Effectiveness of Reinforcing Bent Non-Uniform Pre-Stressed Glulam Beams with Basalt Fibre Reinforced Polymers Rods

Abstract

1. Introduction

2. Testing Materials

2.1. Wood

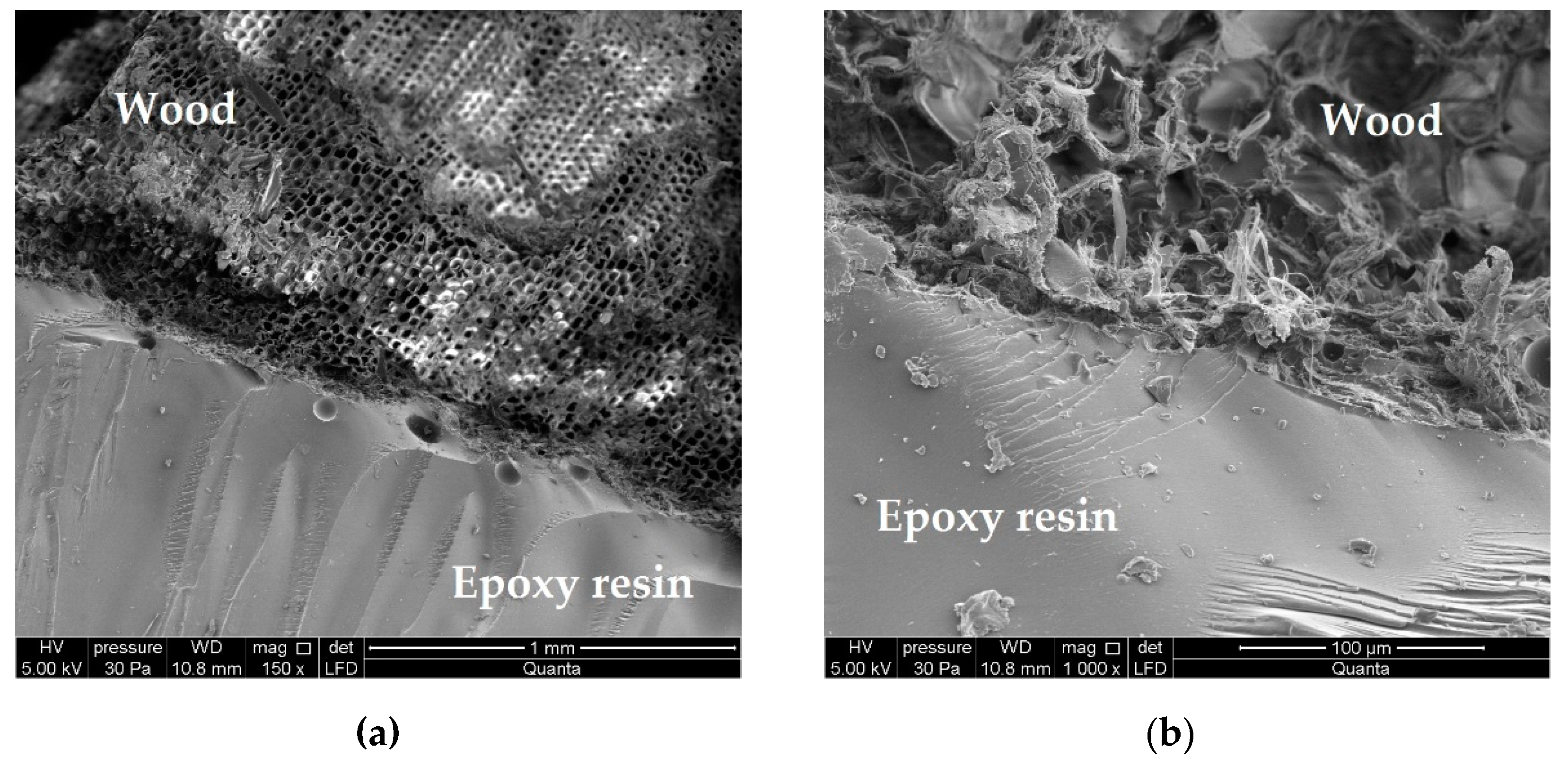

2.2. Applied Glues

2.3. Fibrous Composites

3. Testing Program

4. Test Results and Analysis

5. Conclusions

- A pre-stressed BFRP rod placed in the stretched fibre zone has satisfactorily improved the tested beams’ bearing capacity.

- The glulam wood reinforced with pre-stressed BFRP rods achieved higher bearing capacities in the “loading-relief” testing scheme—bearing capacity of approx. 47% and rigidity of approx. 10.4% were achieved, whereas for Wa-B beams, bearing capacity of approx. 54% and rigidity of approx. 9.8% were attained. It is possible to see that the BFRP basalt rods perfectly compensated the non-uniform wood structure and improved the material’s reliability.

- In locations of wood defects (knots, spiral grain, cracking, resin blisters, etc.), we observed increase in wood and fibrous composite deformations and stresses.

- The presence of composite rods halts or limits the propagation of cracking. Furthermore, as seen in u-F/2 (deflection–force) type curves, there is a lower spread of test results because of cracking neutralisation.

- In lower class elements, the destruction usually occurred in the stretched zone through cracking of wood fibres near the wood flaws, i.e., knots. The pre-stressed BFRP basalt rods improved the interoperation between the cracking knot and the “glue-rod” connection that stiffened it. Then, the beam damage usually started in the compressed zone.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Khatib, J.M. Sustainability of Construction Materials; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Anshari, B.; Guan, Z.; Komatsu, K.; Kitamori, A.; Jung, K. Explore novel ways to strengthen glulam beams by using compressed Japanese cedar. In Proceedings of the World Conference on Timber Engineering (WCTE), Trentino, Italy, 20–24 June 2010. [Google Scholar]

- Biliszczuk, J.; Bień, J.; Maliszkiewicz, P. Mosty Z Drewna Klejonego; Wydawnictwo Komunikacji i Łączności: Warsaw, Poland, 2001. [Google Scholar]

- Wdowiak, A. Defects in structural timber. Struct. Environ. 2017, 9, 112–122. [Google Scholar]

- Wdowiak, A. Struktura drewna konstrukcyjnego. J. Civil. Eng. Environ. Archit. 2017, 34, 365–380. [Google Scholar] [CrossRef][Green Version]

- Yang, H.; Ju, D.; Liu, W.; Lu, W. Prestressed glulam beams reinforced with CFRP bars. Constr. Build. Mater. 2016, 109, 73–83. [Google Scholar] [CrossRef]

- Krystofiak, T.; Proszyk, S.; Lis, B. Kleje do Produkcji Wielkowymiarowych Elementów Konstrukcyjnych Z Drewna Dla Budownictwa; Instytut Technologii Drewna: Poznań, Poland, 2007. [Google Scholar]

- Rajczyk, M.; Stachecki, B. Przegląd rozwiązań konstrukcyjnych wzmacniania belek z drewna klejonego zbrojeniem w postaci prętów. Zesz. Nauk. Politech. Częstochowskiej. Bud. 2011, 17, 186–195. [Google Scholar]

- Borri, A.; Corradi, M.; Vignoli, A. New materials for strengthening and seismic upgrading interventions. In Proceedings of the International Workshop Ariadne 10, Arcchip, Prague, Czech Republic, 22–28 April 2002; pp. 1–24. [Google Scholar]

- Borri, A.; Corradi, M.; Grazini, A. A method for flexural reinforcement of old wood beams with CFRP materials. Compos. Part. B Eng. 2005, 36, 143–153. [Google Scholar] [CrossRef]

- Triantafillou, T.C. Shear reinforcement of wood using FRP materials. J. Mater. Civil. Eng. 1997, 9, 65–69. [Google Scholar] [CrossRef]

- Wdowiak, A. Assessment of technical condition of wooden structures. In Transcom Proceedings 2015, Section 7, Civil Engineering; University of Zilina: Zilina, The Slovak Republic, 2015; pp. 326–332. [Google Scholar]

- Brol, J. Analiza doświadczalno-teoretyczna wzmacniania konstrukcji drewnianych kompozytami polimerowo-węglowymi. Ph.D. Thesis, Silesian University of Technology, Gliwice, Poland, 2005. [Google Scholar]

- Wdowiak, A. Analysis of bent timber beam reinforcement with the application of composite materials. Struct. Environ. 2016, 8, 10–16. [Google Scholar]

- Bank, L.C. Composites for Construction: Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Hollaway, L.; Teng, J.G. Strengthening and Rehabilitation of Civil Infrastructures Using Fibre-Reinforced Polymers (FRP) Composites; Woodhead Publishing Limited: Cambridge, UK, 2008. [Google Scholar]

- Niczyj, J.; Wojtaszewski, R. Obliczanie belek drewnianych zbrojonych kompozytem szklano—epoksydowym. Inżynieria I Bud. 1979, 5, 182–185. [Google Scholar]

- Plevris, N.; Triantafillou, T.C. FRP–reinforced wood as structural material. J. Mater. Civ. Eng. 1992, 4, 300–317. [Google Scholar] [CrossRef]

- Raftery, G.M.; Whelan, C. Low-grade glued laminated timber beams reinforced using improved arrangements of bonded-in GFRP rods. Constr. Build. Mater. 2014, 52, 209–220. [Google Scholar] [CrossRef]

- Karbhari, V.M. Durability of Composites for Civil Structural Applications; Woodhead Publishing Limited: Cambridge, UK, 2007. [Google Scholar]

- De la Rosa García, P.; Escamilla, A.C.; González García, M.N. Bending reinforcement of timber beams with composite carbon fiber and basalt fiber materials. Compos. Part. B Eng. 2013, 55, 528–536. [Google Scholar] [CrossRef]

- Raftery, G.M.; Kelly, F. Basalt FRP rods for reinforcement and repair of timber. Compos. Part. B Eng. 2015, 70, 9–19. [Google Scholar] [CrossRef]

- Yang, H.; Liu, W.; Lu, W.; Zhu, S.; Geng, Q. Flexural behavior of FRP and steel reinforced glulam beams: Experimental and theoretical evaluation. Constr. Build. Mater. 2016, 106, 550–563. [Google Scholar] [CrossRef]

- Yeboah, D.; Taylor, S.; McPolin, D.; Gilfillan, R. Pull-out behaviour of axially loaded basalt fibre reinforced polymer (BFRP) rods bonded perpendicular to the grain of glulam elements. Constr. Build. Mater. 2013, 38, 962–969. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M.; Speranzini, E. Reinforcement of wood with natural fibers. Compos. Part. B Eng. 2013, 53, 1–8. [Google Scholar] [CrossRef]

- Gallant, B.K. Development of a New Natural Fiber–Reinforced Polymer Composite and its Application in Glulam Tudor Arches. Master’s Thesis, Department of Civil Engineering, Dalhousie University, Halifax, NS, Canada, 2004. [Google Scholar]

- Speranzini, E.; Agnetti, S. Structural performance of natural fibers reinforced timber beams. In Proceedings of the 6th International Conference on FRP Composites in Civil Engineering (CICE 2012), Rome, Italy, 13–15 June 2012. [Google Scholar]

- Speranzini, E.; Tralascia, S. Engineered lumber: LVL and solid wood reinforced with natural fibres. In Proceedings of the World Conference on Timber Engineering (WCTE 2010), Riva del Garda, Italy, 20–24 June 2010. [Google Scholar]

- Al-Hayek, H.; Svecova, D. Flexural strength of post tensioned timber beams. J. Compos. Constr. 2014, 18. [Google Scholar] [CrossRef]

- Bohannan, B. Prestressing Wood Members; Forest Products Journal; University of Wisconsin: Madison, WI, USA, 1962. [Google Scholar]

- Brady, J.F.; Harte, A.M. Prestressed FRP flexural strengthening of softwood glue–laminated timber beams. In Proceedings of the 10th World Conference on Timber Engineering, WCTE 2008, Miyazaki, Japan, 2–5 June 2008. [Google Scholar]

- De Luca, V.; Marano, C. Prestressed glulam timbers reinforced with steel bars. Constr. Build. Mater. 2012, 30, 206–217. [Google Scholar] [CrossRef]

- Guan, Z.W.; Rodd, P.D.; Pope, D.J. Study of glulam beams pre-stressed with pultruded GRP. Comput. Struct. 2005, 83, 2476–2487. [Google Scholar] [CrossRef]

- McConnell, E.; McPolin, D.; Taylor, S. Post-tensioning of glulam timber with steel tendons. Constr. Build. Mater. 2014, 73, 426–433. [Google Scholar] [CrossRef]

- Negrão, J.H. Preliminary study on wire prestressing methods for timber pieces reinforcement. Constr. Build. Mater. 2016, 102, 1093–1100. [Google Scholar] [CrossRef]

- Persson, M.P.; Wogelberg, S. Analytical Models of Pre–Stressed and Reinforced Glulam Beams, a Competitive Analysis of Strengthened Glulam Beams. Master’s Thesis, Department of Civil and Environmental Engineering, Chalmers University of Technology, Göteborg, Sweden, 2011. [Google Scholar]

- Rajczyk, M.; Stachecki, B. Współczesne materiały kompozytowe. Wybrane kierunki rozwoju nowych technologii. Bud. O Zoptymalizowanym Potencjale Energetycznym 2011, 8, 202–211. [Google Scholar]

- Zachary, C.; Kavan, S. Feasibility of Strengthening Glulam Beams with Prestressed Basalt Fibre Reinforced Polymers. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2012. [Google Scholar]

- Brol, J.; Nowak, T.; Wdowiak, A. Numerical analysis and modelling of timber elements strengthened with FRP materials. In Annals of Warsaw University of Life Sciences, Forestry and Wood Technology, No. 104; Warsaw University of Life Sciences Press: Warsaw, Poland, 2018; pp. 274–282. [Google Scholar]

- Fiorelli, J.; Dias, A.A. Analysis of the strength and stiffness of timber beams reinforced with carbon fiber and glass fiber. Mater. Res. 2003, 6, 193–202. [Google Scholar] [CrossRef]

- Fiorelli, J.; Dias, A.A. Glulam beams reinforced with FRP externally-bonded: Theoretical and experimental evaluation. Mater. Struct. 2011, 44, 1431–1440. [Google Scholar] [CrossRef]

- Johnsson, H.; Blanksvärd, T.; Carolin, A. Glulam members strengthened by carbon fibre reinforcement. Mater. Struct. 2007, 40, 47–56. [Google Scholar] [CrossRef]

- Micelli, F.; Scialpi, V.; La Tegola, A. Flexural reinforcement of glulam timber beams and joints with carbon fiber-reinforced polymer rods. J. Compos. Constr. 2005, 9, 337–347. [Google Scholar] [CrossRef]

- Raftery, G.M.; Harte, A.M. Nonlinear numerical modeling of FRP plate reinforced glued laminated timber. Compos. Part. B Eng. 2013, 52, 40–50. [Google Scholar] [CrossRef]

- Wdowiak, A. Właściwości strukturalno–wytrzymałościowe zginanych belek drewnianych wzmocnionych kompozytami włóknistymi. Ph.D. Thesis, Kielce University of Technology, Kielce, Poland, 2018. [Google Scholar]

- PN-EN 13183-2:2004 Moisture Content of a Sawn Timber Piece—Part 2: Designation of the Moisture Content Using an Electrical Resistance Hygrometer; Polish Standards Committee: Warsaw, Poland, 2004.

- PN-EN 13183-3:2007 Moisture Content of a Sawn Timber Piece. Part 3: Designation Using the Capacity-Based Method; Polish Standards Committee: Warsaw, Poland, 2007.

- PN-D-94021:2013-10 Coniferous Structural Sawn Timber Sorted Using Strength-Based Methods; Polish Standards Committee: Warsaw, Poland, 2013.

- Kozakiewicz, P.; Krzosek, S. Inżynieria Materiałów Drzewnych (Wooden Materials Engineering); Wydawnictwo SGGW: Warsaw, Poland, 2013. [Google Scholar]

- Krzosek, S. Wytrzymałościowe Sortowanie Polskiej Sosnowej Tarcicy Konstrukcyjnej Różnymi Metodami (Strength-Sorting of the Polish Pine Structural Sawn Wood Using Various Methods); Wydawnictwo SGGW: Warsaw, Poland, 2009. [Google Scholar]

- PN-EN 844-11:2001 Round and Sawn Timber–Terminology—Definitions Concerning Damage Caused by Insects; Polish Standards Committee: Warsaw, Poland, 2001.

- Rudziński, L.; Wdowiak, A. Strength and structural properties of structural timber. Struct. Environ. 2016, 8, 103–108. [Google Scholar]

- Wdowiak, A. Using the visual method to sort Polish pine structural sawn timber with respect to strength. Tech. Trans. Czas. Tech. 2016, 2016, 219–224. [Google Scholar]

- Wdowiak, A. Badanie cech strukturalnych i geometrycznych podczas sortowania wytrzymałościowego tarcicy konstrukcyjnej metodą wizualną. Przegląd Bud. 2017, 88, 42–46. [Google Scholar]

- Wdowiak, A.; Kroner, A. Wpływ niejednorodności struktury zginanych belek z drewna klejonego na efekt ich wzmocnienia. Mater. Bud. 2017, 1, 87–89. [Google Scholar] [CrossRef]

- Brol, J.; Wdowiak, A. The use of glass and aramid fibres for the strengthening of timber structures. In Annals of Warsaw University of Life Sciences, Forestry and Wood Technology, No. 100; Warsaw University of Life Sciences Press: Warsaw, Poland, 2017; pp. 128–138. [Google Scholar]

- Krzysik, F. Nauka o Drewnie (Wood Science); Państwowe Wydawnictwo Naukowe: Warsaw, Poland, 1975. [Google Scholar]

- PN-EN 14080:2013-07 Wooden Structures—Glulam Wood and Solid Glulam Wood–Requirements; Polish Standards Committee: Warsaw, Poland, 2013.

- PN-EN 408+A1:2012 Wooden Structures—Structural Solid and Glulam Wood—Designation of Certain Physical and Mechanical Properties; Polish Standards Committee: Warsaw, Poland, 2012.

| BEAM TYPE | DESCRIPTION |

|---|---|

| NWa | non-reinforced medium and lower quality glulam beams |

| Wa-A | reinforced medium and lower quality glulam beams, BFRP rod reinforcement, pre-stressed, 10 mm diameter, (LG 385 + HG 385), reinforcement ratio 1.18% |

| Wa-B | reinforced medium and lower quality glulam beams, BFRP rod reinforcement, pre-stressed, 10 mm diameter, (LG 385 + HG 385), reinforcement ratio 1.76% |

| NWa-1 | Front: healthy oval knot at the edge (lamella I, bases 1, 3, 6, 9, lamella II, base 12, lamella III, base 4), healthy oval knot on the plane (lamella I, bases 5, 8, 13, lamella II, base 3, lamella IV, base 11), degraded knot at the edge (lamella III, base 12, lamella IV, bases 3, 8), deteriorating knot at the edge (lamella IV, base 6), deteriorating knot on the plane (lamella III, base 9), deteriorated knot on the plane (lamella II, bases 9, 13, lamella III, base 7), burls (lamella I, bases 7, 8, lamella III, base 7). Back: healthy oval knot on the plane (lamella I, base 13, lamella III, base 13, lamella I, III, IV, base 4 and 5), resin blister on the plane (length 35 mm, depth 1.8 mm, lamella III, base 9), burls (lamella III, base 7). |

| Lamella I—USM = 0.41, USC = 0.23, spiral grain 9.4%, growth ring occurrence 4.8 mm (share of late wood 1.3 mm), Lamella II—USM = 0.56, USC = 0.31, spiral grain 10.3%, growth ring occurrence 6.1 mm (share of late wood 0.9 mm), Lamella III—USM = 0.51, USC = 0.29, spiral grain 10.1%, growth ring occurrence 6.4 mm (share of late wood 1.0 mm), Lamella IV—USM = 0.47, USC = 0.24, spiral grain 9.2%, growth ring occurrence 6.3 mm (share of late wood 1.2 mm), | |

| Density 397.82 kg/m3. | |

| Wa-A1 | Front: healthy oval knot at the edge (lamella III, base 7, lamella IV, bases 1, 3, 6), deteriorating oval knot at the edge (lamella III, base 2), deteriorated oval knot on the plane (lamella II, base 4), deteriorated knot at the edge (lamella I, base 7), healthy oval knot on the plane (lamella II, base 8), deteriorating oval knot on the plane (lamella I, base 11, lamella III, base 10, lamella IV, base 11), healthy oval knot on the plane (lamella II, base 13), longitudinal knot on the plane (lamella IV, base 13), burls (lamella IV, base 8). Back: healthy oval knot on the plane (lamella I, bases 7, 9, lamella II, bases 8, 9, lamella III, bases 7, 13, lamella IV, bases 1, 3), deteriorating oval knot at the edge (lamella I, bases 1, 4, lamella IV, bases 8, 9), healthy oval knot at the edge (lamella I, base 5, lamella III, bases 2, 5), deteriorated oval knot at the edge (lamella II, base 6, lamella III, base 3, lamella IV, base 13), deteriorating oval knot on the plane (lamella I, base 5, lamella IV, base 13), resin blister on the plane (length 33 mm, depth 1.8 mm, lamella II, base 10, lamella IV, base 12), burls (lamella III, bases 7, 8, lamella IV, base 8). |

| Lamella I—USM = 0.44, USC = 0.18, spiral grain 9.4%, growth ring occurrence 6.2 mm (share of late wood 1.2 mm), Lamella II—USM = 0.62, USC = 0.33, spiral grain 10.1%, growth ring occurrence 6.9 mm (share of late wood 0.8 mm), Lamella III—USM = 0.58, USC = 0.32, spiral grain 10.7%, growth ring occurrence 8.4 mm (share of late wood 0.9 mm), Lamella IV—USM = 0.42, USC = 0.21, spiral grain 9.0%, growth ring occurrence 6.3 mm (share of late wood 1.4 mm), | |

| Density 406.11 kg/m3. |

| BEAM NWa | Mmax [kNm] | BEAM Wa-A | Mmax [kNm] | BEAM Wa-B | Mmax [kNm] |

|---|---|---|---|---|---|

| NWa-1 | 12.50 | Wa-A1 | 18.50 | Wa-B1 | 16.00 |

| NWa-2 | 9.50 | Wa-A2 | 15.50 | Wa-B2 | 20.50 |

| NWa-3 | 12.00 | Wa-A3 | 16.00 | Wa-B3 | 16.00 |

| AVERAGE | 11.33 | AVERAGE | 16.67 | AVERAGE | 17.50 |

| INCREASE [%] | - | INCREASE [%] | 47% | INCREASE [%] | 54% |

| Conf. int. (0.05), kNm | 2.71 | 2.71 | 4.38 | ||

| Relative error (0.05), % | 23.9% | 16.3% | 25% | ||

| Conf.int. (0.1), kNm | 1.75 | 1.75 | 2.83 | ||

| Relative error (0.1), % | 15.4% | 10.5% | 16.2% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wdowiak, A.; Brol, J. Effectiveness of Reinforcing Bent Non-Uniform Pre-Stressed Glulam Beams with Basalt Fibre Reinforced Polymers Rods. Materials 2019, 12, 3141. https://doi.org/10.3390/ma12193141

Wdowiak A, Brol J. Effectiveness of Reinforcing Bent Non-Uniform Pre-Stressed Glulam Beams with Basalt Fibre Reinforced Polymers Rods. Materials. 2019; 12(19):3141. https://doi.org/10.3390/ma12193141

Chicago/Turabian StyleWdowiak, Agnieszka, and Janusz Brol. 2019. "Effectiveness of Reinforcing Bent Non-Uniform Pre-Stressed Glulam Beams with Basalt Fibre Reinforced Polymers Rods" Materials 12, no. 19: 3141. https://doi.org/10.3390/ma12193141

APA StyleWdowiak, A., & Brol, J. (2019). Effectiveness of Reinforcing Bent Non-Uniform Pre-Stressed Glulam Beams with Basalt Fibre Reinforced Polymers Rods. Materials, 12(19), 3141. https://doi.org/10.3390/ma12193141