Corrosion Inhibition of Honeycomb Waste Extracts for 304 Stainless Steel in Sulfuric Acid Solution

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

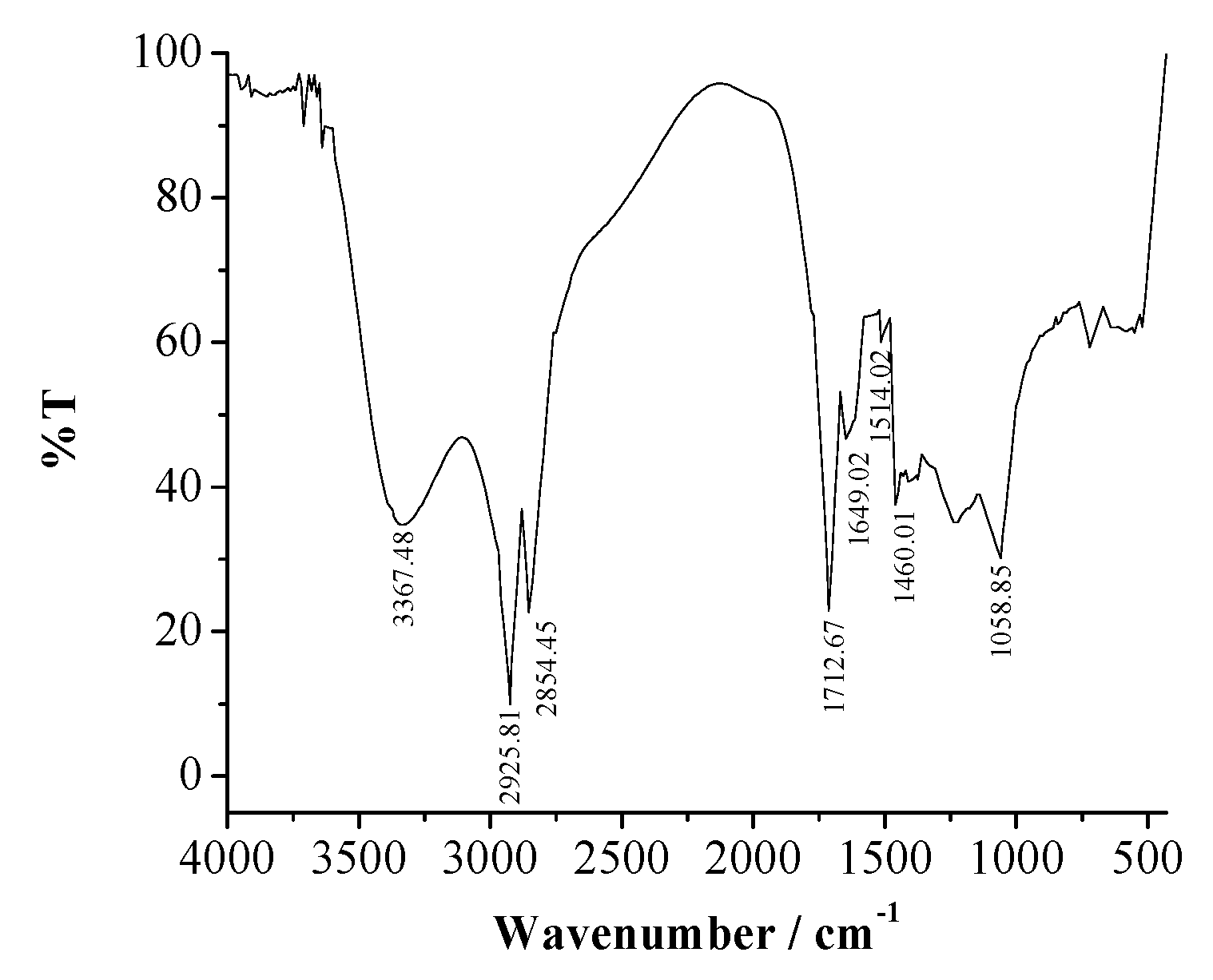

2.2. Characterization of Honeycomb Waste Extract

2.3. Electrochemical Measurement

2.4. Surface Analysis

3. Results

3.1. Characterization of Honeycomb Waste Extract

3.2. Potentiodynamic Polarization

3.3. Electrochemical Impedance Spectroscopy (EIS) Measurement

3.4. The Effect of Acid Concentration

3.5. Adsorption Isotherm and Thermodynamic Calculations

3.6. Surface Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bogdanov, S. Beeswax: Production, Properties Composition and Control. 2009, Volume 17. Available online: https://www.researchgate.net/publication/304012435_Beeswax_Production_Properties_Composition_Control (accessed on 24 May 2019).

- Kalogeropoulos, N.; Konteles, S.J.; Troullidou, E.; Mourtzinos, I.; Karathanos, V.T. Chemical composition, antioxidant activity and antimicrobial properties of propolis extracts from Greece and Cyprus. Food Chem. 2009, 116, 452–461. [Google Scholar] [CrossRef]

- Wan Nik, W.B.; Zulkifli, M.F.; Rosliza, R.; Ghazali, M.J.; Khaled, K.F. Potential of honey as corrosion inhibitor for alluminium alloy in seawater. World Appl. Sci. J. 2011, 14, 215–220. [Google Scholar]

- Khadraoui, A.; Khelifa, A. Ethanolic extract of Ruta chalepensis as an eco-friendly inhibitor of acid corrosion of steel. Res. Chem. Intermed. 2012, 39, 3937–3948. [Google Scholar] [CrossRef]

- Firdausi, S.; Kurniawan, F. Corrosion Inhibition by Tithonia diversifolia (Hemsl) A. Gray leaves extract for 304 SS in hydrochloric acid solution. J. Physics: Conf. Ser. 2016, 710, 12042. [Google Scholar]

- Indis, N.A.; Kurniawan, F. Determination of free radical scavenging activity from aqueous extract of Curcuma mangga by DPPH method. J. Physics: Conf. Ser. 2016, 710, 12043. [Google Scholar]

- Hosseini, S.M.A.; Salari, M.; Motlagh, M.G. Thioamide Compounds as corrosion inhibitors for stainless steel in H2SO4 solution. Corrosion 2010, 66, 115003. [Google Scholar] [CrossRef]

- Fouda, A.; El-Abbasy, H.; Fouda, A. Inhibitive action of ampicillin and benzyl penicillin drugs for corrosion of type 304 stainless steel in 1.0 M HCl solution. Corrosion 2012, 68, 015002-1. [Google Scholar] [CrossRef]

- Kurniawan, F.; Madurani, K.A. Electrochemical and optical microscopy study of red pepper seed oil corrosion inhibition by self–assembled monolayers (SAM) on 304 SS. Prog. Org. Coat. 2015, 88, 256–262. [Google Scholar] [CrossRef]

- Mahgoub, F.M.; Al-Nowaiser, F.M.; Al-Sudairi, A.M. Effect of temperature on the inhibition of the acid corrosion of steel by benzimidazole derivatives. Prot. Met. Phys. Chem. Surf. 2011, 47, 381–394. [Google Scholar] [CrossRef]

- Gopiraman, M.; Sakunthala, P.; Kesavan, D.; Alexramani, V.; Kim, I.S.; Sulochana, N. An investigation of mild carbon steel corrosion inhibition in hydrochloric acid medium by environment friendly green inhibitors. J. Coat. Technol. Res. 2012, 9, 15–26. [Google Scholar] [CrossRef]

- Kumar, P.E.; Govindaraju, M.; Sivakumar, V. Experimental and theoretical studies on corrosion inhibition performance of an environmentally friendly drug on the corrosion of copper in acid media. Anti-Corros. Methods Mater. 2017, 65, 19–33. [Google Scholar]

- Hussin, M.H.; Rahim, A.A.; Ibrahim, M.N.M.; Brosse, N. The capability of ultrafiltrated alkaline and organosolv oil palm (Elaeis guineensis) fronds lignin as green corrosion inhibitor for mild steel in 0.5 M HCl solution. Measurement 2016, 78, 90–103. [Google Scholar] [CrossRef]

- Li, M.; Dai, C.; Yang, B.; Qiao, Y.; Zhu, Z. New and Green Multi–component scaling and corrosion inhibitor for the cooling water of central air conditioners. J. Mater. Eng. Perform. 2017, 26, 764–772. [Google Scholar] [CrossRef]

- Gong, Z.; Peng, S.; Huang, X.; Gao, L. Investigation the corrosion inhibition effect of itraconazole on copper in H2SO4 at different temperatures: Combining experimental and theoretical studies. Materials 2018, 11, 2107. [Google Scholar] [CrossRef] [PubMed]

- Obot, I.B.; Obi-Egbedi, N. Adsorption properties and inhibition of mild steel corrosion in sulphuric acid solution by ketoconazole: Experimental and theoretical investigation. Corros. Sci. 2010, 52, 198–204. [Google Scholar] [CrossRef]

- Gapsari, F.; Soenoko, R.; Suprapto, A. Bee wax propolis extract as eco-friendly corrosion inhibitors for 304SS in sulfuric acid. Int. J. Corros. 2015, 2015, 567202. [Google Scholar] [CrossRef]

- Fekry, A.; Ameer, M. Electrochemical investigation on the corrosion and hydrogen evolution rate of mild steel in sulphuric acid solution. Int. J. Hydrog. Energy 2011, 36, 11207–11215. [Google Scholar] [CrossRef]

- Omar, B.; Mokhtar, O. Inhibition of cold rolled steel corrosion in sulphuric acid solution by 2-mercapto-1-methylimidazole: Time and temperature effects treatments. Arab. J. Chem. 2011, 4, 443–448. [Google Scholar] [CrossRef]

- Hussin, M.H.; Rahim, A.A.; Ibrahim, M.N.M.; Brosse, N. Improved corrosion inhibition of mild steel by chemically modified lignin polymers from Elaeis guineensis agricultural waste. Mater. Chem. Phys. 2015, 163, 201–212. [Google Scholar] [CrossRef]

- Hussin, M.H.; Kassim, M.J. The corrosion inhibition and adsorption behavior of Uncaria gambir extract on mild steel in 1 M HCl. Mater. Chem. Phys. 2011, 125, 461–468. [Google Scholar] [CrossRef]

- Hermas, A.; Morad, M. A comparative study on the corrosion behaviour of 304 austenitic stainless steel in sulfamic and sulfuric acid solutions. Corros. Sci. 2008, 50, 2710–2717. [Google Scholar] [CrossRef]

- Quartarone, G.; Battilana, M.; Bonaldo, L.; Tortato, T. Investigation of the inhibition effect of indole-3-carboxylic acid on the copper corrosion in 0.5 M H2SO4. Corros. Sci. 2008, 50, 3467–3474. [Google Scholar] [CrossRef]

- Yang, J.; Blawert, C.; Lamaka, S.V.; Yasakau, K.A.; Wang, L.; Laipple, D.; Schieda, M.; Di, S.; Zheludkevich, M.L. Corrosion inhibition of pure Mg containing a high level of iron impurity in pH neutral NaCl solution. Corros. Sci. 2018, 142, 222–237. [Google Scholar] [CrossRef]

- Fu, J.; Pan, J.; Liu, Z.; Li, S.; Wang, Y. Corrosion inhibition of mild steel by benzopyranone derivative in 1.0 M HCl solutions. Int. J. Electrochem. Sci. 2011, 6, 2072–2089. [Google Scholar]

- Solmaz, R. Investigation of corrosion inhibition mechanism and stability of Vitamin B1 on mild steel in 0.5M HCl solution. Corros. Sci. 2014, 81, 75–84. [Google Scholar] [CrossRef]

- Yüce, A.O.; Solmaz, R.; Kardaş, G. Investigation of inhibition effect of rhodanine-N-acetic acid on mild steel corrosion in HCl solution. Mater. Chem. Phys. 2012, 131, 615–620. [Google Scholar] [CrossRef]

- Li, X.; Deng, S.; Fu, H. Inhibition of the corrosion of steel in HCl, H2SO4 solutions by bamboo leaf extract. Corros. Sci. 2012, 62, 163–175. [Google Scholar] [CrossRef]

- Kar, B.; Paul, S. Mitigation of mild steel corrosion in acid by green inhibitors: Yeast, pepper, garlic, and coffee. ISRN Corros. 2012, 2012, 641386. [Google Scholar]

- Al-Mhyawi, S.R. Inhibition of mild steel corrosion using Juniperus plants as green inhibitior. Afr. J. Pure Appl. Chem. 2014, 8, 9–22. [Google Scholar]

- Awad, M.I. Eco friendly corrosion inhibitors: Inhibitive action of quinine for corrosion of low carbon steel in 1 m HCl. J. Appl. Electrochem. 2006, 36, 1163–1168. [Google Scholar] [CrossRef]

| Peak | RT (min) | Area (uV s) | Height (uV) | Area (%) | Molecular Weight | Molecular Formula | Compound |

|---|---|---|---|---|---|---|---|

| 1 | 2.90 | 16,787.68 | 2813.08 | 1.17 | 286.24 | C15H10O6 | Luteolin |

| 2 | 3.42 | 214,035.89 | 34,555.55 | 14.96 | 432.00 | C21H20O10 | Vitexin |

| 3 | 3.59 | 628,240.32 | 95,418.53 | 43.90 | 301.90 | C15H10O7 | Quercetin |

| 4 | 3.76 | 35,082.10 | 5569.59 | 2.45 | 287.00 | C15H10O6 | Fisetin |

| 5 | 3.96 | 25,177.60 | 4213.24 | 1.76 | 315.00 | C16H12O7 | Isohamnetin |

| 6 | 5.60 | 13,670.09 | 2334.22 | 0.96 | 194.00 | C10H10O4 | Isoferulic |

| 7 | 17.50 | 39,787.95 | 4860.57 | 2.78 | 270.24 | C15H10O5 | Apigenin |

| 8 | 19.1 | 241,347.00 | 29,633.18 | 16.87 | 272.00 | C15H12O5 | Pinobanksin |

| 9 | 20.3 | 216,906.26 | 20,458.26 | 15.16 | 286.00 | C15H10O6 | Kaempferol |

| [H2SO4] | Cinh (mg/L) | βa (V/dec) | βc (V/dec) | Ecorr (V) | Icorr (A/cm2) | CR (mmpy) | IE (%) |

|---|---|---|---|---|---|---|---|

| 0.5 M | 0 | 0.059 | −7.958 | −0.286 | 2.19 × 10−5 | 0.228 | – |

| 1000 | 0.224 | −0.794 | −0.033 | 2.67 × 10−6 | 0.028 | 87.79 | |

| 2000 | 0.103 | 0.172 | −0.001 | 5.93 × 10−7 | 0.006 | 97.29 | |

| 3000 | 0.062 | 0.359 | −0.278 | 7.97 × 10−6 | 0.083 | 63.60 | |

| 4000 | 0.082 | −0.707 | −0.280 | 8.32 × 10−6 | 0.087 | 61.99 | |

| 1.0 M | 0 | 0.073 | −0.422 | −0.382 | 8.83 × 10−4 | 9.186 | – |

| 1000 | 0.056 | −0.111 | −0.346 | 2.03 × 10−4 | 2.116 | 76.96 | |

| 2000 | 0.075 | 0.442 | −0.284 | 3.10 × 10−5 | 0.323 | 96.49 | |

| 3000 | 0.072 | −0.138 | −0.354 | 3.38 × 10−4 | 3.513 | 61.75 | |

| 4000 | 0.063 | −0.168 | −0.365 | 4.21 × 10−4 | 4.376 | 52.36 | |

| 1.5 M | 0 | 0.101 | −0.238 | −0.372 | 1.62 × 10−3 | 16.793 | – |

| 1000 | 0.074 | −0.119 | −0.335 | 2.94 × 10−4 | 3.053 | 81.82 | |

| 2000 | 0.098 | −0.181 | −0.257 | 7.17 × 10−5 | 0.745 | 95.56 | |

| 3000 | 0.053 | −0.103 | −0.362 | 6.55 × 10−4 | 6.807 | 59.46 | |

| 4000 | 0.087 | −0.166 | −0.364 | 8.59 × 10−4 | 8.929 | 46.82 | |

| 2.0 M | 0 | 0.165 | 0.360 | −0.403 | 3.97 × 10−3 | 41.311 | – |

| 1000 | 0.066 | 0.069 | −0.359 | 6.26 × 10−4 | 6.509 | 84.24 | |

| 2000 | 0.118 | −0.189 | −0.299 | 2.14 × 10−4 | 2.227 | 94.61 | |

| 3000 | 0.068 | −0.345 | −0.376 | 2.15 × 10−3 | 22.325 | 45.96 | |

| 4000 | 0.649 | 0.129 | −0.375 | 2.70 × 10−3 | 28.086 | 32.01 |

| [H2SO4] | Cinh (mg/L) | Rs (Ω cm2) | Rct (Ω cm2) | CPE (F/cm2) | n | R1 (kΩ cm2) | R2 (kΩ cm2) | C1 (F) | C2 (F) | W YW (Ω−1 cm−2 sn) | χ2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 M | 0 | 7.307 | 27.961 | 8.30 × 10−4 | 0.8599 | – | – | – | – | 0.0839 | 0.0378 |

| 1000 | 7.584 | 252.100 | 9.91 × 10−5 | 1.0099 | −3.896 | 3.846 | 3.70 × 10−4 | 9.00 × 10−13 | 0.0032 | 0.2389 | |

| 2000 | 2.797 | 389.97 | 1.80 × 10−4 | 0.8855 | −33.827 | 33.744 | 4.10 × 10−4 | 9.00 × 10−13 | 0.0026 | 0.1319 | |

| 3000 | 5.406 | 350.37 | 1.40 × 10−4 | 0.9418 | −2.036 | 1.966 | 4.30 × 10−4 | 9.00 × 10−13 | 0.0029 | 0.1011 | |

| 4000 | 4.511 | 315.58 | 1.40 × 10−4 | 0.9560 | −6.998 | 9.00 × 10−16 | 4.40 × 10−4 | 9.00 × 10−13 | 0.0032 | 0.1058 | |

| 1.0 M | 0 | 7.342 | 25.654 | 7.60 × 10−4 | 0.8674 | – | – | – | – | 0.0915 | 0.0163 |

| 1000 | 12.339 | 227.180 | 1.90 × 10−4 | 0.8939 | −14.090 | −40.123 | 9.00 × 10−13 | 5.50 × 10−4 | 0.0045 | 0.6122 | |

| 2000 | −2.207 | 340.760 | 1.30 × 10−4 | 0.9109 | −70.889 | 2.082 | 3.60 × 10−4 | 8.70 × 10−8 | 0.0034 | 0.4138 | |

| 3000 | −1.421 | 271.340 | 1.80 × 10−4 | 0.8847 | −82.736 | 45.708 | 5.60 × 10−4 | 9.00 × 10−13 | 0.0049 | 0.6476 | |

| 4000 | 1.064 | 140.780 | 1.50 × 10−4 | 0.9336 | −59.671 | 43.807 | 8.70 × 10−4 | 9.00 × 10−13 | 0.0115 | 0.1446 | |

| 1.5 M | 0 | 2.779 | 25.607 | 5.30 × 10−4 | 0.862 | – | – | – | – | 0.1009 | 0.0279 |

| 1000 | −34.995 | 122.820 | 2.60 × 10−4 | 0.949 | −41.686 | 76.859 | 9.00 × 10−13 | 9.00 × 10−13 | 0.0113 | 0.3348 | |

| 2000 | −2.944 | 342.560 | 2.60 × 10−4 | 0.895 | −4616.100 | 4547.000 | 8.90 × 10−4 | 9.00 × 10−13 | 0.0039 | 0.0438 | |

| 3000 | −395.090 | 264.590 | 1.60 × 10−4 | 0.954 | 164.050 | 230.330 | 9.00 × 10−13 | 9.00 × 10−13 | 0.0044 | 0.7933 | |

| 4000 | −85.645 | 257.450 | 2.30 × 10−4 | 0.915 | −4308.000 | 4385.300 | 9.00 × 10−13 | 8.35 × 10−12 | 0.0433 | 0.6357 | |

| 2.0 M | 0 | 0.865 | 15.330 | 0.87 × 10−2 | 0.866 | – | – | – | – | 0.2329 | 0.0513 |

| 1000 | 1.173 | 105.700 | 4.00 × 10−4 | 0.845 | −97.542 | 90.361 | 3.11 × 10−3 | 6.23 × 10−7 | 0.0284 | 0.0042 | |

| 2000 | −1.762 | 276.930 | 1.90 × 10−5 | 0.895 | −15.848 | −24.151 | 5.50 × 10−4 | 5.54 × 10−10 | 0.0045 | 0.6122 | |

| 3000 | −52.314 | 25.708 | 4.10 × 10−4 | 0.839 | 35.063 | 19.000 | 1.44 × 10−8 | 9.00 × 10−13 | 0.1715 | 0.0533 | |

| 4000 | 3.809 | 17.723 | 1.15 × 10−3 | 0.777 | −2.083 | 5.033 | 3.40 × 10−6 | 6.00 × 10−4 | 0.1701 | 0.0279 |

| Systems | R2 | k (mmpy) | B (M−1) |

|---|---|---|---|

| Blank | 0.987 | 1.944 | 1.503 |

| Inhibitor | 0.994 | 0.045 | 1.931 |

| Systems | Isotherm | R2 |

|---|---|---|

| in 0.5 H2SO4 | Langmuir | 0.9706 |

| Freundlich | 0.5882 | |

| Temkin | 0.7285 | |

| Frumkin | 0.9979 | |

| in 1.0 M H2SO4 | Langmuir | 0.9515 |

| Freundlich | 0.4410 | |

| Temkin | 0.6193 | |

| Frumkin | 0.9884 | |

| in 1.5 M H2SO4 | Langmuir | 0.9443 |

| Freundlich | 0.5890 | |

| Temkin | 0.7574 | |

| Frumkin | 0.9922 | |

| in 2.0 M H2SO4 | Langmuir | 0.9186 |

| Freundlich | 0.6936 | |

| Temkin | 0.8691 | |

| Frumkin | 0.9973 |

| Systems | a | |log Kads| | (kJ/mol) | (kJ/mol) | (J/mol K) |

|---|---|---|---|---|---|

| in 0.5 H2SO4 | 4.586 | 3.191 | −35.301 | −18.195 | 57.40 |

| in 1 M H2SO4 | 3.976 | 2.650 | −32.216 | −15.110 | 57.40 |

| in 1.5 M H2SO4 | 3.613 | 2.383 | −30.694 | −13.588 | 57.40 |

| in 2 M H2SO4 | 3.086 | 1.932 | −28.123 | −11.016 | 57.41 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gapsari, F.; Madurani, K.A.; Simanjuntak, F.M.; Andoko, A.; Wijaya, H.; Kurniawan, F. Corrosion Inhibition of Honeycomb Waste Extracts for 304 Stainless Steel in Sulfuric Acid Solution. Materials 2019, 12, 2120. https://doi.org/10.3390/ma12132120

Gapsari F, Madurani KA, Simanjuntak FM, Andoko A, Wijaya H, Kurniawan F. Corrosion Inhibition of Honeycomb Waste Extracts for 304 Stainless Steel in Sulfuric Acid Solution. Materials. 2019; 12(13):2120. https://doi.org/10.3390/ma12132120

Chicago/Turabian StyleGapsari, Femiana, Kartika A. Madurani, Firman Mangasa Simanjuntak, Andoko Andoko, Hastono Wijaya, and Fredy Kurniawan. 2019. "Corrosion Inhibition of Honeycomb Waste Extracts for 304 Stainless Steel in Sulfuric Acid Solution" Materials 12, no. 13: 2120. https://doi.org/10.3390/ma12132120

APA StyleGapsari, F., Madurani, K. A., Simanjuntak, F. M., Andoko, A., Wijaya, H., & Kurniawan, F. (2019). Corrosion Inhibition of Honeycomb Waste Extracts for 304 Stainless Steel in Sulfuric Acid Solution. Materials, 12(13), 2120. https://doi.org/10.3390/ma12132120