Advanced machining is a highly sophisticated technological process based on stock removal from a workpiece. The physical nature of the stock material is that the action of external energy, especially mechanical, disrupts the interconnections between the elementary particles of the material from which the chip is gradually separated, that is, the material in the form of smaller particles. The result of machining is a component of the required geometric dimensions with the required dimensional accuracy and surface quality, functional and with a sufficient service life in the given machinery equipment. Todd et al. [

1] have classified different manufacturing processes as property modification processes and geometry modification processes.

The technologically more demanding type of material machining, from the viewpoint of achieving the desired surface properties, is machining of coatings. The filler material for welding is chosen in connection with the welding technology. Durable materials are usually divided by the type of matrix, i.e., materials with iron, cobalt and nickel matrices. From the viewpoint of the physical properties of the material, i.e., in particular, the thermal expansion of the basic and filler material, the values of the coefficients of thermal expansion of both materials must be approximately similar in order to prevent the creation of cracks during solidification. A wide range of iron-based materials exists at present on the market. Materials with high contents of carbide have lower impact strength, but excellent abrasion resistance. Martensitic and austenitic alloys have better impact resistance and sufficient abrasion resistance; therefore, they are used to harden surfaces. Kracke and Allvac [

2] described the history of the superalloy industry, and their work addressed the present and future uses of superalloys that are possible thanks to their properties. Nickel and cobalt alloys are used for high-temperature applications. Significant progress has been achieved in developing new materials and in machine tool design. Rivin [

3] provided a survey on six essential subjects related to tooling structures, namely, the influence of machining system parameters on tool life and process stability, stiffness and damping of tools, tool–tool holder interfaces (tool clamping devices), modular tooling, tool–machine interfaces and tool balancing for high-speed machine tools. During the cutting process, the division of material is realised by a cutting wedge. Cutting is, in principle, the stock removal of the cut-off layer by a cutting edge at a certain cutting speed, caused by the corresponding cutting force and cutting resistance, which are particularly significant in the case of materials difficult to machine. Due to the considerable cutting resistance and the corresponding strong friction, considerable heat is also generated, and the mechanisms of wear of the tool cutting edge are activated. The associated result of machining is then a surface of the workpiece that can be characterised by the topography and integrity of the surface layer explicitly required by the use. The term machinability is often used for determining how easily a material can be machined. Davim [

4] described in his book the level of difficulty involved in machining a material, or multiple materials, with the appropriate tooling and cutting parameters. A combination of specific operating conditions with the condition and physical properties of the machined workpiece influence and determine machinability. The surface finish left on the workpiece during a machining operation is used to determine the rate of machinability of a metal. The surface roughness is one of the first visible factors of the quality of the product.

1.1. Investigation of Surface Roughness

Valíček et al. [

5] dealt with the surface roughness and machinability of different materials through the identification of surfaces after machining in a non-contact manner. They presented a new, modified measurement method, where the scanned intensity distribution at the defocusing plane gives the information necessary to assess the second derivatives, and thus, surface functions, which can be used to determine the groove curvatures of the real surface morphology.

Hloch and Valíček [

6] proposed a new way of classifying morphologically different zones, based on the quantitative parameters

Ra and

Rz as a base for optimisation and control of different technologies, such as abrasive water-jet cutting. They found a close connection between the geometric condition of the surface and the physical–mechanical parameters of materials machined by abrasive water-jet, including tensometric changes due to external stress in the elastic and plastic regions that can be easy to use for control of the process. Valíček et al. [

7,

8] have been awarded American and Czech patents covering the design of technology for the cutting of materials by abrasive water-jet using a constant of cuttability, which was derived from the surface deformation parameters. Harničárová et al. [

9] presented an approach based on the integrity of the system (technology parameters–tool–material–surface topography) and parameters and interrelations of selected geometric elements that are measurable on the surface of the final cut wall. Their solution enables the prediction of process functions of the technological process for any material, including technological parameters, and an interactive modelling of the technological process of laser cutting.

Results of recent investigations into the surface roughness generated during turning have shown that many machining parameters which control the quality of the surface must be taken into account. The most important are: depth of cut, speed of cut, feed rate, vibration and tool geometry. Machined surfaces have then been analysed in order to find out the most suitable model for the prediction and optimisation of the turning process [

10,

11,

12,

13,

14,

15]. Benardos and Vosniakos performed a comprehensive review of the prediction of surface roughness, considering the various methodologies and approaches [

16]. They described many aspects and problems that researchers face in connection with surface roughness modelling.

Machining is the most extensive area for the application of scientific achievements and for the research of methods that can be used for the measurement and control of surface quality. Knowledge of the topography of surfaces and their classification is essential for different machining processes.

Current materials research is focused on the applications of available materials and the creation of new materials with desired properties. Materials are generally represented by ceramics, metals and polymers. Each class of materials is the subject of intense interest from many researchers, who are conducting systematic investigations regarding the structure, properties and performance of the material. Generally, they are trying to find answers to the following three essential criteria that are used for the selection of machining parameters: the minimum production cost criterion, the minimum production time and the maximum production rate criterion. One material with specific properties used in industry is Stellite. Stellite is the most widely used of the wear-resistant cobalt-based alloys.

1.2. Stellite Alloy and High-Velocity Oxygen Fuel (HVOF) Technology

The Stellite alloy was invented in 1900 by American metallurgist Haymer E. Haynes as a substitute for silver. In 1907, the company Deloro Smelting and Refining was founded by M. J. O’Brien and E. Haynes in the Canadian village of Deloro. When Haynes began in 1912 to focus on nickel-based components, O’Brien founded the company Deloro Stellite for the production of cobalt-based alloys. Nowadays, this company is recognised worldwide as a renowned producer of approximately 60 types of alloys that contain 4 to 6 of the most significant elements: cobalt, molybdenum, chromium, nickel, tungsten, iron, boron, aluminium, manganese, carbon, phosphorus, silicon, sulphur and titanium in such ratios that the alloys are always characterised by non-magnetism, hardness, toughness and high corrosion resistance.

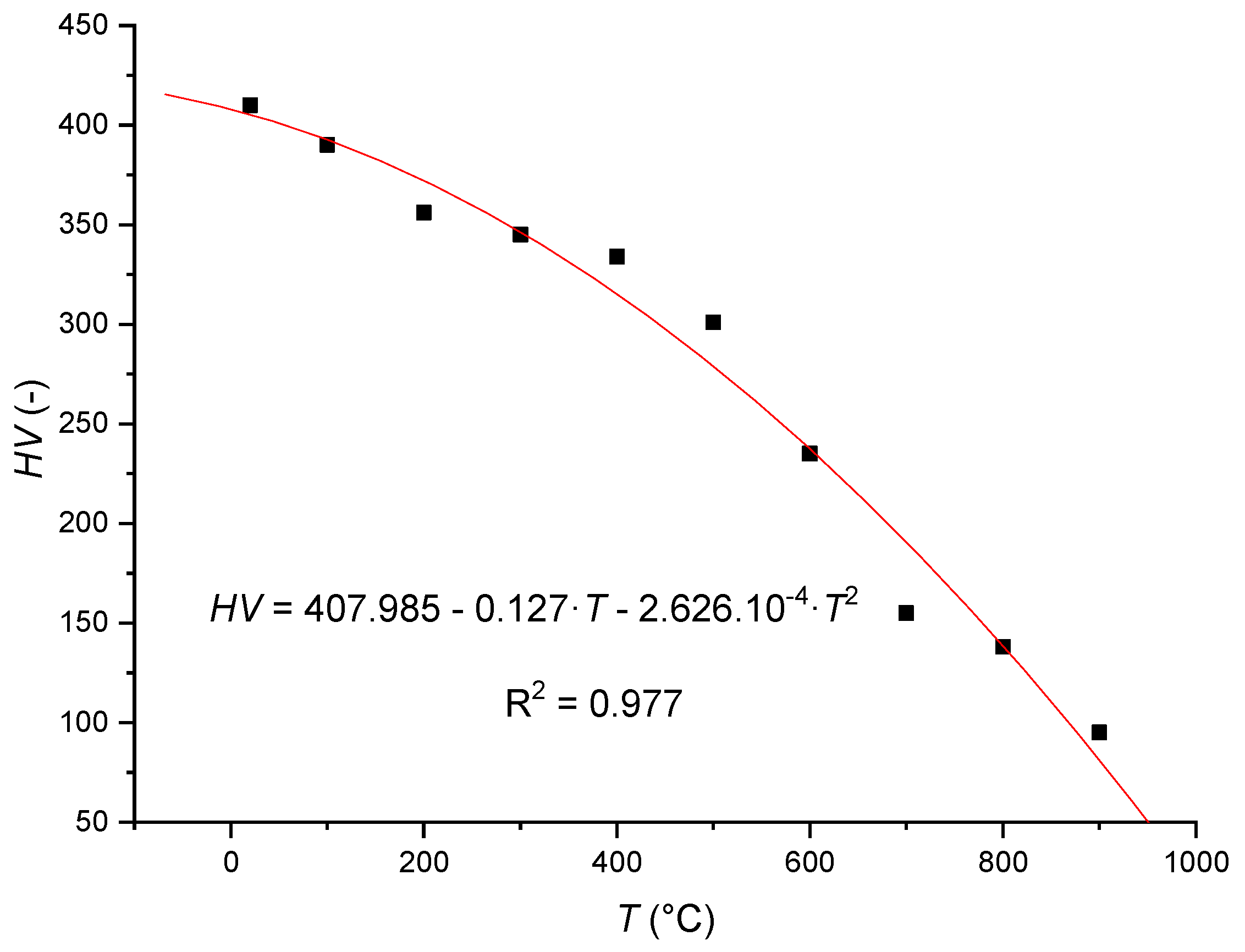

Stellite 6 is a material based on a cobalt–chromium matrix; it is characterised by high wear resistance and excellent chemical and corrosion resistance over a wide range of temperatures. Chromium, tungsten and molybdenum provide to this alloy resistance to cavitation, abrasion and erosion. The combination of cobalt and chromium contributes to a high melting point that allows the use of this alloy for the production of cutting tools. Due to its high hardness, it is difficult to machine the weld deposits during finishing operations; machining of this material requires the use of specific high-performance machining equipment, which most often grinds material, while cutting is used only in exceptional circumstances.

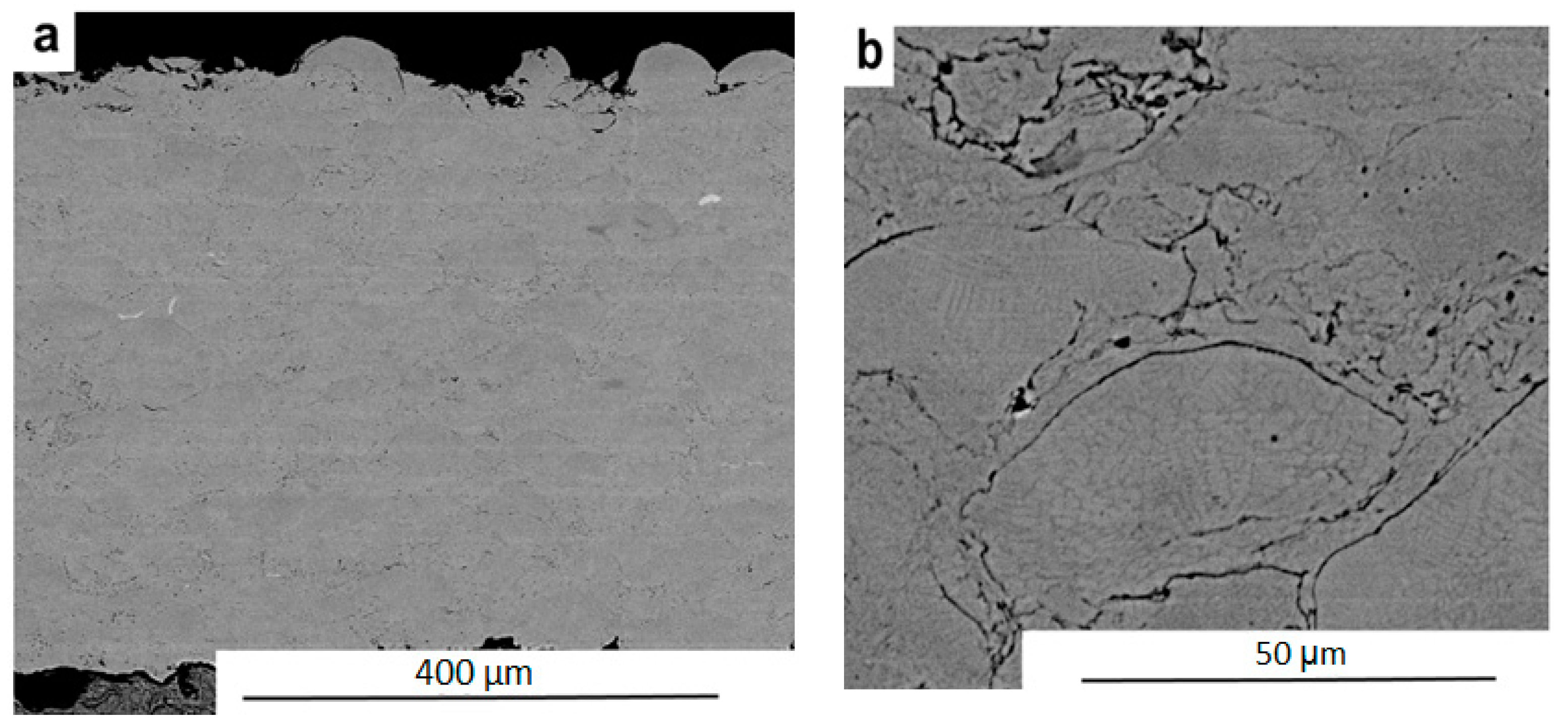

The high-velocity oxy-fuel (HVOF) processes are a group of thermal spraying techniques, which are widely used to protect components against corrosion or wear. Sidhu et al. [

17] studied the application of Stellite 6 metallic coatings on Ni- and Fe-based superalloys by HVOF process for hot corrosion applications. Coatings had high hardness values in the range of 800–900 Hv, and the porosity of coatings was less than 2%. There have only been a small number of papers published on HVOF-sprayed Stellite 6 coatings. Jegadeeswaran et al. [

18] dealt with the high-temperature hot corrosion behaviour of HVOF-sprayed Stellite 6 coatings on gas turbine alloys in a molten salt (Na

2SO

4—50% V

2O

5) environment at 800 °C, and compared it with uncoated SuperCo-605 and MDN-121. They found a noticeable improvement in corrosion resistance and corrosion behaviour when using sprayed Stellite 6 coatings.

Nowadays, machinability of cobalt-based alloys is an important research topic for researchers, due to the difficulties of such machining. Several authors have studied the problem of machining of Stellite. Shao et al. [

19] made attempts to investigate the machinability of Stellite alloys, and focused on the wear mechanisms and failure modes of the uncoated carbide cutting tools YG610 (K01-K10) and YT726 (K05-K10/M20), and coated tool (SNMG150612-SM1105) when turning. They chose Stellite 12, with a higher hardness than other series of Stellite alloys, and, during turning, an extremely high temperature was reached in the cutting areas in a very short time. It significantly affected the strength of the cutting edge. Zaman et al. [

20] presented a general review of the machinability of cobalt-based and cobalt–chromium–molybdenum alloys. They confirmed that studies focused on cutting temperature, chip formation, surface integrity, residual stresses and wear mechanisms were still lacking and provided a great opportunity for future research, especially in the case of high-speed machining. Hasan et al. [

21,

22] performed experimental research on cutting parameters for turning operations of Stellite 6 using coated carbide inserts. It was revealed that coated carbide inserts with a medium-size nose radius performed better with respect to hardness changes and heat generation, producing minimum phase changes on machined surfaces of Stellite 6. Saidi et al. [

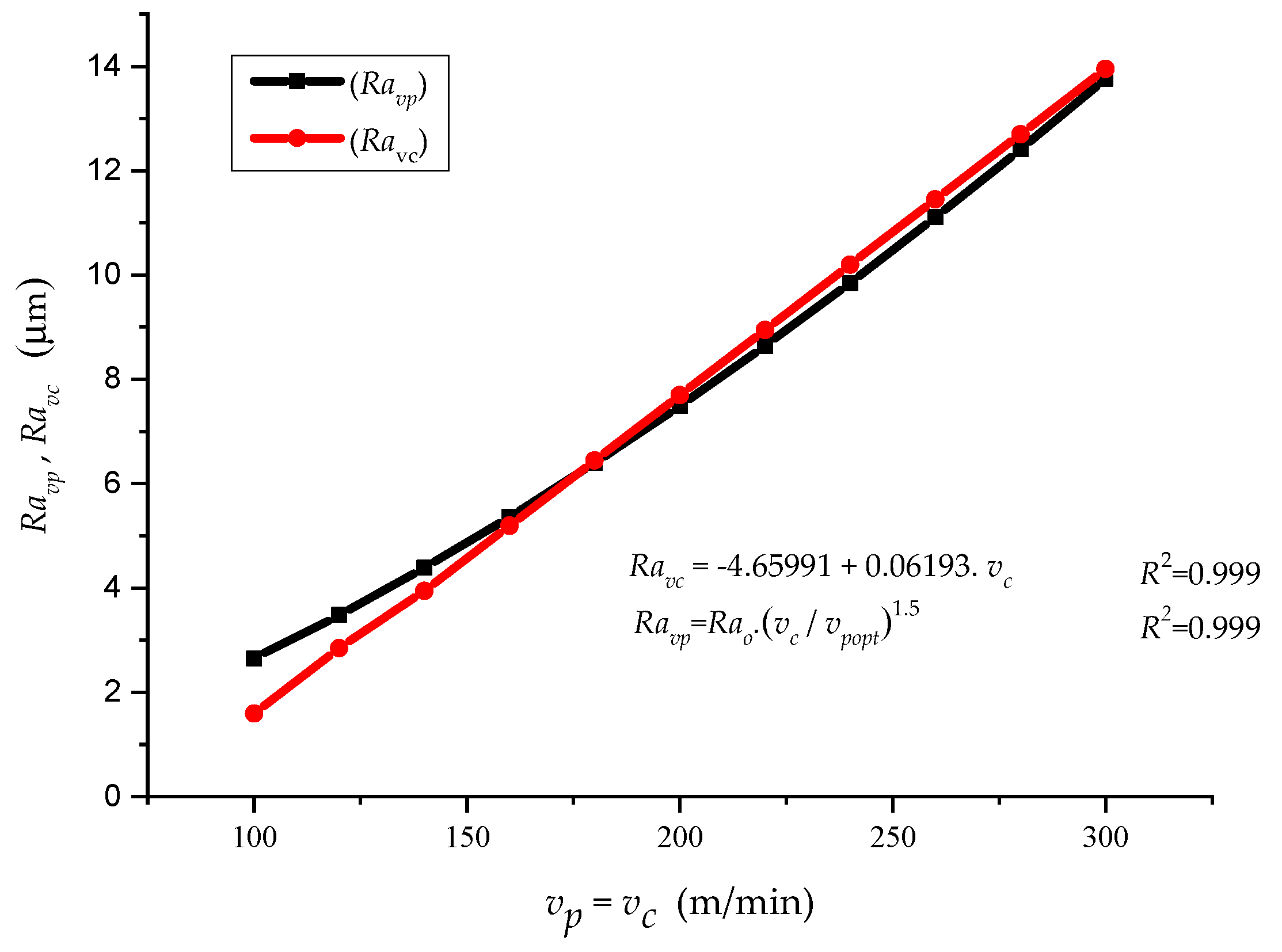

23] also dealt with the problem of machinability of Stellite 6. The effects of the turning conditions of cobalt alloy (Stellite 6) were studied. The experimental design method was a tool used for conducting their research. Predictive models concerning the evolutions of the arithmetic mean roughness, tangential force, the rate of stock removal and cutting power were established. Based on ANOVA—analysis of variance, and PARETO principle optimal cutting parameters for Stellite 6 were proposed. Sabri Ozturk [

24] is another researcher who examined the machinability of Stellite 6 coating using a ceramic cutting tool. He successfully implemented the Taguchi experimental design to determine the optimal cutting parameters with which to analyse the effects of the cutting speed and feed rate on the surface quality. Sabri Ozturk [

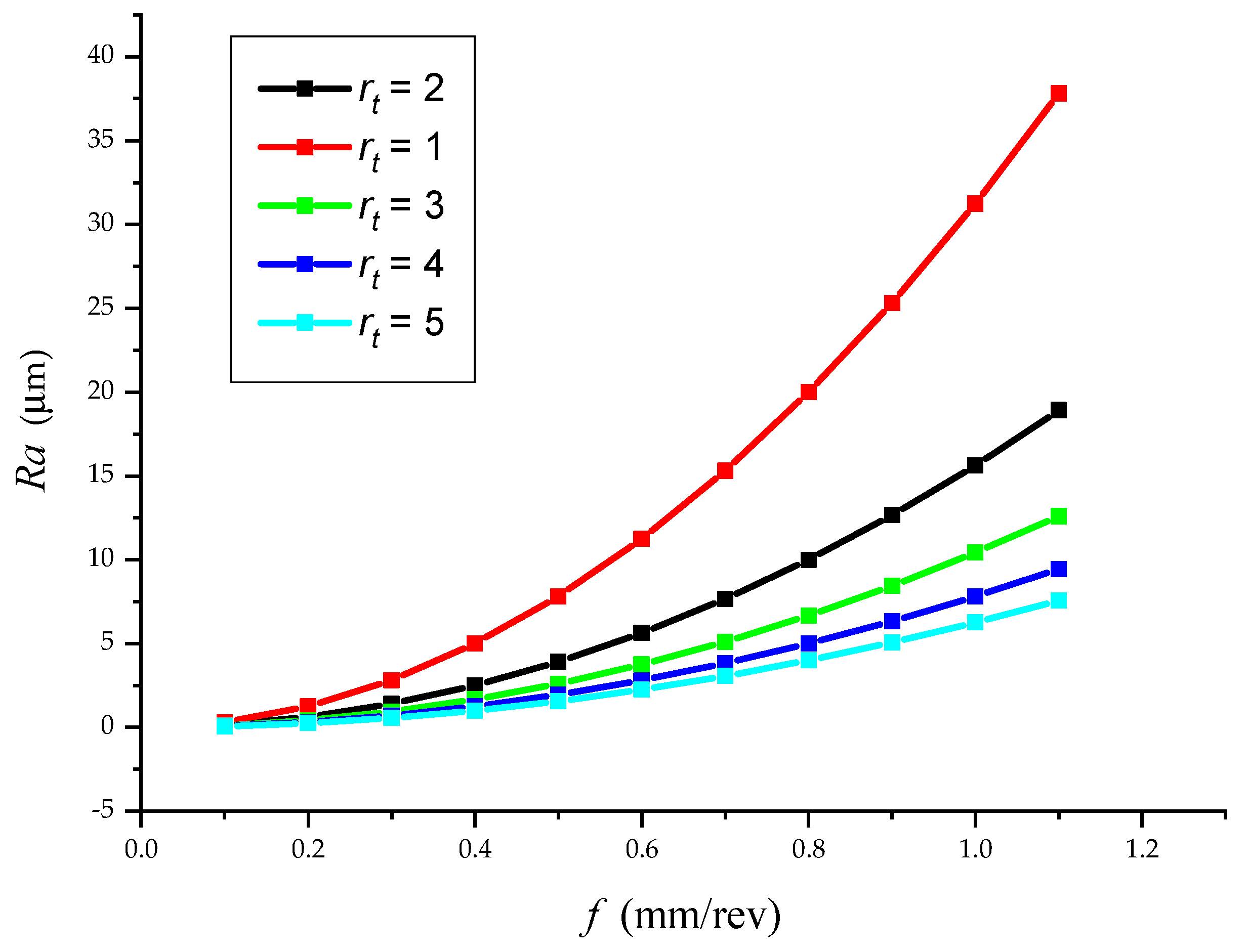

25] also estimated the turning conditions for Stellite 6 coatings in his other work. He tried to find the optimal cutting speed and feed rate in turning operations in terms of surface roughness using two different types of cutting tool: whisker-reinforced ceramic and tungsten carbide. It was found that a better surface finish could be achieved by low feed rates, and that feed rate had a higher impact on surface roughness than the cutting speed. Yingfei et al. [

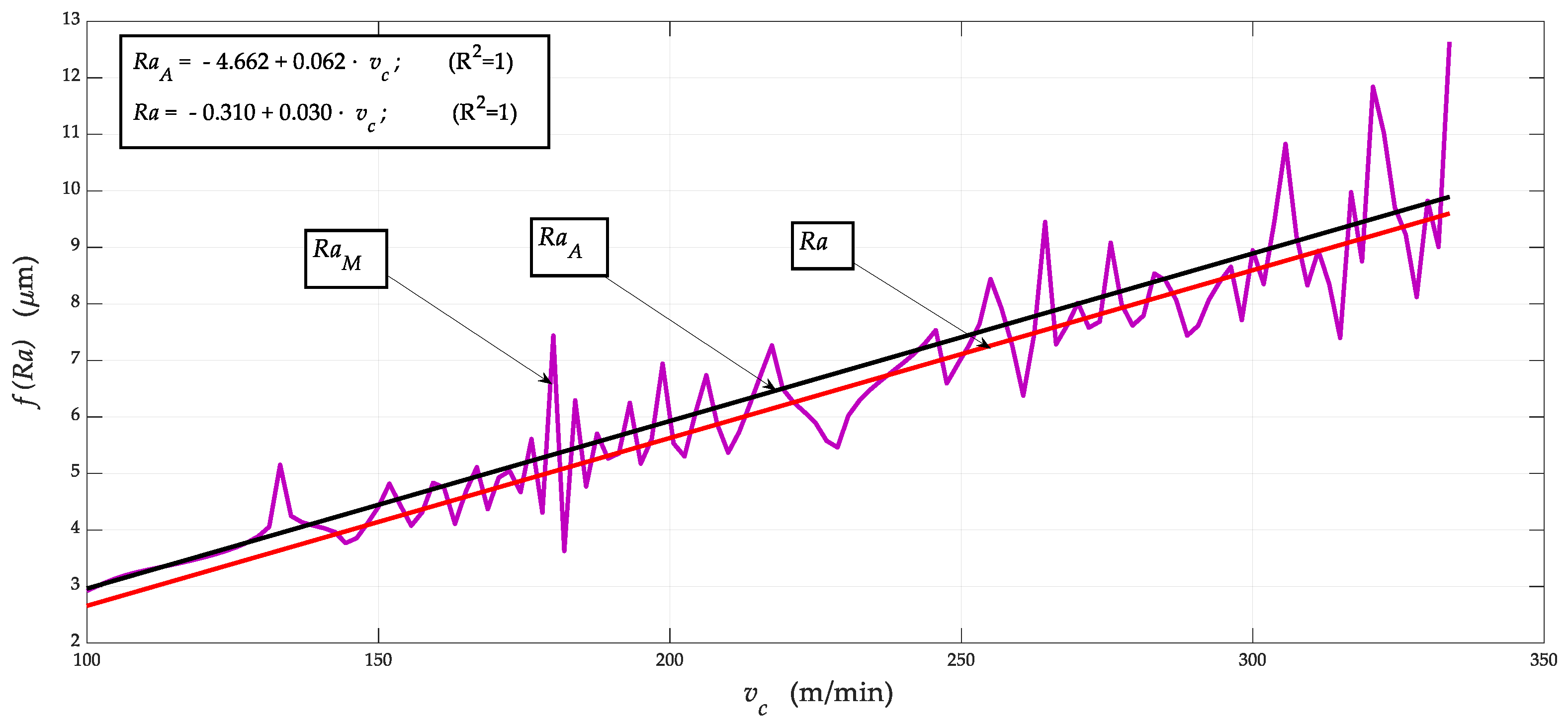

26] focused on the effect of cutting parameters on the surface and residual stress during all conditions in turning operations. They found that as tool wear increased, the surface roughness increased, and the deformation layer was found to be influenced more by the cutting parameters than by the tool wear.

1.3. Machining of Coatings

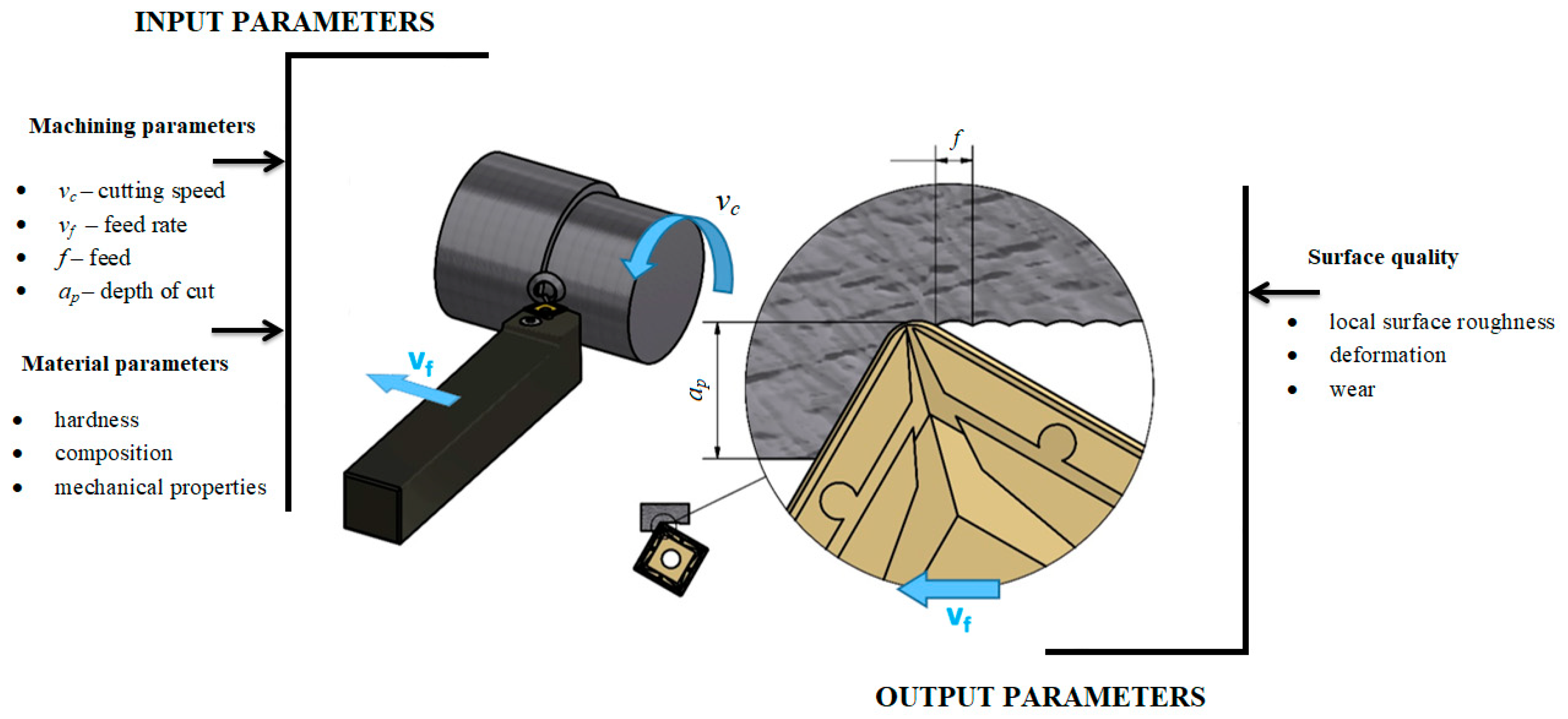

According to the authors [

27,

28,

29], the machining of coatings, especially after thermal spraying, has to address two main problems: the adhesion of the coating to the substrate and the wear of the tool. Moreover, the authors [

30] state that the efficiency of the machining process depends on the structure and properties of the materials in contact. Achievement of the expected and desirable results, therefore, depends to a large extent on selected tool materials and selected machining parameters [

31]. Adequate selection of machining parameters can help to achieve acceptable surface quality and tool wear. Typically, cutting rates of approximately 30–40 m·min

−1 and relatively low values of cutting depth and feed rate are used [

27]. Although machining is a complex process that is influenced by many factors, current studies have focused on selecting the machining parameters for turning operations. An empirical and mechanical approach to selecting machining parameters has been identified by the authors [

32] for surface roughness analysis, although both approaches could be used for assessment of other outputs. The considerable complexity of the mechanical approach is simplified by the empirical approach. Therefore, several experimental tests with different machining parameters are usually performed to predict the final effect on the results. The empirical methodology is particularly suitable for machining processes, representing a strong background for stabilising the initial values of the machining parameters. However, this background is not large enough for machining of coatings, which are difficult to cut. Although the choice of machining parameters plays an important role in the process results, it should be emphasised that other factors can also have a significant impact. The influence of machining parameters is more accepted in the scientific literature than it is monitored by technical practice; in this sense, more results of the machining process are affected. In the case of hard turning, the authors [

33] confirmed the influence of cutting rate, cutting depth, feed rate and machining times, surface roughness and wear of the tool. The effects of machining parameters on surface quality have been given by the authors [

34], who evaluated the turning of sintered WC–25Co with the use of cutting tools by tests, which identified an unequivocal relationship between cutting rate and surface roughness. At cutting rates of 15 and 40 m·min

−1, the surface roughness was limited to less than 0.2 μm for all machining times tested. However, at a cutting rate of 100 m·min

−1, the surface roughness achieved significantly higher values and reduced the machining time.

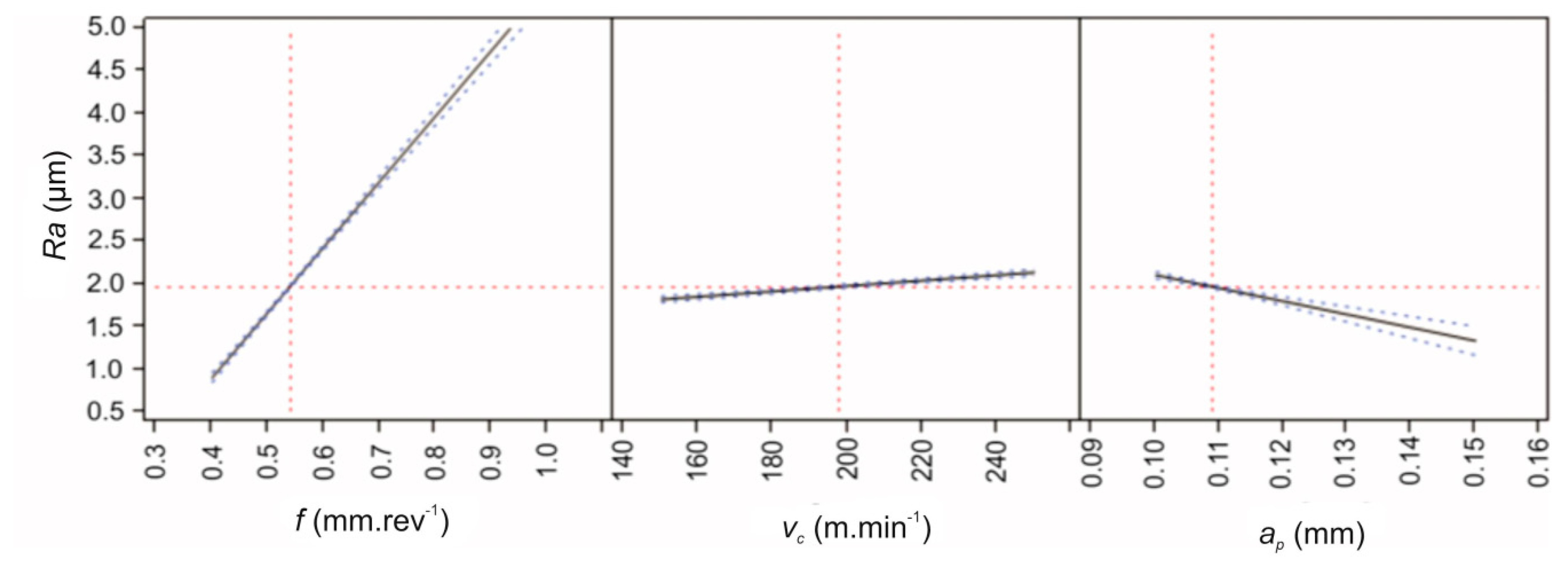

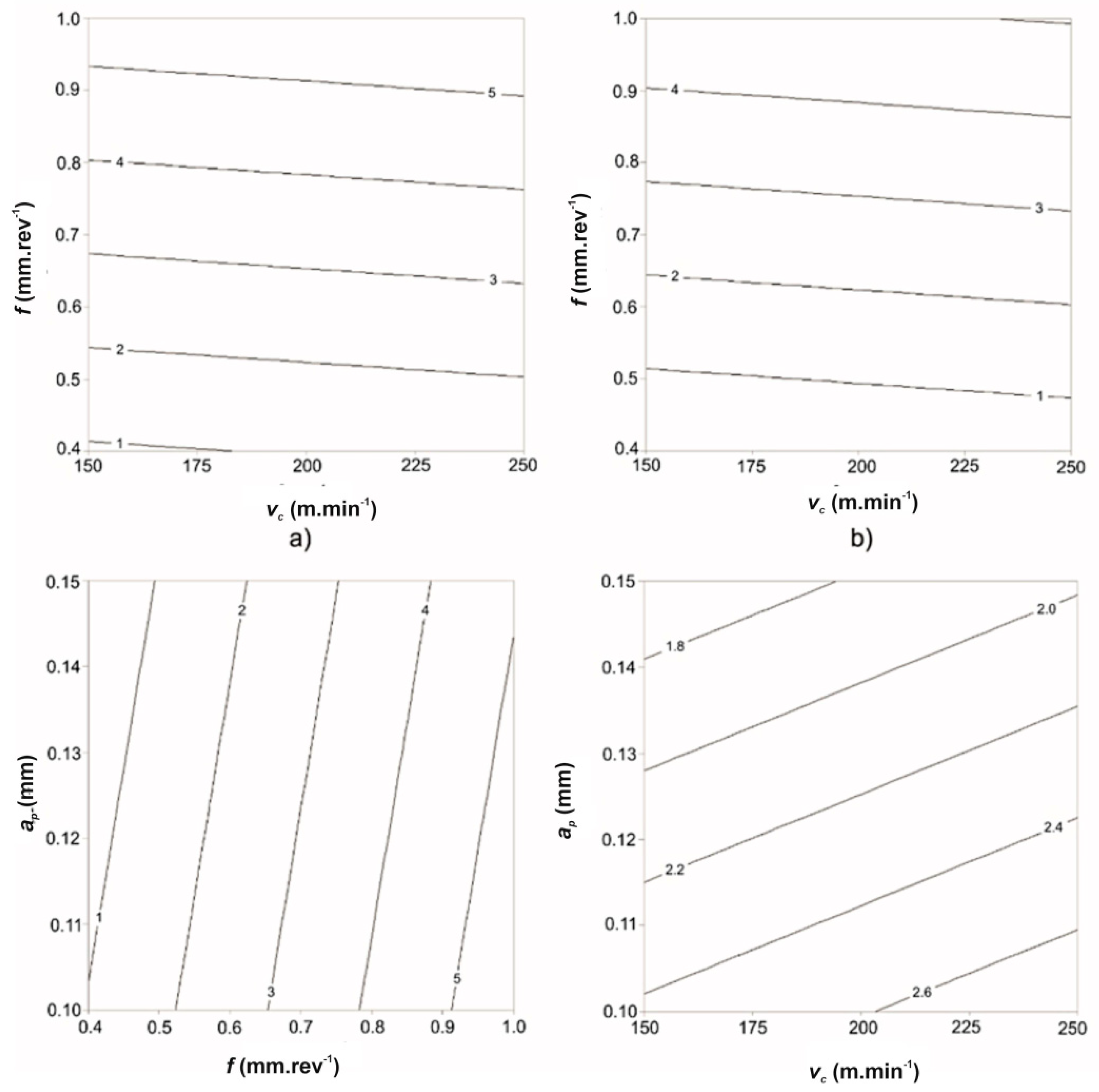

On the other hand, the authors [

35] found that the choice of feed rate (from 0.03 to 0.3 mm·rev

−1) played an essential role in the development of surface roughness. In analysing the effect of cutting depth, it was found that the use of sharp-edged tools caused an increase in cutting depth and lower values of surface roughness. Based on the research conducted on Stellite 6 plasma transferred arc (PTA) coatings on a steel substrate and knowledge about the machinability of this hard coating, the authors [

36] optimised the machining parameters through the surface roughness. Surface roughness values were examined at different cutting speeds, feed rates and depths of cut.

1.4. Modelling and Optimisation Techniques

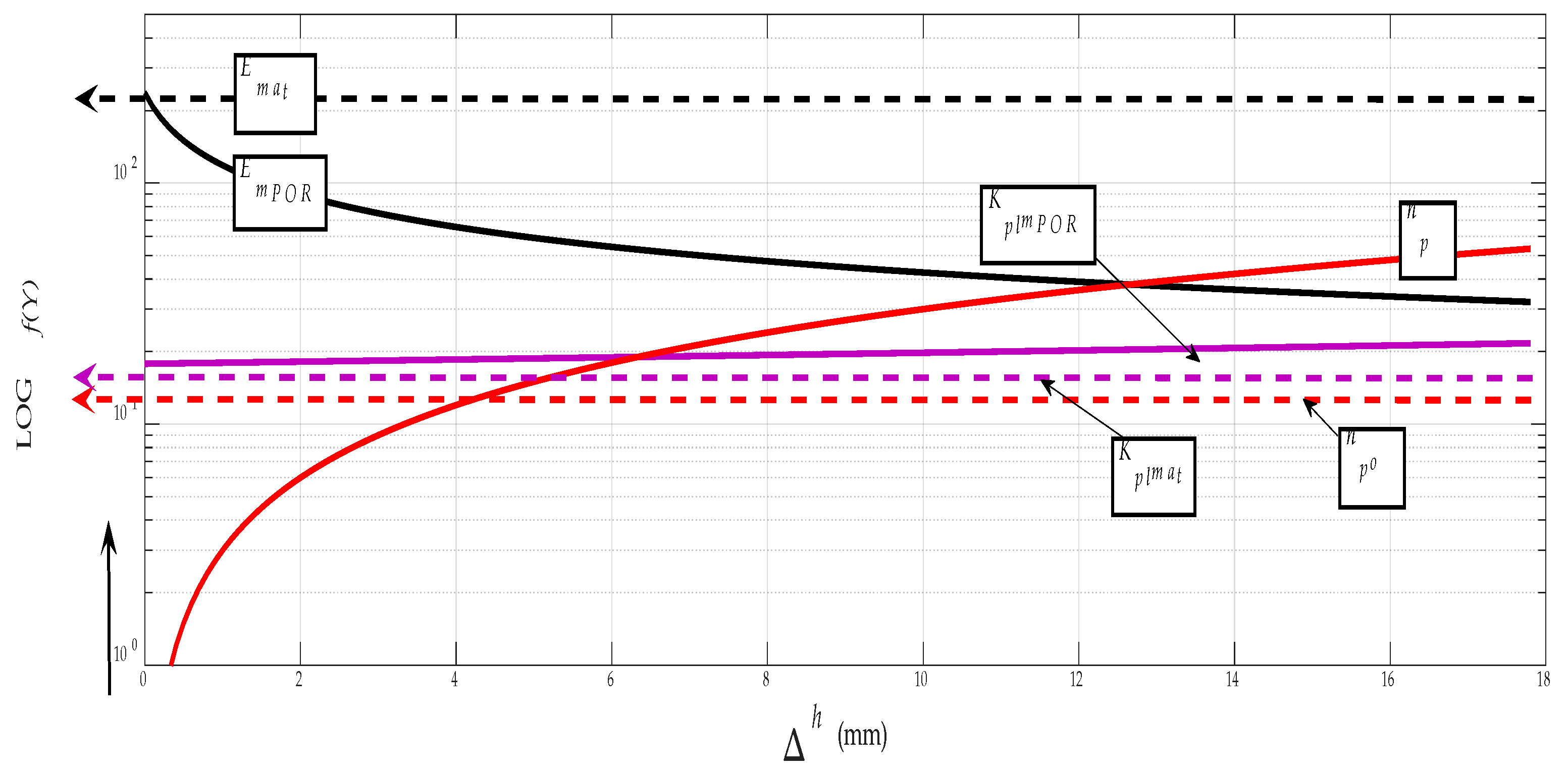

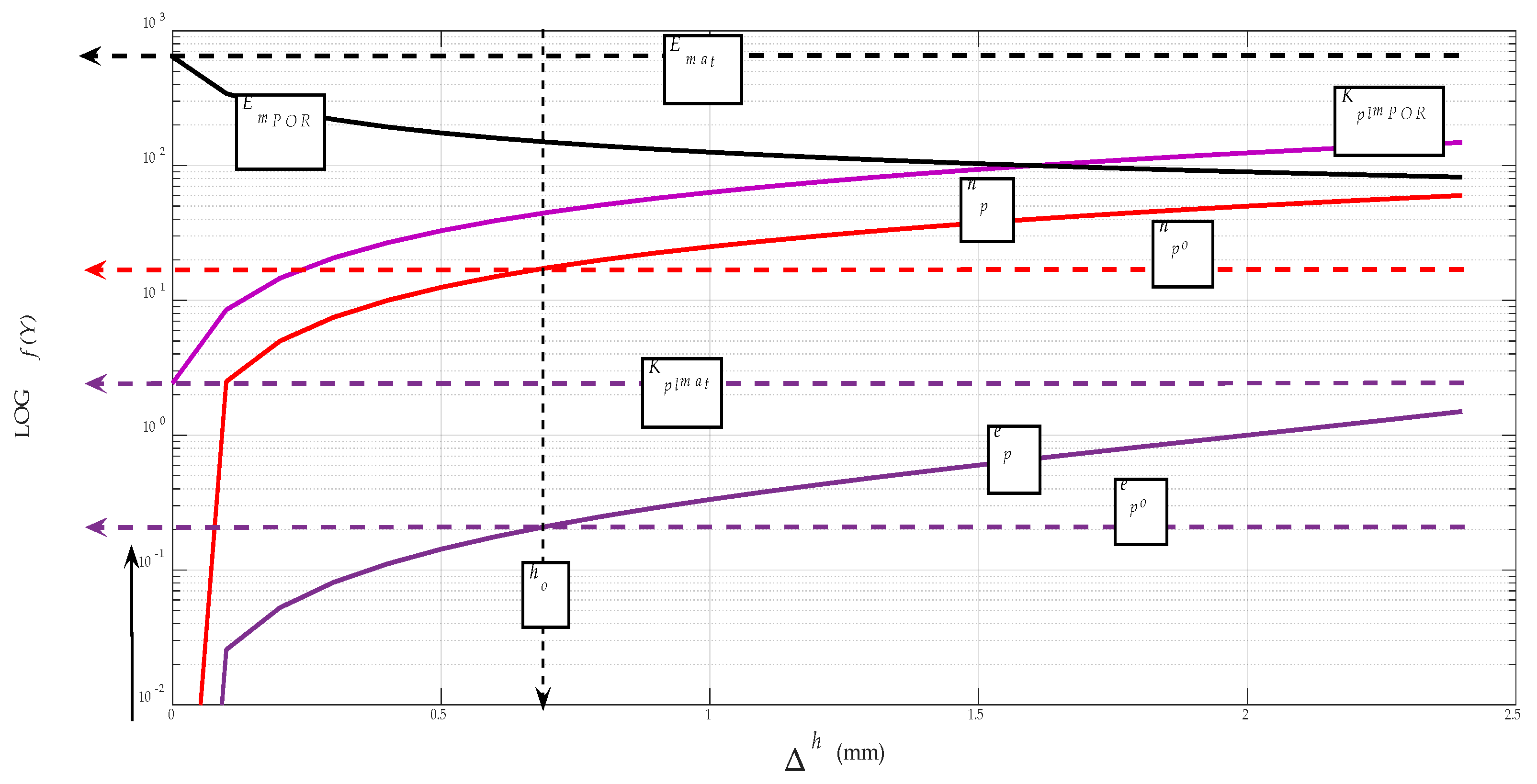

There are many modelling and optimisation techniques that can be used in turning processes. Kumar et al. [

37] published a review on modelling and optimisation methods in the turning process. This work discussed modelling and optimisation techniques, multi optimisation techniques, their applications and the advantages and limitations of them. With an appropriate model, showing the relationship between the input cutting conditions and the response of a system, an improved understanding of the process can be reached. Some researchers have focused on using regression-based modelling, artificial neural networks or fuzzy modelling. Aykut et al. [

38] used artificial neural networks (ANNs) to model the effects of machinability on chip-removal cutting parameters for face milling of Stellite 6 in asymmetric milling processes. ANN has been proven to be an excellent tool for prediction of the asymmetric milling process. None of the previously published studies have focused on prediction of both material and technological parameters of the longitudinal turning of cobalt alloys using the mathematical–physical model. No authors have, so far, theoretically dealt with combining the coating machinability parameters (in particular, Stellite 6 applied to the base material) and the roughness parameters of the coating, i.e., by developing a prediction model for binding the machining technology parameters with the surface topography parameters.

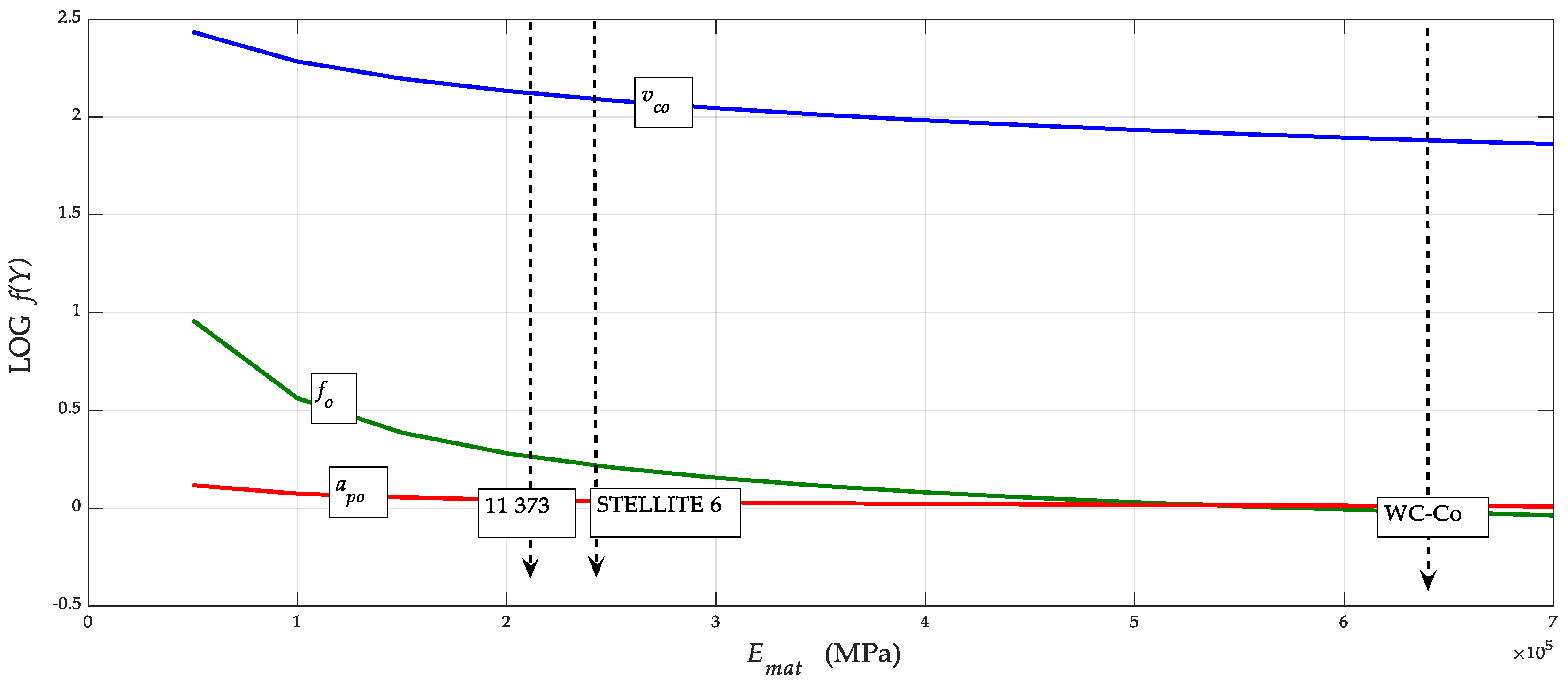

For this reason, the present paper dealt particularly with a new method of predicting the material and technological parameters of longitudinal turning, so that the exceptional Stellite alloy might become more easily machinable and, therefore, available for other, more demanding applications. This model can be used in practice and research for the determination of optimum machining parameters (feed, cutting speed, depth of cut and others) through surface roughness, according to the pre-determined machinability of a specific material.