Characteristics of the Supersonic Combustion Coherent Jet for Electric Arc Furnace Steelmaking

Abstract

1. Introduction

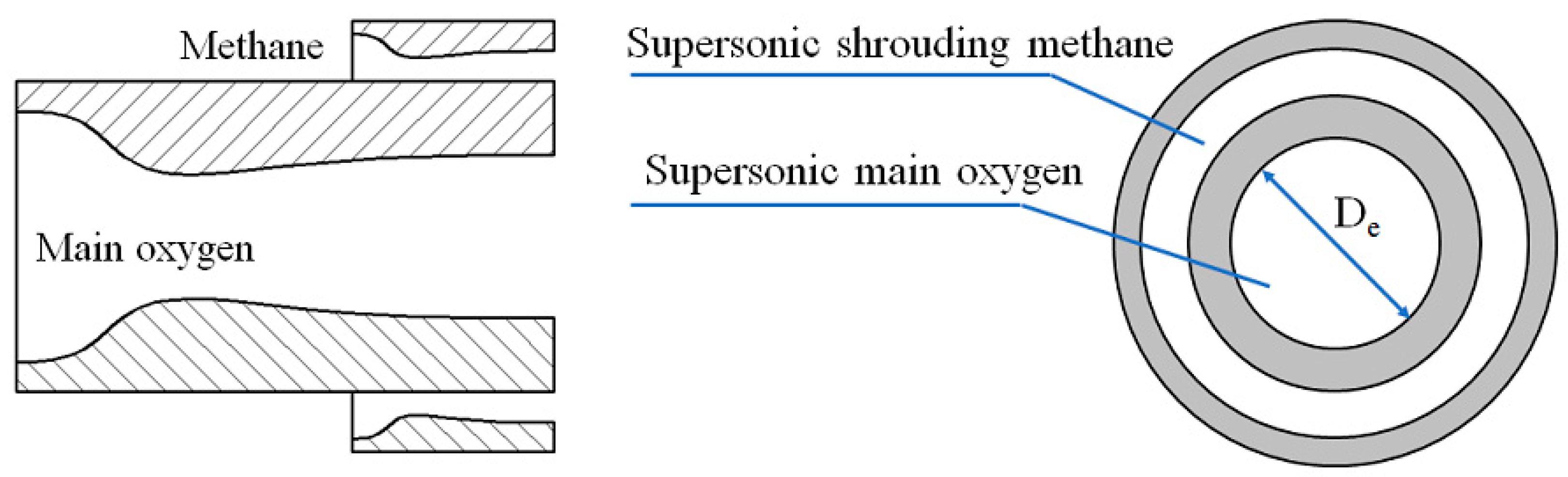

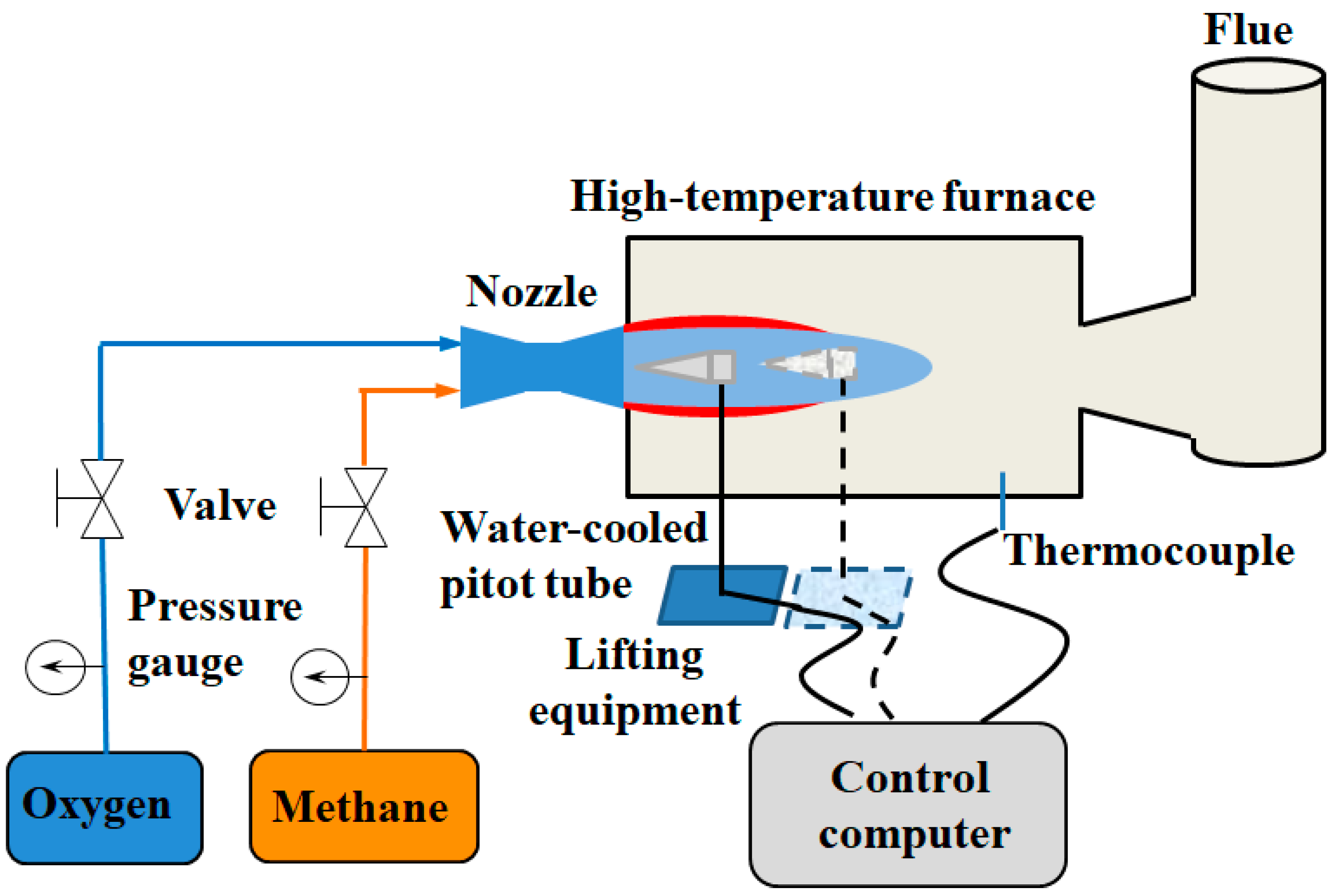

2. Experimental Equipment and Numerical Simulations

2.1. Experimental Equipment

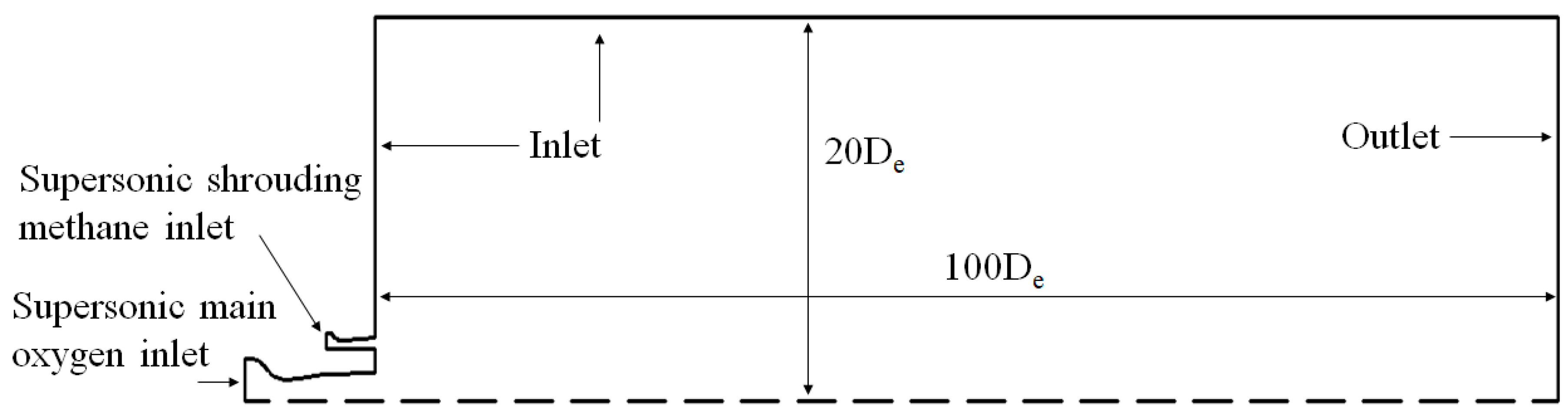

2.2. Numerical Simulation

2.3. Simulation Details

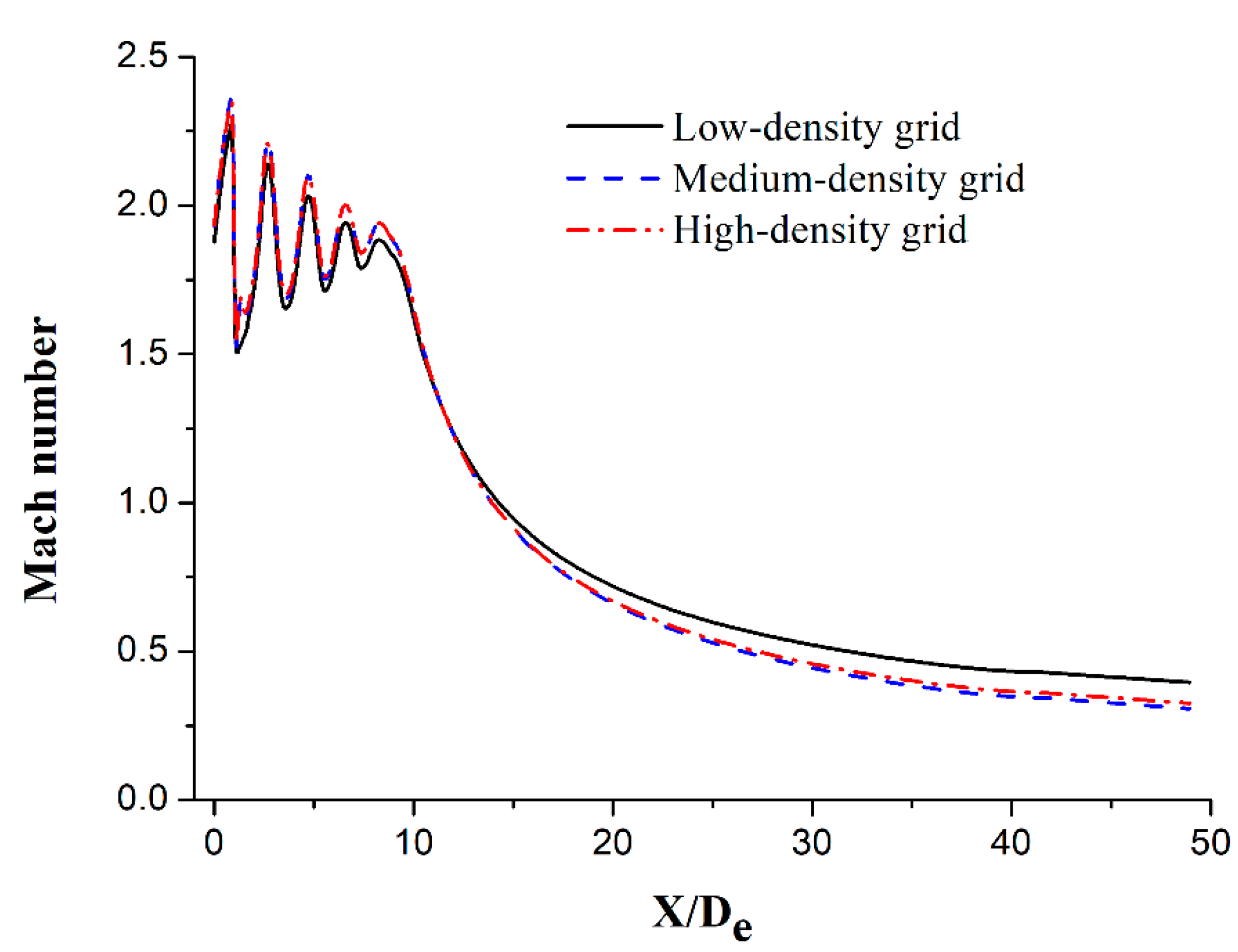

2.4. Grid Independence Test

3. Results and Discussion

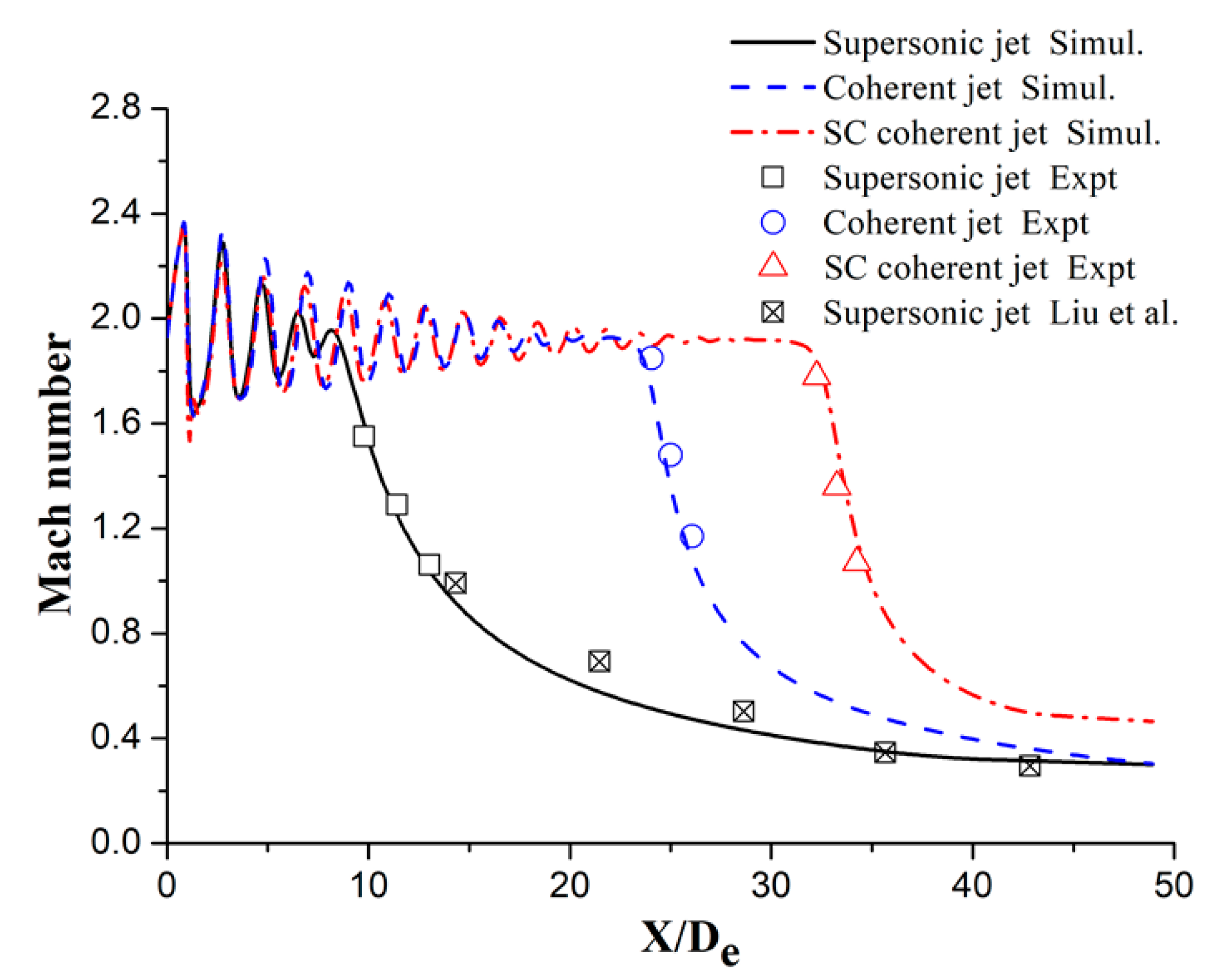

3.1. Mach Number Distribution

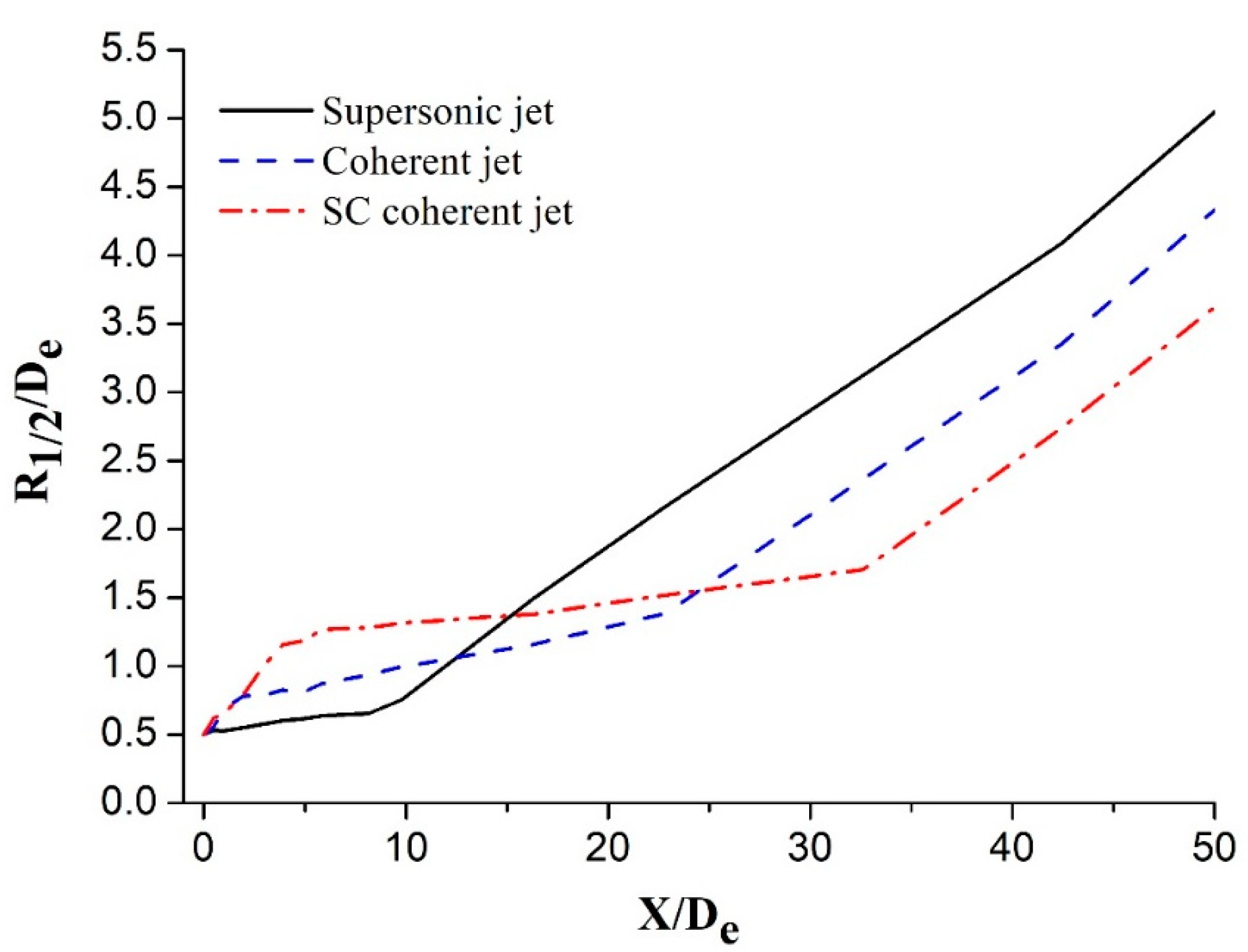

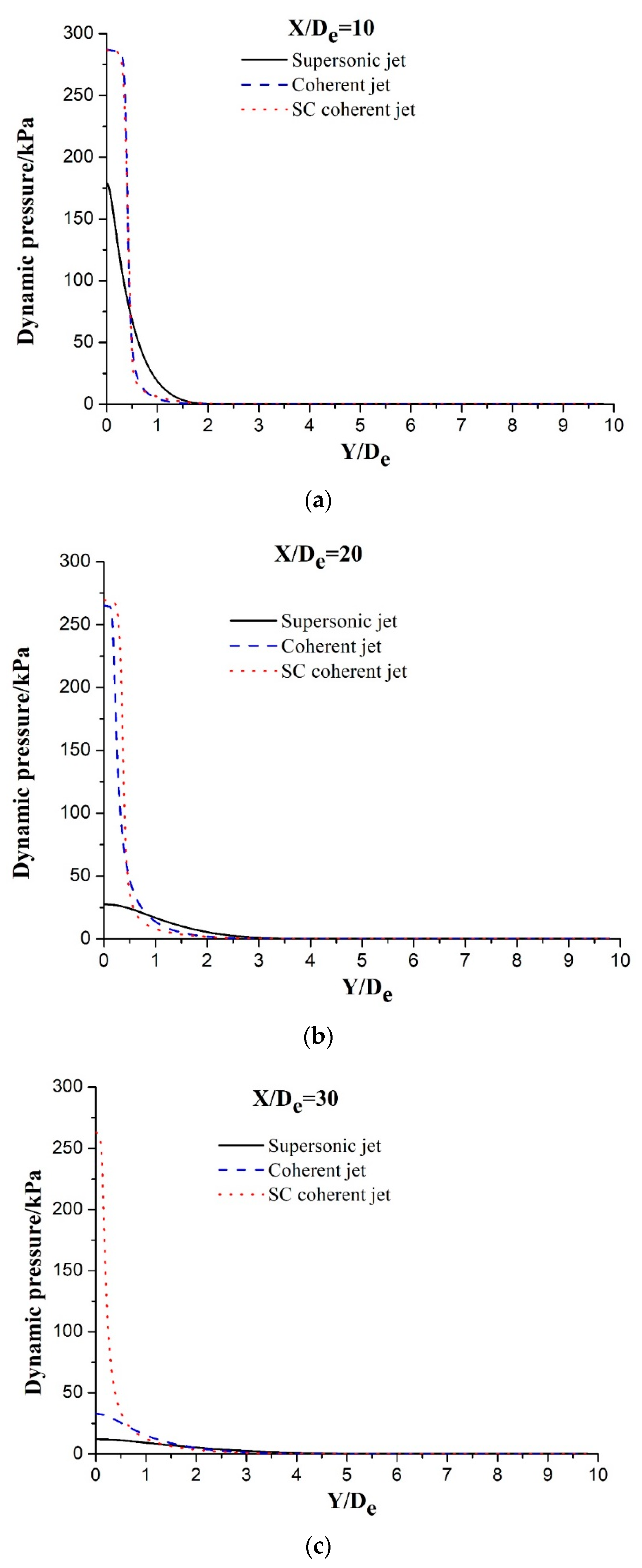

3.2. Pressure Distribution

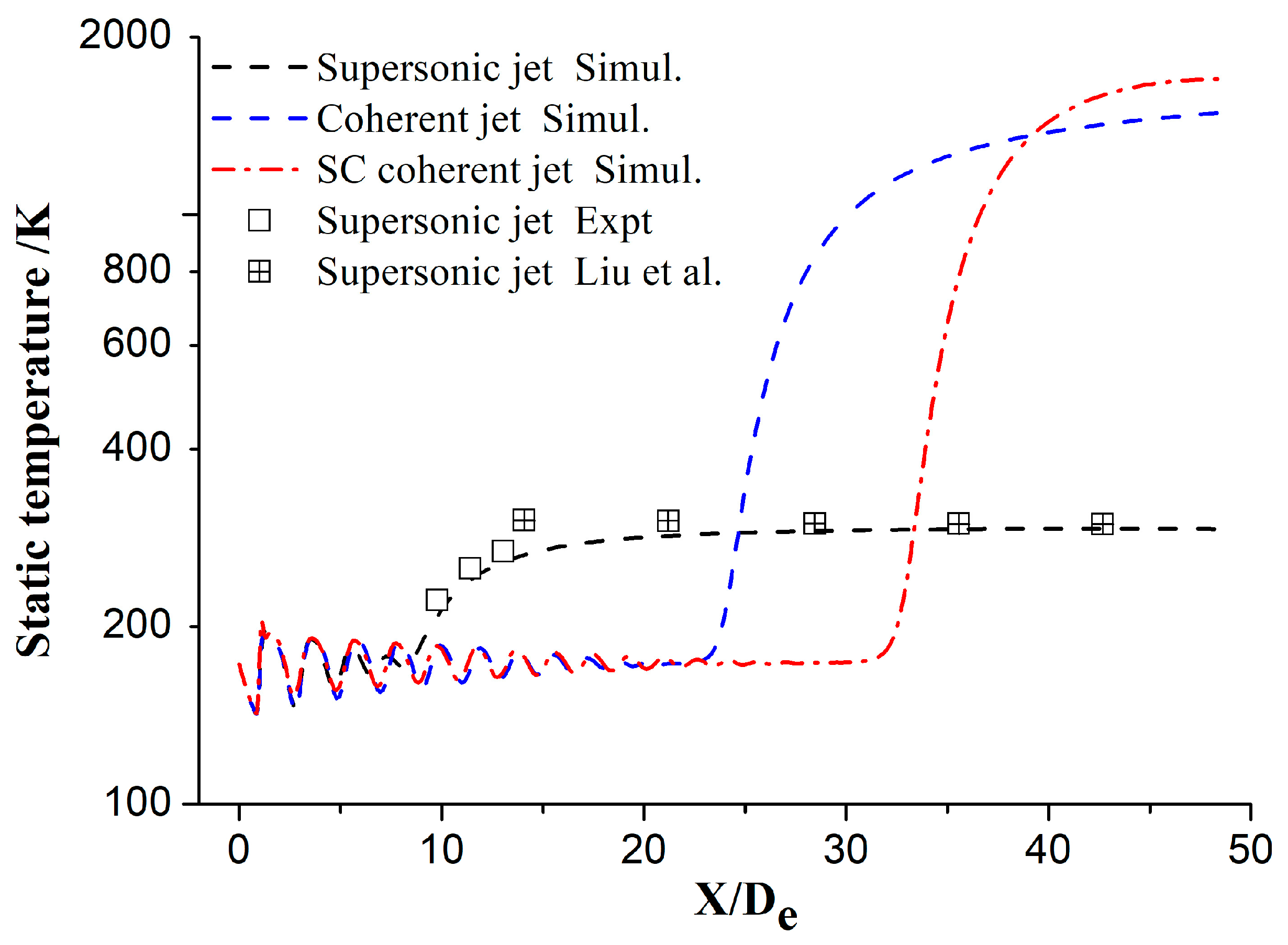

3.3. Temperature Distribution

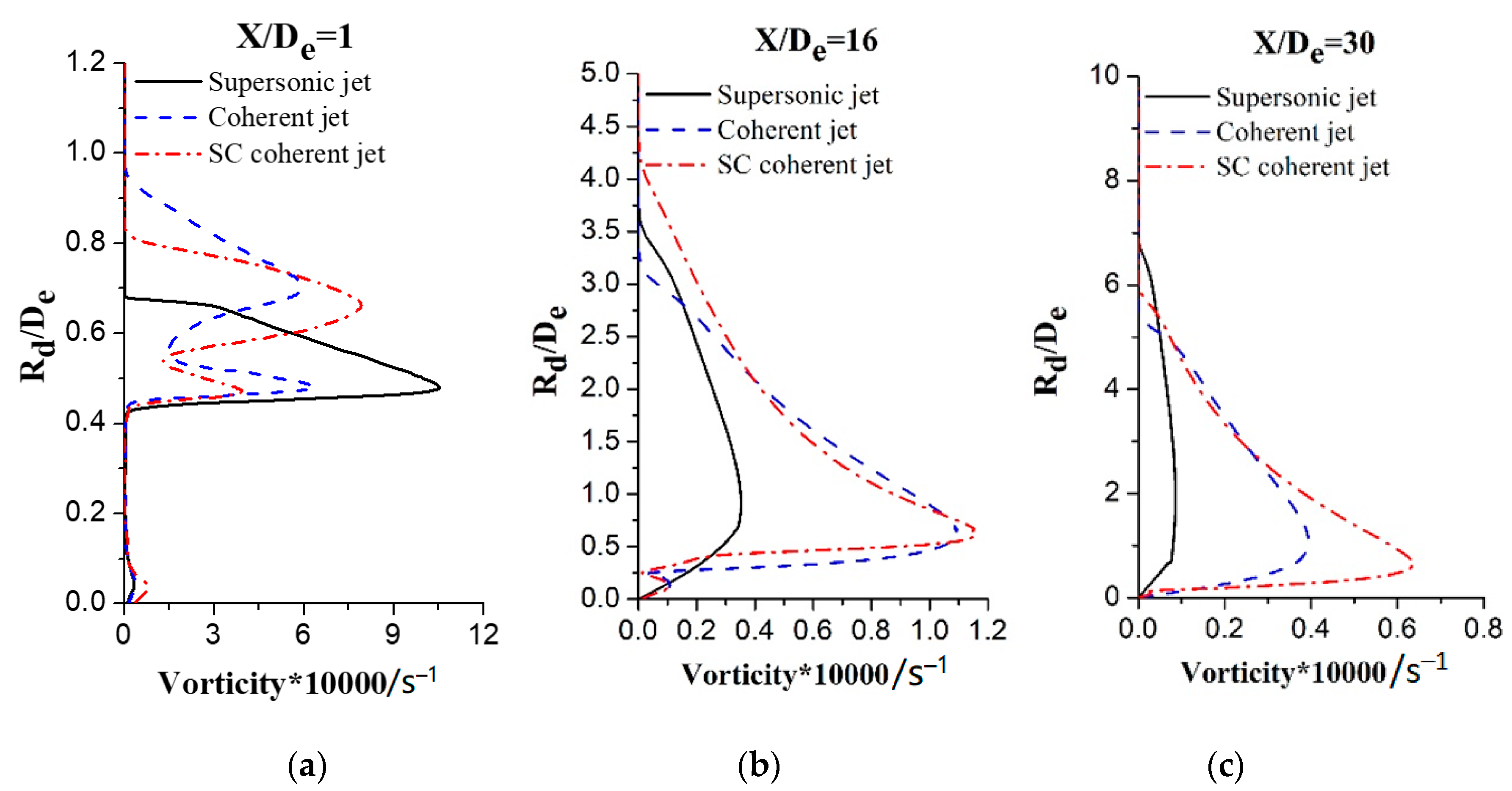

3.4. Vorticity and Turbulence Intensity

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eshwar, K.R.; Ville, V.V.; Petri, S. Numerical modelling of the influence of argon flow rate and slag layer height on open-eye formation in a 150 ton steelmaking ladle. Metals 2019, 9, 1048. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, K.; Wang, R.F. Physical modelling of splashing triggered by the gas jet of an oxygen lance in a converter. Metals 2019, 9, 409. [Google Scholar] [CrossRef]

- Odenthal, H.J.; Kemminger, A.; Krause, F. Review on modeling and simulation of the electric arc furnace (EAF). Steel Res. Int. 2017, 89, 1700098. [Google Scholar] [CrossRef]

- Ersson, M.; Tilliander, A. Review on CFD simulation and modeling of decarburization processes. Steel Res. Int. 2018, 89, 1700108. [Google Scholar] [CrossRef]

- Kärnä, A.; Järvinen, M.; Fabritius, T. Supersonic lance mass transfer modelling. In Proceedings of the International Conference on Physical and Numerical Simulation of Materials Processing, Oulu, Finland, 16–19 June 2013. [Google Scholar]

- Anderson, J.E.; Farrenkopf, D.R. Coherent Gas Jet. U.S. Patent 5823762, 20 October 1998. [Google Scholar]

- Ersson, M.; Tilliander, A.; Jonsson, L. A mathematical model of an impinging air jet on a water surface. ISIJ Int. 2008, 48, 377–384. [Google Scholar] [CrossRef]

- Sabah, S.; Brooks, G. Splash distribution in oxygen steelmaking. Metall. Mater. Trans. B 2015, 46, 863–872. [Google Scholar] [CrossRef]

- Malfa, E.; Giavani, C.; Memoli, F. Numerical simulation of a supersonic oxygen lance for industrial application in EAFs. MPT Int. 2005, 28, 44–50. [Google Scholar]

- Zhao, F.; Sun, D.; Zhu, R. Effect of shrouding gas parameters on characteristics of supersonic coherent jet. Metall. Mater. Trans. B 2017, 48, 1807–1816. [Google Scholar] [CrossRef]

- Meidani, A.R.N.; Isac, M.; Richardson, A. Modelling shrouded supersonic jets in metallurgical reactor vessels. ISIJ Int. 2004, 44, 1639–1645. [Google Scholar] [CrossRef]

- Tang, G.W.; Chen, Y.; Silaen, A.K. Effects of fuel input on coherent jet length at various ambient temperatures. App. Ther. Eng. 2019, 153, 513–523. [Google Scholar] [CrossRef]

- Tang, G.W.; Chen, Y.; Silaen, A.K. Investigation on coherent jet potential core length in an electric arc furnace. Steel Res. Int. 2018, 90, 1504–1516. [Google Scholar] [CrossRef]

- Odenthal, H.J.; Bader, J.; Nörthemann, R. The new generation of SIS injector for improved EAF processes. In Proceedings of the METEC & 2nd ESTAD–European Steel Technology and Application Conference, Düsseldorf, Germany, 15–19 June 2015; pp. 69–78. [Google Scholar]

- Sumi, I.; Kishimoto, Y.; Kikuchi, Y. Effect of high-temperature field on supersonic oxygen jet behavior. ISIJ Int. 2006, 46, 1312–1317. [Google Scholar] [CrossRef]

- Sumi, I.; Okuyama, G.; Nabeshima, S. Behavior of top-blown jet under reduced pressure. ISIJ Int. 2007, 47, 73–79. [Google Scholar] [CrossRef]

- Klioutchnikov, I.; Olivier, H.; Odenthal, J. Numerical investigation of coaxial jets entering into a hot environment. Comp. Fluids 2013, 86, 490–499. [Google Scholar] [CrossRef]

- Alam, M.; Naser, J.; Brooks, G. Computational fluid dynamics modeling of supersonic coherent jets for electric arc furnace steelmaking process. Metall. Mater. Trans. B 2010, 47, 1354–1367. [Google Scholar] [CrossRef]

- Alam, M.; Naser, J.; Brooks, G. Computational fluid dynamics simulation of supersonic oxygen jet behavior at steelmaking temperature. Metall. Mater. Trans. B 2010, 41, 636–645. [Google Scholar] [CrossRef]

- Alam, M.; Naser, J.; Brooks, G. A computational fluid dynamics model of shrouded supersonic jet impingement on a water surface. ISIJ Int. 2018, 52, 1026–1035. [Google Scholar] [CrossRef]

- Liu, F.; Sun, D.; Zhu, R. Effect of shrouding gas temperature on characteristics of a supersonic jet flow field with a shrouding Laval nozzle structure. Metall. Mater. Trans. B 2017, 49, 2050–2062. [Google Scholar] [CrossRef]

- Liu, F.; Sun, D.; Zhu, R. Effect of shrouding Mach number and ambient temperature on the flow field of coherent jet with shrouding Laval nozzle structure. Can. Metall. Q. 2019, 58, 96–106. [Google Scholar] [CrossRef]

- Anderson, J.D. Introduction to Flight; McGraw-Hill Education (Asia): Singapore, 2013; pp. 125–131. [Google Scholar]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics, the Finite Volume Method; Prentice Hall: London, UK, 2007; pp. 157–179. [Google Scholar]

- Abdolhamid, K.S.; Pao, S.P.; Massey, S.J. Temperature corrected turbulence model for high temperature jet flow. J. Fluids Eng. 2006, 126, 844–850. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Liu, F.; Zhu, R.; Dong, K. Flow field characteristics of coherent jet with preheating oxygen under various ambient temperatures. ISIJ Int. 2016, 56, 1519–1528. [Google Scholar] [CrossRef]

- Jones, W.P.; Whitelaw, J.H. Calculation methods for reacting turbulent flows: A review. Combust. Flame 1982, 48, 1–26. [Google Scholar] [CrossRef]

- Papamoschou, D.; Roshko, A. The compressible turbulent shear layer: An experimental study. J. Fluid Mech. 1988, 197, 453–477. [Google Scholar] [CrossRef]

| Name of the Boundary | Type of Boundary Conditions | Values |

|---|---|---|

| Supersonic main oxygen inlet | mass flow rate | 0.8 kg·s−1 |

| mass fractions | O2 = 100% | |

| total temperature | 300 K | |

| Supersonic shrouding gas inlet | Mach number | 2/0.8 |

| mass fractions | CH4 = 100% | |

| temperature | 300 K | |

| Pressure inlet | static pressure | 101,325 Pa |

| mass fractions | O2 = 21%, N2 = 79% | |

| temperature | 1700 K/300 K | |

| Pressure outlet | static pressure | 101,325 Pa |

| mass fractions | O2 = 21%, N2 = 79% | |

| temperature | 1700 K/300 K | |

| Wall | no-slip | 300 K |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, F.; Zhu, R.; Wang, W. Characteristics of the Supersonic Combustion Coherent Jet for Electric Arc Furnace Steelmaking. Materials 2019, 12, 3504. https://doi.org/10.3390/ma12213504

Zhao F, Zhu R, Wang W. Characteristics of the Supersonic Combustion Coherent Jet for Electric Arc Furnace Steelmaking. Materials. 2019; 12(21):3504. https://doi.org/10.3390/ma12213504

Chicago/Turabian StyleZhao, Fei, Rong Zhu, and Wenrui Wang. 2019. "Characteristics of the Supersonic Combustion Coherent Jet for Electric Arc Furnace Steelmaking" Materials 12, no. 21: 3504. https://doi.org/10.3390/ma12213504

APA StyleZhao, F., Zhu, R., & Wang, W. (2019). Characteristics of the Supersonic Combustion Coherent Jet for Electric Arc Furnace Steelmaking. Materials, 12(21), 3504. https://doi.org/10.3390/ma12213504