Chemical, Physical, and Mechanical Properties and Microstructures of Laser-Sintered Co–25Cr–5Mo–5W (SP2) and W–Free Co–28Cr–6Mo Alloys for Dental Applications

Abstract

1. Introduction

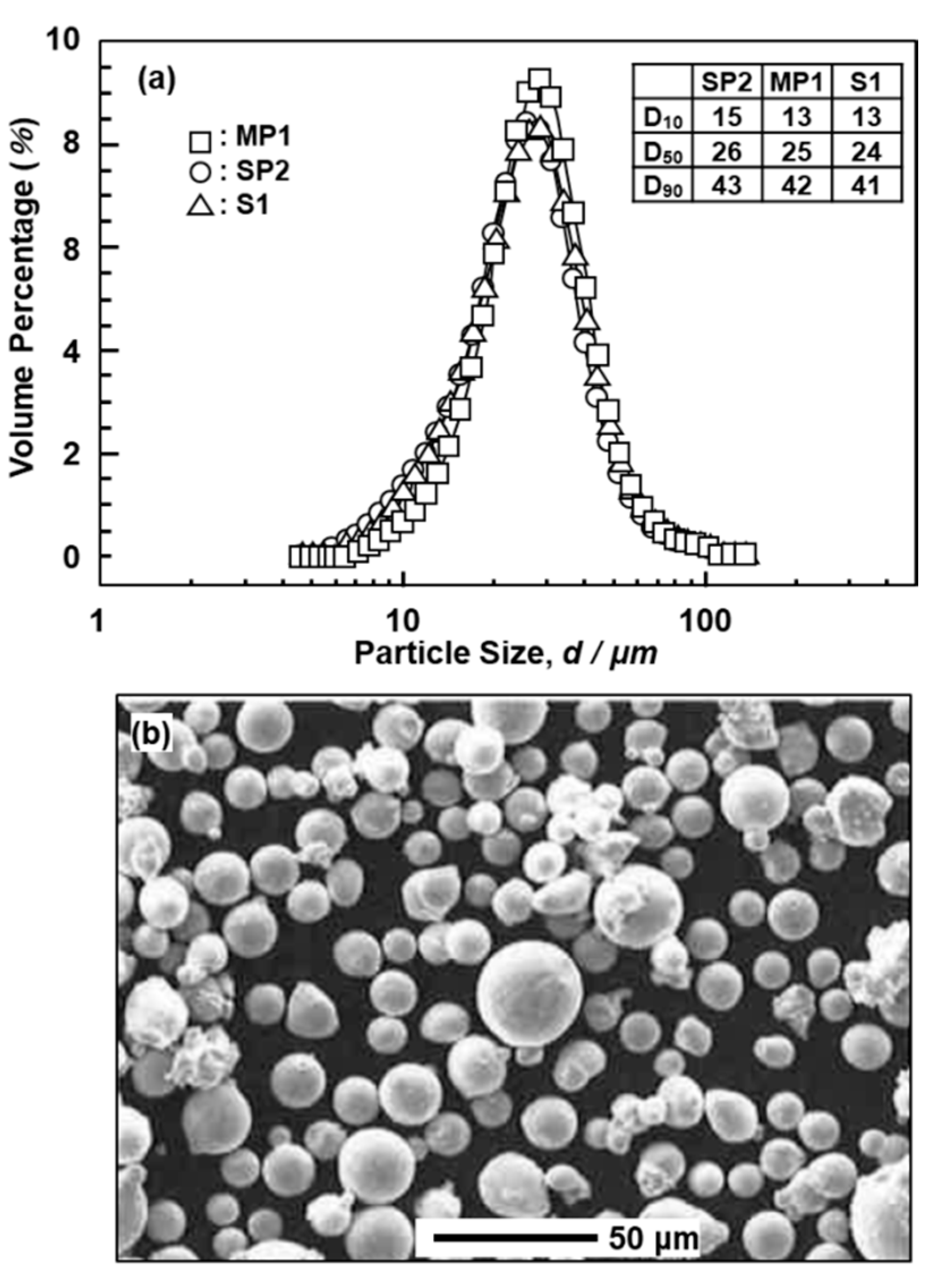

2. Experimental Procedure

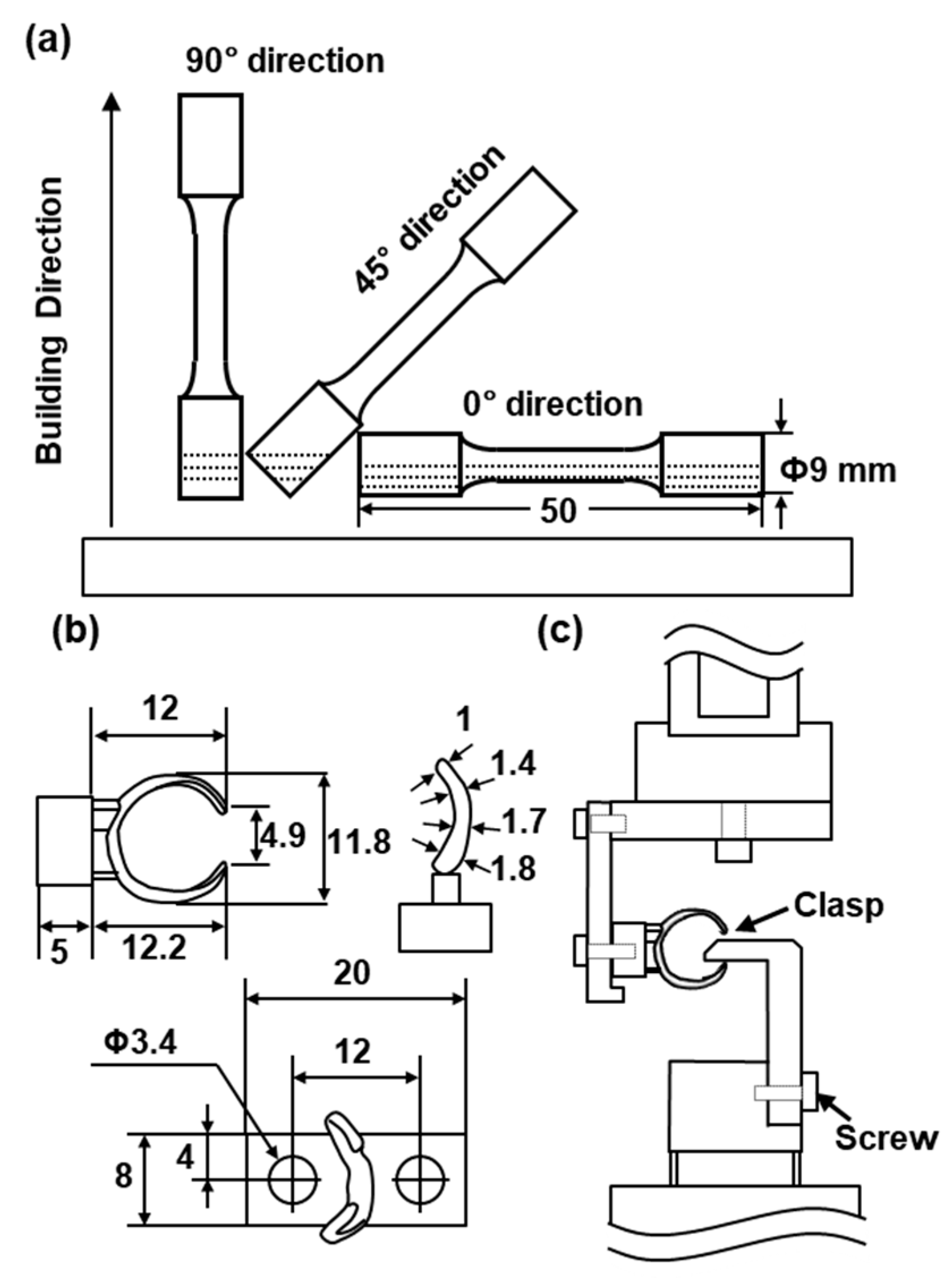

2.1. Test Samples

2.2. Evaluation of Physical Properties

2.3. Microstructural Observation

2.4. Static Immersion Test

2.5. Room-Temperature Tensile Tests

2.6. Fatigue Tests

3. Results and Discussion

3.1. Chemical Compositions and Physical Properties

3.2. Static Immersion Property of Laser-Sintered Co–Cr–Mo Alloys

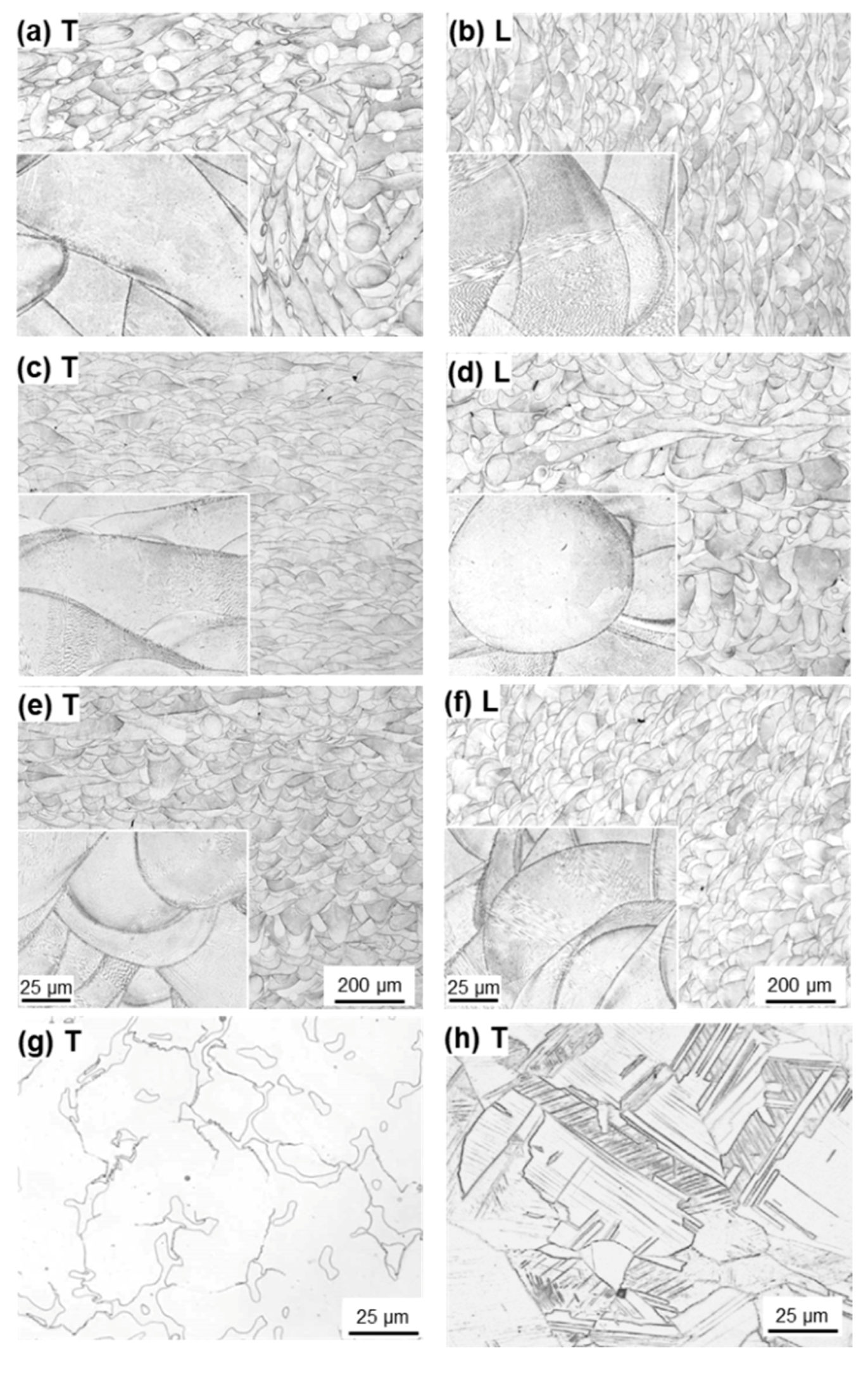

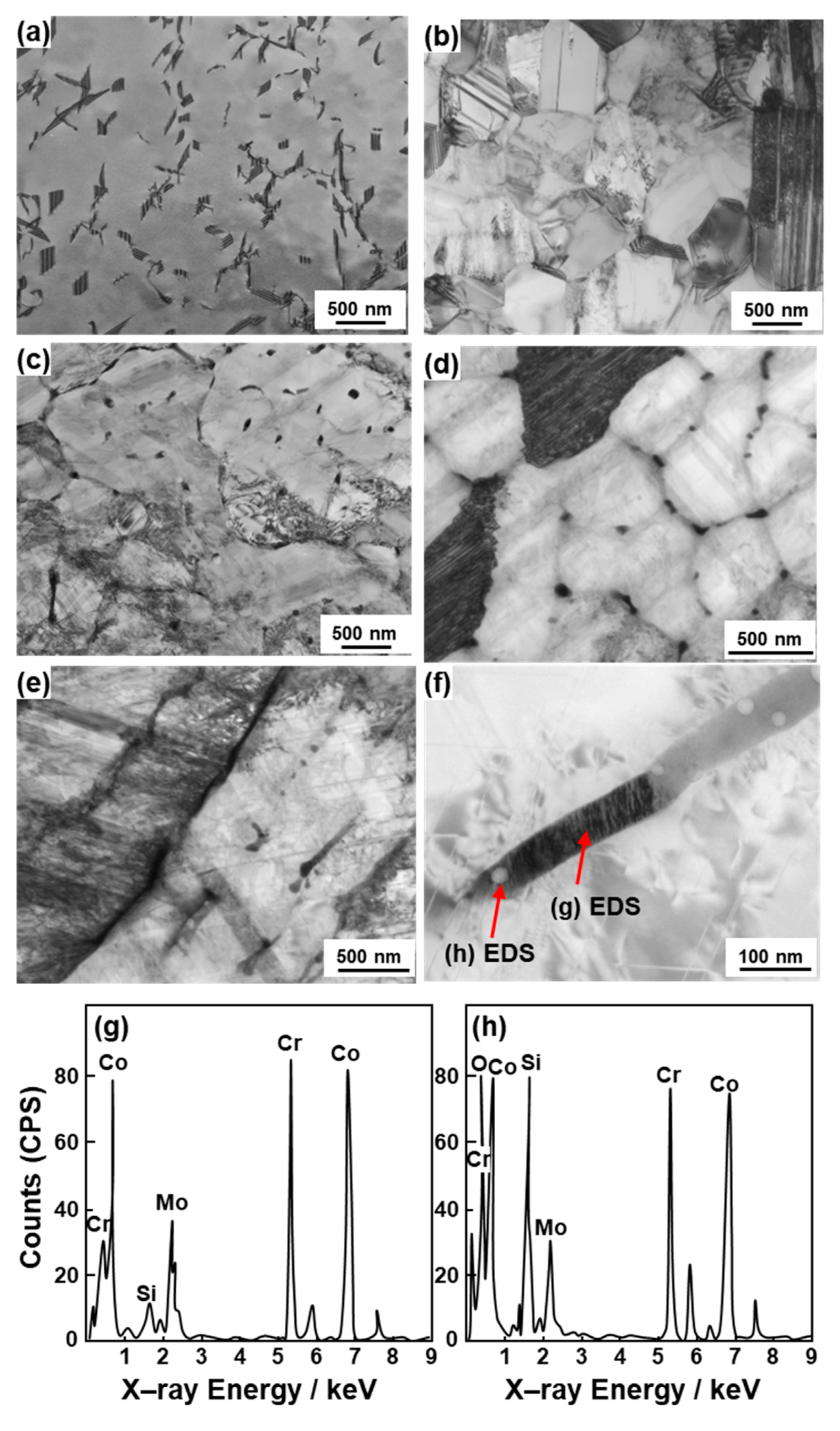

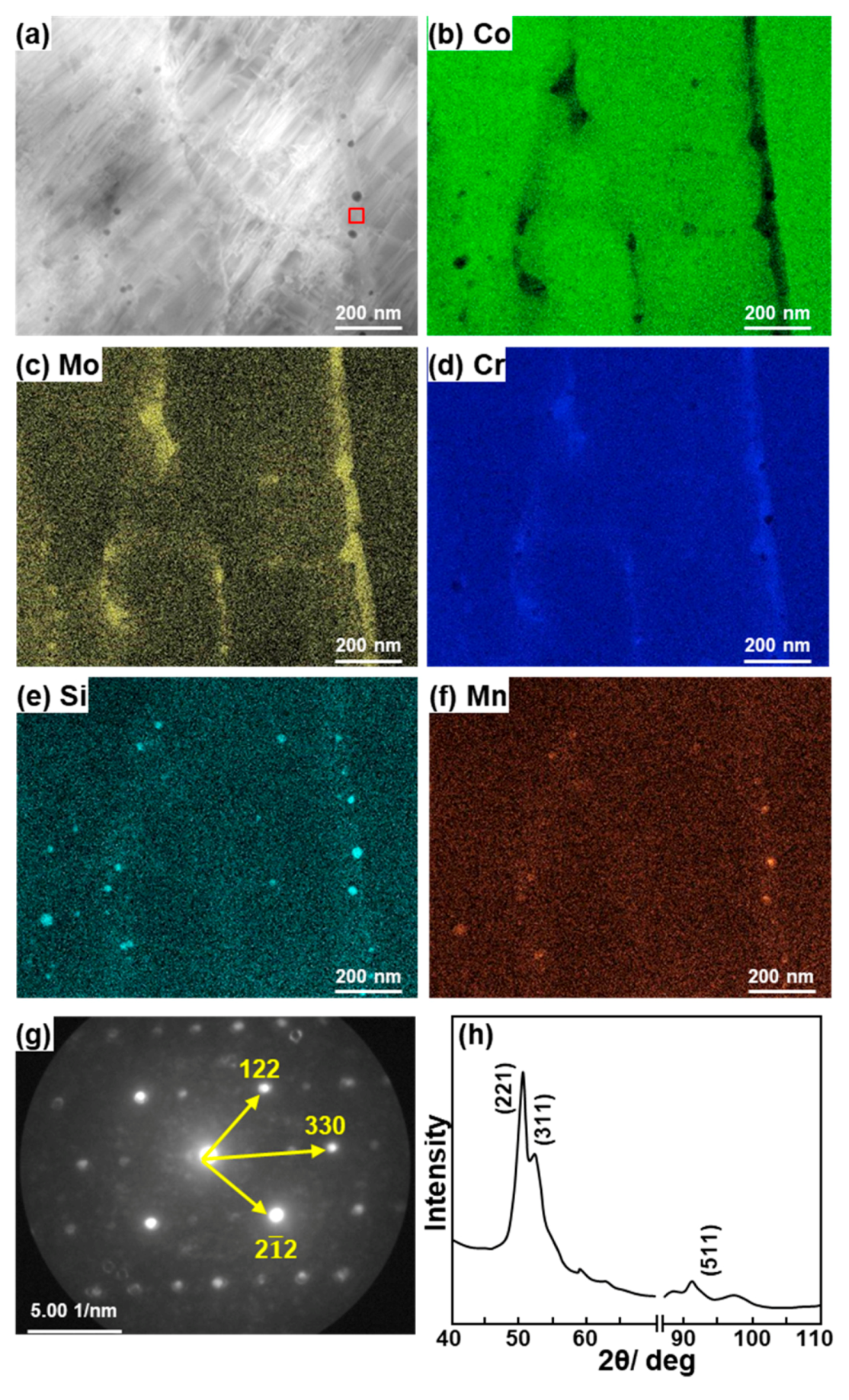

3.3. Microstructure of Laser-Sintered Co–Cr–Mo Alloys

3.4. Mechanical Properties of Laser-Sintered Co–Cr–Mo Alloys

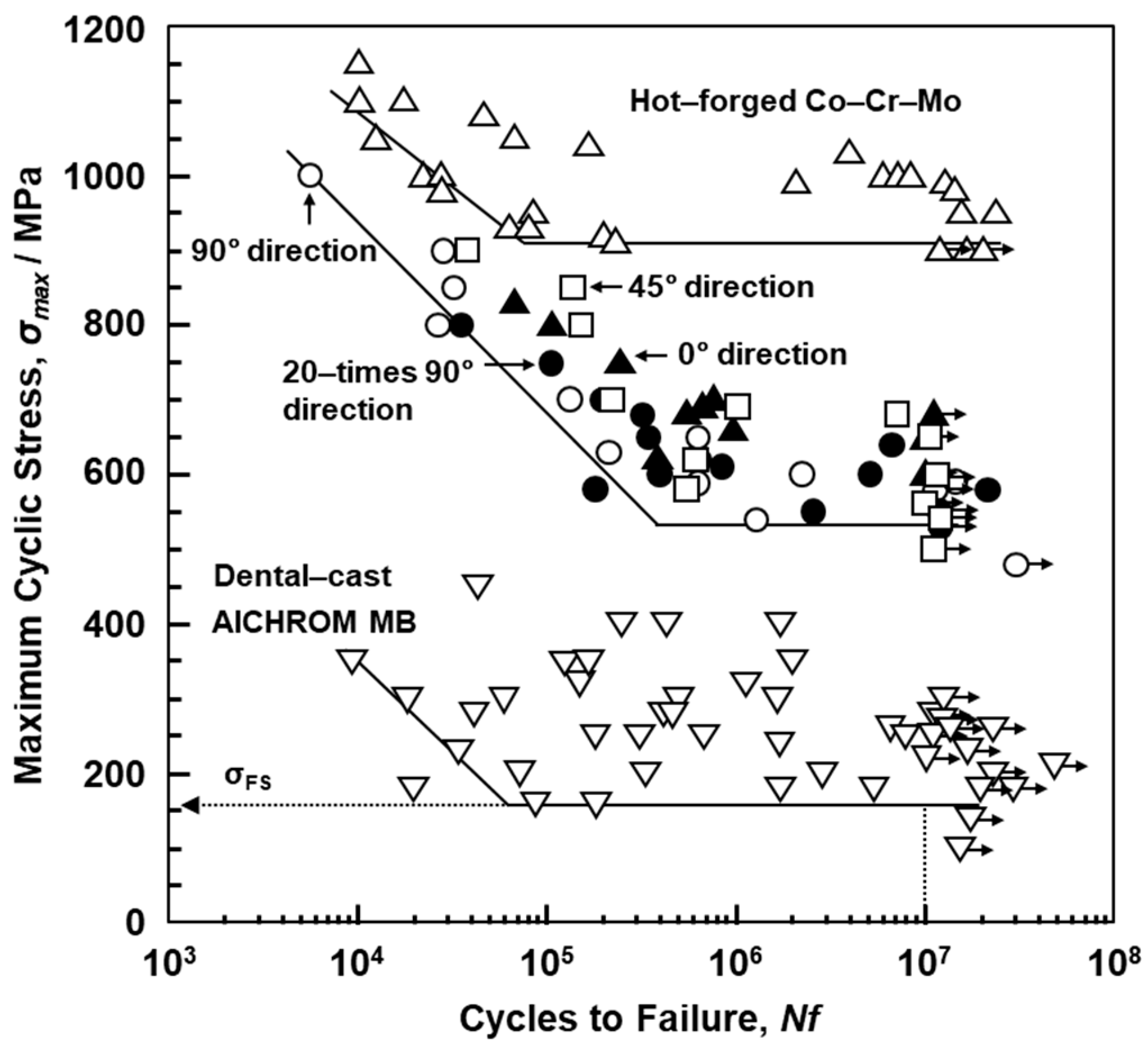

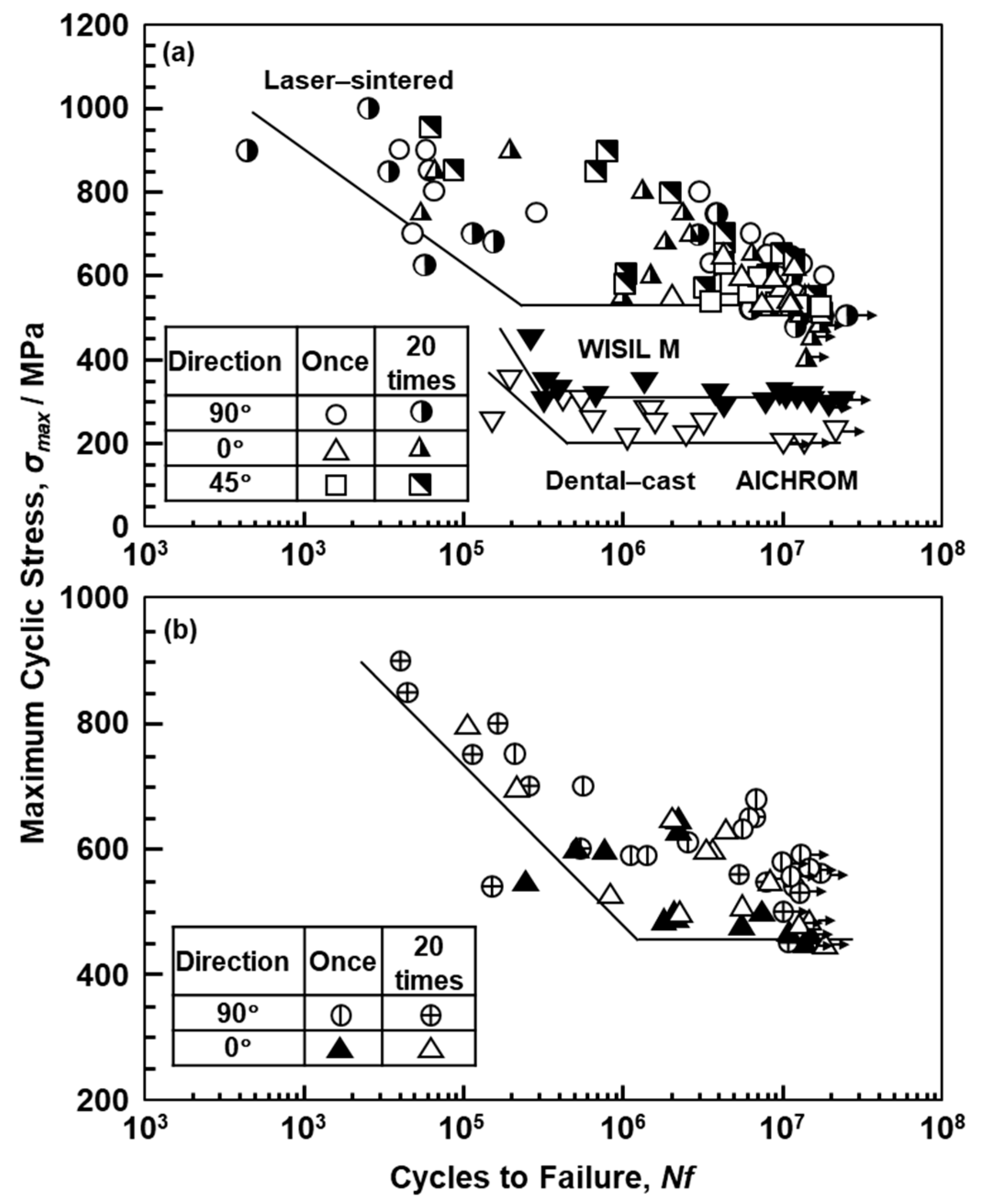

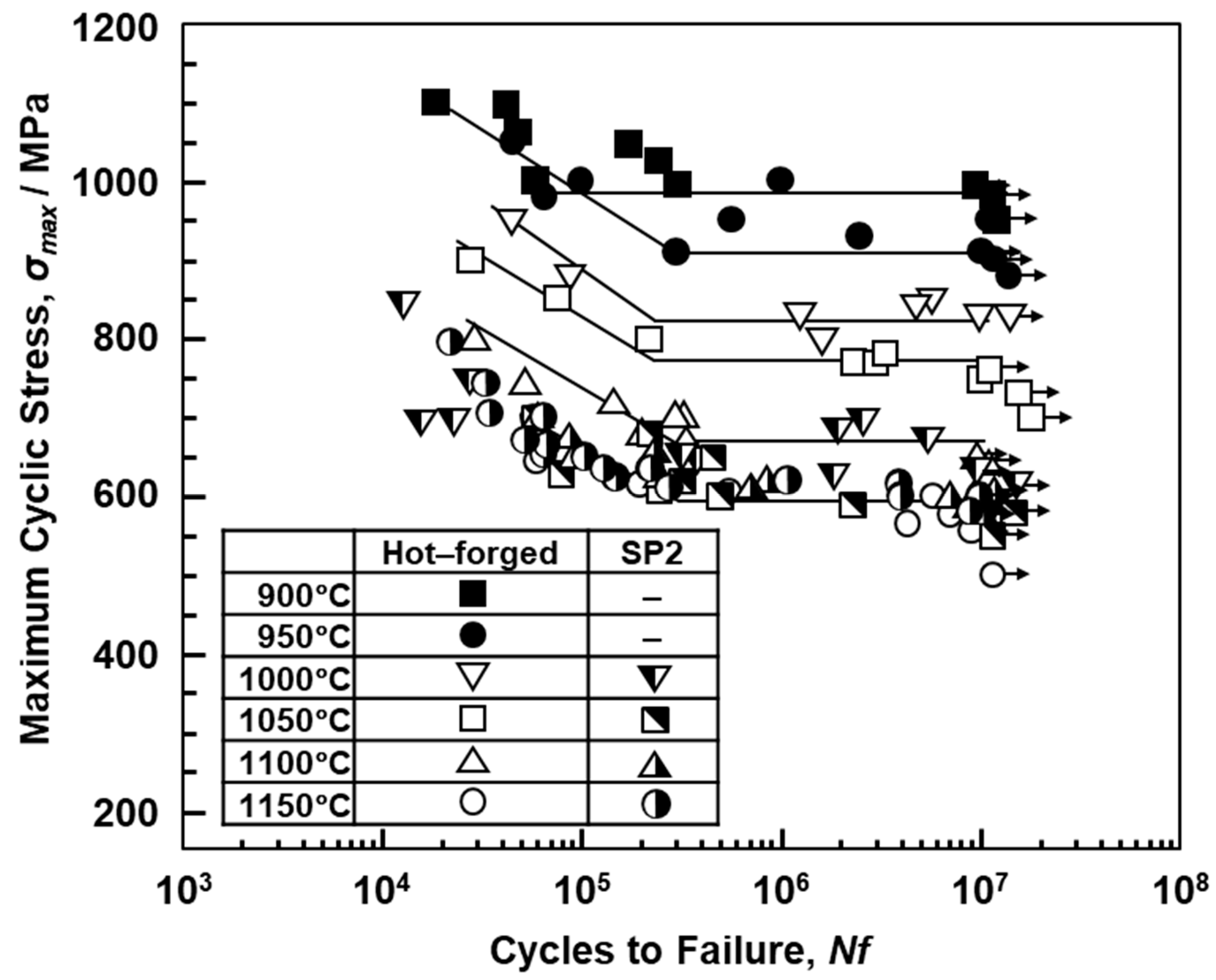

3.5. Fatigue Strengths of Laser-Sintered Co–Cr–Mo Alloys

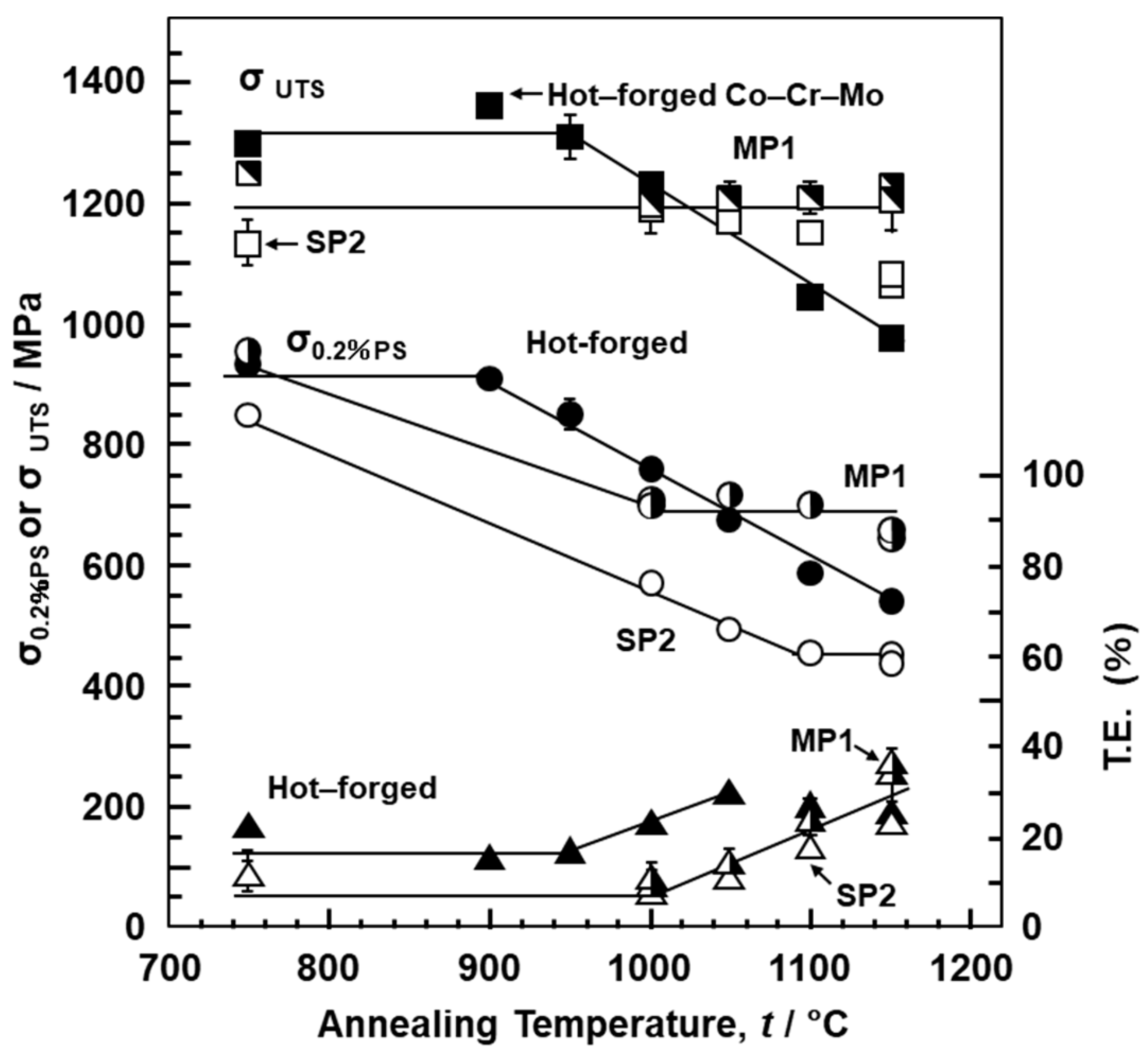

3.6. Effects of Annealing on Mechanical Properties and Microstructure of Laser-Sintered Co–Cr–Mo Alloys

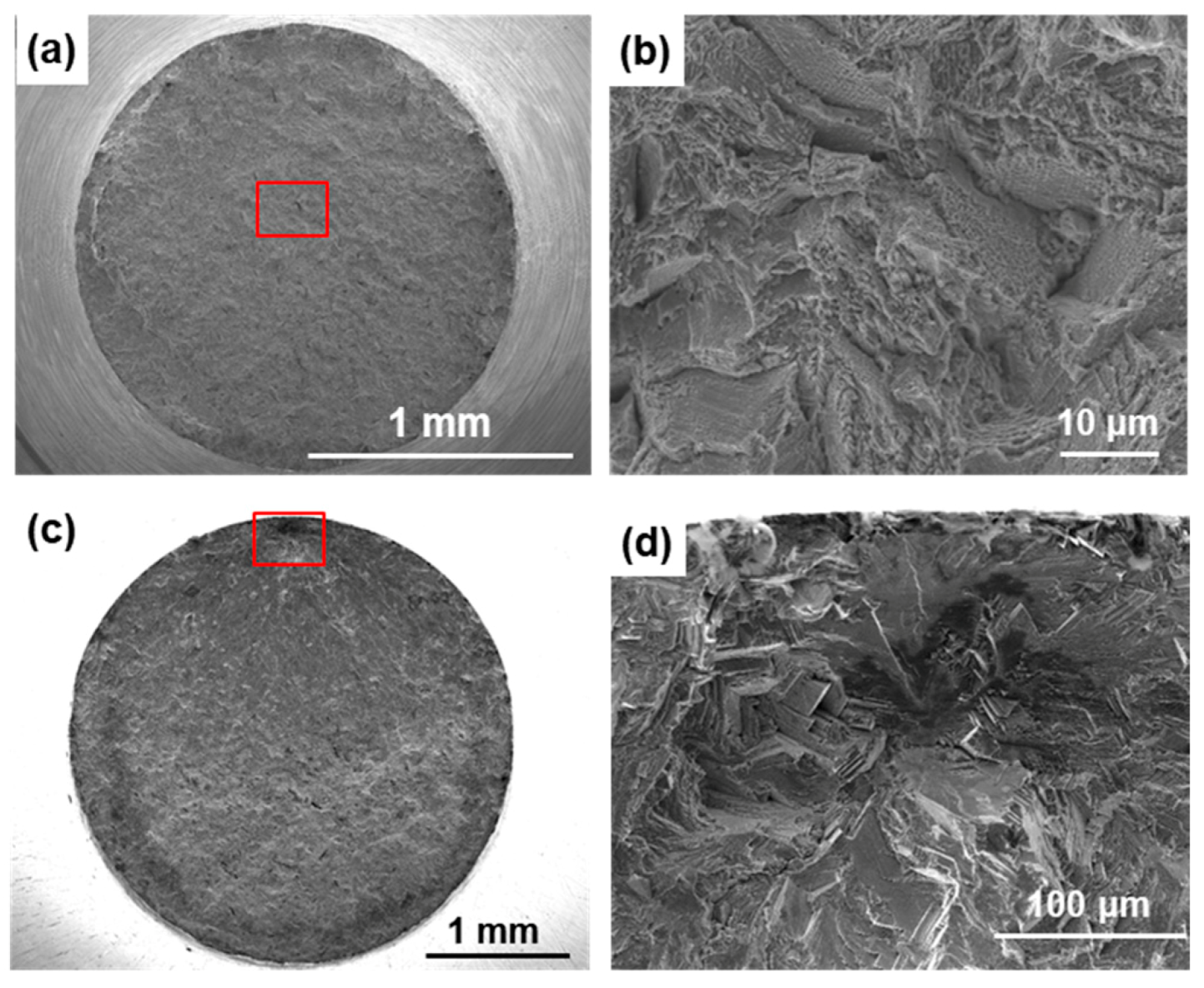

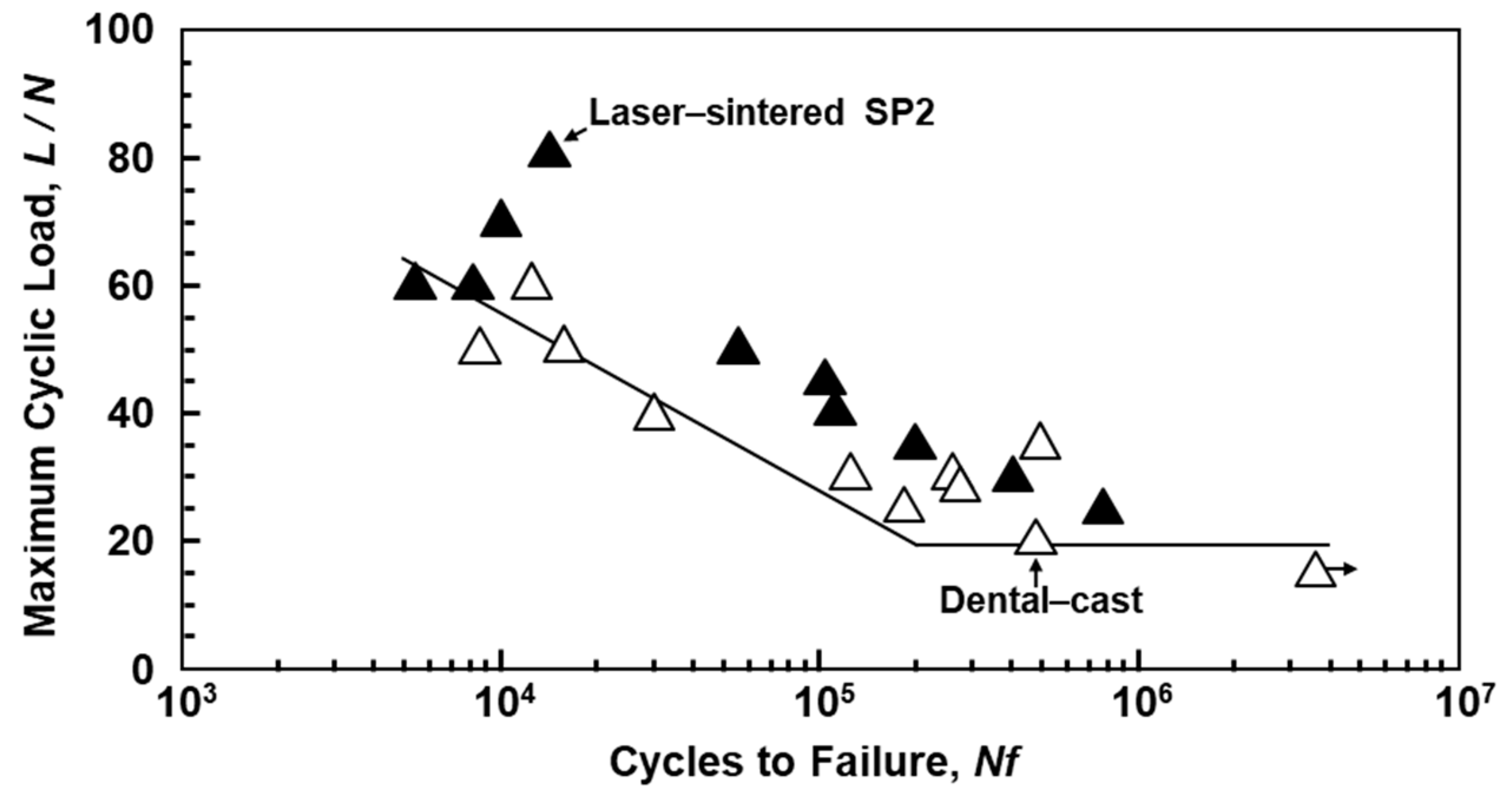

3.7. Durability of Laser-Sintered Co–Cr–Mo Alloy Clasps

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- ISO 5832–12. Implants for Surgery—Metallic Materials—Part 12: Wrought Cobalt–Chromium–Molybdenum Alloy; International Organization for Standardization: Geneva, Switzerland, 2007.

- ISO 22674. Dentistry–Metallic Materials for Fixed and Removable Restorations and Appliances; International Organization for Standardization: Geneva, Switzerland, 2016.

- ASTM F 11537–11. Standard Specification for Wrought Cobalt–28Chromium–6Molybdenum Alloy for Surgical Implants; American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- ASTM F 75–12. Standard Specification for Cobalt–28Chromium–6Molybdenum Alloy Casting and Casting Alloy for Surgical Implants; American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- JIS T 6121. Base Metal Materials for Dental Metal–Ceramic Restorations; Japanese Standards Association: Tokyo, Japan, 2013.

- JIS T 6115. Dental Casting Cobalt Chromium Alloys; Japanese Standards Association: Tokyo, Japan, 2013.

- JIS T 7402–2. Cobalt Based Alloys for Surgical Implant Applications–Part 2: Wrought Cobalt–Chromium–Molybdenum Alloy; Japanese Standards Association: Tokyo, Japan, 2005.

- Nakata, T.; Shimpo, H.; Ohkubo, C. Clasp fabrication using one–process molding by repeated laser sintering and high–speed miling. J. Prosthodont. Res. 2017, 61, 276–282. [Google Scholar] [CrossRef] [PubMed]

- Takaichi, A.; Suyalatu, T.; Nakamoto, N.; Joko, N.; Nomura, Y.; Tsutumi, S.; Migita, H.; Doi, S.; Kurosu, A.; Chiba, N.; et al. Microstructures and mechanical properties of Co–29Cr–6Mo alloy fabricated by selective laser melting process for dental applications. J. Mech. Behav. Biomed. Mater. 2013, 21, 67–76. [Google Scholar] [CrossRef] [PubMed]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. Effect of selective laser melting process parameters on the quality of Al alloy parts: Powder characterization, density, surface roughness, and dimensional accuracy. Materials 2018, 11, 2343. [Google Scholar] [CrossRef] [PubMed]

- Puskar, T.; Jevremovic, D.; Williams, R.; Eggbeer, D.; Vukelic, D.; Budak, I. A comparative analysis of the corrosive effect of artificial saliva of variable pH on DMLS and cast Co–Cr–Mo dental alloy. Materials 2014, 7, 6486–6501. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Health, Labour and Welfare. Guidance on Evaluation of Customized Orthopedic Devices for Osteosynthesis; PFSB/ELD/OMDE (Yakushokuki) Notification 1215 No. 1 of the Director of Medical Devices and Regenerative Medicine Evaluation Division; Pharmaceutical Safety and Environmental Health Bureau: Tokyo, Japan, 2010.

- Ministry of Health, Labour and Welfare. Guidance on Evaluation of Orthopedic Customized Artificial Hip Joint Prosthesis; PFSB/ELD/OMDE (Yakushokuki) Notification 1207 No. 1 of the Director of Medical Devices and Regenerative Medicine Evaluation Division; Pharmaceutical Safety and Environmental Health Bureau: Tokyo, Japan, 2011.

- FDA Guidance. Technical Considerations for Additive Manufactured Medical Devices; Food and Drug Administration: New Hampshire, NH, USA, 2017. [Google Scholar]

- Ministry of Health, Labour and Welfare. Guidance on Evaluation of the Orthopedic Implants Manufactured by Additive Manufacturing Technology; Annex 3, Notification 0912 No. 2 of the Director of Medical Devices and Regenerative Medicine Evaluation Division; Pharmaceutical Safety and Environmental Health Bureau: Tokyo, Japan, 2014.

- Ministry of Health, Labour and Welfare. Guidance on Evaluation of Customized Orthopedic Devices Manufactured by Additive Manufacturing Technology with Medical Image Data Obtained from the Patient; Annex 3, Notification 0925 No. 1 of the Director of Medical Devices and Regenerative Medicine Evaluation Division; Pharmaceutical Safety and Environmental Health Bureau: Tokyo, Japan, 2015.

- Yakumukoho, No. 2489; Yakumukohosha: Tokyo, Japan, 2018; p. 385.

- Yakumukoho, No. 2540; Yakumukohosha: Tokyo, Japan, 2019; p. 1357.

- JIS K 0129. General Rules for Thermal Analysis; Japanese Standards Association: Tokyo, Japan, 2005.

- JIS Z 8807. Methods of Measuring Density and Specific Gravity of Solid; Japanese Standards Association: Tokyo, Japan, 2012.

- JIS Z 2285. Measuring Method of Coefficient of Linear Thermal Expansion of Metallic Materials; Japanese Standards Association: Tokyo, Japan, 2003.

- JIS G 1258–2. Iron and Steel–ICP Atomic Emission Spectrometric Method–Part 2: Determination of Various Elements–Decomposition with Phosphoric and Sulfuric Acids; Japanese Standards Association: Tokyo, Japan, 2014.

- JIS G 1228. Iron and Steel–Methods for Determination of Nitrogen Content; Japanese Standards Association: Tokyo, Japan, 1997.

- JIS G 1211–3. Iron and Steel–Determination of Carbon Content–Part 3: Infrared Absorption Method after Combusion; Japanese Standards Association: Tokyo, Japan, 2011.

- ISO 10271. Dentistry–Corrosion Test Methods for Metallic Materials; International Organization for Standardization: Geneva, Switzerland, 2011.

- JIS Z 2241. Test Method for Tensile Test; Japanese Standards Association: Tokyo, Japan, 2009.

- JIS T 0309. Test Method for Fatigue Properties of Metallic Biomaterials; Japanese Standards Association: Tokyo, Japan, 2009.

- Narushima, T.; Mineta, S.; Kurihara, Y. Precipitates in biomedical Co–Cr alloys. JOM 2013, 65, 98–107. [Google Scholar] [CrossRef]

- Lippard, H.E.; Kennedy, R.L. Process Metallurgy of Wrought CoCrMo Alloy, Cobalt–Base Alloys for Biomedical Applications; Disegi, J.A., Kennedy, R.L., Pilliar, R., Eds.; ASTM STP 1365; American Society for Testing and Materials: West Conshohocken, PA, USA, 1999; pp. 98–107. [Google Scholar]

| Alloy | Cr | Mo | Ni | Fe | C | N | Mn | Si | W | Co |

|---|---|---|---|---|---|---|---|---|---|---|

| SP2 virgin powder | 24.6 | 5.0 | 0.021 | 0.02 | 0.006 | <0.01 | <0.001 | 1.09 | 5.67 | Bal. |

| Once-sintered | 24.0 | 5.16 | 0.034 | 0.034 | 0.008 | 0.012 | 0.011 | 1.05 | 5.48 | Bal. |

| 20-times-sintered | 24.4 | 5.05 | 0.023 | 0.029 | 0.007 | 0.01 | <0.001 | 1.10 | 5.62 | Bal. |

| MP1 virgin powder | 27.4 | 5.88 | 0.016 | 0.037 | 0.054 | 0.16 | 0.66 | 0.81 | − | Bal. |

| Once-sintered | 27.4 | 6.03 | 0.017 | 0.073 | 0.13 | 0.13 | 0.62 | 0.81 | − | Bal. |

| 20-times-sintered | 27.5 | 6.06 | 0.017 | 0.039 | 0.13 | 0.13 | 0.61 | 0.82 | − | Bal. |

| S1 virgin powder | 27.6 | 5.85 | 0.005 | 0.16 | 0.086 | 0.16 | 0.69 | 0.67 | − | Bal. |

| Once-sintered | 27.2 | 6.27 | 0.005 | 0.13 | 0.095 | 0.14 | 0.63 | 0.67 | − | Bal. |

| 20-times-sintered | 27.4 | 6.04 | 0.005 | 0.11 | 0.094 | 0.15 | 0.54 | 0.69 | − | Bal. |

| Specimen | σ0.2%PS/MPa | σUTS/MPa | T.E. (%) | R.A. (%) | σFS/MPa | σFS/σUTS |

|---|---|---|---|---|---|---|

| Laser-sintered | ||||||

| SP2 Once-sintered 90° | 520 ± 5 | 1164 ± 6 | 25 ± 1 | 21 ± 1 | 500 | 0.43 |

| SP2 Once-sintered 0° | 793 ± 6 | 1310 ± 13 | 13 ± 2 | 13 ± 2 | 600 | 0.43 |

| SP2 Once-sintered 45° | 805 ± 5 | 1309 ± 3 | 15 ± 1 | 15 ± 2 | 560 | 0.46 |

| SP2 20-times-sintered 90° | 508 ± 10 | 1159 ± 11 | 27 ± 2 | 23 ± 2 | 500 | 0.43 |

| MP1 Once-sintered 90° | 660 ± 60 | 1301 ± 16 | 22 ± 2 | 21 ± 1 | 500 | 0.38 |

| MP1 Once-sintered 0° | 1029 ± 8 | 1415 ± 7 | 13 ± 1 | 13 ± 2 | 500 | 0.35 |

| MP1 Once-sintered 45° | 948 ± 77 | 1388 ± 6 | 14 ± 1 | 14 ± 2 | 500 | 0.36 |

| MP1 20-times-sintered 90° | 758 ± 9 | 1303 ± 12 | 23 ± 2 | 20 ± 2 | 500 | 0.38 |

| MP1 20-times-sintered 0° | 1034 ± 5 | 1399 ± 3 | 12 ± 1 | 13 ± 3 | 500 | 0.36 |

| MP1 20-times-sintered 45° | 1019 ± 15 | 1381 ± 10 | 13 ± 2 | 14 ± 1 | 500 | 0.36 |

| S1 Once-sintered 90° | 766 ± 4 | 1269 ± 5 | 22 ± 1 | 18 ± 1 | 500 | 0.39 |

| S1 Once-sintered 0° | 1011 ± 8 | 1391 ± 3 | 13 ± 1 | 13 ± 2 | 500 | 0.36 |

| S1 20-times-sintered 90° | 755 ± 10 | 1265 ± 7 | 23 ± 2 | 19 ± 1 | 500 | 0.40 |

| S1 20-times-sintered 0° | 1009 ± 3 | 1399 ± 5 | 13 ± 1 | 12 ± 1 | 500 | 0.36 |

| Dental–cast | ||||||

| AICHROM MB | 580 ± 13 | 658 ± 21 | 2 ± 2 | 6 ± 3 | 160 | 0.33 |

| AICHROM | 512 ± 75 | 628 ± 60 | 2 ± 1 | 5 ± 5 | 200 | 0.32 |

| WISIL M | 722 ± 20 | 781 ± 133 | 2 ± 1 | 2 ± 1 | 300 | 0.38 |

| Hot–forged | ||||||

| Hot–forged Co–Cr–Mo | 903 ± 5 | 1269 ± 6 | 24 ± 1 | 23 ± 1 | 900 | 0.71 |

| Specimen | σ0.2%PS/MPa | σUTS/MPa | T. E. (%) | R. A. (%) | σFS/MPa | σFS/σUTS |

|---|---|---|---|---|---|---|

| 20-times-sintered 90° | ||||||

| SP2 Annealed 750 °C for 1 h | 849 ± 17 | 1132 ± 37 | 13 ± 5 | 14 ± 3 | 500 | 0.44 |

| SP2 Annealed 1000 °C for 0.5 h | 569 ± 14 | 1188 ± 10 | 7 ± 1 | 8 ± 1 | 620 | 0.52 |

| SP2 Annealed 1050 °C for 0.5 h | 493 ± 3 | 1166 ± 15 | 11 ± 1 | 10 ± 1 | 580 | 0.50 |

| SP2 Annealed 1100 °C for 0.5 h | 455 ± 5 | 1147 ± 14 | 17 ± 2 | 15 ± 1 | 590 | 0.51 |

| SP2 Annealed 1150 °C for 0.5 h | 436 ± 3 | 1083 ± 24 | 23 ± 1 | 21 ± 1 | 600 | 0.56 |

| Once-sintered 90° | ||||||

| MP1 Annealed 1000 °C for 0.5 h | 707 ± 3 | 1196 ± 48 | 11 ± 3 | 11 ± 2 | 650 | 0.54 |

| MP1 Annealed 1150 °C for 0.5 h | 649 ± 2 | 1228 ± 7 | 36 ± 1 | 28 ± 1 | 650 | 0.53 |

| Once-sintered 45° | ||||||

| SP2 Annealed 1000 °C for 0.5 h | 644 ± 7 | 1310 ± 7 | 7 ± 1 | 7 ± 1 | 690 | 0.53 |

| SP2 Annealed 1150 °C for 0.5 h | 460 ± 15 | 1096 ± 9 | 27 ± 1 | 22 ± 1 | 600 | 0.55 |

| Once-sintered 0° | ||||||

| SP2 Annealed 1000 °C for 0.5 h | 635 ± 6 | 1344 ± 12 | 8 ± 1 | 8 ± 1 | 660 | 0.49 |

| SP2 Annealed 1150 °C for 0.5 h | 459 ± 12 | 1116 ± 8 | 26 ± 1 | 21 ± 1 | 550 | 0.49 |

| Hot–forged Co–Cr–Mo | ||||||

| Annealed 750 °C for 1 h | 934 ± 12 | 1296 ± 4 | 22 ± 1 | 19 ± 1 | 1010 | 0.78 |

| Annealed 900 °C for 1 h | 909 ± 13 | 1360 ± 21 | 15 ± 1 | 13 ± 1 | 995 | 0.73 |

| Annealed 950 °C for 1 h | 850 ± 23 | 1308 ± 35 | 17 ± 1 | 14 ± 1 | 900 | 0.69 |

| Annealed 1000 °C for 1 h | 759 ± 4 | 1231 ± 1 | 22 ± 1 | 19 ± 1 | 820 | 0.65 |

| Annealed 1050 °C for 1 h | 676 ± 4 | 1196 ± 9 | 30 ± 1 | 25 ± 1 | 755 | 0.63 |

| Annealed 1100 °C for 1 h | 587 ± 1 | 1040 ± 10 | 27 ± 2 | 23 ± 1 | 655 | 0.63 |

| Annealed 1150 °C for 1 h | 538 ± 5 | 975 ± 6 | 25 ± 1 | 23 ± 1 | 555 | 0.57 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okazaki, Y.; Ishino, A.; Higuchi, S. Chemical, Physical, and Mechanical Properties and Microstructures of Laser-Sintered Co–25Cr–5Mo–5W (SP2) and W–Free Co–28Cr–6Mo Alloys for Dental Applications. Materials 2019, 12, 4039. https://doi.org/10.3390/ma12244039

Okazaki Y, Ishino A, Higuchi S. Chemical, Physical, and Mechanical Properties and Microstructures of Laser-Sintered Co–25Cr–5Mo–5W (SP2) and W–Free Co–28Cr–6Mo Alloys for Dental Applications. Materials. 2019; 12(24):4039. https://doi.org/10.3390/ma12244039

Chicago/Turabian StyleOkazaki, Yoshimitsu, Akira Ishino, and Shizuo Higuchi. 2019. "Chemical, Physical, and Mechanical Properties and Microstructures of Laser-Sintered Co–25Cr–5Mo–5W (SP2) and W–Free Co–28Cr–6Mo Alloys for Dental Applications" Materials 12, no. 24: 4039. https://doi.org/10.3390/ma12244039

APA StyleOkazaki, Y., Ishino, A., & Higuchi, S. (2019). Chemical, Physical, and Mechanical Properties and Microstructures of Laser-Sintered Co–25Cr–5Mo–5W (SP2) and W–Free Co–28Cr–6Mo Alloys for Dental Applications. Materials, 12(24), 4039. https://doi.org/10.3390/ma12244039