Microstructure and Enhanced Properties of Copper-Vanadium Nanocomposites Obtained by Powder Metallurgy

Abstract

1. Introduction

2. Materials and Methods

3. Results

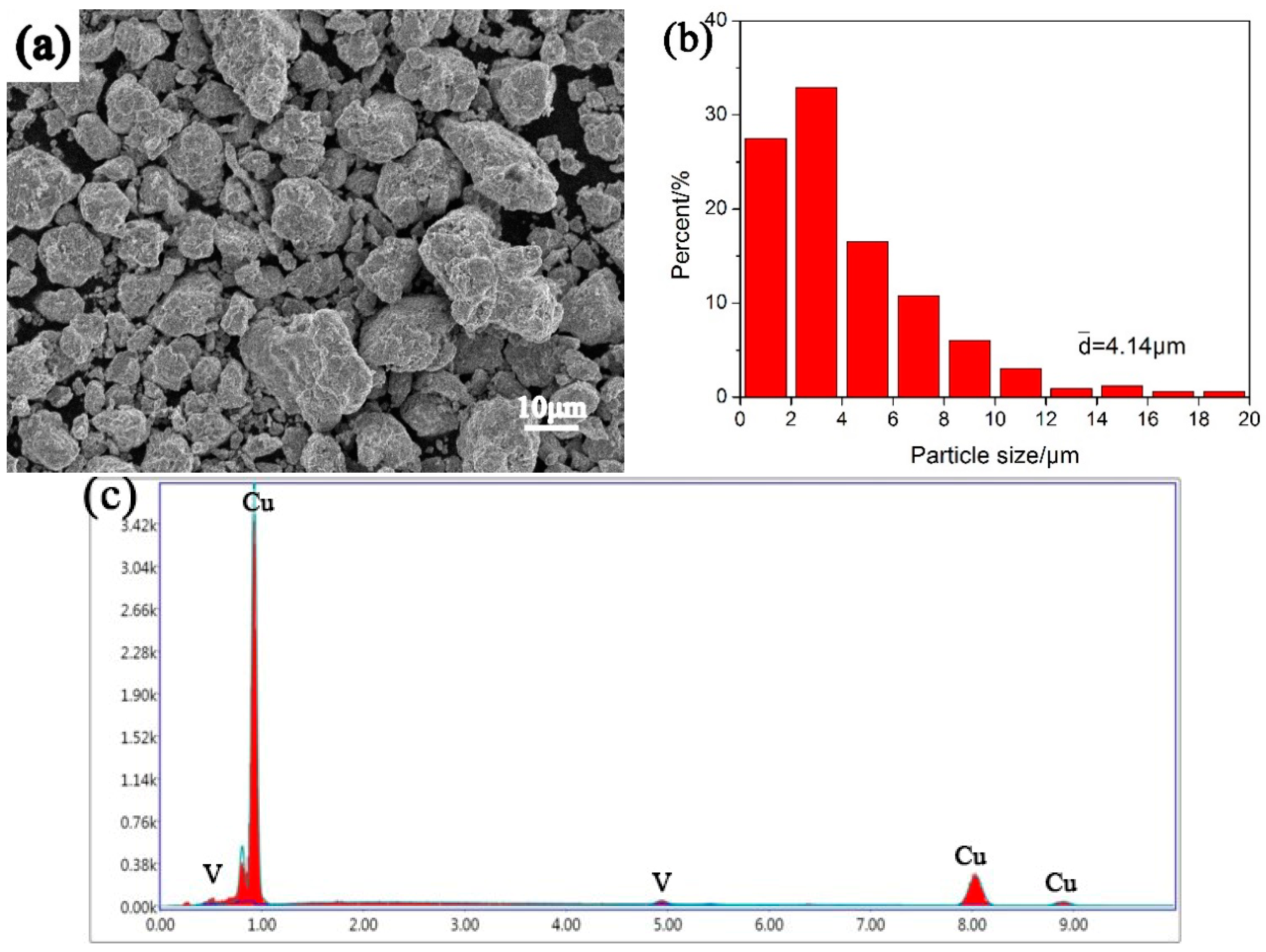

3.1. Phase and Morphology of Samples

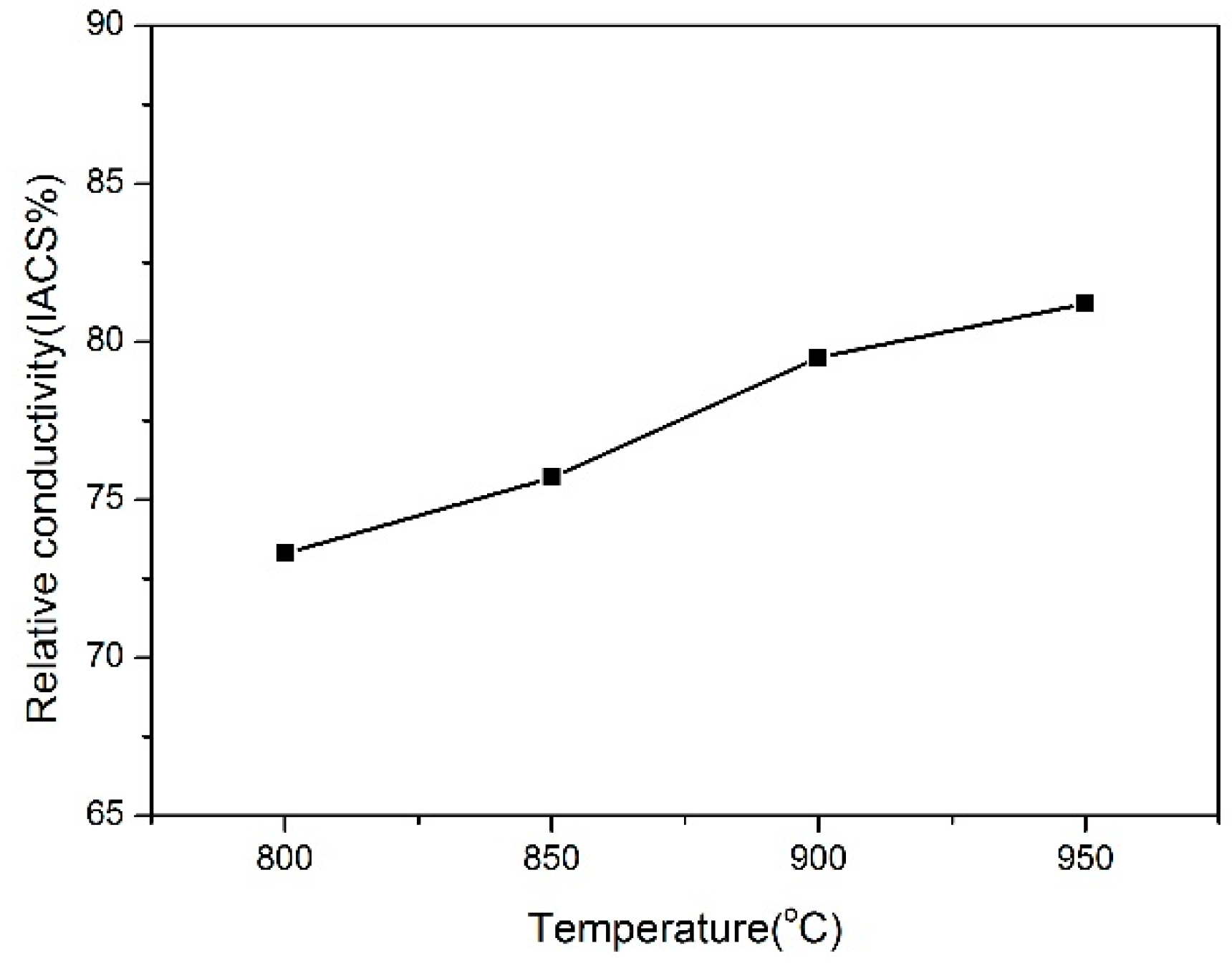

3.2. Properties of Samples

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Murashkin, M.Y.; Sabirov, I.; Sauvage, X.; Valiev, R.Z. Nanostructured Al and Cu alloys with superior strength and electrical conductivity. J. Mater. Sci. 2016, 51, 33–49. [Google Scholar] [CrossRef]

- Popovich, A.; Sufiiarov, V.; Polozov, I.; Borisov, E.; Masaylo, D.; Orlov, A. Microstructure and mechanical properties of additive manufactured copper alloy. Mater. Lett. 2016, 179, 38–41. [Google Scholar] [CrossRef]

- YTian, Z.; Zhao, L.J.; Park, N.; Liu, R.; Zhang, P.; Zhang, Z.J.; Shibata, A.; Zhang, Z.F.; Tsuji, N. Revealing the deformation mechanisms of Cu–Al alloys with high strength and good ductility. Acta Mater. 2016, 110, 61–72. [Google Scholar]

- Li, A.; Szlufarska, I. Morphology and mechanical properties of nanocrystalline Cu/Ag alloy. J. Mater. Sci. 2017, 52, 4555–4567. [Google Scholar] [CrossRef]

- Shen, D.P.; Zhu, Y.J.; Yang, X.; Tong, W.P. Investigation on the microstructure and properties of Cu-Cr alloy prepared by in-situ synthesis method. Vacuum 2018, 149, 207–213. [Google Scholar] [CrossRef]

- Wei, H.; Cui, Y.C.; Cui, H.Q.; Wei, Y.H.; Hou, L.F. Effects of multiple trace alloying elements on the microstructure and properties of Cu-4 wt.% Ti alloys. Mater. Sci. Eng. A 2017, 707, 392–398. [Google Scholar] [CrossRef]

- Shadkam, A.; Sinclair, C.W. The coupled effect of grain size and solute on work hardening of Cu–Ni alloys. Philos. Mag. Lett. 2015, 95, 555–563. [Google Scholar] [CrossRef]

- Lee, S.; Matsunaga, H.; Sauvage, X.; Horita, Z. Strengthening of Cu–Ni–Si alloy using high-pressure torsion and aging. Mater. Charact. 2014, 90, 62–70. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Nesterov, K.M.; Bourgon, J.; Champion, Y.; Valiev, R.Z. Nanostructured Cu-Cr alloy with high strength and electrical conductivity. J. Appl. Phys. 2014, 115, 194301. [Google Scholar] [CrossRef]

- Zuo, X.; Zhu, J.; An, B.; Han, K.; Han, K.; Han, K. Influence of Fe addition on microstructure and properties of Cu-Ag composite. Met. Mater. Int. 2017, 23, 974–983. [Google Scholar] [CrossRef]

- Kardani, A.; Montazeri, A. Temperature-based plastic deformation mechanism of Cu/Ag nanocomposites: A molecular dynamics study. Comput. Mater. Sci. 2018, 144, 223–231. [Google Scholar] [CrossRef]

- Rabiee, M.; Mirzadeh, H.; Ataie, A. Processing of Cu-Fe and Cu-Fe-SiC nanocomposites by mechanical alloying. Adv. Powder Technol. 2017, 28, 1882–1887. [Google Scholar] [CrossRef]

- Hong, S.I.; Hill, M.A. Microstructureal stability of Cu-Nb microcompotite wires fabricated by the bundling and drawing process. Mater. Sci. Eng. A 2000, 281, 189–197. [Google Scholar] [CrossRef]

- Lei, R.S.; Xu, S.Q.; Wang, M.P.; Wang, H.P. Microstructure and properties of nanocrystalline copper-niobium alloy with high strength and high conductivity. Mater. Sci. Eng. A 2013, 586, 367–373. [Google Scholar] [CrossRef]

- Pantsyrnyi, V.I.; Drobyshev, V.A.; Khlebova, N.E.; Kukina, O.D.; Zinov’ev, V.G.; Zurabov, V.S. Microstructure of cast ingots of Cu-V alloys after vacuum melting by different methods. Met. Sci. Heat Treat. 2011, 53, 176. [Google Scholar] [CrossRef]

- Pantsyrny, V.I.; Khlebova, N.E.; Sudyev, S.V.; Kukina, O.V.; Beliakov, N.A.; Polikarpova, M.V. Thermal Stability of the High Strength High Conductivity Cu–Nb, Cu–V, and Cu–Fe Nanostructured Microcomposite Wires. IEEE Trans. Appl. Supercond. 2014, 24, 1–4. [Google Scholar] [CrossRef]

- Pantsyrny, V.; Shikov, A.; Khlebova, N.; Drobishev, V.; Kozlenkova, N.; Polikarpova, M.; Belyakov, N.; Kukina, O. The Nanostructured High Strength High Conductivity Cu Matrix Composites with Different BCC Metals Strengthening Filaments. IEEE Trans. Appl. Supercond. 2010, 20, 1614–1618. [Google Scholar] [CrossRef]

- Nikulin, S.A.; Rogachev, S.O.; Rozhnov, A.B.; Pantsyrnyi, V.I.; Khlebova, N.E.; Nechaykina, T.A.; Khatkevich, V.M.; Zadorozhnyy, M.Y. Microstructure and fatigue strength of high-strength Cu–Fe and Cu–V in-situ nanocomposite wires. Compos. Part B 2015, 70, 92–98. [Google Scholar] [CrossRef]

- Zeng, L.F.; Gao, R.; Xie, Z.M.; Miao, S.; Fang, Q.F.; Wang, X.P.; Zhang, T.; Liu, C.S. Development of interface-dominant bulk Cu/V nanolamellar composites by cross accumulative roll bonding. Sci. Rep. 2017, 7, 40742. [Google Scholar] [CrossRef] [PubMed]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Watanabe, D.; Watanabe, C.; Monzen, R. Determination of the interface energies of spherical, cuboidal and octahedral face-centered cubic precipitates in Cu–Co, Cu–Co–Fe and Cu–Fe alloys. Acta Mater. 2009, 57, 1899–1911. [Google Scholar] [CrossRef]

- Fujii, T.; Nakazawa, H.; Kato, M.; Dahmen, U. Crystallography and morphology of nanosized Cr particles in a Cu–0.2% Cr alloy. Acta Mater. 2000, 48, 1033–1045. [Google Scholar] [CrossRef]

- Benghalem, A.; Morris, D.G. Microstructure and mechanical properties of concentrated copper-niobium alloys prepared by mechanical alloying. Mater. Sci. Eng. A 1993, 161, 255–266. [Google Scholar] [CrossRef]

- Chen, B.A.; Pan, L.; Wang, R.H.; Liu, G.; Cheng, P.M.; Xiao, L.; Sun, J. Effect of solution treatment on precipitation behaviors and age hardening response of Al–Cu alloys with Sc addition. Mater. Sci. Eng. A 2011, 530, 607–617. [Google Scholar] [CrossRef]

- Benson, D.J.; Fu, H.; Meyers, M.A. On the effect of grain size on yield stress: Extension into nanocrystalline domain. Mater. Sci. Eng. A 2001, 319–321, 854–861. [Google Scholar] [CrossRef]

| Sample | Mass (%) | Atom (%) |

|---|---|---|

| 1 | 2.51 | 3.11 |

| 2 | 2.12 | 2.62 |

| 3 | 2.24 | 2.76 |

| Consolidation Temperature (°C) | Copper Grain Size (nm) | V Nanoparticle Size (nm) | V Nanoparticle Content (vol.%) | Yield Strength (MPa) | ||

|---|---|---|---|---|---|---|

| 800 | 138 | 8.5 | 2.1 | 243.36 | 369.50 | 603.96 |

| 850 | 186 | 10.4 | 1.6 | 185.77 | 322.29 | 502.55 |

| 900 | 264 | 12.1 | 1.2 | 144.85 | 275.18 | 404.41 |

| 950 | 285 | 13.8 | 0.9 | 114.63 | 265.94 | 374.84 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, J.; Zou, H.; Wang, Y.; Ran, X. Microstructure and Enhanced Properties of Copper-Vanadium Nanocomposites Obtained by Powder Metallurgy. Materials 2019, 12, 339. https://doi.org/10.3390/ma12030339

Wang Y, Wang J, Zou H, Wang Y, Ran X. Microstructure and Enhanced Properties of Copper-Vanadium Nanocomposites Obtained by Powder Metallurgy. Materials. 2019; 12(3):339. https://doi.org/10.3390/ma12030339

Chicago/Turabian StyleWang, Yong, Jinguo Wang, Haohao Zou, Yutong Wang, and Xu Ran. 2019. "Microstructure and Enhanced Properties of Copper-Vanadium Nanocomposites Obtained by Powder Metallurgy" Materials 12, no. 3: 339. https://doi.org/10.3390/ma12030339

APA StyleWang, Y., Wang, J., Zou, H., Wang, Y., & Ran, X. (2019). Microstructure and Enhanced Properties of Copper-Vanadium Nanocomposites Obtained by Powder Metallurgy. Materials, 12(3), 339. https://doi.org/10.3390/ma12030339