Measurements of Temperature Distribution for High Temperature Steel Plates Based on Digital Image Correlation

Abstract

1. Introduction

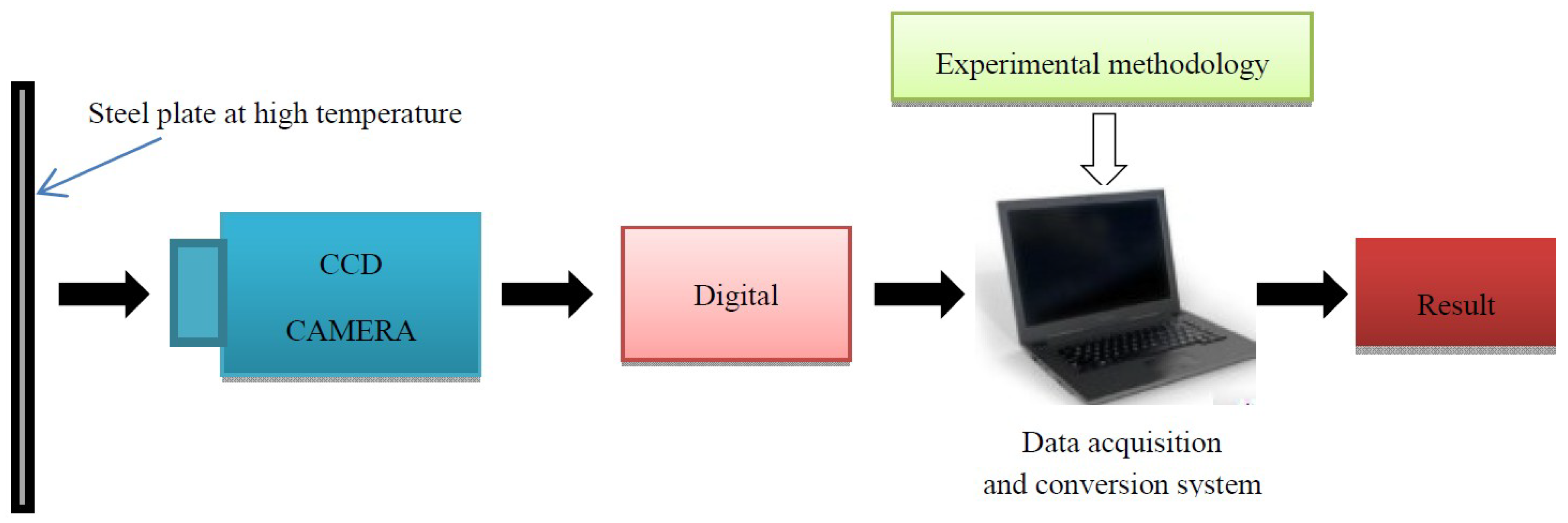

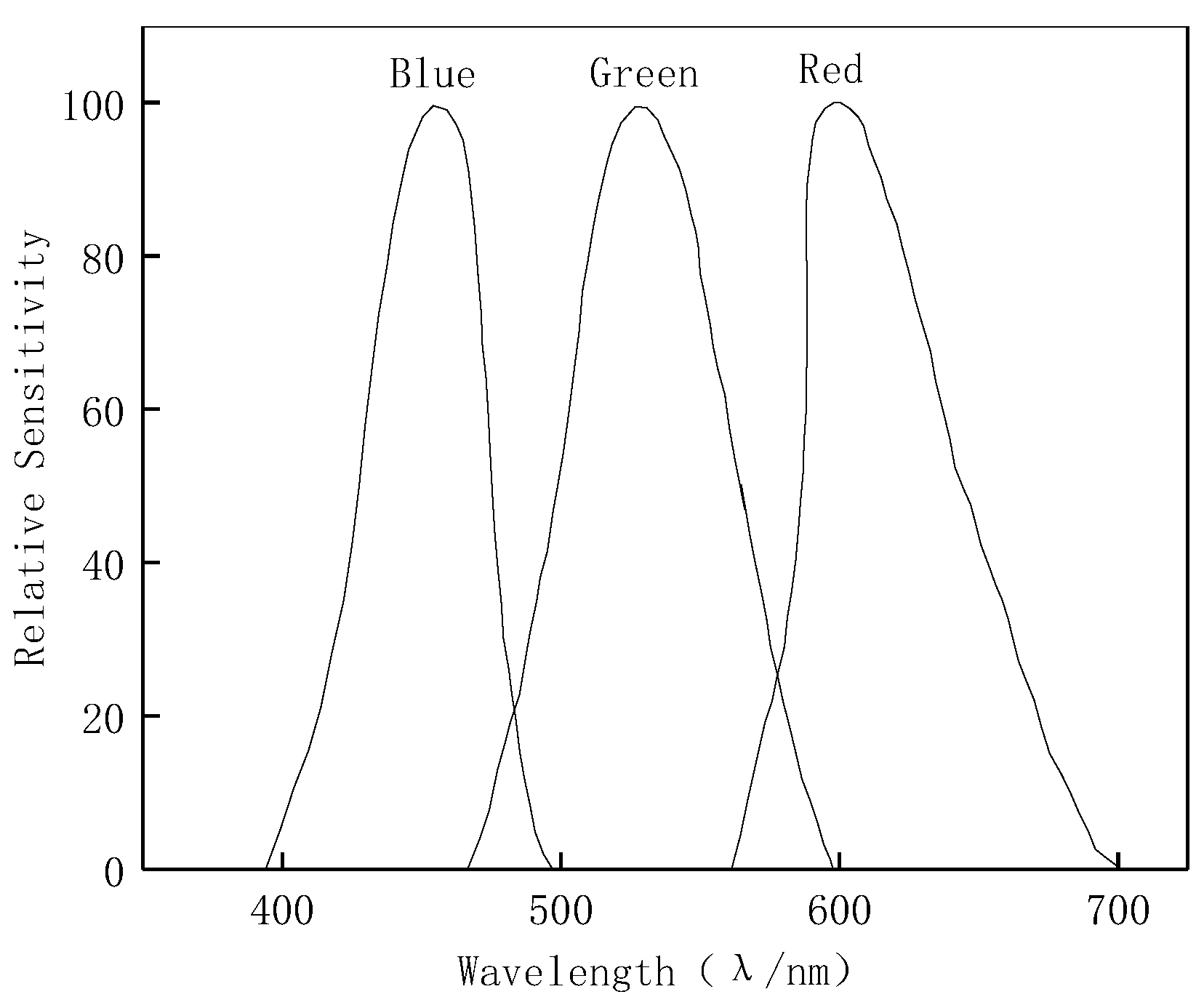

2. Principle of Thermal Radiation Temperature Measurement

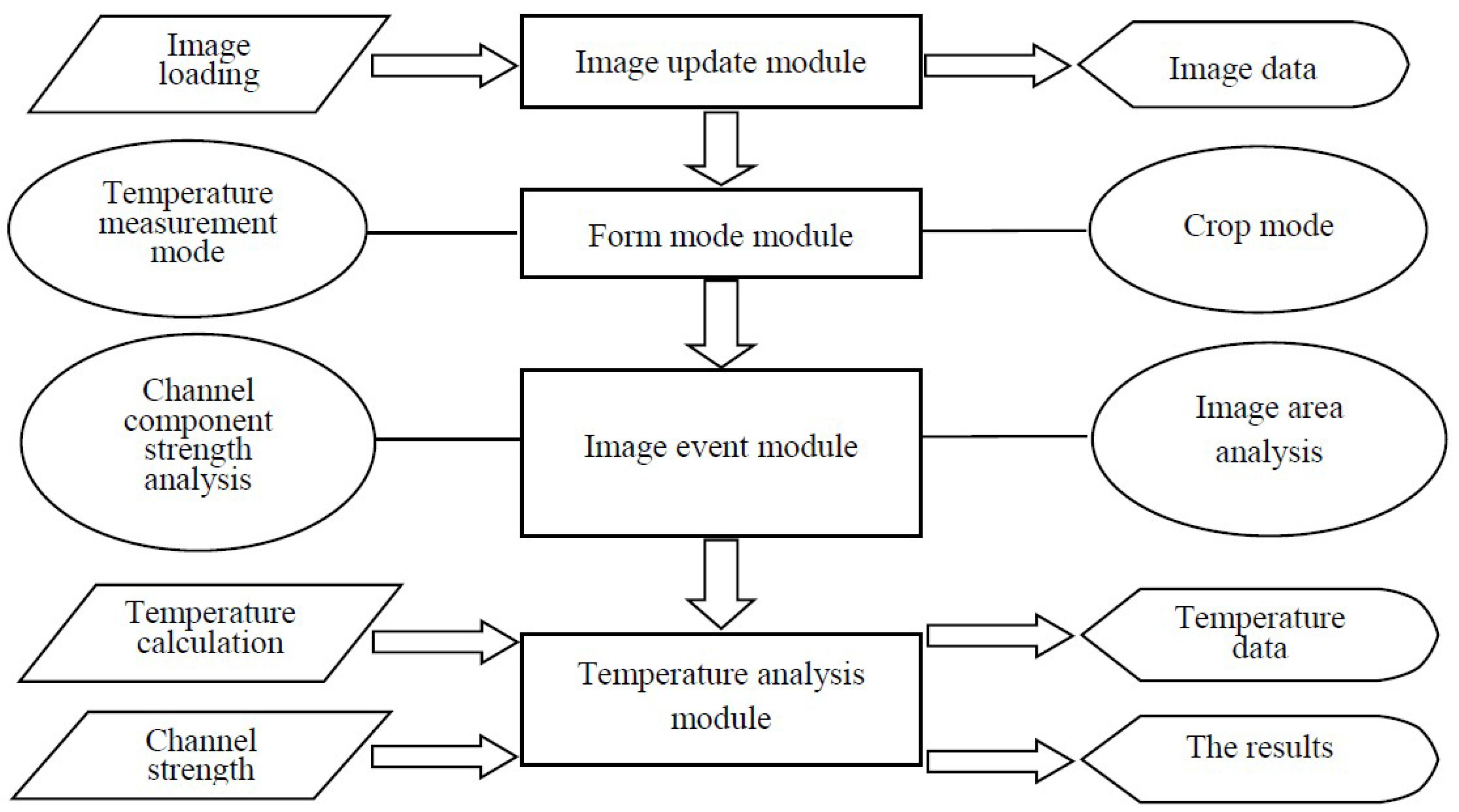

3. Image Processing System

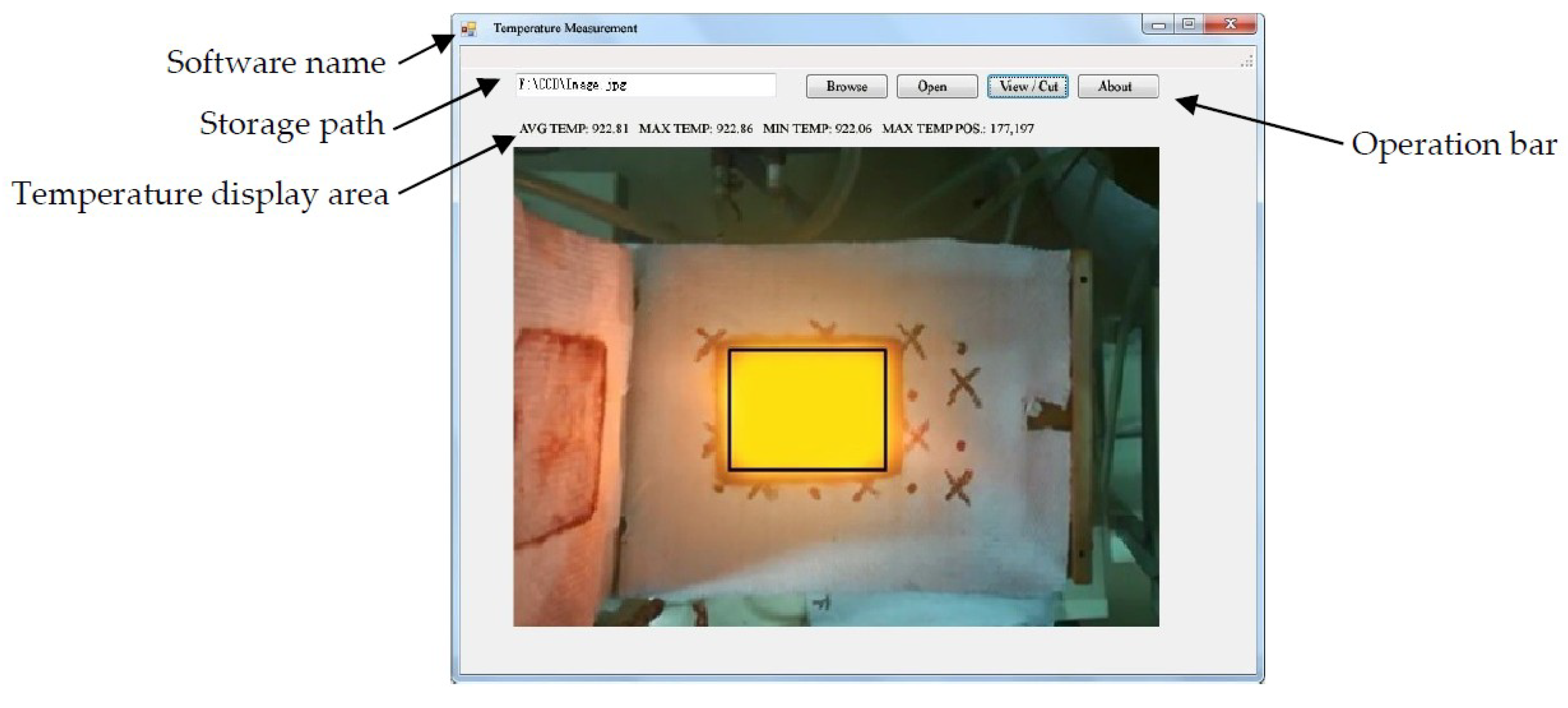

3.1. Image Update Module

- The captured pictures are written to the memory in the format of a bitmap and the picture is displayed.

- Input of image data is realized and stored in an external memory; output is browsed.

- The picture size is automatically adjusted to fit the window output.

3.2. Form Mode Module

- Complete the selection of the temperature detection mode or the picture cropping mode.

- Select the temperature detection mode and perform temperature measurement on the entire window image.

- Select the picture cropping mode and cut the window image to analyze the area for temperature analysis.

3.3. Image Event Module

- Complete the image update display of the frame selection area.

- Digitize the image area by pixels.

- Traverse the area pixels, record the number of occurrences of the color component intensity values of each channel and store them in an array.

3.4. Temperature Analysis Module

4. Temperature Calibration and Results Analysis

4.1. Error Analysis

4.1.1. CCD Halo

4.1.2. Acquisition Distance

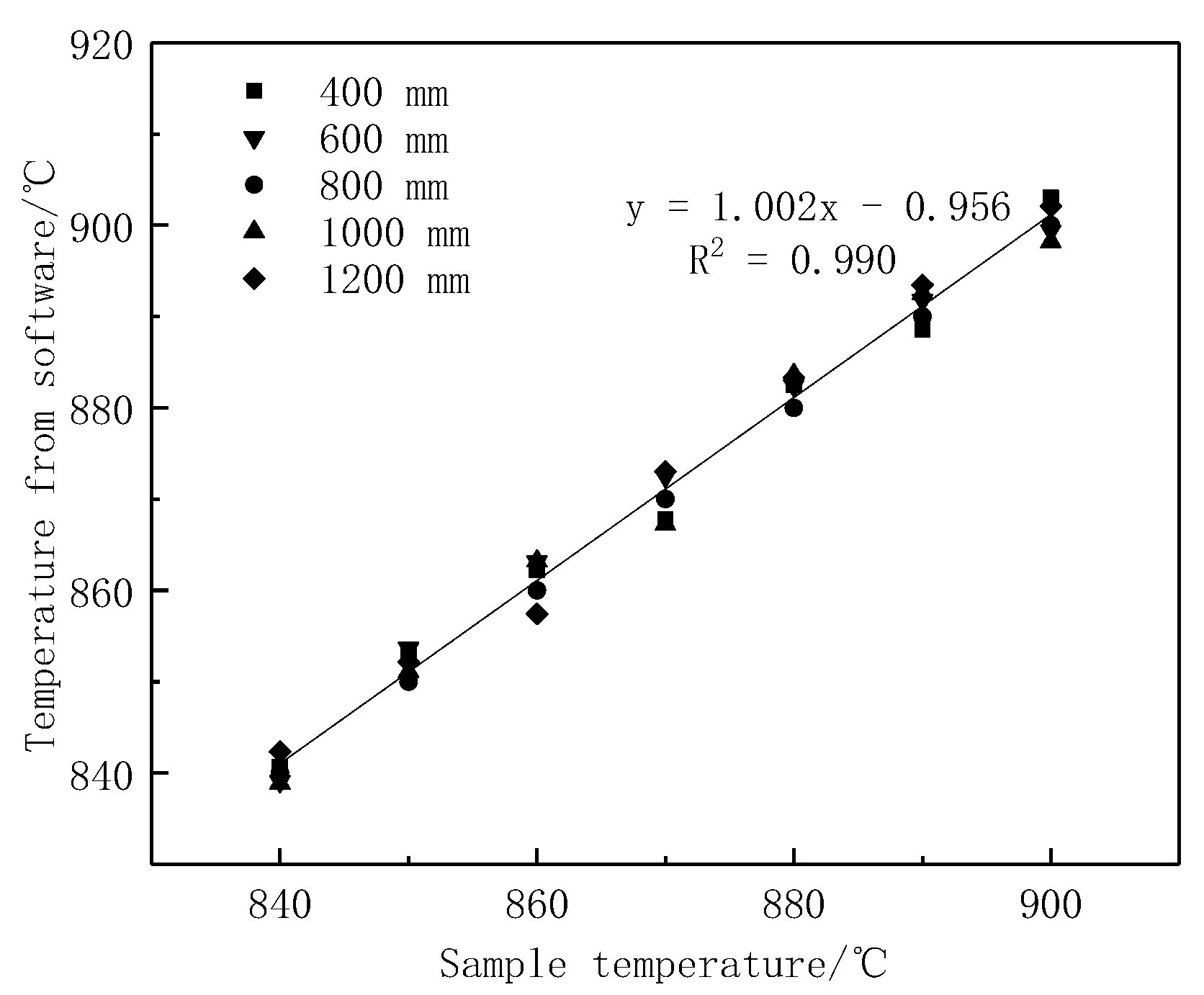

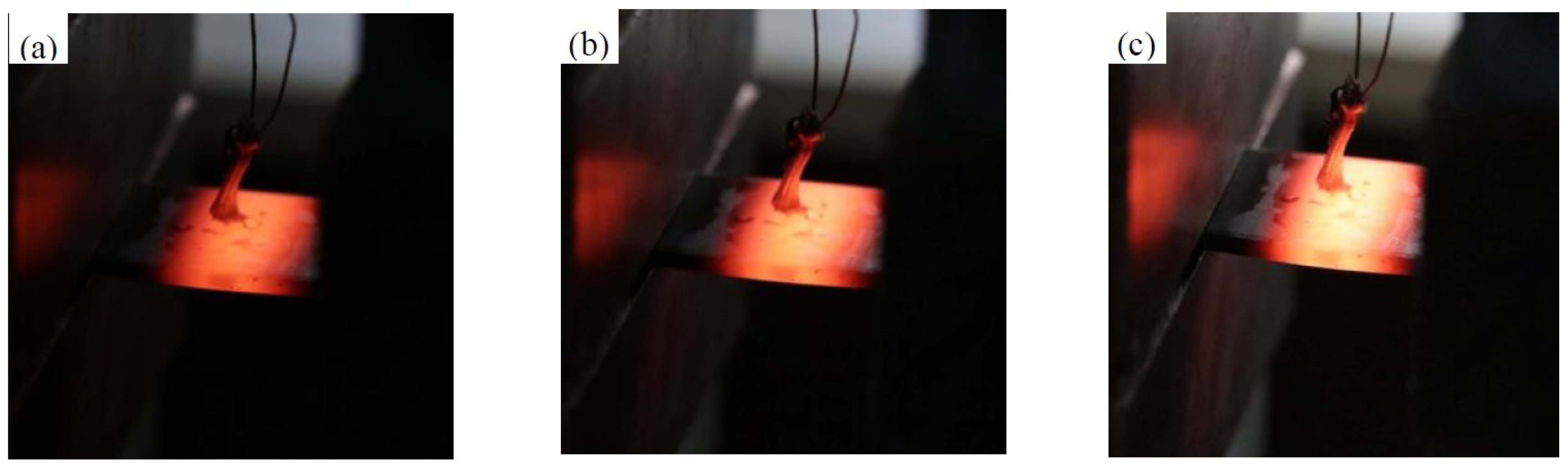

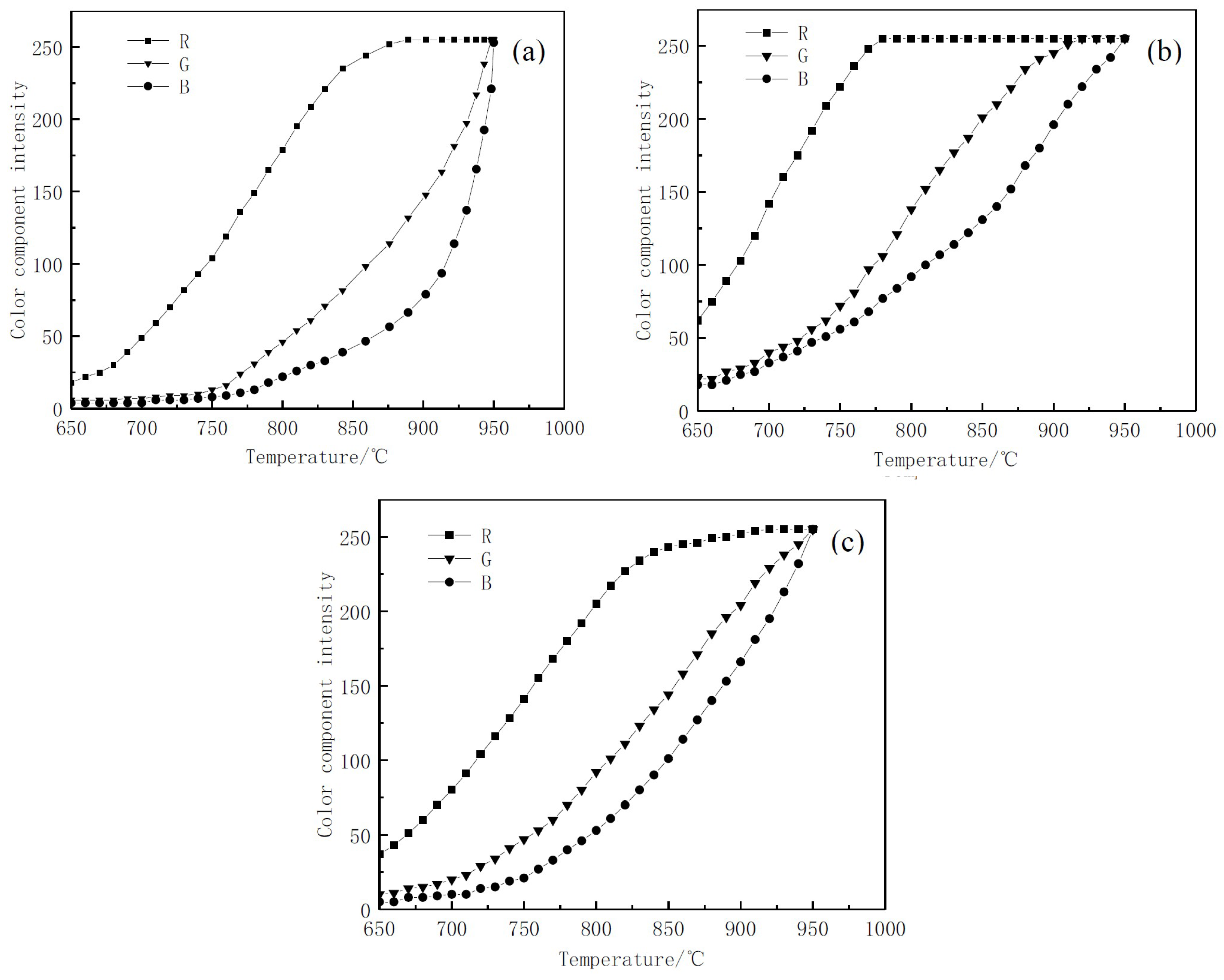

4.2. Temperature Calibration

4.2.1. Calibration Experiment

4.2.2. Image Processing Analysis

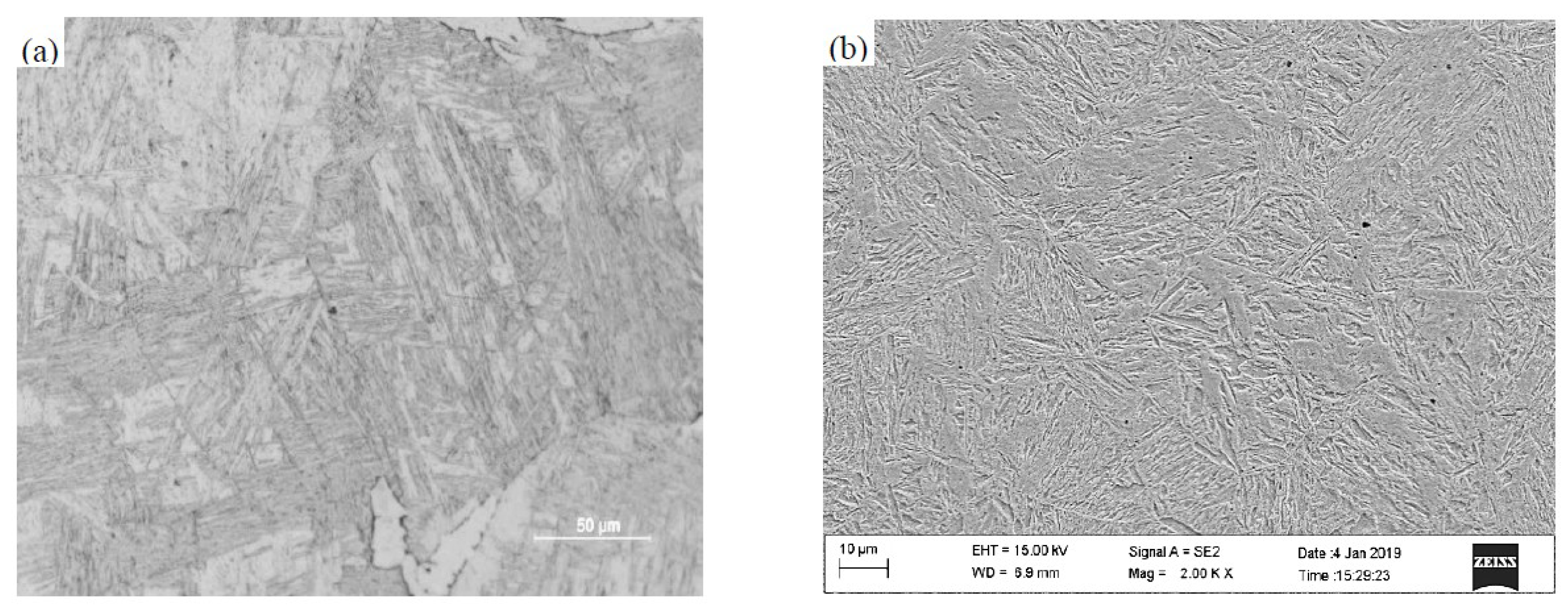

4.3. Experimental Test Analysis

5. Conclusions

- Based on the theoretical analysis, the relevant functional modules of the temperature measurement system were developed. It realized functions such as image reading, image preprocessing, point temperature calculation, field average temperature calculation, field minimum and minimum value calculation and coordinate display.

- Through error analysis and temperature calibration, the error of the temperature measurement system was acceptable and the error range was within 8 °C.

- Through the B1500HS boron steel test of quenching by electromagnetic induction heating, the temperature measurement system was stable and met the experimental requirements. The temperature measurement system has a simple structure and strong practicability, and it could become an effective tool for non-contact measurement of high temperature steel plates after further development.

Author Contributions

Funding

Conflicts of Interest

References

- Shi, L.; Wen, Y.-B.; Zhao, G.-S.; Yu, T. Recognition of blast furnace gas flow center distribution based on infrared image processing. J. Iron Steel Res. Int. 2016, 23, 203–209. [Google Scholar] [CrossRef]

- Nele, L.; Sarno, E.; Keshari, A. An image acquisition system for real-time seam tracking. Int. J. Adv. Manuf. Technol. 2013, 69, 2099–2110. [Google Scholar] [CrossRef]

- Cho, Y.-S.; Park, H.-S. Optimization of image capturing method of wear particles for condition diagnosis of machine parts. Trans. Nonferrous Met. Soc. China 2009, 19, s215–s219. [Google Scholar] [CrossRef]

- Herrera-Solaz, V.; Patriarca, L.; Foletti, S.; Segurado, J.; Niffenegger, M. Microstructure-based modelling and digital image correlation measurement of strain fields in austenitic stainless steel 316L during tension loading. Mater. Sci. Eng. A 2019, 751, 99–106. [Google Scholar] [CrossRef]

- Le, D.B.; Tran, S.D.; Torero, J.L.; Dao, V.T. Application of digital image correlation system for reliable deformation measurement of concrete structures at high temperatures. Eng. Struct. 2019, 192, 181–189. [Google Scholar] [CrossRef]

- Jung, A.; Al Majthoub, K.; Jochum, C.; Kirsch, S.-M.; Welsch, F.; Seelecke, S.; Diebels, S. Correlative digital image correlation and infrared thermography measurements for the investigation of the mesoscopic deformation behaviour of foams. J. Mech. Phys. Solids 2019, 130, 165–180. [Google Scholar] [CrossRef]

- Krstulović-Opara, L.; Surjak, M.; Vesenjak, M.; Tonković, Z.; Kodvanj, J.; Domazet, Ž. Comparison of infrared and 3D digital image correlation techniques applied for mechanical testing of materials. Infrared Phys. Technol. 2015, 73, 166–174. [Google Scholar] [CrossRef]

- Nowak, M.; Maj, M. Determination of coupled mechanical and thermal fields using 2D digital image correlation and infrared thermography: Numerical procedures and results. Arch. Civ. Mech. Eng. 2018, 18, 630–644. [Google Scholar] [CrossRef]

- Zhu, Q.; Lu, C.-L.; Yin, Y.-X.; Chen, X.-Z. Burden Distribution Calculation of Bell-Less Top of Blast Furnace Based on Multi-Radar Data. J. Iron Steel Res. Int. 2013, 20, 33–37. [Google Scholar] [CrossRef]

- Gang, T.; Zhang, J.; Zhang, M.B.; Liu, F.X. Background rectification and feature extraction of image in a spot weld of Al alloy X-ray detection. Acta Metall. Sin. 2000, 17, 75–79. [Google Scholar]

- Meng, X.T.; Kang, A.G.; Zhang, X.M.; Li, J.H.; Huang, Q.; Li, F.M.; Liu, X.G.; Zhou, H.Y. Difference in electron-and gamma-irradiation effects on output characteristic of color CMOS digital image sensors. Rare Met. 2004, 23, 165–170. [Google Scholar]

- Zhang, X.Y.; Wang, J.H.; Cheng, Q.; Zhang, B.; Xiang, X.; Xu, H. Experimental research on temperature measurement by wide dynamic RAW image processing. Proc. CSEE 2015, 35, 3338–3344. [Google Scholar]

- Cai, Y.; Lu, X.; Jiang, N. A Survey on Quantum Image Processing. Chin. J. Electron. 2018, 27, 718–727. [Google Scholar] [CrossRef]

- Dong, X.; Pinson, D.; Zhang, S.; Yu, A.; Zulli, P. Gas-powder flow in blast furnace with different shapes of cohesive zone. Appl. Math. Model. 2006, 30, 1293–1309. [Google Scholar] [CrossRef]

- Gade, R.; Moeslund, T.B. Thermal cameras and applications: A survey. Mach. Vis. Appl. 2014, 25, 245–262. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared Thermography for Temperature Measurement and Non-Destructive Testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef] [PubMed]

- Vladimir, F. High-temperature three-colour thermal imager. Prz. Elektrotechniczny 2015, 1, 210–216. [Google Scholar]

- Han, M.-S.; Han, S.M.; Kim, H.J.; Shin, J.C.; Ahn, M.S.; Kim, H.W.; Han, Y.H. Low-cost compact thermal imaging sensors for body temperature measurement. SPIE Def. Secur. Sens. 2013, 8704, 87041. [Google Scholar]

- Gutschwager, B.; Taubert, D.; Hollandt, J. Analysis of reference sources for the characterization and calibration of infrared cameras. Int. J. Thermophys. 2015, 36, 303–314. [Google Scholar] [CrossRef]

- Zhang, Y.-C.; Chen, Y.-M.; Luo, C. A method for improving temperature measurement precision on the uncooled infrared thermal imager. Measurement 2015, 74, 64–69. [Google Scholar] [CrossRef]

- Valiorgue, F.; Brosse, A.; Naisson, P.; Rech, J.; Hamdi, H.; Bergheau, J.M. Emissivity calibration for temperatures measurement using thermography in the context of machining. Appl. Therm. Eng. 2013, 58, 321–326. [Google Scholar] [CrossRef]

- Zhang, J.; Tang, Z.; Xu, N.; Wang, Y.; Sun, H.; Wang, Z.; Fang, L. A generalized model of TiOx-based memristive devices and its application for image processing. Chin. Phys. B 2017, 26, 90502. [Google Scholar] [CrossRef]

- Sun, Y.; Lou, C.; Zhou, H. A simple judgment method of gray property of flames based on spectral analysis and the two-color method for measurements of temperatures and emissivity. Proc. Combust. Inst. 2011, 33, 735–741. [Google Scholar] [CrossRef]

- Yan, J.H.; Bai, X.Q. Research on slab surface temperature-measurement of continuous casting based on CCD imaging. In Proceedings of the International Conference on Electronic Measurement & Instruments IEEE, Beijing, China, 16 August 2011; pp. 29–32. [Google Scholar]

- Wei, C.Y.; Wang, F.; Ma, Z.Y.; Xue, F.; Hu, G.; Li, X.D.; Yan, J.H.; Cen, K.F. Research on colorimetric flame temperature measurement using colored CCD. Proc. CSEE 2000, 20, 70–76. [Google Scholar]

- Cui, D.C.D.; Ren, L.R.L.; Shi, F.S.F.; Shi, J.S.J.; Qian, Y.Q.Y.; Wang, H.W.H.; Chang, B.C.B. Test and analysis of the halo in low-light-level image intensifiers. Chin. Opt. Lett. 2012, 10, 60401–60403. [Google Scholar]

- Yongbin, Y.U.; Nijing, Y.; Chenyu, Y.; Tashi, N. Memristor bridge-based low pass filter for image processing. J. Syst. Eng. Electron. 2019, 30, 448–455. [Google Scholar]

- Wang, H.J.; Huang, Z.F.; Wang, D.D.; Luo, Z.X.; Sun, Y.P.; Fang, Q.Y.; Lou, C.; Zhou, H.C. Measurements on flame temperature and its 3D distribution in a 660 MWe arch-fired coal combustion furnace by visible image processing and verification by using an infrared pyrometer. Meas. Sci. Technol. 2009, 20, 114006. [Google Scholar]

- Fan, Y.; Ni, D.; Ma, H. HyperDB: A hyperspectral land class database designed for an image processing system. Tsinghua Sci. Technol. 2017, 22, 112–118. [Google Scholar] [CrossRef]

| Different Distances (mm) | Temperature Measurement Point (°C) | ||||||

|---|---|---|---|---|---|---|---|

| 800 | 840 | 850 | 860 | 870 | 880 | 890 | 900 |

| 400 | 840.7 | 853.4 | 862.2 | 867.8 | 882.5 | 888.6 | 903.0 |

| 600 | 839.1 | 853.7 | 863.1 | 872.5 | 882.4 | 891.8 | 899.4 |

| 1000 | 838.9 | 851.1 | 863.2 | 867.2 | 883.6 | 892.6 | 898.2 |

| 1200 | 842.3 | 852.2 | 857.4 | 873.0 | 883.3 | 893.5 | 902.1 |

| Absolute deviation | 2.3 | 3.6 | 3.2 | 3.0 | 3.6 | 3.5 | 3.0 |

| Maximum standard deviation | 1.6 | 2.6 | 2.3 | 2.1 | 2.6 | 2.4 | 2.1 |

| Measuring Method | Temperature Results (°C) | ||||

|---|---|---|---|---|---|

| Temperature measurement software system | 910.6 | 915.3 | 922.8 | 929.3 | 931.1 |

| Temperature measuring gun | 902.9 | 910.7 | 918.4 | 922.6 | 925.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, P.; Wang, G.; Gao, Z.; Liu, X.; Liu, W. Measurements of Temperature Distribution for High Temperature Steel Plates Based on Digital Image Correlation. Materials 2019, 12, 3322. https://doi.org/10.3390/ma12203322

Qi P, Wang G, Gao Z, Liu X, Liu W. Measurements of Temperature Distribution for High Temperature Steel Plates Based on Digital Image Correlation. Materials. 2019; 12(20):3322. https://doi.org/10.3390/ma12203322

Chicago/Turabian StyleQi, Pengyuan, Gang Wang, Zhen Gao, Xianghua Liu, and Weijie Liu. 2019. "Measurements of Temperature Distribution for High Temperature Steel Plates Based on Digital Image Correlation" Materials 12, no. 20: 3322. https://doi.org/10.3390/ma12203322

APA StyleQi, P., Wang, G., Gao, Z., Liu, X., & Liu, W. (2019). Measurements of Temperature Distribution for High Temperature Steel Plates Based on Digital Image Correlation. Materials, 12(20), 3322. https://doi.org/10.3390/ma12203322