Dynamic Mechanical Analysis on Delaminated Flax Fiber Reinforced Composites

Abstract

1. Introduction

2. Materials and Methods

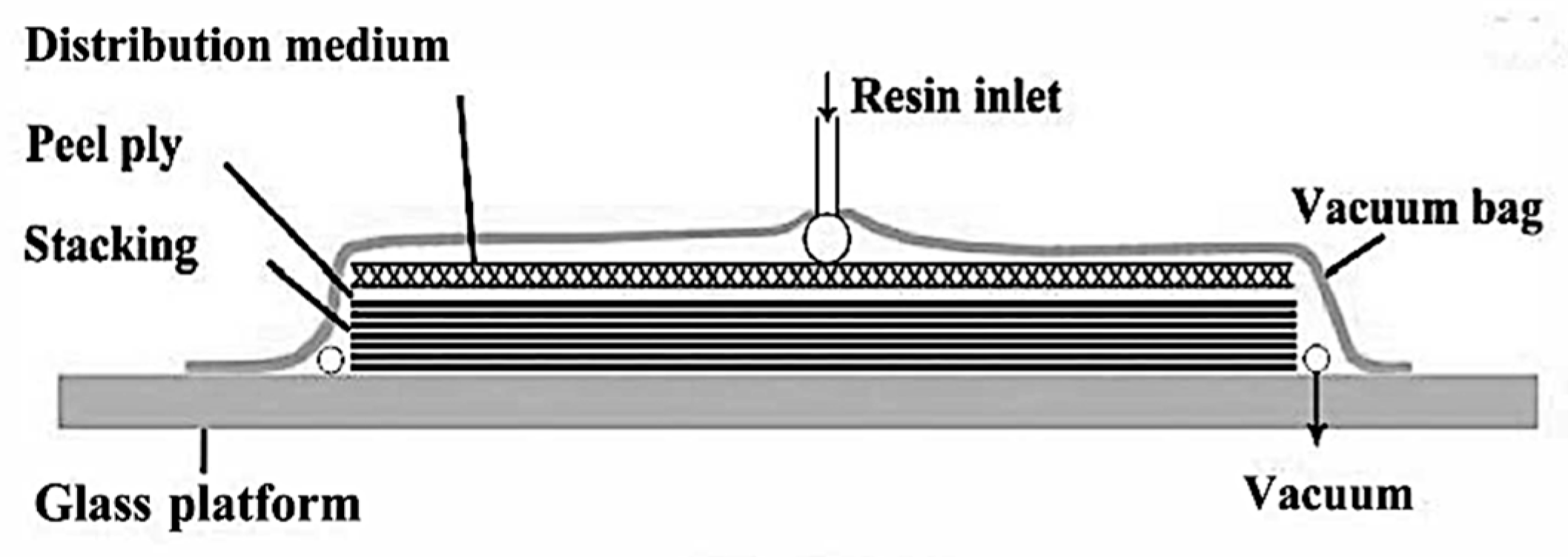

2.1. Materials and Fabrication

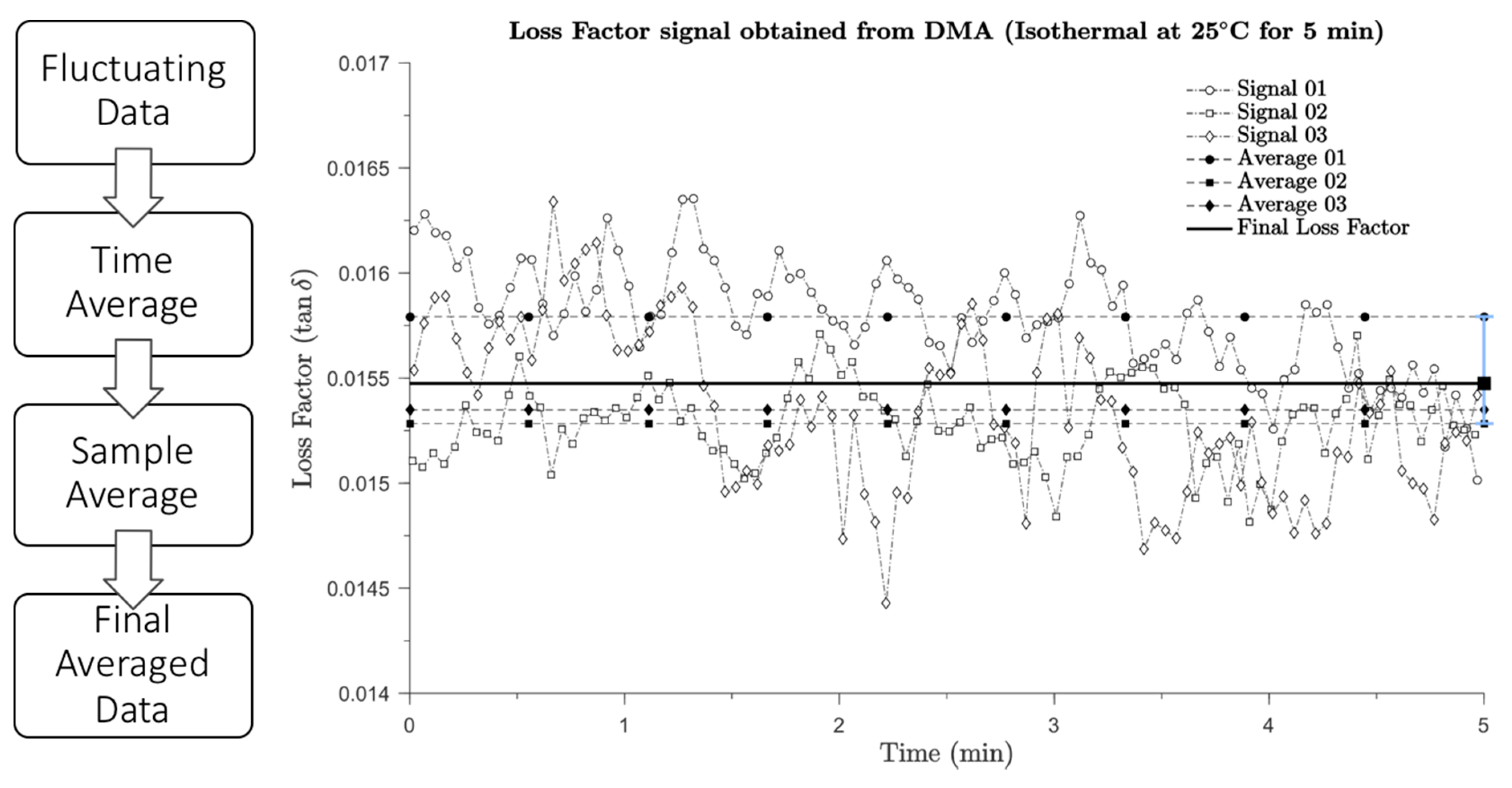

2.2. Testing and Data Processing

3. Results

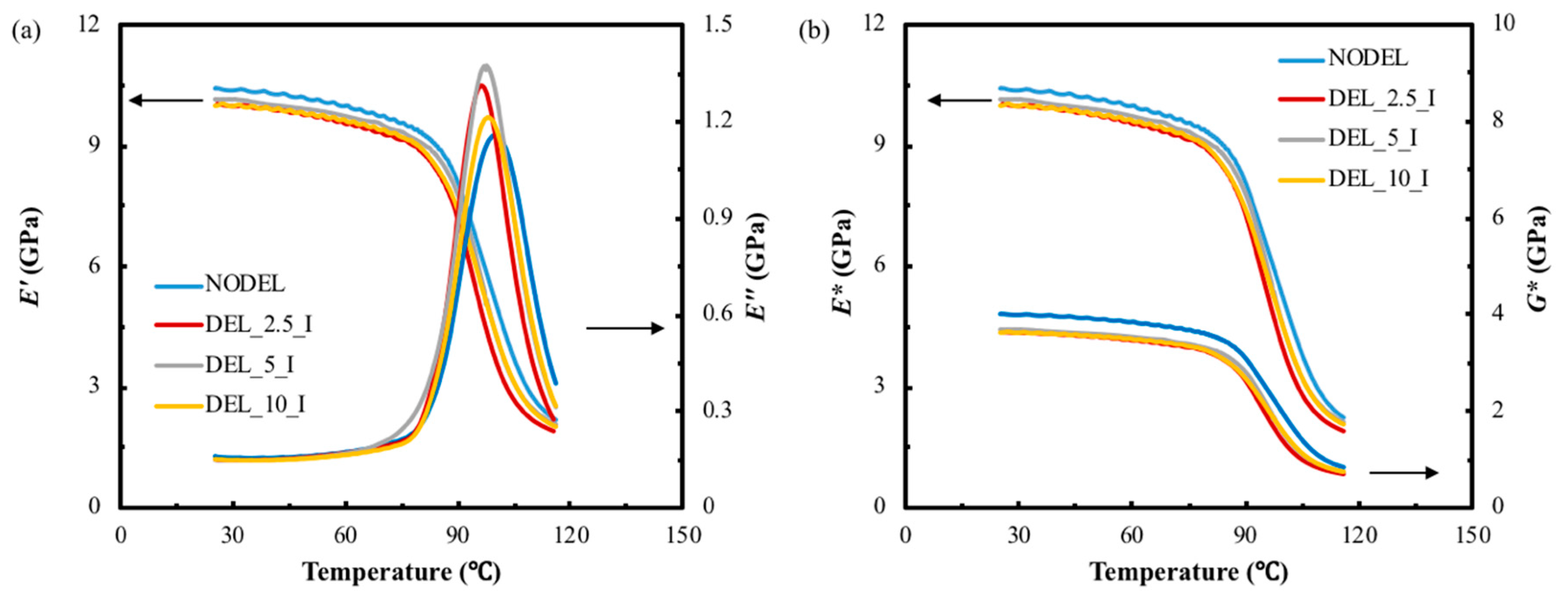

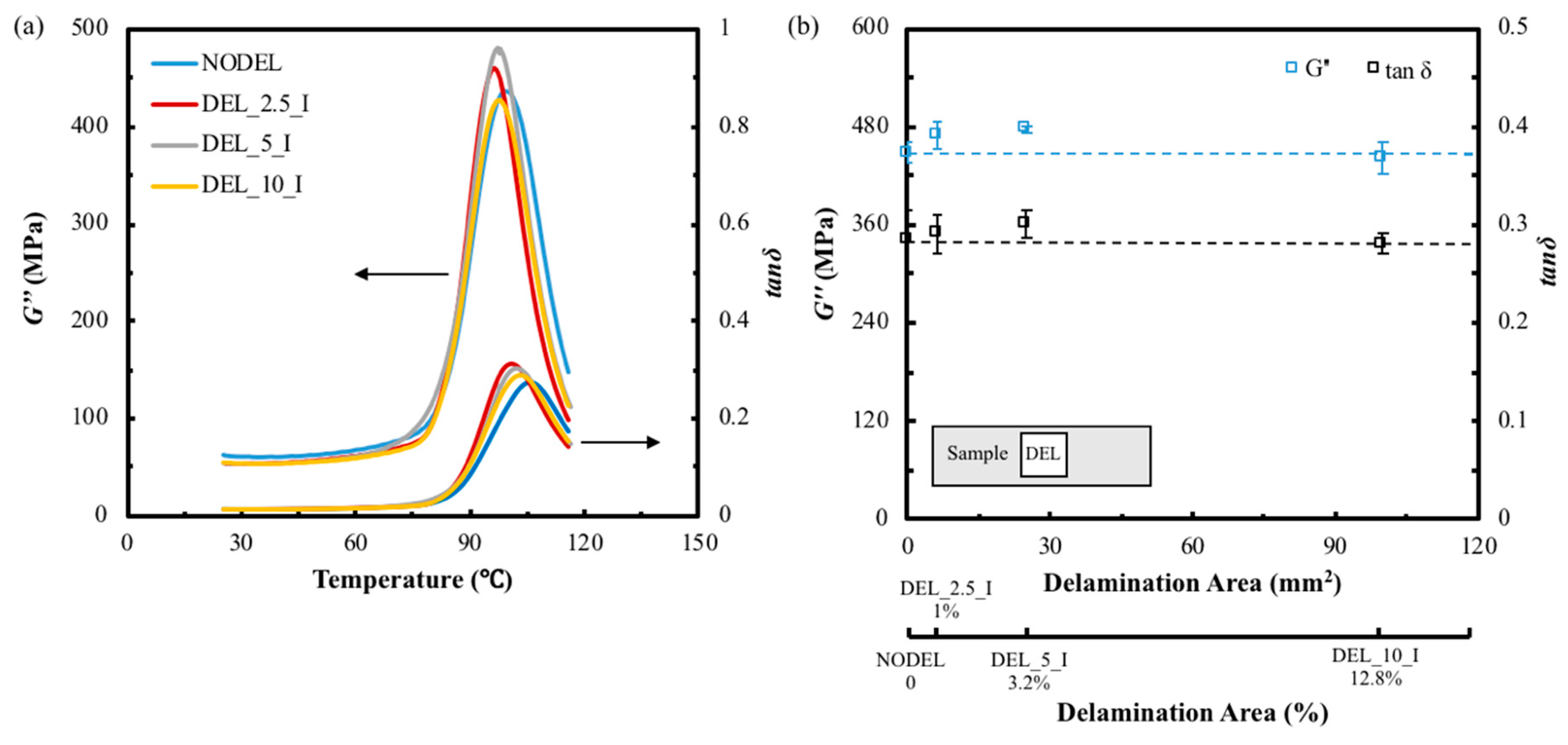

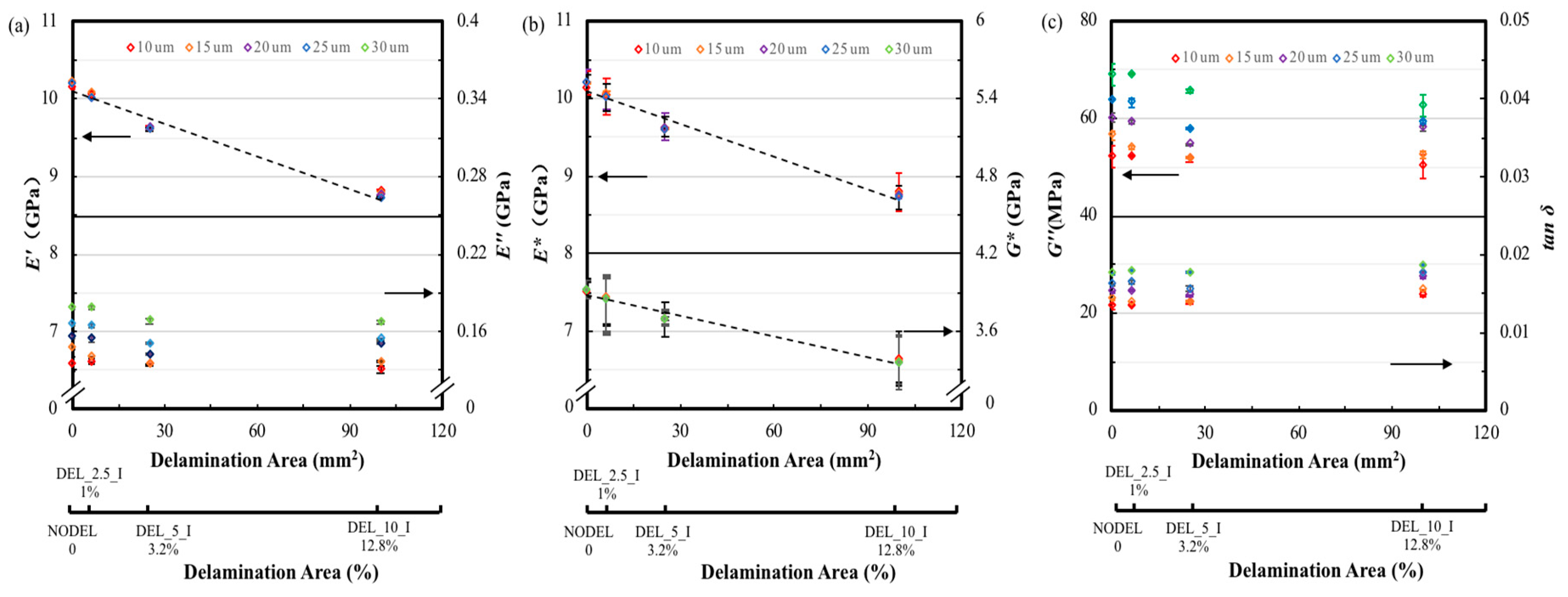

3.1. Influence of the Delamination Area

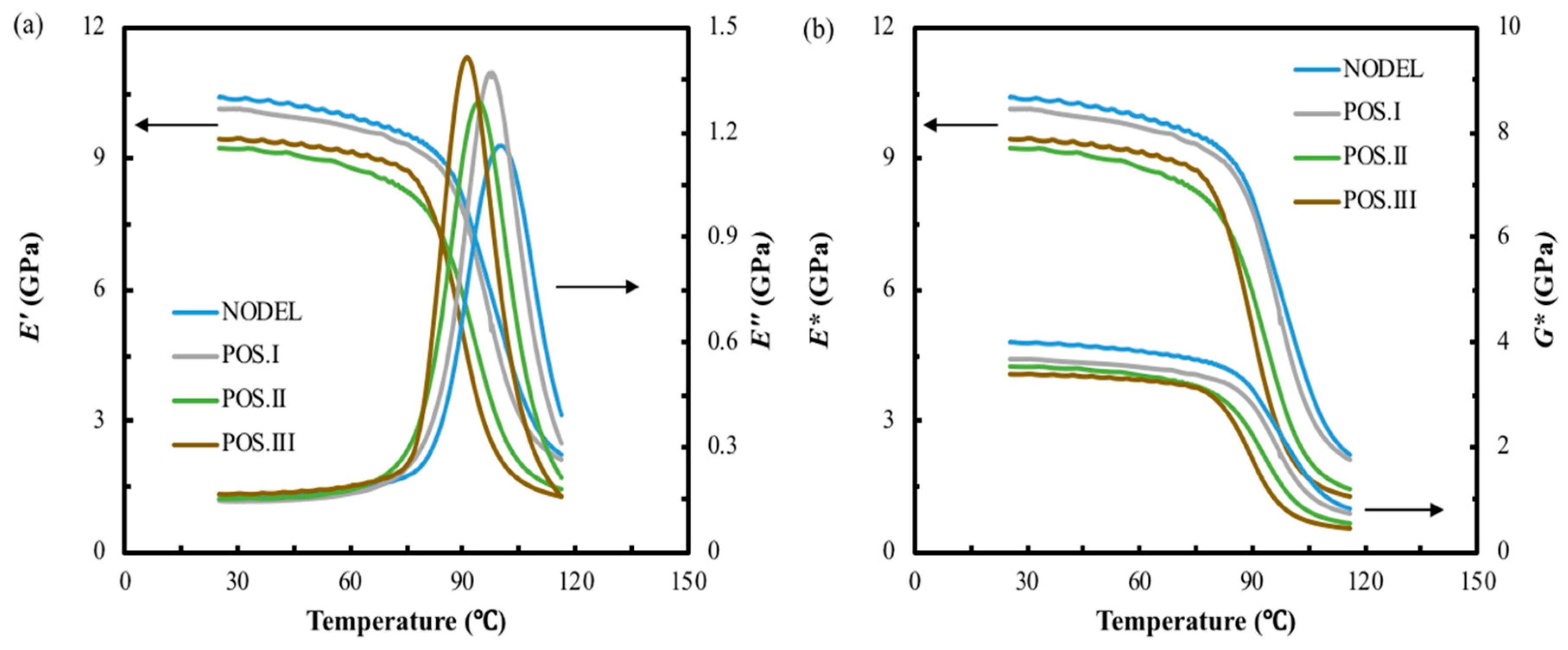

3.1.1. Temperature Scans

3.1.2. Frequency Scans

3.1.3. Amplitude Scans

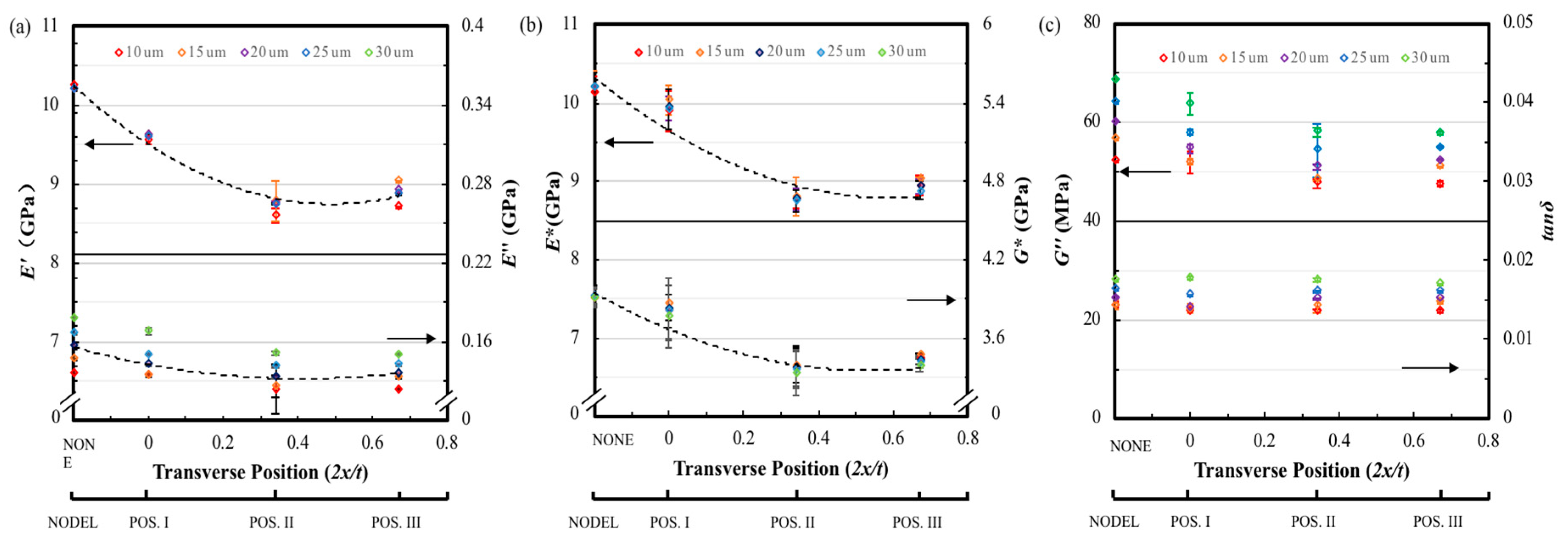

3.2. Influence of Transverse Delamination Position

3.2.1. Temperature Effect

3.2.2. Frequency Effect

3.2.3. Amplitude Effect

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pickering, K.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Fuqua, M.A.; Huo, S.; Ulven, C.A. Natural fiber reinforced composites. Polym. Rev. 2012, 52, 259–320. [Google Scholar] [CrossRef]

- Wang, Z.X.; Qiao, P.; Xu, J. Vibration analysis of laminated composite plates with damage using the perturbation method. Compos. Part B Eng. 2015, 72, 160–174. [Google Scholar] [CrossRef]

- Aslan, Z.; Daricik, F. Effects of multiple delaminations on the compressive, tensile, flexural, and buckling behaviour of E–glass/epoxy composites. Compos. Part B Eng. 2016, 100, 186–196. [Google Scholar] [CrossRef]

- Shen, Y.; Zhong, J.; Cai, S.; Ma, H.; Qu, Z.; Guo, Y.; Li, Y. Effect of temperature and water absorption on low–velocity impact damage of composites with multi–layer structured flax fiber. Materials 2019, 12, 453. [Google Scholar] [CrossRef] [PubMed]

- Valencia, C.A.M.; Pazos-Ospina, J.F.; Franco, E.E.; Ealo, J.L.; Collazos-Burbano, D.A.; Garcia, G.F.C. Ultrasonic determination of the elastic constants of epoxy–natural fiber composites. Phys. Proc. 2015, 70, 467–470. [Google Scholar] [CrossRef]

- Sabbagh, E.l.; Steuernagel, L.; Ziegmann, G. Characterisation of flax polypropylene composites using ultrasonic longitudinal sound wave technique. Compos. Part B Eng. 2013, 45, 1164–1172. [Google Scholar] [CrossRef]

- Loganathan, T.M.; Sultan, M.T.H.; Gobalakrishnan, M.K. Ultrasonic inspection of natural fiber–reinforced composites. In Sustainable Composites for Aerospace Applications; Jawaid, M., Thariq, M., Eds.; Woodhead Publishing: Duxford, UK, 2018; pp. 227–251. [Google Scholar]

- Sarasini, F.; Santulli, C. Non–destructive testing (NDT) of natural fibre composites: Acoustic emission technique. Nat. Fibre Compos. 2014, 273–302. [Google Scholar]

- De Rosa, I.M.; Santulli, C.; Sarasini, F. Acoustic emission for monitoring the mechanical behaviour of natural fiber composites: A literature review. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1456–1469. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ali, A.; Khalina, A.; Sapuan, S.M.; Abdullah, S. Detection of defects in kenaf/epoxy using infrared thermal imaging technique. Proc. Chem. 2012, 4, 172–178. [Google Scholar] [CrossRef]

- Lai, J.Y.; Young, K.F. Dynamics of graphite/epoxy composite under delamination fracture and environmental effects. Compos. Struct. 1995, 30, 25–32. [Google Scholar] [CrossRef]

- Junker, P.; Kochmann, D.M. Damage–induced mechanical damping in phase–transforming composites materials. Int. J. Solid. Struct. 2017, 132–146. [Google Scholar] [CrossRef]

- Zhang, Z.; Shankar, K.; Morozov, E.V. Vibration–based delamination detection in composite beams through frequency changes. J. Vib. Contr. 2016, 22, 496–512. [Google Scholar] [CrossRef]

- Zhang, Z.; He, M.; Liu, A.; Singh, H.K.; Ramakrishnan, K.R.; Hui, D.; Shankar, K.; Morozov, E.V. Vibration–based assessment of delaminations in FRP composite plates. Compos. Part B Eng. 2018, 144, 254–266. [Google Scholar] [CrossRef]

- Yang, C.; Oyadiji, S.O. Detection of delamination in composite beams using frequency deviations due to concentrated mass loading. Compos Struct. 2016, 146, 1–13. [Google Scholar] [CrossRef]

- Menard, H.P. Dynamic Mechanical Analysis: A Practical Introduction, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Chua, P.S. Dynamic mechanical analysis studies of the interphase. Polym. Rev. 1987, 8, 308–313. [Google Scholar] [CrossRef]

- Kennedy, J.M.; Edie, D.D.; Banerjee, A. Characterization of interfacial bond strength by dynamic analysis. J. Compos. Mater. 1992, 26, 869–882. [Google Scholar] [CrossRef]

- Dong, S.; Gauvin, R. Application of dynamic mechanical analysis for the study of the interfacial region in carbon fiber/epoxy composite materials. Polym. Compos. 1993, 14, 414–420. [Google Scholar] [CrossRef]

- Joseph, S.; Sreekumar, P.A.; Kenny, J.M. Dynamic mechanical analysis of oil palm microfibril-reinforced acrylonitrile butadiene rubber composites. Polym. Compos. 2010, 31, 236–244. [Google Scholar] [CrossRef]

- Shanmugam, D.; Thiruchitrambalam, M. Static and dynamic mechanical properties of alkali treated unidirectional continuous palmyra palm leaf stalk fibre/jute fibre reinforced hybrid polyester composites. Mater. Des. 2013, 97, 533–542. [Google Scholar] [CrossRef]

- Idicula, M.; Malhotra, S.K.; Josheph, K.; Thomas, S. Dynamic mechanical analysis of randomly oriented intimately mixed short banana/sisal fibre reinforced polyester composites. Compos. Sci. Technol. 2003, 65, 1077–1087. [Google Scholar] [CrossRef]

- Gupta, M.K.; Deep, V. Effect of stacking sequence on flexural and dynamic mechanical properties of hybrid sisal/glass polyester composite. Ame. J. Polym. Sci. Eng. 2017, 5, 53–62. [Google Scholar]

- Ornaghi, H.L.; da Silva, H.S.P.; Zattera, A.J.; Amico, S.C. Hybridization effect on the mechanical and dynamic mechanical properties of curaua composites. Mater. Sci. Eng. A 2011, 528, 7285–7289. [Google Scholar] [CrossRef]

- Sreenivasan, V.S.; Rajini, N.; Alavudeen, A. Dynamic mechanical and thermo–gravimetric analysis of Sansevieria cylindrica /polyester composite: Effect of fiber length, fiber loading and chemical treatment. Compos. Part B Eng. 2015, 69, 76–86. [Google Scholar] [CrossRef]

- Gupta, M.K.; Bharti, A. Natural fibre reinforced polymer composites: A review on dynamic mechanical properties. Curr Trends Fash. Technol Text. Eng. 2017, 1, 1–4. [Google Scholar] [CrossRef]

- International Organization for Standardization. International Standard ISO 6721-1: 2011 (E), Plastics—Determination of Dynamic Mechanical Properties; Third Version; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- Li, Z.; Crocker, M.J. Effects of thickness and delamination on the damping in honeycomb–foam sandwich beams. J. Sound. Vib. 2006, 294, 473–485. [Google Scholar] [CrossRef]

- Pardoen, G.C. Effect of delamination on the natural frequencies of composite laminates. J. Compos. Mater. 1989, 23, 1200–1215. [Google Scholar] [CrossRef]

- Mei, H.; Migot, A.; Haider, M.F.; Joseph, R.; Bhuiyan, M.Y.; Giurgiutiu, V. Vibration–based in–situ detection and quantification of delamination in composite plates. Sensors 2019, 19, 1734. [Google Scholar] [CrossRef]

| Sample ID | Dimensions (mm3) | Fiber Volume Fraction (%) | Delamination Area (mm2) | Delamination Position |

|---|---|---|---|---|

| NODEL | 50 × 13 × 1.3 | 40 | – | – |

| DEL_2.5_I | 6.25 | I | ||

| DEL_5_I | 25 | I | ||

| DEL_10_I | 100 | I | ||

| DEL_5_II | 25 | II | ||

| DEL_5_III | 25 | III |

| Scanning Manner | Temperature (°C) | Ramp Rate (°C/min) | Frequency (Hz) | Amplitude (μm) |

|---|---|---|---|---|

| Temperature scans | 25–120 | 5 | 10 | 10 |

| Frequency scans | 25 | / | 1, 10, 50, 100 | 10 |

| Amplitude scans | 25 | / | 10 | 10, 15, 20, 25, 30 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.; Tan, J.; Fernandes, L.; Qu, Z.; Li, Y. Dynamic Mechanical Analysis on Delaminated Flax Fiber Reinforced Composites. Materials 2019, 12, 2559. https://doi.org/10.3390/ma12162559

Shen Y, Tan J, Fernandes L, Qu Z, Li Y. Dynamic Mechanical Analysis on Delaminated Flax Fiber Reinforced Composites. Materials. 2019; 12(16):2559. https://doi.org/10.3390/ma12162559

Chicago/Turabian StyleShen, Yiou, Jiayi Tan, Luis Fernandes, Zehua Qu, and Yan Li. 2019. "Dynamic Mechanical Analysis on Delaminated Flax Fiber Reinforced Composites" Materials 12, no. 16: 2559. https://doi.org/10.3390/ma12162559

APA StyleShen, Y., Tan, J., Fernandes, L., Qu, Z., & Li, Y. (2019). Dynamic Mechanical Analysis on Delaminated Flax Fiber Reinforced Composites. Materials, 12(16), 2559. https://doi.org/10.3390/ma12162559