On the Path to a New Generation of Cement-Based Composites through the Use of Lignocellulosic Micro/Nanofibers

Abstract

1. Introduction

2. Results

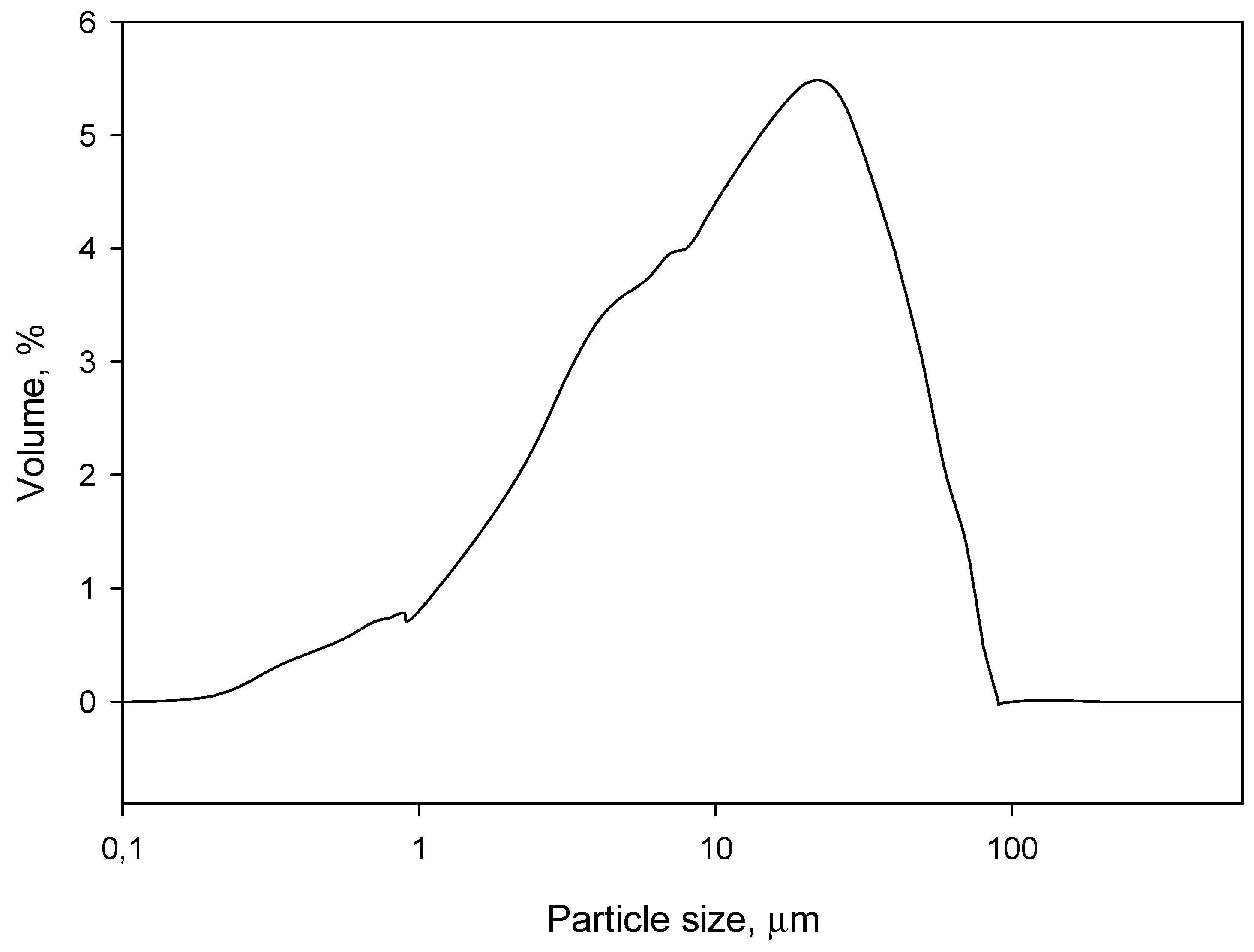

2.1. Characterization of the Pulp and LCMNF

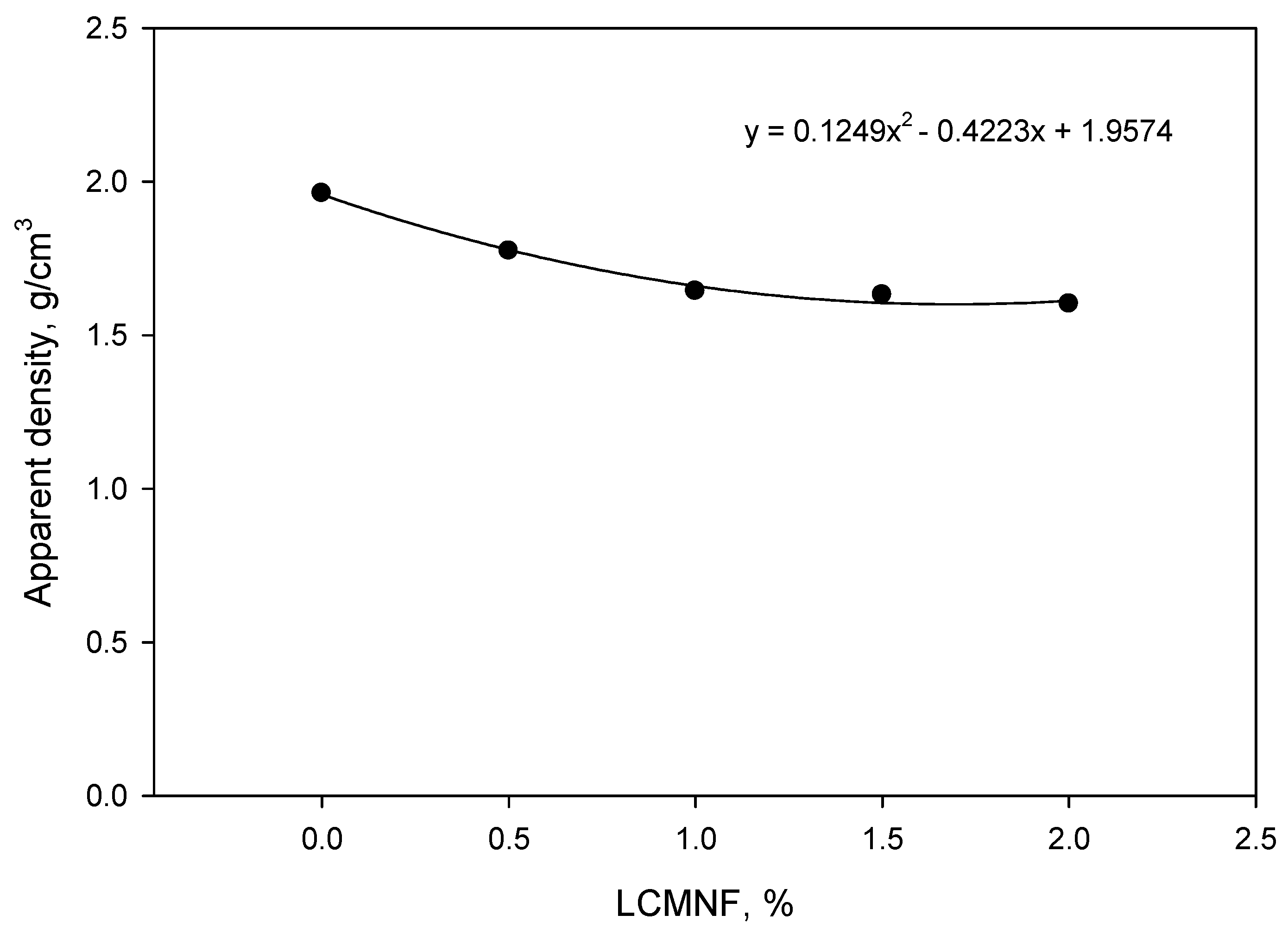

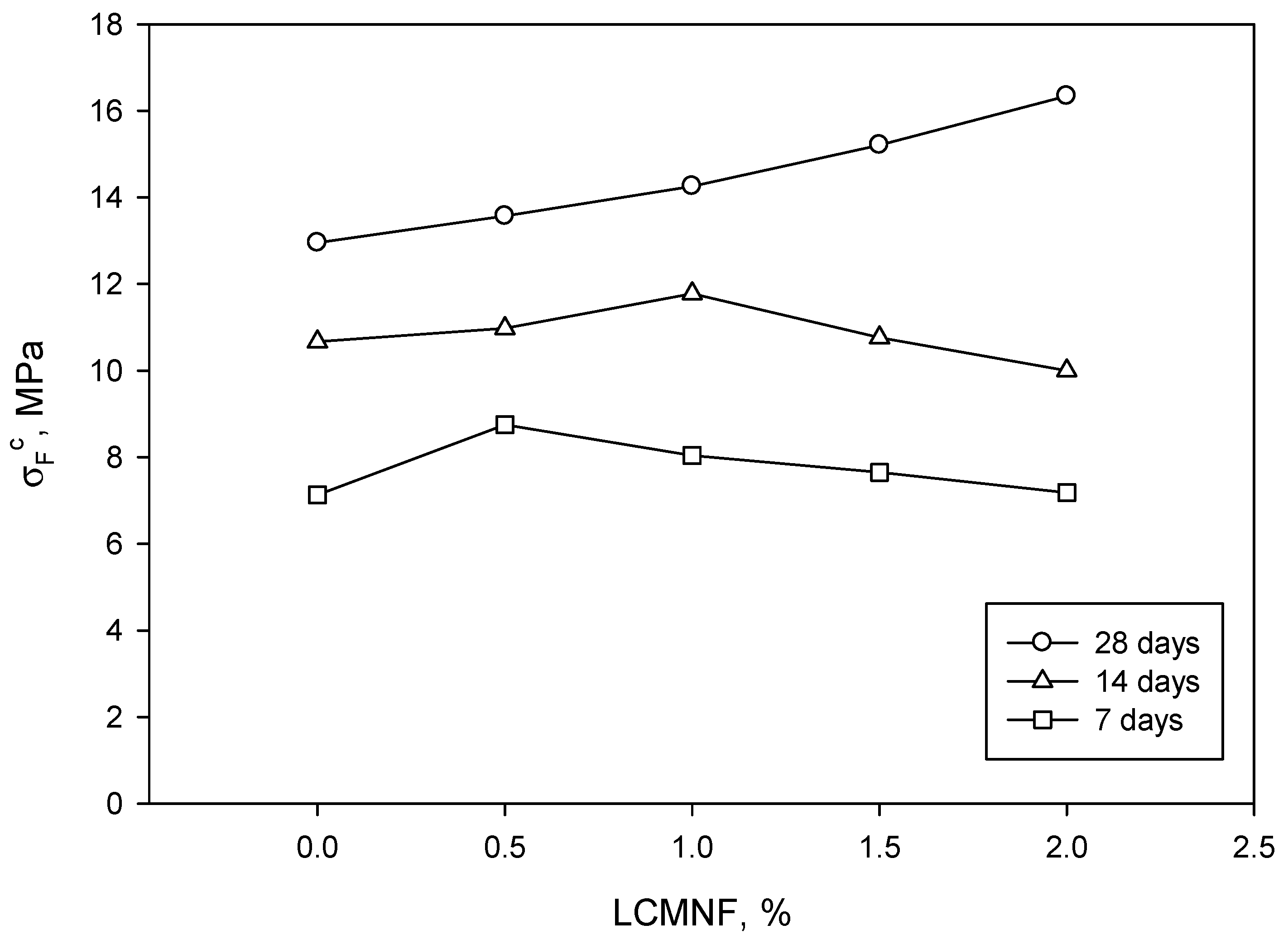

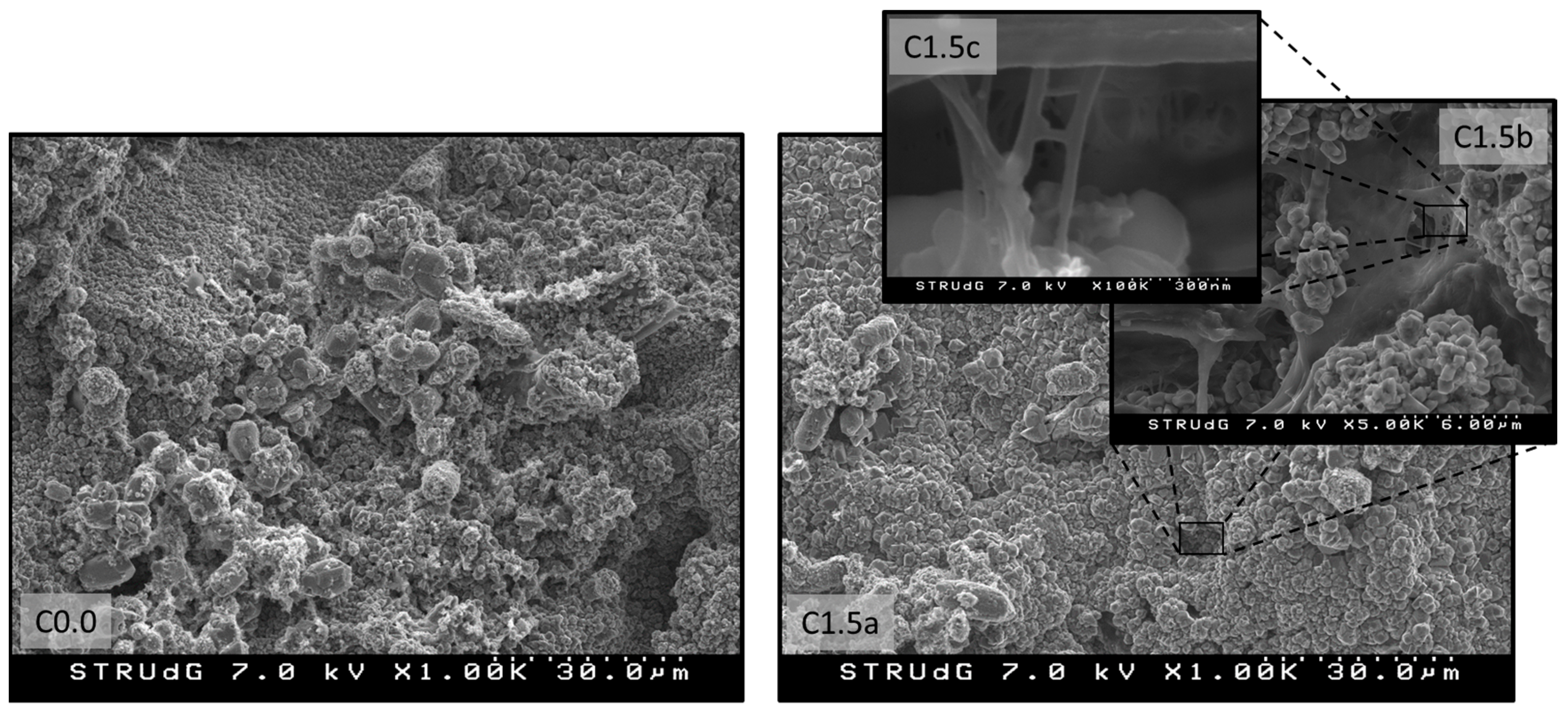

2.2. Characterization of the Cement-Based Composites

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Chemi-Thermomechanical Pulp Production and Characterization

4.3. Production of LCMNF

4.4. Characterization of LCMNF

4.5. Preparation of the Cement-Based Composites

4.6. Characterization of the Cement-Based Composites

5. Conclusions

- The flexural strength of all the dosages analyzed shows that samples improved their flexural strength when the amount of LCMNF was increased. The most important increase occurred between 1.0 and 1.5 wt% at 28 days curing;

- FE-SEM micrographs for reinforced cement with 1.5 wt% CMNF showed the right bond formation between LCMNF and the hydration product;

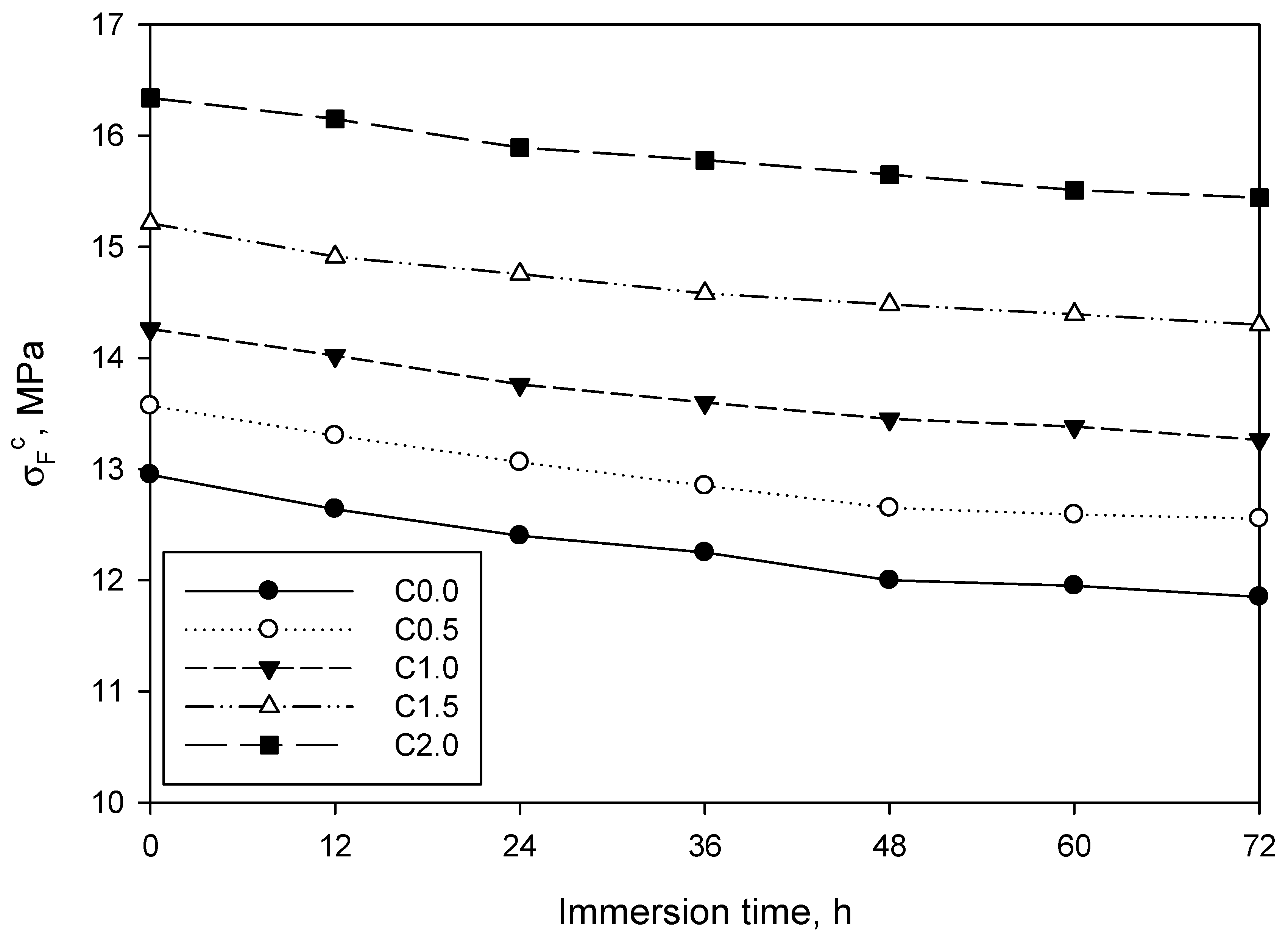

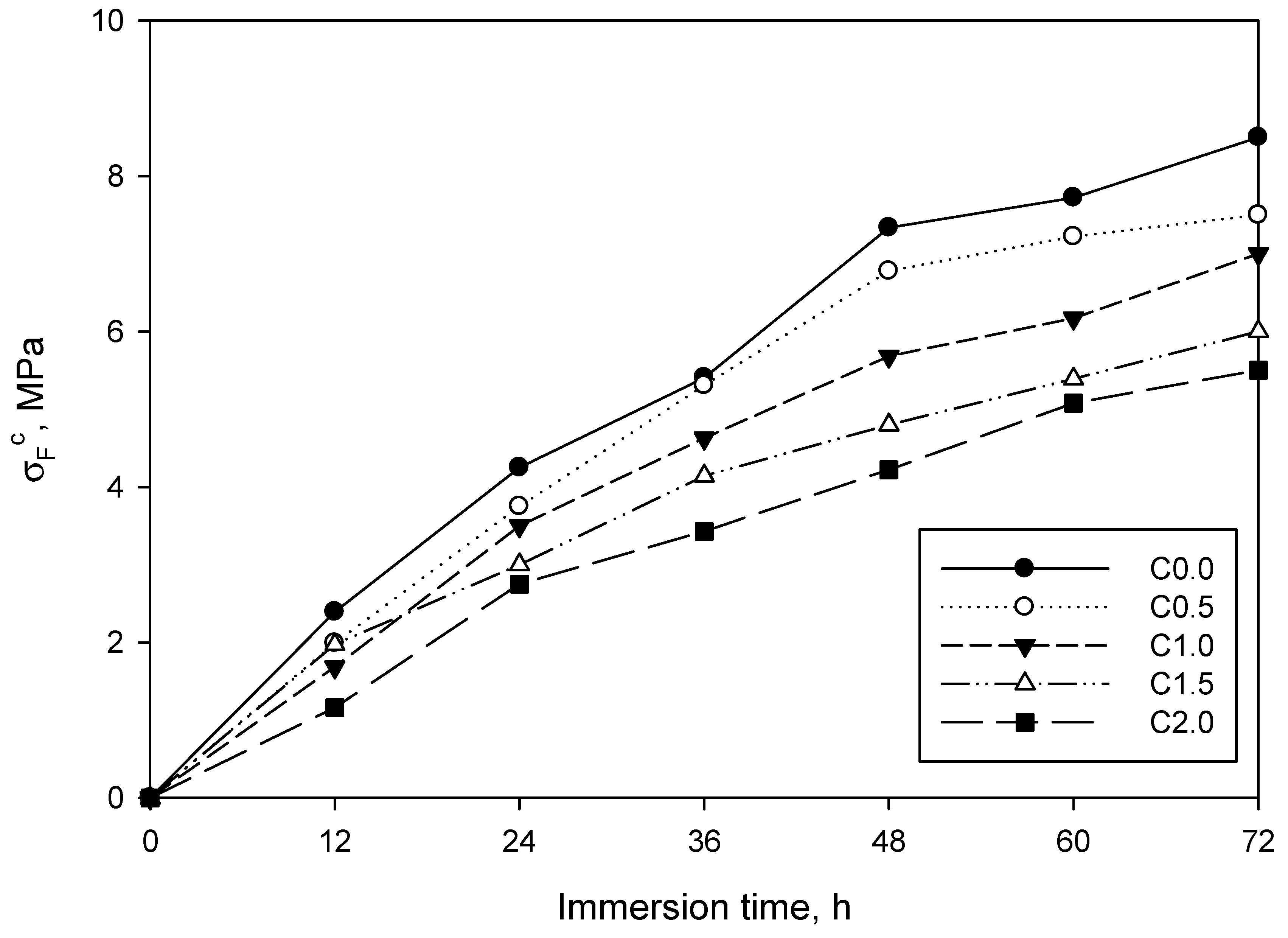

- A slight reduction in the flexural strength of the mixtures with LCMNF was observed after immersion time in water during 72 h;

- The use of LCMNF substantially increased flexural strength if we compare with the control sample and with other cement composites made with processed or unprocessed natural fibers.

Author Contributions

Funding

Conflicts of Interest

References

- Ardanuy, M.; Antunes, M.; Velasco, J.I. Vegetable fibres from agricultural residues as thermo-mechanical reinforcement in recycled polypropylene-based green foams. Waste Manag. 2012, 32, 256–263. [Google Scholar] [CrossRef] [PubMed]

- Beckermann, G.W.; Pickering, K.L. Engineering and evaluation of hemp fibre reinforced polypropylene composites: Micro-mechanics and strength prediction modelling. Compos. Part A Appl. Sci. Manuf. 2009, 40, 210–217. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Singleton, A.C.N.; Baillie, C.A.; Beaumont, P.W.R.; Peijs, T. On the mechanical properties, deformation and fracture of a natural fibre/recycled polymer composite. Compos. Part B Eng. 2003. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.T.; Jawaid, M. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Constr. Build. Mater. 2015, 76, 87–96. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Microstructure and mechanical properties of waste fibre–cement composites. Cem. Concr. Compos. 2005, 27, 583–592. [Google Scholar] [CrossRef]

- Pandey, J.K.; Ahn, S.H.; Lee, C.S.; Mohanty, A.K.; Misra, M. Recent advances in the application of natural fiber based composites. Macromol. Mater. Eng. 2010. [Google Scholar] [CrossRef]

- Coutts, R.S.P. A review of Australian research into natural fibre cement composites. Cem. Concr. Compos. 2005. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.; Coutts, R.S. Potential of alternative fibre cements as building materials for developing areas. Cem. Concr. Compos. 2003, 25, 585–592. [Google Scholar] [CrossRef]

- D’Almeida, A.; Toledo Filho, R.; Melo Filho, J. Cement composites reinforced by short curaua fibers. Rev. Mater. 2010. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Filho, R.D.T.; de Almeida Melo Filho, J.; Fairbairn, E.D.M.R. Physical and mechanical properties of durable sisal fiber-cement composites. Constr. Build. Mater. 2010. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.A.; Barra, M. Fiber-matrix interactions in cement mortar composites reinforced with cellulosic fibers. Cellulose 2011. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Constr. Build. Mater. 2011. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; de Andrade Silva, F.; Fairbairn, E.M.R.; de Almeida Melo Filho, J. Durability of compression molded sisal fiber reinforced mortar laminates. Constr. Build. Mater. 2009. [Google Scholar] [CrossRef]

- Wei, J.; Ma, S.; Thomas, D.G. Correlation between hydration of cement and durability of natural fiber-reinforced cement composites. Corros. Sci. 2016. [Google Scholar] [CrossRef]

- Ozerkan, N.G.; Ahsan, B.; Mansour, S.; Iyengar, S.R. Mechanical performance and durability of treated palm fiber reinforced mortars. Int. J. Sustain. Built Environ. 2013. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Arévalo, R.; Parés, F.; Aracri, E.; Vidal, T. Nanofibrillated cellulose (Nfc) as a potential reinforcement for high performance cement mortar composites. BioResources 2012. [Google Scholar] [CrossRef]

- Jiao, L.; Su, M.; Chen, L.; Wang, Y.; Zhu, H.; Dai, H. Natural cellulose nanofibers as sustainable enhancers in construction cement. PLoS ONE 2016. [Google Scholar] [CrossRef]

- Da Costa Correia, V.; Santos, S.F.; Soares Teixeira, R.; Savastano Junior, H. Nanofibrillated cellulose and cellulosic pulp for reinforcement of the extruded cement based materials. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K.; Sain, M. Properties of nanofibre reinforced cement composites. Constr. Build. Mater. 2014. [Google Scholar] [CrossRef]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef] [PubMed]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crops Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Syverud, K.; Chinga-Carrasco, G.; Toledo, J.; Toledo, P.G. A comparative study of Eucalyptus and Pinus radiata pulp fibres as raw materials for production of cellulose nanofibrils. Carbohydr. Polym. 2011. [Google Scholar] [CrossRef]

- Cao, Y.; Zavattieri, P.; Youngblood, J.; Moon, R.; Weiss, J. The relationship between cellulose nanocrystal dispersion and strength. Constr. Build. Mater. 2016. [Google Scholar] [CrossRef]

- Vo, L.T.T.; Navard, P. Treatments of plant biomass for cementitious building materials—A review. Constr. Build. Mater. 2016, 121, 161–176. [Google Scholar] [CrossRef]

- Bonavetti, V.L.; Rahhal, V.F.; Irassar, E.F. Evolution of the hydration in cements with additions. Mater. Construcción 2002. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Smith, W. Fundamentos de la Ciencia e Ingenieria de Materiales; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Neville, A.M. Properties of Concrete, 4th ed.; Longman: London, UK, 2011; ISBN 0470235276. [Google Scholar]

- Fu, T.; Montes, F.; Suraneni, P.; Youngblood, J.; Weiss, J. The influence of cellulose nanocrystals on the hydration and flexural strength of Portland cement pastes. Polymers 2017, 9, 424. [Google Scholar] [CrossRef]

- Gómez Hoyos, C.; Cristia, E.; Vázquez, A. Effect of cellulose microcrystalline particles on properties of cement based composites. Mater. Des. 2013. [Google Scholar] [CrossRef]

- Cao, Y.; Zavaterri, P.; Youngblood, J.; Moon, R.; Weiss, J. The influence of cellulose nanocrystal additions on the performance of cement paste. Cem. Concr. Compos. 2015, 56, 73–83. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; González, I.; Tarrés, Q.; Pèlach, M.À.; Alcalà, M.; Mutjé, P. The key role of lignin in the production of low-cost lignocellulosic nanofibres for papermaking applications. Ind. Crops Prod. 2016, 86, 295–300. [Google Scholar] [CrossRef]

- Tarrés, Q.; Ehman, N.V.; Vallejos, M.E.; Area, M.C.; Delgado-Aguilar, M.; Mutjé, P. Lignocellulosic nanofibers from triticale straw: The influence of hemicelluloses and lignin in their production and properties. Carbohydr. Polym. 2017. [Google Scholar] [CrossRef] [PubMed]

- Hausser, N.; Marinkovic, S.; Estrine, B. Improved sulfuric acid decrystallization of wheat straw to obtain high yield carbohydrates. Cellulose 2011. [Google Scholar] [CrossRef]

- Tarrés, Q.; Delgado-Aguilar, M.; Pèlach, M.A.; González, I.; Boufi, S.; Mutjé, P. Remarkable increase of paper strength by combining enzymatic cellulose nanofibers in bulk and TEMPO-oxidized nanofibers as coating. Cellulose 2016, 23, 3939–3950. [Google Scholar] [CrossRef]

- Lizundia, E.; Delgado-Aguilar, M.; Mutjé, P.; Fernández, E.; Robles-Hernandez, B.; de la Fuente, M.R.; Vilas, J.L.; León, L.M. Cu-coated cellulose nanopaper for green and low-cost electronics. Cellulose 2016. [Google Scholar] [CrossRef]

- Henriksson, M.; Henriksson, G.; Berglund, L.A.; Lindström, T. An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur. Polym. J. 2007, 43, 3434–3441. [Google Scholar] [CrossRef]

| Parameter | Sawdust | Unbleached Pulp | Bleached Pulp |

|---|---|---|---|

| Yield (%) | - | 45.4 | 96.7 |

| Kappa number | 88 | 25 | 20 |

| Klason lignin (%) | 30.61 | 14.72 | 11.7 |

| Extractives (%) | 2.04 | 0.80 | 0.64 |

| Hemicellulose (%) | 12.30 | 5.89 | 5.51 |

| Cellulose (%) | 55.05 | 78.62 | 82.15 |

| Length 1 (µm) | - | 576 | 572 |

| Diameter (µm) | - | 24.1 | 23.9 |

| Fines 2 (%) | - | 67.4 | 68.9 |

| Yield of Fibrillation (%) | Transmittance at 800 nm (%) | CC (µeq-g/g) | CD (µeq-g/g) | σ (m2/g) | Diameter (nm) | DP |

|---|---|---|---|---|---|---|

| 21.03 | 41.6 | 46.74 | 228.11 | 88.3 | 28 | 307 |

| Sample | LCMNF (wt %) | Cement (g) | Wet LCMNF (g) | Dry LCMNF (g) | Water (g) |

|---|---|---|---|---|---|

| C0 | 0.00 | 37.50 | 0.00 | 0.00 | 12.50 |

| C0.5 | 0.50 | 37.31 | 2.34 | 0.19 | 10.34 |

| C1.0 | 1.00 | 37.13 | 4.69 | 0.38 | 8.19 |

| C1.5 | 1.50 | 36.94 | 7.03 | 0.56 | 6.03 |

| C2.0 | 2.00 | 36.75 | 9.38 | 0.75 | 3.88 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reixach, R.; Claramunt, J.; Chamorro, M.À.; Llorens, J.; Pareta, M.M.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M. On the Path to a New Generation of Cement-Based Composites through the Use of Lignocellulosic Micro/Nanofibers. Materials 2019, 12, 1584. https://doi.org/10.3390/ma12101584

Reixach R, Claramunt J, Chamorro MÀ, Llorens J, Pareta MM, Tarrés Q, Mutjé P, Delgado-Aguilar M. On the Path to a New Generation of Cement-Based Composites through the Use of Lignocellulosic Micro/Nanofibers. Materials. 2019; 12(10):1584. https://doi.org/10.3390/ma12101584

Chicago/Turabian StyleReixach, Rafel, Josep Claramunt, M. Àngel Chamorro, Joan Llorens, M. Mercè Pareta, Quim Tarrés, Pere Mutjé, and Marc Delgado-Aguilar. 2019. "On the Path to a New Generation of Cement-Based Composites through the Use of Lignocellulosic Micro/Nanofibers" Materials 12, no. 10: 1584. https://doi.org/10.3390/ma12101584

APA StyleReixach, R., Claramunt, J., Chamorro, M. À., Llorens, J., Pareta, M. M., Tarrés, Q., Mutjé, P., & Delgado-Aguilar, M. (2019). On the Path to a New Generation of Cement-Based Composites through the Use of Lignocellulosic Micro/Nanofibers. Materials, 12(10), 1584. https://doi.org/10.3390/ma12101584