Atomistic Simulation on the Twin Boundary Migration in Mg under Shear Deformation

Abstract

1. Introduction

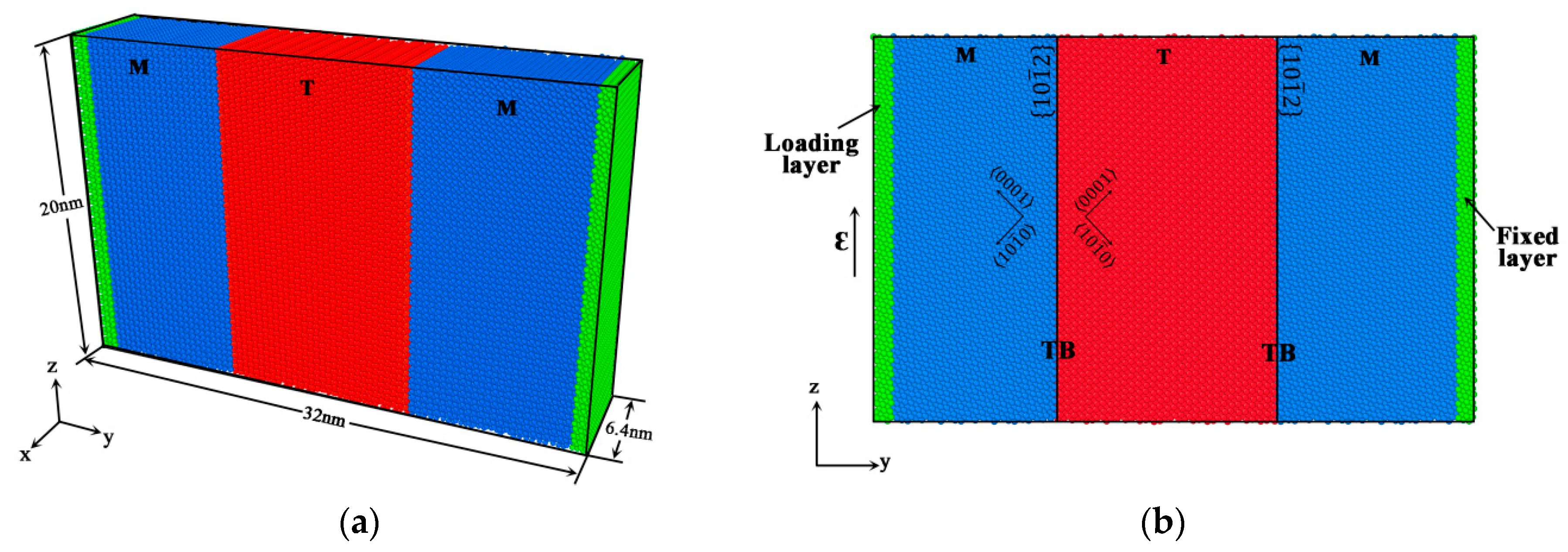

2. Materials and Methods

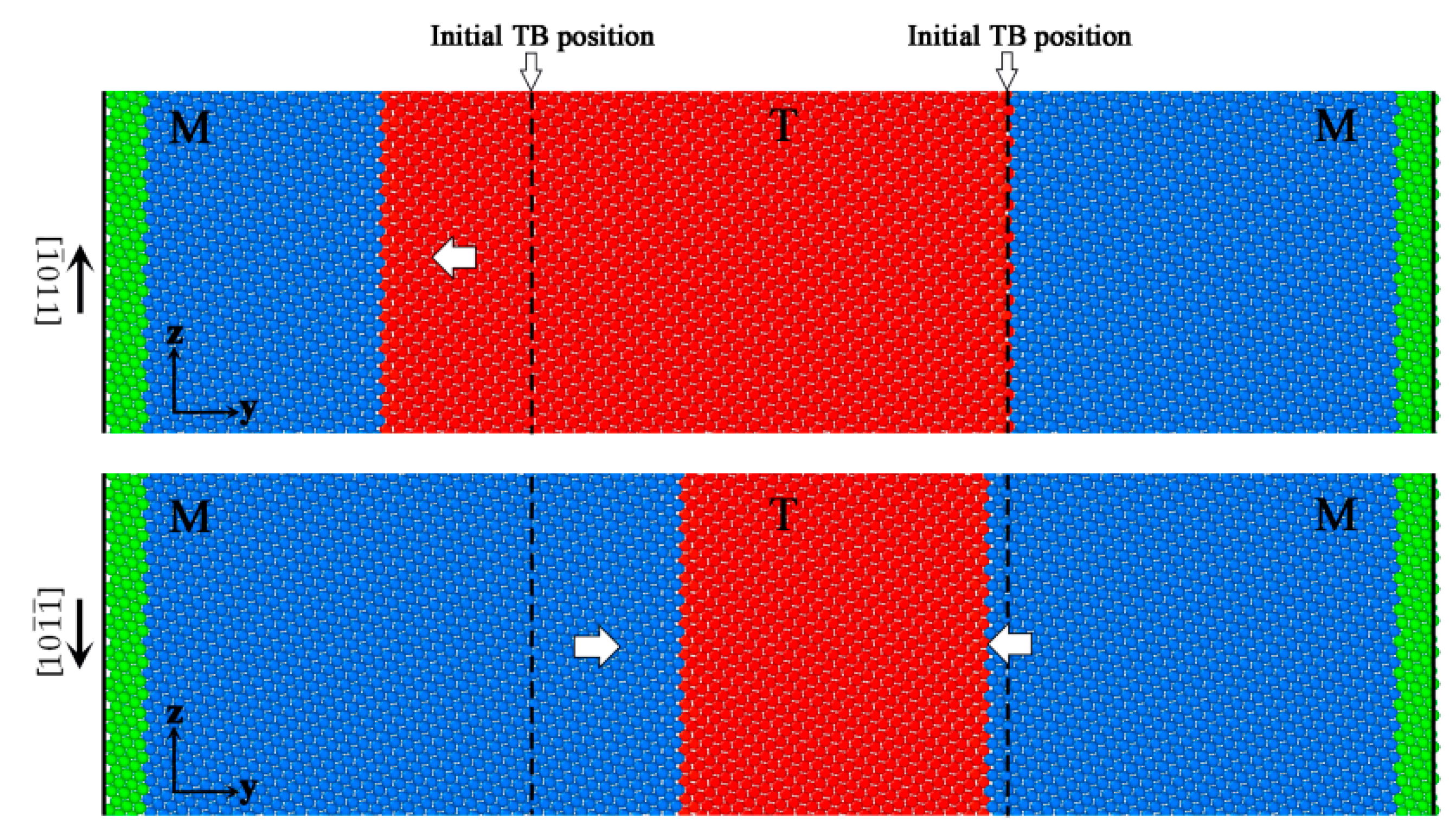

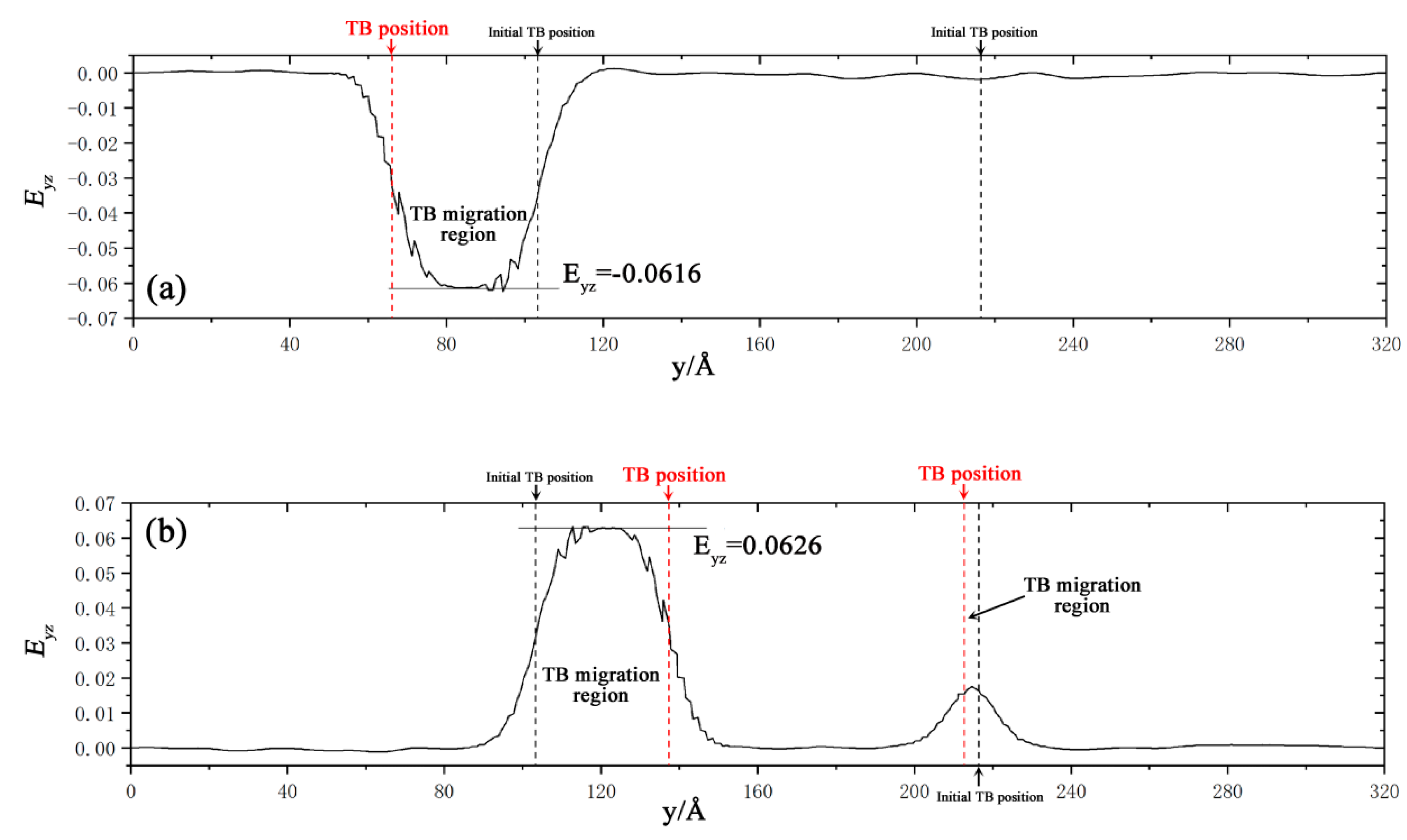

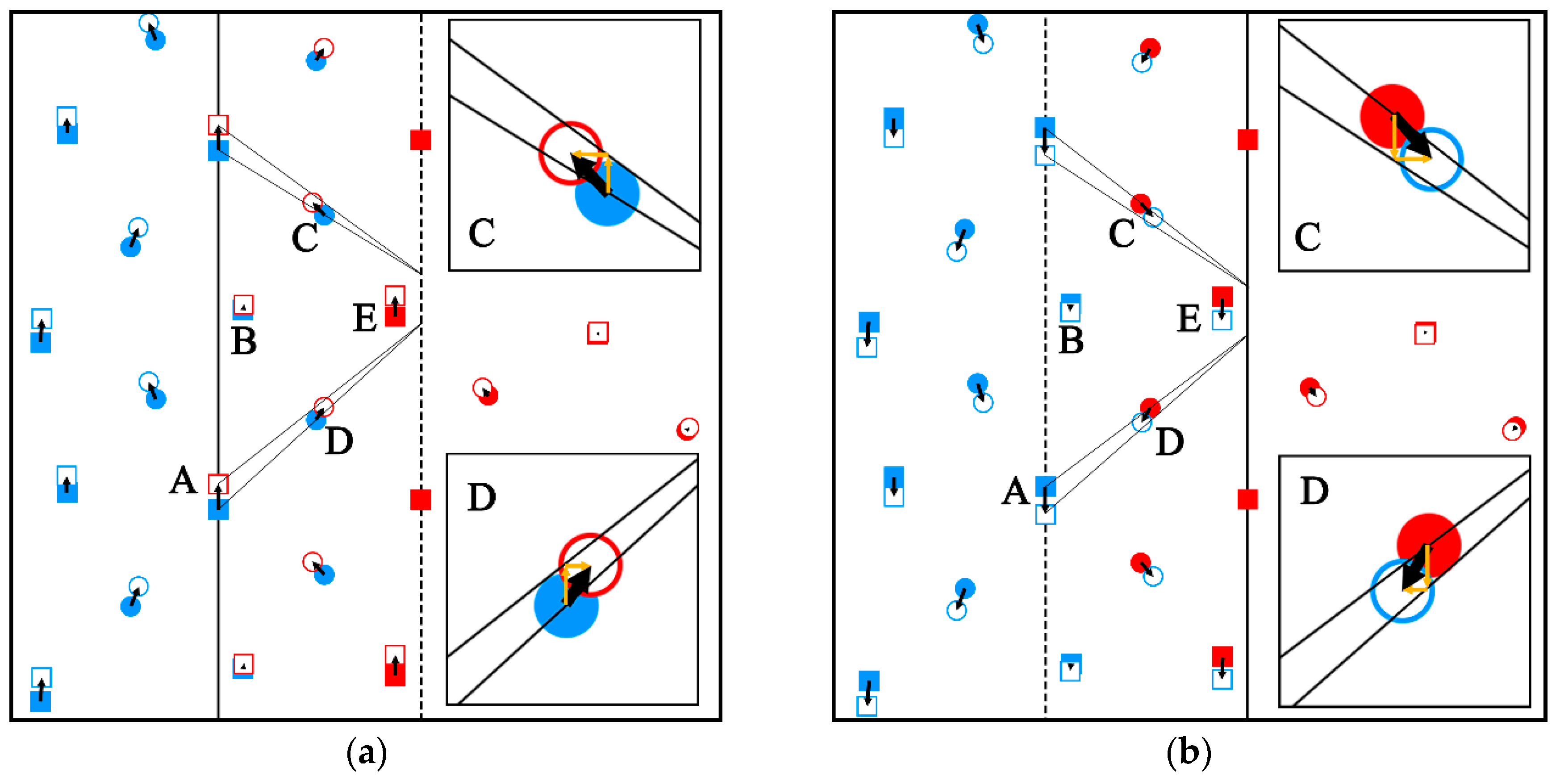

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hirsch, J.; Al-Samman, T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 2013, 61, 818–843. [Google Scholar] [CrossRef]

- El, K.H.; Barrett, C.D.; Wang, J.; Tomé, C.N. Why are {} twins profuse in magnesium? Acta Mater. 2015, 85, 354–361. [Google Scholar]

- Barnett, M.R. Twinning and the ductility of magnesium alloys: Part I: “Tension” twins. Mater. Sci. Eng. A 2007, 464, 1–7. [Google Scholar] [CrossRef]

- Barnett, M.R. Twinning and the ductility of magnesium alloys: Part II. “Contraction” twins. Mater. Sci. Eng. A 2007, 464, 8–16. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- He, W.J.; Zeng, Q.H.; Yu, H.H.; Xin, Y.C.; Luan, B.F.; Liu, Q. Improving the room temperature stretch formability of a Mg alloy thin sheet by pre-twinning. Mater. Sci. Eng. A 2016, 655, 1–8. [Google Scholar] [CrossRef]

- Chen, H.H.; Liu, T.M.; Hou, D.; Shi, D.F. Improving the mechanical properties of a hot-extruded AZ31 alloy by {} twinning lamella. J. Alloys Compd. 2016, 680, 191–197. [Google Scholar] [CrossRef]

- Sarker, D.; Chen, D.L. Detwinning and strain hardening of an extruded magnesium alloy during compression. Scr. Mater. 2012, 67, 165–168. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, D.F.; Fan, X.W.; Li, J.X.; Jiang, L.Y.; Pan, F.S. Microstructure, texture and mechanical properties evolution of pre-twinning Mg alloys sheets during large strain hot rolling. Mater. Sci. Eng. A 2016, 655, 92–99. [Google Scholar] [CrossRef]

- Kim, S.J.; Yim, C.D.; Lee, Y.S.; Yoon, J.H.; Lee, J.H. Controlling the microstructure of magnesium alloy sheet during rolling. Mater. Sci. Eng. A 2014, 596, 216–221. [Google Scholar] [CrossRef]

- Park, S.H.; Hong, S.G.; Lee, C.S. Enhanced stretch formability of rolled Mg–3Al–1Zn alloy at room temperature by initial {} twins. Mater. Sci. Eng. A 2013, 578, 271–276. [Google Scholar] [CrossRef]

- Wu, L.; Jain, A.; Brown, D.W.; Stoica, G.M.; Agnew, S.R.; Clausen, B.; Liaw, P.K. Twinning–detwinning behavior during the strain-controlled low-cycle fatigue testing of a wrought magnesium alloy, ZK60A. Acta Mater. 2008, 56, 688–695. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, J.; Jiang, Y. Direct observation of twinning–detwinning–retwinning on magnesium single crystal subjected to strain-controlled cyclic tension–compression in [0 0 0 1] direction. Philos. Mag. Lett. 2011, 91, 757–765. [Google Scholar] [CrossRef]

- Wu, W.; Liaw, P.K.; An, K. Unraveling cyclic deformation mechanisms of a rolled magnesium alloy using in situ neutron diffraction. Acta Mater. 2015, 85, 343–353. [Google Scholar] [CrossRef]

- Brown, D.W.; Jain, A.; Agnew, S.R.; Clausen, B. Twinning and detwinning during cyclic deformation of Mg alloy AZ31B. In Materials Science Forum; Trans Tech Publications: Zurich Switzerland, 2007; Volume 539, pp. 3407–3413. [Google Scholar]

- Hong, S.G.; Park, S.H.; Lee, C.S. Enhancing the fatigue property of rolled AZ31 magnesium alloy by controlling {} twinning-detwinning characteristics. J. Mater. Res. 2010, 25, 784–792. [Google Scholar] [CrossRef]

- Park, S.H.; Hong, S.G.; Lee, C.S. Role of initial {} twin in the fatigue behavior of rolled Mg–3Al–1Zn alloy. Scr. Mater. 2010, 62, 666–669. [Google Scholar] [CrossRef]

- Cáceres, C.H.; Sumitomo, T.; Veidt, M. Pseudoelastic behaviour of cast magnesium AZ91 alloy under cyclic loading–unloading. Acta Mater. 2003, 51, 6211–6218. [Google Scholar] [CrossRef]

- Lee, S.Y.; Gharghouri, M.A. Pseudoelastic behavior of magnesium alloy during twinning-dominated cyclic deformation. Mater. Sci. Eng. A 2013, 572, 98–102. [Google Scholar] [CrossRef]

- Muránsky, O.; Carr, D.G.; Šittner, P.; Oliver, E.C. In situ neutron diffraction investigation of deformation twinning and pseudoelastic-like behaviour of extruded AZ31 magnesium alloy. Int. J. Plast. 2009, 25, 1107–1127. [Google Scholar] [CrossRef]

- Watanabe, H.; Sasakura, Y.; Ikeo, N.; Mukai, T. Effect of deformation twins on damping capacity in extruded pure magnesium. J. Alloys Compd. 2015, 626, 60–64. [Google Scholar] [CrossRef]

- Cui, Y.; Li, Y.; Sun, S.; Bian, H.; Huang, H.; Wang, Z.; Chiba, A. Enhanced damping capacity of magnesium alloys by tensile twin boundaries. Scr. Mater. 2015, 101, 8–11. [Google Scholar] [CrossRef]

- Xu, S.; Liu, T.; Chen, H.; Miao, Z.; Zhang, Z.; Zeng, W. Reducing the tension–compression yield asymmetry in a hot-rolled Mg–3Al–1Zn alloy via multidirectional pre-compression. Mater. Sci. Eng. A 2013, 565, 96–101. [Google Scholar] [CrossRef]

- Wang, J.; Liu, L.; Tomé, C.N.; Mao, S.X.; Gong, S.K. Twinning and de-twinning via glide and climb of twinning dislocations along serrated coherent twin boundaries in hexagonal-close-packed metals. Mater. Res. Lett. 2013, 1, 81–88. [Google Scholar] [CrossRef]

- Yuasa, M.; Hayashi, M.; Mabuchi, M.; Chino, Y. Atomic simulations of {}, {} twinning and {} detwinning in magnesium. J. Phys. Condens. Matter 2013, 26, 015003. [Google Scholar] [CrossRef]

- Li, B.; Zhang, X.Y. Twinning with zero twinning shear. Scr. Mater. 2016, 125, 73–79. [Google Scholar] [CrossRef]

- Li, B.; Ma, E. Atomic shuffling dominated mechanism for deformation twinning in magnesium. Phys. Rev. Lett. 2009, 103, 035503. [Google Scholar] [CrossRef] [PubMed]

- Molodov, K.D.; Al-Samman, T.; Molodov, D.A.; Korte-Kerzel, S. On the twinning shear of {} twins in magnesium—Experimental determination and formal description. Acta Mater. 2017, 134, 267–273. [Google Scholar] [CrossRef]

- Liu, B.Y.; Li, B.; Shan, Z.W. Twin Boundary Migration Creating Zero Shear Strain: In-Situ TEM Observations and Atomistic Simulations. In Magnesium Technology 2013; Springer: Cham, Switzerland, 2013; pp. 107–111. [Google Scholar]

- Cahn, J.W.; Mishin, Y.; Suzuki, A. Coupling grain boundary motion to shear deformation. Acta Mater. 2006, 54, 4953–4975. [Google Scholar] [CrossRef]

- Li, J.; Lu, C.; Pei, L.; Zhang, C.; Wang, R.; Tieu, K. Effects of H segregation on shear-coupled motion of <110> grain boundaries in α-fe. International. J. Hydrog. Energy 2019, 44, 18616–18627. [Google Scholar]

- Chen, K.; Han, J.; Thomas, S.L.; Srolovitz, D.J. Grain boundary shear coupling is not a grain boundary property. Acta Mater. 2019, 167, 241–247. [Google Scholar] [CrossRef]

- Yin, J.; Wang, Y.; Yan, X.; Hou, H.; Wang, J.T. Atomistic simulation of shear-coupled motion of [110] symmetric tilt grain boundary in α-iron. Comput. Mater. Sci. 2018, 148, 141–148. [Google Scholar] [CrossRef]

- Cheng, K.; Zhang, L.; Lu, C.; Tieu, K. Coupled grain boundary motion in aluminium: The effect of structural multiplicity. Sci. Rep. 2016, 6, 25427. [Google Scholar] [CrossRef] [PubMed]

- Niu, L.L.; Zhang, Y.; Shu, X.; Gao, F.; Jin, S.; Zhou, H.B.; Lu, G.H. Shear-coupled grain boundary migration assisted by unusual atomic shuffling. Sci. Rep. 2016, 6, 23602. [Google Scholar] [CrossRef] [PubMed]

- Brandenburg, J.E.; Molodov, D.A. On shear coupled migration of low angle grain boundaries. Scr. Mater. 2019, 163, 96–100. [Google Scholar] [CrossRef]

- Niu, L.L.; Shu, X.; Zhang, Y.; Gao, F.; Jin, S.; Zhou, H.B.; Lu, G.H. Atomistic insights into shear-coupled grain boundary migration in bcc tungsten. Mater. Sci. Eng. A 2016, 677, 20–28. [Google Scholar] [CrossRef]

- Sun, D.Y.; Mendelev, M.I.; Becker, C.A.; Kudin, K.; Haxhimali, T.; Asta, M.; Srolovitz, D.J. Crystal-melt interfacial free energies in hcp metals: A molecular dynamics study of Mg. Phys. Rev. B 2006, 73, 024116. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Larsen, P.M.; Schmidt, S.; Schiøtz, J. Robust structural identification via polyhedral template matching. Model. Simul. Mater. Sci. Eng. 2016, 24, 055007. [Google Scholar] [CrossRef]

- Plimpton, S. LAMMPS Users Manual. Available online: https://lammps.sandia.gov/doc/compute_stress_atom.html (accessed on 1 September 2019).

- Rodney, D. Activation enthalpy for kink-pair nucleation on dislocations: Comparison between static and dynamic atomic-scale simulations. Phys. Rev. B 2007, 76, 144108. [Google Scholar] [CrossRef]

- Yi, P.; Cammarata, R.C.; Falk, M.L. Atomistic simulation of solid solution hardening in Mg/Al alloys: Examination of composition scaling and thermo-mechanical relationships. Acta Mater. 2016, 105, 378–389. [Google Scholar] [CrossRef]

- Yi, P.; Falk, M.L. Thermally activated twin thickening and solute softening in magnesium alloys-a molecular simulation study. Scr. Mater. 2019, 162, 195–199. [Google Scholar] [CrossRef]

- Li, J.; Shimizu, F. Least-Square Atomic Strain. Available online: http://li.mit.edu/A/Archive/Graphics/A/annotate_atomic_strain/Doc/main.pdf (accessed on 1 September 2019).

- Pei, Z.Z.; Zhang, X.; Hickel, T.; Martin, F.; Stefanie, S.; Biswanath, D.; Jörg, N. Atomic structures of twin boundaries in hexagonal close-packed metallic crystals with particular focus on Mg. NPJ Comput. Math. 2017, 3, 6. [Google Scholar] [CrossRef]

- Kostianyn, K.; Andriy, O. Variability of Twin Boundary Structure in Computer Simulations of Tensile Twins in Magnesium. Defect Diffus. Forum 2018, 385, 241–244. [Google Scholar]

| Strain Rate (s−1) | Ratio of Loading Displacement and Migration Distance | |

|---|---|---|

| [] | [] | |

| 107 | 0.123 | 0.124 |

| 5 × 107 | 0.124 | 0.124 |

| 108 | 0.124 | 0.125 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, S.; Wang, Y.; Wang, Y.; Wang, X. Atomistic Simulation on the Twin Boundary Migration in Mg under Shear Deformation. Materials 2019, 12, 3129. https://doi.org/10.3390/ma12193129

Song S, Wang Y, Wang Y, Wang X. Atomistic Simulation on the Twin Boundary Migration in Mg under Shear Deformation. Materials. 2019; 12(19):3129. https://doi.org/10.3390/ma12193129

Chicago/Turabian StyleSong, Shichao, Yu Wang, Yang Wang, and Xi Wang. 2019. "Atomistic Simulation on the Twin Boundary Migration in Mg under Shear Deformation" Materials 12, no. 19: 3129. https://doi.org/10.3390/ma12193129

APA StyleSong, S., Wang, Y., Wang, Y., & Wang, X. (2019). Atomistic Simulation on the Twin Boundary Migration in Mg under Shear Deformation. Materials, 12(19), 3129. https://doi.org/10.3390/ma12193129