Predicting the Tensile Behavior of Ti-6.6Al-3.3Mo-1.8Zr-0.29Si Alloy via the Temperature-Dependent Crystal Plasticity Method

Abstract

1. Introduction

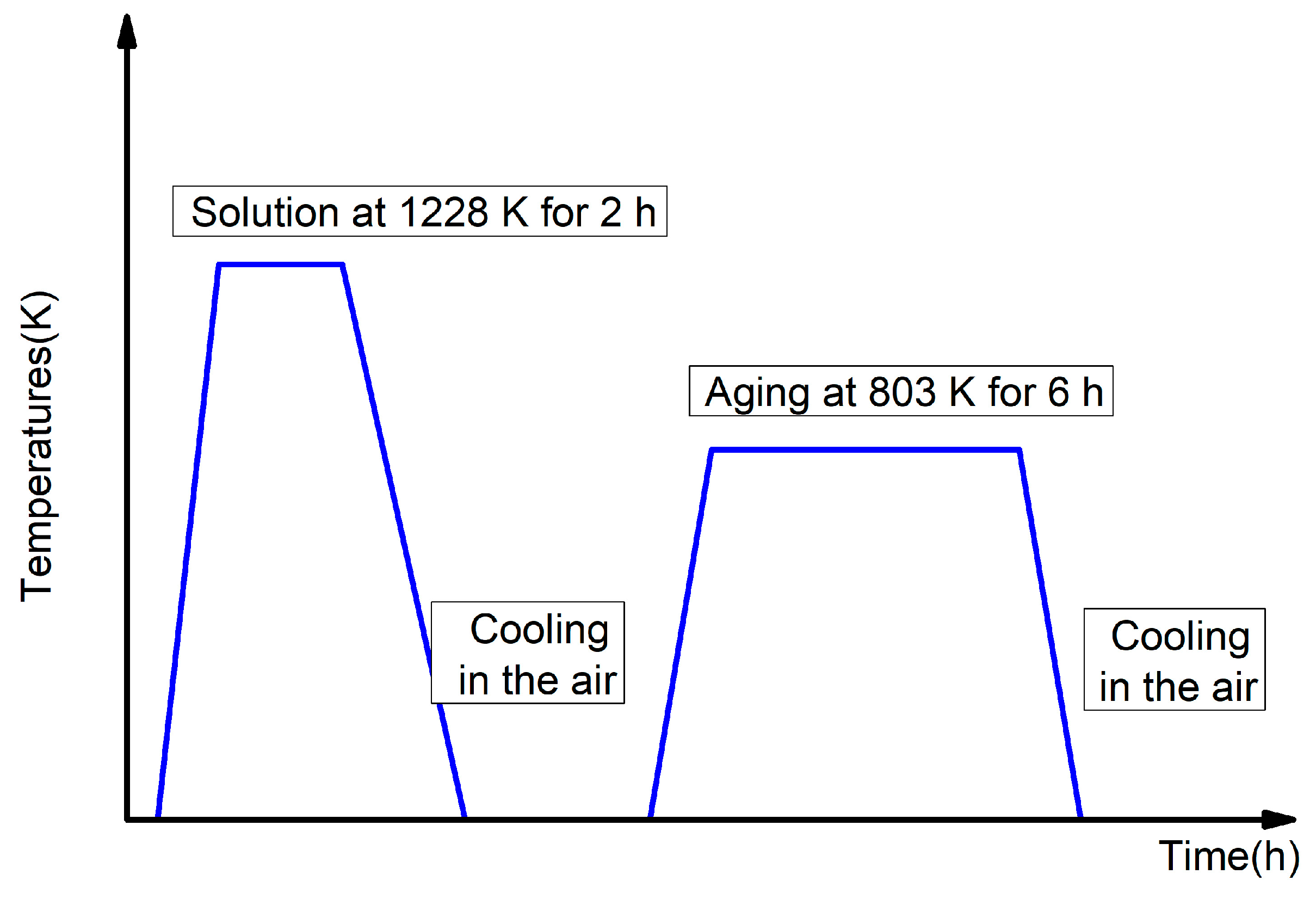

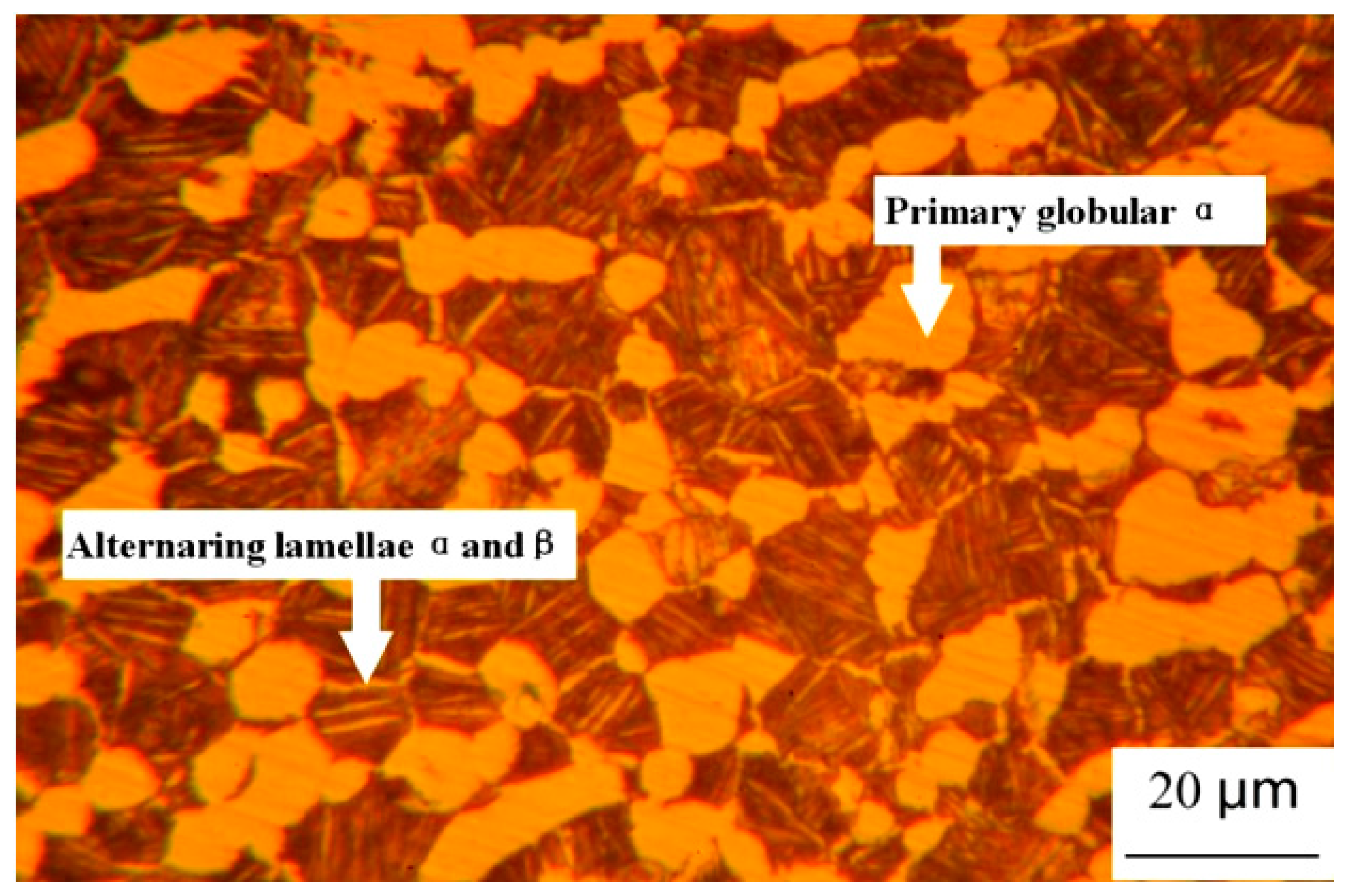

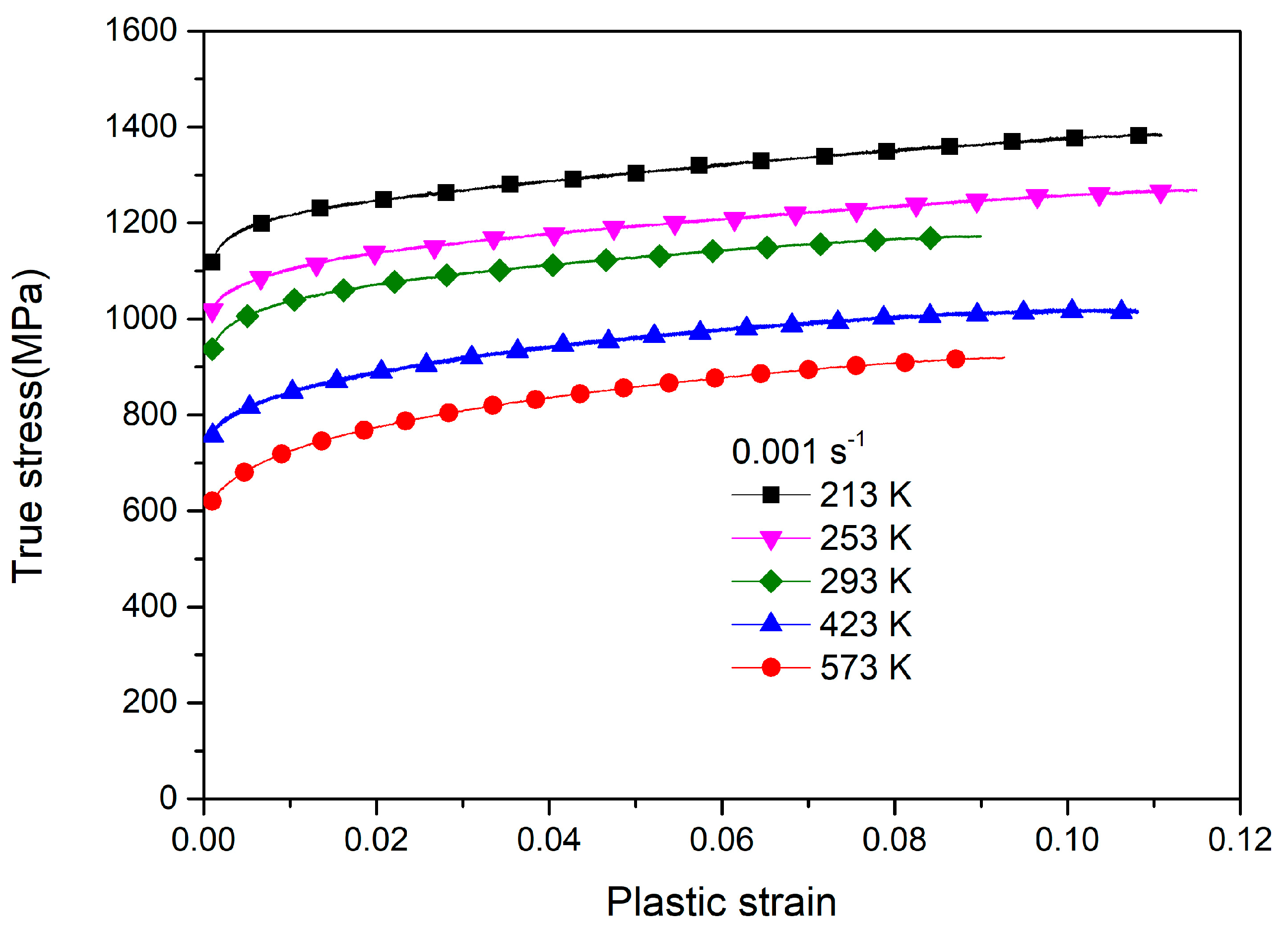

2. Deformation Features at Various Temperatures

3. Model Set Up

3.1. The Classical Crystal Plasticity Framework

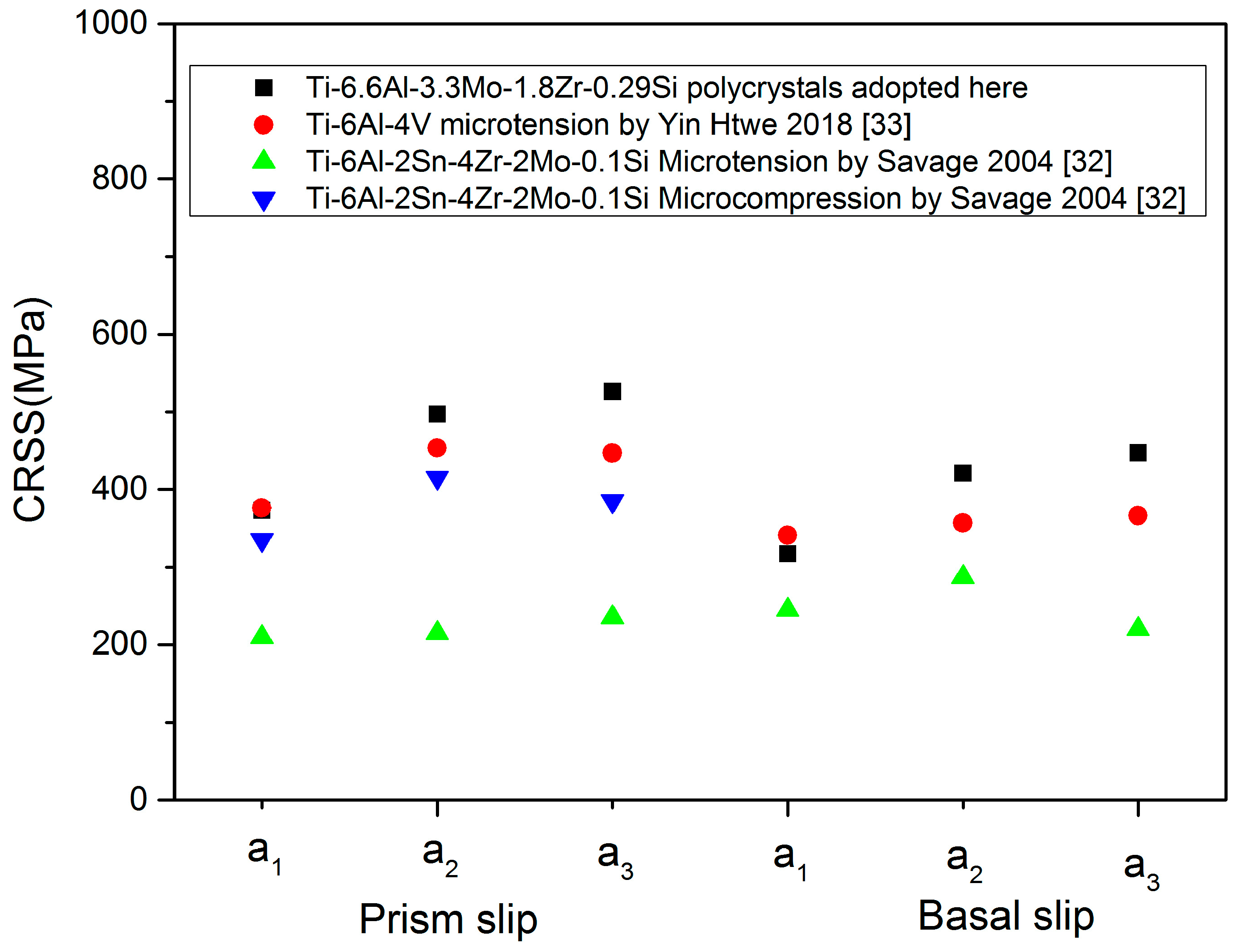

3.2. Temperature Dependence of CRSS

3.3. Construction of the Duplex Microstructure

3.4. Determination of Material Parameters

4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Motyka, M.; Baran-Sadleja, A.; Sieniawski, J.; Wierzbinska, M.; Gancarczyk, K. Decomposition of deformed α′(α″) martensitic phase in Ti-6Al-4V alloy. Mater. Sci. Technol. 2019, 35, 260–272. [Google Scholar] [CrossRef]

- Huang, S.S.; Zhang, J.H.; Ma, Y.J.; Zhang, S.; Youssef, S.S.; Qi, M.; Wang, H.; Qiu, J.; Xu, D.; Lei, J.; et al. Influence of thermal treatment on element partitioning in α+β titanium alloy. J. Alloy Compd. 2019, 791, 575–585. [Google Scholar] [CrossRef]

- Khan, A.; Kazmi, R.; Farrokh, B.; Zupan, M. Effect of oxygen content and microstructure on the thermo-mechanical response of three Ti–6Al–4V alloys: Experiments and modeling over a wide range of strain-rates and temperatures. Int. J. Plast. 2007, 23, 1105–1125. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.D.; Bieler, T.; Raabe, D. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Tang, T.; Zhou, G.; Li, Z.; Li, D.; Peng, L.; Peng, Y.; Wu, P.; Wang, H.; Lee, M.-G. A polycrystal plasticity based thermo-mechanical-dynamic recrystallization coupled modeling method and its application to light weight alloys. Int. J. Plast. 2019, 116, 159–191. [Google Scholar] [CrossRef]

- Yaghoobi, M.; Ganesan, S.; Sundar, S.; Lakshmanan, A.; Rudraraju, S.; Allison, J.E.; Sundararaghavan, V. PRISMS-Plasticity: An open-source crystal plasticity finite element software. Comput. Mater. Sci. 2019, 169, 109078. [Google Scholar] [CrossRef]

- Cyr, E.; Mohammadi, M.; Brahme, A.; Mishra, R.K.; Inal, K. Modeling the formability of aluminum alloys at elevated temperatures using a new thermo-elasto-viscoplastic crystal plasticity framework. Int. J. Mech. Sci. 2017, 128, 312–325. [Google Scholar] [CrossRef]

- Daphalapurkar, N.P.; Patil, S.; Nguyen, T.; Prasad, K.E.; Ramesh, K.T. A crystal plasticity model for body-centered cubic molybdenum: Experiments and simulations. Mater. Sci. Eng. A 2018, 738, 283–294. [Google Scholar] [CrossRef]

- Liu, Q.; Roy, A.; Silberschmidt, V.V. Temperature-dependent crystal-plasticity model for magnesium: A bottom-up approach. Mech. Mater. 2017, 113, 44–56. [Google Scholar] [CrossRef]

- Ardeljan, M.; Beyerlein, I.J.; McWilliams, B.A.; Knezevic, M. Strain rate and temperature sensitive multi-level crystal plasticity model for large plastic deformation behavior: Application to AZ31 magnesium alloy. Int. J. Plast. 2016, 83, 90–109. [Google Scholar] [CrossRef]

- Hasija, V.; Ghosh, S.; Mills, M.J.; Joseph, D.S. Deformation and creep modeling in polycrystalline Ti–6Al alloys. Acta Mater. 2003, 51, 4533–4549. [Google Scholar] [CrossRef]

- Anahid, M.; Samal, M.K.; Ghosh, S. Dwell fatigue crack nucleation model based on crystal plasticity finite element simulations of polycrystalline titanium alloys. J. Mech. Phys. Solids 2011, 59, 2157–2176. [Google Scholar] [CrossRef]

- Venkatramani, G.; Ghosh, S.; Mills, M. A size-dependent crystal plasticity finite-element model for creep and load shedding in polycrystalline titanium alloys. Acta Mater. 2007, 55, 3971–3986. [Google Scholar] [CrossRef]

- Shahba, A.; Ghosh, S. Crystal plasticity FE modeling of Ti alloys for a range of strain-rates. Part I: A unified constitutive model and flow rule. Int. J. Plast. 2016, 87, 48–68. [Google Scholar] [CrossRef]

- Mayeur, J.R.; McDowell, D.L. A three-dimensional crystal plasticity model for duplex Ti-6Al-4V. Int. J. Plast. 2007, 23, 1457–1485. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, J.; McDowell, D. Microstructure-based crystal plasticity modeling of cyclic deformation of Ti–6Al–4V. Int. J. Plast. 2007, 23, 1328–1348. [Google Scholar] [CrossRef]

- Bridier, F.; McDowell, D.L.; Villechaise, P.; Mendez, J. Crystal plasticity modeling of slip activity in Ti–6Al–4V under high cycle fatigue loading. Int. J. Plast. 2009, 25, 1066–1082. [Google Scholar] [CrossRef]

- Waheed, S.; Zheng, Z.; Balint, D.S.; Dunne, F.P. Microstructural effects on strain rate and dwell sensitivity in dual-phase titanium alloys. Acta Mater. 2019, 162, 136–148. [Google Scholar] [CrossRef]

- Zhang, Z.; Dunne, F.P. Microstructural heterogeneity in rate-dependent plasticity of multiphase titanium alloys. J. Mech. Phys. Solids 2017, 103, 199–220. [Google Scholar] [CrossRef]

- Fan, X.; Jiang, X.; Zeng, X.; Shi, Y.; Gao, P.; Zhan, M. Modeling the anisotropy of hot plastic deformation of two-phase titanium alloys with a colony microstructure. Int. J. Plast. 2018, 104, 173–195. [Google Scholar] [CrossRef]

- Fan, X.; Yang, H. Internal-state-variable based self-consistent constitutive modeling for hot working of two-phase titanium alloys coupling microstructure evolution. Int. J. Plast. 2011, 27, 1833–1852. [Google Scholar] [CrossRef]

- Williams, J.C.; Baggerly, R.G.; Paton, N.E. Deformation behavior of HCP Ti-Al alloy single crystals. Met. Mater. Trans. A 2002, 33, 837–850. [Google Scholar] [CrossRef]

- Salem, A.; Semiatin, S.; Salem, A. Anisotropy of the hot plastic deformation of Ti–6Al–4V single-colony samples. Mater. Sci. Eng. A 2009, 508, 114–120. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Zan, X.; Wang, Y. The constitutive responses of Ti-6.6Al-3.3Mo-1.8Zr-0.29Si alloy at high strain rates and elevated temperatures. J. Alloy. Compd. 2015, 647, 97–104. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Zhang, B.; Huang, H.; Chen, J.; Wang, P. Strain Rate Sensitivity of Tensile Properties in Ti-6.6Al-3.3Mo-1.8Zr-0.29Si Alloy: Experiments and Constitutive Modeling. Materials 2018, 11, 1591. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, Y. Effect of strain rate on the tension behavior of Ti–6.6Al–3.3Mo–1.8Zr–0.29Si alloy at low temperatures. Mater. Sci. Eng. A 2014, 605, 59–64. [Google Scholar] [CrossRef]

- Meester, B.; Doner, M.; Conrad, H. Deformation kinetics of the Ti-6Al-4V alloy at low temperatures. Met. Mater. Trans. A 1975, 6, 65–75. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Guo, W.-G.; Nesterenko, V.F.; Indrakanti, S.; Gu, Y.-B. Dynamic response of conventional and hot isostatically pressed Ti–6Al–4V alloys: experiments and modeling. Mech. Mater. 2001, 33, 425–439. [Google Scholar] [CrossRef]

- Huang, Y.G. A User-Material Subroutine Incorporating Single Crystal Plasticity in the ABAQUS Finite Element Program; Report MECH-178; Division of Applied Science, Harvard University: Cambridge, MA, USA, June 1991. [Google Scholar]

- Bunge, H.J. Texture Analysis in Materials Science: Mathematical Methods; Butterworths: London, UK, 1982. [Google Scholar]

- Ding, R.; Gong, J.; Wilkinson, A.J.; Jones, I.P. <c + a> Dislocations in deformed Ti-6A1-4V micro-cantilevers. Acta Mater. 2014, 76, 127–134. [Google Scholar] [CrossRef]

- Savage, M.F.; Tatalovich, J.; Mills, M.J. Anisotropy in the room-temperature deformation of α+β colonies in titanium alloys: Role of the α/β interface. Philos Mag. 2004, 84, 1127–1154. [Google Scholar] [CrossRef]

- Htwe, Y.; Kwak, K.; Kishi, D.; Mine, Y.; Ding, R.; Bowen, P.; Takashima, K. Anisotropy of <a> slip behaviour in single-colony lamellar structures of Ti–6Al–4V. Mater. Sci. Eng. A 2018, 715, 315–319. [Google Scholar]

- Gong, J.; Wilkinson, A.J. Anisotropy in the plastic flow properties of single-crystal a titanium determined from micro-cantilever beams. Acta Mater. 2009, 57, 5693–5705. [Google Scholar] [CrossRef]

- Jones, I.; Hutchinson, W. Stress-state dependence of slip in Titanium-6Al-4V and other H.C.P. metals. Acta Metall. 1981, 29, 951–968. [Google Scholar] [CrossRef]

| Constitutive Equations | Model Parameters | |||

|---|---|---|---|---|

| Elasticity | ||||

| μRT = 42 GPa; C11 = 162 MPa; C33 = 180 MPa; C12 = C21 = 92 MPa; C13 = C31 = C23 = C32 = 69 MPa; C44 = C55 = 46 MPa; C66 = (C11 − C12)/2 =35 MPa; Other = 0 [15] | ||||

| Slip | ||||

| ; m = 0.02 [11,18] | ||||

| q1 = 1, p = 0.5 and q = 2 for α grains; q1 = 1, p = 0.5 and q = 1.25 for β grains [8] | ||||

| Globular α phase | ||||

| Parameters | Basal<a> | Prism<a> | Pyr<c + a> | |

| 246 | 230 | 610 | ||

| 788 | 765 | 1500 | ||

| 1.56 | 1.43 | 2.1 | ||

| 200 | 160 | 440 | ||

| 660 | 780 | 1600 | ||

| 20.1 | 23.1 | 28 | ||

| Lamellar α phase (Basal) | ||||

| Parameters | a1 | a2 | a3 | |

| 195 | 259 | 297 | ||

| 650 | 862 | 988 | ||

| 1.43 | 1.43 | 1.43 | ||

| 140 | 187 | 218 | ||

| 560 | 740 | 855 | ||

| 23.1 | 23.1 | 23.1 | ||

| Lamellar α phase (Prism) | ||||

| Parameters | a1 | a2 | a3 | |

| 209 | 277 | 294 | ||

| 670 | 889 | 943 | ||

| 1.56 | 1.56 | 1.56 | ||

| 160 | 216 | 234 | ||

| 660 | 883 | 890 | ||

| 20.1 | 20.1 | 20.1 | ||

| Lamellar β phase ({110}<111>) | ||||

| Parameters | Soft | Hard | ||

| 239 | 358 | |||

| 778 | 1167 | |||

| 1.34 | 1.34 | |||

| 165 | 250 | |||

| 660 | 990 | |||

| 24.1 | 24.1 | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wang, Y.; Wang, P.; Chen, J.; Zheng, S. Predicting the Tensile Behavior of Ti-6.6Al-3.3Mo-1.8Zr-0.29Si Alloy via the Temperature-Dependent Crystal Plasticity Method. Materials 2019, 12, 3138. https://doi.org/10.3390/ma12193138

Zhang J, Wang Y, Wang P, Chen J, Zheng S. Predicting the Tensile Behavior of Ti-6.6Al-3.3Mo-1.8Zr-0.29Si Alloy via the Temperature-Dependent Crystal Plasticity Method. Materials. 2019; 12(19):3138. https://doi.org/10.3390/ma12193138

Chicago/Turabian StyleZhang, Jun, Yang Wang, Peng Wang, Junhong Chen, and Songlin Zheng. 2019. "Predicting the Tensile Behavior of Ti-6.6Al-3.3Mo-1.8Zr-0.29Si Alloy via the Temperature-Dependent Crystal Plasticity Method" Materials 12, no. 19: 3138. https://doi.org/10.3390/ma12193138

APA StyleZhang, J., Wang, Y., Wang, P., Chen, J., & Zheng, S. (2019). Predicting the Tensile Behavior of Ti-6.6Al-3.3Mo-1.8Zr-0.29Si Alloy via the Temperature-Dependent Crystal Plasticity Method. Materials, 12(19), 3138. https://doi.org/10.3390/ma12193138