Structural and Mechanical Properties of Ti–Co Alloys Treated by High Pressure Torsion

Abstract

:1. Introduction

2. Experimental

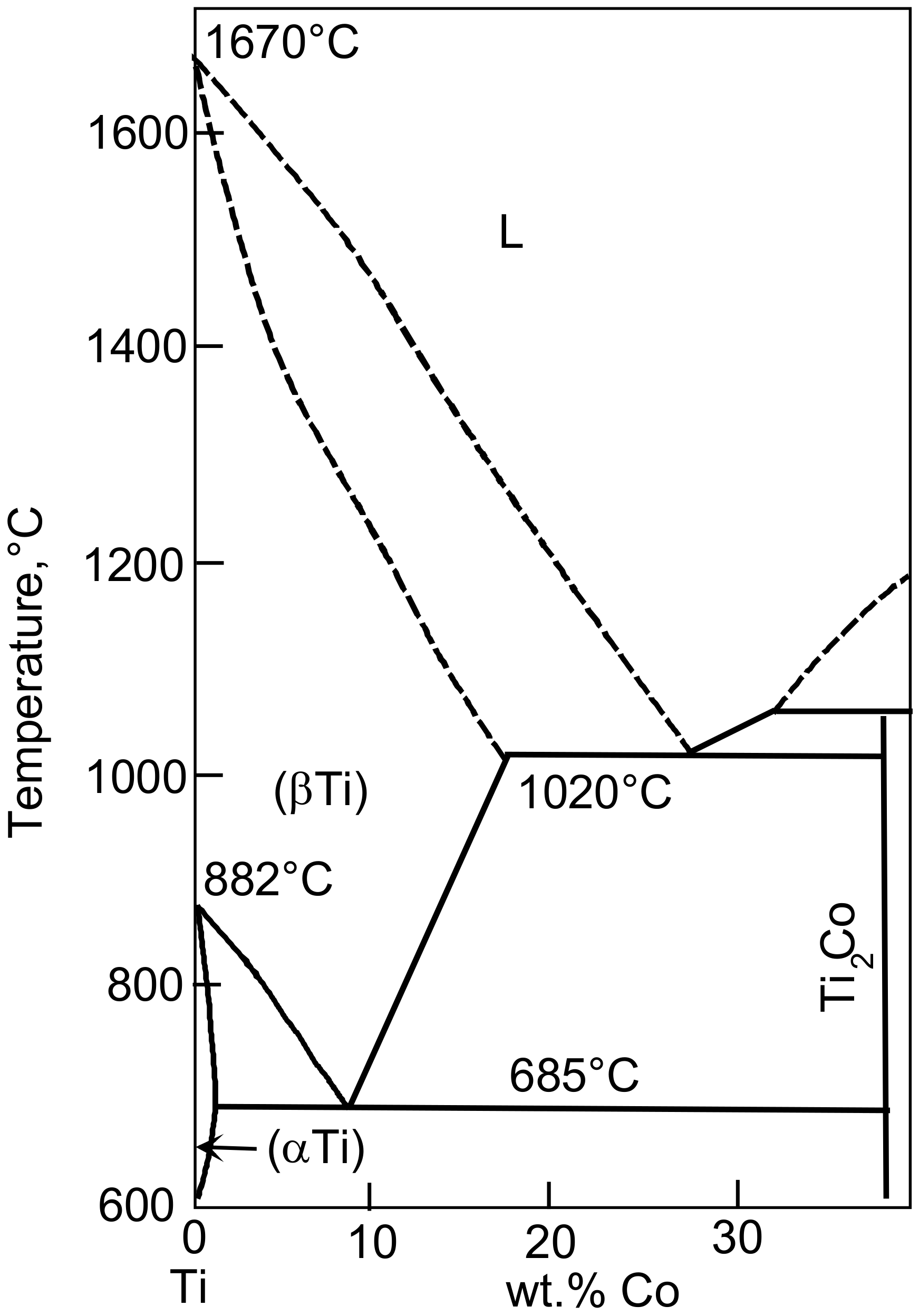

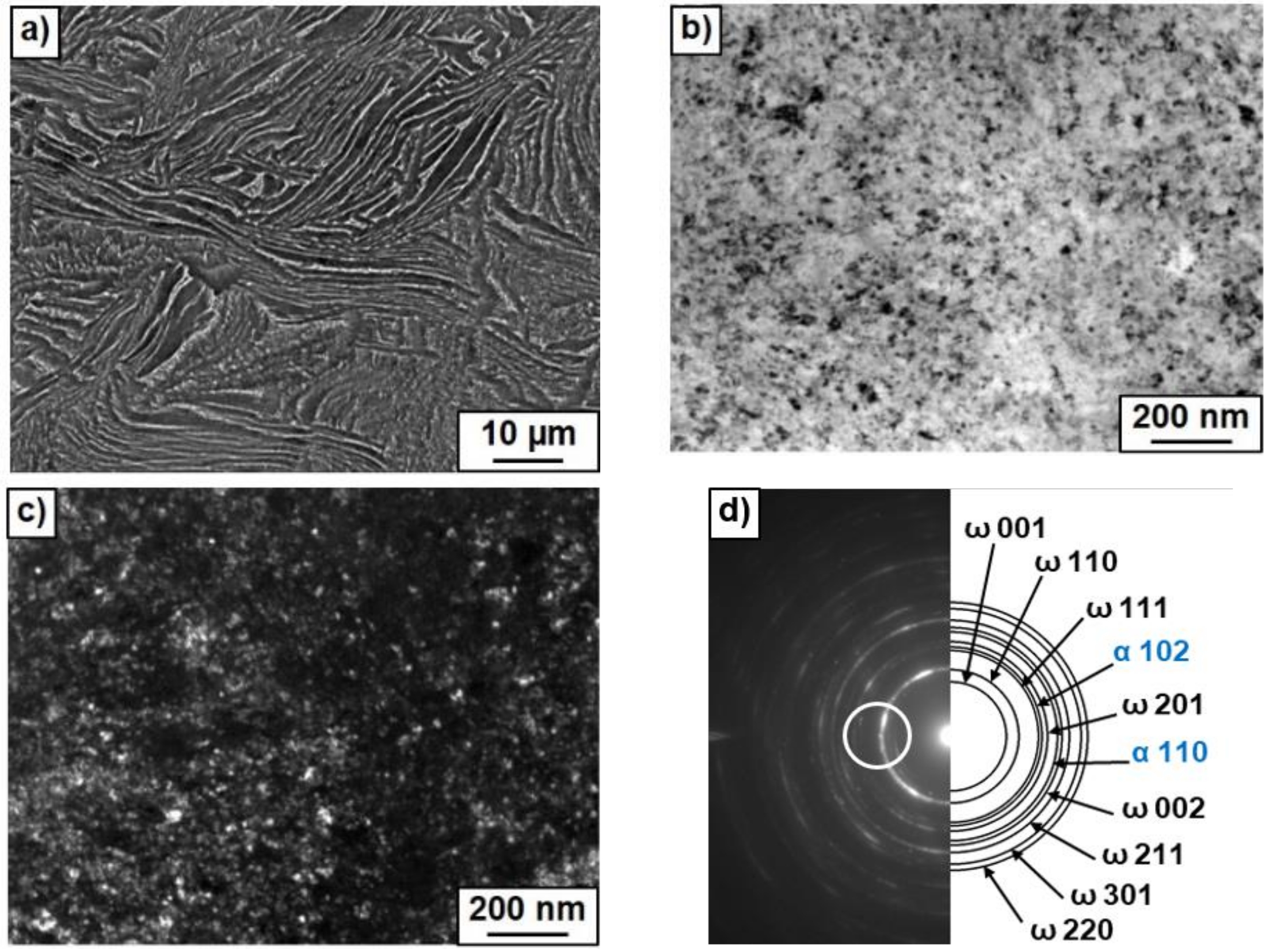

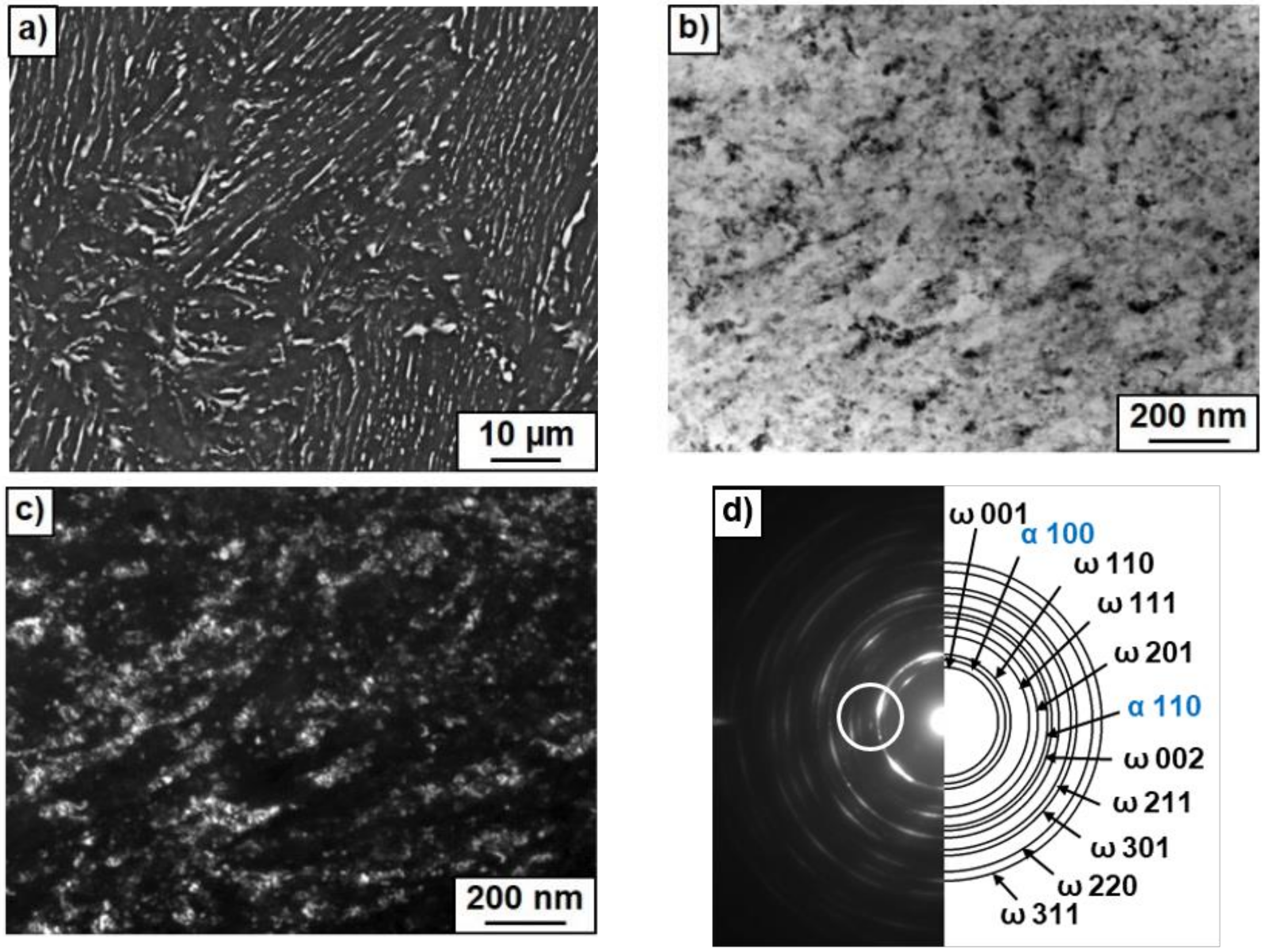

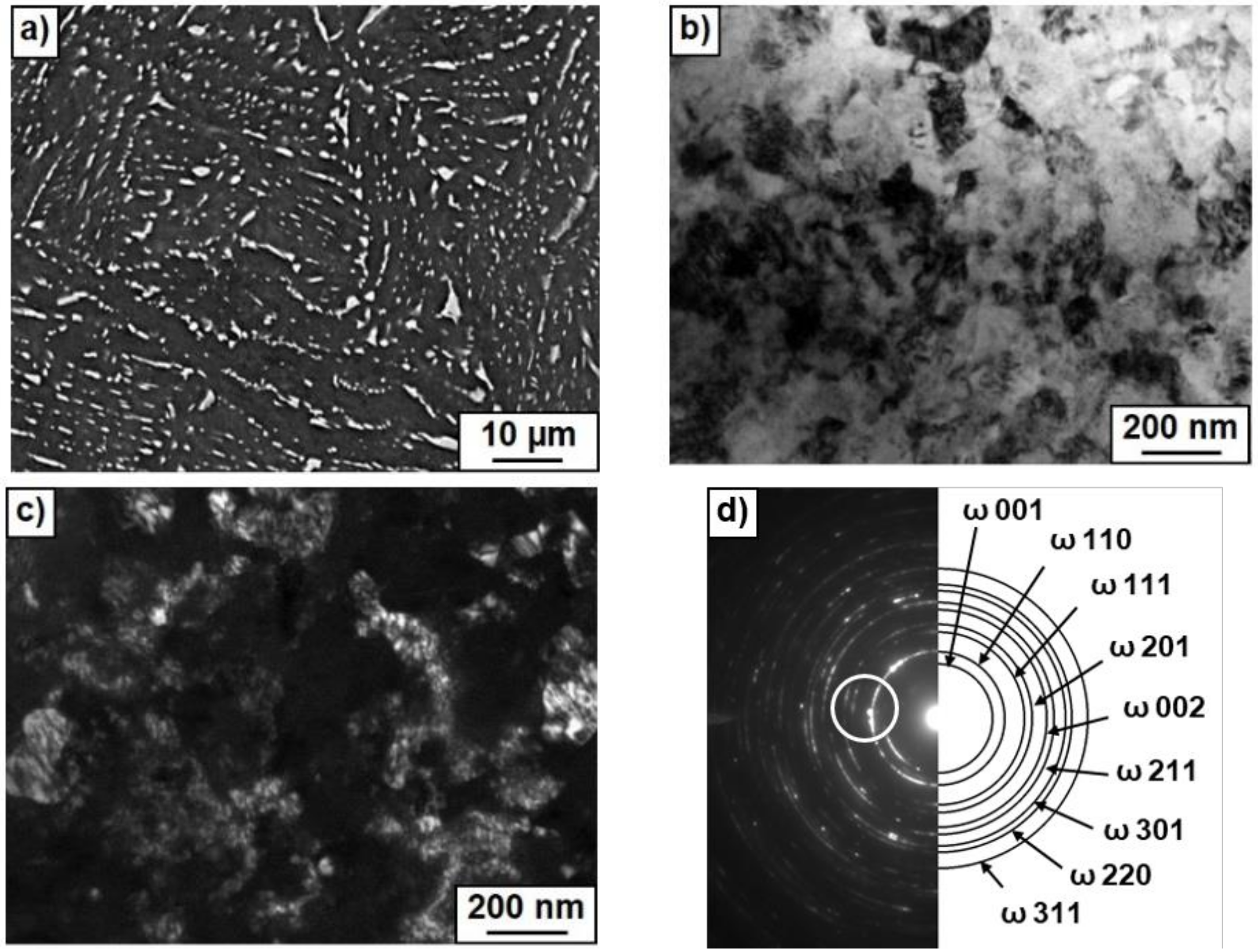

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Long, M.; Rack, H.J. Titanium alloys in total joint replacement-a materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef]

- Niinomi, M. Recent metallic materials for biomedical applications. Metall. Mater. Trans. A 2002, 33, 477–486. [Google Scholar] [CrossRef]

- Matsuno, H.; Yokoyama, A.; Watari, F.; Uo, M.; Kawasaki, T. Biocompatibility and osteogenesis of refractory metal implants, titanium, hafnium, niobium, tantalum and rhenium. Biomaterials 2001, 22, 1253–1262. [Google Scholar] [CrossRef]

- Wang, K. The use of titanium for medical applications in the USA. Mater. Sci. Eng. A 1996, 213, 134–137. [Google Scholar] [CrossRef]

- Fasching, A.; Norwich, D.; Geiser, T.; Paul, G.W. An evaluation of a NiTiCo alloy and its suitability for medical device applications. J. Mater. Eng. Perform. 2011, 20, 641–645. [Google Scholar] [CrossRef]

- Wang, R.; Welsch, G. Evaluation of an experimental Ti-Co alloy for dental restorations. J. Biomed. Mater. Res. B 2013, 101, 1419–1427. [Google Scholar] [CrossRef] [PubMed]

- Niinomi, M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J. Mech. Behav. Biomed. 2008, 1, 30–42. [Google Scholar] [CrossRef] [PubMed]

- Mutlu, I. Synthesis and characterization of Ti-Co alloy foam for biomedical applications. Trans. Nonferr. Met. Soc. China 2016, 26, 126–137. [Google Scholar] [CrossRef]

- Liu, X.T.; Chen, S.Y.; Tsoi, J.K.H.; Matinlinna, J.P. Binary titanium alloys as dental implant materials-a review. Regenerat. Biomater. 2017, 4, 315–323. [Google Scholar] [CrossRef]

- Ohnsorge, J.; Holm, R. Surface investigations of oxide layers on cobalt-chromium alloyed orthopedic implants using ESCA technique. Med. Prog. Technol. 1978, 5, 171–177. [Google Scholar]

- Onagawa, J. Preparation of high corrosion resistant titanium alloys by spark plasma sintering. J. Jpn. Inst. Met. 1999, 63, 1149–1152. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, W.Y.; Chen, G.L. On superplasticity of two phase alpha-titanium-intermetallic Ti–(Co, Ni)–Al alloy. Acta Metall. Mater. 1995, 43, 3571–3582. [Google Scholar] [CrossRef]

- Hu, K.; Huang, X.M.; Lu, J.; Liu, H.S.; Cai, G.M.; Jin, Z.P. Measurement of phase equilibria in Ti-Co-Pt ternary system. Calphad 2018, 60, 191–199. [Google Scholar] [CrossRef]

- Zeng, Y.; Zhu, L.L.; Cai, G.M.; Liu, H.S.; Huang, J.W.; Jin, Z.P. Investigation of phase equilibria in the Ti-Co-Zr ternary system. Calphad 2017, 56, 260–269. [Google Scholar] [CrossRef]

- Fartushna, I.; Bulanova, M.; Ayral, R.M.; Tedenac, J.C.; Zhludenko, N.; Meleshevich, K.; Romanenko, Y. Phase equilibria in the crystallization interval in the Ti-Co-Sn system at above 50 at % Ti. J. Alloys Compd. 2016, 673, 433–440. [Google Scholar] [CrossRef]

- Samal, S.; Agarwal, S.; Gautam, P.; Biswas, K. Microstructural evolution in novel suction cast multicomponent Ti-Fe-Co alloys. Metall. Mater. Trans. A 2015, 46A, 851–868. [Google Scholar] [CrossRef]

- Xue, Y.; Wang, H.M. Microstructure and properties of Ti-Co-Si ternary intermetallic alloys. J. Alloys Compd. 2008, 464, 138–145. [Google Scholar] [CrossRef]

- Lin, J.H.C.; Chen, Y.F.; Ju, C.P. Effect of nickel addition on microstructure and properties of Ti-Co-Ni alloys. Biomaterials 1995, 18, 1401–1407. [Google Scholar] [CrossRef]

- Fatoba, O.S.; Adesina, O.S.; Popoola, A.P.I. Evaluation of microstructure, microhardness, and electrochemical properties of laser-deposited Ti-Co coatings on Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2018, 97, 2341–2350. [Google Scholar] [CrossRef]

- Adesina, O.S.; Popoola, A.P.I.; Pityana, S.L.; Oloruntoba, D.T. Microstructural and tribological behavior of in situ synthesized Ti/Co coatings on Ti-6Al-4V alloy using laser surface cladding technique. Int. J. Adv. Manuf. Technol. 2018, 95, 1265–1280. [Google Scholar] [CrossRef]

- Adesina, O.S.; Popoola, A.P.I. A study on the influence of laser power on microstructural evolution and tribological functionality of metallic coatings deposited on Ti-6Al-4V alloy. Tribology 2017, 11, 145–155. [Google Scholar] [CrossRef]

- Adesina, O.S.; Mthisi, A.; Popoola, A.P.I. The effect of laser based synthesized Ti–Co coating on microstructure and mechanical properties of Ti6A14V alloy. Procedia Manuf. 2016, 7, 46–52. [Google Scholar] [CrossRef]

- Langelier, B.C.; Esmaeili, S. In-situ laser-fabrication and characterization of TiC-containing Ti-Co composite on pure Ti substrate. J. Alloys Compd. 2009, 482, 246–252. [Google Scholar] [CrossRef]

- Gromov, D.G.; Mochalov, A.I.; Pugachevich, V.P.; Kirilenko, E.P.; Trifonov, A.Y. Study of phase separation in Ti-Co-N thin films on silicon substrate. Appl. Phys. A 1997, 64, 517–521. [Google Scholar] [CrossRef]

- Gromov, D.G.; Mochalov, A.I.; Pugachevich, V.P. CoSi2 formation in contact systems based on Ti-Co alloy with low cobalt content. Appl. Phys. A 1995, 61, 565–567. [Google Scholar]

- Kilmametov, A.; Ivanisenko, Y.; Mazilkin, A.A.; Straumal, B.B.; Gornakova, A.S.; Fabrichnaya, O.B.; Kriegel, M.J.; Rafaja, D.; Hahn, H. The α→ω and β→ω phase transformations in Ti-Fe alloys under high-pressure torsion. Acta Mater. 2018, 144, 337–351. [Google Scholar] [CrossRef]

- Kilmametov, A.; Ivanisenko, Y.; Straumal, B.; Mazilkin, A.A.; Gornakova, A.S.; Kriegel, M.J.; Fabrichnaya, O.B.; Rafaja, D.; Hahn, H. Transformations of α′ martensite in Ti-Fe alloys under high pressure torsion. Scr. Mater. 2017, 136, 46–49. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Sauvage, X.; Wetscher, F.; Pareige, P. Mechanical alloying of Cu and Fe induced by severe plastic deformation of a Cu-Fe composite. Acta Mater. 2005, 53, 2127–2135. [Google Scholar] [CrossRef]

- Straumal, B.B.; Sauvage, X.; Baretzky, B.; Mazilkin, A.A.; Valiev, R.Z. Grain boundary films in Al–Zn alloys after high pressure torsion. Scr. Mater. 2014, 70, 59–62. [Google Scholar] [CrossRef]

- Straumal, B.; Korneva, A.; Zięba, P. Phase transitions in metallic alloys driven by the high pressure torsion. Arch. Civ. Mech. Eng. 2014, 14, 242–249. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kilmametov, A.R.; Ivanisenko, Y.; Mazilkin, A.A.; Kogtenkova, O.A.; Kurmanaeva, L.; Korneva, A.; Zięba, P.; Baretzky, B. Phase transitions induced by severe plastic deformation: Steady-state and equifinality. Int. J. Mater. Res. 2015, 106, 657–664. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kilmametov, A.R.; Korneva, A.; Mazilkin, A.A.; Straumal, P.B.; Zięba, P.; Baretzky, B. Phase transitions in Cu-based alloys under high pressure torsion. J. Alloys Compd. 2017, 707, 20–26. [Google Scholar] [CrossRef]

- Donachie, M.J., Jr. Titanium: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Errandonea, D.; Meng, Y.; Somayazulu, M.; Häusermann, D. Pressure-induced α→ω transition in titanium metal: A systematic study of the effects of uniaxial stress. Physica B 2005, 355, 116–125. [Google Scholar] [CrossRef]

- Trinkle, D.R.; Hennig, R.G.; Srinivasan, S.G.; Hatch, D.M.; Jones, M.D.; Stokes, H.T.; Albers, R.C.; Wilkins, J.W. New mechanism for the α to ω martensitic transformation in pure titanium. Phys. Rev. Lett. 2003, 91, 025701. [Google Scholar] [CrossRef] [PubMed]

- Sikka, S.K.; Vohra, Y.K.; Chidambaram, R. Omega phase in materials. Prog. Mater. Sci. 1982, 27, 245–310. [Google Scholar] [CrossRef]

- Banerjee, S.; Mukhopadhyay, P. Phase Transformations: Examples from Titanium and Zirconium Alloy; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Hickman, B.S. The formation of omega phase in titanium and zirconium alloys: A review. J. Mater. Sci. 1969, 4, 554–563. [Google Scholar] [CrossRef]

- Kriegel, M.J.; Kilmametov, A.; Rudolph, M.; Straumal, B.B.; Gornakova, A.S.; Stöcker, H.; Ivanisenko, Y.; Fabrichnaya, O.; Hahn, H.; Rafaja, D. Transformation pathway upon heating of Ti–Fe alloys deformed by high-pressure torsion. Adv. Eng. Mater. 2018, 20, 1700933. [Google Scholar] [CrossRef]

- Kriegel, M.J.; Kilmametov, A.; Klemm, V.; Schimpf, C.; Straumal, B.B.; Gornakova, A.S.; Ivanisenko, Y.; Fabrichnaya, O.; Hahn, H.; Rafaja, D. Thermal stability of athermal ω-Ti(Fe) produced upon quenching of β-Ti(Fe). Adv. Eng. Mater. 2018, 20, 201800158. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kilmametov, A.R.; Ivanisenko, Y.; Gornakova, A.S.; Mazilkin, A.A.; Kriegel, M.J.; Fabrichnaya, O.B.; Baretzky, B.; Hahn, H. Phase transformations in Ti-Fe alloys induced by high pressure torsion. Adv. Eng. Mater. 2015, 17, 1835–1841. [Google Scholar] [CrossRef]

- Kilmametov, A.R.; Ivanisenko, Y.; Straumal, B.B.; Gornakova, A.S.; Mazilkin, A.A.; Hahn, H. The α→ω transformation in titanium-cobalt alloys under high-pressure torsion. Metals 2018, 8, 1. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kilmametov, A.R.; Ivanisenko, Y.; Mazilkin, A.A.; Valiev, R.Z.; Afonikova, N.S.; Gornakova, A.S.; Hahn, H. Diffusive and displacive phase transitions in Ti-Fe and Ti-Co alloys under high pressure torsion. J. Alloys Compd. 2018, 735, 2281–2286. [Google Scholar] [CrossRef]

- Permyakova, I.E.; Glezer, A.M.; Grigorovich, K.V. Deformation behavior of amorphous Co-Fe-Cr-Si-B alloys in the initial stages of severe plastic deformation. Bull. Russ. Acad. Sci. Phys. 2014, 78, 996–1000. [Google Scholar] [CrossRef]

- Binary Alloy Phase Diagrams; Massalski, T.B. (Ed.) American Society for Metals: Metals Park, OH, USA, 1991. [Google Scholar]

- Gornakova, A.S.; Straumal, A.B.; Khodos, I.I.; Gnesin, I.B.; Mazilkin, A.A.; Afonikova, N.S.; Straumal, B.B. Effect of composition, annealing temperature and high pressure torsion on structure and hardness of Ti-V and Ti-V-Al alloys. J. Appl. Phys. 2019, 125. [Google Scholar] [CrossRef]

- Lojkowski, W.; Djahanbakhsh, M.; Burkle, G.; Gierlotka, S.; Zielinski, W.; Fecht, H.J. Nanostructure formation on the surface of railway tracks. Mater. Sci. Eng. A 2001, 303, 197–208. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.M.; García-Infanta, J.M.; Zhilyaev, A.P.; Ruano, O.A.; Carreño, F. Influence of the thermal treatment on the deformation-induced precipitation of a hypoeutectic Al-7 wt% Si casting alloy deformed by high-pressure torsion. J. Alloys Compd. 2011, 509, 636–643. [Google Scholar] [CrossRef]

- Ivanisenko, Y.; Lojkowski, W.; Valiev, R.Z.; Fecht, H.J. The mechanism of formation of nanostructure and dissolution of cementite in a pearlitic steel during high pressure torsion. Acta Mater. 2003, 51, 5555–5570. [Google Scholar] [CrossRef]

- Sagaradze, V.V.; Shabashov, V.A. Deformation-induced anomalous phase transformations in nanocrystalline FCC Fe-Ni based alloys. Nanostruct. Mater. 1997, 9, 681–684. [Google Scholar] [CrossRef]

- Ohsaki, S.; Kato, S.; Tsuji, N.; Ohkubo, T.; Hono, K. Bulk mechanical alloying of Cu–Ag and Cu/Zr two-phase microstructures by accumulative roll-bonding process. Acta Mater. 2007, 55, 2885–2895. [Google Scholar] [CrossRef]

- Sergueeva, A.V.; Song, C.; Valiev, R.Z.; Mukherjee, A.K. Structure and properties of amorphous and nanocrystalline NiTi prepared by severe plastic deformation and annealing. Mater. Sci. Eng. A 2003, 339, 159–165. [Google Scholar] [CrossRef]

- Prokoshkin, S.D.; Khmelevskaya, I.Y.; Dobatkin, S.V.; Trubitsyna, I.B.; Tatyanin, E.V.; Stolyarov, V.V.; Prokofiev, E.A. Alloy composition, deformation temperature, pressure and post-deformation annealing effects in severely deformed Ti-Ni based shape memory alloys. Acta Mater. 2005, 53, 2703–2714. [Google Scholar] [CrossRef]

- Sauvage, X.; Renaud, L.; Deconihout, B.; Blavette, D.; Ping, D.H.; Hono, K. Solid state amorphization in cold drawn Cu/Nb wires. Acta Mater. 2001, 49, 389–394. [Google Scholar] [CrossRef]

- Miyazaki, T.; Terada, D.; Miyajima, Y.; Suryanarayana, C.; Murao, R.; Yokoyama, Y.; Sugiyama, K.; Umemoto, M.; Todaka, T.; Tsuji, N. Synthesis of non-equilibrium phases in immiscible metals mechanically mixed by high pressure torsion. J. Mater. Sci. 2011, 46, 4296–4301. [Google Scholar] [CrossRef]

- Straumal, B.B.; Protasova, S.G.; Mazilkin, A.A.; Goering, E.; Schütz, G.; Straumal, P.B.; Baretzky, B. Ferromagnetic behaviour of ZnO: Role of grain boundaries. Beilstein J. Nanotechnol. 2016, 7, 1936–1947. [Google Scholar] [CrossRef] [PubMed]

- Ivanisenko, Y.; Sauvage, X.; Mazilkin, A.; Kilmametov, A.; Beach, J.A.; Straumal, B.B. Bulk nanocrystalline ferrite stabilized through grain boundary carbon segregation. Adv. Eng. Mater. 2018, 20, 1800443. [Google Scholar] [CrossRef]

- Straumal, B.B.; Mazilkin, A.A.; Protasova, S.G.; Dobatkin, S.V.; Rodin, A.O.; Baretzky, B.; Goll, D.; Schütz, G. Fe–C nanograined alloys obtained by high pressure torsion: Structure and magnetic properties. Mater. Sci. Eng. A 2009, 503, 185–189. [Google Scholar] [CrossRef]

- Straumal, B.B.; Dobatkin, S.V.; Rodin, A.O.; Protasova, S.G.; Mazilkin, A.A.; Goll, D.; Baretzky, B. Structure and properties of nanograined Fe–C alloys after severe plastic deformation. Adv. Eng. Mater. 2011, 13, 463–469. [Google Scholar] [CrossRef]

- Molodov, D.A.; Straumal, B.B.; Shvindlerman, L.S. The effect of pressure on migration of the [001] tilt grain boundaries in the tin bicrystals. Scr. Metall. 1984, 18, 207–211. [Google Scholar] [CrossRef]

- Straumal, B.B.; Klinger, L.M.; Shvindlerman, L.S. The influence of pressure on indium diffusion along single tin–germanium interphase boundaries. Scr. Metall. 1983, 17, 275–279. [Google Scholar] [CrossRef]

- Trofimov, E.A.; Lutfullin, R.Y.; Kashaev, R.M. Elastic modulus of TI-6AL-4V titanium alloy. Lett. Mater. 2015, 5, 67–69. [Google Scholar] [CrossRef]

- Elmer, J.W.; Palmer, T.A.; Babu, S.S.; Specht, E.D. In situ observations of lattice expansion and transformation rates of α and β phases in Ti-6Al-4V. Mater. Sci. Eng. A 2005, 391, 104–113. [Google Scholar] [CrossRef]

- Murzinova, M.A.; Zherebtsov, S.V.; Salishchev, G.A. Dependence of the specific energy of the β/α interface in the VT6 titanium alloy on the heating temperature in the interval 600–975 °C. JETP 2016, 122, 705–715. [Google Scholar] [CrossRef]

| Sample | Lattice Parameter, nm | Lattice Parameter, nm | Lattice Parameter, nm | Volume |

|---|---|---|---|---|

| - | Before HPT | After HPT | After HPT | Fraction, % |

| - | α-Ti | α-Ti | ω-Ti | ω-Ti |

| Ti–4 wt. %Co 600 °C, 2774 h | a = 0.2941, c = 0.4689, c/a = 1.594 | a = 0.2957, c = 0.4703, c/a = 1.590 | a = 0.4622, c = 0.2833 | 5 |

| Ti–4 wt. %Co 500 °C, 5685 h | a = 0.2954, c = 0.4759, c/a = 1.611 | a = 0.2966, c = 0.4718, c/a = 1.591 | a = 0.4622, c = 0.2833 | 65 |

| Ti–4 wt. %Co 400 °C, 5685 h | a = 0.2953, c = 0.4729, c/a = 1.602 | a = 0.2963, c = 0.4725, c/a = 1.595 | a = 0.4622, c = 0.2833 | 80 |

| Pure Ti | a = 0.2953, c = 0.4694, c/a = 1.588 | a = 0.2959, c = 0.4690, c/a = 1.585 | a = 0.4627, c = 0.2830 | 40 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Straumal, B.B.; Korneva, A.; Kilmametov, A.R.; Lityńska-Dobrzyńska, L.; Gornakova, A.S.; Chulist, R.; Karpov, M.I.; Zięba, P. Structural and Mechanical Properties of Ti–Co Alloys Treated by High Pressure Torsion. Materials 2019, 12, 426. https://doi.org/10.3390/ma12030426

Straumal BB, Korneva A, Kilmametov AR, Lityńska-Dobrzyńska L, Gornakova AS, Chulist R, Karpov MI, Zięba P. Structural and Mechanical Properties of Ti–Co Alloys Treated by High Pressure Torsion. Materials. 2019; 12(3):426. https://doi.org/10.3390/ma12030426

Chicago/Turabian StyleStraumal, Boris B., Anna Korneva, Askar R. Kilmametov, Lidia Lityńska-Dobrzyńska, Alena S. Gornakova, Robert Chulist, Mikhail I. Karpov, and Paweł Zięba. 2019. "Structural and Mechanical Properties of Ti–Co Alloys Treated by High Pressure Torsion" Materials 12, no. 3: 426. https://doi.org/10.3390/ma12030426

APA StyleStraumal, B. B., Korneva, A., Kilmametov, A. R., Lityńska-Dobrzyńska, L., Gornakova, A. S., Chulist, R., Karpov, M. I., & Zięba, P. (2019). Structural and Mechanical Properties of Ti–Co Alloys Treated by High Pressure Torsion. Materials, 12(3), 426. https://doi.org/10.3390/ma12030426