Effects of Ce-Rich Mischmetal on Microstructure Evolution and Mechanical Properties of 5182 Aluminum Alloy

Abstract

1. Introduction

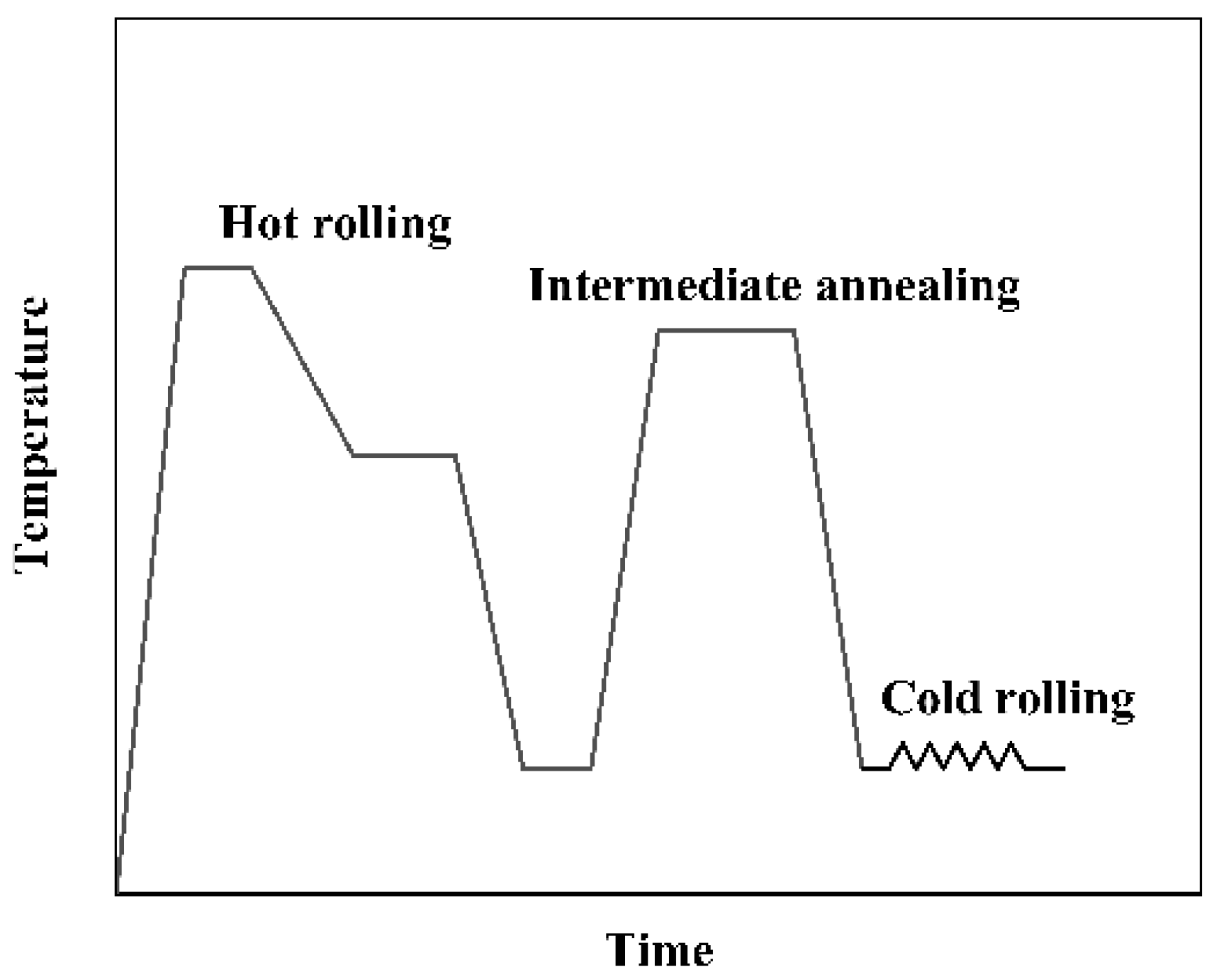

2. Materials and Methods

3. Results

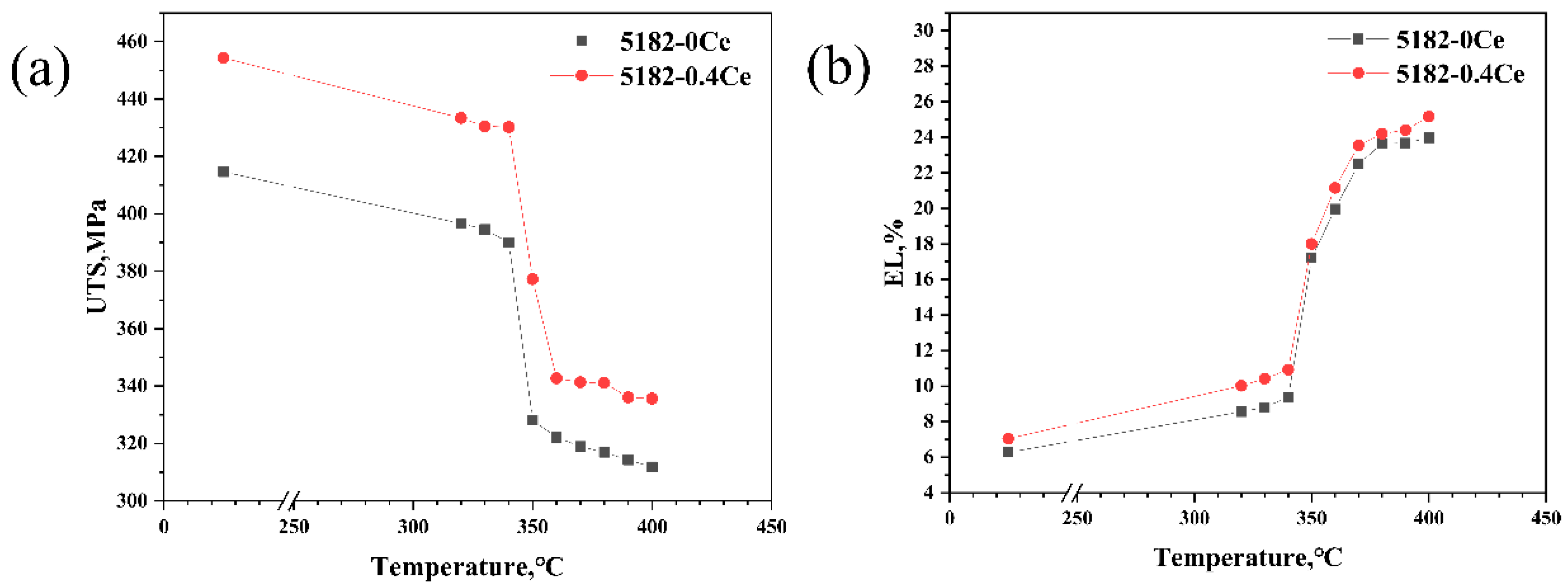

3.1. Mechanical Properties

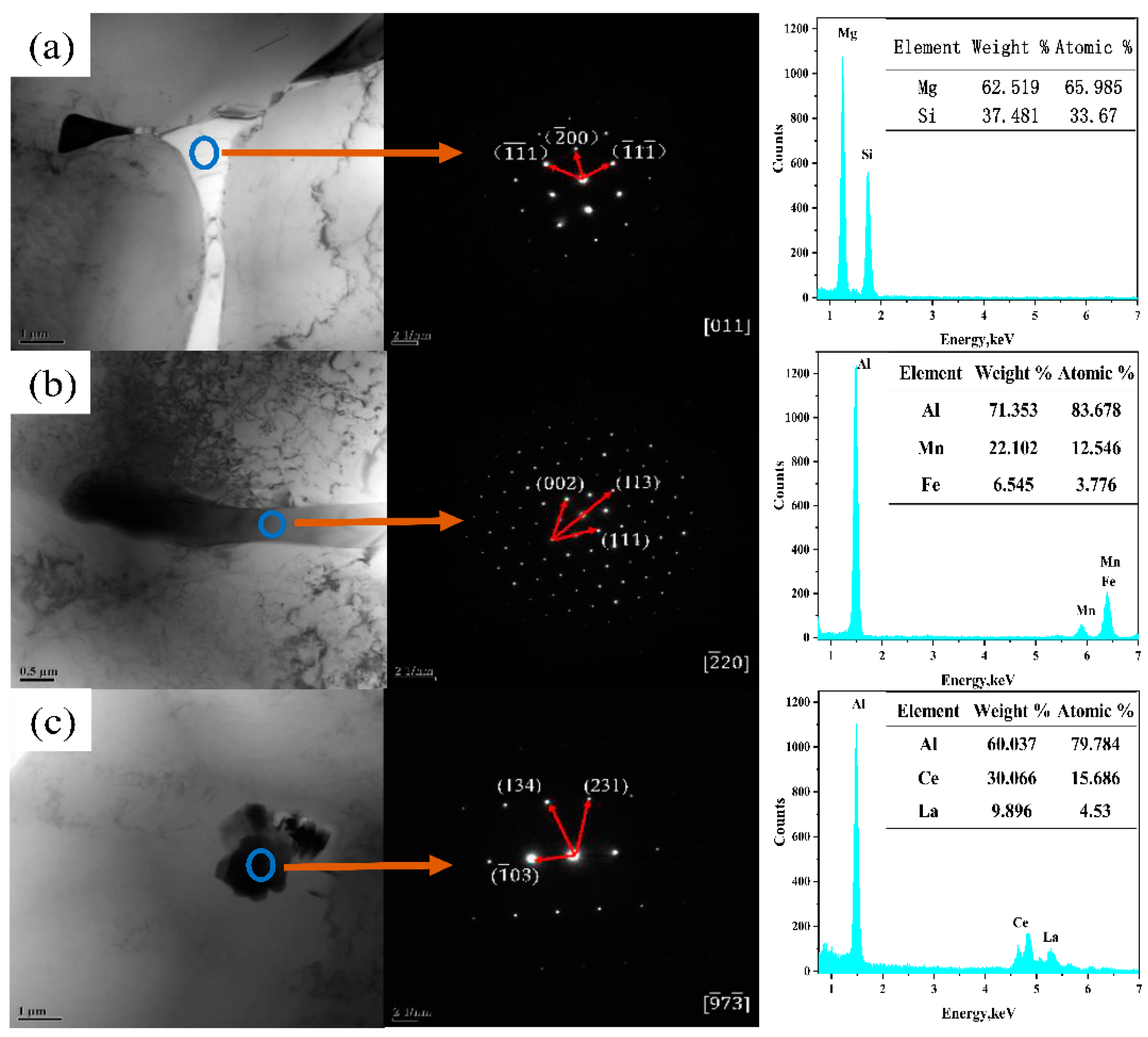

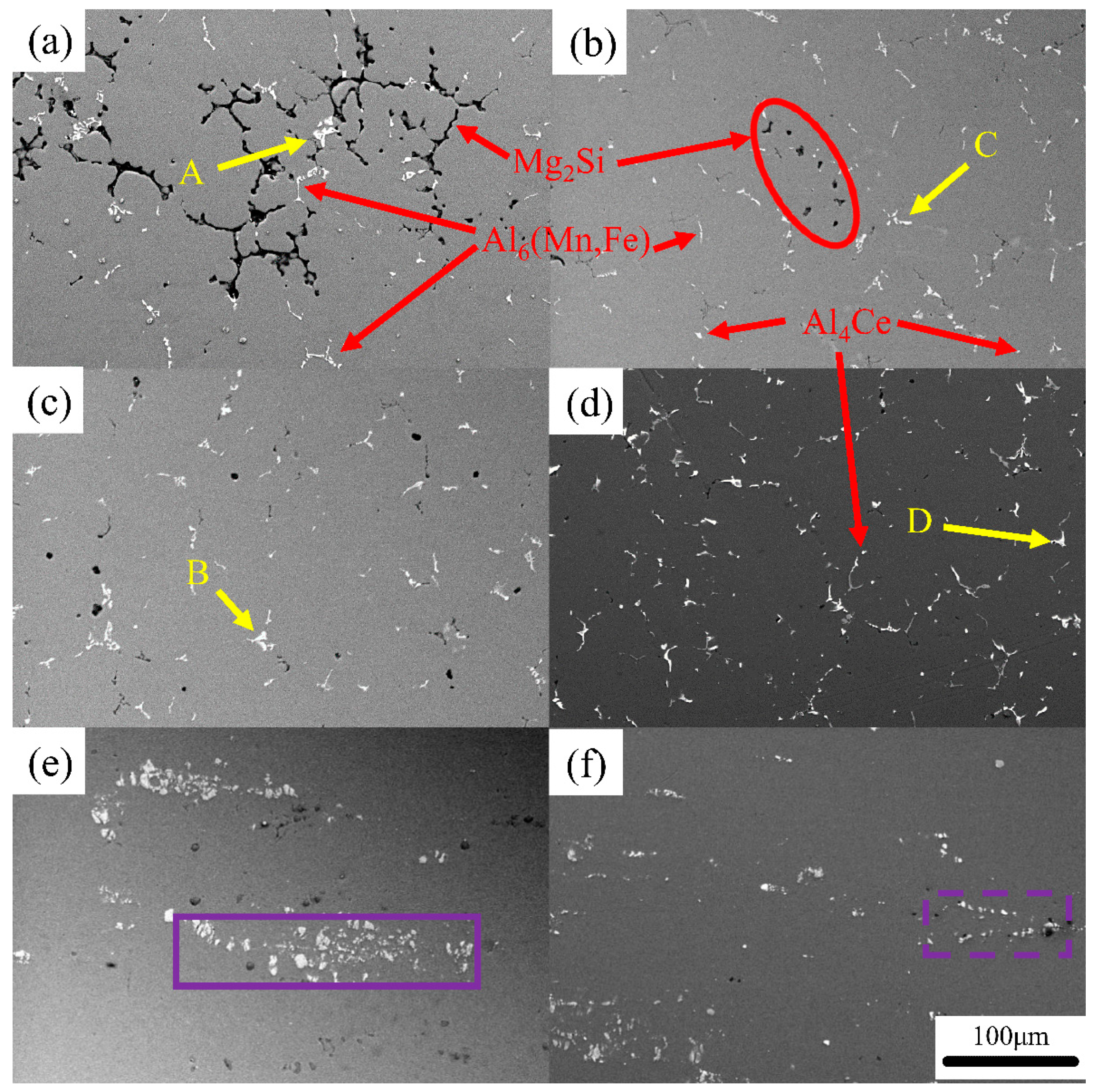

3.2. Microstructure Evolution

4. Discussions

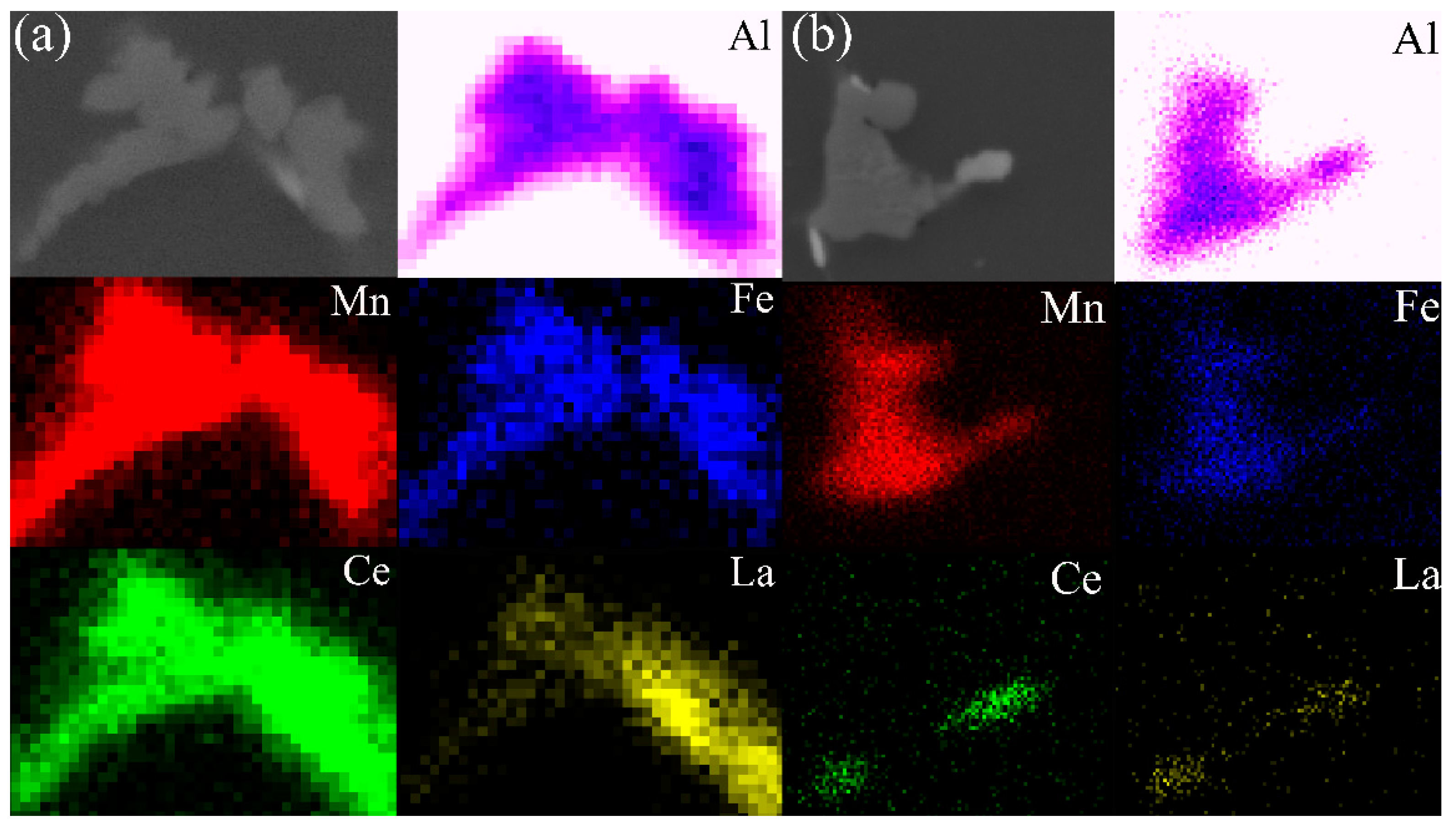

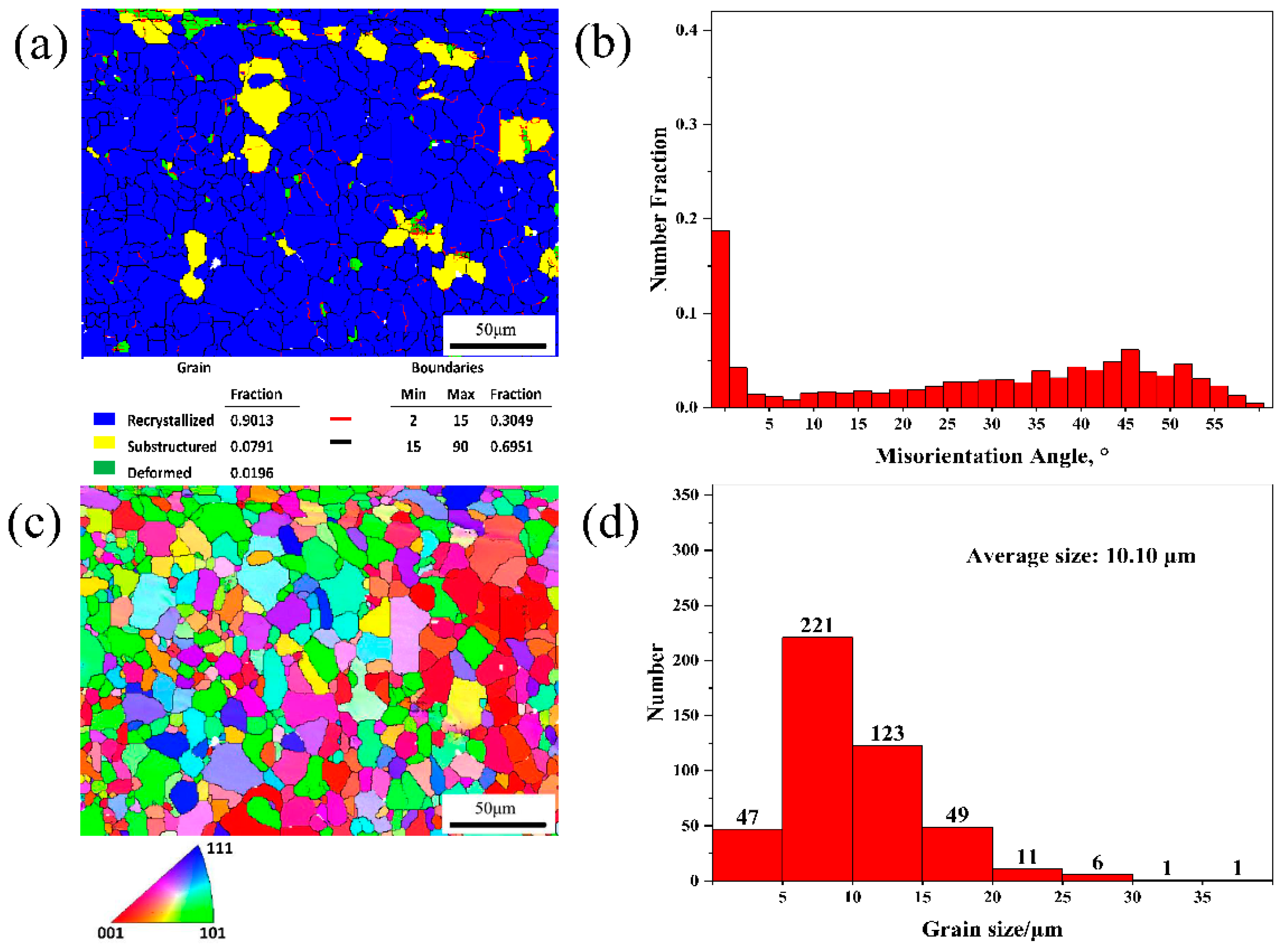

4.1. Effect of Ce-Rich Mischmetal on Microstructure Evolution

4.2. Effect of Ce-Rich Mischmetal on Mechanical Properties

5. Conclusions

- The addition of Ce-rich mischmetal refined the as-cast α-Al grains, making the grain aspect ratio larger after cold rolling. Moreover, the recrystallized grains were refined from 10.01 to 7.18 μm.

- Ce-rich mischmetal addition prevented Cr and Si atoms of the solid-solve from diffusing into the Al6(Mn, Fe) phase, which made it refine after cold rolling. In the 5182-0.4Ce Al alloy, the network structure of the Mg2Si phase in the as-cast state was broken.

- Ce-rich mischmetal addition enhanced the mechanical properties of the 5182 Al alloy. The UTS of the cold-rolled 5182 Al alloy increased by 9.6% through cell-size strengthening, dislocation density strengthening, and particle strengthening. The UTS of the recrystallization annealed 5182 Al alloy increased by 6.5% through grain size strengthening. After recrystallization annealing, the UTS of the 5182-0.4Ce Al alloy was more stable than that of the 5182-0Ce alloy.

Author Contributions

Funding

Conflicts of Interest

References

- Groche, P.; Nitzsche, G.; Elsen, A. Adhesive wear in deep drawing of aluminum sheets. CIRP Ann. 2008, 57, 295–298. [Google Scholar] [CrossRef]

- Ding, W.; Peng, L.; Fu, P. Automobile Lightweight Technology: Development Trends of Aluminum/Magnesium Alloys and Their Forming Technologies. Chin. J. Eng. Sci. 2018, 20, 84. [Google Scholar]

- Du, J.; Ding, D.; Zhang, W.; Xu, Z.; Gao, Y.; Chen, G.; You, X.; Chen, R.; Huang, Y.; Tang, J. Effect of Ce addition on the microstructure and properties of Al-Cu-Mn-Mg-Fe lithium battery shell alloy. Mater. Charact. 2018, 142, 252–260. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, Y.; Zhang, Y.; Qin, T.; Zhou, X.R.; Thompson, G.E.; Pennycook, T.; Hashimoto, T. Grain refining mechanism in the Al/Al-Ti-B system. Acta Mater. 2015, 84, 292–304. [Google Scholar] [CrossRef]

- Barkov, R.Y.; Pozdniakov, A.V.; Tkachuk, E.; Zolotorevskiy, V.S. Effect of Y on microstructure and mechanical properties of Al–Mg–Mn–Zr–Sc alloy with low Sc content. Mater. Lett. 2018, 217, 135–138. [Google Scholar] [CrossRef]

- Fakhraei, O.; Emamy, M.; Farhangi, H. The effect of Al–5Ti–1B grain refiner on the structure and tensile properties of Al–20%Mg alloy. Mater. Sci. Eng. A 2013, 560, 148–153. [Google Scholar] [CrossRef]

- Jin, B.H.; Zhu, B.H.; Li, X.W. Effect of Addition Zr on As-Homogenization Microstructures of 5182 Aluminum Alloy. Mater. Sci. Forum 2013, 749, 47–53. [Google Scholar] [CrossRef]

- Croteau, J.R.; Griffiths, S.; Rossell, M.D.; Leinenbach, C.; Kenel, C.; Jansen, V.; Seidman, D.N.; Dunand, D.C.; Vo, N.Q. Microstructure and mechanical properties of Al-Mg-Zr alloys processed by selective laser melting. Acta Mater. 2018, 153, 35–44. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Z.; Dai, W.; Han, Q. On the Understanding of Aluminum Grain Refinement by Al-Ti-B Type Master Alloys. Metall. Mater. Trans. B 2014, 46, 1620–1625. [Google Scholar] [CrossRef]

- Kendig, K.L.; Miracle, D.B. Strengthening mechanisms of an Al-Mg-Sc-Zr alloy. Acta Mater. 2002, 50, 4165–4175. [Google Scholar] [CrossRef]

- Mogucheva, A.; Yuzbekova, D.; Kaibyshev, R.; Lebedkina, T.; Lebyodkin, M. Effect of Grain Refinement on Jerky Flow in an Al–Mg–Sc Alloy. Metall. Mater. Trans. A 2016, 47, 2093–2106. [Google Scholar] [CrossRef]

- He, L.Z.; Li, X.H.; Liu, X.T.; Wang, X.J.; Zhang, H.T.; Cui, J.Z. Effects of homogenization on microstructures and properties of a new type Al–Mg–Mn–Zr–Ti–Er alloy. Mater. Sci. Eng. A 2010, 527, 7510–7518. [Google Scholar] [CrossRef]

- Sofia, D.; Barletta, D.; Poletto, M. Laser sintering process of ceramic powders: The effect of particle size on the mechanical properties of sintered layers. Addit. Manuf. 2018, 23, 215–224. [Google Scholar] [CrossRef]

- Sofia, D.; Granese, M.; Barletta, D.; Poletto, M. Laser Sintering of Unimodal Distributed Glass Powders of Different Size. Procedia Eng. 2015, 102, 749–758. [Google Scholar] [CrossRef]

- Wang, X.; Guo, M.; Zhang, J.; Zhuang, L. Effect of Zn addition on the microstructure, texture evolution and mechanical properties of Al-Mg-Si-Cu alloys. Mater. Sci. Eng. A 2016, 677, 522–533. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Murashkin, M.Y.; Enikeev, N.A.; Bikmukhametov, I.; Valiev, R.Z.; Hodgson, P.D.; Lapovok, R. Effect of the eutectic Al-(Ce,La) phase morphology on microstructure, mechanical properties, electrical conductivity and heat resistance of Al-4.5(Ce,La) alloy after SPD and subsequent annealing. J. Alloy. Compd. 2019, 796, 321–330. [Google Scholar] [CrossRef]

- Gong, T.; Dong, J.; Shi, Z.; Yaer, X.; Liu, H. Enhancement of mechanical properties of as-cast 5182 aluminum alloy by Ce-rich modification engineering. Mater. Res. Express 2019, 6, 086548. [Google Scholar] [CrossRef]

- Shen, L.; Guo, Y.J.; Shi, Z.M. Microstructure and Mechanical Properties of As-cast 5182 Aluminum alloy Modified with Al-RE and Al-5Ti-1B Master Alloys. In Proceedings of the International Symposium on Materials Application and Engineering, Chiang Mai, Thailand, 20–21 August 2016; Jawaid, M., Kenawy, E.R., Eds.; EDP Sciences: Les Ulis, France, 2016; Volume 67. [Google Scholar]

- Zhu, Y.; Cullen, D.A.; Kar, S.; Free, M.L.; Allard, L.F. Evaluation of Al3Mg2 Precipitates and Mn-Rich Phase in Aluminum-Magnesium Alloy Based on Scanning Transmission Electron Microscopy Imaging. Metall. Mater. Trans. A 2012, 43, 4933–4939. [Google Scholar] [CrossRef]

- Shi, Z.M.; Gao, K.; Shi, Y.T.; Wang, Y. Microstructure and mechanical properties of rare-earth-modified Al−1Fe binary alloys. Mater. Sci. Eng. A 2015, 632, 62–71. [Google Scholar] [CrossRef]

- Elgallad, E.M.; Doty, H.W.; Alkahtani, S.A.; Samuel, F.H. Effects of La and Ce Addition on the Modification of Al-Si Based Alloys. Adv. Mater. Sci. Eng. 2016, 2016, 1–13. [Google Scholar] [CrossRef]

- Goswami, R.; Spanos, G.; Pao, P.S.; Holtz, R.L. Precipitation behavior of the ß phase in Al-5083. Mater. Sci. Eng. A 2010, 527, 1089–1095. [Google Scholar] [CrossRef]

- Starke, E.A.; Sanders, T.H. Aluminum-Lithium Alloys II; Metallurgical Society of Aime: Warrendale, PA, USA, 1984; pp. 236–239. [Google Scholar]

- Tamimi, S.; Correia, J.P.; Lopes, A.B.; Ahzi, S.; Barlat, F.; Gracio, J.J. Asymmetric rolling of thin AA-5182 sheets: Modelling and experiments. Mater. Sci. Eng. A 2014, 603, 150–159. [Google Scholar] [CrossRef]

- Liu, W.C.; Zhai, T.; Morris, J.G. Comparison of recrystallization and recrystallization textures in cold-rolled DC and CC AA 5182 aluminum alloys. Mater. Sci. Eng. A 2003, 358, 84–93. [Google Scholar] [CrossRef]

- Jang, D.H.; Park, Y.B.; Kim, W.J. Significant strengthening in superlight Al-Mg alloy with an exceptionally large amount of Mg (13 wt.%) after cold rolling. Mater. Sci. Eng. A 2019, 744, 36–44. [Google Scholar] [CrossRef]

- Li, C.L.; Mei, Q.S.; Li, J.Y.; Chen, F.; Ma, Y.; Mei, X.M. Hall-Petch relations and strengthening of Al-ZnO composites in view of grain size relative to interparticle spacing. Scr. Mater. 2018, 153, 27–30. [Google Scholar] [CrossRef]

- Xu, X.; Li, C.; Wang, S.; Tabie, V.M.; Liu, Z.; Zhang, T. Microstructural evolution and mechanical properties of Al–Zn–Mg–Cu alloy processed by integrated extrusion and equal channel angular pressing (iECAP) and heat treatment. Mater. Res. Express 2019, 6, 0865b8. [Google Scholar] [CrossRef]

- Zhang, J.X.; Ma, M.; Liu, W.C. Effect of initial grain size on the recrystallization and recrystallization texture of cold-rolled AA 5182 aluminum alloy. Mater. Sci. Eng. A 2017, 690, 233–243. [Google Scholar] [CrossRef]

| Element | Ce | La | Pr | Nd | Sm | Al |

|---|---|---|---|---|---|---|

| Content | 6.95 | 1.54 | 0.32 | 0.58 | 0.10 | Bal |

| Re | Mg | Mn | Fe | Si | Cr | Ti | Cu | Zn | Al | |

|---|---|---|---|---|---|---|---|---|---|---|

| 5182-0Ce | - | 4.90 | 0.35 | 0.34 | 0.17 | 0.05 | 0.11 | 0.06 | 0.13 | Bal |

| 5182-0.4Ce | 0.36 | 4.93 | 0.36 | 0.31 | 0.16 | 0.08 | 0.06 | 0.06 | 0.14 | Bal |

| Al | Mg | Mn | Fe | Si | Cr | Ce | La | Total | |

|---|---|---|---|---|---|---|---|---|---|

| A | 69.30 | 4.21 | 16.33 | 5.09 | 1.85 | 3.21 | - | - | 100 |

| B | 70.06 | 4.18 | 17.20 | 4.71 | 1.82 | 2.03 | - | - | 100 |

| C | 68.06 | 2.44 | 17.10 | 3.58 | - | - | 6.55 | 2.27 | 100 |

| D | 71.82 | 3.63 | 15.82 | 4.34 | - | - | 2.96 | 1.43 | 100 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, T.; Dong, J.; Shi, Z.; Yaer, X.; Liu, H. Effects of Ce-Rich Mischmetal on Microstructure Evolution and Mechanical Properties of 5182 Aluminum Alloy. Materials 2019, 12, 4230. https://doi.org/10.3390/ma12244230

Gong T, Dong J, Shi Z, Yaer X, Liu H. Effects of Ce-Rich Mischmetal on Microstructure Evolution and Mechanical Properties of 5182 Aluminum Alloy. Materials. 2019; 12(24):4230. https://doi.org/10.3390/ma12244230

Chicago/Turabian StyleGong, Tianhao, Junhui Dong, Zhiming Shi, Xinba Yaer, and Huimin Liu. 2019. "Effects of Ce-Rich Mischmetal on Microstructure Evolution and Mechanical Properties of 5182 Aluminum Alloy" Materials 12, no. 24: 4230. https://doi.org/10.3390/ma12244230

APA StyleGong, T., Dong, J., Shi, Z., Yaer, X., & Liu, H. (2019). Effects of Ce-Rich Mischmetal on Microstructure Evolution and Mechanical Properties of 5182 Aluminum Alloy. Materials, 12(24), 4230. https://doi.org/10.3390/ma12244230