Tailoring Strength and Ductility of a Cr-Containing High Carbon Steel by Cold-Working and Annealing

Abstract

1. Introduction

2. Materials and Methods

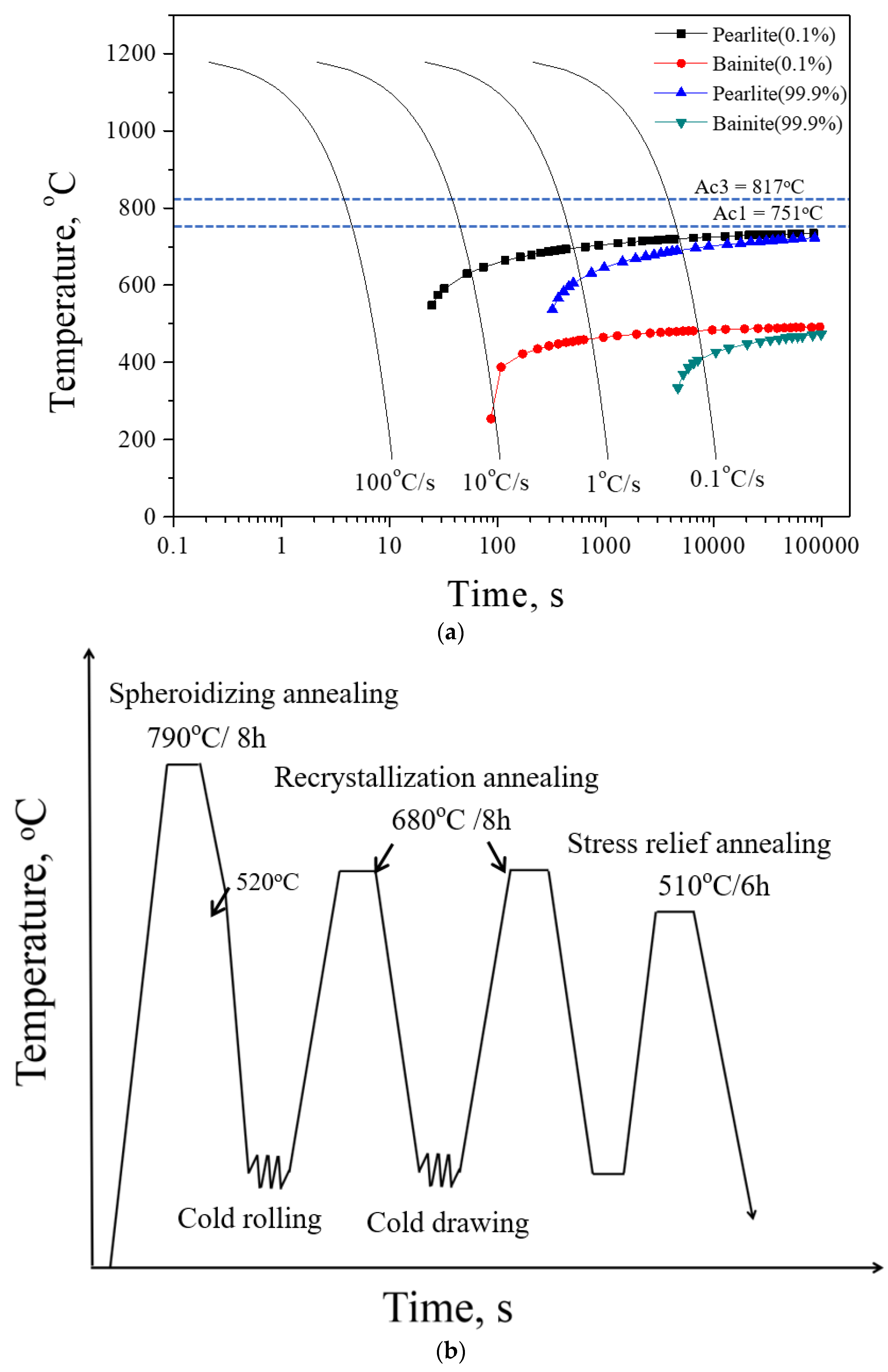

2.1. Sample Preparation

2.2. Microstructural Characterization

2.3. Mechanical Properties Tests

2.4. Simulation of the Cold Rolling Process

3. Results

3.1. Microstructure Characteristics

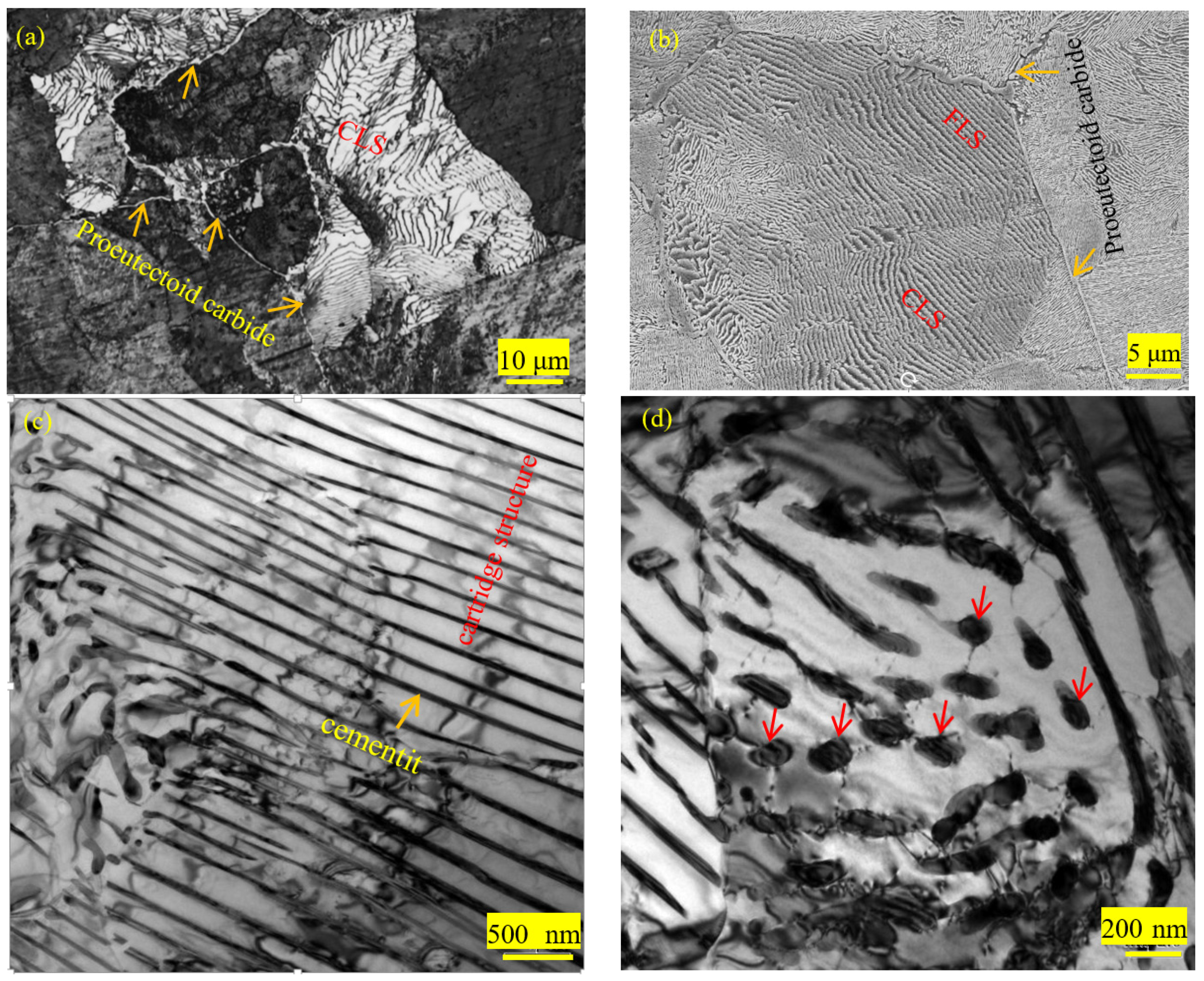

3.1.1. Hot Rolled 1.0C-1.5Cr Steel

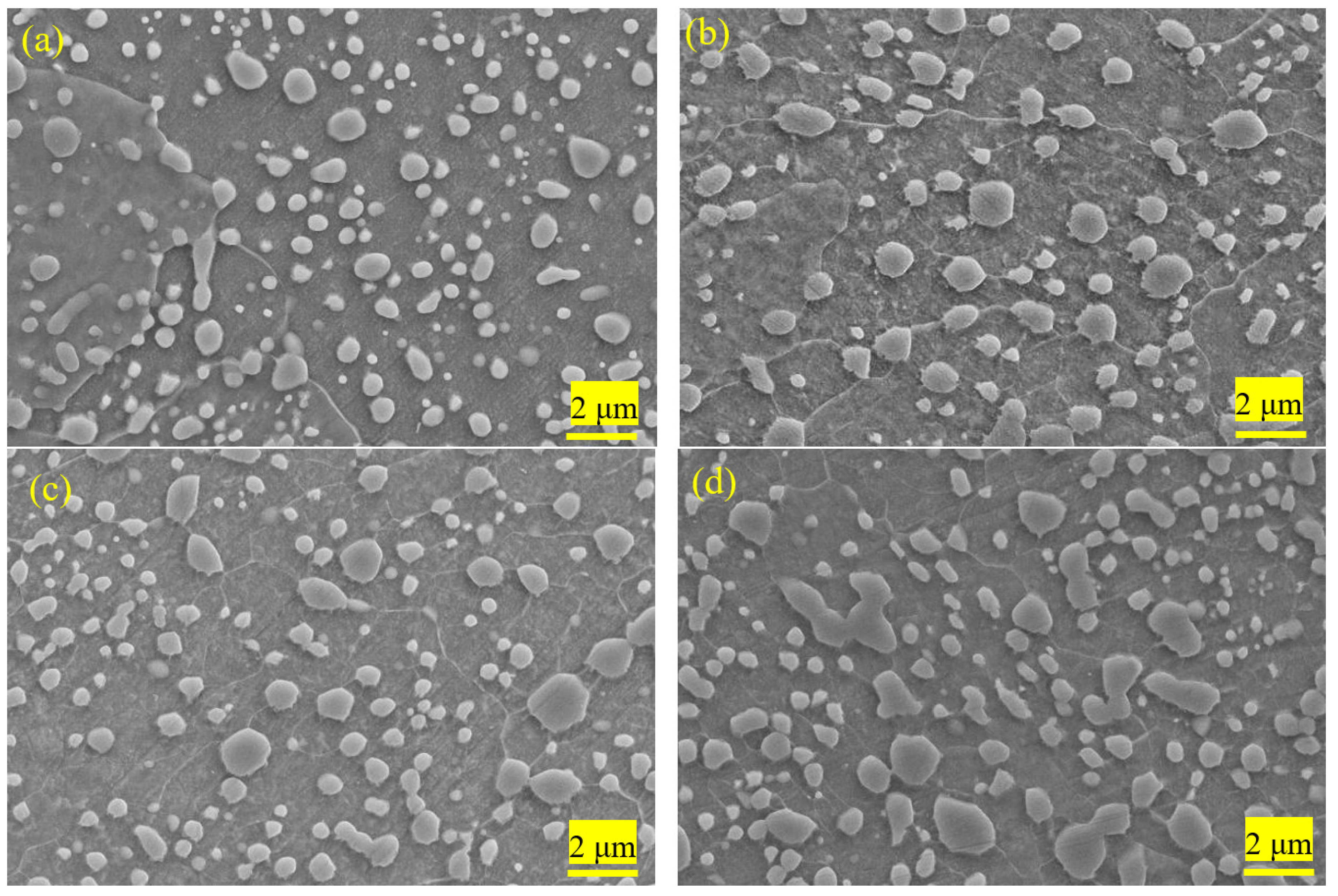

3.1.2. Cementite Size in 1.0C-1.5Cr Steel after Different Processes

3.1.3. EBSD Analysis of 1.0C-1.5Cr Steel after Different Processes

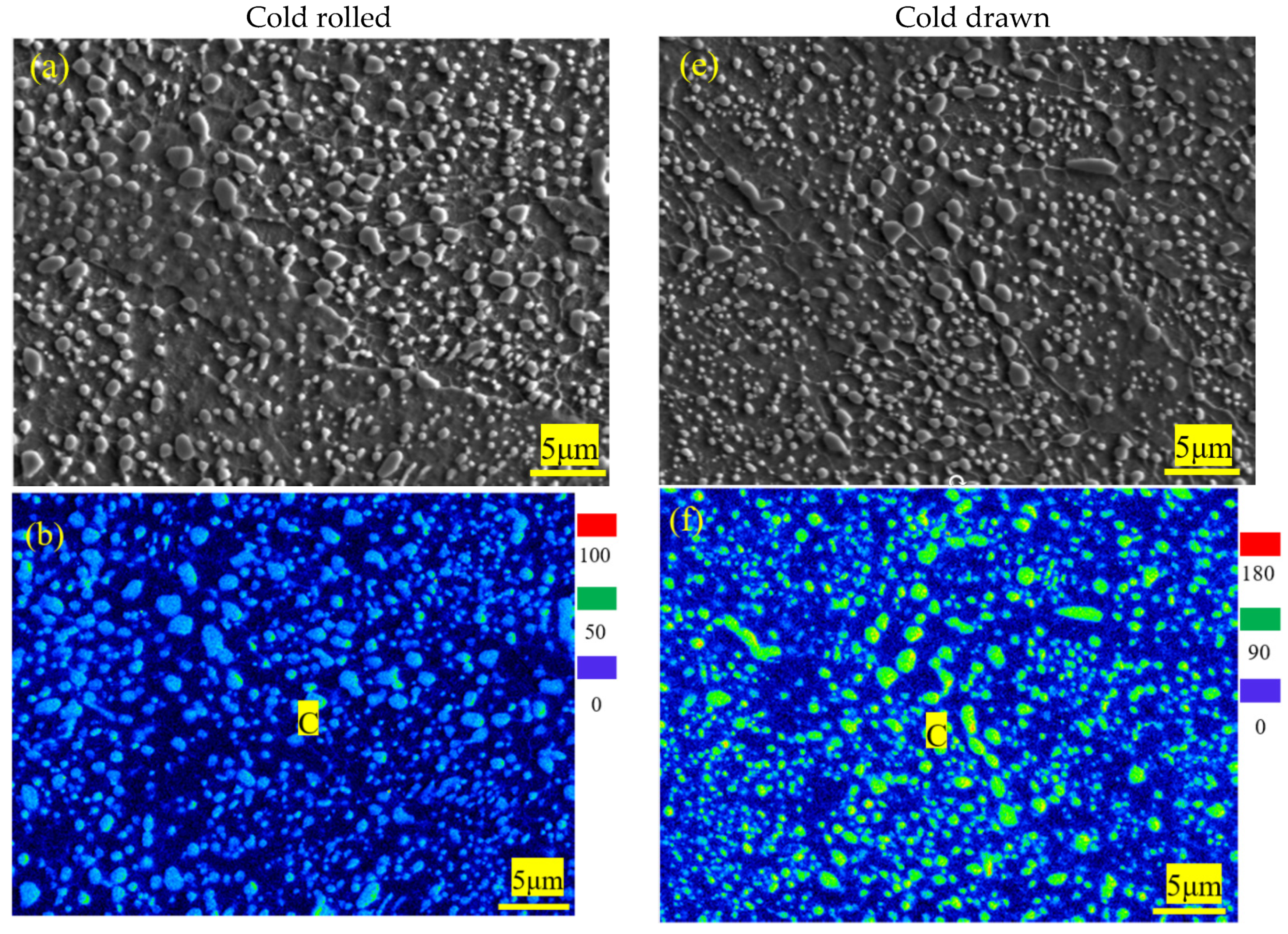

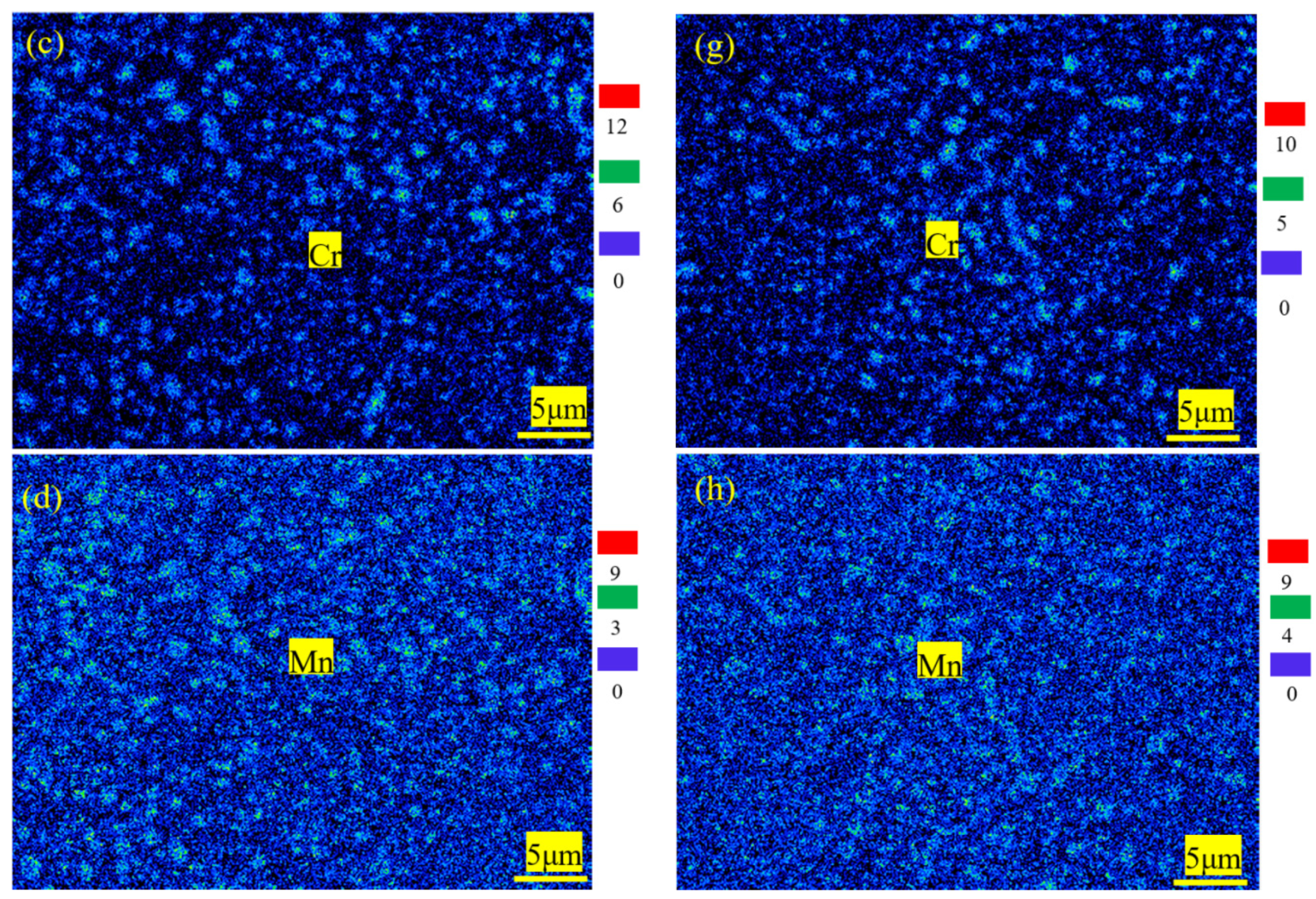

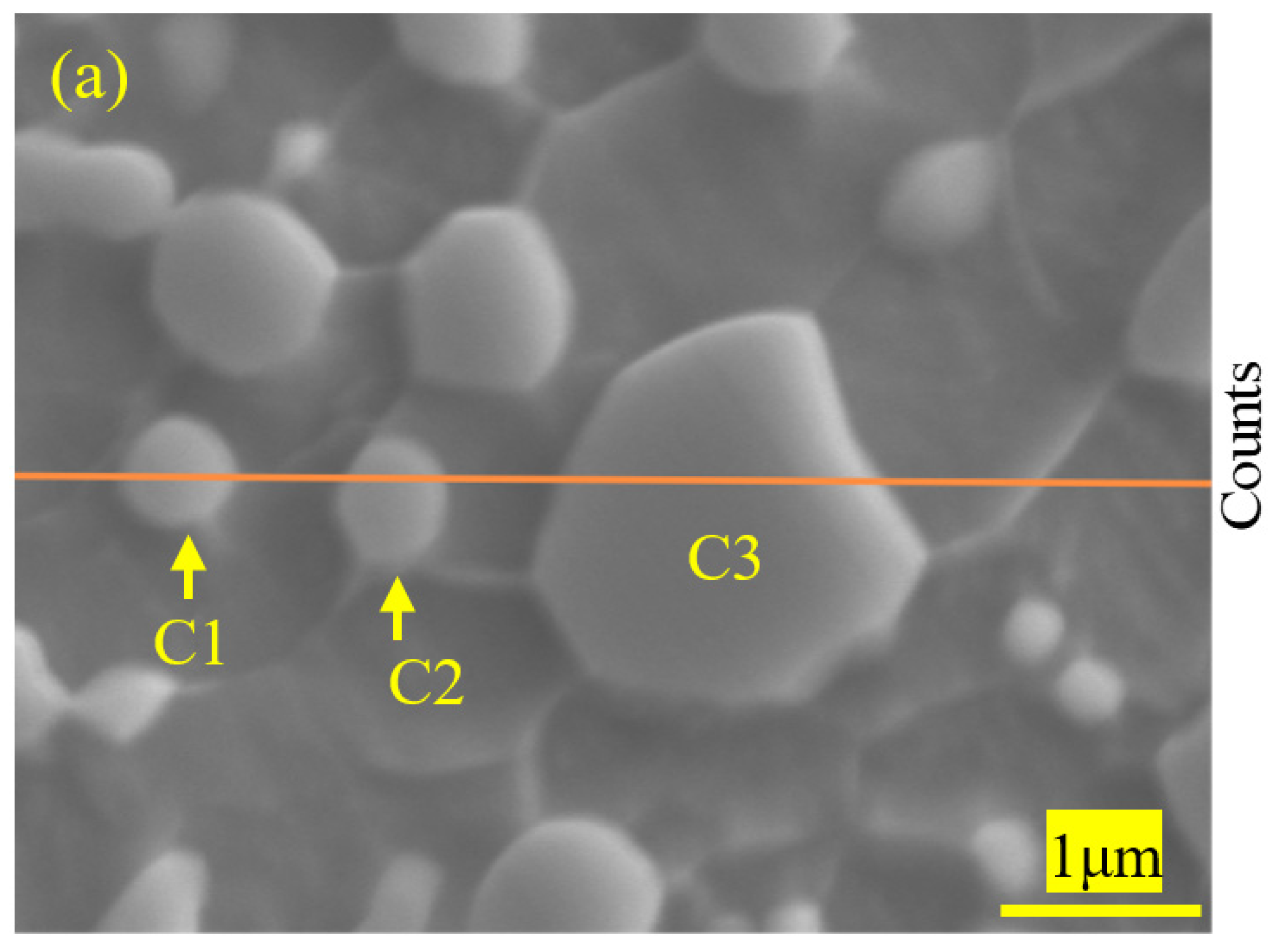

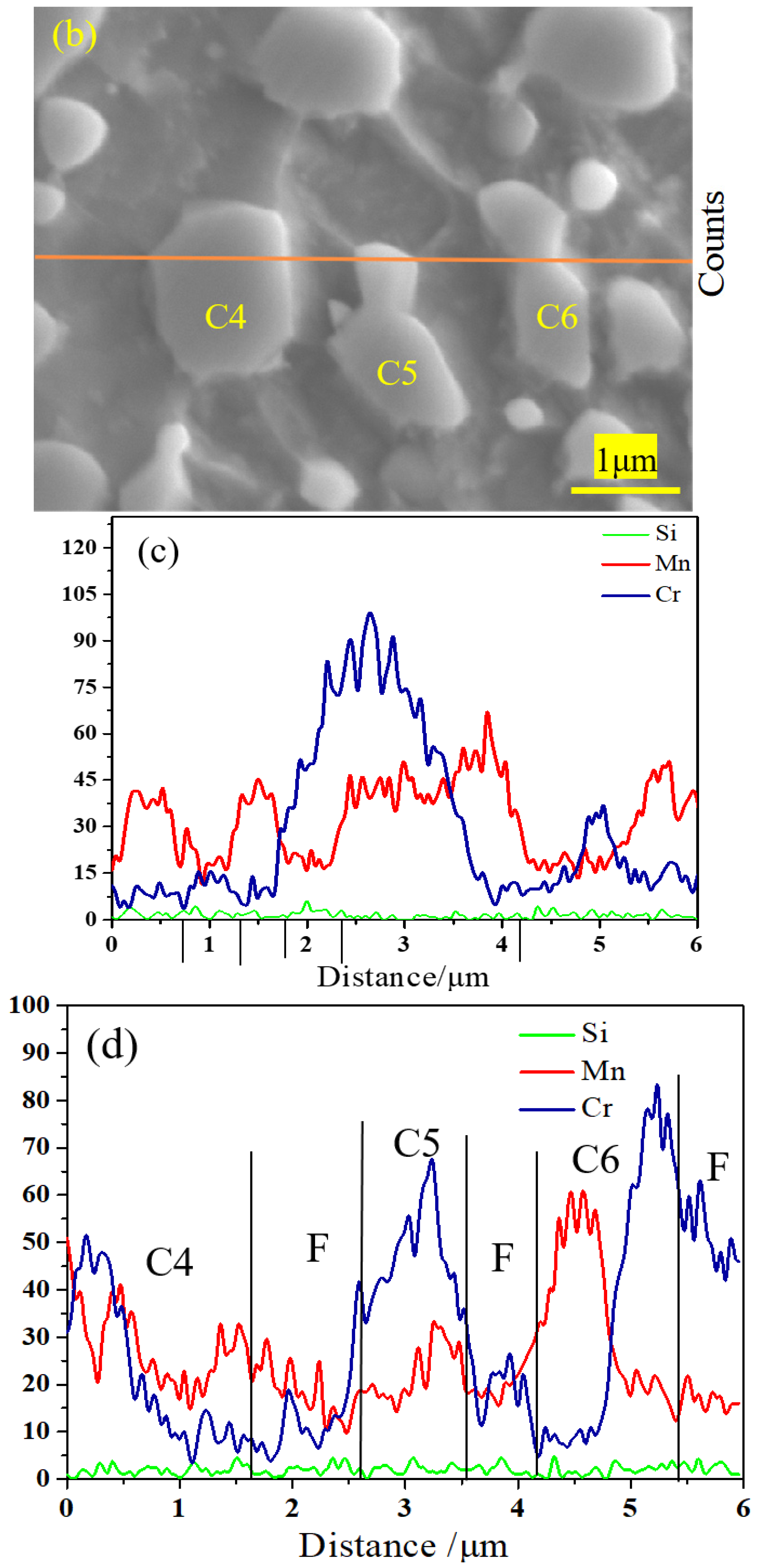

3.1.4. EPMA Maps and Energy Dispersive Spectroscopy (EDS) of 1.0C-1.5Cr Steel after Cold-Working

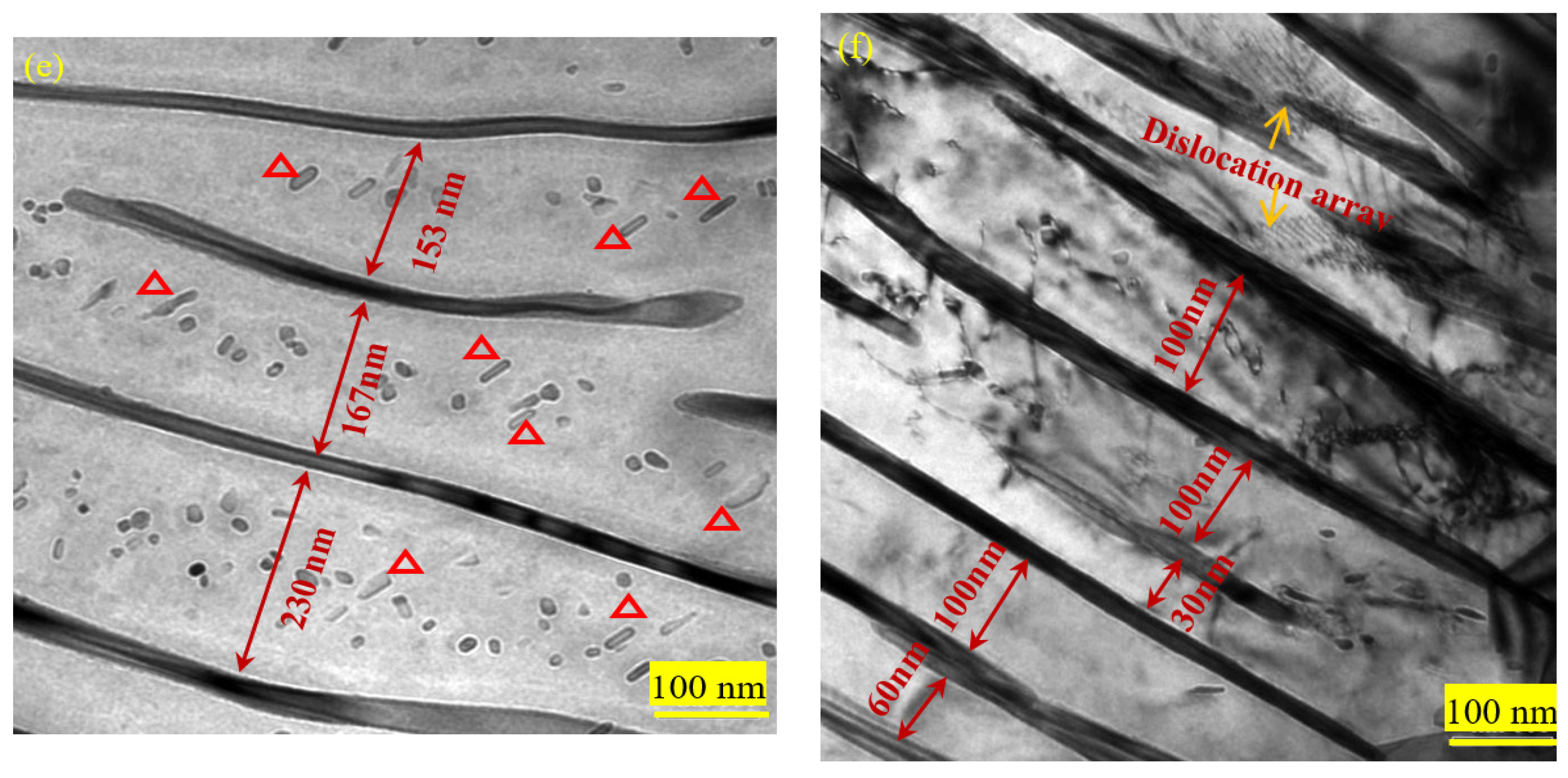

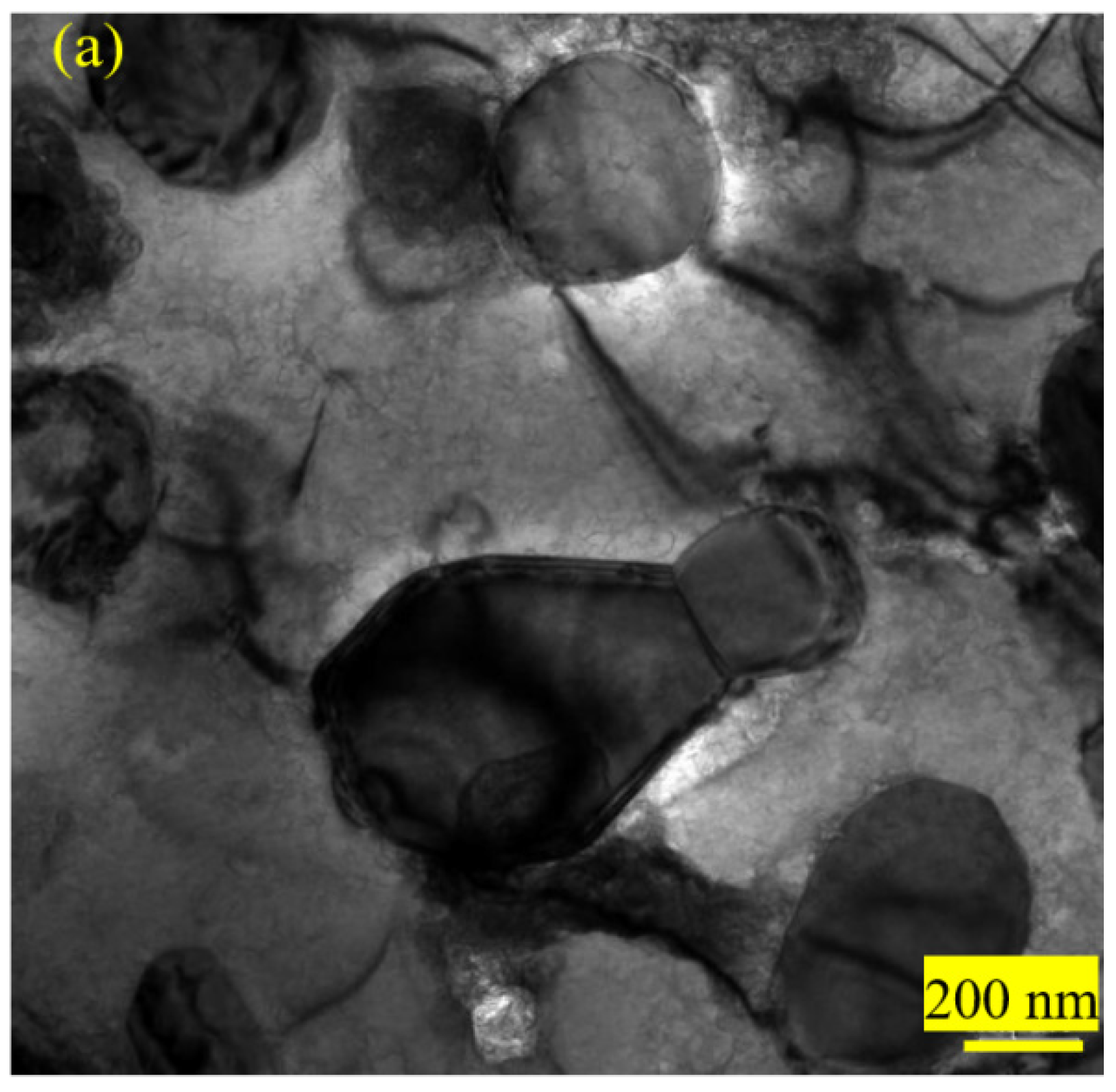

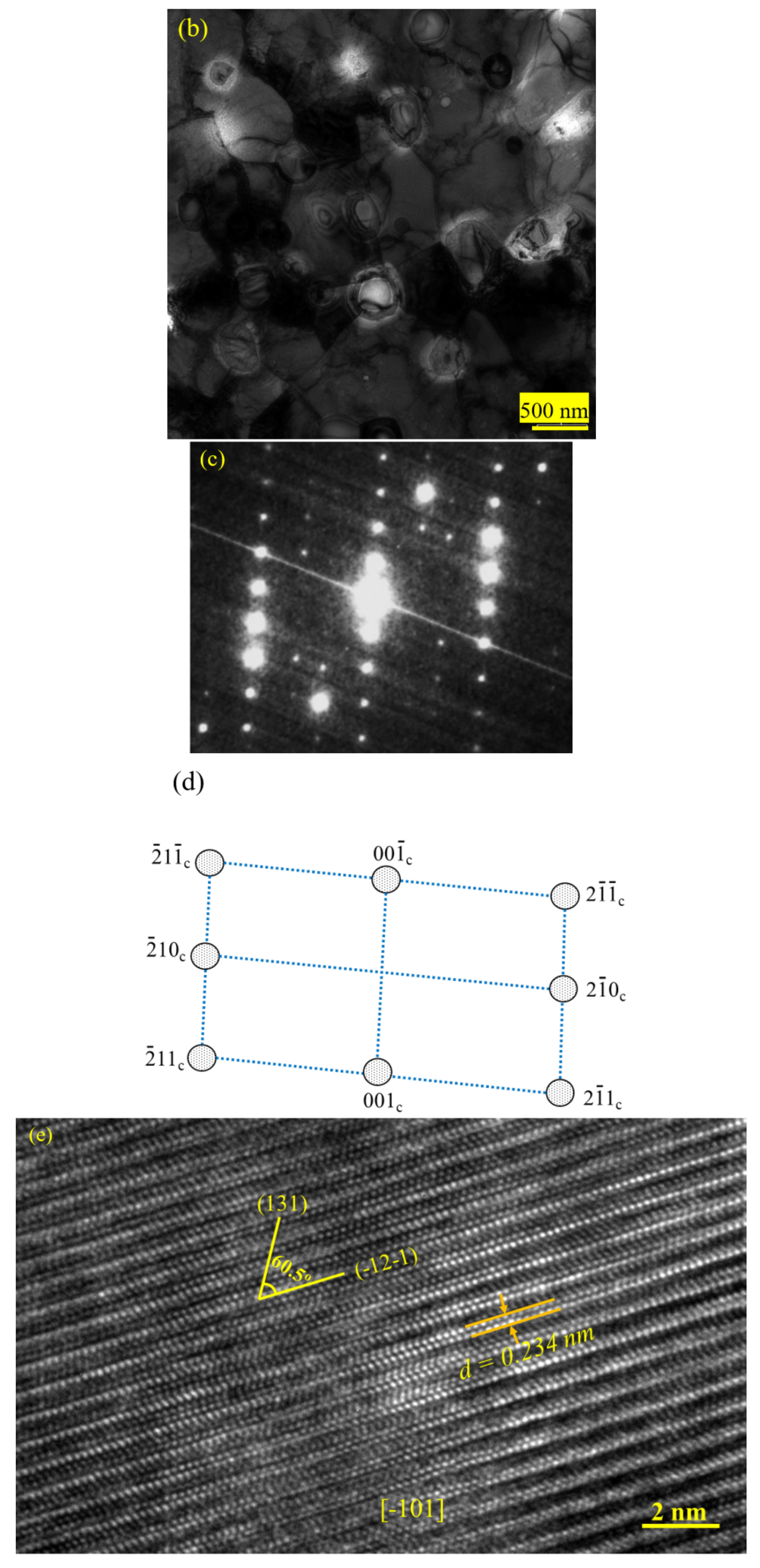

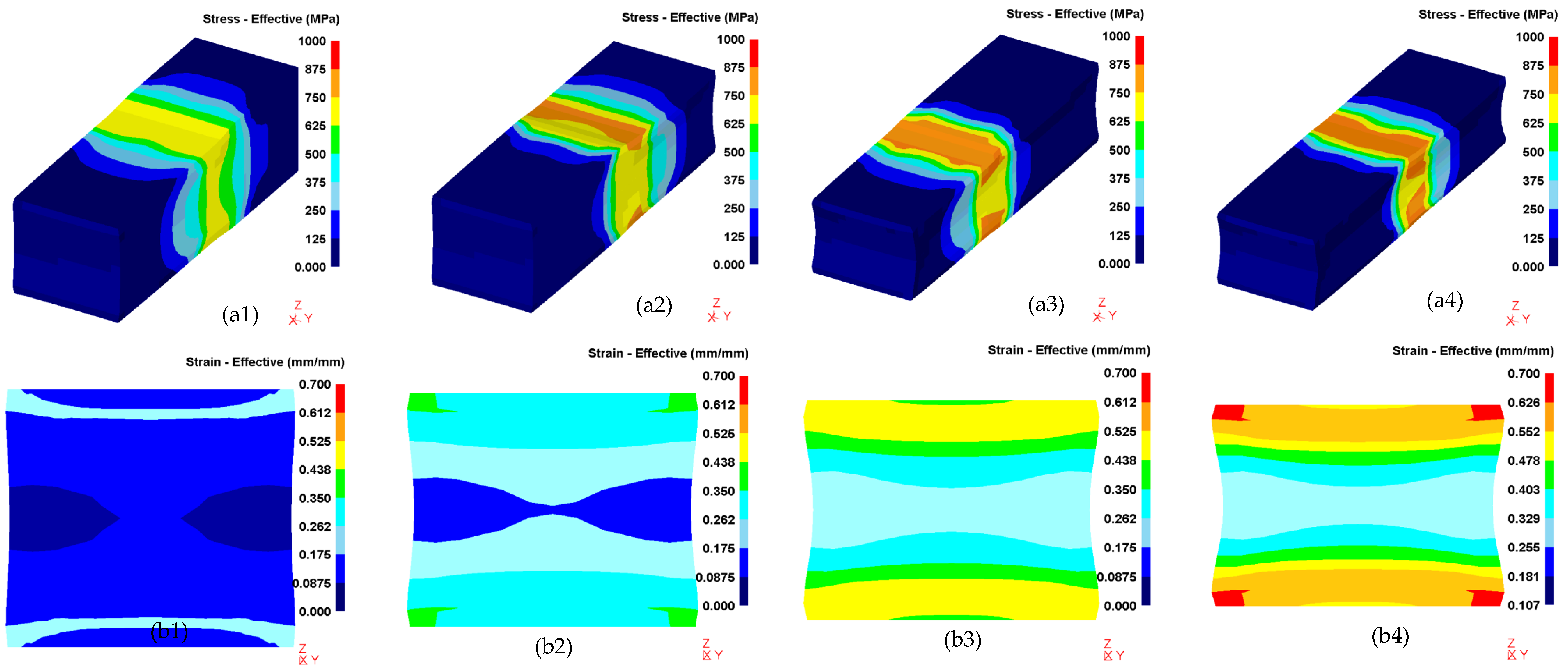

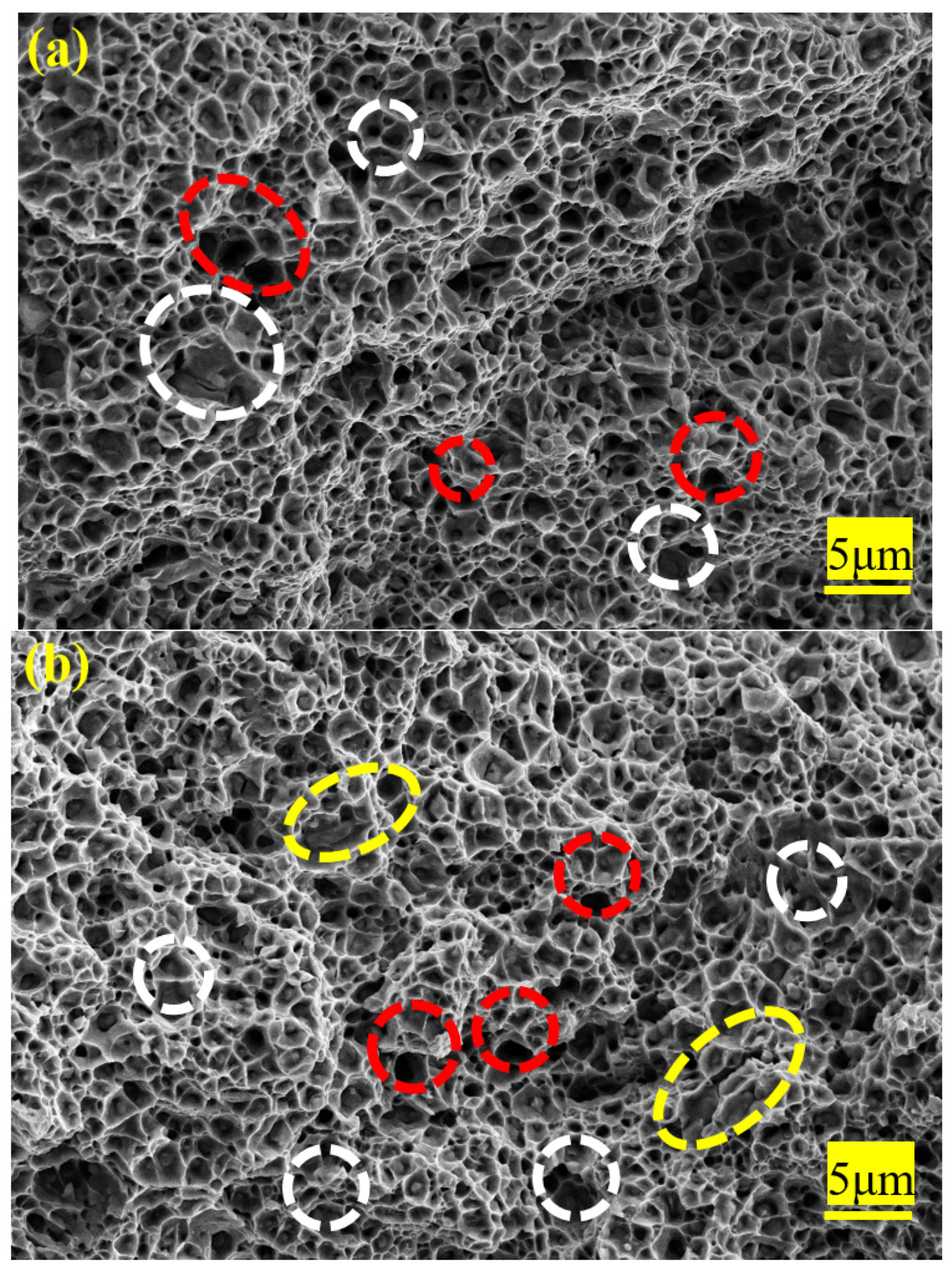

3.1.5. TEM Observations

3.2. Mechanical Properties

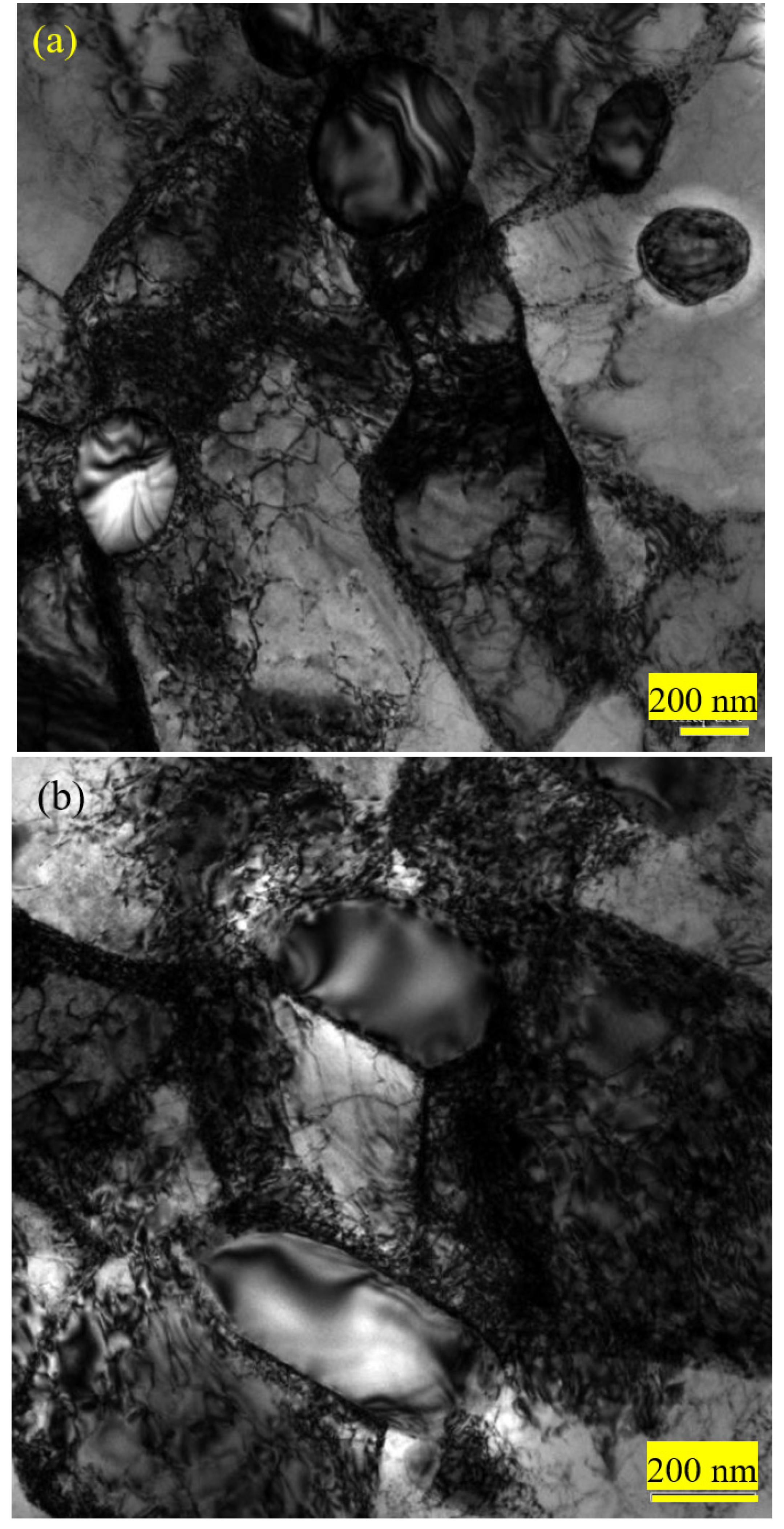

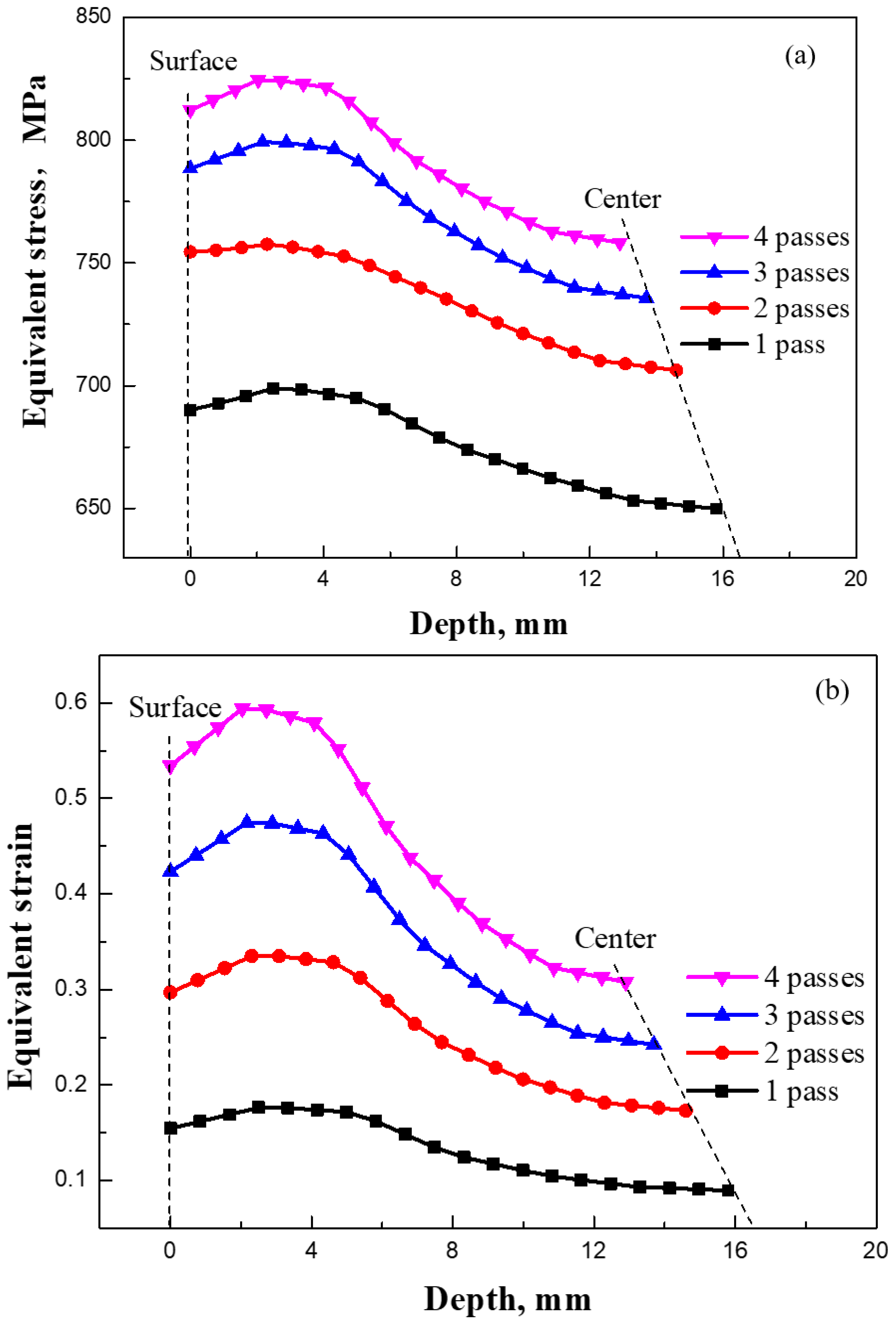

3.3. Simulation of Cold Rolling Process

4. Discussion

4.1. Cementite Particles Size

4.2. Microstructure-Mechanical Properties Relationship

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Data Availability Statement

References

- Bhadeshia, H.K.D.H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Zaretsky, E.V. Rolling bearing steels—A technical and historical perspective. Mater. Sci. Technol. 2013, 28, 58–69. [Google Scholar] [CrossRef]

- Panda, A.; Sahoo, A.K.; Kumar, R.; Das, R.K. A review on machinability aspects for AISI 52100 bearing steel. Mater. Today 2019, 5, 319–328. [Google Scholar] [CrossRef]

- Kang, J.H.; Vegter, R.H.; Rivera-Díaz-del-Castillo, P.E.J. Rolling contact fatigue in martensitic 100Cr6: Subsurface hardening and crack formation. Mater. Sci. Eng. A 2014, 607, 328–333. [Google Scholar] [CrossRef]

- Zhang, F.C.; Yang, Z.N. Development of and perspective on high-performance nanostructured bainitic bearing steel. Engineering 2019, 5, 319–329. [Google Scholar] [CrossRef]

- Li, Z.X.; Li, C.S.; Zhang, J.; Qiao, B.; Li, Z.Z. Effects of annealing on carbides size and distribution and cold formability of 1.0C–1.5Cr bearing steel. Metall. Mater. Trans. A 2015, 46, 3220–3231. [Google Scholar] [CrossRef]

- Lee, J.W.; Lee, J.C.; Lee, Y.S.; Park, K.T.; Nam, W.J. Effects of post-deformation annealing conditions on the behavior of lamellar cementite and the occurrence of delamination in cold drawn steel wires. J. Mater. Process. Technol. 2009, 209, 5300–5304. [Google Scholar] [CrossRef]

- Xu, H.F.; Wu, G.L.; Wang, C.; Li, J.; Cao, W.Q. Microstructure, hardness and contact fatigue properties of X30N high nitrogen stainless bearing steel. J. Iron Steel Res. Int. 2019, 25, 954–967. [Google Scholar] [CrossRef]

- Li, Z.X.; Li, C.S.; Zhang, J.; Li, B.Z.; Pang, X.D. Microstructure of hot rolled 1.0C–1.5Cr bearing steel and subsequent spheroidization annealing. Metall. Mater. Trans. A 2016, 47, 3607–3621. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, F.C.; Yang, Z.N.; Wang, M.M.; Zheng, C.L. Effects of Al and Mn on the formation and properties of nanostructured pearlite in high-carbon steels. Mater. Des. 2016, 93, 73–80. [Google Scholar] [CrossRef]

- Luzginova, N.V.; Zhao, L.; Sietsma, J. The cementite spheroidization process in high-carbon steels with different chromium contents. Metall. Mater. Trans. A 2008, 39, 513–521. [Google Scholar] [CrossRef]

- Lu, Z.Q.; Wang, B.; Wang, Z.H.; Sun, S.H.; Fu, W.T. Effect of cyclic heat treatments on spheroidizing behavior of cementite in high carbon steel. Mater. Sci. Eng. A 2013, 574, 143–148. [Google Scholar]

- Zhang, S.L.; Sun, X.J.; Dong, H. Effect of deformation on the evolution of spheroidization for the ultra high carbon steel. Mater. Sci. Eng. A 2006, 432, 324–332. [Google Scholar] [CrossRef]

- Arruabarrena, J.; Lopez, B.; Rodriguez-Ibabe, J.M. Influence of prior warm deformation on cementite spheroidization process in a low-alloy medium carbon steel. Metall. Mater. Trans. A 2014, 45, 279–287. [Google Scholar] [CrossRef]

- Sourmail, T.; Caballero, F.G.; Moudian, F.; De Castro, D.; Benito, M. High hardness and retained austenite stability in Si-bearing hypereutectoid steel through new heat treatment design principles. Mater. Des. 2018, 142, 158–161. [Google Scholar] [CrossRef]

- Hwang, H.; Bruno, D.C. Influence of the initial microstructure on the spheroidization of SAE 52100 bearing steel. Steel Res. Int. 2016, 87, 112–125. [Google Scholar] [CrossRef]

- Han, D.X.; Du, L.X.; Yao, C.X.; Misra, R.D.K. The evolution of deformation-induced carbides during divorced eutectoid transformation in GCr15 steels. J. Mater. Eng. Perform. 2019, 28, 5277–5288. [Google Scholar] [CrossRef]

- Yi, H.L.; Hou, Z.Y.; Xu, Y.B.; Wu, D.; Wang, G.D. Acceleration of spheroidization in eutectoid steels by the addition of aluminum. Scr. Mater. 2012, 67, 645–648. [Google Scholar] [CrossRef]

- Lu, X.H.; Qian, D.S.; Li, W.; Jin, X.J. Enhanced toughness of bearing steel by combining prior cold deformation with martensite pre-quenching and bainite transformation. Mater. Des. 2019, 234, 5–8. [Google Scholar] [CrossRef]

- Chakraborty, J.; Bhattacharjee, D.; Manna, I. Development of ultrafine bainite + martensite duplex microstructure in SAE 52100 bearing steel by prior cold deformation. Scr. Mater. 2009, 61, 604–607. [Google Scholar] [CrossRef]

- Li, Z.X.; Li, C.S.; Ren, J.Y.; Li, B.Z.; Zhang, J.; Ma, Y.Q. Effect of cold deformation on the microstructure and impact toughness during the austenitizing process of 1.0C–1.5Cr bearing steel. Mater. Sci. Eng. A 2016, 674, 262–269. [Google Scholar] [CrossRef]

- An, X.X.; Tian, Y.; Wang, H.J.; Shen, Y.F.; Wang, Z.D. Suppression of austenite grain coarsening by using Nb–Ti microalloying in high temperature carburizing of a gear steel. Adv. Eng. Mater. 2019, 21, 1900132. [Google Scholar] [CrossRef]

- Kral, M.V.; Spanos, G. Three-dimensional analysis of proeutectoid cementite precipitates. Acta Mater. 1999, 47, 711–724. [Google Scholar] [CrossRef]

- Leitner, T.; Trummeri, G.; Pippan, R.; Hohenwarter, A. Influence of severe plastic deformation and specimen orientation on the fatigue crack propagation behavior of a pearlitic steel. Mater. Sci. Eng. A 2018, 710, 260–270. [Google Scholar] [CrossRef]

- Wang, Y.T.; Adachi, Y.; Nakajima, K.; Sugimoto, Y. Quantitative three-dimensional characterization of pearlite spheroidization. Acta Mater. 2010, 58, 4849–4858. [Google Scholar] [CrossRef]

- Tian, Y.L.; Kraft, R.W. Mechanisms of pearlite spheroidization. Metall. Trans. A 1987, 18, 1403–1414. [Google Scholar] [CrossRef]

- Seo, S.W.; Bhadeshia, H.; Suh, D.W. Pearlite growth rate in Fe-C and Fe-Mn-C steels. Mater. Sci. Technol. 2015, 31, 487–493. [Google Scholar] [CrossRef]

- Zhang, M.X.; Kelly, P.M. The morphology and formation mechanism of pearlite in steels. Mater. Charact. 2009, 60, 545–554. [Google Scholar] [CrossRef]

- Wang, M.M.; Zhang, F.C.; Yang, Z.N. Effects of high-temperature deformation and cooling process on the microstructure and mechanical properties of an ultrahigh-strength pearlite steel. Mater. Charact. 2017, 114, 102–110. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.Y.; Zhou, X.G.; Wang, G.D.; Misra, R.D.K. Precipitation behavior of nanoscale cementite in hypoeutectoid steels during ultrafast cooling (UFC) and their strengthening effects. Mater. Sci. Eng. A 2013, 575, 189–198. [Google Scholar]

- Zhao, L.; Vermolen, F.J.; Sietsma, J.; Wauthier, A. Cementite dissolution at 860 °C in an Fe-Cr-C steel. Metall. Mater. Trans. A 2006, 37, 1841–1850. [Google Scholar] [CrossRef]

- Zhang, G.H.; Chae, J.Y.; Kim, K.H.; Suh, D.W. Effects of Mn, Si and Cr addition on the dissolution and coarsening of pearlitic cementite during intercritical austenitization in Fe-1mass%C alloy. Mater. Charact. 2013, 81, 56–67. [Google Scholar] [CrossRef]

- Jia, N.; Shen, Y.F.; Liang, J.W.; Feng, X.W.; Wang, H.B.; Misra, R.D.K. Nanoscale spheroidized cementite induced ultrahigh strength-ductility combination in innovatively processed ultrafine-grained low alloy medium-carbon steel. Sci. Rep. 2017, 7, 2679. [Google Scholar] [CrossRef]

- Mayers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Prentice Hall, Inc.: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Hua, L.; Qian, D.S.; Pan, L.B. Deformation behaviors and conditions in L-section profile cold ring rolling. J. Mate. Process. Technol. 2009, 209, 5087–5096. [Google Scholar] [CrossRef]

- Whiting, M.J. Reappraisal of kinetic data for the growth of pearlite in high purity Fe-C eutectoid alloys. Scr. Mater. 2003, 43, 969–975. [Google Scholar] [CrossRef]

- Wang, F.; Qian, D.S.; Hua, L.; Lu, X.H. The effect of prior cold rolling on the carbide dissolution, precipitation and dry wear behaviors of M50 bearing steel. Tribol. Int. 2019, 132, 253–264. [Google Scholar] [CrossRef]

- Li, J.R.; Zhang, C.L.; Jiang, B.; Zhou, L.Y.; Liu, Y.Z. Effect of large-size M23C6-type carbides on the low-temperature toughness of martensitic heat-resistant steels. J. Alloy. Compd. 2016, 685, 248–257. [Google Scholar] [CrossRef]

- Tsai, S.P.; Su, S.T.; Yang, J.R.; Chen, C.Y.; Wang, Y.T.; Huang, C.Y. Effect of Cr and Al additions on the development of interphase-precipitated carbides strengthened dual-phase Ti-bearing steels. Mater. Des. 2017, 119, 319–325. [Google Scholar] [CrossRef]

- Zheng, Y.X.; Wang, F.M.; Li, C.R.; Li, Y.L.; Chen, J. Microstructural evolution, coarsening behavior of precipitates and mechanical properties of boron bearing steel 25CrMoNbB during tempering. Mater. Sci. Eng. A 2018, 712, 453–465. [Google Scholar] [CrossRef]

- Saha, A.; Mondal, D.K.; Biswas, K.; Maity, J. Development of high strength ductile hypereutectoid steel by cyclic heat treatment process. Mater. Sci. Eng. A 2012, 541, 204–215. [Google Scholar] [CrossRef]

- Xiong, Y.; He, T.T.; Guo, Z.Q.; He, H.Y.; Ren, F.Z.; Volinsky, A.A. Mechanical properties and fracture characteristics of high carbon steel after equal channel angular pressing. Mater. Sci. Eng. A 2013, 563, 163–167. [Google Scholar] [CrossRef]

- Mishra, K.; Singh, A. Effect of interlamellar spacing on fracture toughness of nano-structured pearlite. Mater. Sci. Eng. A 2017, 706, 22–26. [Google Scholar] [CrossRef]

- Zheng, C.S.; Singh, A. Enhancement of mechanical properties by changing microstructure in the eutectoid steel. Mater. Sci. Eng. A 2012, 558, 158–161. [Google Scholar] [CrossRef]

- Xu, Y.T.; Zhang, X.Y.; Tian, Y.B.; Chen, C.; Nan, Y.J.; He, H.; Wang, M.J. Study on the nucleation and growth of M23C6 carbides in a 10% Cr martensite ferritic steel after long-term aging. Mater. Charact. 2016, 111, 122–127. [Google Scholar] [CrossRef]

- Isik, M.I.; Kostka, A.; Yardley, V.A.; Pradeep, K.G.; Duarte, M.J.; Choi, P.P.; Raabe, D.; Eggeler, G. The nucleation of Mo-rich Laves phase particles adjacent to M23C6 micrograin boundary carbides in 12% Cr tempered martensite ferritic steels. Acta Mater. 2015, 90, 94–104. [Google Scholar] [CrossRef]

| C | Cr | Mn | Si | S | P | Al | Ti | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.10 | 1.50 | 0.31 | 0.20 | 0.01 | 0.011 | 0.005 | 0.0023 | Bal. |

| Process | Yield Strength ± 10 MPa | Tensile Strength ± 15 MPa | Elongation ± 1% | Hardness ± 0.03 GPa |

|---|---|---|---|---|

| Spherodizing annealing | 340 | 640 | 48 | 1.42 |

| Cold rolling | 565 | 680 | 37 | 2.05 |

| Recrystallization annealing | 470 | 660 | 42 | 1.87 |

| Cold drawing | 670 | 740 | 26 | 2.36 |

| Stress relief annealing | 600 | 740 | 28 | 2.18 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Shen, Y.; Liu, Y.; Wang, F.; Jia, N. Tailoring Strength and Ductility of a Cr-Containing High Carbon Steel by Cold-Working and Annealing. Materials 2019, 12, 4136. https://doi.org/10.3390/ma12244136

Wang J, Shen Y, Liu Y, Wang F, Jia N. Tailoring Strength and Ductility of a Cr-Containing High Carbon Steel by Cold-Working and Annealing. Materials. 2019; 12(24):4136. https://doi.org/10.3390/ma12244136

Chicago/Turabian StyleWang, Jing, Yongfeng Shen, Yan Liu, Fuguo Wang, and Nan Jia. 2019. "Tailoring Strength and Ductility of a Cr-Containing High Carbon Steel by Cold-Working and Annealing" Materials 12, no. 24: 4136. https://doi.org/10.3390/ma12244136

APA StyleWang, J., Shen, Y., Liu, Y., Wang, F., & Jia, N. (2019). Tailoring Strength and Ductility of a Cr-Containing High Carbon Steel by Cold-Working and Annealing. Materials, 12(24), 4136. https://doi.org/10.3390/ma12244136