Laser Surface Hardening of Gun Metal Alloys

Abstract

1. Introduction

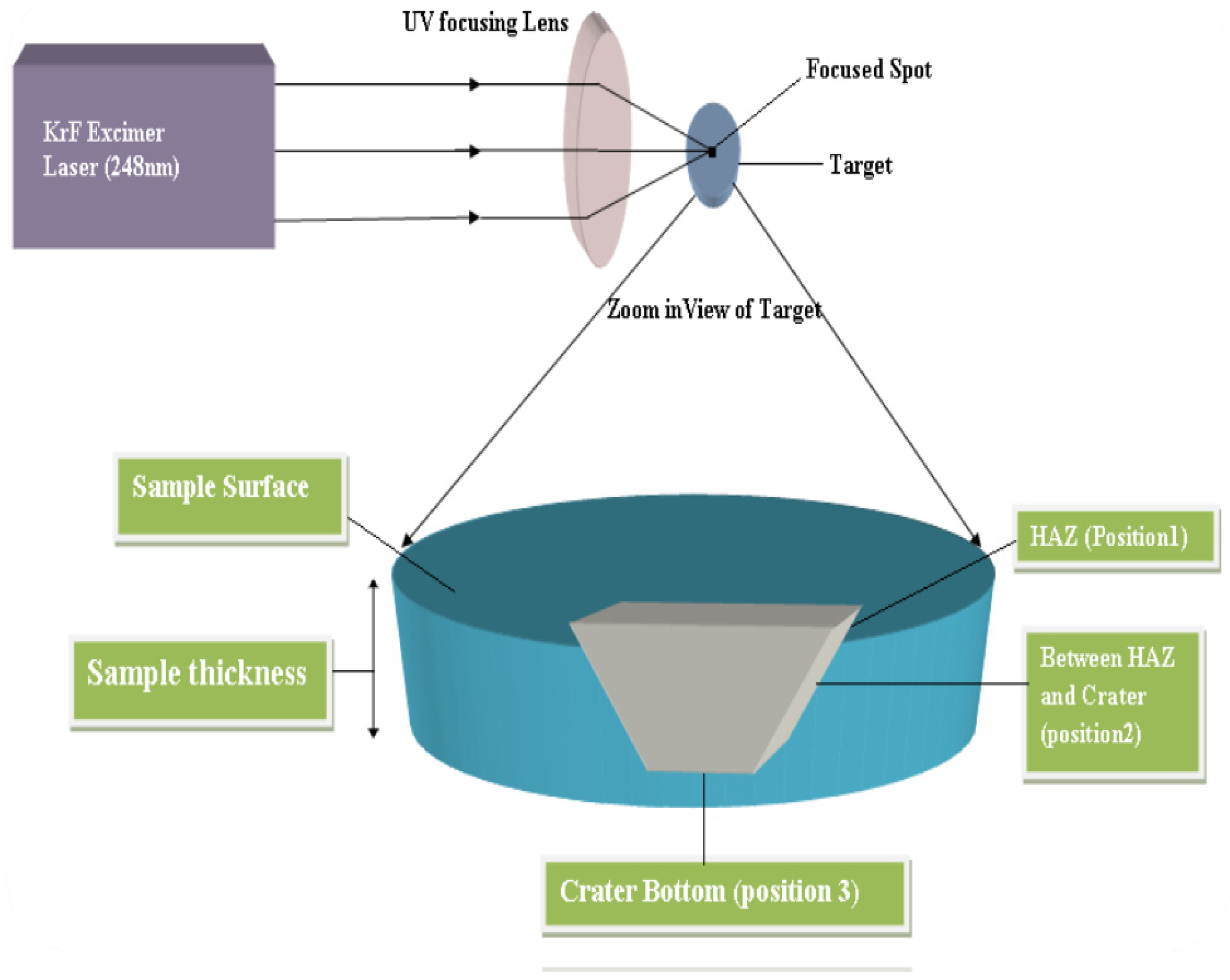

2. Experimental Details

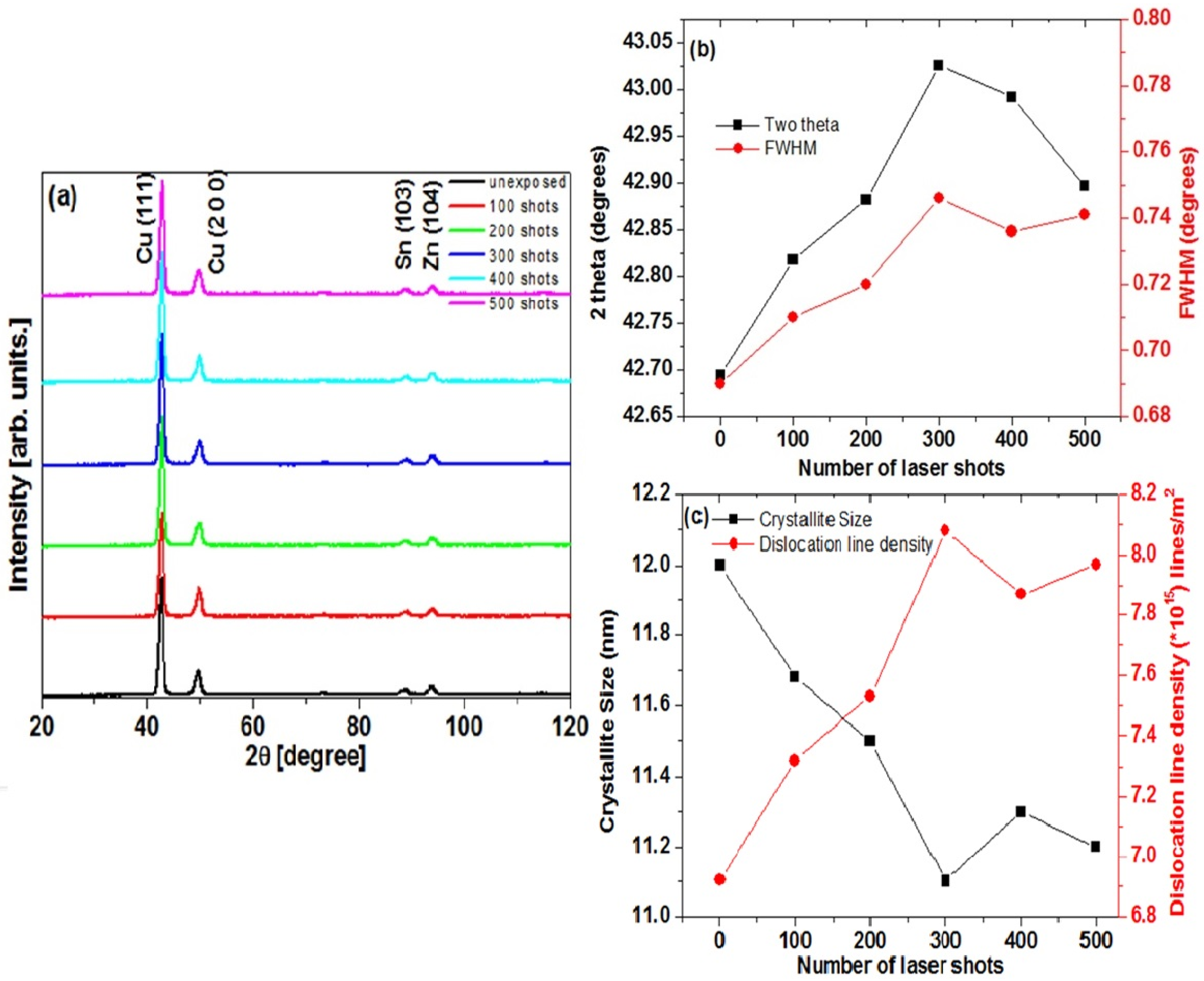

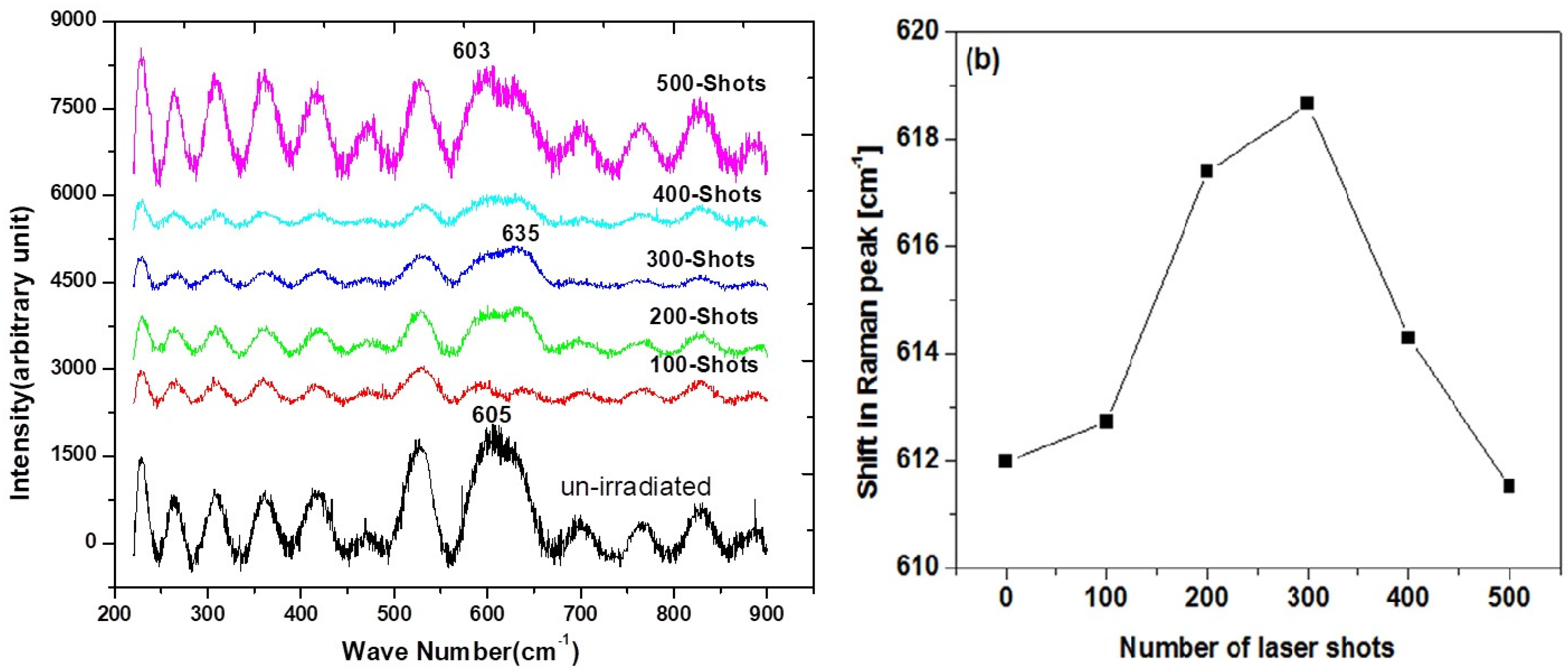

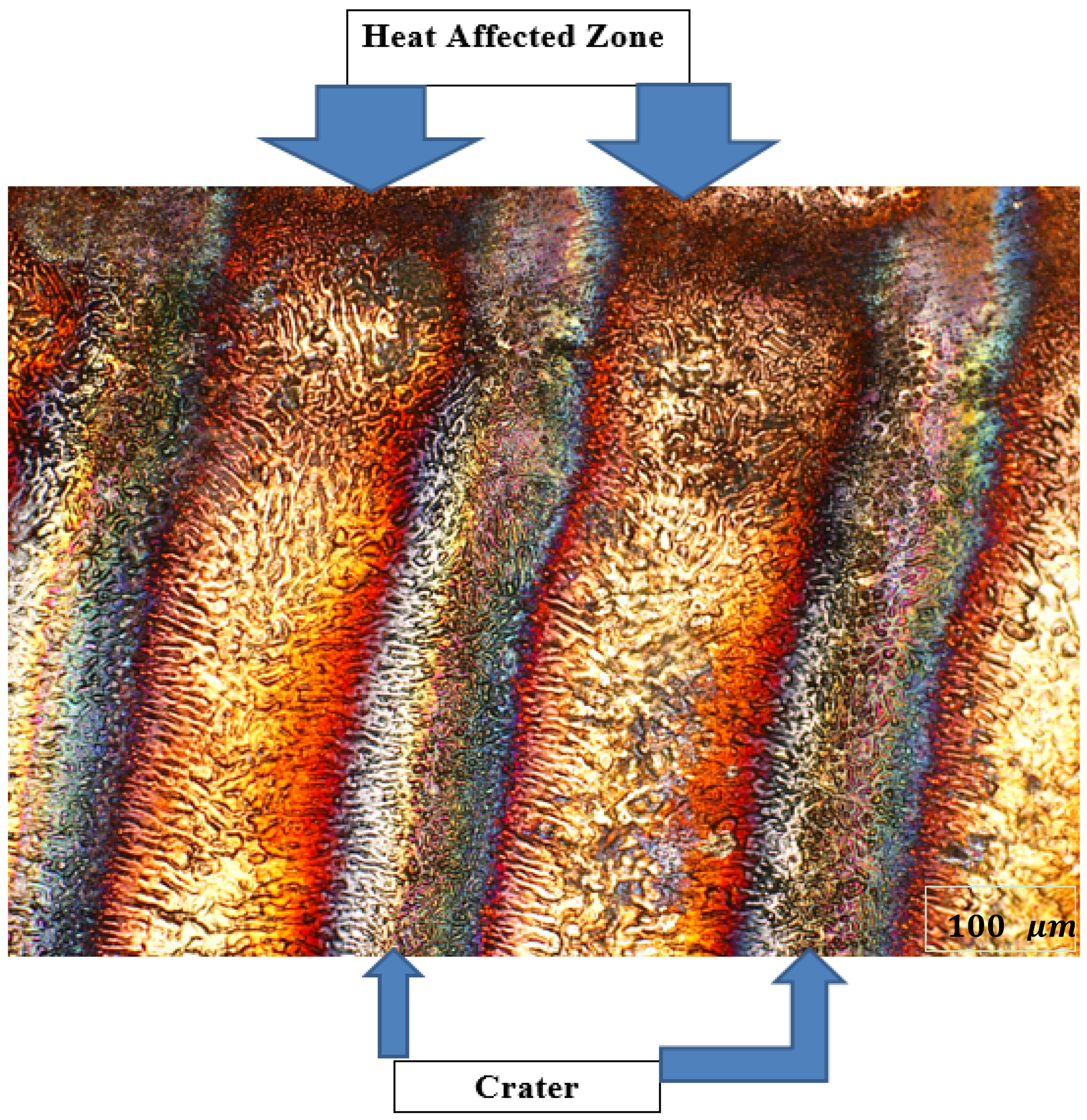

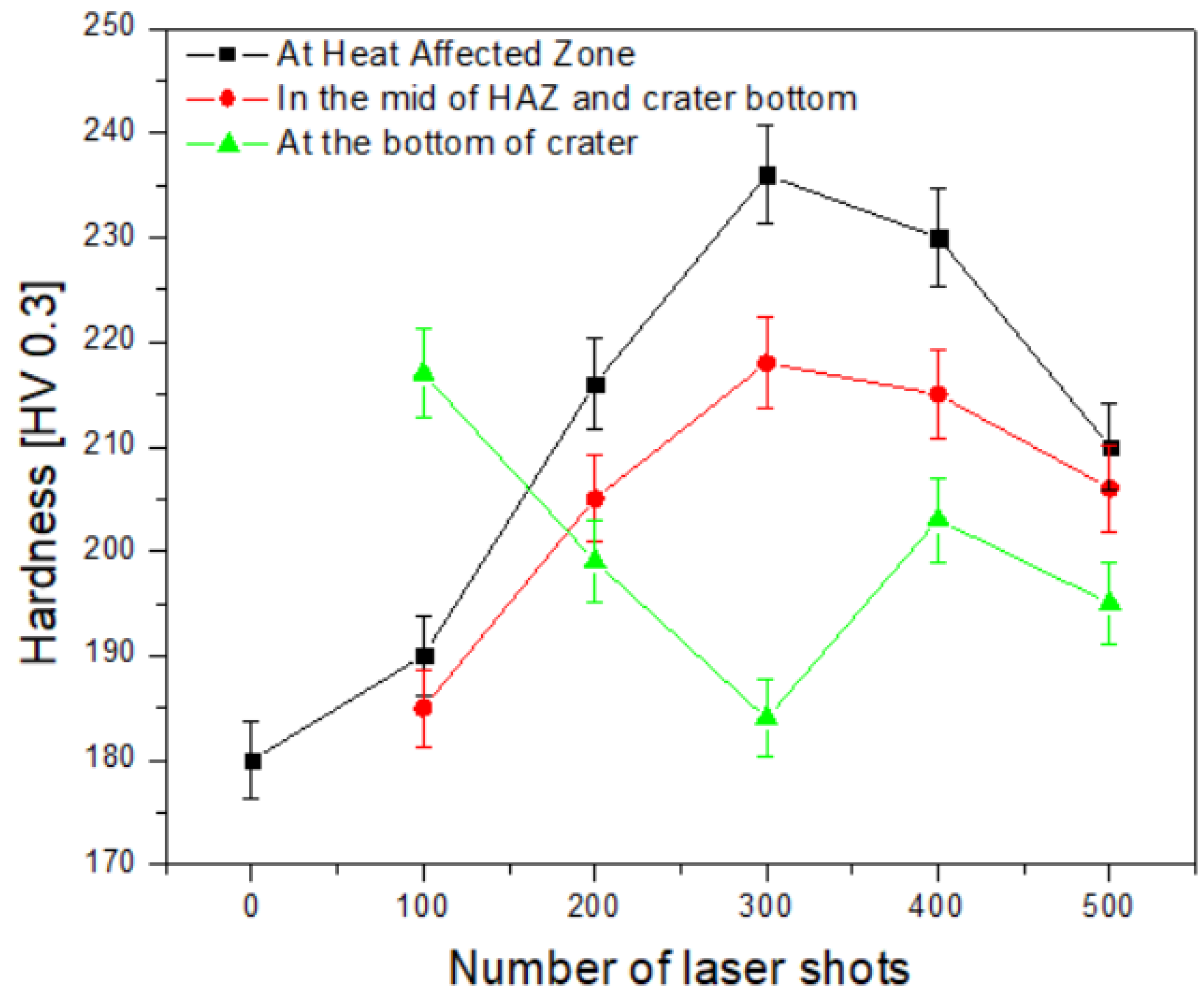

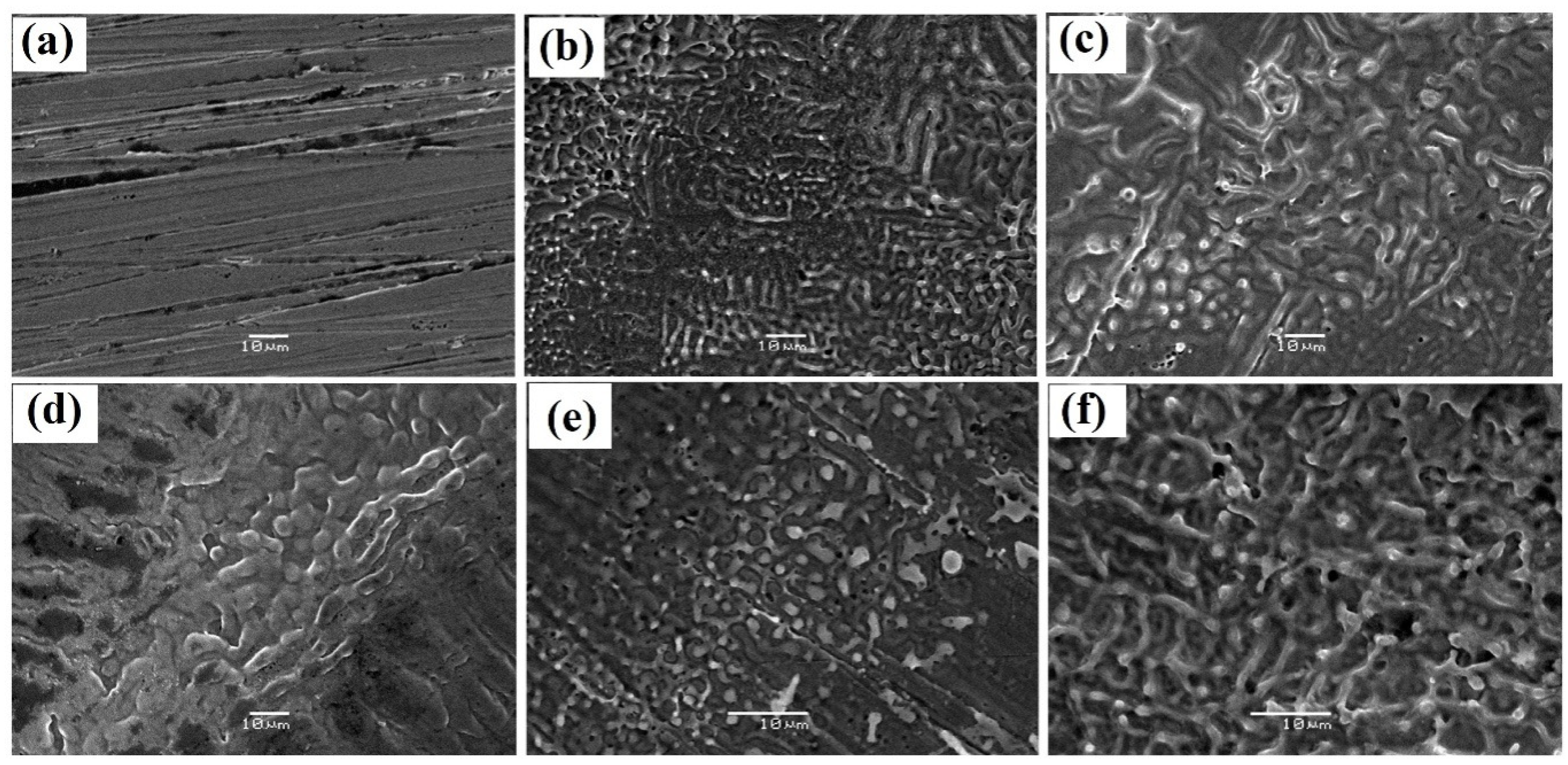

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Campbell, H.S. The compromise between mechanical properties and corrosion resistance in copper and aluminium alloys for marine applications. Ocean Eng. 1969, 1, 387–393. [Google Scholar] [CrossRef]

- Bhandari, V. Introduction to Machine Design; Tata McGraw-Hill Education: New York, NY, USA, 2013. [Google Scholar]

- Ion, J. Laser Processing of Engineering Materials: Principles, Procedure and Industrial Application; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Ward, G.W. The Grove Encyclopedia of Materials and Techniques in Art; Oxford University Press: Oxford, UK, 2008. [Google Scholar]

- Craddock, P.T. The composition of the copper alloys used by the Greek, Etruscan and Roman civilizations: 3. The origins and early use of brass. J. Archaeol. Sci. 1978, 5, 1–16. [Google Scholar] [CrossRef]

- Gliozzo, E.; Kockelmann, W.A.; Artioli, G. Neutron diffraction of Cu–Zn–Sn ternary alloys: Non-invasive assessment of the compositions of historical bronze/brass copper ternary alloys. J. Appl. Crystallogr. 2017, 50, 49–60. [Google Scholar] [CrossRef]

- Higgins, R.A. Materials for Engineers and Technicians; Routledge: Abington, UK, 2010. [Google Scholar]

- Wilbur, C.T.; Wight, D. Pounder’s Marine Diesel Engines; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Zohdy, K.; Sadawy, M.; Ghanem, M. Corrosion behavior of leaded-bronze alloys in sea water. Mater. Chem. Phys. 2014, 147, 878–883. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Debnath, U.K.; Nuruzzaman, D.M.; Islam, M. Experimental evaluation of erosion of gunmetal under asymmetrical shaped sand particle. Adv. Tribol. 2015, 2015. [Google Scholar] [CrossRef]

- Babu, P.D.; Buvanashekaran, G.; Balasubramanian, K.R. Experimental studies on the microstructure and hardness of laser transformation hardening of low alloy steel. Trans. Can. Soc. Mech. Eng. 2012, 36, 242–257. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Manna, I.; Kumar, A.; Bhargava, P.; Nath, A. Direct laser cladding of Co on Ti–6Al–4V with a compositionally graded interface. J. Mater. Process. Technol. 2009, 209, 2237–2243. [Google Scholar] [CrossRef]

- Kurita, T.; Ogura, I.; Ashida, K. Proposal of laser assisted hot embossing technology for glass. J. Mater. Process. Technol. 2018, 254, 248–253. [Google Scholar] [CrossRef]

- Kala, S.; Kaur, H.; Rastogi, A.; Singh, V.; Senguttuvan, T. Structural and opto-electronic features of pulsed laser ablation grown Cu2ZnSnS4 films for photovoltaic applications. J. Alloy. Compd. 2016, 658, 324–330. [Google Scholar] [CrossRef]

- Shamim, M.K.; Sharma, S.; Choudhary, R. Laser ablated lead free (Na, K) NbO3 thin films with excess alkali-content. J. Mater. Sci. Mater. Electron. 2017, 28, 11609–11614. [Google Scholar] [CrossRef]

- Khaleeq-ur-Rahman, M.; Butt, M.; Samuel, A.; Siraj, K. Investigation of laser irradiation effects on the hardness of Al 5086 alloy under different conditions. Vacuum 2010, 85, 474–479. [Google Scholar] [CrossRef]

- Borisov, V.; Trofimov, V.; Sapozhkov, A.Y.; Kuzmenko, V.; Mikhaylov, V.; Cherkovets, V.Y.; Yakushkin, A.; Yakushin, V.; Dzhumayev, P. Capabilities to improve corrosion resistance of fuel claddings by using powerful laser and plasma sources. Phys. At. Nucl. 2016, 79, 1656–1662. [Google Scholar] [CrossRef]

- Gambino, L.V.; Magdefrau, N.J.; Aindow, M. Microstructural evolution in manganese cobaltite films grown on Crofer 22 APU substrates by pulsed laser deposition. Surf. Coat. Technol. 2016, 286, 206–214. [Google Scholar] [CrossRef]

- Ahmad, S.; Bashir, S.; Yousaf, D.; Ali, N.; Hussain, T. Surface Analysis Correlated with Structural and Mechanical Properties of Laser Irradiated Brass. Mater. Sci. Appl. 2015, 6, 23. [Google Scholar] [CrossRef][Green Version]

- Makinson, J.; Lee, J.; Magner, S.; De Angelis, R.; Weins, W.; Hieronymus, A. X-ray diffraction signatures of defects in nanocrystalline materials. Adv. X-ray Anal. 2000, 42, 407–411. [Google Scholar]

- Ozen, I.; Gülgün, M.A. Residual stress relaxation and microstructure in ZnO thin films. Adv. Sci. Technol. 2006, 45, 1316–1321. [Google Scholar] [CrossRef]

- Thomas, G.S.; Kamath, P.V. Line broadening in the PXRD patterns of layered hydroxides: The relative effects of crystallite size and structural disorder. J. Chem. Sci. 2006, 118, 127–133. [Google Scholar] [CrossRef]

- Deceased, B.C.; Stock, S. Elements of X-ray Diffraction; Prentice Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Kissinger, N.S.; Jayachandran, M.; Perumal, K.; Raja, C.S. Structural and optical properties of electron beam evaporated CdSe thin films. Bull. Mater. Sci. 2007, 30, 547–551. [Google Scholar] [CrossRef]

- Cao, L.; Cheng, B.; Wang, S.; Fu, W.; Ding, S.; Sun, Z.; Yuan, H.; Zhou, Y.; Chen, Z.; Yang, G. Influence of stress on Raman spectra in Ba1−xSrxTiO3 thin films. J. Phys. D Appl. Phys. 2006, 39, 2819. [Google Scholar] [CrossRef]

- Zatryb, G.; Podhorodecki, A.; Misiewicz, J.; Cardin, J.; Gourbilleau, F. Correlation between matrix structural order and compressive stress exerted on silicon nanocrystals embedded in silicon-rich silicon oxide. Nanoscale Res. Lett. 2013, 8, 40. [Google Scholar] [CrossRef]

- Di, X.J.; Xie, H.J.; Chen, C.X.; Deng, C.Y.; Wang, D.-P. Microstructural Evolution and Softening Behavior of Simulated Heat-Affected Zone in 2219 Aluminum Alloy. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 1177–1184. [Google Scholar] [CrossRef][Green Version]

- Budinski, K.G.; Budinski, M.K. Engineering materials. Nature 2009, 25, 28. [Google Scholar]

- Gaković, B.; Trtica, M.; Petrović, S.; Panjan, P.; Čekada, M.; Samardžija, Z. Surface structures formed on AISI 420 stainless steel by pulsed laser irradiation. Mater. Sci. Forum 2005, 494, 309–314. [Google Scholar] [CrossRef]

- Zhang, Y.; Turghun, M.; Huang, C.; Wang, T.; Wang, F.; Shi, W. Structure and Magnetic Properties of Magnetostrictive FeGa Film on Single-Crystal (100) GaAs and (001) Si Substrate Fabricated by Pulsed Laser Deposition. Acta Metall. Sin. (Engl. Lett.) 2018, 31, 1–6. [Google Scholar] [CrossRef]

- Medvid, A.; Onufrijevs, P.; Jarimaviciute-Gudaitiene, R.; Dauksta, E.; Prosycevas, I. Formation mechanisms of nano and microcones by laser radiation on surfaces of Si, Ge, and SiGe crystals. Nanoscale Res. Lett. 2013, 8, 264. [Google Scholar] [CrossRef] [PubMed]

- Schade, M.; Varlamova, O.; Reif, J.; Blumtritt, H.; Erfurth, W.; Leipner, H. High-resolution investigations of ripple structures formed by femtosecond laser irradiation of silicon. Anal. Bioanal. Chem. 2010, 396, 1905–1911. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Shin, H.; Yoo, Y.; Ahn, D.; Im, K. Laser surface hardening of S45C medium carbon steel using ND: YAG laser with a continuous wave. J. Mater. Process. Technol. 2007, 187, 467–470. [Google Scholar] [CrossRef]

- Leung, M.K.; Man, H.; Yu, J. Theoretical and experimental studies on laser transformation hardening of steel by customized beam. Int. J. Heat Mass Transf. 2007, 50, 4600–4606. [Google Scholar] [CrossRef]

| Material | Symbol | Percentage |

|---|---|---|

| Copper | (Cu) | 84–88% |

| Tin | (Sn) | 4–10% |

| Zinc | (Zn) | 4–6% |

| Lead | (Pb) | 4–6% |

| Phosphorus | (P) | 0.05% max |

| Aluminum | (Al) | 0.005% max |

| Property | Standard Value (S.I.) | Actual or Measured Data | Units (S.I.) |

|---|---|---|---|

| Density | 8719 | 8710 | kg/m3 |

| Tensile yield Strength | 110 | 118 | MPa |

| Ultimate tensile Strength | 220 | 225 | MPa |

| Hardness | 80 | 85 | HB |

| Melting Point | 1810 | - | °F |

| No. of Shots | 2θ (Degrees) | d-Spacing (Å) | FWHM (Degrees) | Crystalline Size (nm) | Dislocation Lines Density (×1015/m2) |

|---|---|---|---|---|---|

| 0 | 42.695 | 2.1160 | 0.69 | 12 | 6.92 |

| 100 | 42.818 | 2.1102 | 0.71 | 11.68 | 7.32 |

| 200 | 42.882 | 2.1072 | 0.72 | 11.5 | 7.53 |

| 300 | 43.026 | 2.1005 | 0.746 | 11.1 | 8.08 |

| 400 | 42.992 | 2.1054 | 0.736 | 11.3 | 7.87 |

| 500 | 42.897 | 2.1065 | 0.741 | 11.2 | 7.97 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naeem, S.; Mehmood, T.; Wu, K.M.; Khan, B.S.; Majid, A.; Siraj, K.; Mukhtar, A.; Saeed, A.; Riaz, S. Laser Surface Hardening of Gun Metal Alloys. Materials 2019, 12, 2632. https://doi.org/10.3390/ma12162632

Naeem S, Mehmood T, Wu KM, Khan BS, Majid A, Siraj K, Mukhtar A, Saeed A, Riaz S. Laser Surface Hardening of Gun Metal Alloys. Materials. 2019; 12(16):2632. https://doi.org/10.3390/ma12162632

Chicago/Turabian StyleNaeem, Samia, Tahir Mehmood, K. M. Wu, Babar Shahzad Khan, Abdul Majid, Khurrum Siraj, Aiman Mukhtar, Adnan Saeed, and Saira Riaz. 2019. "Laser Surface Hardening of Gun Metal Alloys" Materials 12, no. 16: 2632. https://doi.org/10.3390/ma12162632

APA StyleNaeem, S., Mehmood, T., Wu, K. M., Khan, B. S., Majid, A., Siraj, K., Mukhtar, A., Saeed, A., & Riaz, S. (2019). Laser Surface Hardening of Gun Metal Alloys. Materials, 12(16), 2632. https://doi.org/10.3390/ma12162632