Study on In-Doped CdMgTe Crystals Grown by a Modified Vertical Bridgman Method Using the ACRT Technique

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Crystal Structure

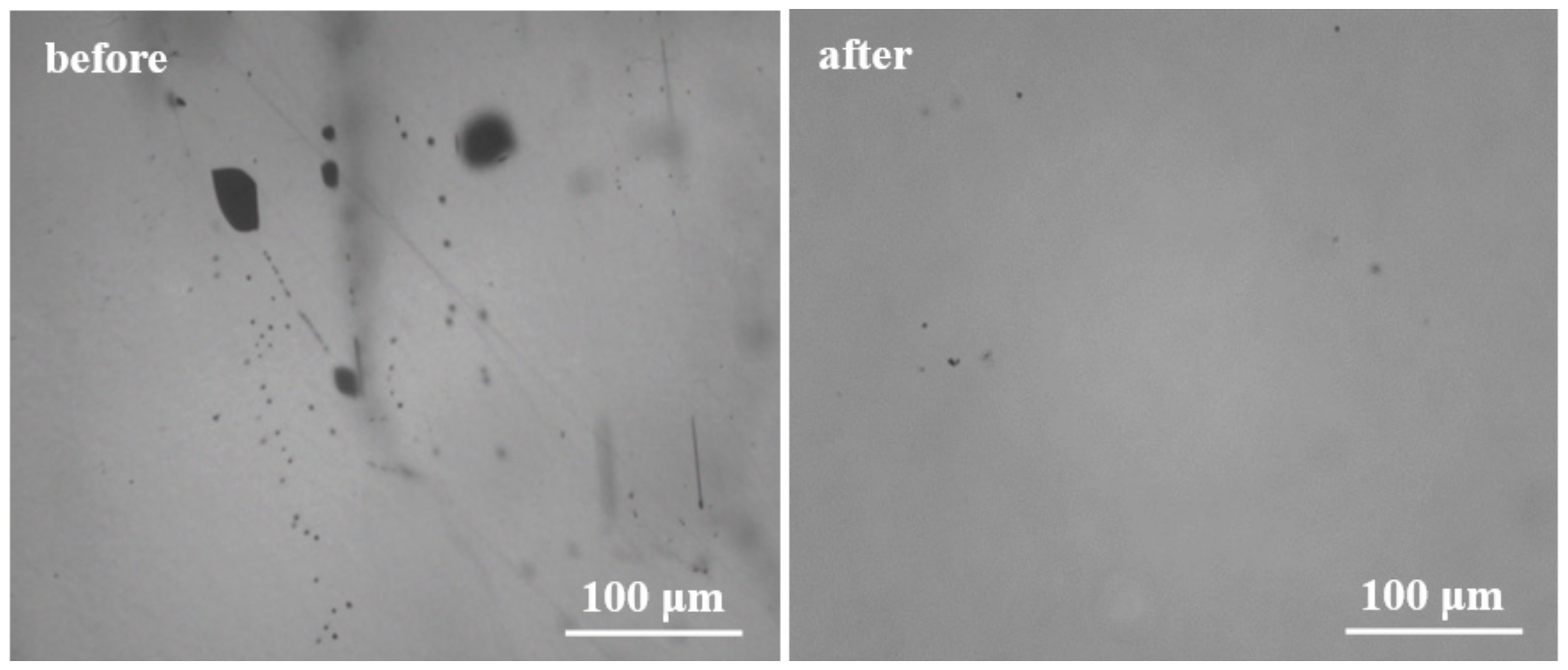

3.2. Te Inclusions in CdMgTe Crystals

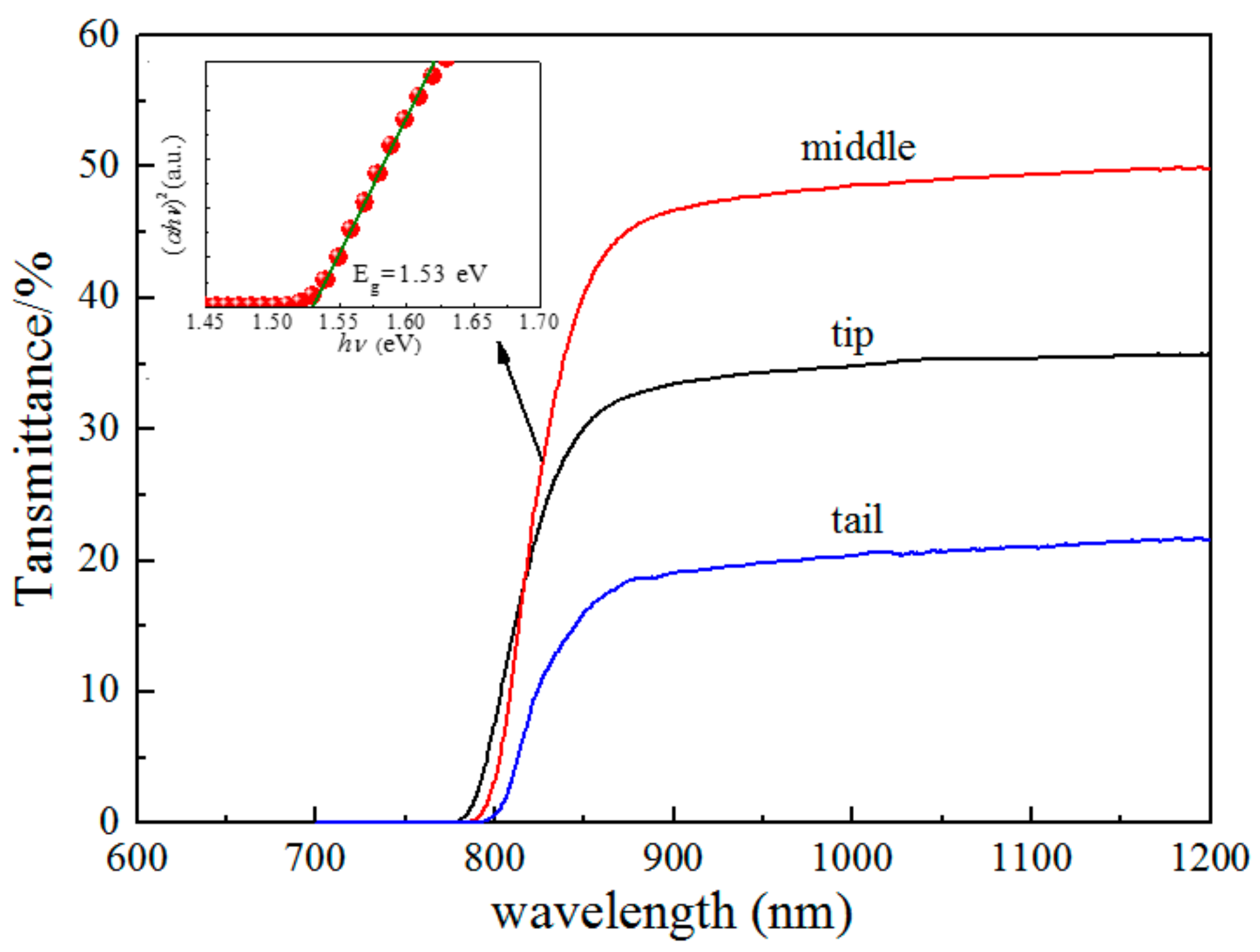

3.3. Energy Bang Gap

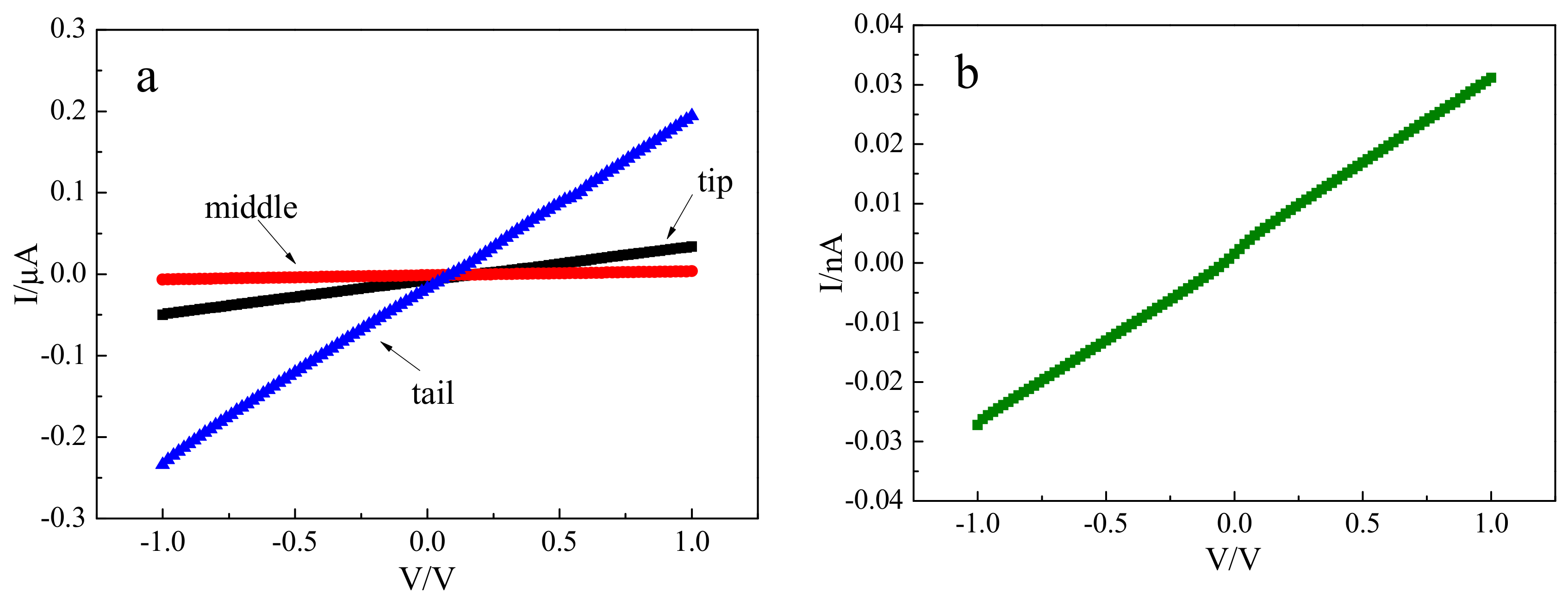

3.4. Electrical Property

3.5. Optical Property

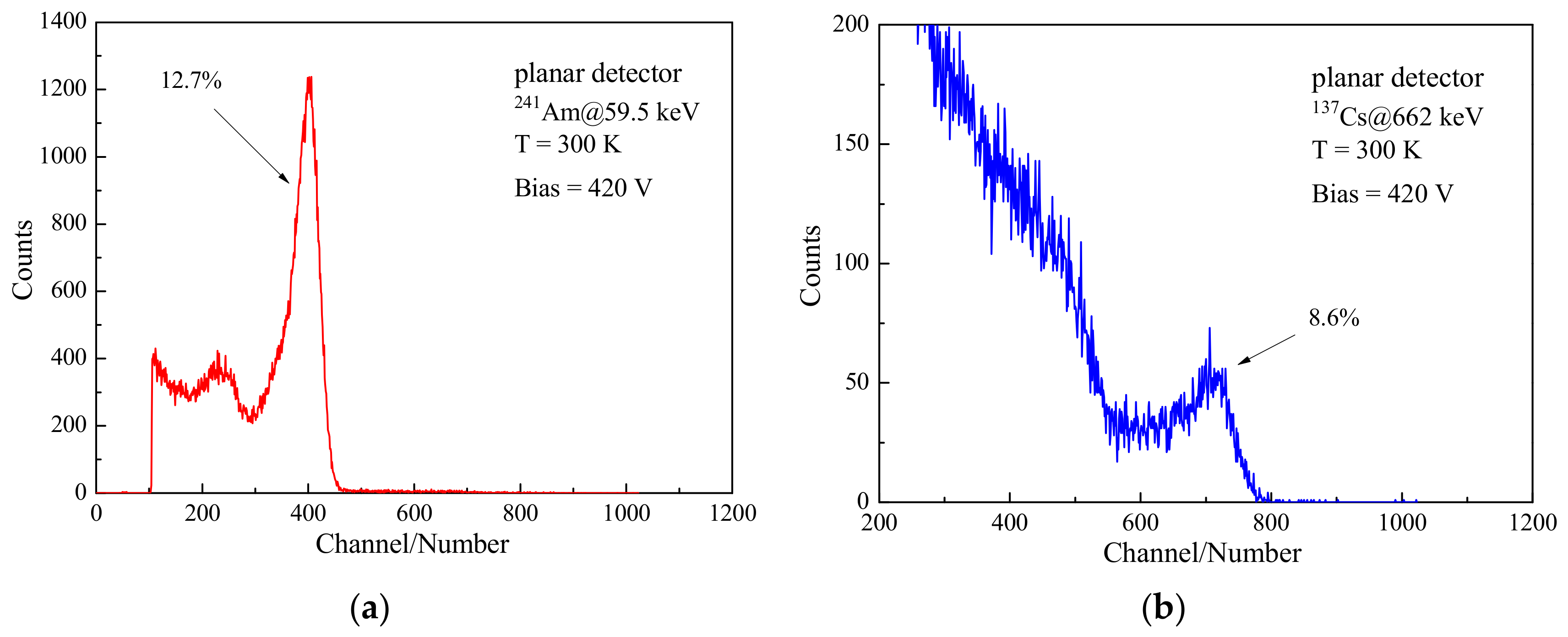

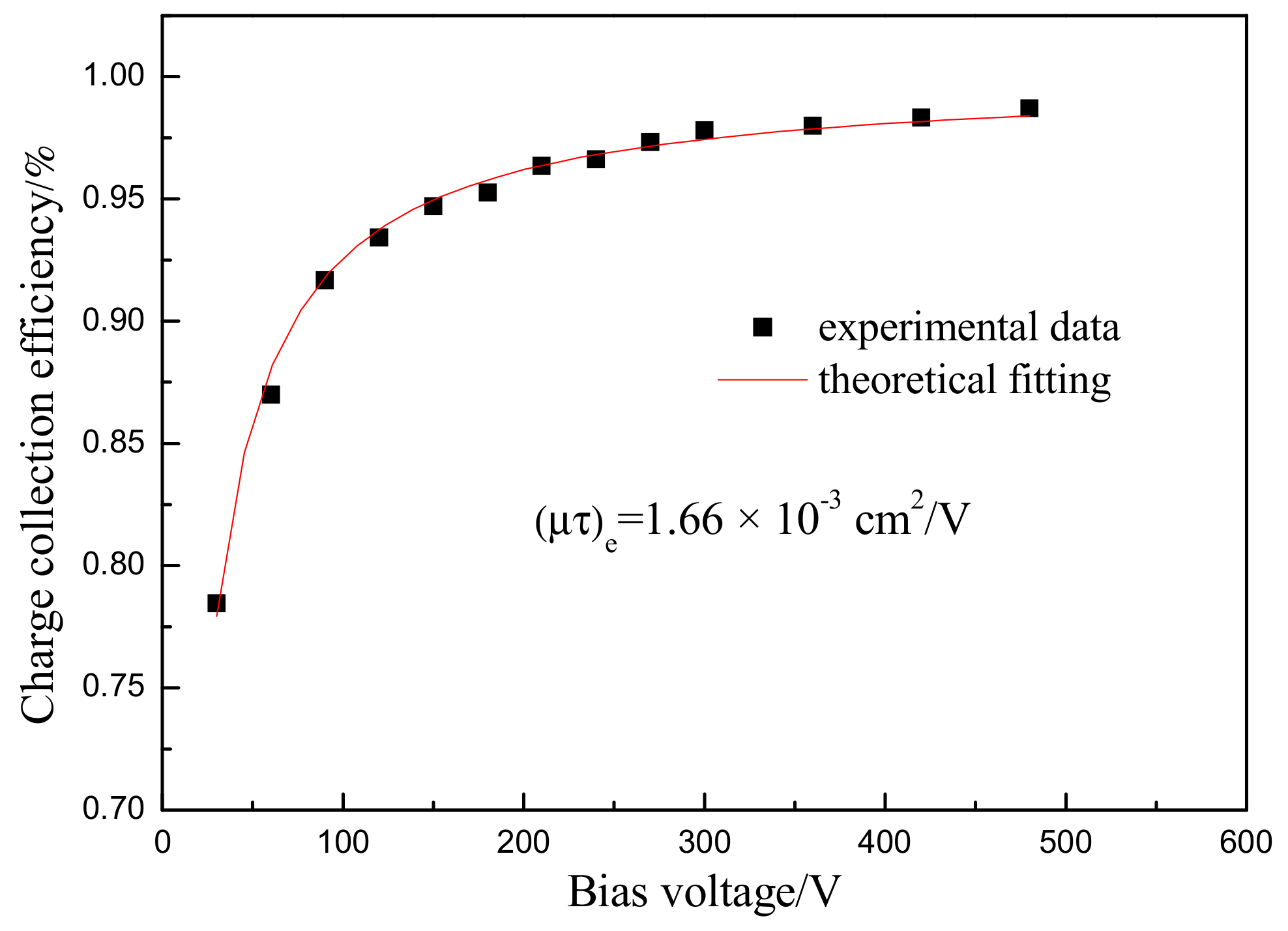

3.6. Detector Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schlesinger, T.E.; Toney, J.E.; Yoon, H.; Lee, E.Y.; Brunett, B.A.; Franks, L.; James, R.B. Cadmium zinc telluride and its use as a nuclear radiation detector material. Mater. Sci. Eng. R 2001, 32, 103–189. [Google Scholar] [CrossRef]

- Sellin, P.J. Recent advances in compound semiconductor radiation detectors. Nucl. Instrum. Meth. A 2003, 513, 332–339. [Google Scholar] [CrossRef]

- Owens, A.; Peacock, A. Compound semiconductor radiation detectors. Nucl. Instrum. Meth. A 2004, 531, 18–37. [Google Scholar] [CrossRef]

- Itoh, K. Preparation and some properties of solid solutions Cd1-xMgxTe. J. Phys. Soc. Jpn. 1967, 22, 1119. [Google Scholar] [CrossRef]

- Yamamoto, R.; Itoh, K. Preparation and electroluminescent properties of p-n junction in Cd1-xMgxTe. Jpn. J. Appl. Phys. 1969, 8, 341–347. [Google Scholar] [CrossRef]

- Hömmerich, U.; Bluiett, A.G.; Jones, I.K.; Trivedi, S.B.; Shah, R.T. Crystal growth and infrared spectroscopy of Cr: Cd1-xZnxTe and Cr: Cd1-xMgxTe. J. Cryst. Growth 2006, 287, 243–247. [Google Scholar] [CrossRef]

- Hossain, A.; Yakimovich, V.; Bolotnikov, A.E.; Bolton, K.; Camarda, G.S.; Cui, Y.; Franc, J.; Gul, R.; Kim, K.H.; Pittman, H.; et al. Development of Cadmium Magnesium Telluride (Cd1-xMgxTe) for room temperature X- and gamma-ray detectors. J. Cryst. Growth 2013, 379, 34–40. [Google Scholar] [CrossRef]

- Woodbury, H.H.; Lewandowski, R.S. Improved sealed-ingot zone refining technique for growth of CdTe crystals. J. Cryst. Growth 1971, 10, 6–12. [Google Scholar] [CrossRef]

- Yang, J.; Chen, S.; Yin, W.J.; Gong, X.; Walsh, G.A.; Wei, S.H. Electronic structure and phase stability of MgTe, ZnTe, CdTe, and their alloys in the B3, B4, and B8 structures. Phys. Rev. B 2009, 79, 1–7. [Google Scholar] [CrossRef]

- Mycielski, A.; Kochanowska, D.M.; Witkowska-Baran, M.; Wardak, A.; Szot, M.; Domagała, J.; Witkowski, B.S.; Jakieła, R.; Kowalczyk, L.; Witkowska, B. Investigation of Cd1-xMgxTe as possible materials for X and gamma ray detectors. J. Cryst. Growth 2018, 491, 73–76. [Google Scholar] [CrossRef]

- Chu, M.; Terterian, S.; Ting, D.; Wang, C.C.; Gurgenian, H.K.; Mesropian, S. Tellurium antisites in CdZnTe. Appl. Phys. Lett. 2001, 79, 2728–2730. [Google Scholar]

- Chu, M.; Terterian, S.; Ting, D.; Wang, C.C.; Benson, J.D.; Dinan, J.H.; James, R.B.; Burger, A. Effects of excess tellurium on the properties of CdZnTe radiation detectors. J. Electron. Mater. 2003, 32, 779–782. [Google Scholar] [CrossRef]

- Li, G.; Zhang, X.; Hua, H.; Jie, W. A modified vertical Bridgman method for growth high-quality Cd1-xZnxTe crystals. J. Electron. Mater. 2005, 34, 1215–1224. [Google Scholar] [CrossRef]

- Palomera, R.C.; Martínez, O.S.; Pantoja-Enriquez, J.; Mathews, N.R.; Reyes-Banda, M.G.; Krishnan, B.; Mathew, X. Development and studies of Cd1–xMgxTe thin films with varying band gaps to understand the Mg incorporation and the related material properties. Appl. Eng. 2017, 114, 1169–1175. [Google Scholar] [CrossRef]

- Yu, P.; Jie, W. Observation, morphology evolution and elimination of Te inclusions in CdZnTe:In single crystals. J. Cryst. Growth 2013, 381, 57–60. [Google Scholar] [CrossRef]

- Liang, X.; Min, J.; Yang, L.; Zhang, J.; Wang, L.; Zhao, Y.; Shi, W. Study on Te inclusions distributions of different solid–liquid interface shapes within CdZnTe crystals. Mat. Sci. Semicon. Proc. 2015, 40, 939–942. [Google Scholar] [CrossRef]

- Du, Y.; Jie, W.; Wang, T.; Zheng, X.; Xu, Y.; Luan, L. Solution growth of In-doped CdMnTe crystals by the vertical Bridgman method with the ACRT technique. J. Cryst. Growth 2012, 355, 33–37. [Google Scholar] [CrossRef]

- Schwarz, R.; Benz, K.W. Thermal field influence on the formation of Te inclusions in CdTe grown by the travelling heater method. J. Cryst. Growth 1994, 144, 150–156. [Google Scholar] [CrossRef]

- Yu, P.; Jie, W. Effects of post-growth annealing on the performance of CdZnTe: In radiation detectors with different thickness. Nucl. Instrum. Meth. A 2014, 737, 29–32. [Google Scholar] [CrossRef]

- Du, Y.; Jie, W.; Wang, T.; Xu, Y.; Yin, L.; Yu, P.; Zha, G. Vertical Bridgman growth and characterization of CdMnTe crystals for gamma-ray radiation detector. J. Cryst. Growth 2011, 318, 1062–1066. [Google Scholar] [CrossRef]

- Vydyanath, H.R.; Ellsworth, J.A.; Parkinson, J.B.; Kennedy, J.J.; Dean, B.; Johnson, C.J.; Neugebauer, G.T.; Sepich, J.; Liao, P. Thermomigration of Te precipitates and improvement of (Cd,Zn) Te substrate characteristics for the fabrication of LWIR (Hg,Cd) Te photodiodes. J. Electron. Mater. 1993, 22, 1073–1080. [Google Scholar] [CrossRef]

- Waag, A.; Heinke, H.; Scholl, S.; Becker, C.R.; Landwehr, G. Growth of MgTe and Cd1–xMgxTe thin films by molecular beam epitaxy. J. Cryst. Growth 1993, 131, 607–611. [Google Scholar] [CrossRef] [Green Version]

- Mathew, X.; Drayton, J.; Parikh, V.; Mathews, N.R.; Liu, X.; Compaan, A.D. Development of a semitransparent CdMgTe/CdS top cell for applications in tandem solar cells. Semicond. Sci. Technol. 2009, 24, 1–9. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Min, J.; Qin, K.; Huang, J.; Tang, K.; Liang, X.; Shen, P. Annealing of indium-doped CdMnTe single crystals under Cd vapors. J. Cryst. Growth 2012, 358, 12–15. [Google Scholar] [CrossRef]

- Kunjomana, A.G.; Teena, M.; Chandrasekharan, K.A. Synthesis, growth mechanism and physical properties of vapour-deposited GaTe platelets. J. Appl. Cryst. 2014, 47, 1841–1848. [Google Scholar] [CrossRef]

- Yu, P.; Jie, W.; Wang, T. Optical property analysis of CZT: In single crystals after annealing by a two-step method. J. Cryst. Growth 2010, 312, 2876–2880. [Google Scholar] [CrossRef]

- Fiederle, M.; Eiche, C.; Salk, M.; Schwarz, R.; Benz, K.W. Modified compensation model of CdTe. J. Appl. Phys. 1998, 84, 6689–6692. [Google Scholar] [CrossRef]

- Li, G.; Zhang, X.; Jie, W. Correlation between the low-temperature PL spectra and Cd0.9Zn0.1Te quality. Semicond. Sci. Technol. 2005, 20, 86–89. [Google Scholar] [CrossRef]

- Yu, P.; Jie, W. Optical property analysis of high-resistivity CZT: In single crystals before and after annealing. Opt. Mater. 2014, 36, 1213–1218. [Google Scholar] [CrossRef]

- Yang, G.; Jie, W.; Li, Q.; Wang, T.; Li, G.; Hua, H. Effects of In doping on the properties of CdZnTe single crystals. J. Cryst. Growth 2005, 283, 431–437. [Google Scholar] [CrossRef]

- Jones, K.A.; Jones, K.A.; Ciampi, G.; Skrip, C.E.; Lynn, K.G. Hard X-ray and gamma-ray detector physics IX-vertical Bridgman growth of Cd1-xZnxTe for room temperature radiation detectors. Proc. SPIE 2007, 6706, 670607–670614. [Google Scholar]

- Liang, X.; Min, J.; Yang, S.; Zhang, J.; Wang, L.; Zhao, Y.; Shi, W. Cooling process optimization to control Te inclusions for improving CdZnTe detector performance. Mat. Sci. Semicon. Proc. 2015, 30, 14–17. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, P.; Jiang, B.; Chen, Y.; Zheng, J.; Luan, L. Study on In-Doped CdMgTe Crystals Grown by a Modified Vertical Bridgman Method Using the ACRT Technique. Materials 2019, 12, 4236. https://doi.org/10.3390/ma12244236

Yu P, Jiang B, Chen Y, Zheng J, Luan L. Study on In-Doped CdMgTe Crystals Grown by a Modified Vertical Bridgman Method Using the ACRT Technique. Materials. 2019; 12(24):4236. https://doi.org/10.3390/ma12244236

Chicago/Turabian StyleYu, Pengfei, Biru Jiang, Yongren Chen, Jiahong Zheng, and Lijun Luan. 2019. "Study on In-Doped CdMgTe Crystals Grown by a Modified Vertical Bridgman Method Using the ACRT Technique" Materials 12, no. 24: 4236. https://doi.org/10.3390/ma12244236

APA StyleYu, P., Jiang, B., Chen, Y., Zheng, J., & Luan, L. (2019). Study on In-Doped CdMgTe Crystals Grown by a Modified Vertical Bridgman Method Using the ACRT Technique. Materials, 12(24), 4236. https://doi.org/10.3390/ma12244236