Effect of Residual Stress on Thermal Deformation Behavior

Abstract

1. Introduction

2. Experimental Procedure

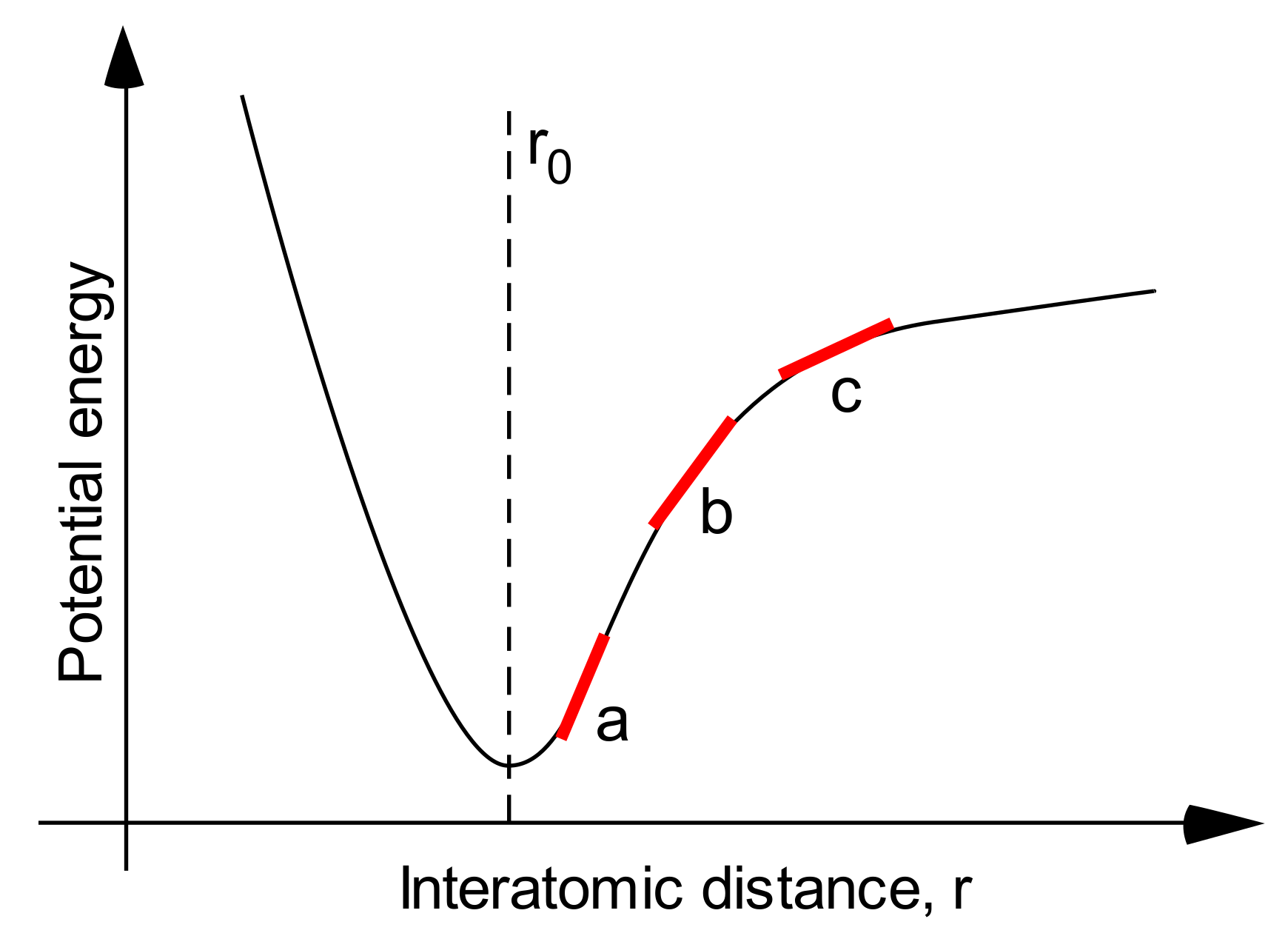

2.1. Principle of Operation

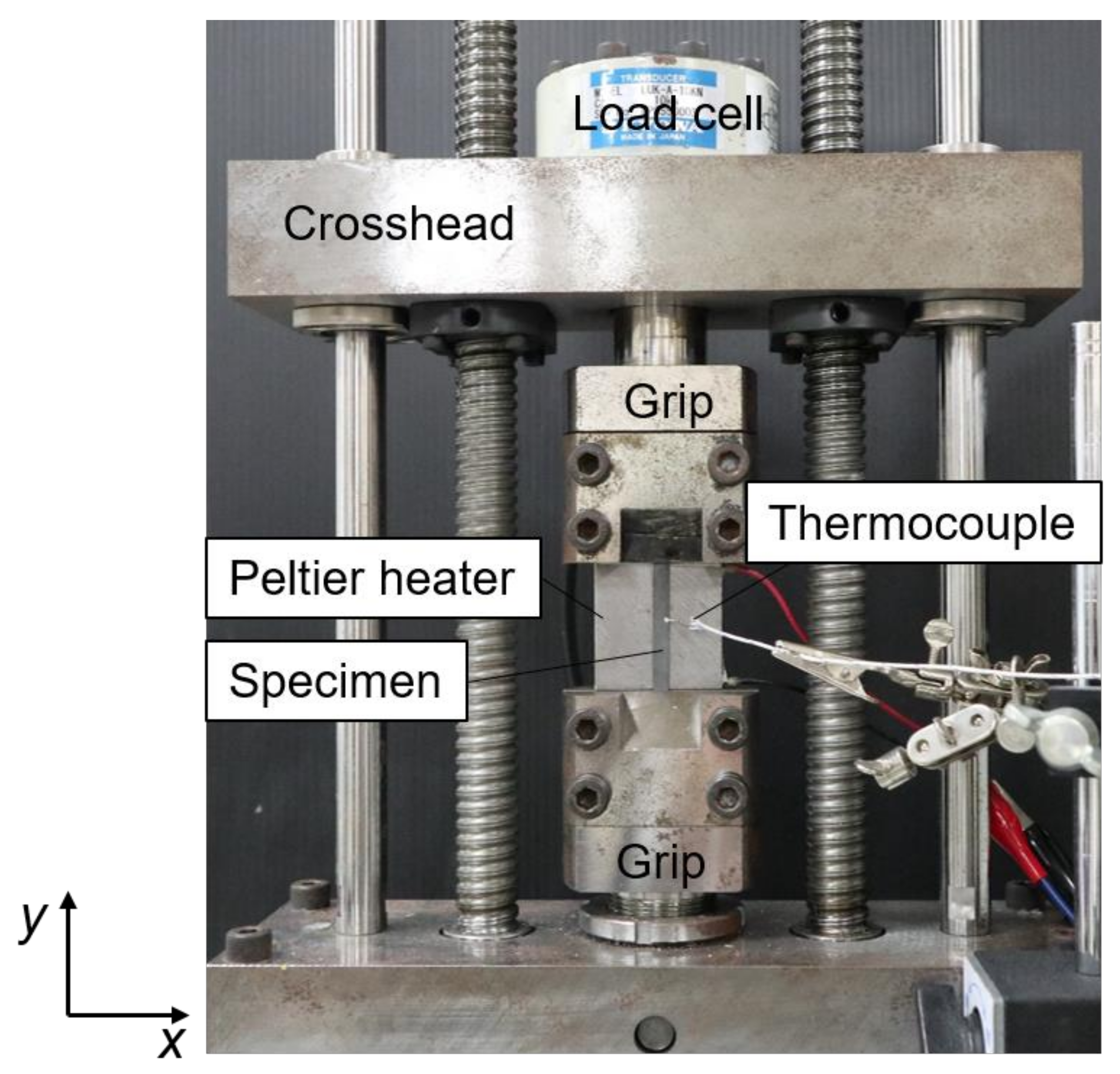

2.2. Thermal Expansion Test for Initial Calibration with Gripped Specimen

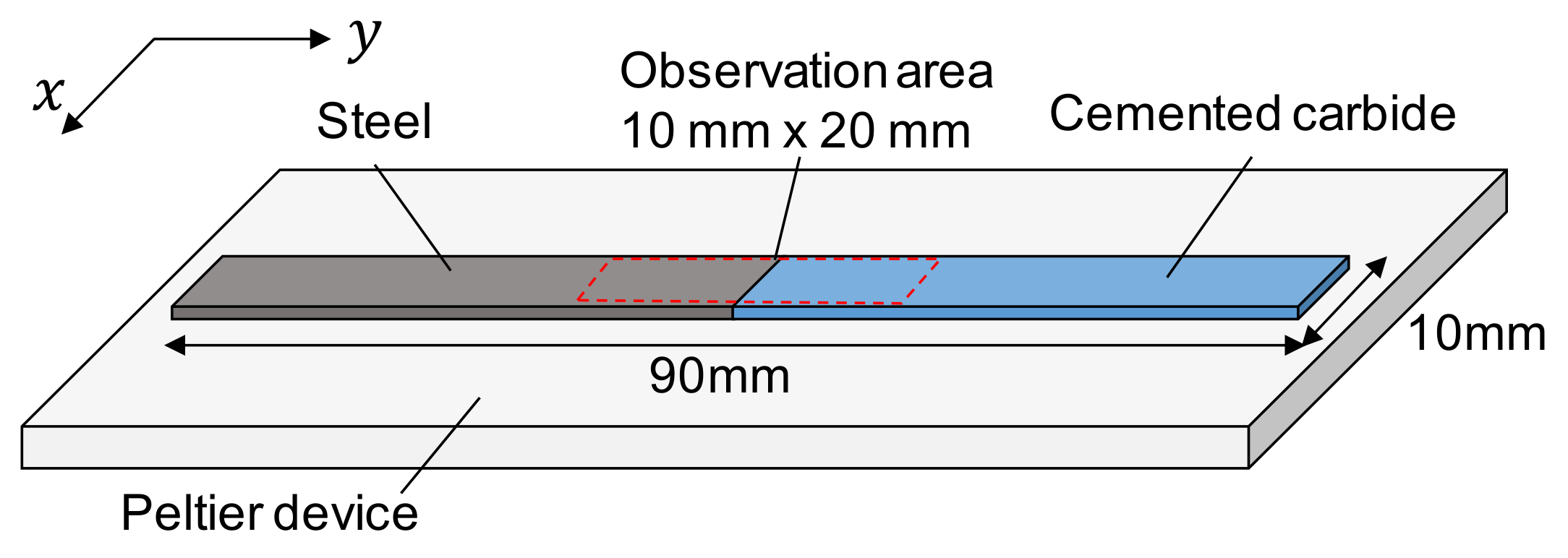

2.3. Thermal Expansion Test for a Dissimilar Joint

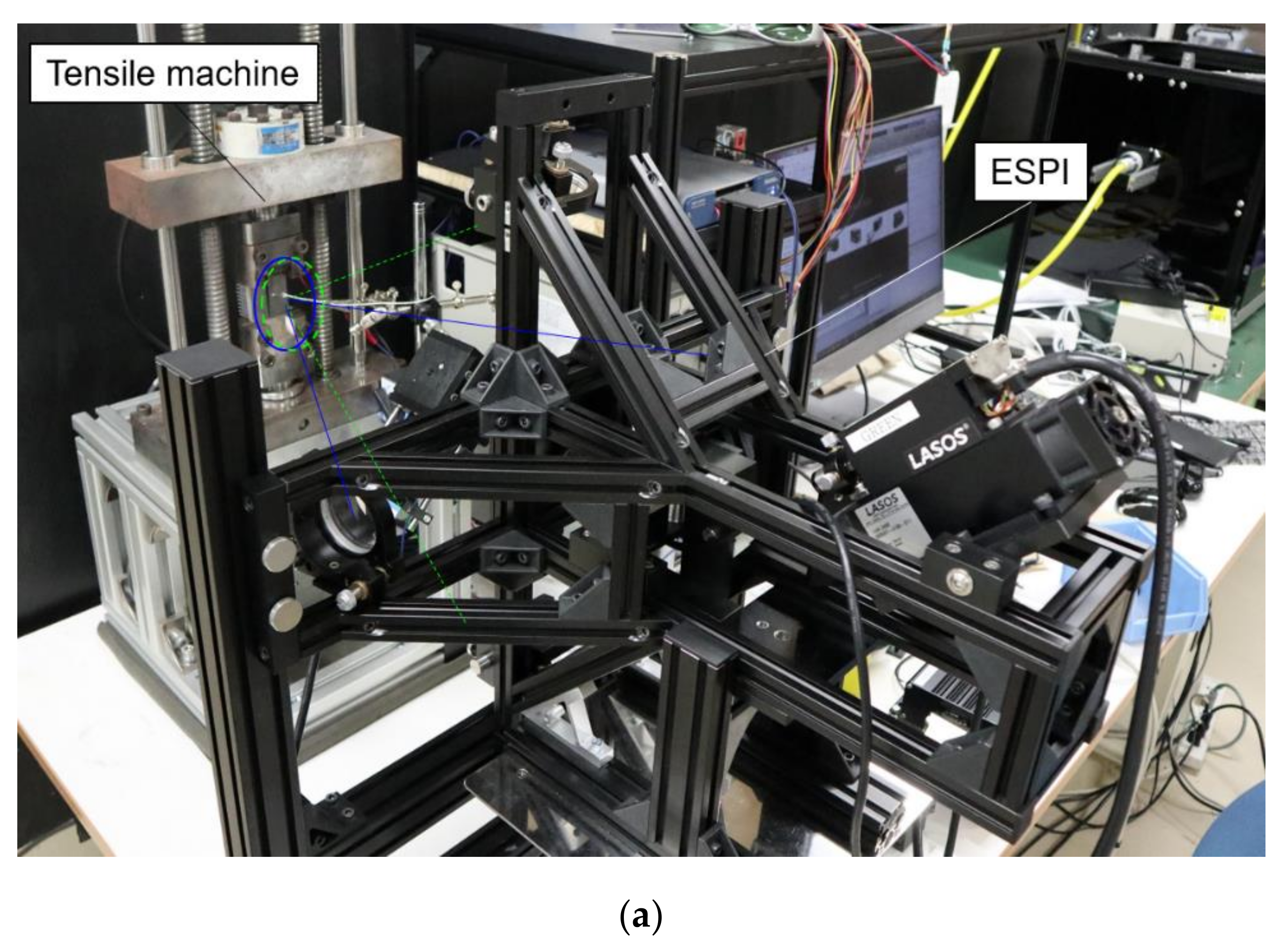

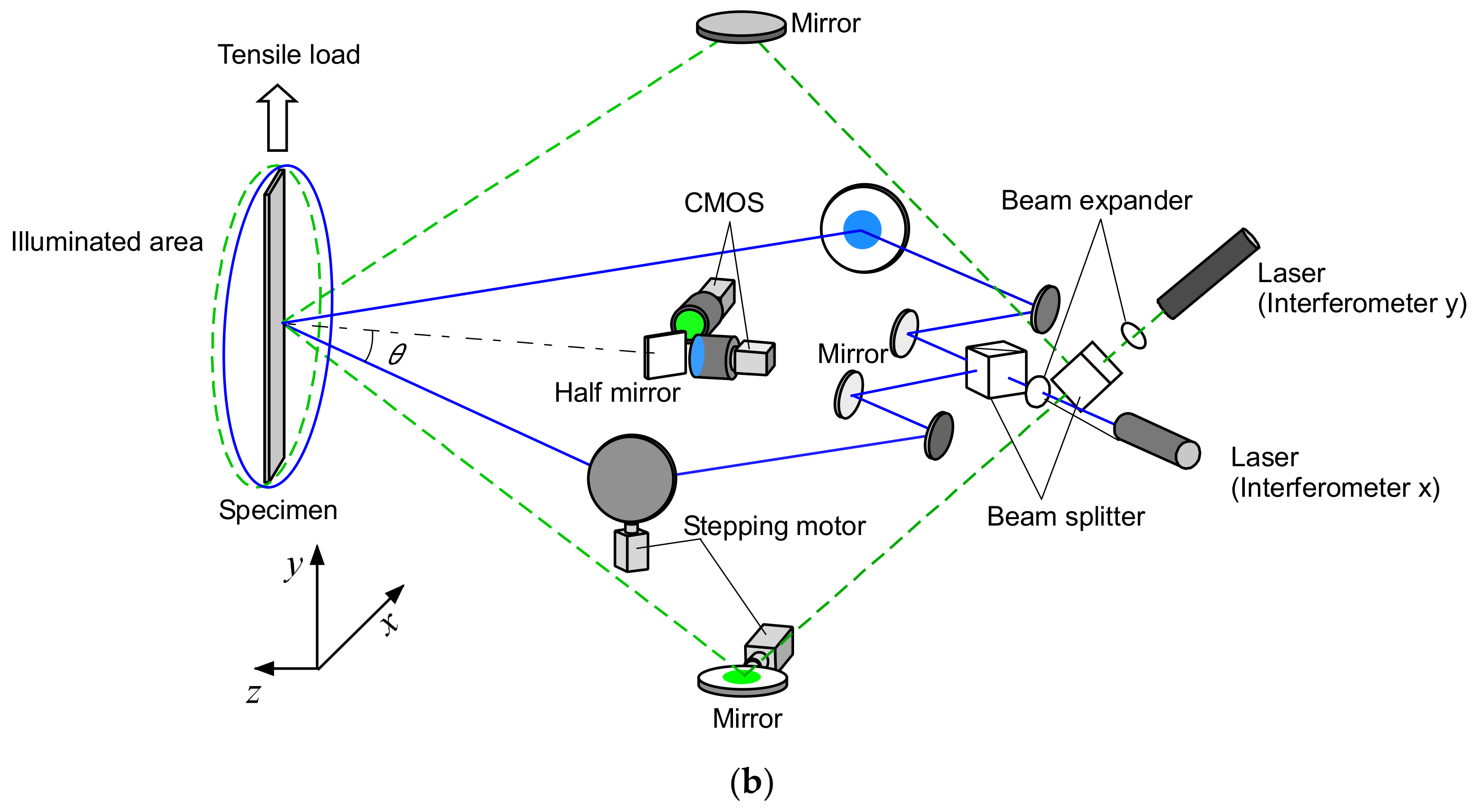

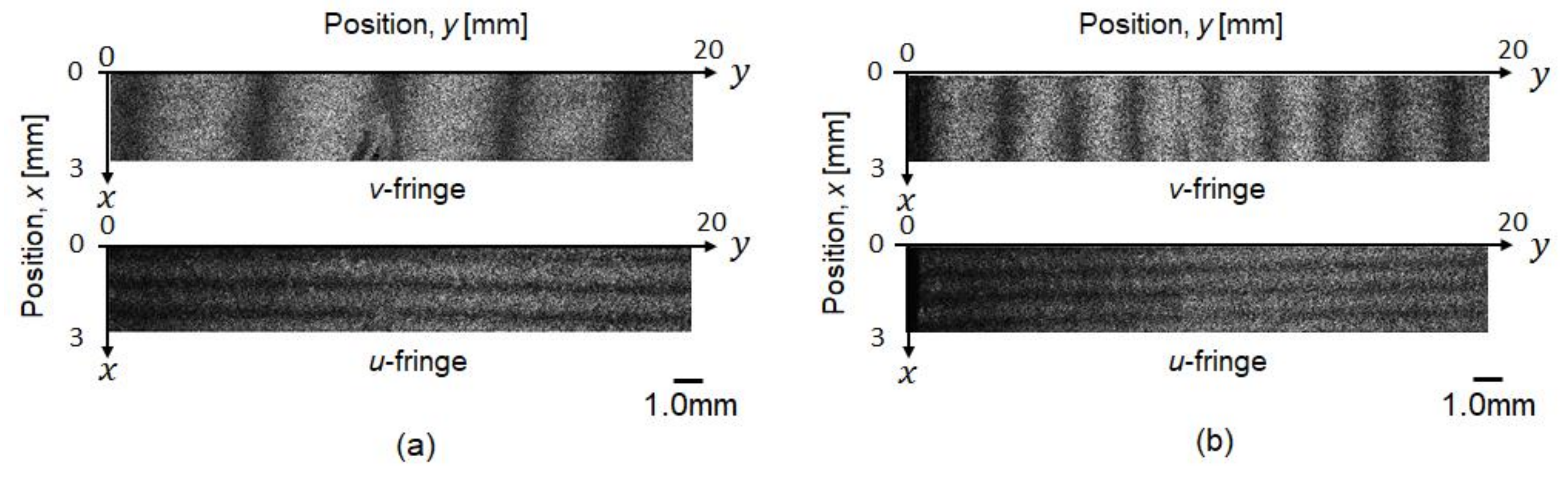

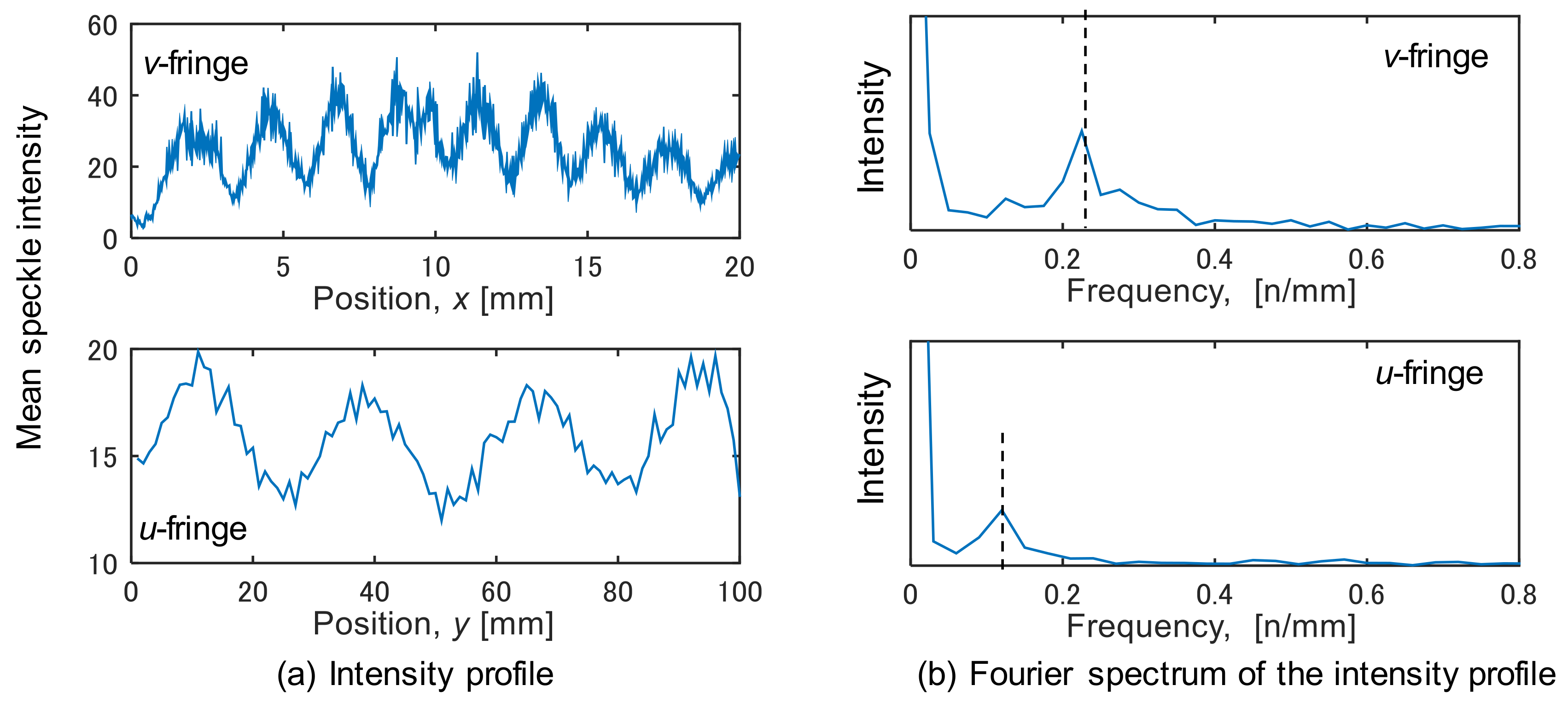

2.4. Electronic Speckle-Pattern Interferometry (ESPI)

3. Results and Discussion

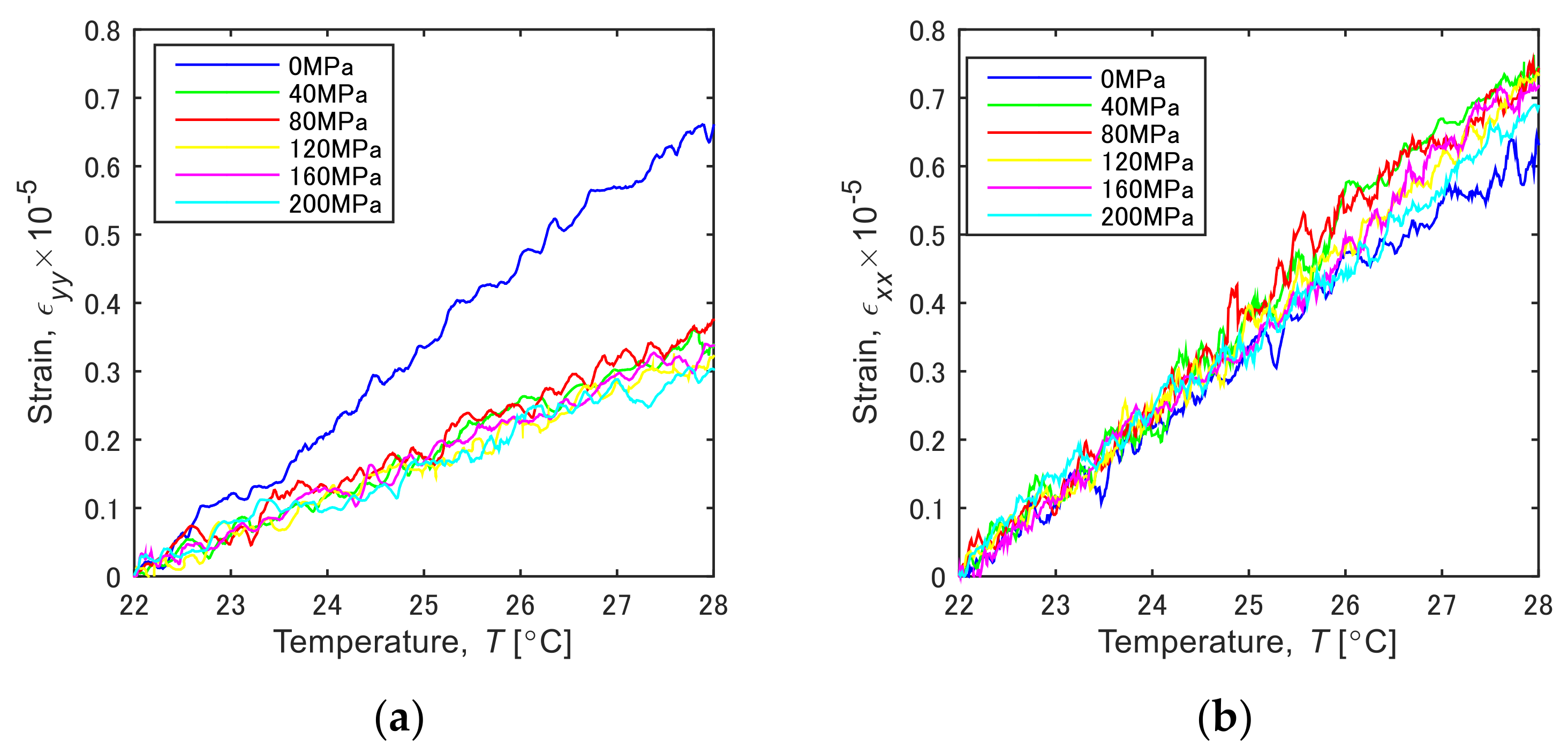

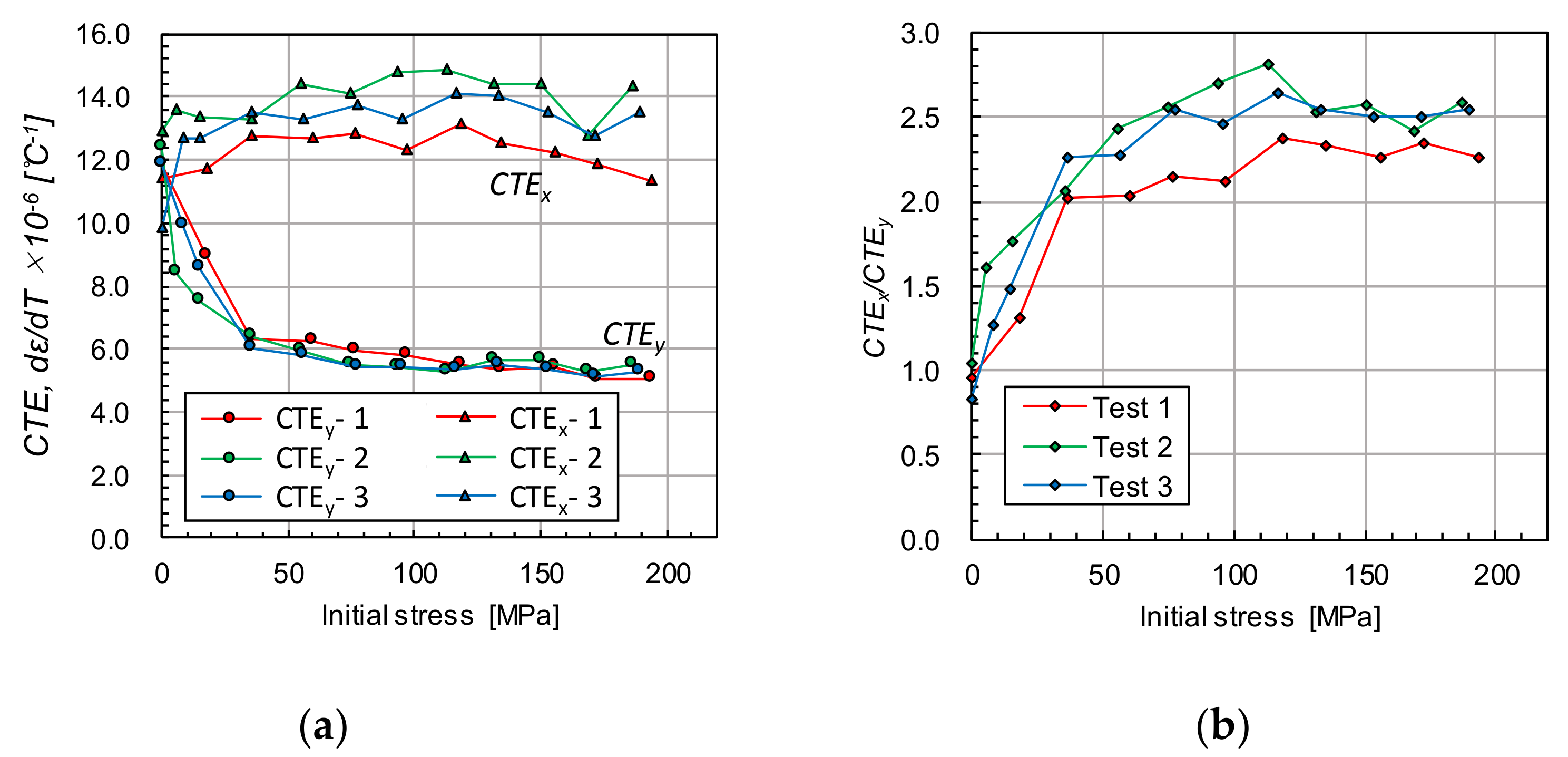

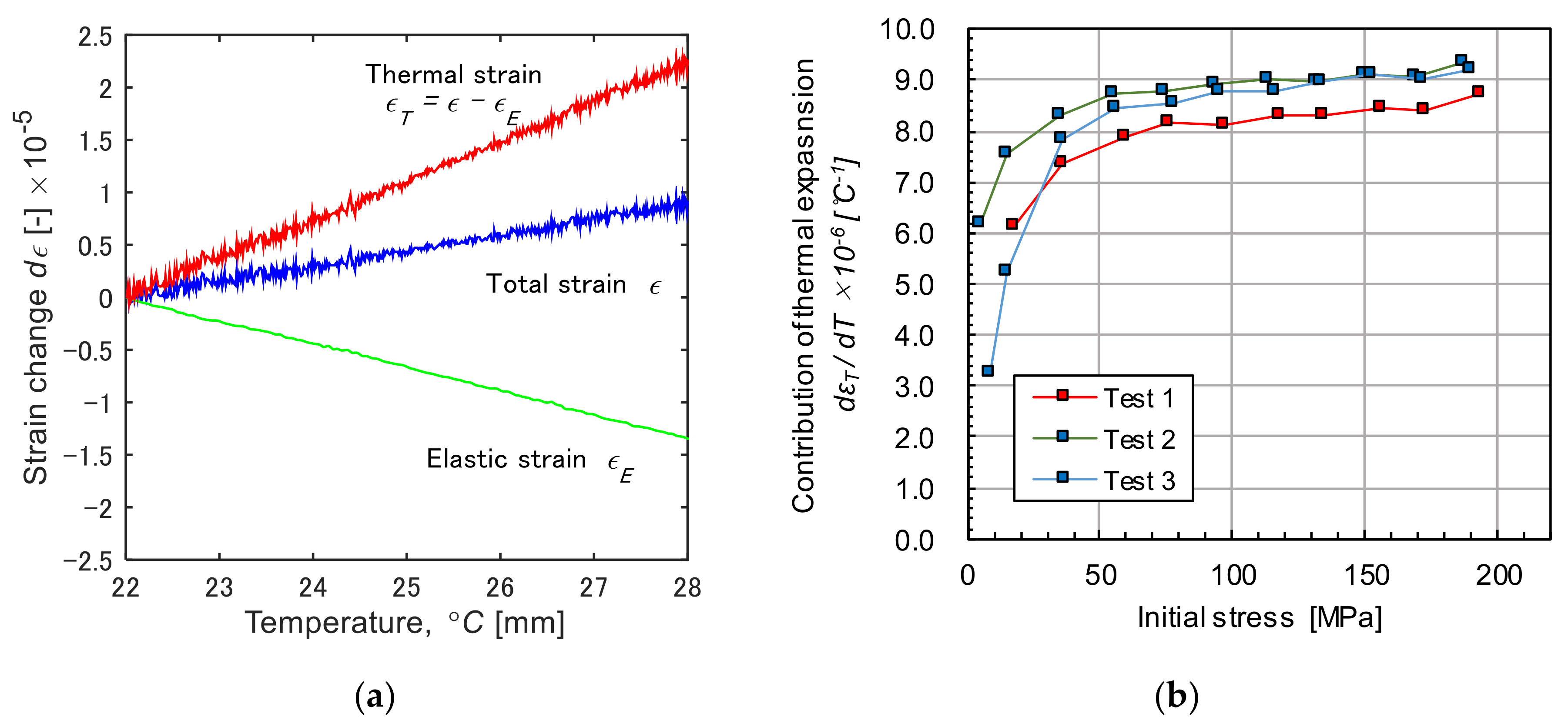

3.1. Effect of External Restraint on Thermal Deformation Behavior

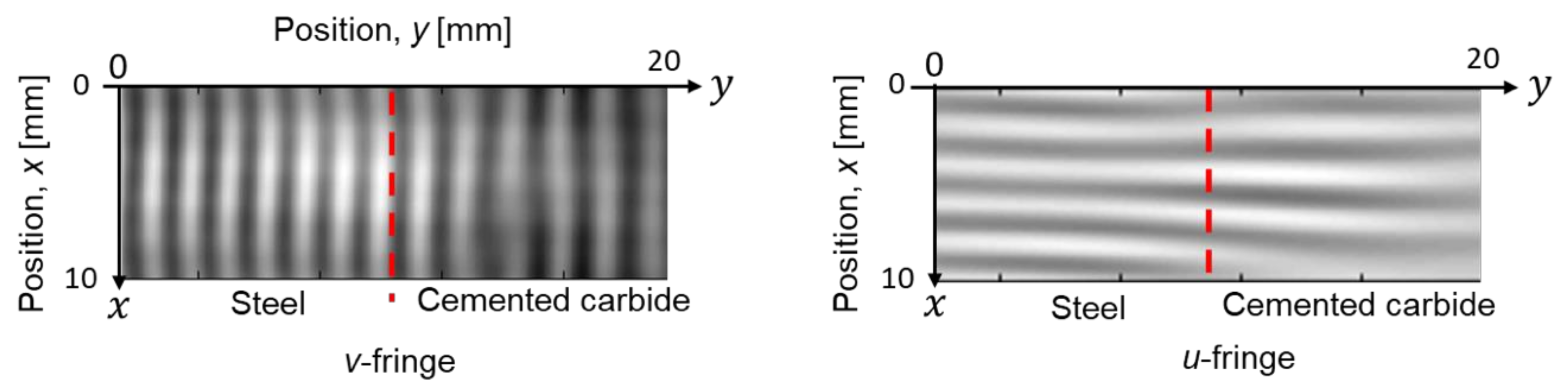

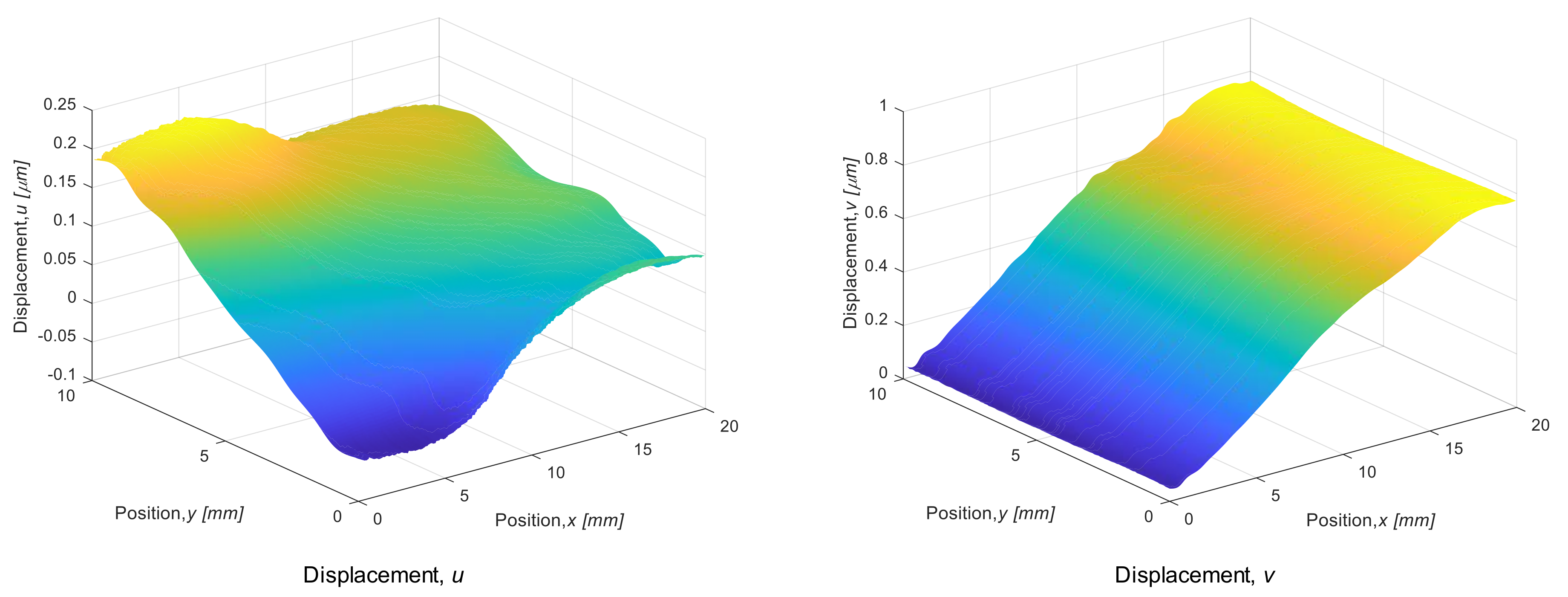

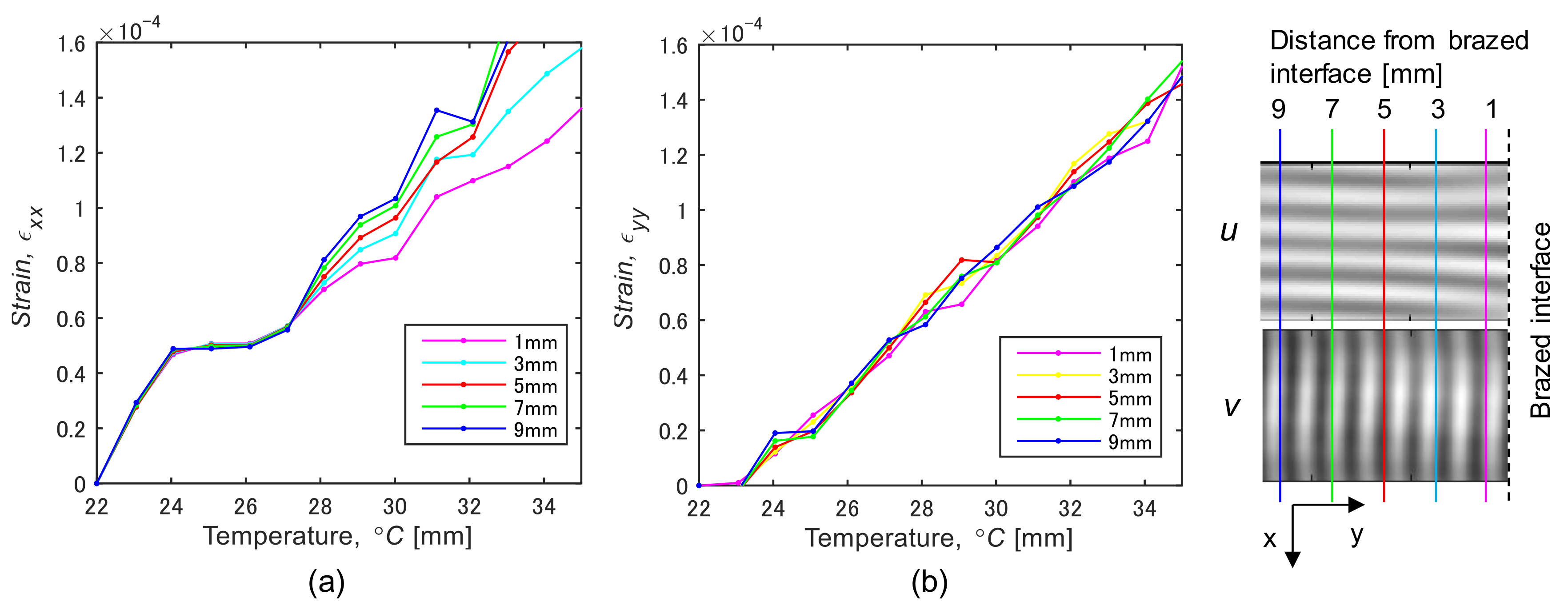

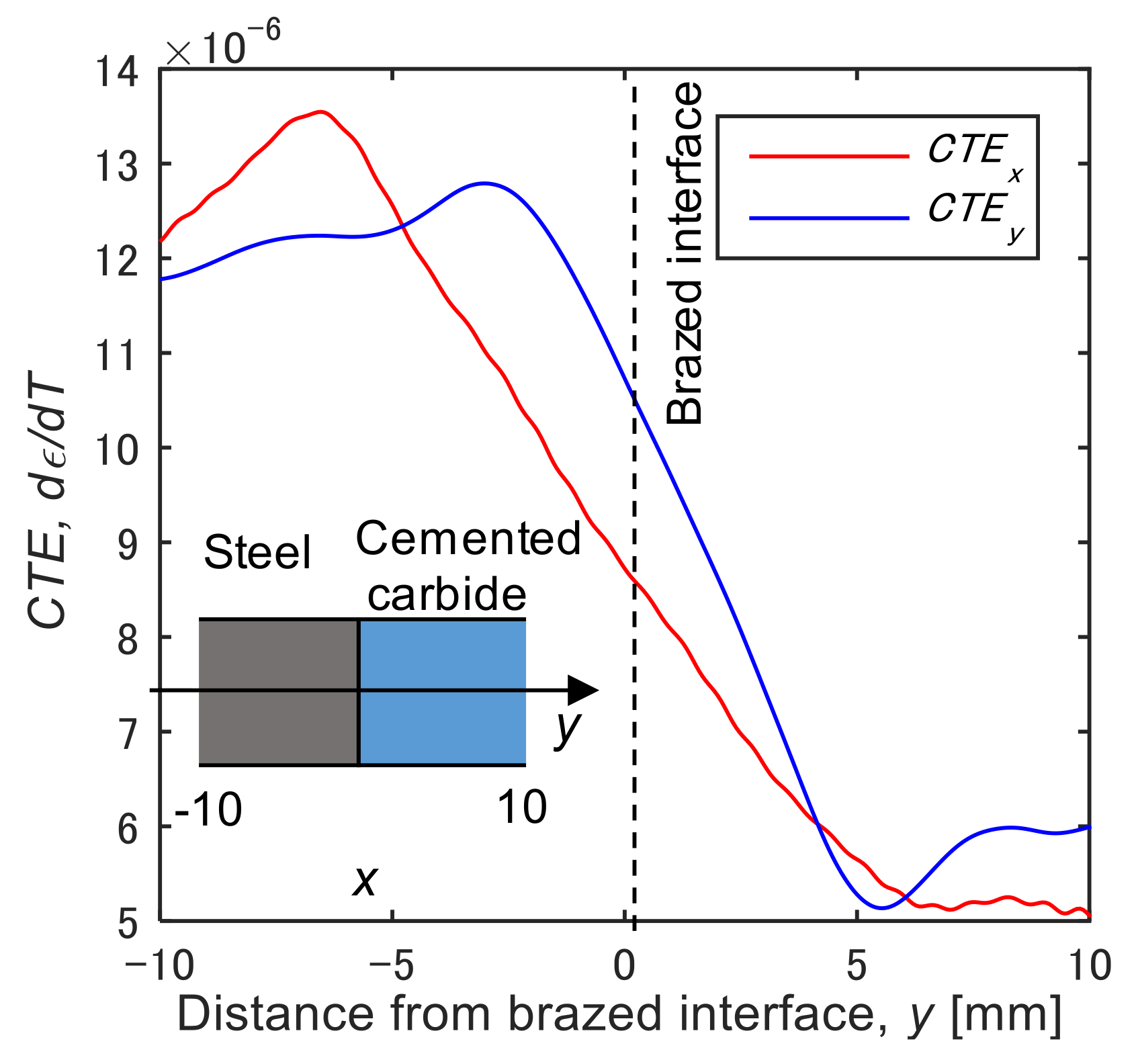

3.2. Thermal Deformation of Dissimilar Joint

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Fitzpatrick, M.E.; Fry, A.T.; Holdway, P.; Kandil, F.A.; Shackleton, J.; Suominen, L. Determination of Residual Stresses by X-Ray Diffraction—Issue 2; Measurement Good Practice Guide No. 52; National Physical Laboratory: Teddington, UK, 2005. [Google Scholar]

- Lorentzen, T.; Ibsø, J.B. Neutron diffraction measurements of residual strains in offshore welds. Mater. Sci. Eng. A 1995, 197, 209–214. [Google Scholar] [CrossRef]

- Hughes, D.S.; Kelly, J.L. Second-order elastic deformation of solids. Phys. Rev. 1953, 92, 1145–1149. [Google Scholar] [CrossRef]

- Dorfi, H.R.; Busby, H.R.; Janssen, M. Ultrasonic stress measurements based on the generalized acoustic ratio technique. Int. J. Solids Struct. 1996, 33, 1157–1174. [Google Scholar] [CrossRef]

- Ya, M.; Marquette, P.; Belahcene, F.; Lu, J. Residual stresses in laser welded aluminium plate by use of ultrasonic and optical methods. Mater. Sci. Eng. A 2004, 382, 257–264. [Google Scholar] [CrossRef]

- Ya, M.; Miao, H.; Zhang, X.; Lu, J. Determination of residual stress by use of phase shifting moiré interferometry and hole-drilling method. Opt. Lasers Eng. 2006, 44, 68–79. [Google Scholar]

- Pedrini, G.; Martínez-García, V.; Weidmann, P.; Wenzelburger, M.; Killinger, A.; Weber, U.; Schmauderc, S.; Gadow, R.; Osten, W. Residual Stress Analysis of Ceramic Coating by Laser Ablation and Digital Holography. Exp. Mech. 2016, 56, 683–701. [Google Scholar] [CrossRef]

- Martínez-García, V.; Pedrini, G.; Weidmannc, P.; Killinger, A.; Gadow, A.R.; Osten, W.; Schmauderc, S. Non-contact residual stress analysis method with displacement measurements in the nanometric range by laser made material removal and SLM based beam conditioning on ceramic coatings. Surf. Coat. Technol. 2019, 371, 14–19. [Google Scholar] [CrossRef]

- Fujigaki, M.; Nishitani, R.; Morimoto, Y. Strain Measurement Using Phase-shifting Digital Holography with Two Cameras. In Proceedings of the 14th International Conference on Experimental Mechanics, Poitiers, France, 4–9 July 2010. [Google Scholar] [CrossRef]

- Steinzig, M.; Ponslet, E. Residual stress measurement using the hole drilling method and laser speckle interferometry: Part I. Exp. Tech. 2003, 27, 43–46. [Google Scholar] [CrossRef]

- Schajer, G.S.; Steinziq, M. Dual-axis hole-drilling ESPI residual stress measurement. J. Eng. Mater. Technol. 2009, 132, 011007. [Google Scholar] [CrossRef]

- Schajer, G.S. Advances in hole-drilling residual stress measurement. Exp. Mech. 2010, 50, 59–68. [Google Scholar] [CrossRef]

- Rickert, T. Residual Stress Measurement by ESPI Hole-Drilling. Procedia CIRP 2016, 46, 203–206. [Google Scholar] [CrossRef]

- Pisarev, V.S.; Balalov, V.V. A role of fringe pattern catalogue in the course of interferometrically based determination of residual stresses by the hole-drilling method. Opt. Lasers Eng. 2004, 41, 411–462. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Pappalettere, C. Analysis of the effects of process parameters in residual stress measurements on Titanium plates by HDM/ESPI. Measurement 2014, 48, 220–227. [Google Scholar] [CrossRef]

- Pisarev, V.; Odintsev, I.; Eleonsky, S.; Apalkov, A. Residual stress determination by optical interferometric measurements of hole diameter increments. Opt. Lasers Eng. 2018, 110, 437–456. [Google Scholar] [CrossRef]

- Hung, M.Y.Y.; Long, K.W.; Wang, J.Q. Measurement of residual stress by phase shift shearography. Opt. Lasers Eng. 1997, 27, 61–73. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Pappalettere, C. Acoustic Emission Analysis of Aluminum Specimen Subjected to Laser Annealing. In Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and Inverse Problems; Springer: Berlin/Heidelberg, Germany, 2014; Volume 8, pp. 309–315. [Google Scholar]

- McGinnis, M.J.; Pessiki, S.; Turker, H. Application of three-dimensional digital image correlation to the core-drilling method. Exp. Mech. 2005, 45, 359–367. [Google Scholar] [CrossRef]

- Hagara, M.; Trebuna, F.; Pástor, M.; Hunˇady, R.; Lengvarsky, P. Analysis of the aspects of residual stresses quantification performed by 3D DIC combined with standardized hole-drilling method. Measurement 2019, 137, 238–256. [Google Scholar] [CrossRef]

- Goodman, J. Speckle Phenomena in Optics: Theory and Applications; Roberts and Company Publishers: Arapahoe County, CO, USA, 2006. [Google Scholar]

- Bianco, V.; Memmolo, P.; Leo, M.; Montresor, S.; Cosimo, D.; Paturzo, M.; Picart, P.; Javidi, B.; Ferraro, P. Strategies for reducing speckle noise in digital holography. Light Sci. Appl. 2018, 7. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, S.; Sasaki, T.; Craft, S.; Usui, M.; Haase, J.; Becker, T.; Park, I.K. Stress Analysis on Welded Specimen with Multiple Methods. Adv. Opt. Methods Exp. Mech. 2014, 3, 143–152. [Google Scholar]

- Yoshida, S.; Sasaki, T.; Usui, M.; Sakamoto, S.; Gurney, D.; Park, I.K. Residual Stress Analysis Based on Acoustic and Optical Method. Materials 2016, 9. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, S.; Miura, F.; Sasaki, T.; Didie, D.; Rouhi, S. Optical Analysis of Residual Stress with Minimum Invasion. In Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and Inverse Problems; Springer: Cham, Switzerland, 2017; Volume 8, pp. 65–72. [Google Scholar]

- Yoshida, S. Deformation and Fracture of Solid-State Materials; Springer: New York, NY, USA, 2015; pp. 165–170. [Google Scholar]

| Initial stress [MPa] | 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 |

| Stress drop [MPa] | 9.1 | 15.4 | 35.7 | 40.6 | 44.1 | 44.5 | 45.9 | 44.4 | 47.1 | 49.6 | 47.5 | 50.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sasaki, T.; Yoshida, S.; Ogawa, T.; Shitaka, J.; McGibboney, C. Effect of Residual Stress on Thermal Deformation Behavior. Materials 2019, 12, 4141. https://doi.org/10.3390/ma12244141

Sasaki T, Yoshida S, Ogawa T, Shitaka J, McGibboney C. Effect of Residual Stress on Thermal Deformation Behavior. Materials. 2019; 12(24):4141. https://doi.org/10.3390/ma12244141

Chicago/Turabian StyleSasaki, Tomohiro, Sanichiro Yoshida, Tadashi Ogawa, Jun Shitaka, and Conor McGibboney. 2019. "Effect of Residual Stress on Thermal Deformation Behavior" Materials 12, no. 24: 4141. https://doi.org/10.3390/ma12244141

APA StyleSasaki, T., Yoshida, S., Ogawa, T., Shitaka, J., & McGibboney, C. (2019). Effect of Residual Stress on Thermal Deformation Behavior. Materials, 12(24), 4141. https://doi.org/10.3390/ma12244141