] [CrossRef]

- Gu, X.; Guo, H.; Zhou, B.; Zhang, W.; Jiang, C. Corrosion non-uniformity of steel bars and reliability of corroded RC beams. Eng. Struct. 2018, 167, 188–202. [Google Scholar] [CrossRef]

- Murthy, A.; Karihaloo, B.; Priya, D. Flexural behavior of RC beams retrofitted with ultra-high strength concrete. Constr. Build. Mater. 2018, 175, 815–824. [Google Scholar] [CrossRef]

- Xu, Y. The Corrosion Characteristics and Tensile Behavior of Reinforcement under Coupled Carbonation and Static Loading. Materials 2015, 8, 8561–8577. [Google Scholar] [CrossRef]

- Liu, Q.F.; Feng, G.L.; Xia, J.; Yang, J.; Li, L.Y. Ionic transport features in concrete composites containing various shaped aggregates: A numerical study. Compos. Struct. 2018, 183, 371–380. [Google Scholar] [CrossRef]

- Mao, L.X.; Hu, Z.; Xia, J.; Feng, G.L.; Azim, I.; Yang, J.; Liu, Q.F. Multi-phase modelling of electrochemical rehabilitation for ASR and chloride affected concrete composites. Compos. Struct. 2019, 207, 176–189. [Google Scholar] [CrossRef]

- Jiang, W.Q.; Shen, X.H.; Xia, J.; Mao, L.X.; Yang, J.; Liu, Q.F. A numerical study on chloride diffusion in freeze-thaw affected concrete. Constr. Build. Mater. 2018, 179, 553–565. [Google Scholar] [CrossRef]

- Xi, X.; Yang, S.; Li, C.Q. A non-uniform corrosion model and meso-scale fracture modelling of concrete. Cem. Concr. Res. 2018, 108, 87–102. [Google Scholar] [CrossRef]

- Yang, S.; Li, K.; Li, C. Numerical determination of concrete crack width for corrosion-affected concrete structures. Comput. Struct. 2018, 207, 75–82. [Google Scholar] [CrossRef]

- Abdelatif, A.O.; Ožbolt, J.; Gambarelli, S. 3D finite element modelling of corrosion of lap splice joints in concrete. Constr. Build. Mater. 2018, 169, 124–131. [Google Scholar] [CrossRef]

- Zhu, X.J.; Zi, G. A 2D mechano-chemical model for the simulation of reinforcement corrosion and concrete damage. Constr. Build. Mater. 2017, 137, 330–344. [Google Scholar] [CrossRef]

- Richard, B.; Quiertant, M.; Bouteiller, V.; Delaplace, A.; Adelaide, L.; Ragueneau, F.; Cremona, C. Experimental and numerical analysis of corrosion-induced cover cracking in reinforced concrete sample. Comput. Concr. 2016, 18, 421–439. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Al-Sakkaf, H.A.; Sharif, A.M.; Ahmad, S.; Baluch, M.H. Finit element modeling of corroded RC beams using cohesive surface bonding approach. Comput. Concr. 2018, 22, 167–182. [Google Scholar]

- Shayanfar, M.A.; Safiey, A. A new approach for nonlinear finite element analysis of reinforced concrete structures with corroded reinforcements. Comput. Concr. 2008, 5, 155–174. [Google Scholar] [CrossRef]

- Khosravani, M.; Weinberg, K. A review on split Hopkinson bar experiments on the dynamic characterisation of concrete. Constr. Build. Mater. 2018, 190, 1264–1283. [Google Scholar] [CrossRef]

- Li, L.; Wu, Z.; Yu, J.; Wang, X.; Zhang, J.; Lu, Z. Numerical simulation of the shear capacity of bolted side-plated RC beams. Eng. Struct. 2018, 171, 373–384. [Google Scholar] [CrossRef]

- Weinberg, K.; Khosravani, M. On the tensile resistance of UHPC at impact. Eur. Phys. J. Spec. Top. 2018, 227, 167–177. [Google Scholar] [CrossRef]

- Khosravani, M.; Silani, M.; Weinberg, K. Fracture studies of Ultra-High Performance Concrete using dynamic Brazilian tests. Theor. Appl. Fract. Mech. 2018, 93, 302–310. [Google Scholar] [CrossRef]

- Dong, J.; Zhao, Y.; Wang, K.; Jin, W. Crack propagation and flexural behaviour of RC beams under simultaneous sustained loading and steel corrosion. Constr. Build. Mater. 2017, 151, 208–219. [Google Scholar] [CrossRef]

- Li, H.; Li, B.; Jin, R.; Li, S.; Yu, J.G. Effects of sustained loading and corrosion on the performance of reinforced concrete beams. Constr. Build. Mater. 2018, 169, 179–187. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, H.; Gu, X.; Liu, W. Structural behavior of corroded reinforced concrete beams under sustained loading. Constr. Build. Mater. 2018, 174, 675–683. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Y. Performance of recycled concrete beams under sustained loads coupled with chloride ion (Cl−) ingress. Constr. Build. Mater. 2016, 128, 96–107. [Google Scholar] [CrossRef]

- Hou, L.; Zhou, B.; Guo, S.; Aslani, F.; Chen, D. Corrosion behavior and flexural performance of reinforced concrete/ultrahigh toughness cementitious composite (RC/UHTCC) beams under sustained loading and shrinkage cracking. Constr. Build. Mater. 2019, 198, 278–287. [Google Scholar] [CrossRef]

- Xu, Y.; Shen, J.; Zheng, Y.; Mao, J.; Wu, P. Corrosion Characteristics of Reinforced Concrete Under the Coupled Effects of Chloride Ingress and Static Loading: Laboratory Tests and Finite Element Analysis. Mater. Sci. 2018, 24, 212–217. [Google Scholar] [CrossRef]

- GB/T 50081-2002. Standard for Test Method of Mechanical Properties on Ordinary Concrete; China Architectural Industry Press: Beijing, China, 2003; p. 27. [Google Scholar]

- Xia, J.; Jin, W.L.; Li, L.Y. Shear performance of reinforced concrete beams with corroded stirrups in chloride environment. Corros. Sci. 2011, 53, 1794–1805. [Google Scholar] [CrossRef]

- Jin, W.L.; Wang, Y. Experimental study on mechanics behaviors of reinforced concrete beams under simultaneous chloride attacks and sustained load. J. Zhejiang Univ. Eng. Sci. 2014, 48, 221–227. [Google Scholar]

- GB/T 50152-2012. Standard for Test Method of Concrete Structures; China Architectural Industry Press: Beijing, China, 2012; p. 119. [Google Scholar]

- Abosrra, L.; Ashour, A.; Youseffi, M. Corrosion of steel reinforcement in concrete of different compressive strengths. Constr. Build. Mater. 2011, 25, 3915–3925. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A. Bond strength between corroded steel reinforcement and recycled aggregate concrete. Structures 2019, in press. [Google Scholar] [CrossRef]

- Dong, Y.; Xu, Z.; Zeng, K.; Cheng, Y.; Xu, C. Seismic behavior and cross-scale refinement model of damage evolution for RC shear walls. Eng. Struct. 2018, 167, 13–25. [Google Scholar] [CrossRef]

- Hibbitt, H.D.; Karlsson, B.I.; Sorensen, E.P. ABAQUS User’s Manual; Dassault Systemes Simulia Corp: Providence, RI, USA, 2011. [Google Scholar]

- Bossio, A.; Monetta, T.; Bellucci, F.; Lignola, G.P.; Prota, A. Modeling of concrete cracking due to corrosion process of reinforcement bars. Cem. Concr. Res. 2015, 71, 78–92. [Google Scholar] [CrossRef]

- Zhang, J.H.; Ling, X.Z.; Guan, Z.G. Finite element modeling of concrete cover crack propagation due to non-uniform corrosion of reinforcement. Constr. Build. Mater. 2017, 132, 487–499. [Google Scholar] [CrossRef]

- Chen, E.; Leung, C.K.Y. Finite element modeling of concrete cover cracking due to non-uniform steel corrosion. Eng. Fract. Mech. 2015, 134, 61–78. [Google Scholar] [CrossRef]

- Xu, Y.; Zheng, Y.; Du, K.; Hu, L. Meso-scale finite element simulation of corrosion-induced cracking in reinforced concrete cover. J. Southeast Univ. Nat. Sci. Ed. 2017, 47, 356–361. [Google Scholar]

| Specimen | Sustained Load | Accelerated Corrosion Process | Description |

|---|---|---|---|

| B | N/A | N/A | Control beam |

| BC | N/A | Step 1: electo-migration for 30 h Step 2: 6 wet–dry cycles under a constant current density of 200 μA/cm2, each cycle includes 3-day drying followed with 4-day wetting. | Non-sustained load |

| BCL-30 | 30% Mu | Sustained load | |

| BCL-50 | 50% Mu | Sustained load | |

| Note: Mu is the ultimate loading capacity of the RC beam. | |||

| Specimen | B | BC | BCL-30 | BCL-50 |

|---|---|---|---|---|

| Load capacity (kN) | 53.9 | 51.8 | 47.2 | 44.1 |

| Reduction as compared to specimen B | N/A | 3.90% | 12.43% | 18.18% |

| Reduction as compared to specimen BC | N/A | N/A | 8.88% | 14.86% |

| Parameters for Concrete | Taken Value | Parameters for Reinforcement | Taken value |

|---|---|---|---|

| Modulus of elasticity | 32.62 GPa | Modulus of elasticity | 190 GPa |

| Poisson’s ratio | 0.2 | Poisson’s ratio | 0.3 |

| Specimen | Sustained Load (mm) | Corrosion Expansion (°C) |

|---|---|---|

| L0-C20 | 0 | 20 |

| L1-C10 | 0.0625 | 10 |

| L1-C20 | 0.0625 | 20 |

| L2-C10 | 0.125 | 10 |

| L2-C20 | 0.125 | 20 |

| L4-C10 | 0.25 | 10 |

| L4-C20 | 0.25 | 20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, J.; Gao, X.; Li, B.; Du, K.; Jin, R.; Chen, W.; Xu, Y. Damage Evolution of RC Beams Under Simultaneous Reinforcement Corrosion and Sustained Load. Materials 2019, 12, 627. https://doi.org/10.3390/ma12040627

Shen J, Gao X, Li B, Du K, Jin R, Chen W, Xu Y. Damage Evolution of RC Beams Under Simultaneous Reinforcement Corrosion and Sustained Load. Materials. 2019; 12(4):627. https://doi.org/10.3390/ma12040627

Chicago/Turabian StyleShen, Jiansheng, Xi Gao, Bo Li, Kun Du, Ruoyu Jin, Wei Chen, and Yidong Xu. 2019. "Damage Evolution of RC Beams Under Simultaneous Reinforcement Corrosion and Sustained Load" Materials 12, no. 4: 627. https://doi.org/10.3390/ma12040627

APA StyleShen, J., Gao, X., Li, B., Du, K., Jin, R., Chen, W., & Xu, Y. (2019). Damage Evolution of RC Beams Under Simultaneous Reinforcement Corrosion and Sustained Load. Materials, 12(4), 627. https://doi.org/10.3390/ma12040627