Effect of Activating Agent on the Properties of TiO2/Activated Carbon Heterostructures for Solar Photocatalytic Degradation of Acetaminophen

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of TiO2/AC Heterostructures

2.2.1. Preparation of Activated Carbons

2.2.2. Solvothermal Synthesis of TiO2/Activated Carbon Heterostructures

2.3. Characterization Techniques

2.4. Photocatalytic Tests

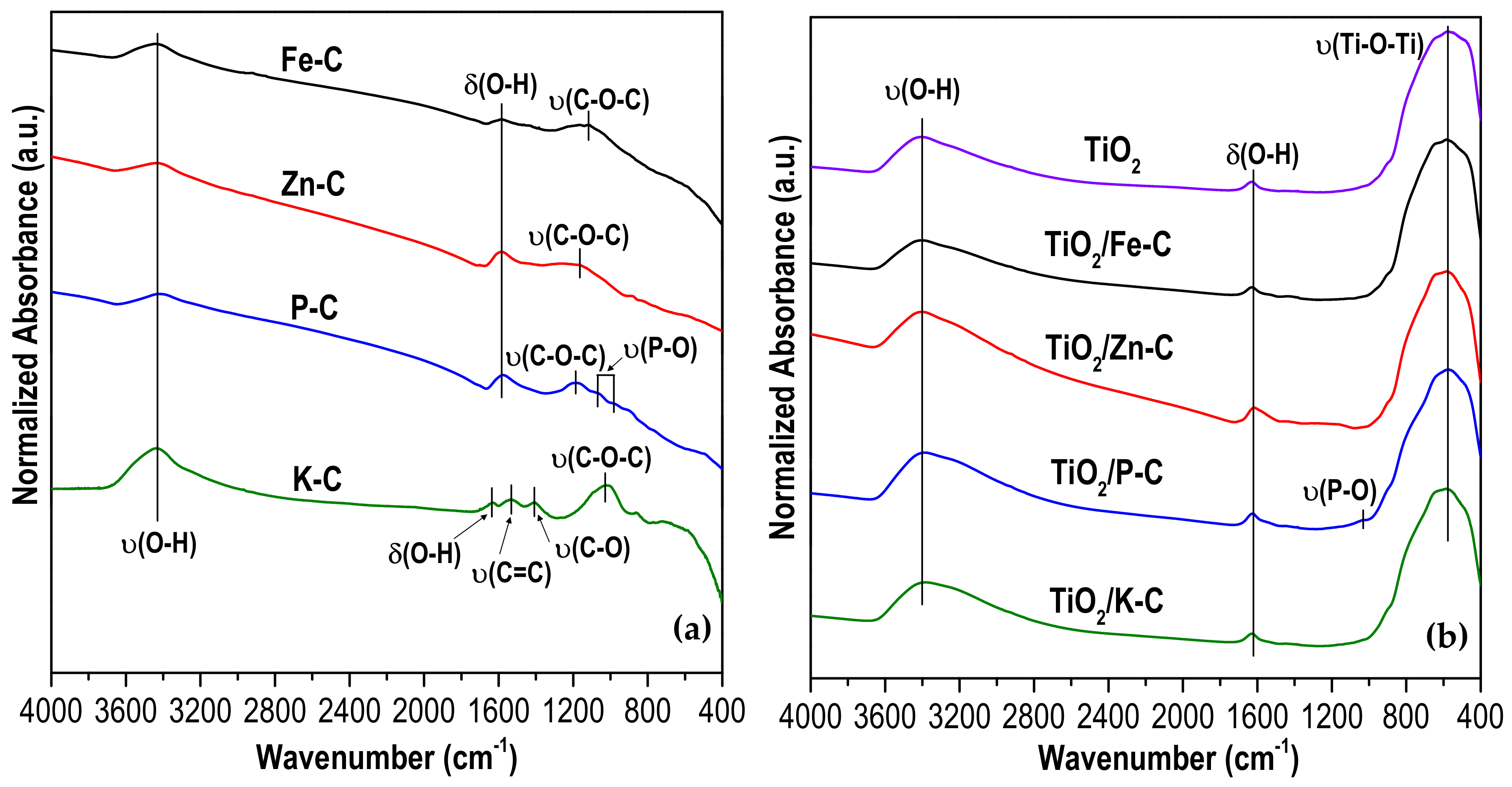

3. Results and Discussion

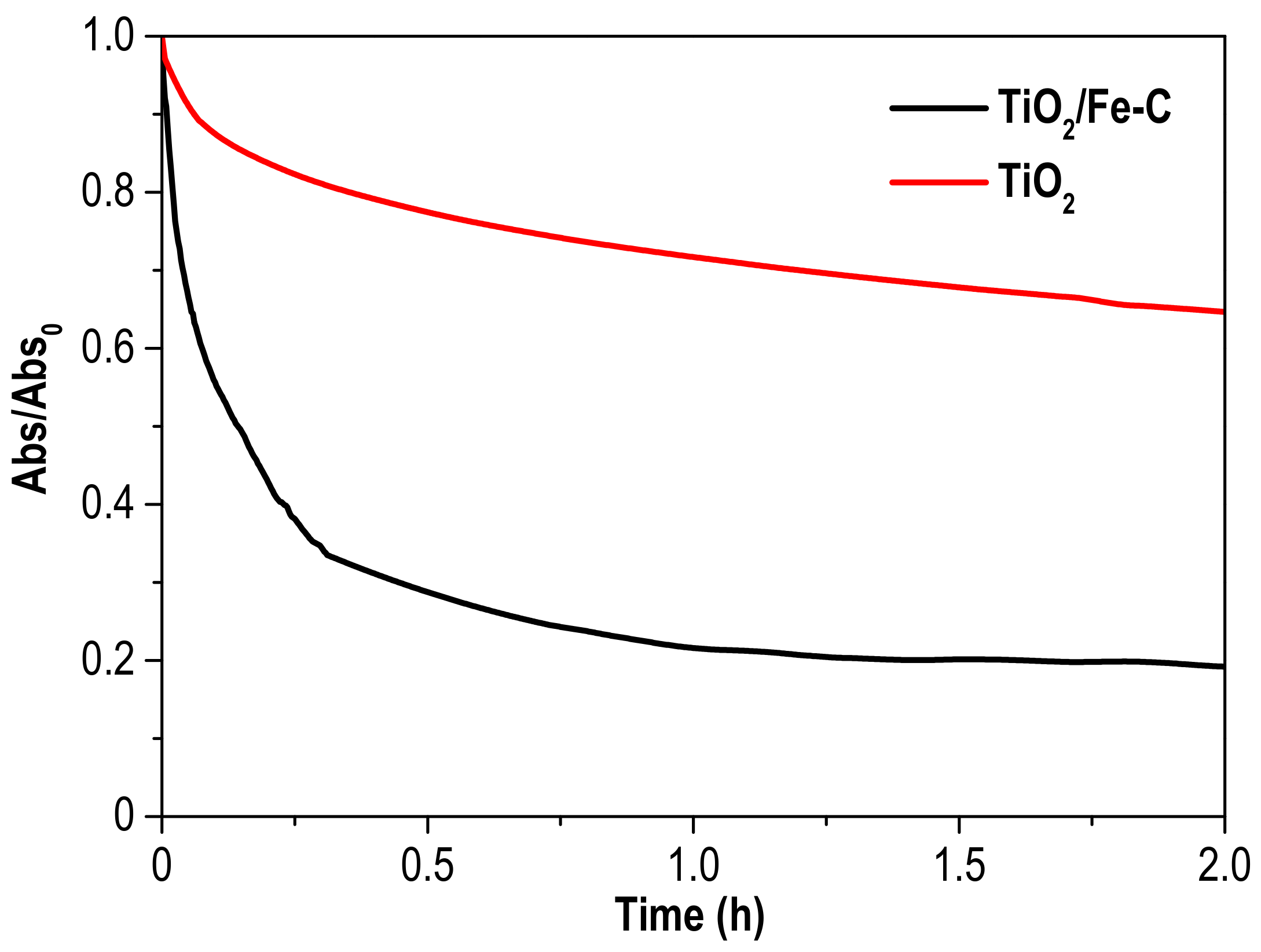

3.1. Characterization of TiO2/Activated Carbon Heterostructures

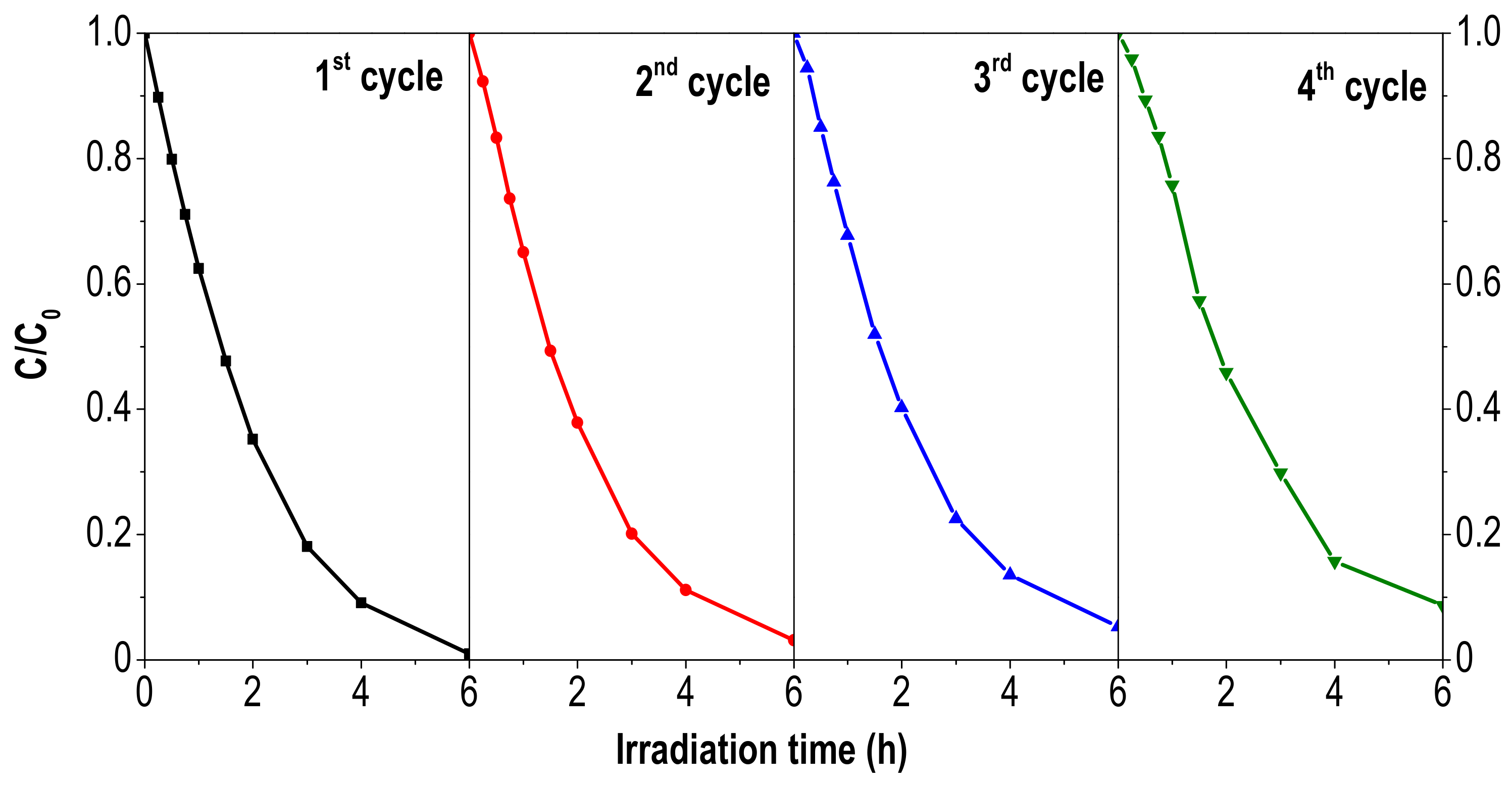

3.2. Photocatalytic Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Čelić, M.; Gros, M.; Farré, M.; Barceló, D.; Petrović, M. Pharmaceuticals as chemical markers of wastewater contamination in the vulnerable area of the Ebro Delta (Spain). Sci. Total Environ. 2018, 652, 952–963. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Ok, Y.S.; Kim, K.H.; Kwon, E.E.; Tsang, Y.F. Occurrences and removal of pharmaceuticals and personal care products (PPCPs) in drinking water and water/sewage treatment plants: A review. Sci. Total Environ. 2017, 596–597, 303–320. [Google Scholar] [CrossRef] [PubMed]

- Álvarez-Muñoz, D.; Rodríguez-Mozaz, S.; Maulvault, A.L.; Tediosi, A.; Fernández-Tejedor, M.; Van den Heuvel, F.; Kotterman, M.; Marques, A.; Barceló, D. Occurrence of pharmaceuticals and endocrine disrupting compounds in macroalgaes, bivalves, and fish from coastal areas in Europe. Environ. Res. 2015, 143, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Tran, N.H.; Reinhard, M.; Gin, K.Y.-H. Occurrence and fate of emerging contaminants in municipal wastewater treatment plants from different geographical regions—A review. Water Res. 2018, 133, 182–207. [Google Scholar] [CrossRef] [PubMed]

- Huerta, B.; Rodriguez-Mozaz, S.; Nannou, C.; Nakis, L.; Ruhí, A.; Acuña, V.; Sabater, S.; Barcelo, D. Determination of a broad spectrum of pharmaceuticals and endocrine disruptors in biofilm from a waste water treatment plant-impacted river. Sci. Total Environ. 2016, 540, 241–249. [Google Scholar] [CrossRef] [PubMed]

- Mohapatra, D.P.; Brar, S.K.; Tyagi, R.D.; Picard, P.; Surampalli, R.Y. Analysis and advanced oxidation treatment of a persistent pharmaceutical compound in wastewater and wastewater sludge-carbamazepine. Sci. Total Environ. 2014, 470–471, 58–75. [Google Scholar] [CrossRef] [PubMed]

- Gomes, J.; Costa, R.; Quinta-Ferreira, R.M.; Martins, R.C. Application of ozonation for pharmaceuticals and personal care products removal from water. Sci. Total Environ. 2017, 586, 265–283. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, T.; Zhang, Y.; Ge, F.; Steel, R.M.; Sun, L. Advances in technologies for pharmaceuticals and personal care products removal. J. Mater. Chem. A 2017, 5, 12001–12014. [Google Scholar] [CrossRef]

- Fujishima, A.; Zhang, X.; Tryk, D.A. TiO2 photocatalysis and related surface phenomena. Surf. Sci. Rep. 2008, 63, 515–582. [Google Scholar] [CrossRef]

- Dong, H.; Zeng, G.; Tang, L.; Fan, C.; Zhang, C.; He, X.; He, Y. An overview on limitations of TiO2-based particles for photocatalytic degradation of organic pollutants and the corresponding countermeasures. Water Res. 2015, 79, 128–146. [Google Scholar] [CrossRef]

- Awfa, D.; Ateia, M.; Fujii, M.; Johnson, M.S.; Yoshimura, C. Photodegradation of pharmaceuticals and personal care products in water treatment using carbonaceous-TiO2 composites: A critical review of recent literature. Water Res. 2018, 142, 26–45. [Google Scholar] [PubMed]

- Leary, R.; Westwood, A. Carbonaceous nanomaterials for the enhancement of TiO2 photocatalysis. Carbon 2011, 49, 741–772. [Google Scholar] [CrossRef]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef]

- Alvira, P.; Tomás-Pejó, E.; Ballesteros, M.; Negro, M.J. Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 2010, 101, 4851–4861. [Google Scholar] [CrossRef]

- Zakzeski, J.; Bruijnincx, P.C.A.; Jongerius, A.L.; Weckhuysen, B.M. The Catalytic Valorization of Lignin for the Production of Renewable Chemicals. Chem. Rev. 2010, 110, 3552–3599. [Google Scholar] [PubMed]

- Rosas, J.M.; Berenguer, R.; Valero-Romero, M.J.; Rodríguez-Mirasol, J.; Cordero, T. Preparation of Different Carbon Materials by Thermochemical Conversion of Lignin. Front. Mater. 2014, 1, 1–17. [Google Scholar] [CrossRef]

- Fernandez-Ruiz, C.; Bedia, J.; Bonal, P.; Rodriguez, J.J.; Gómez-Sainero, L.M. Chloroform conversion into ethane and propane by catalytic hydrodechlorination with Pd supported on activated carbons from lignin. Catal. Sci. Technol. 2018, 8, 3926–3935. [Google Scholar] [CrossRef]

- Rodríguez, J.J.; Cordero, T.; Rodríguez-Mirasol, J. Carbon Materials from Lignin and Their Applications. Biofuels Biorefineries 2016, 6. [Google Scholar] [CrossRef]

- Bouchelta, C.; Medjram, M.S.; Bertrand, O.; Bellat, J.-P. Preparation and characterization of activated carbon from date stones by physical activation with steam. J. Anal. Appl. Pyrolysis 2008, 82, 70–77. [Google Scholar] [CrossRef]

- Bedia, J.; Belver, C.; Ponce, S.; Rodriguez, J.; Rodriguez, J.J. Adsorption of antipyrine by activated carbons from FeCl3-activation of Tara gum. Chem. Eng. J. 2018, 333, 58–65. [Google Scholar] [CrossRef]

- Kumar, A.; Jena, H.M. High surface area microporous activated carbons prepared from Fox nut (Euryale ferox) shell by zinc chloride activation. Appl. Surf. Sci. 2015, 356, 753–761. [Google Scholar] [CrossRef]

- Da Silva Lacerda, V.; López-Sotelo, J.B.; Correa-Guimarães, A.; Hernández-Navarro, S.; Sánchez-Báscones, M.; Navas-Gracia, L.M.; Martín-Ramos, P.; Martín-Gil, J. Rhodamine B removal with activated carbons obtained from lignocellulosic waste. J. Environ. Manag. 2015, 155, 67–76. [Google Scholar] [CrossRef] [PubMed]

- Bedin, K.C.; Martins, A.C.; Cazetta, A.L.; Pezoti, O.; Almeida, V.C. KOH-activated carbon prepared from sucrose spherical carbon: Adsorption equilibrium, kinetic and thermodynamic studies for Methylene Blue removal. Chem. Eng. J. 2016, 286, 476–484. [Google Scholar] [CrossRef]

- Cordero, T.; Duchamp, C.; Chovelon, J.M.; Ferronato, C.; Matos, J. Influence of L-type activated carbons on photocatalytic activity of TiO2 in 4-chlorophenol photodegradation. J. Photochem. Photobiol. A Chem. 2007, 191, 122–131. [Google Scholar] [CrossRef]

- Gonzalez-Serrano, E.; Cordero, T.; Rodríguez-Mirasol, J.; Rodríguez, J.J. Development of Porosity upon Chemical Activation of Kraft Lignin with ZnCl2. Ind. Eng. Chem. Res. 1997, 36, 4832–4838. [Google Scholar] [CrossRef]

- Bolshtyansky, M.A.; Margaryan, H.L.; Tabiryan, N.V.; Zel’dovich, B.Y. Realization and development of BRIEFING beam reconstruction algorithm and visualization methods. In Proceedings of the Conference on Lasers and Electro-Optics Europe—Technical Digest, San Francisco, CA, USA, 3–8 May 1998; Volume 50, pp. 448–449. [Google Scholar]

- Babeł, K.; Jurewicz, K. KOH activated lignin based nanostructured carbon exhibiting high hydrogen electrosorption. Carbon 2008, 46, 1948–1956. [Google Scholar] [CrossRef]

- Marsh, H.; Rodríguez Reinoso, F. Activated Carbon; Elsevier: Amsterdam, The Netherlands, 2006; ISBN 9780080455969. [Google Scholar]

- Wu, H.; Wu, X.L.; Wang, Z.M.; Aoki, H.; Kutsuna, S.; Jimura, K.; Hayashi, S. Anchoring titanium dioxide on carbon spheres for high-performance visible light photocatalysis. Appl. Catal. B Environ. 2017, 207, 255–266. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Lippens, B.C.; De Boer, J.H. Studies on pore systems in catalysts: V. The t method. J. Catal. 1965, 4, 319–323. [Google Scholar] [CrossRef]

- Newcombe, G.; Hayes, R.; Drikas, M. Granular activated carbon: Importance of surface properties in the adsorption of naturally occurring organics. Colloids Surfaces A Physicochem. Eng. Asp. 1993, 78, 65–71. [Google Scholar] [CrossRef]

- Tauc, J. Absorption edge and internal electric fields in amorphous semiconductors. Mater. Res. Bull. 1970, 5, 721–729. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, P.; Liu, J.; Yu, J. New understanding of the difference of photocatalytic activity among anatase, rutile and brookite TiO2. Phys. Chem. Chem. Phys. 2014, 16, 20382–20386. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, A.N. The design, fabrication, and photocatalytic utility of nanostructured semiconductors: Focus on TiO2-based nanostructures. Nanotechnol. Sci. Appl. 2011, 4, 35–65. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.X.; Chen, X.Y.; Chen, X. A TiO2/AC composite photocatalyst with high activity and easy separation prepared by a hydrothermal method. J. Hazard. Mater. 2007, 143, 257–263. [Google Scholar] [CrossRef] [PubMed]

- Ouzzine, M.; Romero-Anaya, A.J.; Lillo-Ródenas, M.A.; Linares-Solano, A. Spherical activated carbon as an enhanced support for TiO2/AC photocatalysts. Carbon 2014, 67, 104–118. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Z.; Chen, Y.; Zhao, G.; Liu, Y.; Wen, Z. A novel approach towards high-performance composite photocatalyst of TiO2 deposited on activated carbon. Appl. Surf. Sci. 2009, 255, 3953–3958. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Lillo-Ródenas, M.; Cazorla-Amorós, D.; Linares-Solano, A. Understanding chemical reactions between carbons and NaOH and KOH. Carbon 2003, 41, 267–275. [Google Scholar] [CrossRef]

- Bedia, J.; Peñas-Garzón, M.; Goméz-Avilés, A.; Rodríguez, J.J.; Belver, C. A Review on Synthesis and Characterization of Biomass-Derived Carbons for Adsorption of Emerging Contaminants from Water. C 2018, 4, 63. [Google Scholar] [CrossRef]

- Caturla, F.; Molina-Sabio, M.; Rodríguez-Reinoso, F. Preparation of activated carbon by chemical activation with ZnCl2. Carbon 1991, 29, 999–1007. [Google Scholar] [CrossRef]

- Shafaee, M.; Goharshadi, E.K.; Mashreghi, M.; Sadeghinia, M. TiO2 nanoparticles and TiO2@graphene quantum dots nancomposites as effective visible/solar light photocatalysts. J. Photochem. Photobiol. A Chem. 2018, 357, 90–102. [Google Scholar] [CrossRef]

- Tsai, W.; Chang, C.; Lin, M.; Chien, S.; Sun, H.; Hsieh, M. Adsorption of acid dye onto activated carbons prepared from agricultural waste bagasse by ZnCl2 activation. Chemosphere 2001, 45, 51–58. [Google Scholar] [CrossRef]

- Mohan, D.; Singh, K.P.; Sinha, S.; Gosh, D. Removal of pyridine from aqueous solution using low cost activated carbons derived from agricultural waste materials. Carbon 2004, 42, 2409–2421. [Google Scholar] [CrossRef]

- Deng, H.; Li, G.; Yang, H.; Tang, J.; Tang, J. Preparation of activated carbons from cotton stalk by microwave assisted KOH and K2CO3 activation. Chem. Eng. J. 2010, 163, 373–381. [Google Scholar] [CrossRef]

- Zeitler, V.A.; Brown, C.A. The Infrared Spectra of Some Ti-O-Si, Ti-O-Ti and Si-O-Si Compounds. J. Phys. Chem. 1957, 61, 1174–1177. [Google Scholar] [CrossRef]

- Vasconcelos, D.C.L.; Costa, V.C.; Nunes, E.H.M.; Sabioni, A.C.S.; Gasparon, M.; Vasconcelos, W.L. Infrared Spectroscopy of Titania Sol-Gel Coatings on 316L Stainless Steel. Mater. Sci. Appl. 2011, 2, 1375–1382. [Google Scholar] [CrossRef]

- Barroso-Bogeat, A.; Alexandre-Franco, M.; Fernández-González, C.; Macías-García, A.; Gómez-Serrano, V. Preparation of Activated Carbon-SnO2, TiO2, and WO3 Catalysts. Study by FT-IR Spectroscopy. Ind. Eng. Chem. Res. 2016, 55, 5200–5206. [Google Scholar] [CrossRef]

- Bredow, T.; Jug, K. Theoretical investigation of water adsorption at rutile and anatase surfaces. Surf. Sci. 1995, 327, 398–408. [Google Scholar] [CrossRef]

- Khalid, N.R.; Majid, A.; Tahir, M.B.; Niaz, N.A.; Khalid, S. Carbonaceous-TiO2 nanomaterials for photocatalytic degradation of pollutants: A review. Ceram. Int. 2017, 43, 14552–14571. [Google Scholar] [CrossRef]

- Carp, O.; Huisman, C.L.; Reller, A. Photoinduced reactivity of titanium dioxide. Prog. Solid State Chem. 2004, 32, 33–177. [Google Scholar] [CrossRef]

- Garcia-Ivars, J.; Durá-María, J.; Moscardó-Carreño, C.; Carbonell-Alcaina, C.; Alcaina-Miranda, M.I.; Iborra-Clar, M.I. Rejection of trace pharmaceutically active compounds present in municipal wastewaters using ceramic fine ultrafiltration membranes: Effect of feed solution pH and fouling phenomena. Sep. Purif. Technol. 2017, 175, 58–71. [Google Scholar] [CrossRef]

- Rey, A.; Quiñones, D.H.; Álvarez, P.M.; Beltrán, F.J.; Plucinski, P.K. Simulated solar-light assisted photocatalytic ozonation of metoprolol over titania-coated magnetic activated carbon. Appl. Catal. B Environ. 2012, 111–112, 246–253. [Google Scholar] [CrossRef]

- Rosa, S.M.C.; Nossol, A.B.S.; Nossol, E.; Zarbin, A.J.G.; Peralta-Zamora, P.G. Non-Synergistic UV-A Photocatalytic Degradation of Estrogens by Nano-TiO2 Supported on Activated Carbon. J. Braz. Chem. Soc. 2016, 28, 582–588. [Google Scholar]

- Ma, R.; Wang, X.; Huang, J.; Song, J.; Zhang, J.; Wang, X. Photocatalytic degradation of salicylic acid with magnetic activated carbon-supported F-N codoped TiO2 under visible light. Vacuum 2017, 141, 157–165. [Google Scholar] [CrossRef]

- Gar Alalm, M.; Tawfik, A.; Ookawara, S. Enhancement of photocatalytic activity of TiO2 by immobilization on activated carbon for degradation of pharmaceuticals. J. Environ. Chem. Eng. 2016, 4, 1929–1937. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Mao, L.; Yang, Z. Dependence of kinetics and pathway of acetaminophen photocatalytic degradation on irradiation photon energy and TiO2 crystalline. Chem. Eng. J. 2017, 330, 1091–1099. [Google Scholar] [CrossRef]

- Chang, C.T.; Wang, J.J.; Ouyang, T.; Zhang, Q.; Jing, Y.H. Photocatalytic degradation of acetaminophen in aqueous solutions by TiO2/ZSM-5 zeolite with low energy irradiation. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2015, 196, 53–60. [Google Scholar] [CrossRef]

| Sample | Activating Agent | Act. Agent: Lignin Mass Ratio | Activation Temperature (°C) |

|---|---|---|---|

| Fe-C | FeCl3 | 3:1 | 800 |

| Zn-C | ZnCl2 | 3:1 | 500 |

| P-C | H3PO4 | 3:1 | 500 |

| K-C | KOH | 4:1 | 900 |

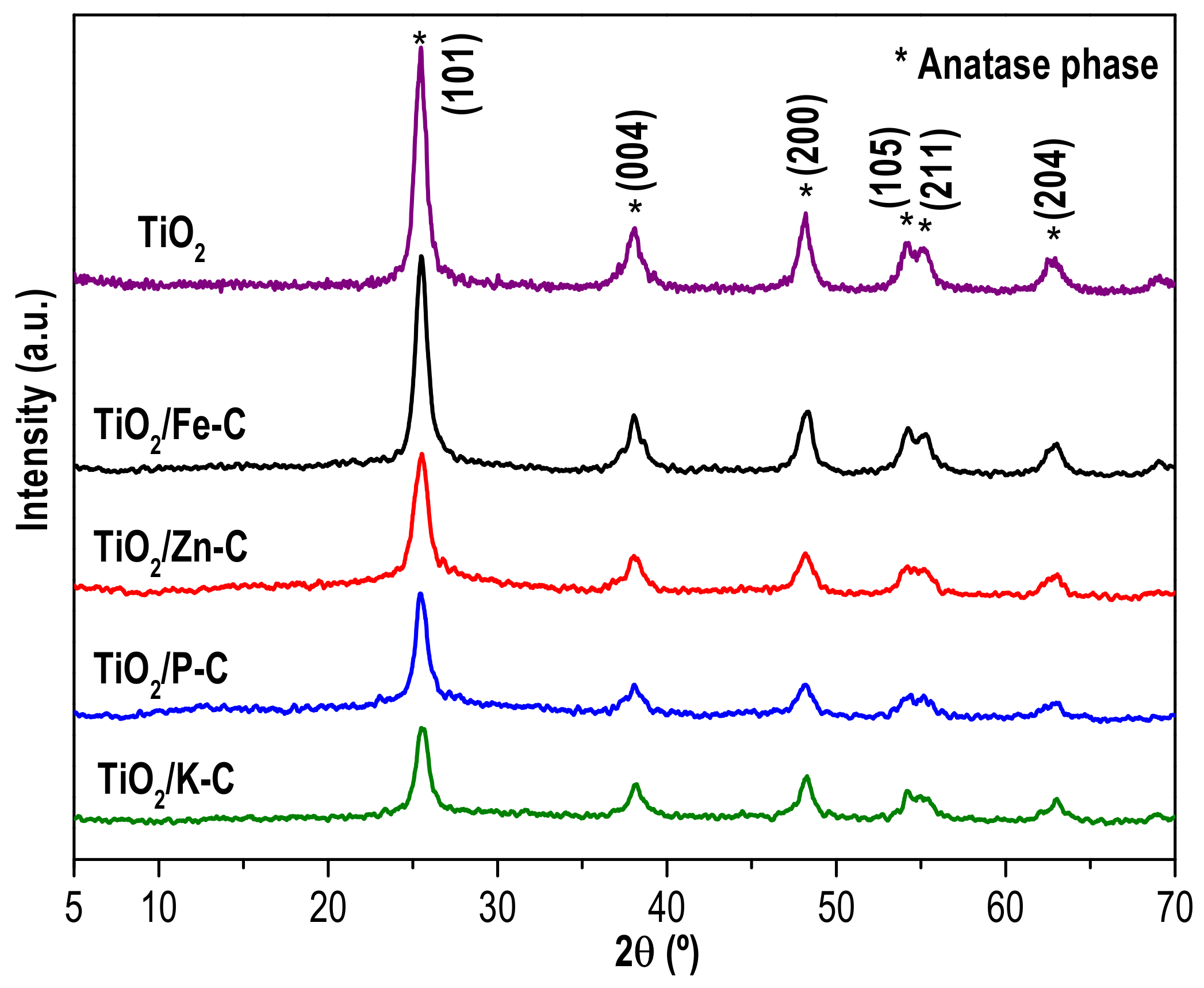

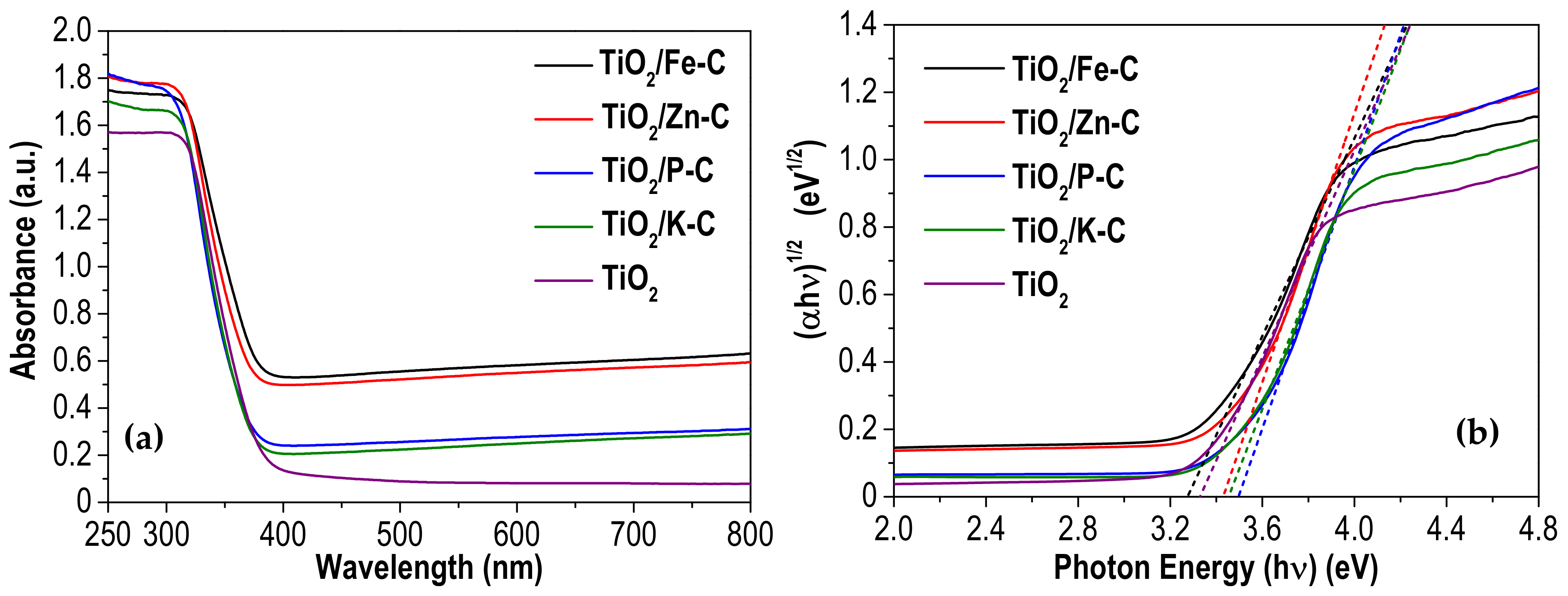

| Sample | %TiO2a | D (nm)b | Eg (eV) | pHpzcc |

|---|---|---|---|---|

| TiO2/Fe-C | 75.9 | 10.1 | 3.28 | 6.36 |

| TiO2/Zn-C | 68.5 | 8.6 | 3.42 | 5.96 |

| TiO2/P-C | 81.3 | 10.6 | 3.50 | 4.86 |

| TiO2/K-C | 83.9 | 9.4 | 3.45 | 6.17 |

| TiO2 | n.m | 10.5 | 3.33 | 6.58 |

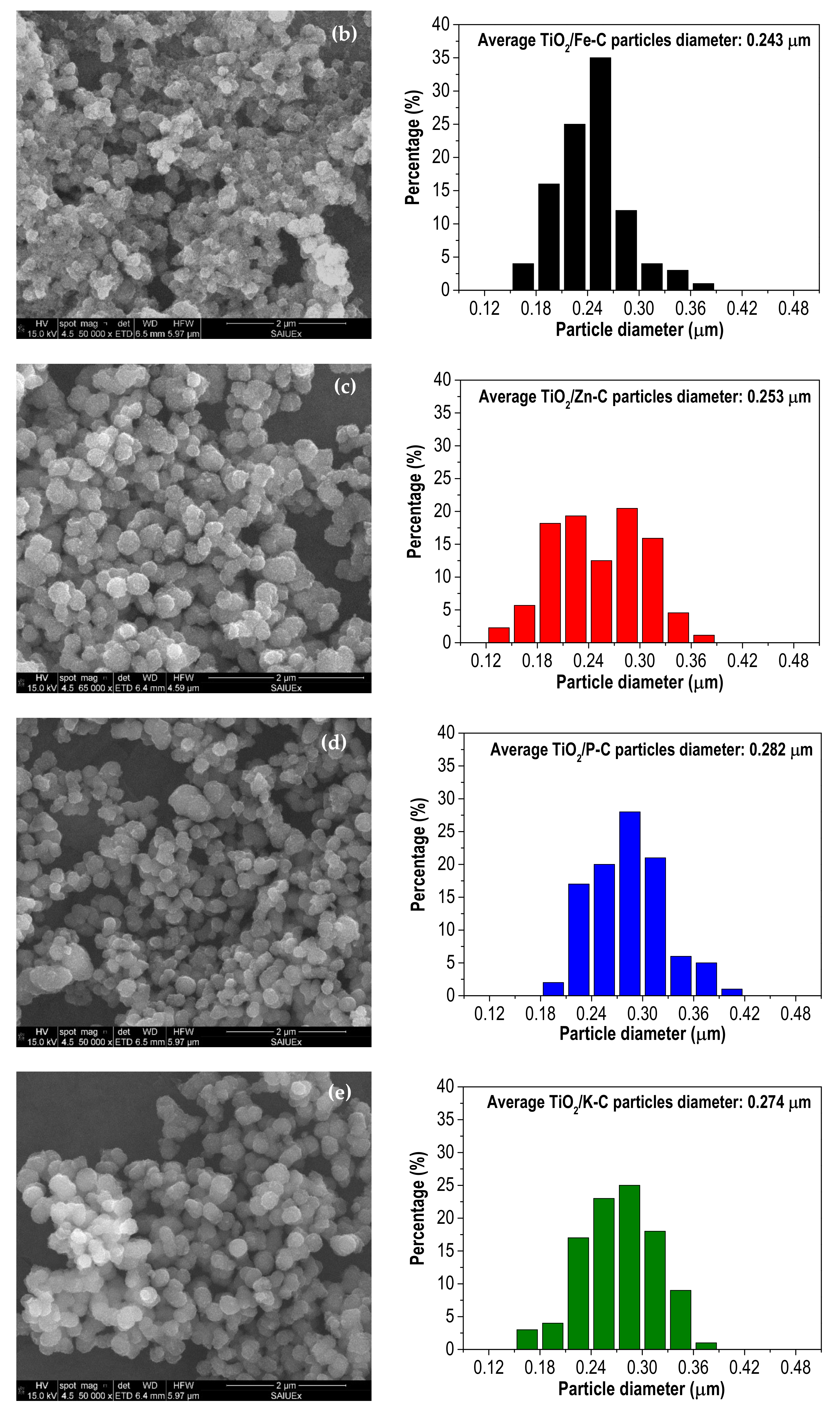

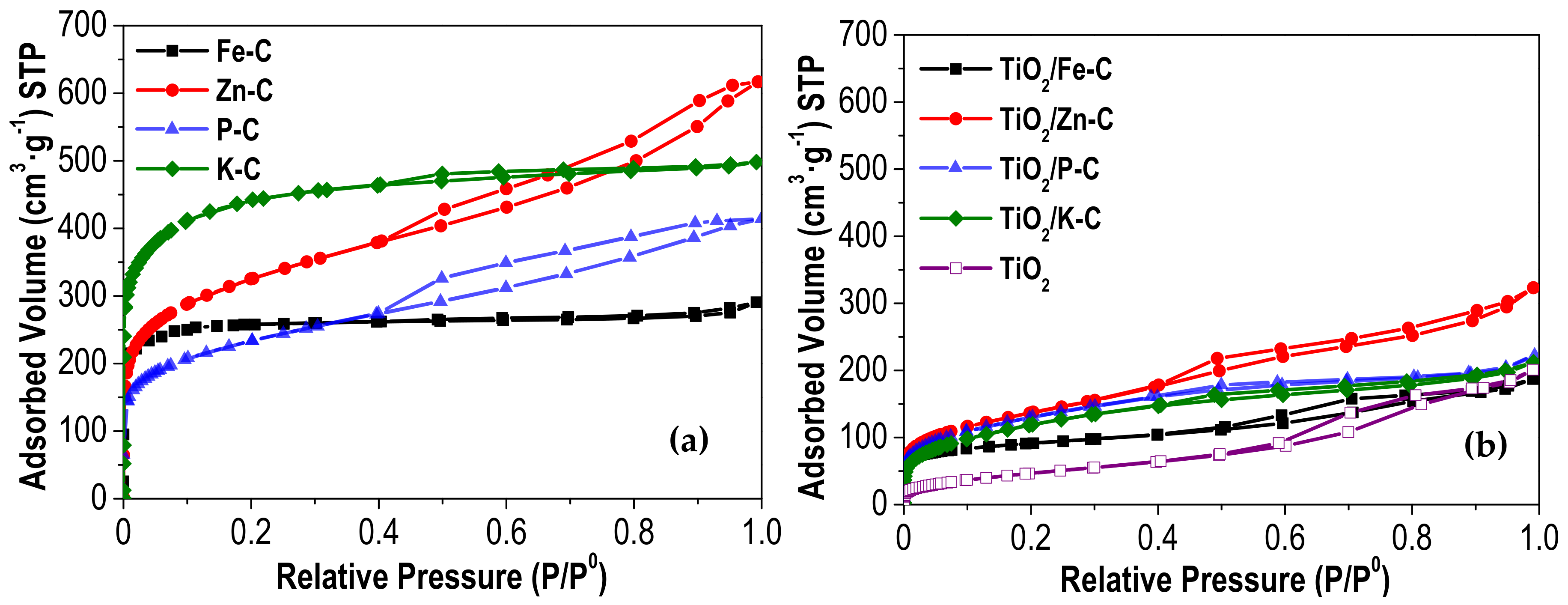

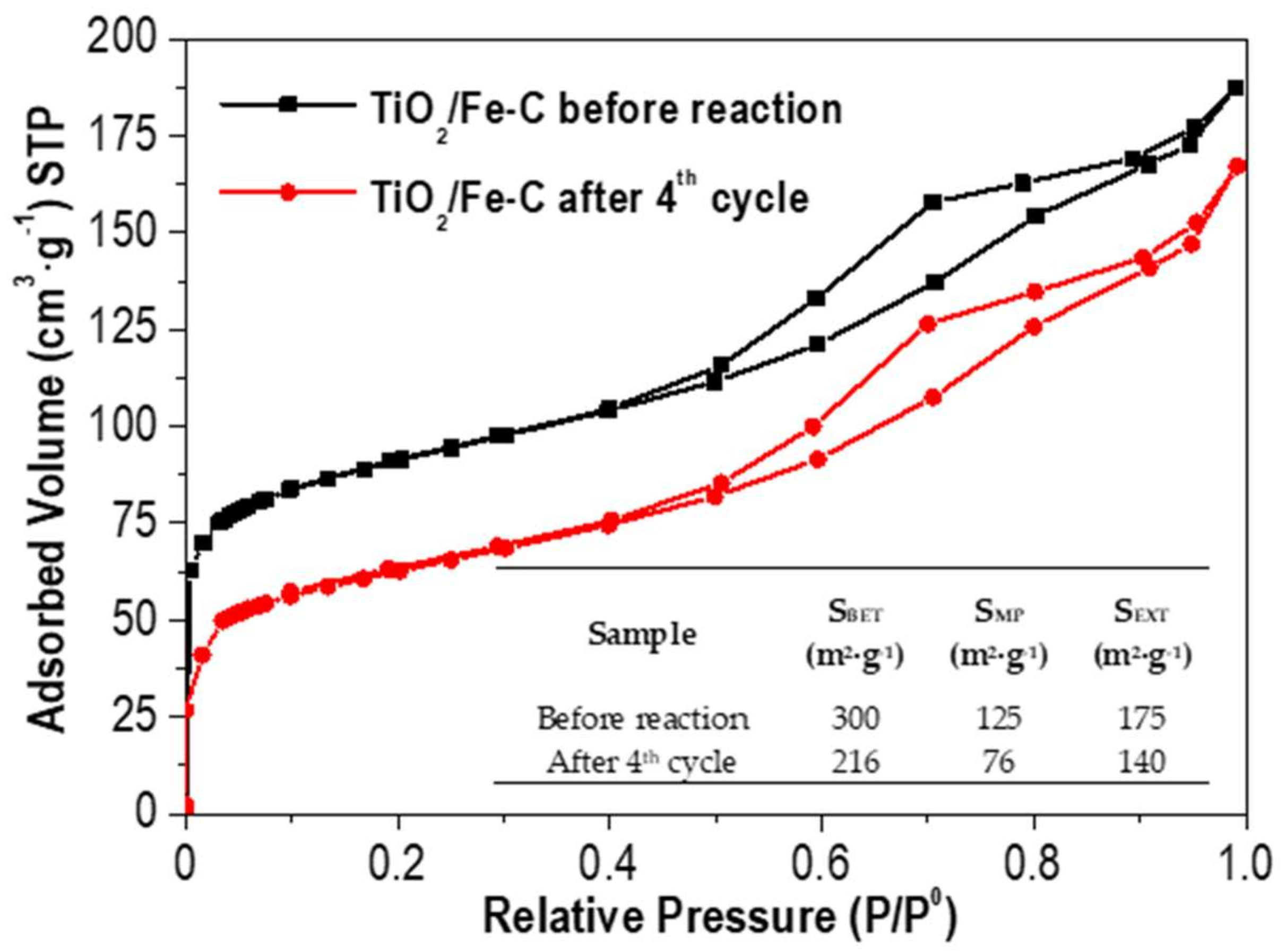

| Sample | SBET (m2·g−1) | SMP (m2·g−1) | SEXT (m2·g−1) |

|---|---|---|---|

| Carbonized lignin | 62 | 62 | - |

| Fe-C | 756 | 695 | 61 |

| Zn-C | 1129 | 451 | 678 |

| P-C | 807 | 303 | 504 |

| K-C | 1446 | 1142 | 304 |

| TiO2/Fe-C | 300 | 125 | 175 |

| TiO2/Zn-C | 491 | 108 | 383 |

| TiO2/P-C | 435 | 109 | 326 |

| TiO2/K-C | 465 | 156 | 309 |

| TiO2 | 178 | - | 178 |

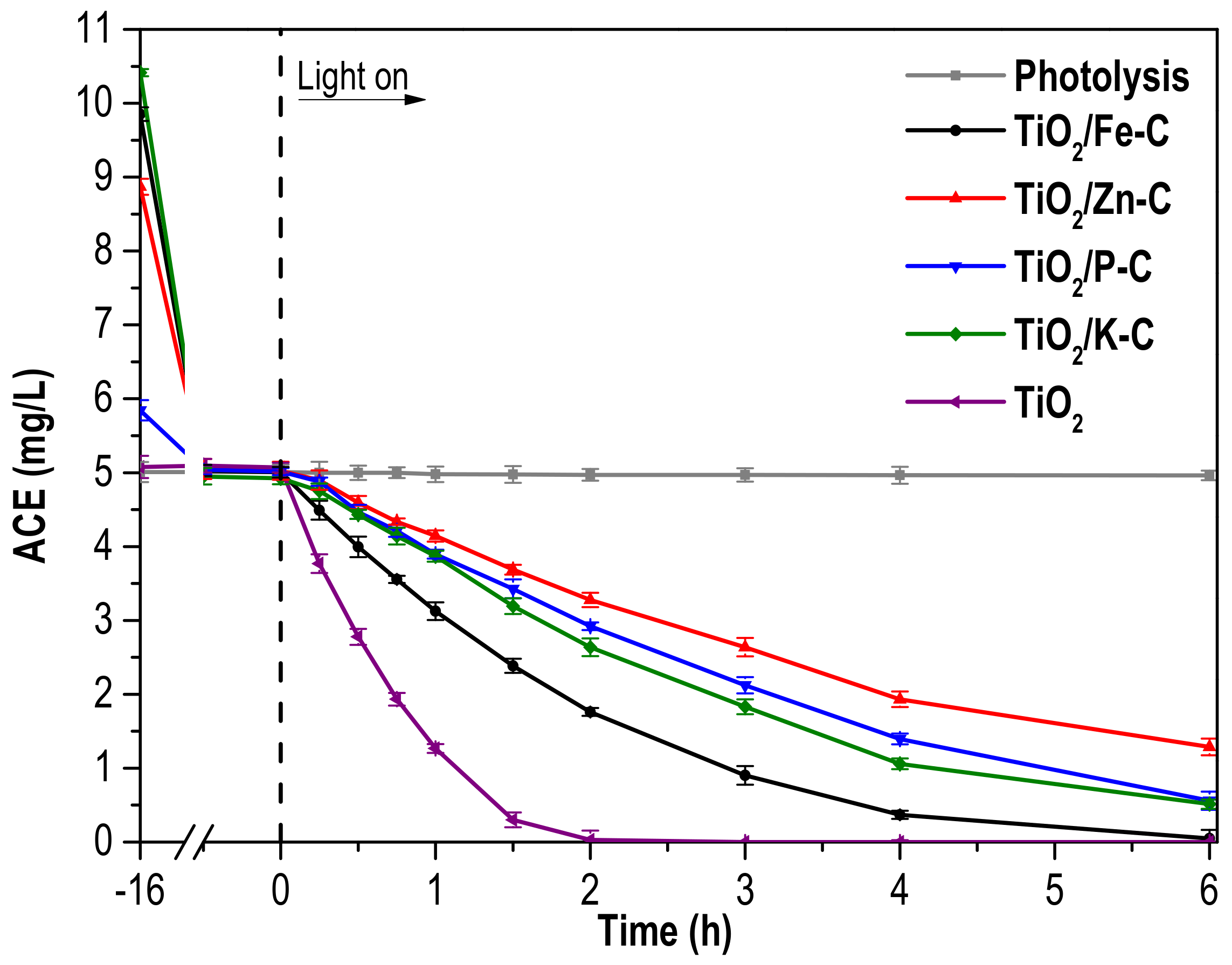

| Photocatalyst | Removed TOC (%) |

|---|---|

| TiO2/Fe-C | 43.3 |

| TiO2/Zn-C | 23.9 |

| TiO2/P-C | 35.5 |

| TiO2/K-C | 30.2 |

| TiO2 | 59.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peñas-Garzón, M.; Gómez-Avilés, A.; Bedia, J.; Rodriguez, J.J.; Belver, C. Effect of Activating Agent on the Properties of TiO2/Activated Carbon Heterostructures for Solar Photocatalytic Degradation of Acetaminophen. Materials 2019, 12, 378. https://doi.org/10.3390/ma12030378

Peñas-Garzón M, Gómez-Avilés A, Bedia J, Rodriguez JJ, Belver C. Effect of Activating Agent on the Properties of TiO2/Activated Carbon Heterostructures for Solar Photocatalytic Degradation of Acetaminophen. Materials. 2019; 12(3):378. https://doi.org/10.3390/ma12030378

Chicago/Turabian StylePeñas-Garzón, Manuel, Almudena Gómez-Avilés, Jorge Bedia, Juan J. Rodriguez, and Carolina Belver. 2019. "Effect of Activating Agent on the Properties of TiO2/Activated Carbon Heterostructures for Solar Photocatalytic Degradation of Acetaminophen" Materials 12, no. 3: 378. https://doi.org/10.3390/ma12030378

APA StylePeñas-Garzón, M., Gómez-Avilés, A., Bedia, J., Rodriguez, J. J., & Belver, C. (2019). Effect of Activating Agent on the Properties of TiO2/Activated Carbon Heterostructures for Solar Photocatalytic Degradation of Acetaminophen. Materials, 12(3), 378. https://doi.org/10.3390/ma12030378