1. Introduction

A corbel is generally described as a short member with shear span-to-depth ratio lower than the unity that cantilevers out from a column or a wall [

1]. Brackets and corbels may be described as short cantilevers that work as a connector between columns and beams to support the heavy load of cranes and precast beams. Internal primary and secondary (closed stirrups) reinforcements are incorporated into the design of the corbels to prevent brittle failure under excessive horizontal and vertical loads. Several studies have been performed, both experimental and analytical, on the main parameters governing the structural behaviour of corbels, such as reinforcement ratio, shape and geometry, and concrete strength [

2,

3,

4]. When the ratio of primary reinforcement is low, it enables the members to achieve higher ductility because of yielding of reinforcement prior to the concrete. It has been shown that the addition of secondary reinforcement generally results in enhancing the strength and deformation capacity of corbels and leads to a less catastrophic failure [

5,

6,

7,

8]. However, in members with congested reinforcement in a small area, other problems might occur, such as honeycomb, voids, and inadequate bonding between the surface of the reinforcement and the concrete, which cause premature failure of the structures. Moreover, several researchers reported that incorporating normal concrete and stirrups as secondary reinforcement is associated with a significant loss in the strength of corbels after reaching the peak load [

9].

The behaviour of high-strength concrete corbels has been investigated in the presence or absence of steel fiber up to a concrete compressive strength of 132 MPa [

10,

11,

12,

13]. Despite the development of novel theoretical models, empirical methods, and common detailing practices remain the typically used approaches since there is no consensus on the most effective design model.

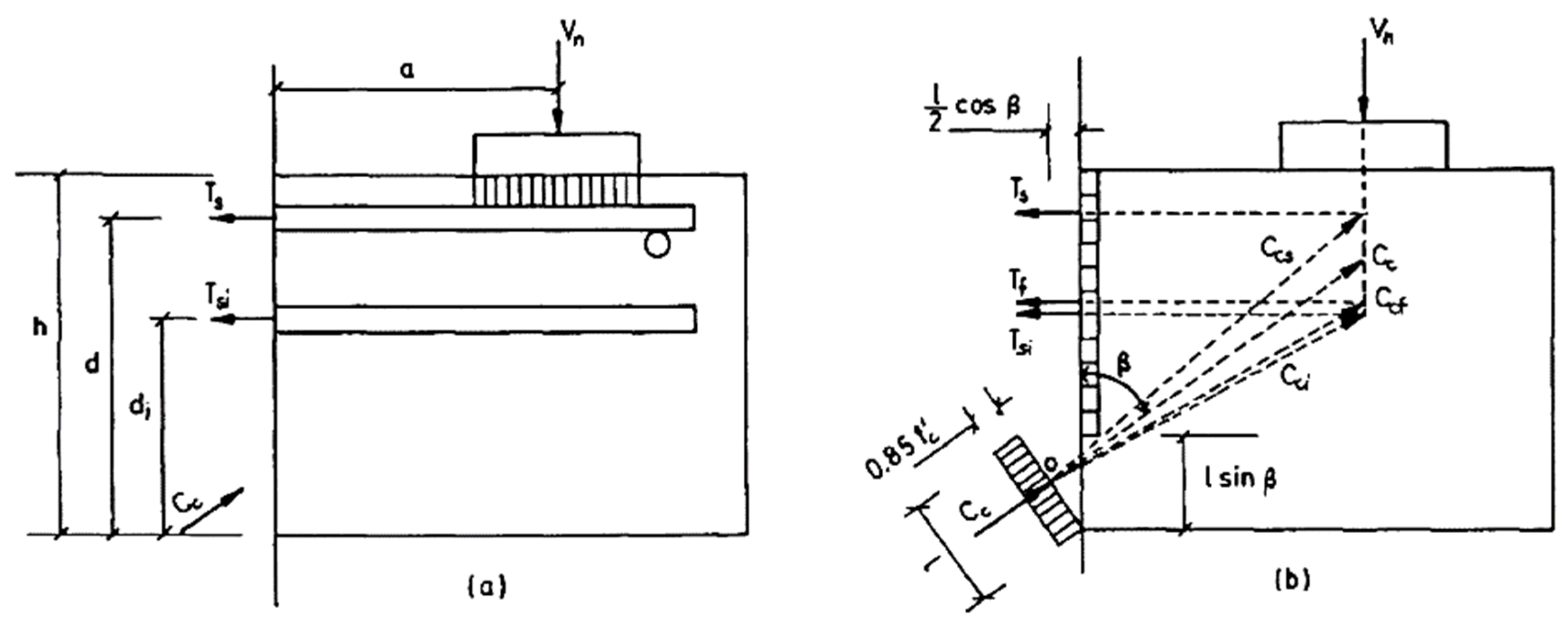

The nonlinear stress behaviour of the short member is affected by the shear deformation in the elastic range, and consequently the shear strength of the section becomes an important parameter for design consideration [

2,

14]. The principal failure mode for corbels reinforced with principal and secondary reinforcements (stirrups) is referred to as beam-shear failure, which is characterized by the cleaving or splitting of one or several diagonal cracks accompanied by shear failure in the compressed region of the strut [

15]. Moreover, corbels exhibit many distinctive modes of failure, which include yielding of the tension tie; failure of the end anchorages of the tension tie, either under the load point or in the column; failure of the compression strut by crushing or shearing; and localized failures under the bearing plate [

16].

For uniaxial compressive behaviour, several experimental works and numerical models have been conducted to investigate the impact of incorporating fiber into normal and high-strength concrete [

17]. The ductility of the stress–strain curves was shown to increase concomitantly with an increase in fiber volume fraction and/or fiber aspect ratio [

18]. The fibrous concrete attained a marginal increase in compressive strength of approximately 9% as compared to non-fibrous concrete.

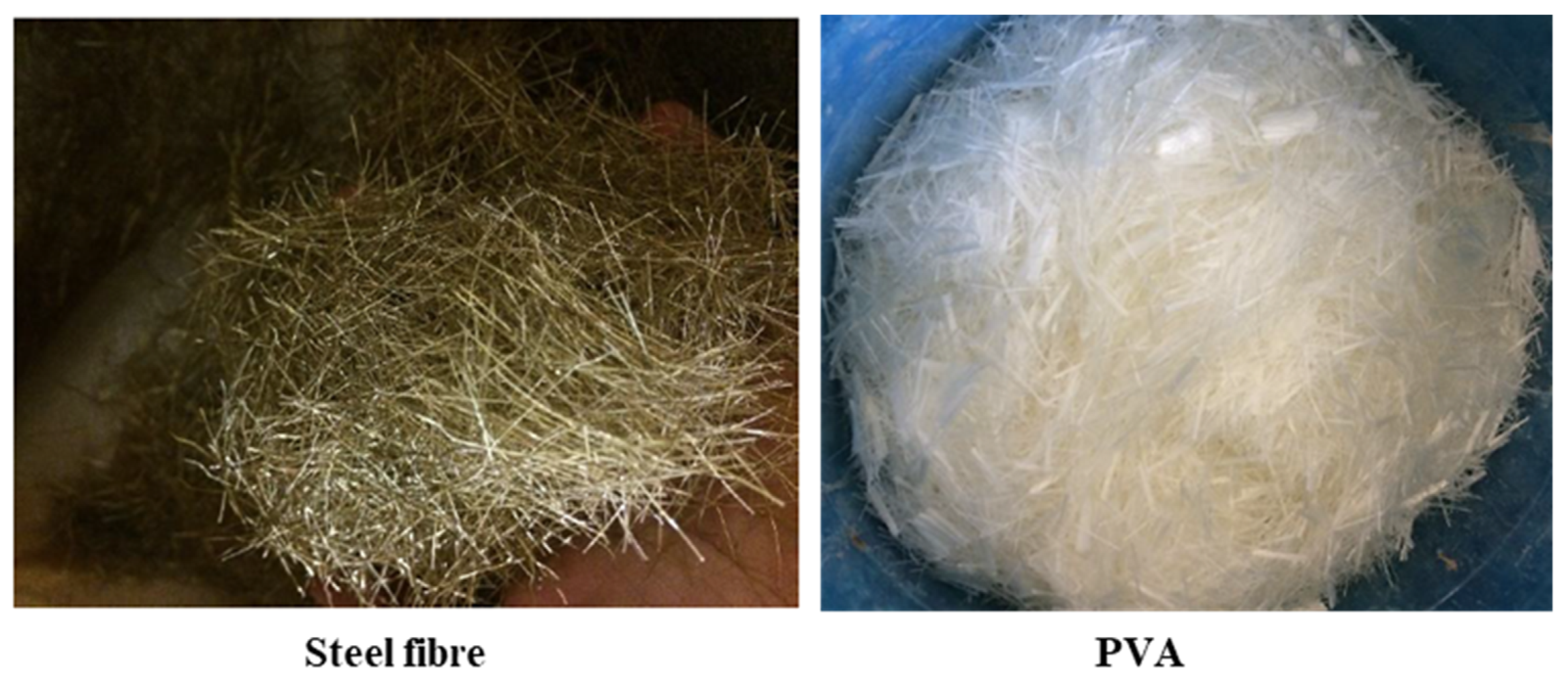

To limit the defects typically observed in the conventional concrete, as well as decrease the quantity of internal reinforcements, high-performance fiber-reinforced cementitious composite (HPFRCC) was introduced. Throughout the last two decades, various HPFRCCs using different fibers have been investigated. HPFRCCs generally retain a fiber volume fraction that is lower than 2% and display a pseudo-strain-hardening behaviour under tensional conditions, and improved tolerance for damage [

19,

20]. These enhanced mechanical properties of HPFRCC are mostly attributable to the increased inter-particle bonding; the utilization of diverse types of fibers, such as steel and polyvinyl alcohol (PVA), and implementation of low water–cement ratio in the mixture design.

Moreover, hybridization of different fiber types at low volume can significantly improve the performance of concrete corbels due to the combined effect of micro- and macrofibres [

21]. This will enhance both mechanical performance and durability. The exceptional properties of these materials make them a practical option for advancing the structural performance of concrete corbels under severe loadings.

To promote the practical and economic benefits of using fibers in concrete corbels, specific aspects associated with their behaviour and design have to be well researched. A vital aspect is to determine the behaviour of corbels under different loads, and their controlling parameters [

21].

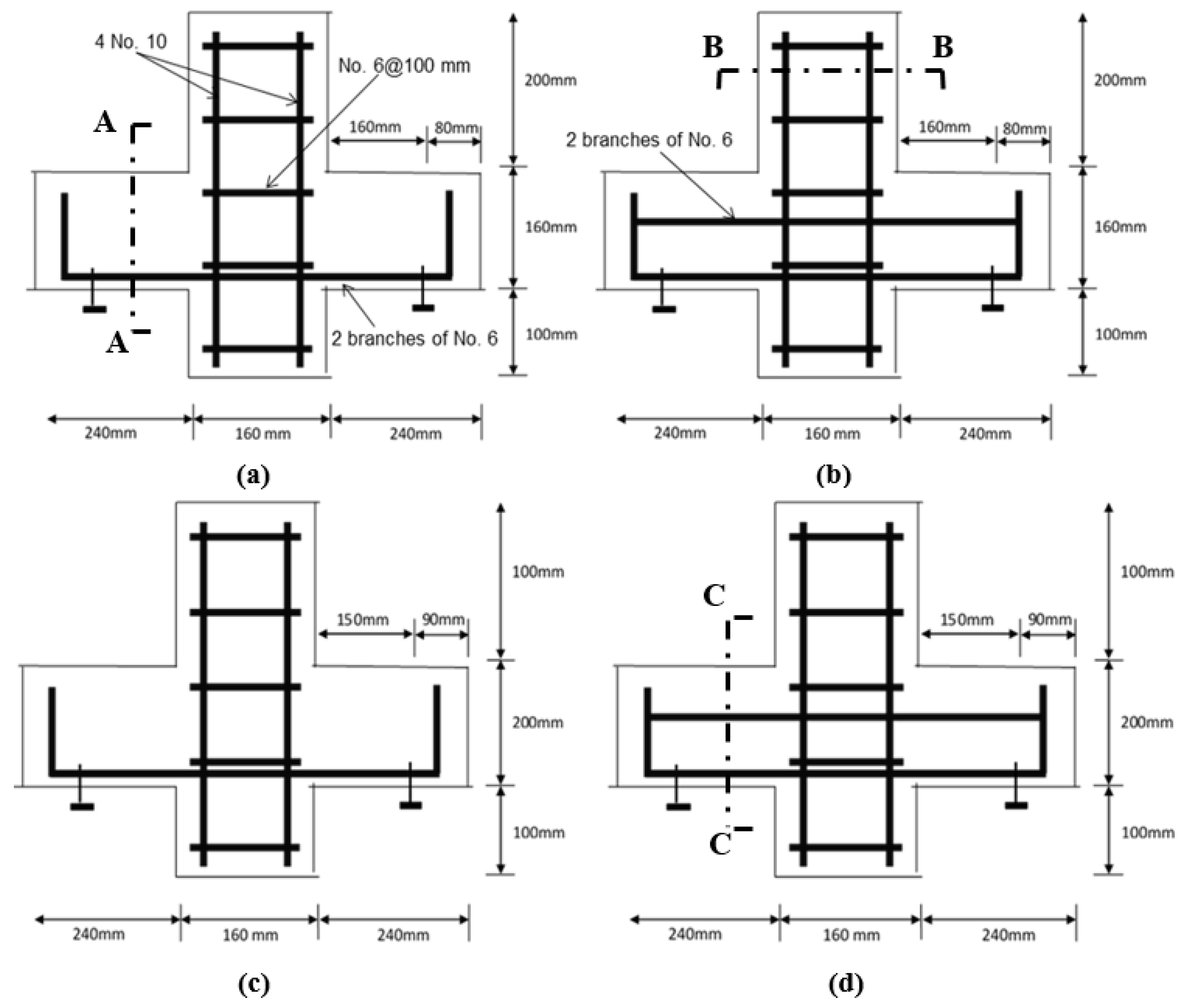

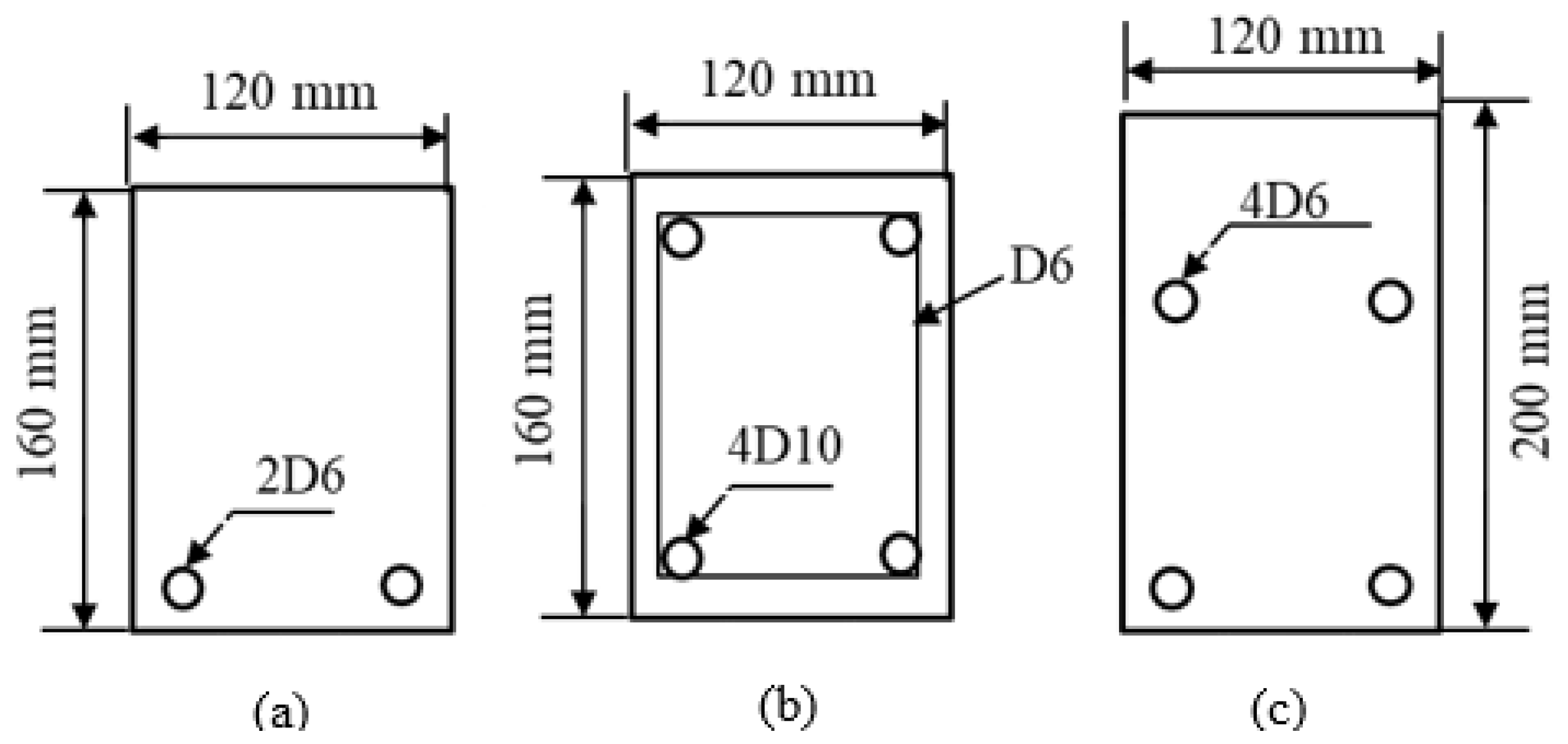

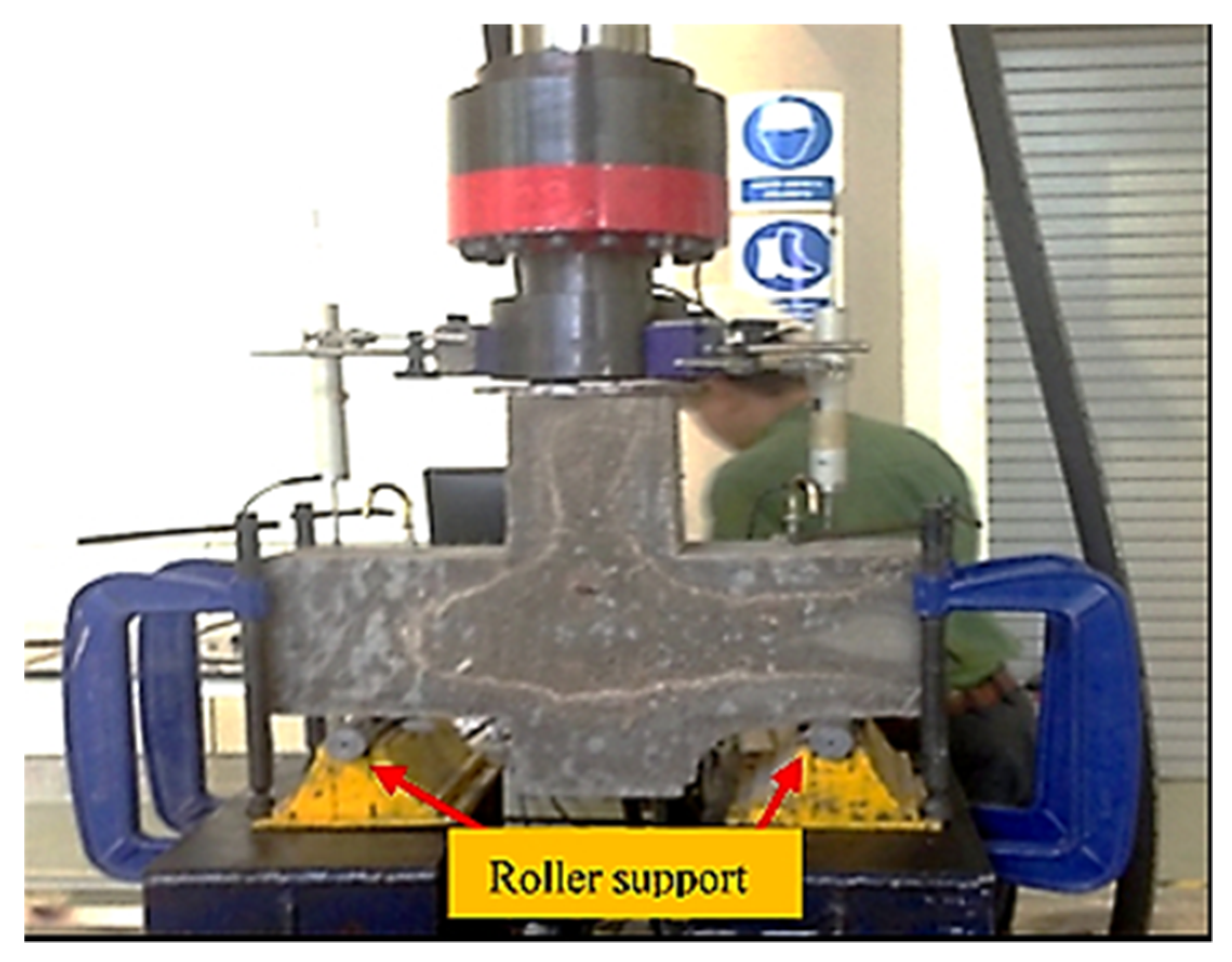

To date, several studies investigated the structural behaviour of high-performance self-compacting concrete (HPSCC) structural members; however, there is limited research conducted on the influence of closed stirrups (secondary reinforcement) on various types of HPSCC corbels including hybrid fiber-reinforced high-performance cementitious composites. In this study, the structural behaviour of corbels with engineered cementitious concrete (ECC), steel fiber-reinforced concrete (SFRC) and hybrid fiber-reinforced composite (HyFRC) in different shear span-to-depth ratios of 0.75 and 1.0 are investigated. The influence of secondary reinforcement on force–displacement behaviour, displacement ductility, and failure modes of corbels made of HyFRC, ECC, and SFRC is examined and compared. For this purpose, corbels with different shear span-to-depth ratio (a/d) are explored. Moreover, the validity of existing analytical models is examined and comparatively analyzed with the results from the experiments on the high-performance cementitious composite corbels investigated in this study.

3. Results and Discussion

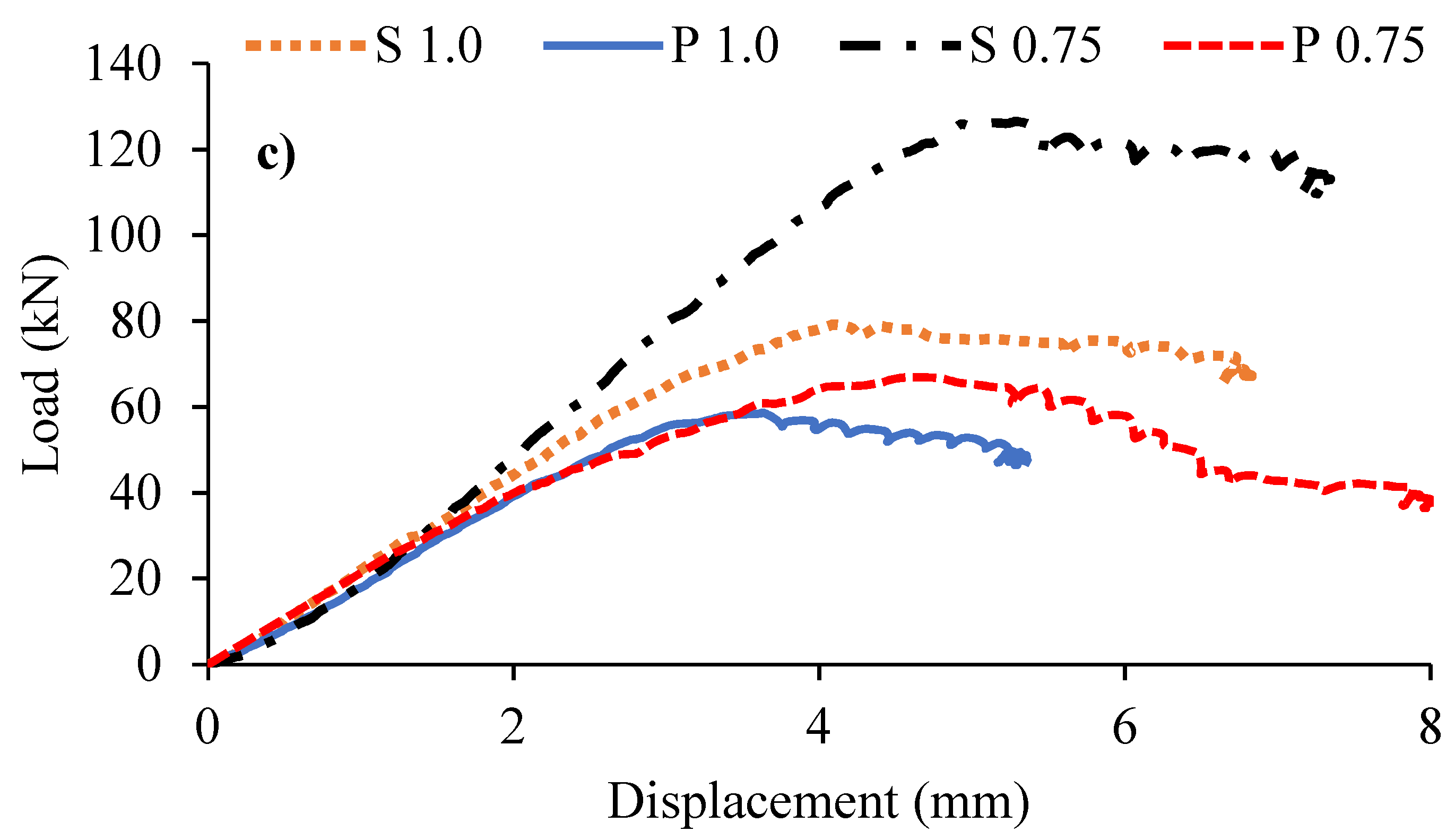

Figure 8 represents the results of the load-displacement responses of the ECC, HyFRC, and SFRC corbels with and without secondary reinforcement. As the results indicate, except for the S 0.75 specimen of the SFRC corbel, all other corbels exhibited a high level of ductility and strength. Moreover, unlike the conventional concrete corbels reported in the literature [

9], there is no considerable loss in the strength of all HPFRCC corbels after the peak load. As can be observed from the figure, the stiffness and strength of the corbels are varied. In general, the corbels with lower shear span to depth ratio (a/d) exhibited higher stiffness compared to the corresponding specimens with lower a/d. Additionally, the corbels with secondary reinforcement exhibit slightly higher stiffness and more ductile behaviour than the specimens without secondary reinforcement. Furthermore, there is a slight increase in the slope of load-displacement responses approximately after 1 to 2 mm of displacement in the graphs, which occurs at the early stage when cracks initiate at the tension zones. This increment is due to the bridging effect of fibers across the cracks, which results in tensile strain hardening and consequently a slight increase of stiffness in the cracked zone in concrete.

As can be seen from the figure, specimens S 0.75 in both SFRC and ECC exhibited approximately similar load capacities of 132 kN and 128 kN, respectively. However, this specimen for HyFRC showed considerably lower strength of 108 kN capacity. This lower strength can be associated with the weaker bonding strength between the particles of HyFRC due to less amount of fly ash in its admixture, as shown in

Table 2. However, this specimen of SFRC exhibited brittle behaviour after reaching the peak load, whereas the other two corbels of HyFRC and ECC show greater ductility. Therefore, when shear is more dominant, i.e., a/d = 0.75 and secondary reinforcement exists (P 0.75), the ECC corbel shows superior performance with a high level of strength without compromising ductility, as compared to SFRC and HyFRC corbel specimens. However, for the specimen without secondary reinforcement, P 0.75, all corbels showed approximately similar strength. On the other hand, when the flexural is dominant (a/d = 1.0) and when there is secondary reinforcement, i.e., S 1.0, the SFRC corbels showed the lowest stiffness and ultimate strength compared to that of corresponding ECC and HyFRC corbels, i.e., the SFRC corbel exhibited 61 kN ultimate strength versus 78 kN and 75 kN strengths of ECC and HyFRC corbels, respectively. However, when there is no secondary reinforcement, similarly to the a/d = 0.75 specimens, P 1.0, the ECC, HyFRC, and SFRC corbels showed approximately similar behaviour and ultimate strengths.

Figure 9 compares the strength increment of HPFRCC corbels due to the presence of secondary reinforcement. As can be observed from the figure, increases of the strengths for the corbels with a/d = 0.75 are more significant. Furthermore, as can be seen from the figure, the SFRC corbel is the most affected among the other cementitious composite corbels, with 51% increment in ultimate strength, followed by the ECC corbel with 45% and lastly the HyFRC with 29% increment. However, for the a/d of 1.0, this order is reversed, where the most impactful corbel is HyFRC with 39%, then ECC corbel with 25% and lastly SFRC with only 11% increment.

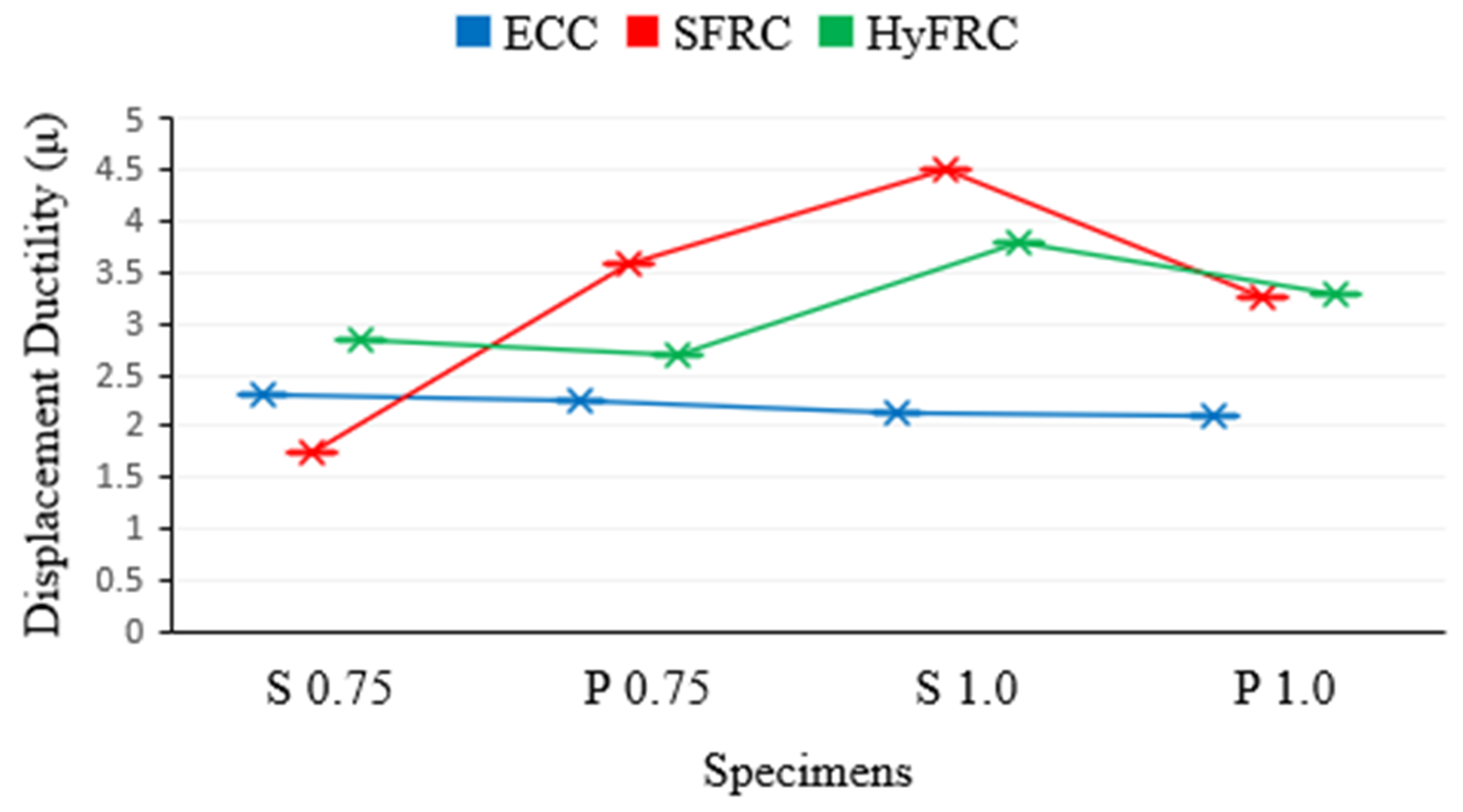

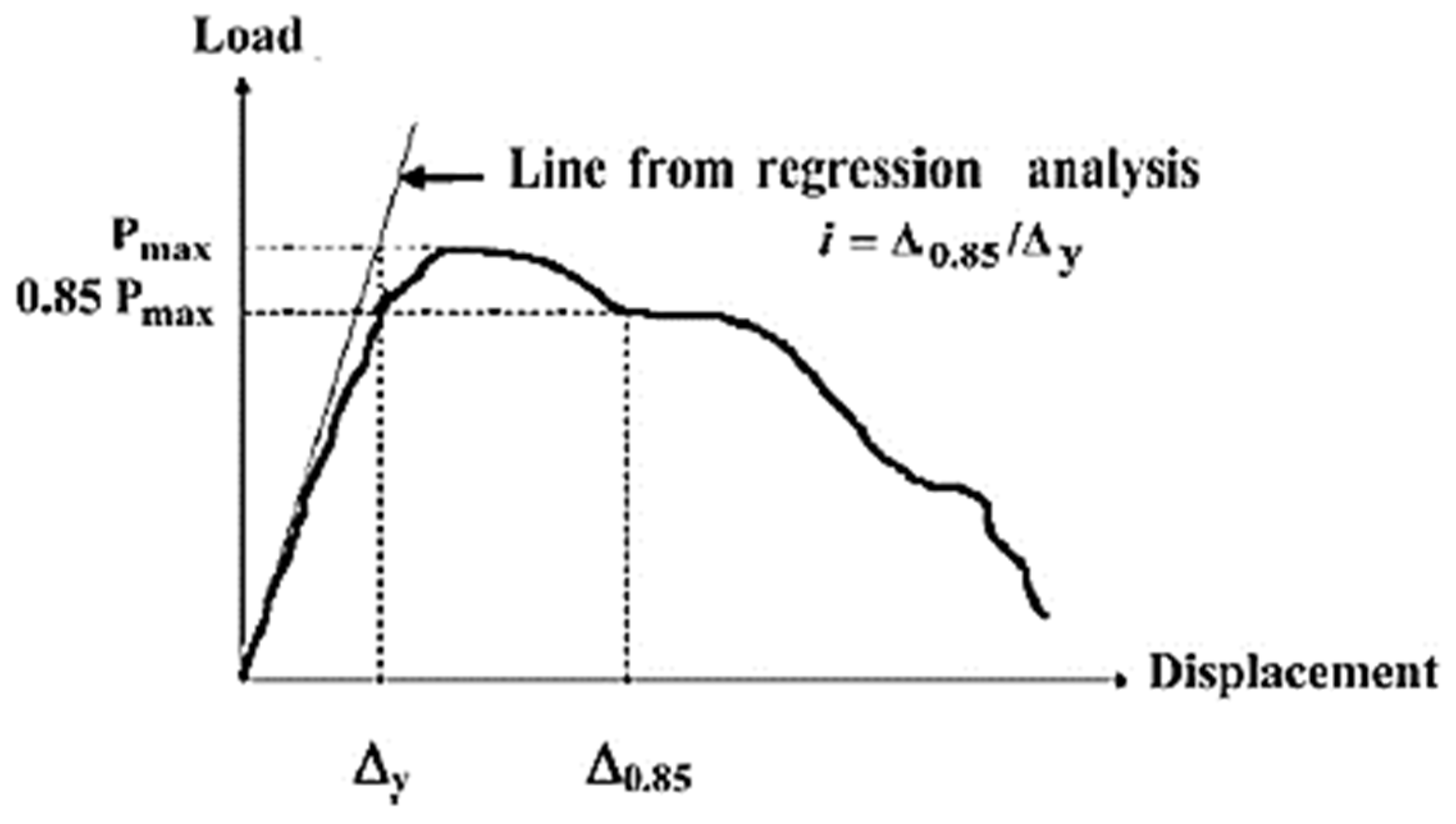

Moreover, the displacement ductility ratio in this study is calculated from the method adopted by [

29,

30], as shown in

Figure 10. The displacement ductility of all HPFRCC corbels is compared in

Figure 11 and

Table 7. Comparing the S series with the P series, it is obvious that the presence of secondary reinforcement slightly increases the displacement ductility of corbels. However, it has a negligible effect on ductility of ECC corbels. Moreover, as shown in

Figure 11, ECC has the lowest ductility among other HPFRCC corbels. The ductility of all ECC corbels for both a/d of 0.75 and 1.0 is approximately constant between the range of 2 to 2.5. In contrast, the SFRC corbels showed the highest level of displacement ductility, followed by HyFRC corbels.

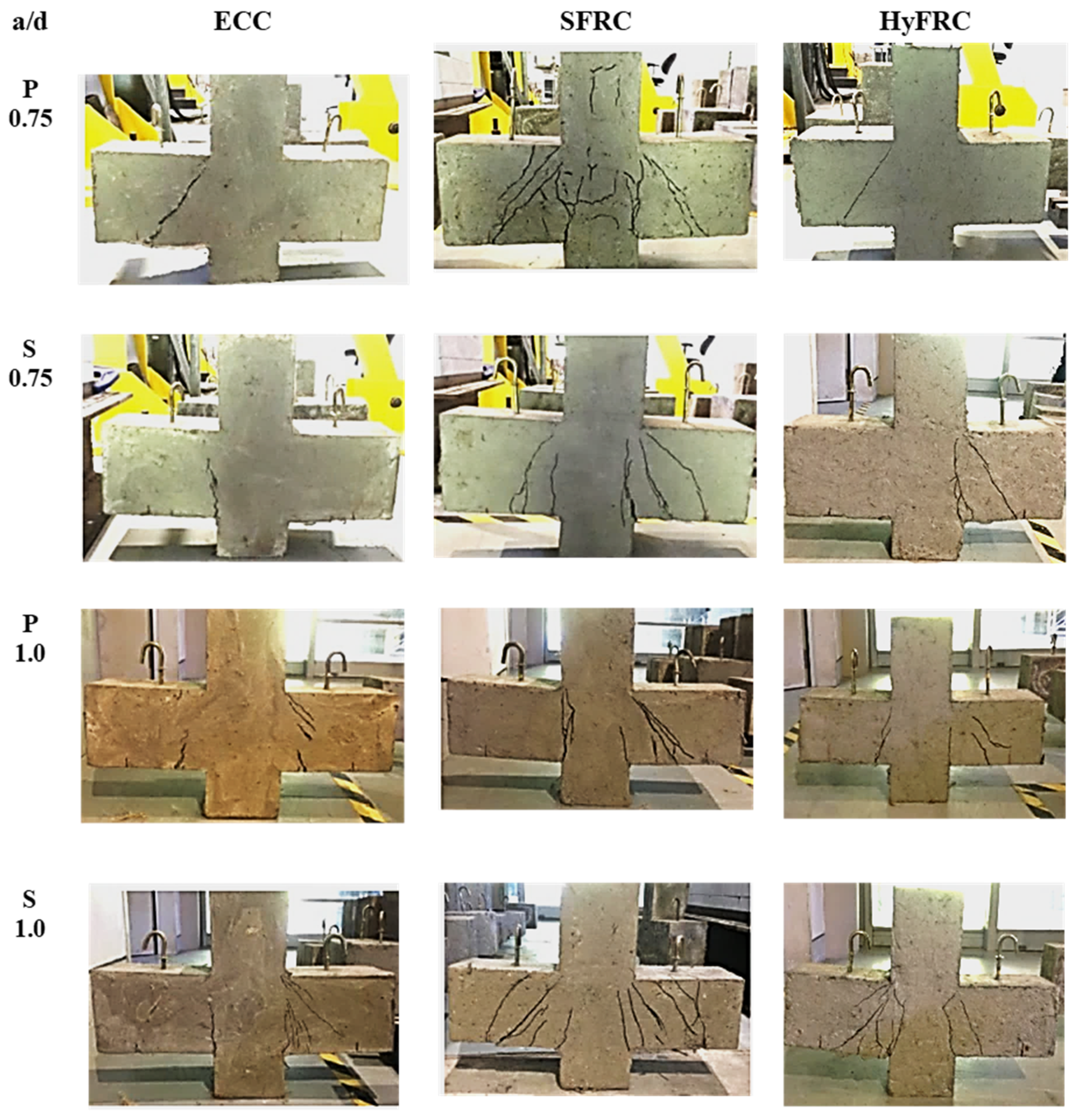

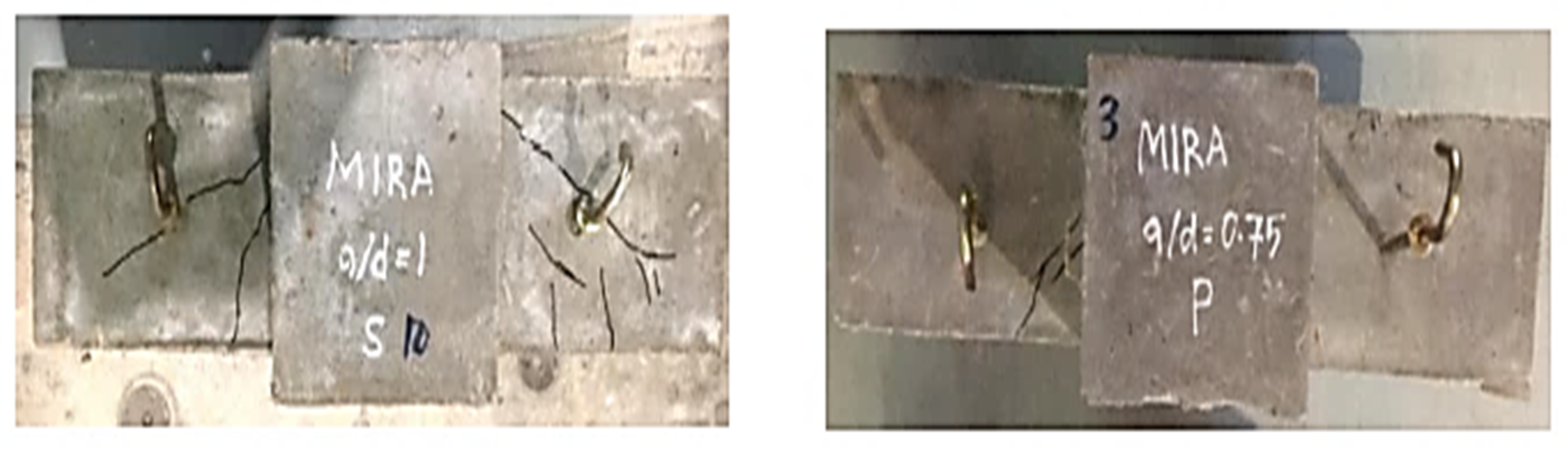

The crack patterns and failure modes of all ECC, HyFRC, and SFRC corbels are depicted in

Figure 12. As observed, fewer cracks and only minor damage occurred in ECC and HyFRC corbels, whereas the SFRC suffered the highest level of damage and cracks. In addition, as shown in

Figure 13, shear cracks emerge in the upper segment of specimen S 1.0 and P 0.75 in SFRC corbels, although this was not identified in the other samples in ECC and HyFRC corbels. The appearance of cracks in S 1.0 can be attributed to the high level of displacement ductility in the sample, which induces significant amounts of concrete cracks at higher level of displacements. Moreover, the P 0.75 sample in SFRC displayed a high level of stiffness and strength prior to the failure. Consequently, excessive stress induced to the concrete and shear cracks are propagated to the compression zone of the specimen.

In general, flexural cracks first emerge in all corbels at the region close to the junction between the column face and the tension face of the corbel. Afterwards, the cracks propagate and expand as the load increases. The cracks for corbels with secondary reinforcement started at the re-entrant corner, and although the crack is propagated laterally along the column–corbel interface, a subsequent crack is initiated at the interior edge of the bearing plate. Conversely, in the absence of secondary reinforcement, the crack is initiated at the inner boundary of the bearing plate, and a second crack originates at the junction of the column. As shown in this study, provision of secondary reinforcement reduces crack width and amount of cracks for SFRC corbels when the shear is more dominant (a/d = 0.75), which is similar to the behaviour of high strength corbels and ultra-high performance concrete (UHPC) corbels with steel fibre [

8,

11,

13]. However, the specimens with a/d of 1.0, where flexure is more dominant, the provision of secondary reinforcement causes more numerous cracks as shown in

Figure 12. Moreover, as displayed in the figure, compared to SFRC corbels, fewer and finer cracks induced to ECC and HyFRC corbels, which make them superior in terms of durability, service life, and sustainability [

8].

5. Conclusions

In this study, the effect of using steel and PVA fibers in various self-compacting HPCC corbels including ECC, SFRC, and HyFRC were investigated. Failure modes, concrete crack patterns, displacement ductility with and without presence of closed stirrups or secondary reinforcements for different shear to depth (a/d) ratios were experimentally investigated and compared. Moreover, the validity of existing analytical models to predict the ultimate shear strengths of self-compacting HPCC corbels were investigated. From the experimental results, a beam-shear failure was observed in all high-performance cementitious composite (ECC, HyFRC, and SFRC corbels). The failure mode of the corbels is stable, as well as ductile. However, none of the corbels failed in a shear-friction mode of failure. Compared to the behaviour of conventional normal strength corbels, the high-performance composite corbels in this study showed insignificant loss in strength after the peak load.

Corbels with secondary reinforcement showed high shear strength capacity and slightly higher ductility compared to the corbels without stirrup. The provision of secondary reinforcement also decreased the crack width and improve the corbel stiffness. However, for the specimens with a/d of 1.0, where flexure is more dominant, the provision of secondary reinforcement causes more numerous cracks. Moreover, the shear span-to-depth ratio (a/d) also affects the shear behaviour of the corbels. In addition, increasing the a/d ratio of corbels increased the deflection, but decreased the shear capacity. The results indicated that the secondary reinforcement initiated a considerable difference in structural behaviour in terms of ultimate strength, ductility and failure, and formation of crack patterns between ECC, HyFRC, and SFRC corbels. In contrast, without secondary reinforcement, the corbels exhibited approximately similar stiffness and strength. Moreover, the results indicated that when the shear is more dominant, with the presence of secondary reinforcement, the ECC corbel shows superior performance than the other high-performance cementitious composite corbels. On the other hand, when the flexural is dominant (a/d = 1.0) and there is secondary reinforcement, SFRC corbels exhibited the lowest stiffness and ultimate strength compared to other cementitious composite corbels investigated in this study. In addition, HyFRC specimens showed slightly lower strength for the specimens with a/d = 0.75, where shear is higher. However, they exhibited higher deflection capacity and ductility for the specimens with higher a/d, where flexure is more dominant. Moreover, in terms of concrete cracks and damages, ECC and HyFRC corbels showed minor damage and fewer cracks induced compared to SFRC corbels.

In terms of ductility, ECC corbels for both a/d of 0.75 and 1.0 exhibited approximately a constant value between the range of 2 to 2.5, whereas SFRC corbels showed the greatest level of ductility, followed by HyFRC corbels.

Furthermore, the strength increase of all cementitious composite corbels was compared. It was shown that the SFRC corbel, among the other corbels, displayed the highest impact with 51% increment, followed by the ECC corbel with 45%, and lastly the HyFRC with 29% increment.

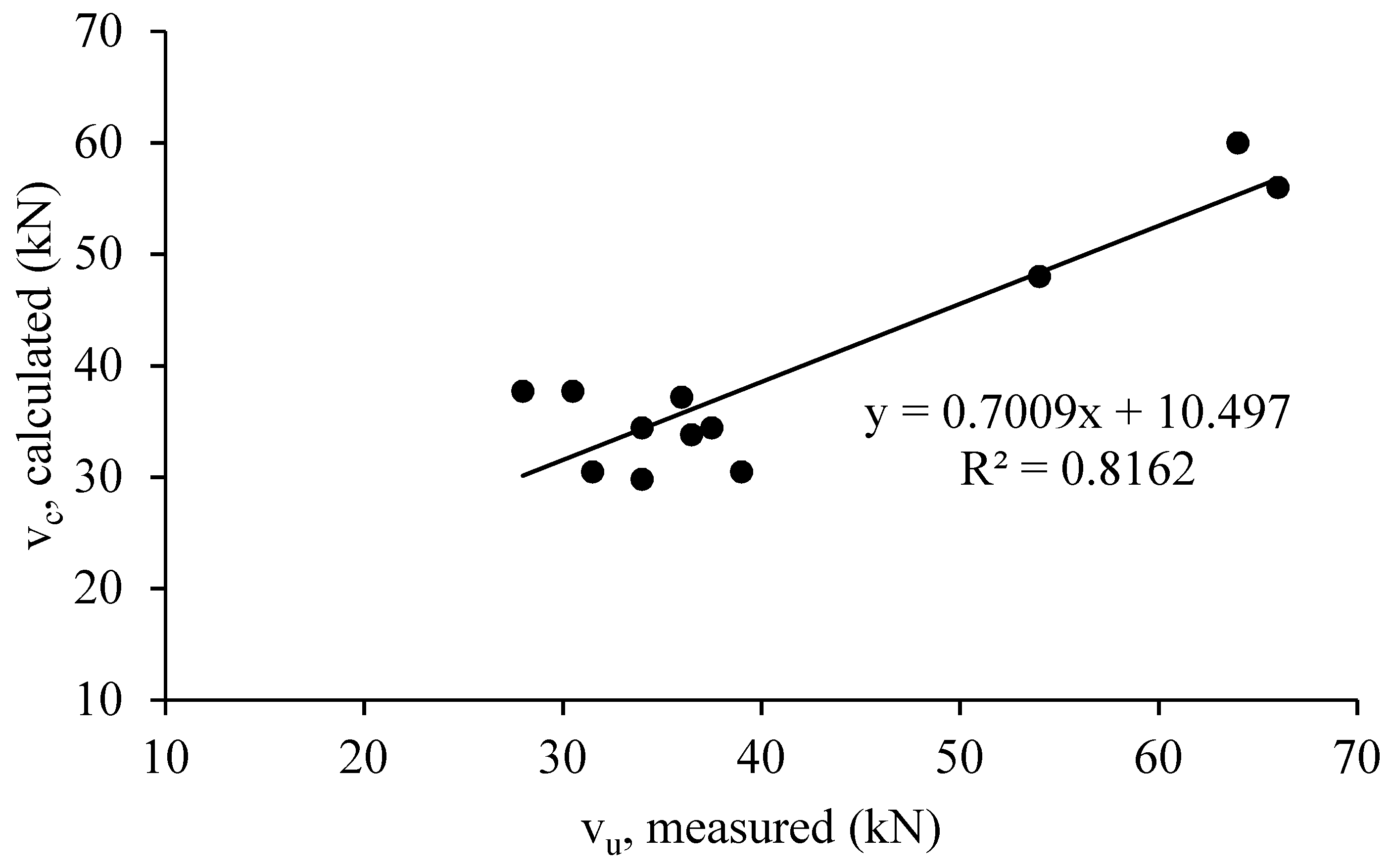

The experimental results demonstrated that fewer cracks and only minor damage were induced to the ECC and HyFRC corbels, Moreover, as displayed in the figure, compared to SFRC corbels, fewer and finer cracks were induced to the ECC and HyFRC corbels, which make them superior in terms of durability, service life, and sustainability compared to SFRC corbels. The comparison of the analytical models and the measured shear capacity of corbels shows very slight variation, which provides reasonable arguments for the suitability of the models of Fattuhi [

7] and Foster et al. [

12] for the design of corbels made of HyFRC, ECC, and SFRC. However, generalization of the models needs more research and empirical evidence.