4.1. Stress Relief Groove Parameters Optimization Following the STANDARD EN 13445-3

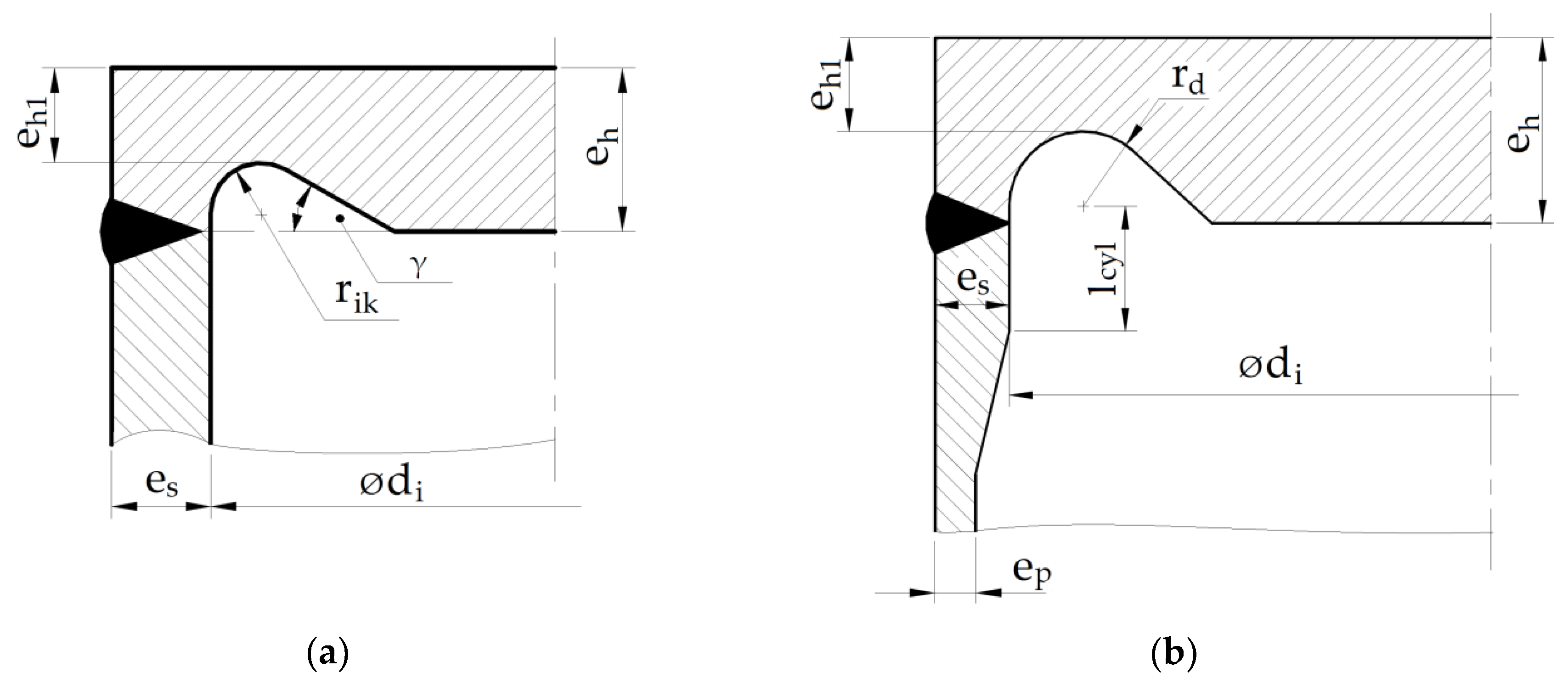

The detailed results presented below were obtained for a cylindrical shell following the shape presented in EN 13445-3 with an external diameter of ϕ406.4 and a basic wall thickness

ep = 20 mm. In the study, the thickness

es was gradually increased from 20.0 mm to 30.0 mm, with a reasonable step of 1 mm (see

Figure 1b). It appeared that for e

s = 31 mm, the admissible area for the minimum thickness at the groove bottom and the radius of the groove became empty, i.e., there were no admissible values fulfilling the set of inequalities (4).

Table 3 shows the sets of variables used in calculations depending on the increased thickness

es.

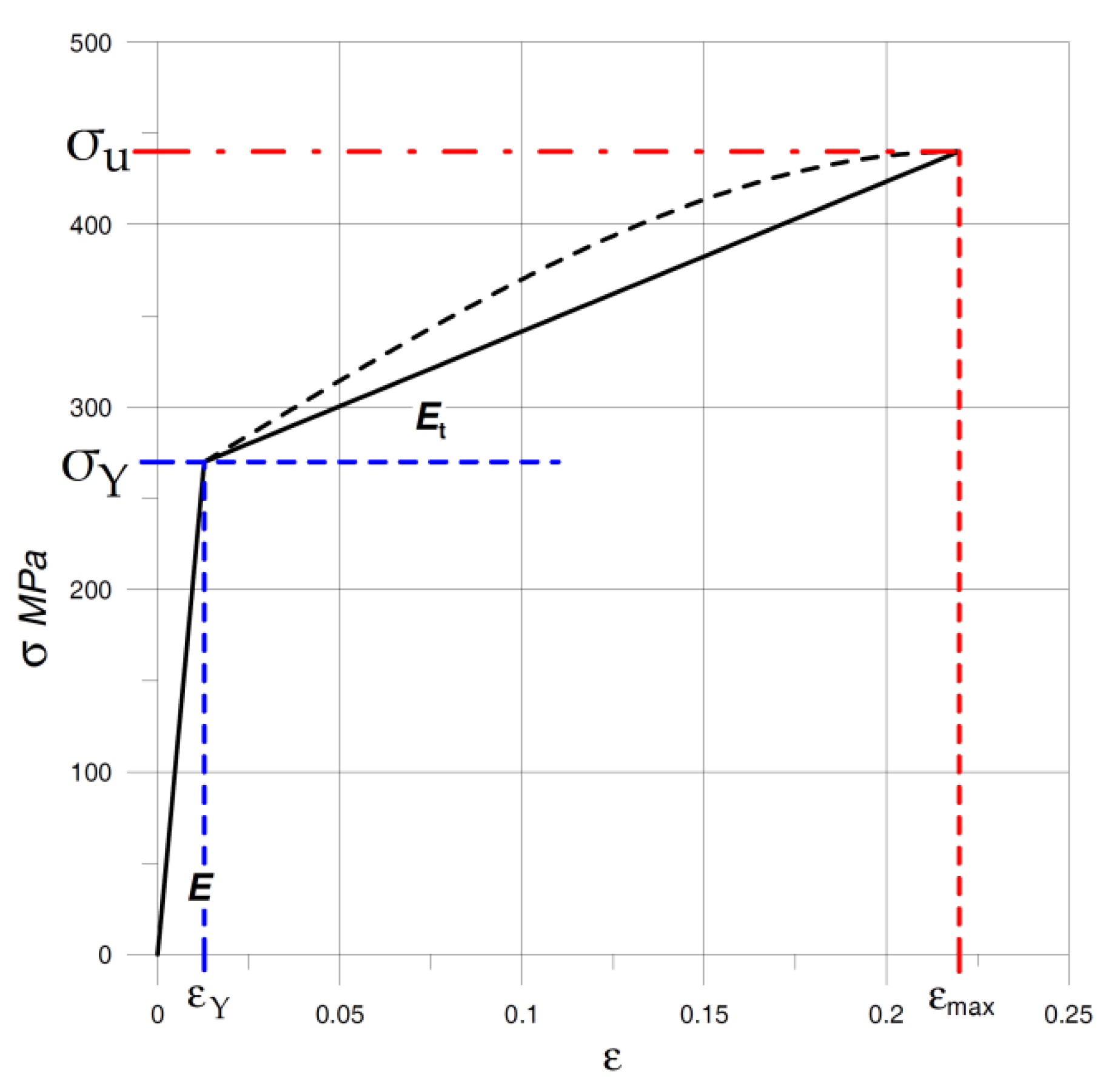

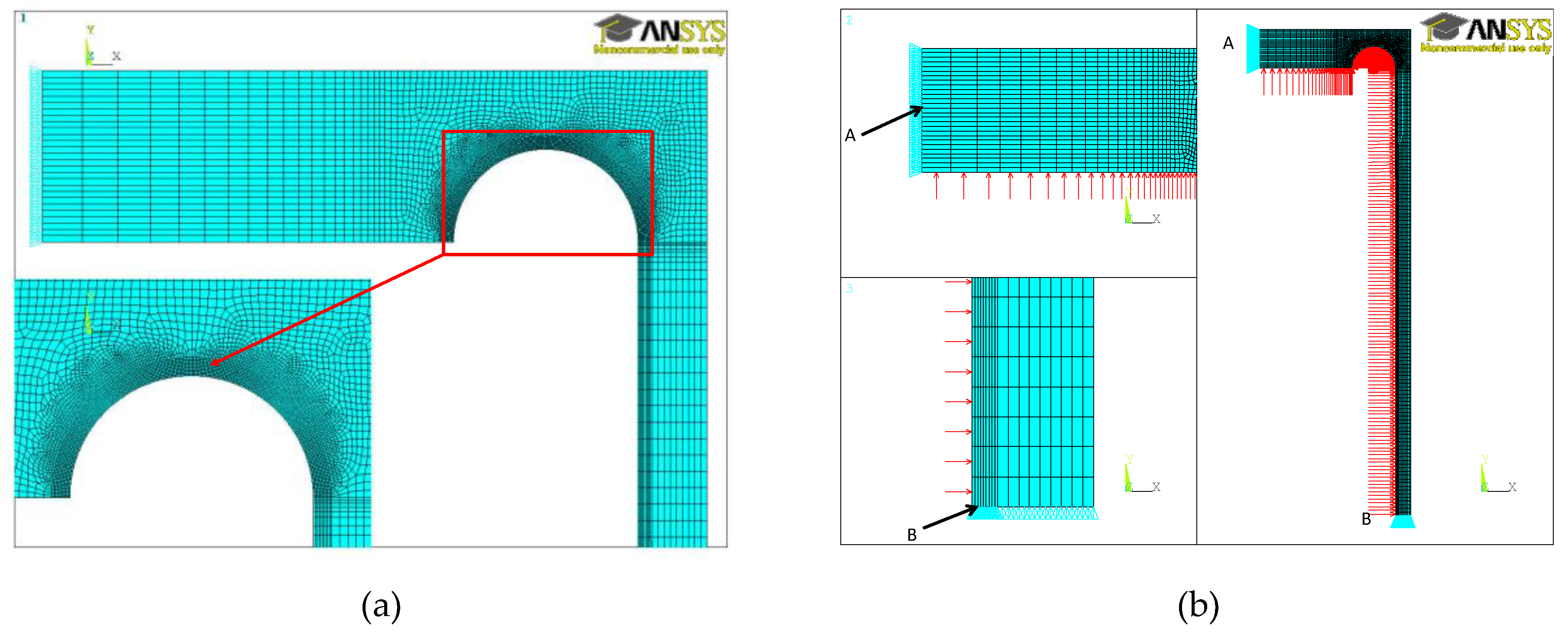

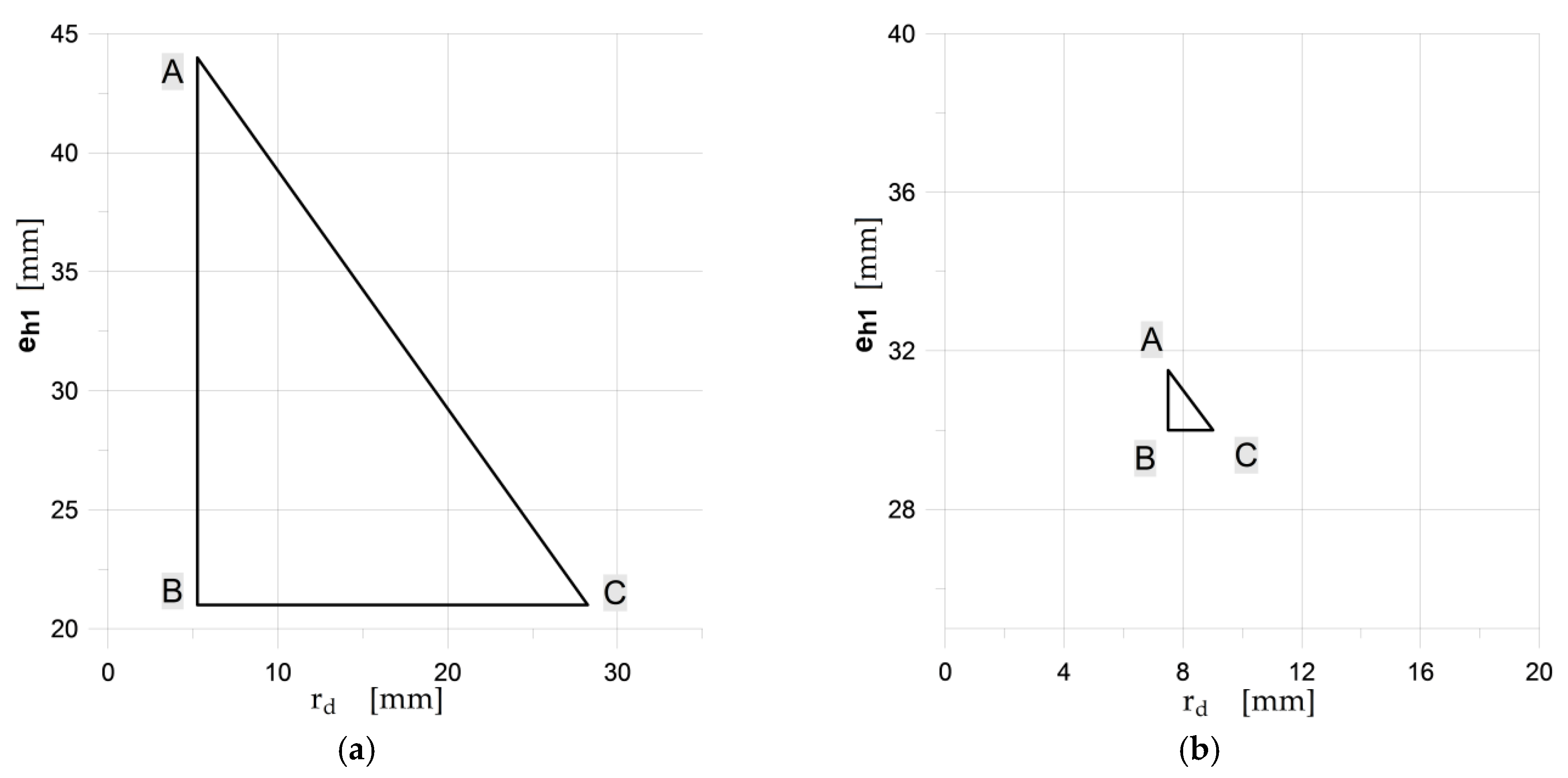

Figure 4 illustrates the admissible areas for the (

eh1,

rd) pairs obtained for the two thicknesses of the reinforced cylindrical shell part (thickness

es).

The optimization process and optimized parameters using the EN 12953:3 code were presented in papers [

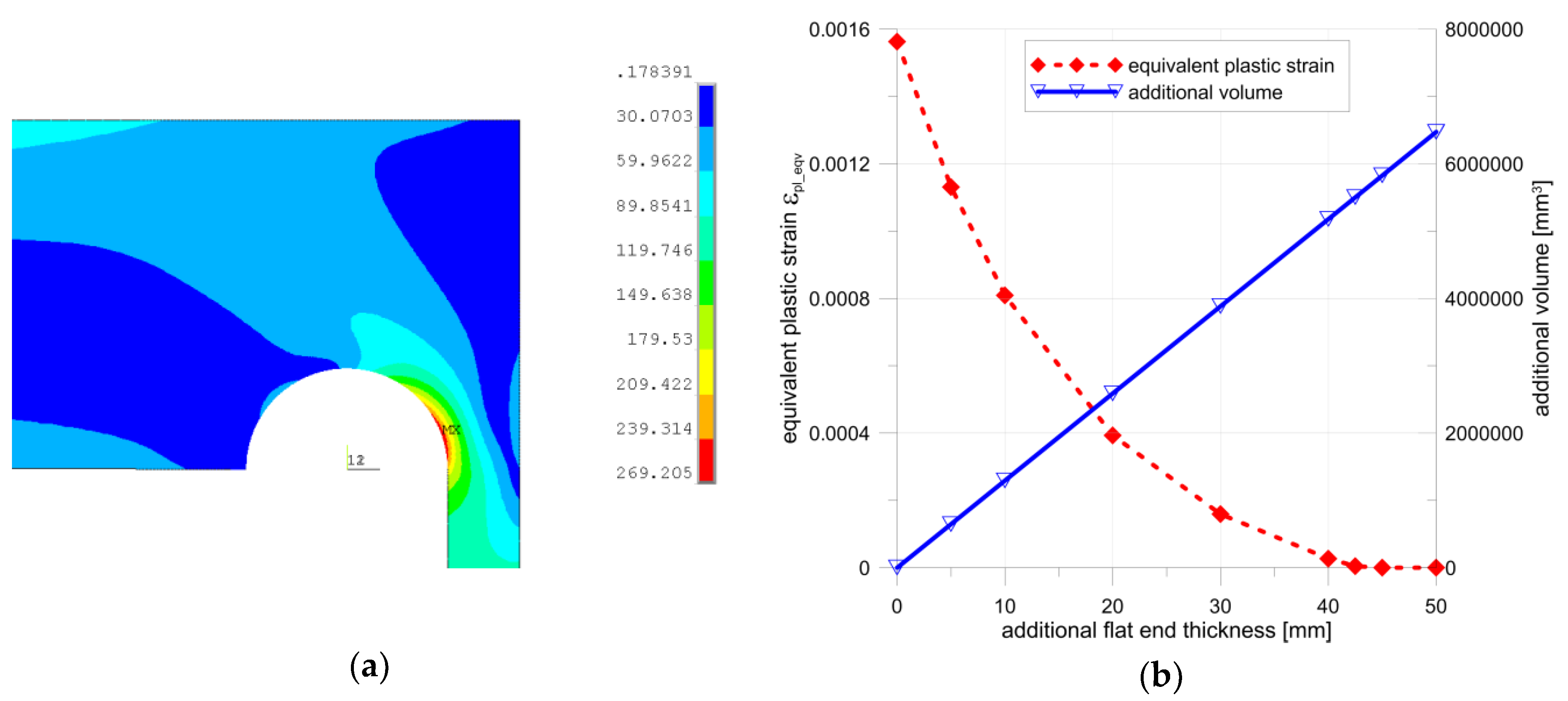

9,

13]. The performed numerical calculations for the elastic-plastic material exemplified the presence of the point, where the minimum of the equivalent plastic strains appeared. For all the analyzed cases, the optimal point appeared on the borderline of the admissible area, where e

h1 + r

d = e

h, the location of the optimal point was rather close to the maximum admissible value of the groove radius. When using the code EN 13445-3, if only e

s is greater than 20.0 mm, then the optimal solution appears in the corner point C of the admitted area, which corresponds to the maximum admissible value of the groove radius. The exemplary results for the optimal configurations of the groove radii

rd and the minimum thickness of the endplate

eh1, obtained for two different values of

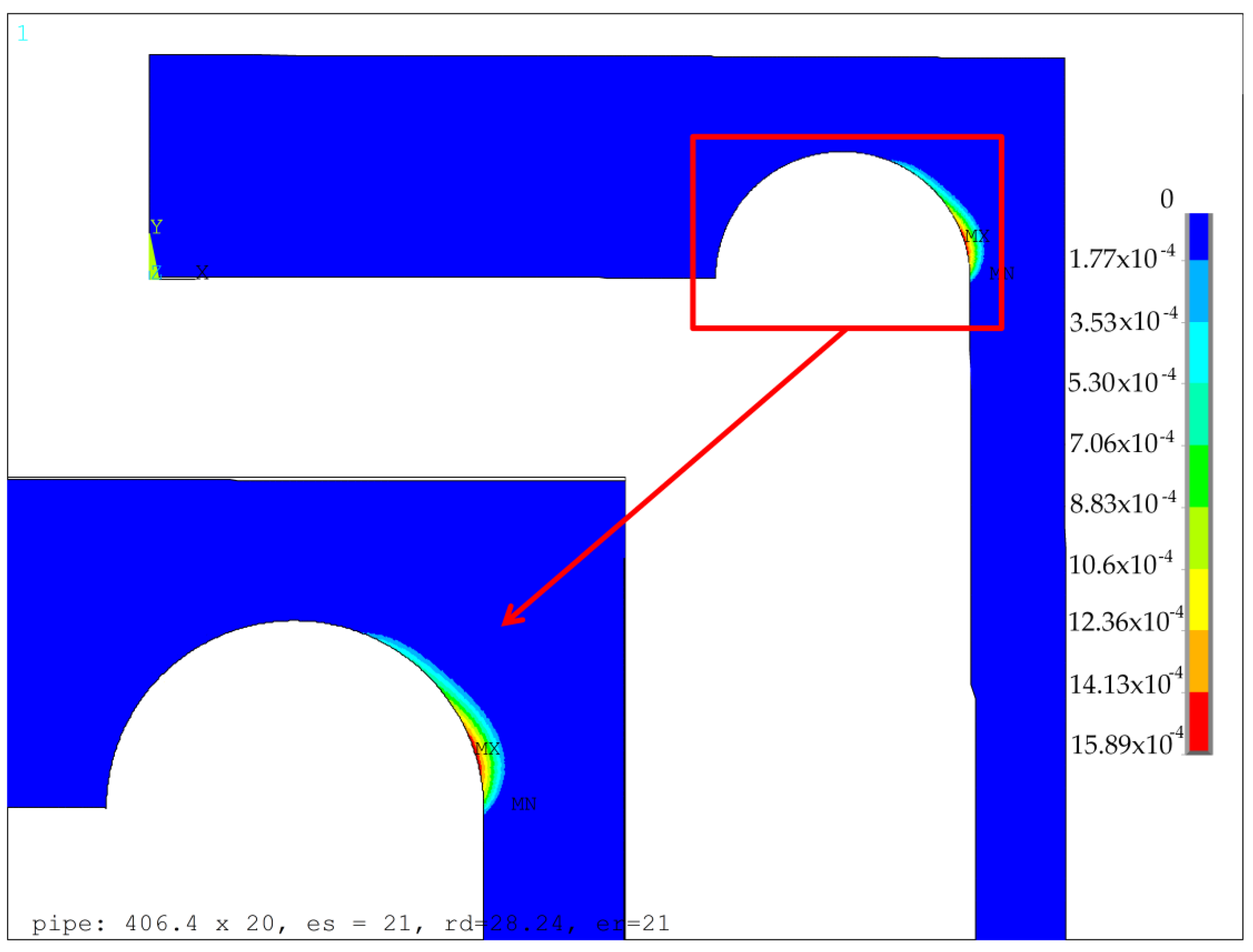

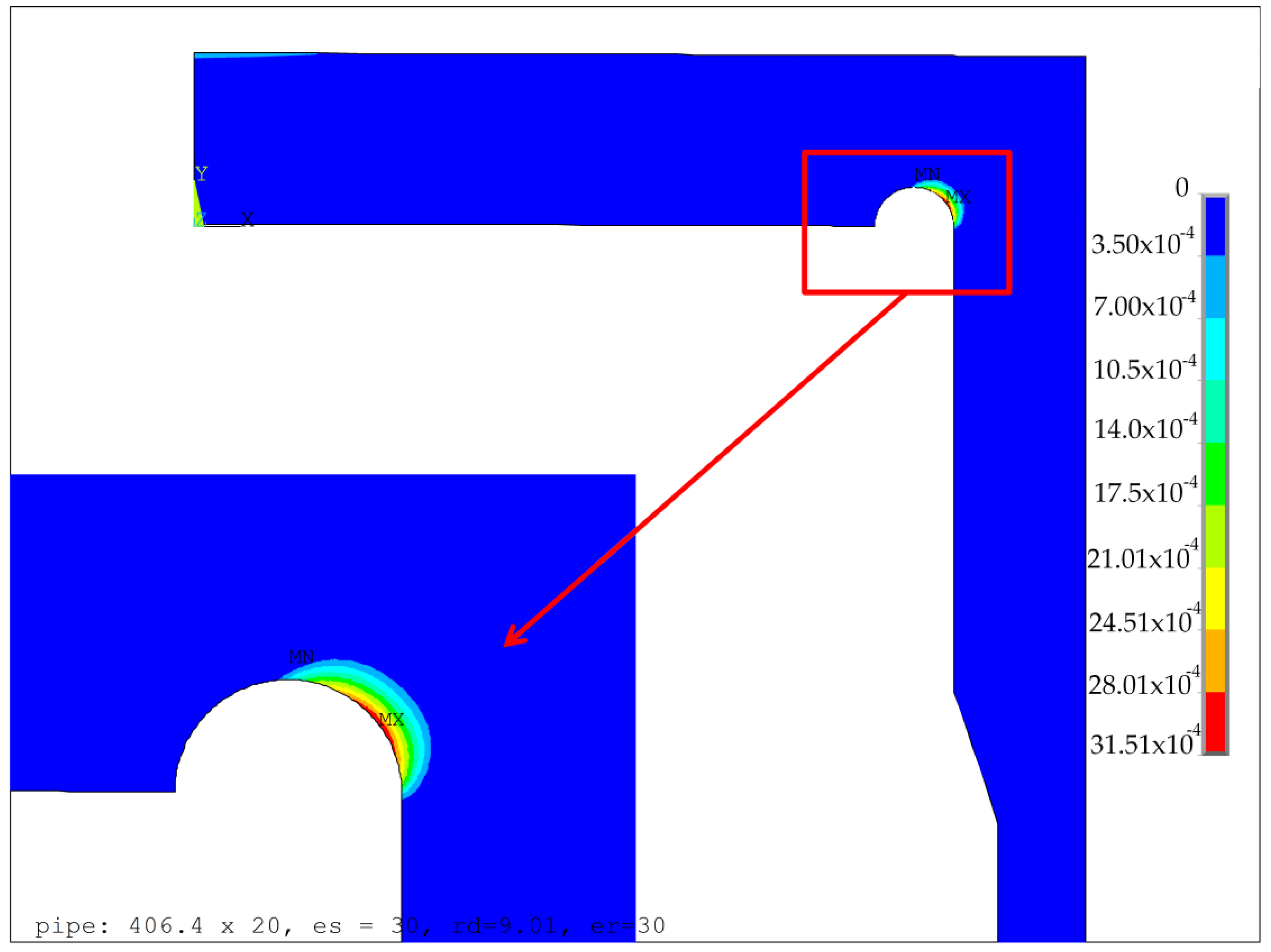

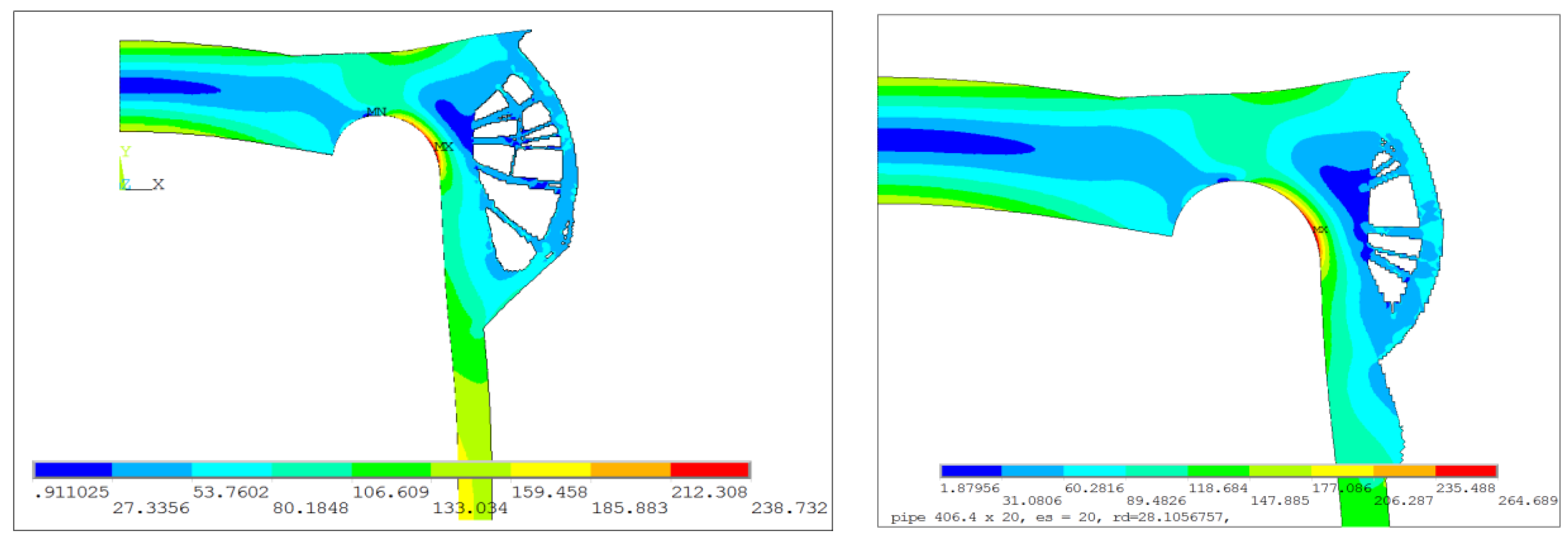

es, namely 21.0 mm and 30.0 mm, are presented in

Figure 5 and

Figure 6, respectively. These are the distributions of the equivalent von Mises plastic strains in the vicinity of the endplate-shell junction. The obtained results clearly showed that the maximum values of plastic strains were much more sensitive to the geometry changes (namely change of

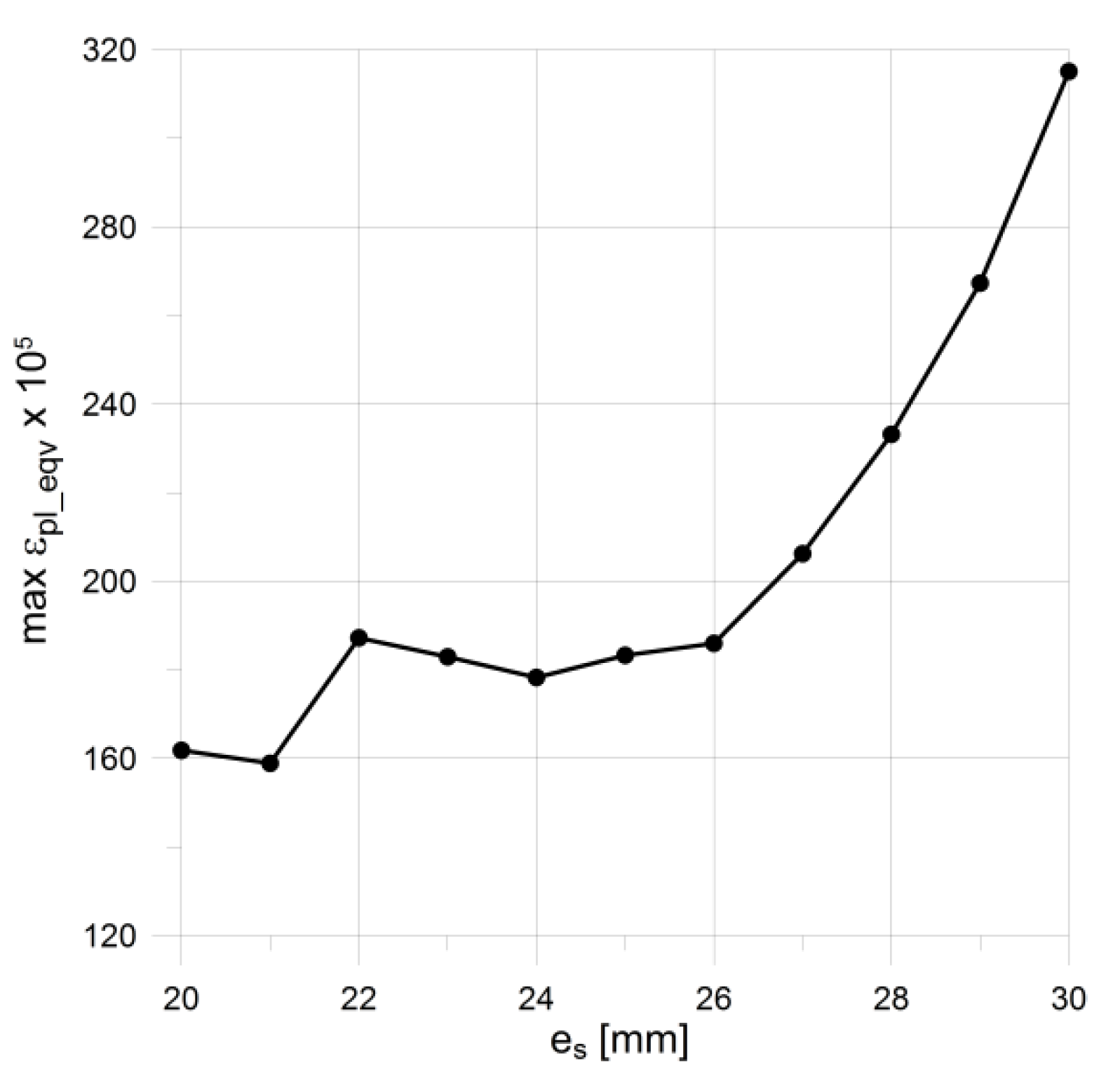

es) than the values of equivalent stresses. This justifies the application of the objective function in the form given in Equation (7). Given the dependency between the maximum equivalent von Mises plastic strain obtained for the optimal parameters of the groove radii and the minimum endplate thickness presented in

Figure 7, it is clearly seen that the minimum value was obtained for the shell with no local reinforcement being applied, namely

ep =

es. This means that the introduction of the locally-thickened zone proposed in the EN 13445-3 code has the opposite effect to the expected one; it even deteriorates the structure resistance. Both codes used in the flat endplate calculations, namely EN 12952:3 and EN 13445-3, result in the presence of plastic deformations in the groove area which are completely unacceptable in applications where high cyclic loadings are applied and fatigue failure may appear. In such a case, the reduction of the applied operating pressure is the only remedy. However certain proposals of modifications of the structure’s topology improving the structure endurance are possible.

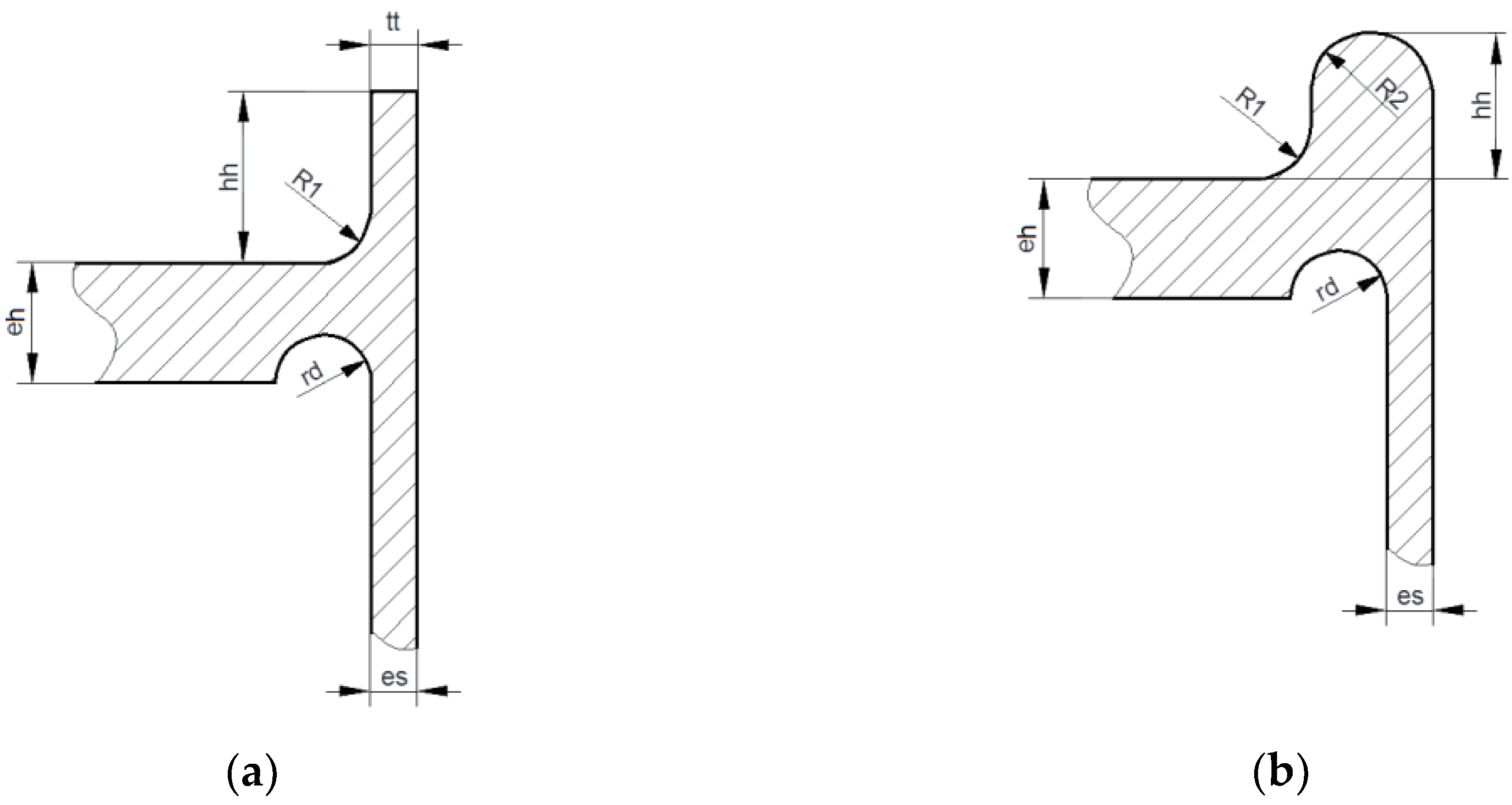

4.2. Increasing of Bending Stiffness of Flat End by External Rings

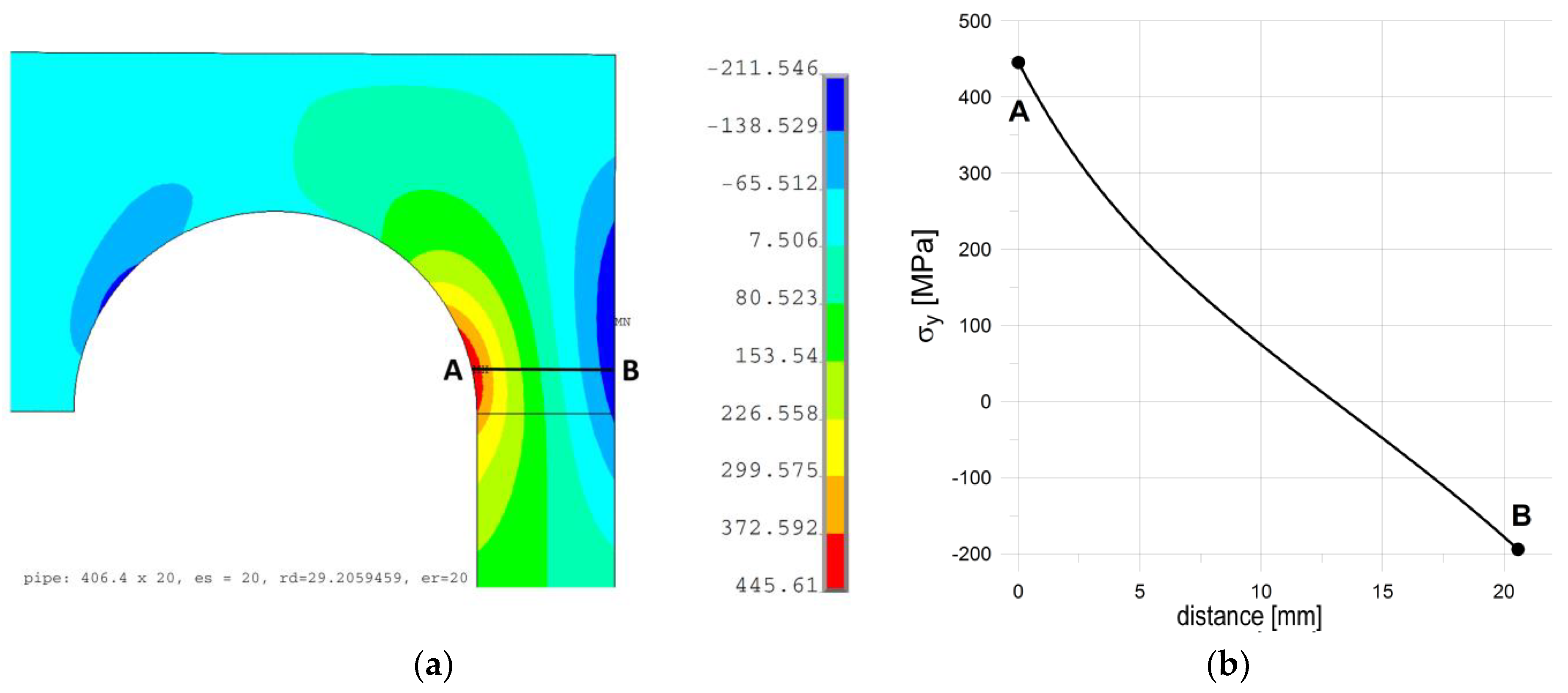

If we apply the purely elastic model of the considered structure to the analysis, then a certain characteristic, structural behavior can be spotted. Detailed study of the maximal meridional (axial) stress shows that the axial stress in the tube, in the most strenuous cross-section, takes the characteristic course shown in

Figure 8b. As shown, the axial stress varies almost linearly across the pipe wall; only a certain discrepancy (rapid increase) is observed inside the tube where stress concentration exists. In such a case, the resulting axial stress may be expressed in the form of the sum of the two components. The first one, i.e., the constant part, may be attributed to axial movement of the flat end subjected to the pressure force, while the second one is the result of bending appearing in the flat end. While the stress attributed to the pressure force cannot be reduced without the reduction of the acting inner pressure, the normal stress corresponding to bending can be limited by adding some material to the endplate which locally increases the end-plate stiffness. The simplest remedy seems to be a uniform increase of the end-plate thickness. Such an investigation was performed, and the results of the numerical calculations are shown in

Figure 9. These studies were performed with the optimal stress relief groove parameters (

rd = 29.206 mm and

ep = es = 20 mm). As shown, a full elimination of plastic deformations was achieved with an additional thickness about 45 mm, which means that the introductory thickness of the endplate, suggested by the codes, was almost doubled. Such a situation of course raises the question of the economic aspects of such a design, i.e., with extremely heavy and massive flat ends. In summary, it means that no simple remedy can be applied to the studied problem.

The application of the biological growth approach proposed by Mattheck [

27] may be useful in this case; this approach respectively adds or removes some material portions in the most and the least strenuous zones of structure. The engineering application of this approach has been presented in papers by Burchill, Heller, Waldman, and others [

28,

29]. Additionally, the proposed modification of the considered design should be low cost, as simple as possible, and should add or remove some parts of the material in a relatively easy way. Following these indications, some additional material is introduced on the outer side of the endplate, while the groove area remains unchanged. The idea of the proposed approach is illustrated in

Figure 10.

Here, the material is added in the form of a short cylindrical ring (

Figure 10a), or in the form of a ring with a circular cross-section (

Figure 10b). These two rings are placed and welded on the top of the endplate along its circumference. The preliminary numerical calculations performed for certain values for both proposals shown in

Figure 10 were encouraging; it appeared that a full elimination of plastic deformations was possible for certain combinations of reinforcing ring dimensions and groove radii. Such observations encouraged the authors to perform detailed parametric numerical optimization with the objective function (6). With the application of a ring with a rectangular cross-section, the ring thickness (

tt), height (

hh), the transition radius (

R1), and the groove radius (

rd) were assumed to conform to the design variables. In order to simplify the study, the height of the additional ring

hh, the thickness of the ring

tt, and the transition radius

R1 are expressed by means of three coefficients

k1,

k2, and

k3, with respect to the cylinder thickness

es as follow:

The choice of the values for coefficients

k1,

k2, and

k3 was justified by the possibility of the use of finished goods which are accessible on the market. Such an approach guarantees the minimum economical cost. On the basis of the preliminary study, it was assumed that the aforementioned coefficients could change within the ranges:

The change of the structure shape, namely, of the flat endplate, requires the search for the optimal combinations of design parameters k1, k2, k3, and rd. Following the former results, it was assumed that the center of the groove was located on the bottom edge of the endplate.

The numerical optimization problem was investigated by means of the two optimization methods, namely, the subproblem optimization procedure, which is the zero-order method, and the first order method, which also takes into account the gradient of the objective function [

26,

30]. The gradient method is much more time consuming and appeared to be less effective in the considered problem. Due to the observed relatively small changes/variations in the objective functions with respect to the design variable variations, certain difficulties with gradient calculations were encountered during the process, and problems with the solution convergence appeared. Finally, the results were obtained by means of the subproblem optimization method. The optimal results are as follows:

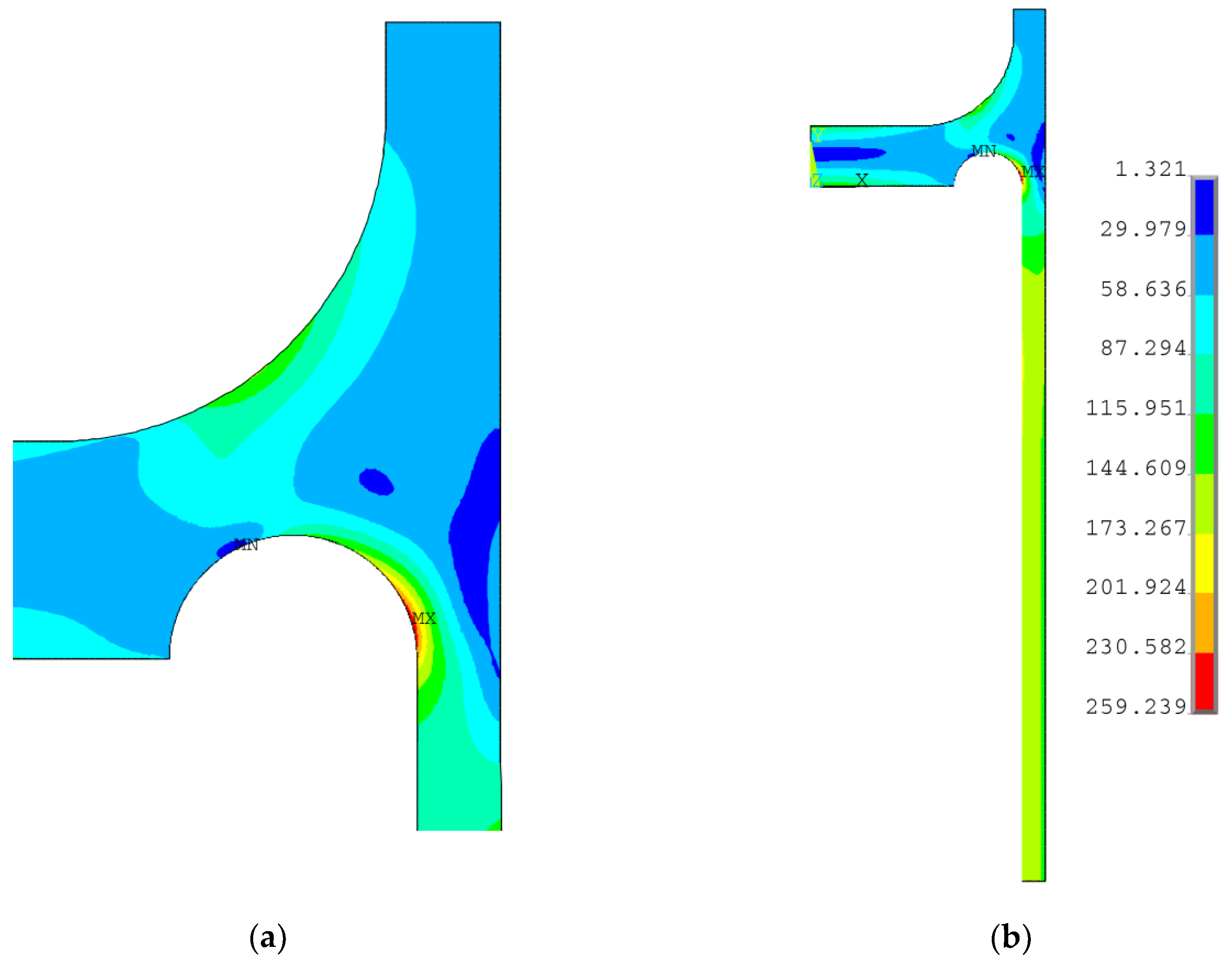

k1 = 5.033,

k2 = 0.788,

k3 = 1.378,

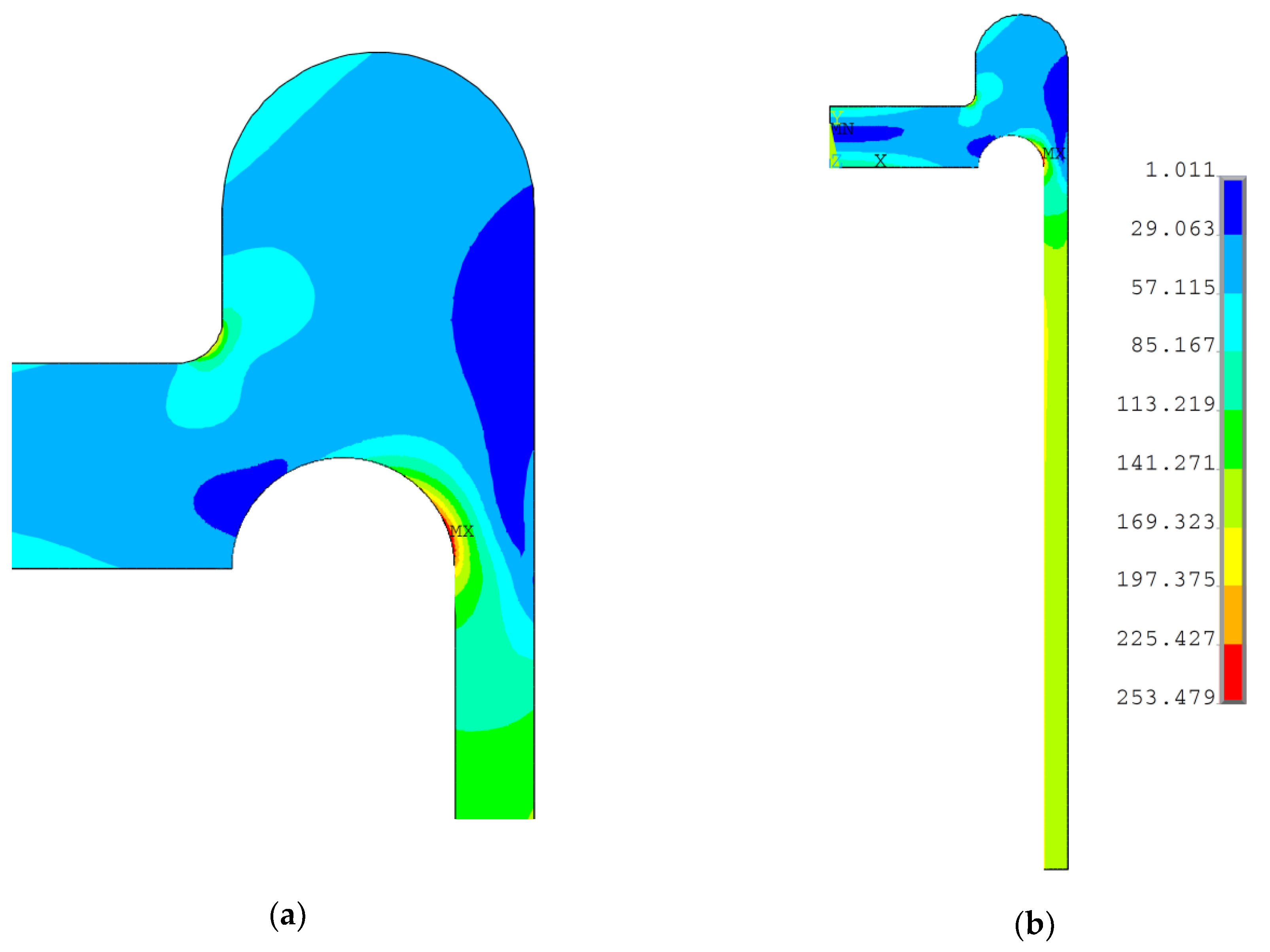

rd = 29.76 mm, and the distribution of the equivalent stress for the optimal point is presented in

Figure 11. As shown, the maximum equivalent stress value is below the yield limit, but still exceeds the allowable stress value,

f. Additionally, the case, in which the reinforcing ring thickness

tt has the same thickness as the cylindrical part

es, was studied (

k3 = 1.0). Such an assumption eliminates one of the design variables (

k3) and seems to be reasonable for application from an economic and technological point of view. In this case, also the full elimination of the equivalent plastic strains was achieved for the following optimal values of the design variables:

k1 = 4.827,

k2 = 0.891, and

rd = 31.616 mm.

Figure 12 presents the distribution of equivalent von Mises stresses obtained for the aforementioned design variable values. As in the previous case, the maximum equivalent stress is below, but close to, the yield limit value.

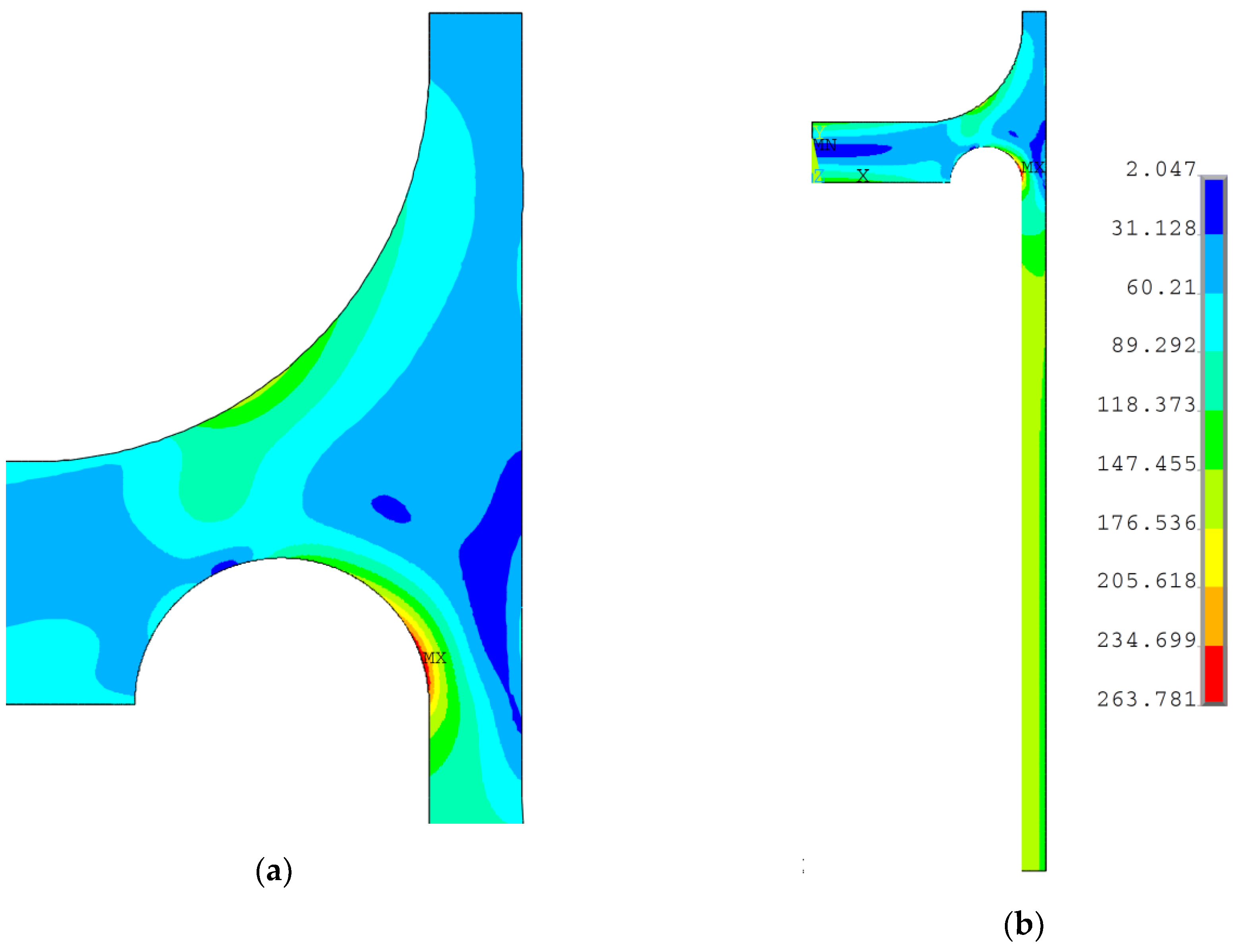

A study was also performed for a rounded ring added to the top of the endplate (see

Figure 10b); again, satisfying results were obtained by means of the subproblem optimization method. In this case, radii

R1, transition radius

R2, and groove radius

rd were assumed as the design variables. As in the previous analysis, the values of the respective radii were defined by means of the coefficients

k1 and

k2, which define the design variables with respect to the shell thickness

es as follows:

On the basis of the preliminary calculations, it was assumed that the aforementioned coefficients would change within the ranges given below:

The optimal values of the design variables obtained in the optimization process were as follows:

k1 = 1.9709,

k2 = 0.2839, and

rd = 28.249 mm; the equivalent stress distribution is shown in

Figure 13. Again, the obtained maximum value of the equivalent stress was high and close to yield limit, but did not exceed this value, which means that the investigated structure was free from plastic deformations.

All the aforementioned results for the performed optimization show that the complete elimination of plastic deformations is possible. However, the maximum value of stress is still very high and demands a certain reduction in the operating pressure. This reduction would be smaller than for a structure with no reinforcing ring, even with optimally-chosen stress relief groove parameters. The performed study has shown that it is possible to introduce relatively simple modifications in the design of the flat end pressure vessel which provide total elimination of plastic deformations.

4.3. Topological Optimization of the Stress Relief Groove

The application of topology optimization makes it possible to distribute the material of a body on the basis of selected criteria [

26,

31,

32,

33,

34]. In this process, the global stiffness, natural frequency, etc. can be stated as objective criteria. These measures can be optimized with respect to the assumed constraints (volume or mass reduction). Recent techniques and FE solvers also offer more advanced topology optimization techniques, the most interesting of which seems to be the stress-based [

35] and fatigue damage-based [

36] topology optimization methods. Such methods, with the simultaneous implementation of the recent multiaxial high-cycle fatigue criteria [

37,

38], are broadly applicable to the optimization and construction of structures which are subjected to both static and fatigue loads. In the performed analyses, the maximization of the structure stiffness was assumed as the objective function to the volume constraint. The use of such a method in the study is associated with the limited possibilities of the software used (ANSYS 13 APDL). In such a situation, it should be noted that the stiffest design is not necessarily equivalent to the design with the optimal, i.e., the smallest, stress concentration. Because of this, the application of the stress-based topology optimization of pressure vessels will be the subject of a future study.

In the FE solver (ANSYS 13) [

26], topology optimization can be performed with the use of structural static compliance (SSC). SSC determines the energy of the work done on the investigated structure by the external loads. The minimization of SSC is equivalent to the maximization of the structure static stiffness. For application in the FE code, the compliance function (SSC) can be defined as:

where

f is body forces,

u is displacements,

t is traction forces,

Fi is the point load on

i-th node,

S is the surface area, and

V is the volume.

In the optimization of the topology, the volume of the base structure is removed. Such a reduction of volume leads to an increase of SSC (reduction of stiffness). The main goal of the performed analysis is to find the best distribution of the material of the structure in order to achieve the minimum SSC (the maximal static stiffness) value, subject to the assumed volume reduction. Such calculations are made with the application of the method, which is known as the Solid Isotropic Material with Penalization Method. This is undertaken by the introduction of the pseudo-densities

ηj for each finite element of the model. Such pseudo-densities can be defined as a fraction of the material density:

where

ρj is the density of the considered

j-th element and

ρ0 is the density of the base material.

The pseudo-densities are assumed as design variables in the topology optimization process. The stiffness,

Kj, of a particular element of the optimal structure is determined by the pseudo-densities

ηj using the penalization method in the following way:

where

K0 is stiffness of the base material and

k is the equivalent for penalization power, usually

k = 3 [

32,

34].

The application of the above formulae leads to the two following cases: Kj > 0, i.e., material exists, and Kj = 0, i.e., no material existence. This is controlled by the values of the pseudo-densities ηj (ηj ∈ <0−1>) and penalization power k.

A mathematical model of the applied topology optimization can be summarized as follows:

where:

V* is the amount of material at our disposal,

V is volume after optimization, and

η1,

η2,…

ηj are the design variables.

Topological optimization of the analyzed flat ends was performed with the use of the aforementioned mathematical model and the ANSYS 13 software. As observed in the previous section, in order to reduce the equivalent stress and to eliminate plastic strains, it was necessary to add some portions of material outside the area of the flat end. In the previous section, certain modifications of the structure followed the common engineering practice that was presented and discussed. However, the question still remains as to whether the reduction of the stress concentration can be achieved using a more optimal distribution of the added material. Such a problem was solved by means of applied topological optimization. Different geometries of the flat end with added material have been used as the initial starting models. In all the performed studies, the material was added only outside the structure. This was caused by the limitations included in the respective Standards [

10,

11]. The topology optimizations were made with the application of the Optimality Criteria Method (OC) and the Sequential Convex Programming approach (SCP). Only the most reasonable and optimal solutions are presented in the following section.

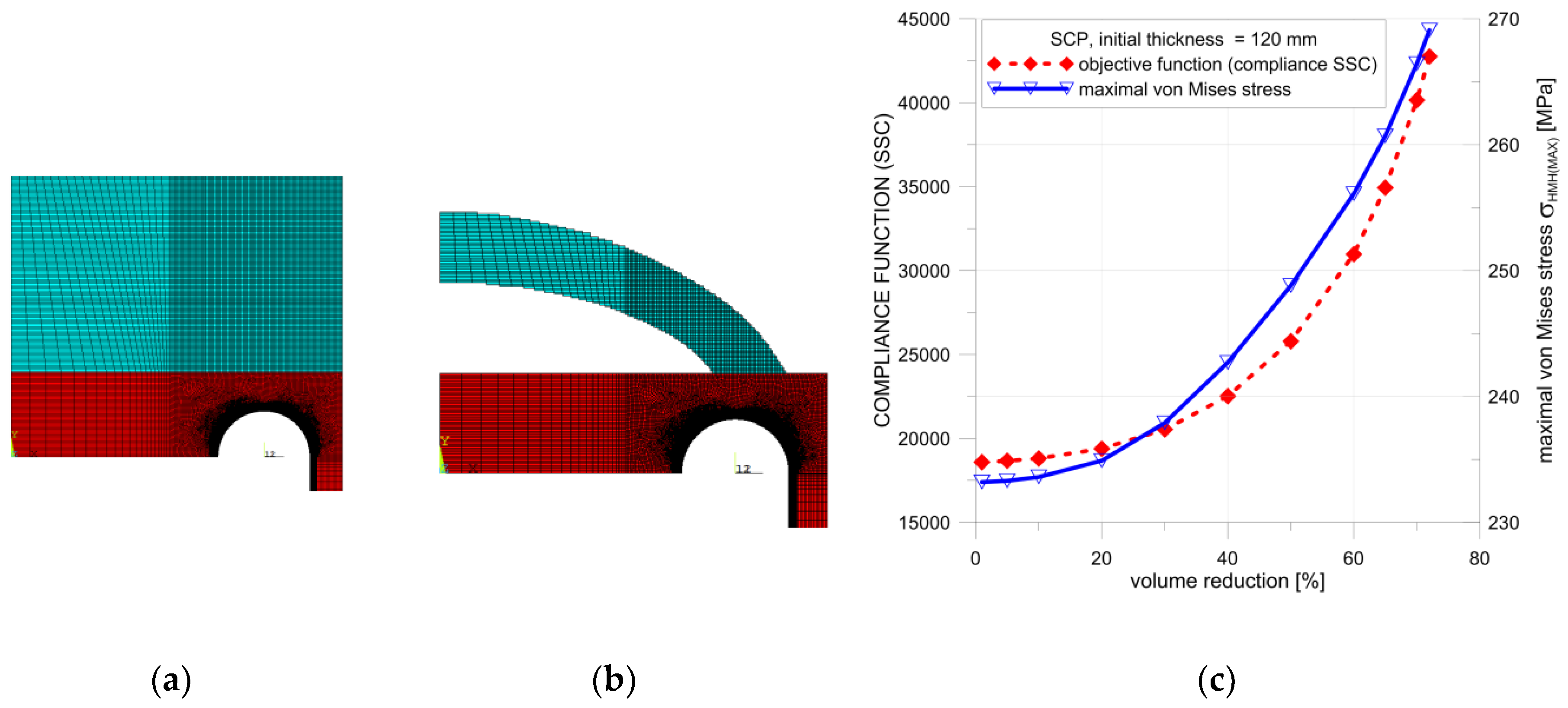

Several calculation attempts were performed; below, the results of only two studies with different material arrangements are presented. A common feature of both proposals was the introduction of the additional material only outside the vessel, in the vicinity of the area where the maximum stress concentration was observed. Only this added material was subjected to the topology optimization, due to the conditions given in Standards [

10,

11]. In the first example, the thickness of the flat end was uniformly increased. The optimal solution (

Figure 14b and

Figure 15b) was obtained from a structure with an increased initial thickness of the endplate set to 120 mm (

Figure 14a). The obtained maximal possible reduction of the added volume was equal to 72% for SCP (

Figure 14b) and 74% for the OC method (

Figure 15b). In both cases, the von Mises stress was slightly lower than the yield stress.

Detailed calculations of the topological optimization were performed with the structure volume reduction, which was reduced with a 5% step. The SSC and von Mises stress values were kept under control during this process. In each step, the structure with the maximum volume reduction was considered optimal only if the von Mises stress remained below the yield limit. The distribution of the controlled SSC process and the maximum von Mises stress values is illustrated in

Figure 14c. The respective calculations were performed for both methods in ANSYS, namely, the SCP and OC methods. In both considered cases, small differences in the final volume reductions were observed. The main difference in the structure geometry was observed in the results of the OC method. In the optimal structure, additional ribs were present between the curvilinear part and flat end using this approach.

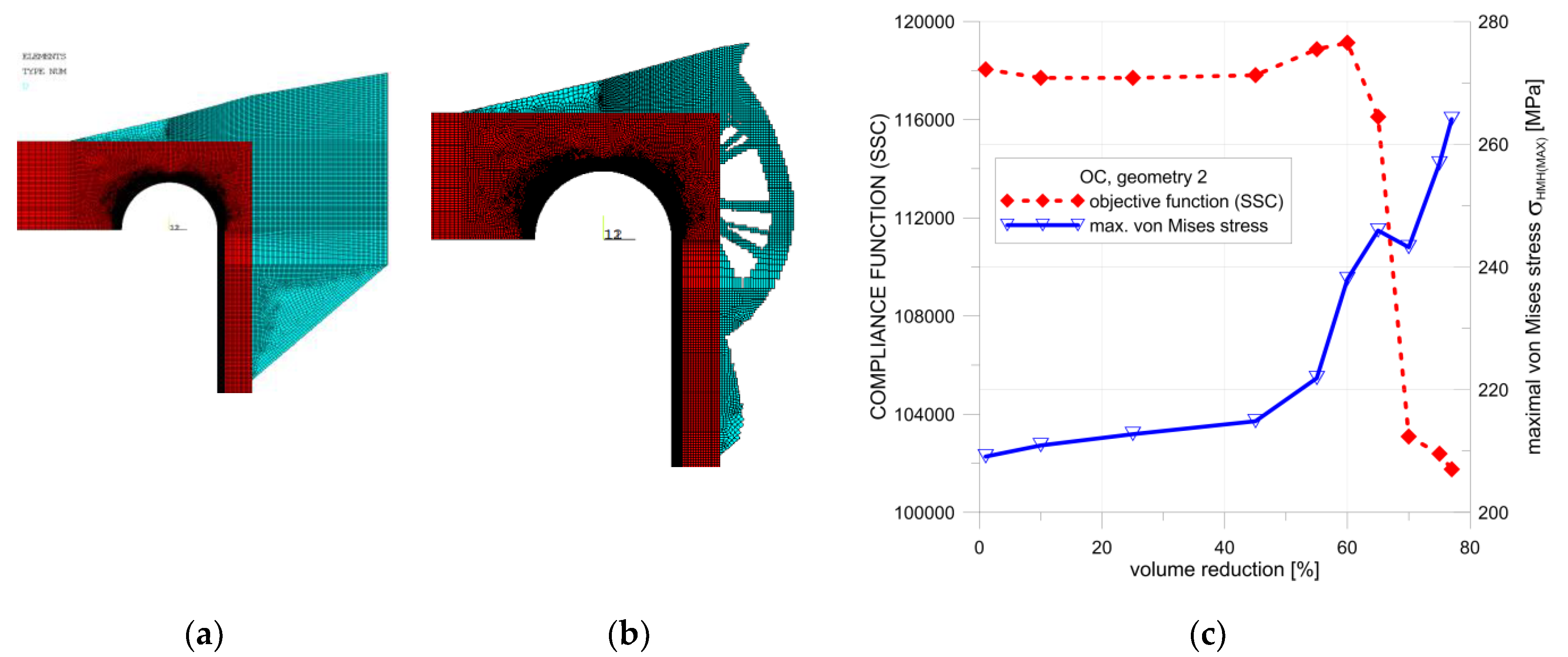

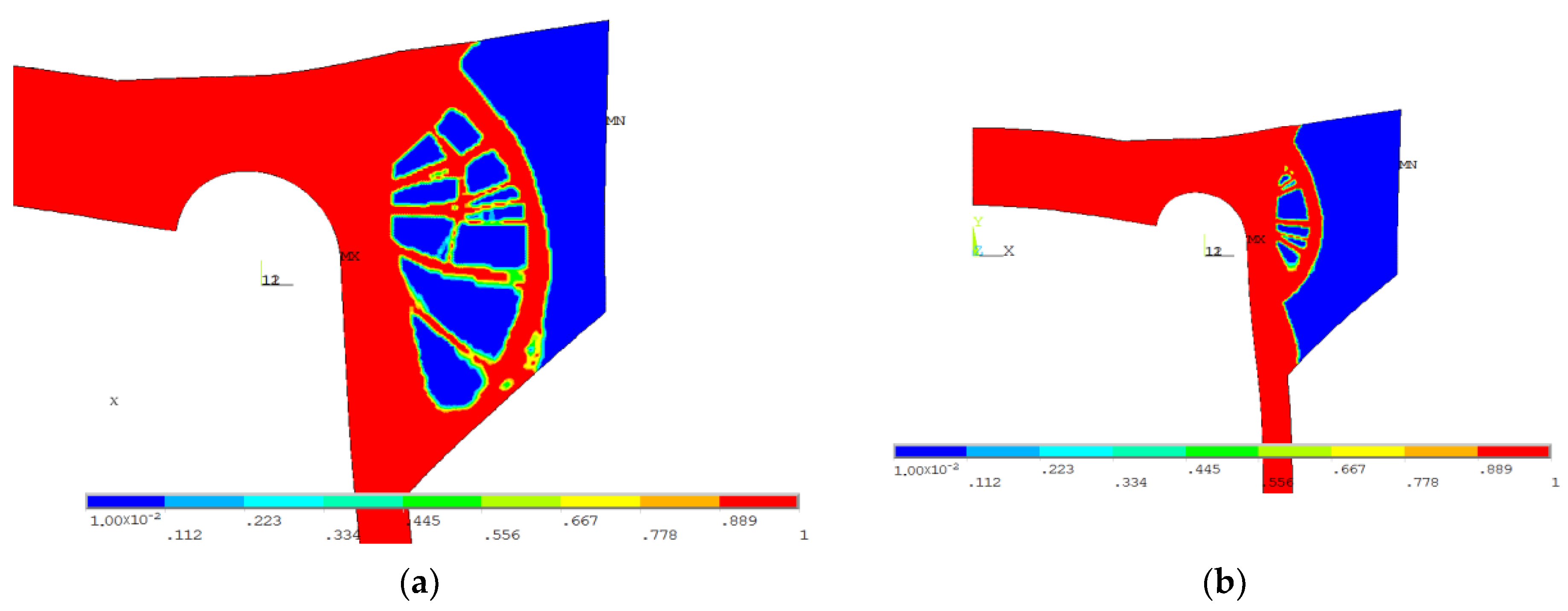

The second presented proposal relied on the introduction of additional material mainly around the top part of the cylindrical pipe and the connection pipe–endplate. Also, some material, rigidifying the vessel bottom, was placed on the top of the endplate. Detailed calculations were performed with the use of the OC method, and the optimal configuration was obtained for the volume reduction using 77% of the added material (

Figure 16b). The dependency between the SSC, the maximum von Mises stress, and the percentage of additional volume reduction are illustrated in

Figure 16c. The surprising course of changes of the SSC parameter when crossing 60% was due to the change of the final geometry, as illustrated in

Figure 17a. The final, optimal distribution of the additional volume is shown in

Figure 17b; it corresponds to 77% of the additional volume reduction. Such a nonsmooth change in the structure geometry results in a rapid change in the SSC value when moving from 60% to 65% of the additional volume. The rapid change of the SSC has no influence on the maximum value of the von Mises stress. The distribution of the von Mises stress for 60% and 77% of the additional volume reduction are presented in

Figure 18a,b. The geometry which was the result of the topological optimization, in this case, was rather complex and difficult to manufacture. Summarizing the first studied proposal, the model illustrated in

Figure 14 and

Figure 15 seems to be more convenient and better-suited to practical applications.

4.4. Discussion

The design of pressure vessels implies optimal shaping with respect to the stability and strength of the shell. Due to the application of such structures in petrochemical, chemical, as well as nuclear applications, the safe and reliable performance of pressure vessels is a very important engineering issue. The performed analyses revealed that the recommendations included in the standards [

10,

11] are not sufficient to optimally design the parameters of the endplate stress relief groove in flat endplates. Moreover, it was observed that significant plastic deformations may occur in the boundary area of the stress relief groove if nonoptimal values for the groove parameters are used in the design. The performed calculations revealed that the geometries of flat ends with a circular stress relief groove proposed in the standards (EN 13445-3) allow only for a reduction (i.e., for an optimal combination of

rd and

eh1), but not a complete elimination, of the plastic strains. However, the presence of such plastic strains is unacceptable in many practical applications. The elimination of excessive elastic-plastic deformations in the groove area demands certain modifications in the structure design. On the basis of a series of numerical tests, simple, technologically-justified modifications were proposed (see

Figure 10). Next the optimization of their dimensions was performed. From the proposed shapes of the reinforcing rings, a full elimination of plastic deformations was achieved when optimal values for design variables were set. However, the level of equivalent stress was still high in the groove area, which demanded the reduction of the operating pressure. Such a design modification and the obtained analysis results became the inspiration for a more general approach in which the topology optimization was applied. Here, two concepts were incorporated.

The first one relied on a uniform increase in the endplate thickness with added material being placed on the outside boundary of the endplate. The second one proposed an increase in the tube thickness in the junction area of the tube and the endplate. Most of the added material was placed outside the top part of the tube, but a certain amount of material was used to locally increase the endplate thickness in the vicinity of the outer diameter. Both proposals gave satisfactory results in terms of plastic deformation elimination. However, the von Mises stress still remained close to the yield limit. The reduction of the added volume values exceeded 70% in both cases. The optimal structure configurations after topology optimization were of a rather complex shape, including internal ribs. A comparison of the obtained optimal results is summarized in

Table 4. The volume of the whole vessel was about 4.0 × 10

7 mm

3. The volumes of the single endplate with optimal configurations of the stress relief groove are given in

Table 4. In order to compare the obtained solutions in the last column of

Table 4, the increase in the weight of the optimal flat end with added material is also presented.