Effect of Pulse Frequency on Microstructure and Mechanical Properties of 2198 Al-Li Alloy Joints Obtained by Ultrahigh-Frequency Pulse AC CMT Welding

Abstract

:1. Introduction

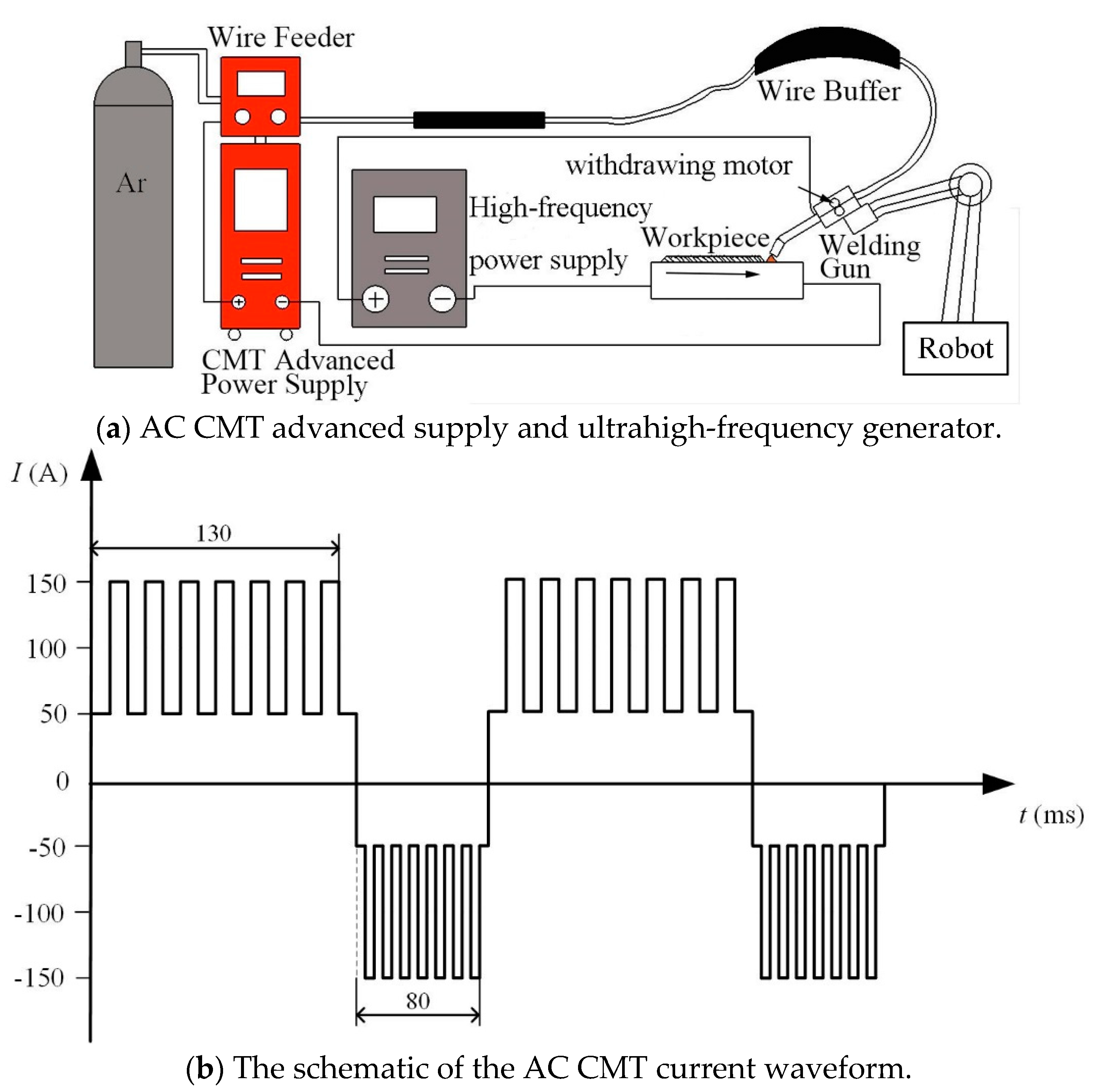

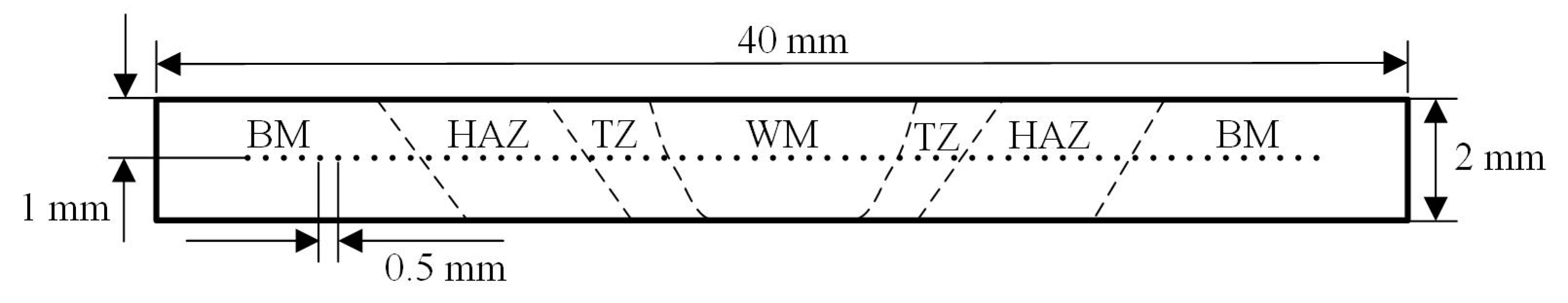

2. Experimental Procedures

3. Results and Discussion

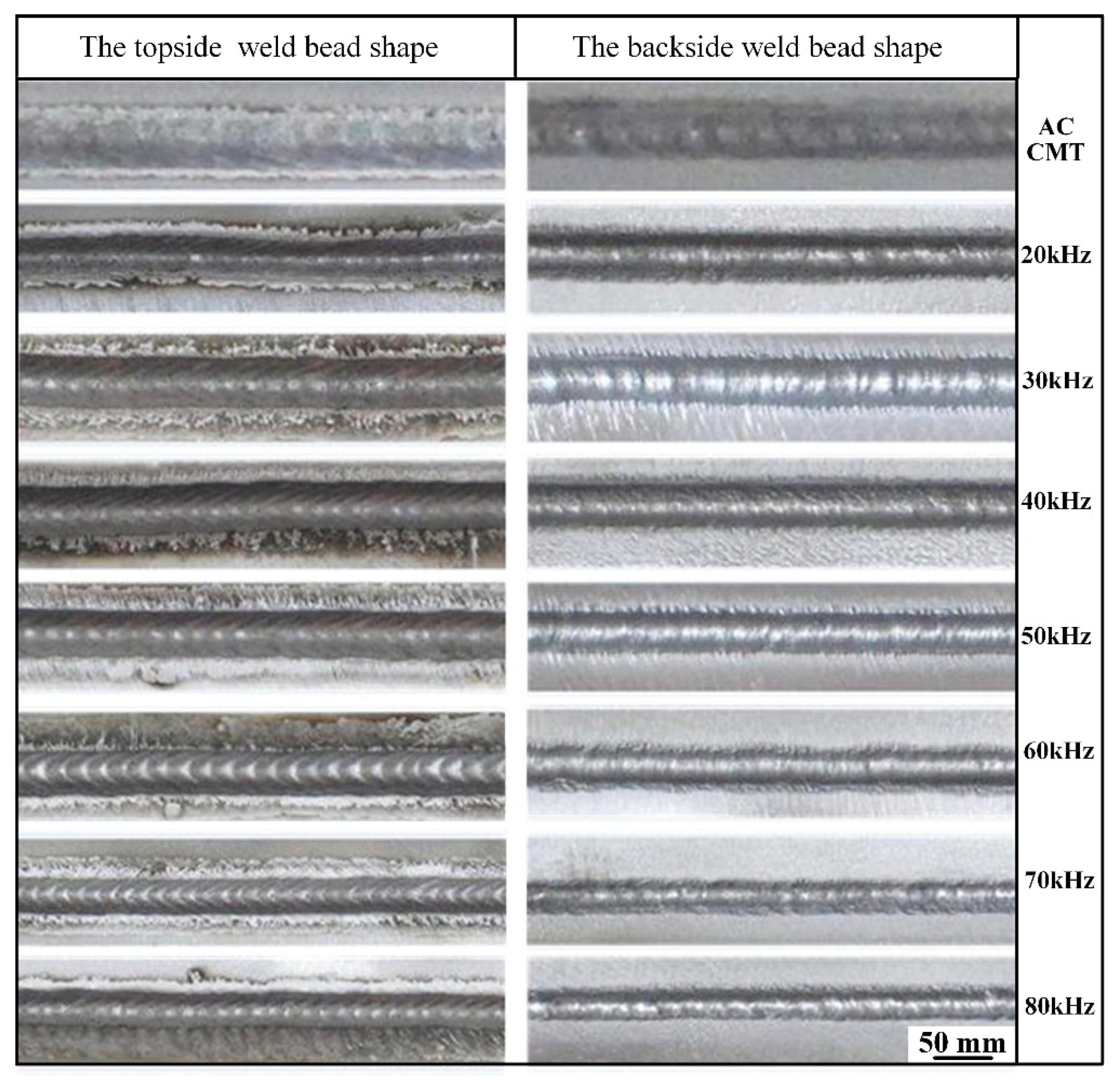

3.1. Macroscopic Morphology of the Welded Joints

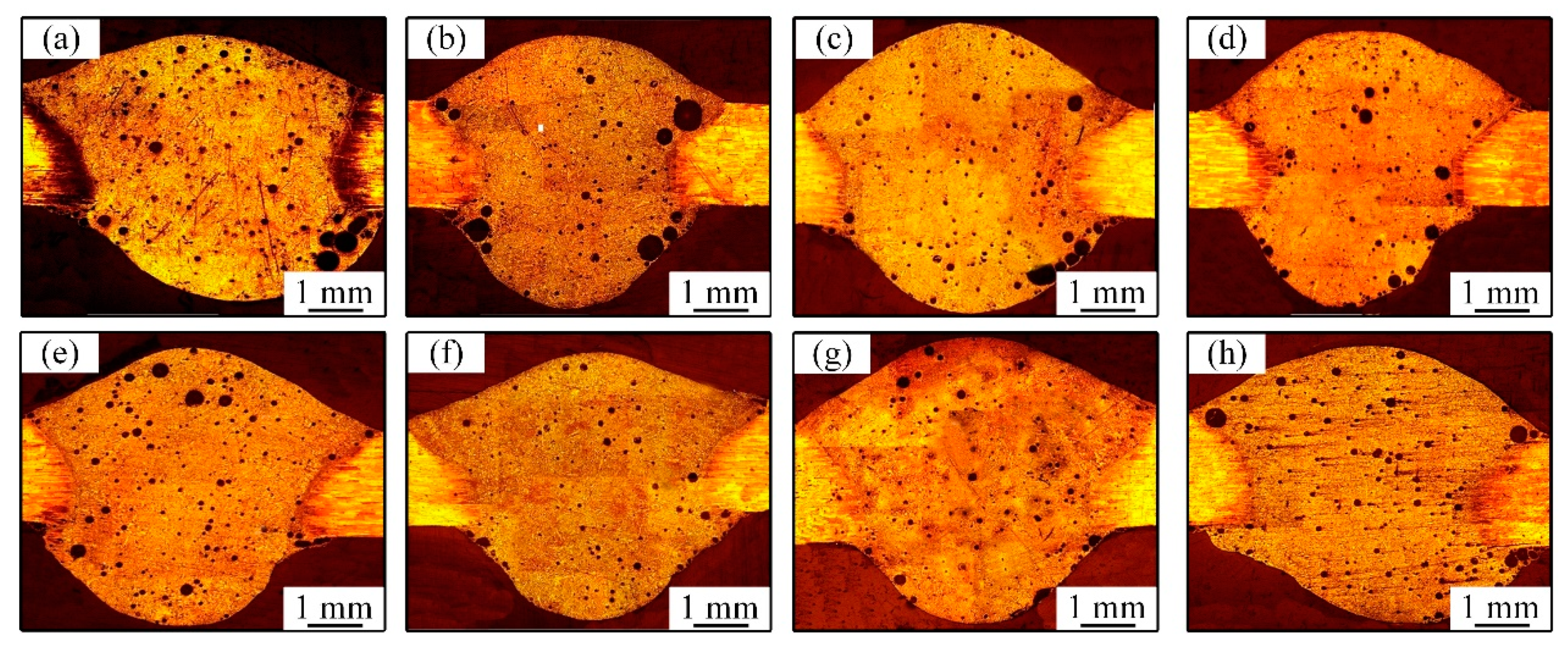

3.2. Pores in Welded Joints

3.3. Microscopic Structure of the Welded Joints

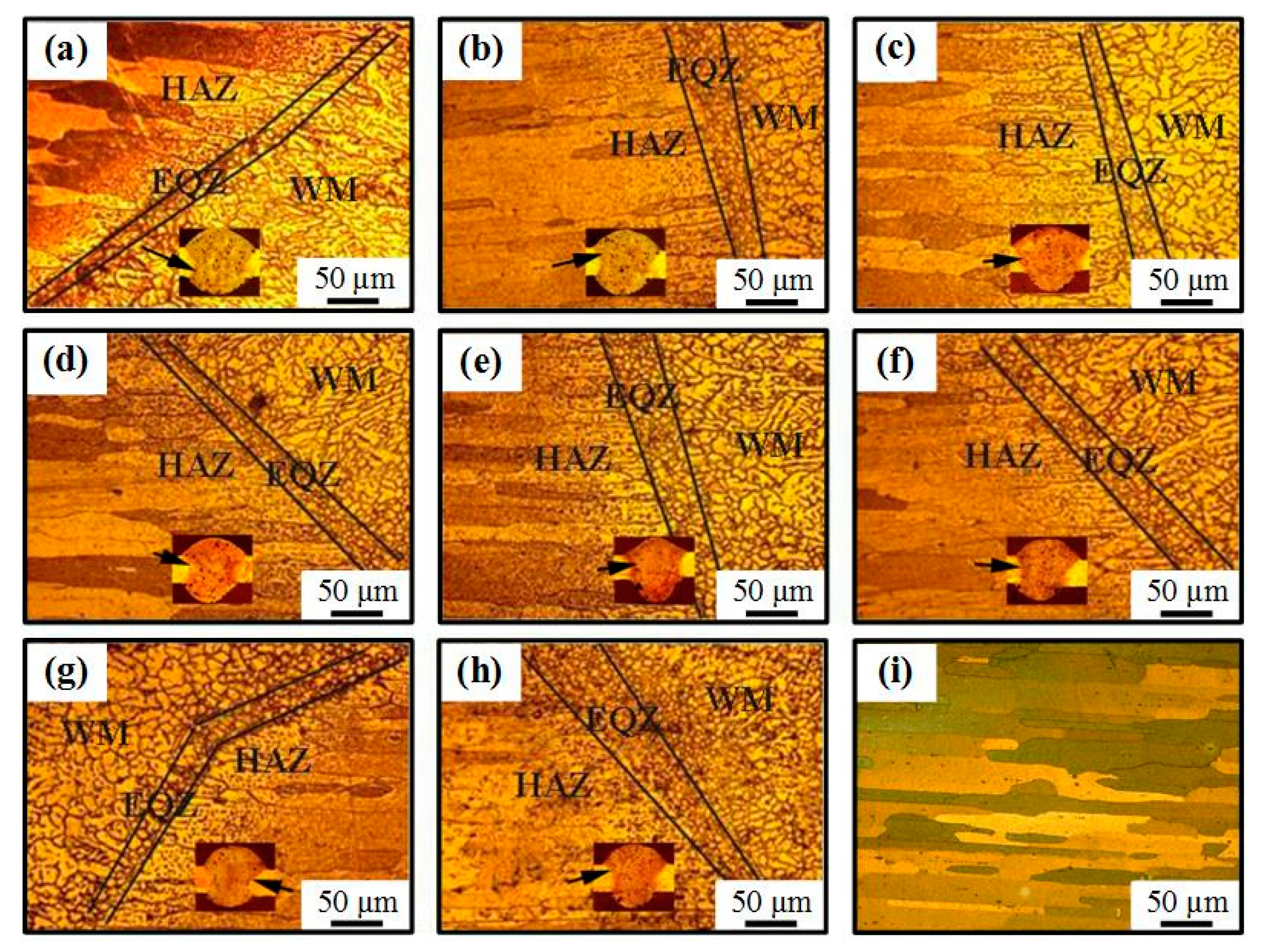

3.3.1. The Microscopic Structure of the Fine Equiaxed Grain Zone (EQZ)

3.3.2. The Microscopic Structure of the WM

3.4. Mechanical Properties of the Welded Joints

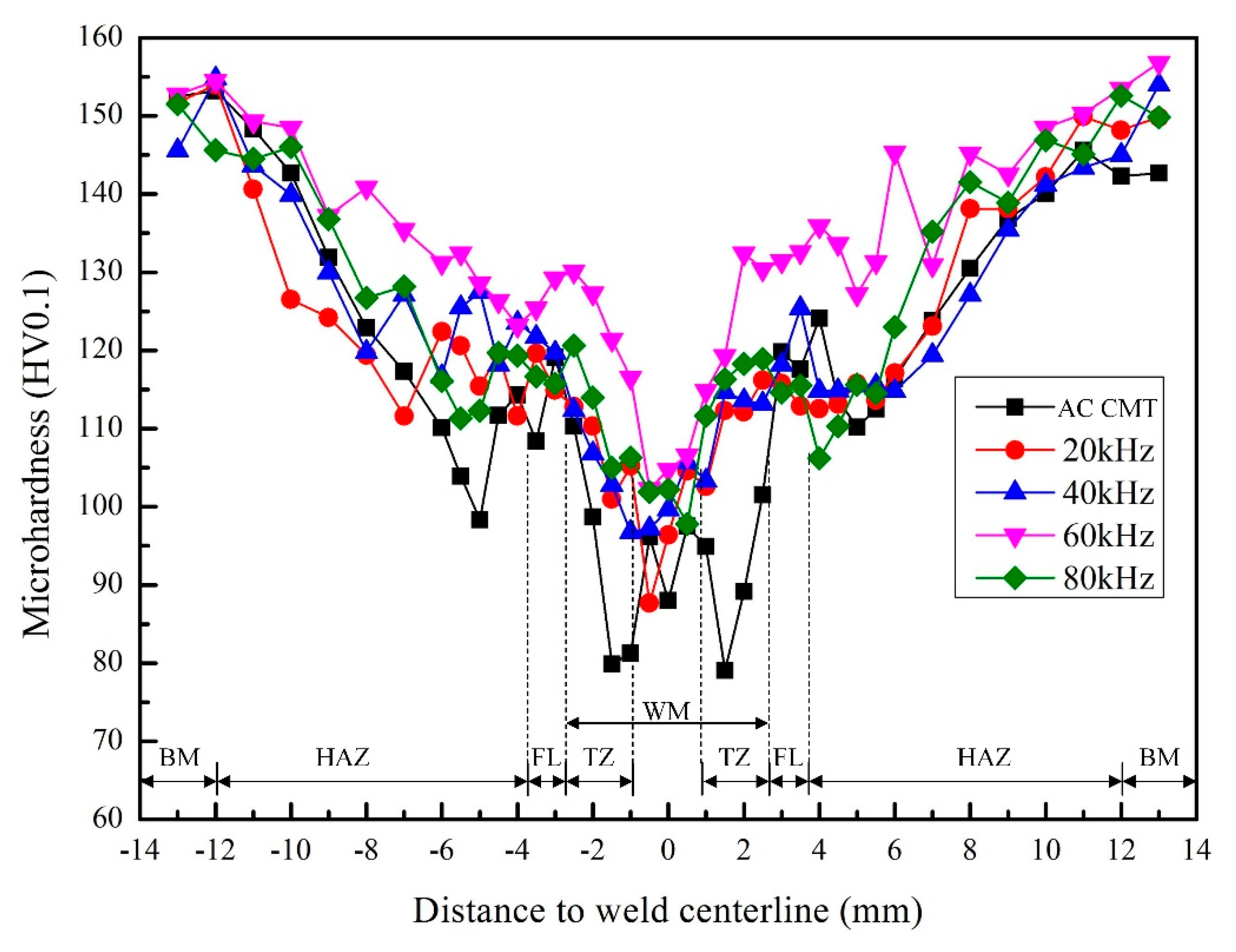

3.4.1. Microhardness of the Welded Joints

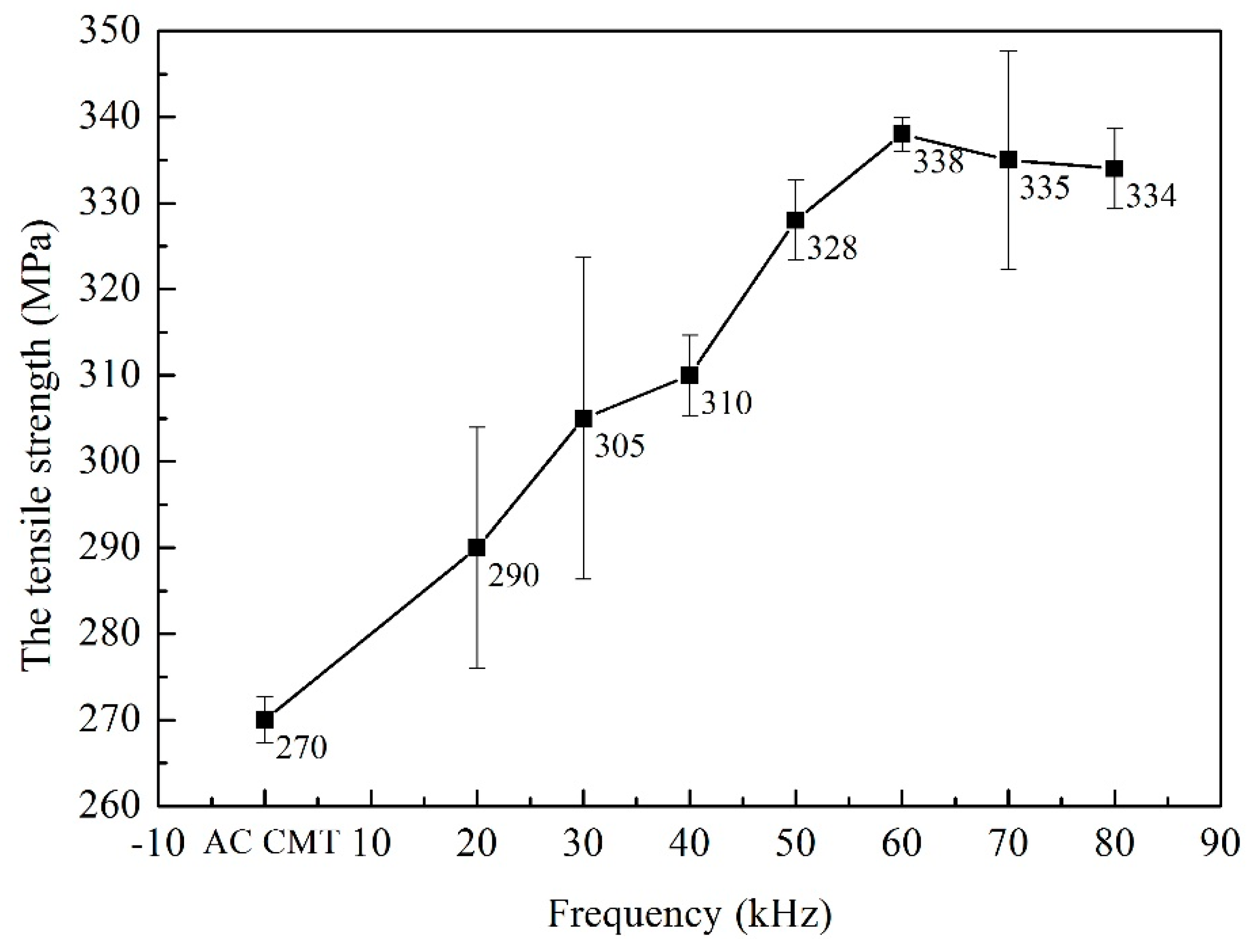

3.4.2. Tensile Properties of the Welded Joints

4. Conclusions

- (1)

- According to the electromagnetic theory, the coupled ultrahigh-frequency current generated electromagnetic force which played a part in stirring the liquid metal in molten pool. The welded joints were smooth and homogeneous; metallic luster and uniform ripples can be seen on the welds surface when the frequency of coupled pulse current were 60 kHz and 70 kHz.

- (2)

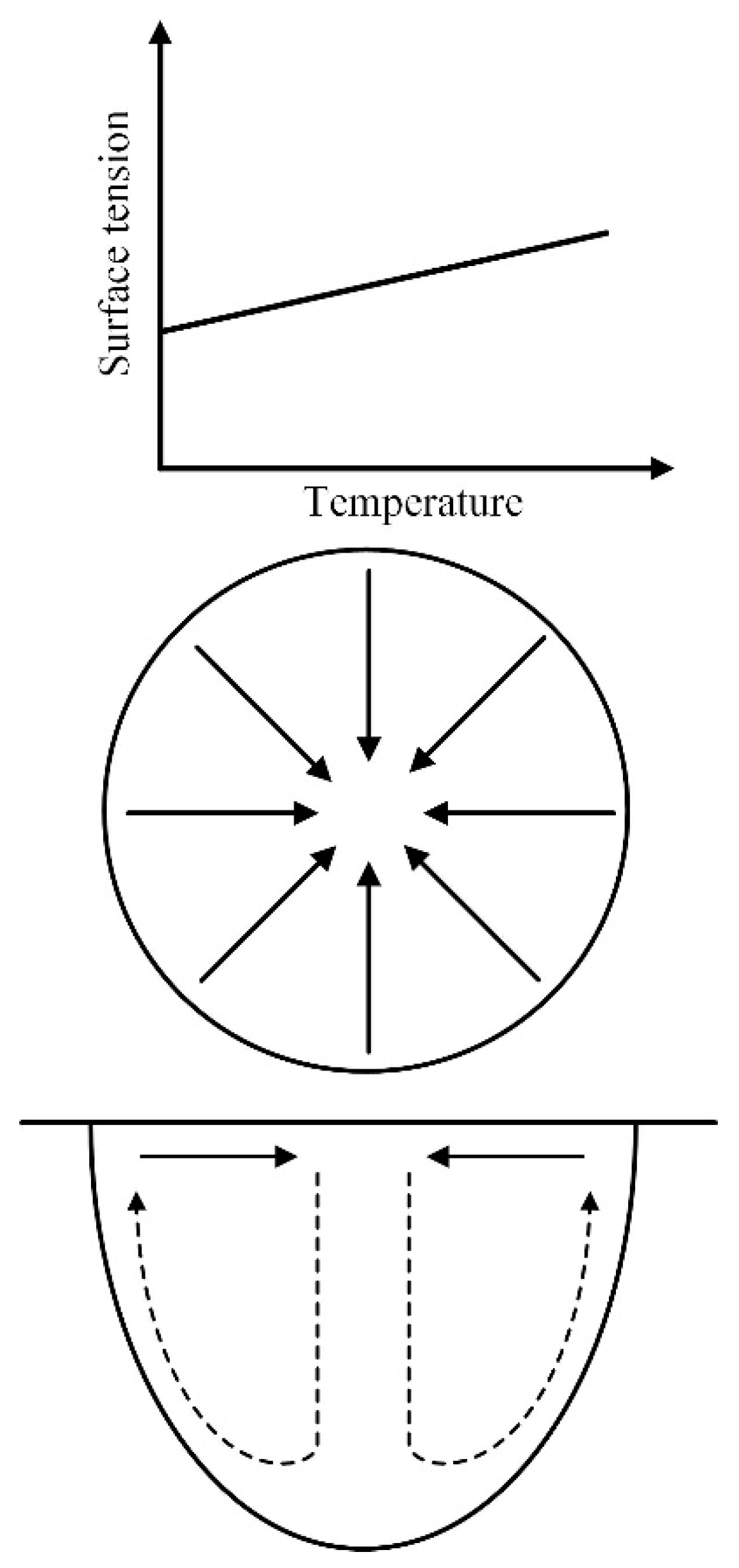

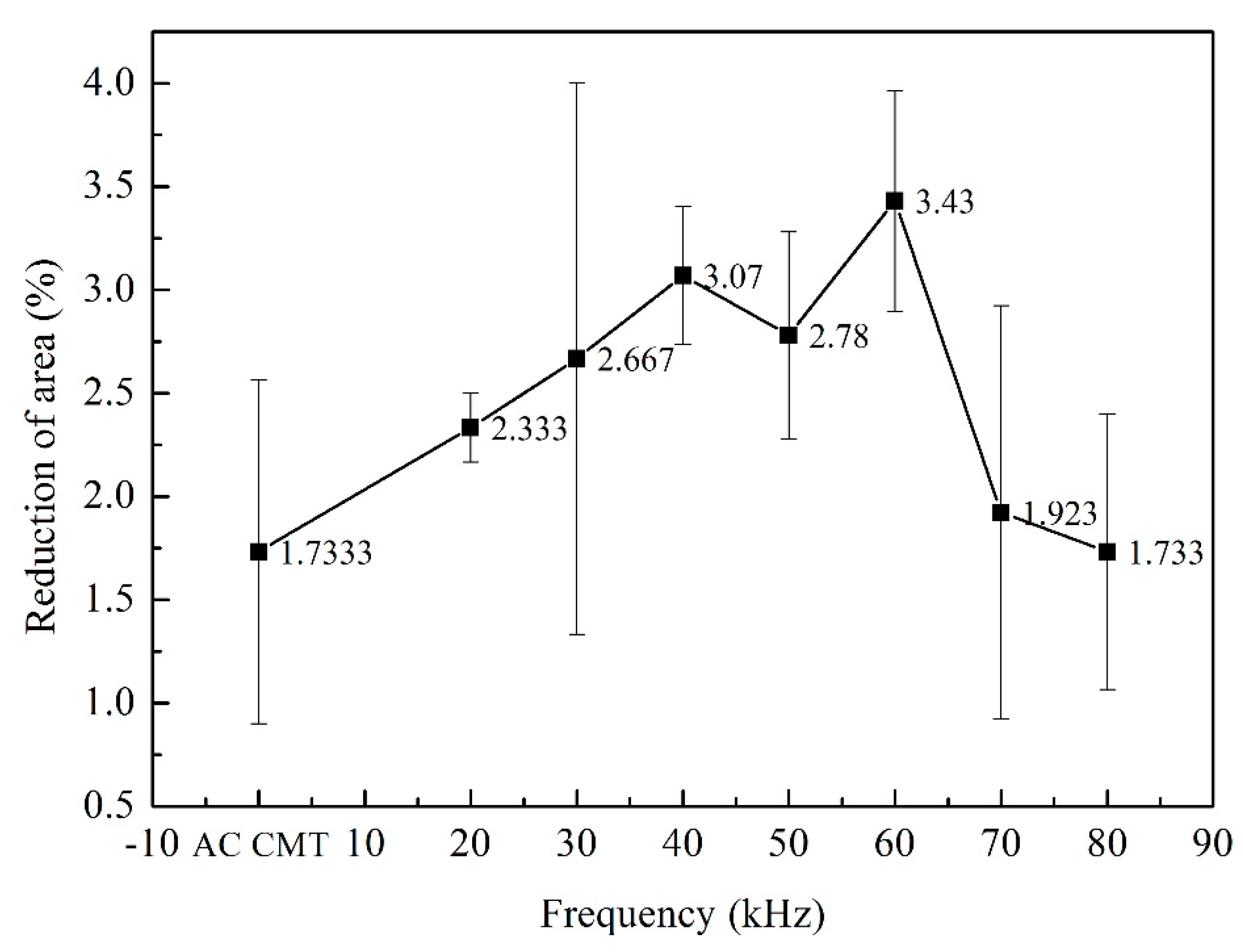

- Under the action of electromagnetic force and surface tension, the flowing liquid metal was conducive to bubbles escaping. The size and number of the weld pores decreased with the increase of coupled current frequency. The porosity was the minimum when the frequency was 60 kHz.

- (3)

- The molten pool was scoured and stirred by the electromagnetic force which provided the sites of heterogeneous nucleation for the nucleation and grain refinement. The width of fine EQZ became larger, and a large amount of equiaxed non-dendrite grains was observed in the WM at frequency of 50 kHz, 60 kHz, and 70 kHz, respectively.

- (4)

- When the frequency of the coupled pulse current was 60 kHz, the weld porosity was the minimum and grain size in WM were the smallest. The average microhardness of WM and tensile strength of the welded joints were the highest, 116 HV0.1 and 338 MPa, respectively. The fracture mode of the welded joints is quasi-cleavage fracture.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems. Acta. Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Rioja, R.J.; Liu, J. The evolution of Al-Li base products for aerospace and space applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Padmanabham, G.; Pandey, S.; Schaper, M. Pulsed gas metal arc welding of Al-Cu-Li alloy. Sci. Technol. Weld. Join. 2005, 10, 67–75. [Google Scholar] [CrossRef]

- Xiao, R.; Zhang, X. Problems and issues in laser beam welding of aluminum–lithium alloys. J. Manuf. Process. 2014, 16, 166–175. [Google Scholar] [CrossRef]

- Wei, S.; Hao, C.; Chen, J. Study of friction stir welding of 1420 aluminum–lithium alloy. Mater. Sci. Eng. A 2007, 452, 170–177. [Google Scholar] [CrossRef]

- Yang, M.C.; Sun, Z.; Rui, M.A. Analysis for microstructure and precipitation phase evolution of friction stir welding 2060 butt joint. Mater. Sci. Technol. 2014, 22, 118–122. [Google Scholar]

- Chang, C.C.; Chou, C.P.; Hsu, S.N.; Hsiung, G.Y. Effect of laser welding on properties of dissimilar joint of Al-Mg-Si and Al-Mn aluminum alloys. J. Mater. Sci. Technol. 2010, 26, 276–282. [Google Scholar] [CrossRef]

- Gibson, B.T.; Ballun, M.C.; Cook, G.E. Friction stir lap joining of 2198 aluminum–lithium alloy with weaving and pulsing variants. J. Manuf. Process. 2015, 18, 12–22. [Google Scholar] [CrossRef]

- Chang, W.S.; Rajesh, S.R.; Chun, C.K. Microstructure and mechanical properties of hybrid laser-friction stir welding between AA6061-T6 Al alloy and AZ31 Mg alloy. J. Mater. Sci. Technol. 2011, 27, 199–204. [Google Scholar] [CrossRef]

- Tian, Y.T.; Robson, J.D.; Riekehr, S.; Kashaev, N.; Wang, L.; Lowe, T.; Karanika, A. Process optimization of dual-laser beam welding of advanced Al-Li alloys through hot cracking susceptibility modeling. Metall. Mater. Trans. A 2016, 47, 3533–3544. [Google Scholar] [CrossRef]

- Han, B.; Chen, Y.B.; Wang, T.; Li, H.; Li, L.Q. Microstructural evolution and interfacial crack corrosion behavior of double-sided laser beam welded 2060/2099 Al-Li alloys T-joints. Mater. Des. 2017, 135, 353–365. [Google Scholar] [CrossRef]

- Liang, Y.; Shen, J.Q.; Hu, S.S.; Wang, H.C.; Pang, J. Effect of TIG current on microstructural and mechanical properties of 6061-T6 aluminum alloy joints by TIG-CMT hybrid welding. J. Mater. Process. Tech. 2018, 255, 161–174. [Google Scholar] [CrossRef]

- Srikanth, T.; Surendran, S.; Balaganesan, G.; Manjunath, G.L. Response of CMT welded aluminum AA5086-H111 to AA6061-T6 plate with AA4043 filler for ballistic. Procedia Eng. 2017, 194, 522–528. [Google Scholar] [CrossRef]

- Shang, J.; Wang, K.H.; Tian, H.J.; Zhou, Q.; Li, G.L. Study on cold metal transfer welded lap joints of Mg/Al dissimilar metals. Trans. China Weld. Inst. 2011, 32, 41–45. [Google Scholar]

- Farzadi, A.; Serajzadeh, S.; Kokabi, A.H. Investigation of weld pool in aluminum alloys, geometry and solidification microstructure. Int. J. Therm. Sci. 2010, 49, 809–819. [Google Scholar] [CrossRef]

- Faraji, A.H.; Goodarzi, M.; Seyedein, S.H.; Zamani, M.H. Experimental study and numerical modeling of arc and weld pool in stationary GTA welding of pure aluminum. Int. J. Adv. Manuf. Technol. 2014, 71, 2059–2071. [Google Scholar] [CrossRef]

- Wang, D.L.; Chen, Y.C.; Li, H.Y.; Liang, Z.M. Effects of AC CMT welding coupled with high-frequency pulse current on microstructure and mechanical properties of 2060 Al-Li alloy joint. J. Hot Work. Technol. 2017, 46, 13–16. [Google Scholar]

- Liu, H.B.; Yang, S.L.; Xie, C.J. Microstructure characterization and mechanism of fatigue crack initiation near pores for 6005A CMT welded joint. Metall. Mater. Trans. A 2017, 707, 22–29. [Google Scholar] [CrossRef]

- Li, J.; Ma, J.H.; Gao, Y.L.; Zhai, Q.J. Research on solidification structure refinement of pure aluminum by electric current pulse with parallel electrodes. Mater. Sci. Eng. A 2008, 490, 452–456. [Google Scholar] [CrossRef]

- Yang, M.X.; Qi, B.J.; Cong, B.Q.; Liu, F.J.; Yang, Z. Effect of pulse frequency on microstructure and properties of Ti-6Al-4V by ultrahigh-frequency pulse gas tungsten arc welding. Int. J. Adv. Manuf. Technol. 2013, 68, 19–31. [Google Scholar] [CrossRef]

- Huang, Y.H.; Yuan, Z.M. Micro-structure and low temperature toughness in welding zone of X65 high-frequency welding pipe. J. Dalian Marit. Univ. 2010, 36, 104–106. [Google Scholar]

- Hao, H.; Lu, G.Q.; Wang, F.Y.; Zhang, X.G. Effects of electromagnetic stirring on solidification of metal foams. J. Iron Steel Res. 2012, S1, 195–198. [Google Scholar]

- Yang, M.X.; Zheng, H.; Qi, B.J.; Yang, Z. Microstructure and fatigue property of Ti-6Al-4V by ultrahigh frequency pulse welding. J. Manuf. Sci. Eng. 2016, 139, 041015. [Google Scholar] [CrossRef]

- Wan, X.H.; Zhao, H.T.; Jin, J.L. High frequency pulse tungsten arc welding process trials of TA15 titanium alloy. Aeronaut. Manuf. Technol. 2017, 7, 82–85. [Google Scholar]

- Feng, J.C.; Zhang, H.T.; He, P. The CMT short-circuiting metal transfer process and its use in thin aluminum sheets welding. Mater. Des. 2009, 30, 1850–1852. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, J.G.; Liu, X.S.; Fang, H.Y. Welding TC4 thin plates by revolution pressing in welding process. Trans. China Weld. Inst. 2010, 31, 81–84. [Google Scholar]

- Ellis, M.B.D. Fusion welding of aluminum-lithium alloys. Weld. Metal. Fabr. 1996, 64, 55–60. [Google Scholar]

- Diao, G.Y.; Wang, D.L.; Li, H.C.; Liang, Z.M. Effects of different welding wires on microstructure and mechanical properties of Al-Zn-Mg series aluminum alloy pulsed MIG welds. J. Hot Work. Technol. 2018, 47, 195–197. [Google Scholar]

- Paramo, V.; Colas, R.; Velasco, E.; Valtierra, S. Spheroidization of the Al-Si eutectic in a cast aluminum alloy. J. Mater. Eng. Perform. 2000, 9, 616–622. [Google Scholar] [CrossRef]

- Chen, K.; Yang, W.X.; Xiao, R.S. Direct laser welding of an Al- Li alloy plate without prior surface cleaning. Laser Eng. 2011, 22, 361–369. [Google Scholar]

- Xiao, R.; Yang, W.; Chen, K. Porosity characterization in laser welds of Al-Li alloy 1420. Appl. Laser 2007, 27, 13–17. [Google Scholar]

- Tang, L.X.; Xiao, Y.; Lan, Z.G.; Fan, X.L.; Li, Y.F. Porosity prevention in MIG welding aluminum and aluminum alloy. Weld. Dig. Mach. Manuf. 2011, 5, 35–39. [Google Scholar]

- Wang, Z.; Oliveira, J.P.; Zeng, Z. Laser beam oscillating welding of 5A06 aluminum alloys: Microstructure, porosity and mechanical properties. Opt. Laser Technol. 2019, 111, 58–65. [Google Scholar] [CrossRef]

- Fan, Z.P. Effect of surface state of aluminum alloy on welding pores. Aerosp. Manuf. Technol. 2000, 2, 19–23. [Google Scholar]

- Huang, Y.; Fan, D. Mechanism of weld penetration increase of AC A-TIG welding for aluminum alloy. Weld. Join. 2003, 4, 9–11. [Google Scholar]

- Lin, D.C.; Wang, G.X.; Srivatsan, T.S. A mechanism for the formation of equiaxed grains in welds of aluminum-lithium alloy 2090. Mater. Sci. Eng. A 2003, 351, 304–309. [Google Scholar] [CrossRef]

- Gupta, R.K.; Niraj, N.; Nagasireesha, G. Development and characterization of Al-Li alloys. Mater. Sci. Eng. A 2006, 420, 228–234. [Google Scholar] [CrossRef]

- Liao, M. Dislocation theory based short crack model and its application for aircraft aluminum alloys. Eng. Fract. Mech. 2010, 77, 22–36. [Google Scholar] [CrossRef]

- An, N.; Zhang, X.Y.; Wang, Q.M.; Yang, W.X.; Xiao, R.S. Fiber laser welding of 2060 aluminum-lithium alloy with filler wire. Chin. J. Lasers 2014, 41, 100–105. [Google Scholar]

- Wang, D.; He, C.S.; Wang, H.; Zhao, X.; Zuo, L. Joint softening in heat affected zone during metal inert gas welding of Al-12.7Si-0.7Mg alloy. Mater. Res. Innov. 2014, 18, 224–227. [Google Scholar] [CrossRef]

- Rajakumar, S.; Muralidharan, C.; Balasubramanian, V. Establishing empirical relationships to predict grain size and tensile strength of friction stir welded AA 6061-T6 aluminium alloy joints. Trans. Nonferr. Metal Soc. 2010, 20, 1863–1872. [Google Scholar] [CrossRef]

- Lin, K.L.; Yang, W.X.; Lv, J.X.; Xiao, R.S. Laser beam welding study of 2198-T851 aluminium-lithium alloy. Chin. J. Lasers 2014, 41, 90–95. [Google Scholar]

- Dvorna, K.M.J.; Frost, R.H.; Olson, D.L. Influence of solidification kinetics on aluminum weld grain refinement. Weld. J. 1991, 70, 271–276. [Google Scholar]

| Base Current Ib/A | Pulse Current Ip/A | Welding Rate v/(cm·min−1) | Gas Flow Rate q/(L·min−1) | EP Duration (ms) | EN Duration (ms) |

|---|---|---|---|---|---|

| 85 | 30 | 70 | 20 | 130 | 80 |

| Materials | Cu | Li | Zn | Mn | Mg | Si | Fe | Al |

|---|---|---|---|---|---|---|---|---|

| 2198 | 2.9–3.5 | 0.8–1.1 | ≤0.35 | ≤0.5 | 0.25–0.8 | ≤0.08 | ≤0.01 | Bal. |

| ER4043 | 0.3 | - | 0.1 | 0.05 | 0.05 | 4.5–6.0 | 0.8 | Bal. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Suo, Y.; Wu, C.; Wang, D.; Liang, Z. Effect of Pulse Frequency on Microstructure and Mechanical Properties of 2198 Al-Li Alloy Joints Obtained by Ultrahigh-Frequency Pulse AC CMT Welding. Materials 2019, 12, 79. https://doi.org/10.3390/ma12010079

Wang L, Suo Y, Wu C, Wang D, Liang Z. Effect of Pulse Frequency on Microstructure and Mechanical Properties of 2198 Al-Li Alloy Joints Obtained by Ultrahigh-Frequency Pulse AC CMT Welding. Materials. 2019; 12(1):79. https://doi.org/10.3390/ma12010079

Chicago/Turabian StyleWang, Liwei, Yingchao Suo, Chaofeng Wu, Dianlong Wang, and Zhimin Liang. 2019. "Effect of Pulse Frequency on Microstructure and Mechanical Properties of 2198 Al-Li Alloy Joints Obtained by Ultrahigh-Frequency Pulse AC CMT Welding" Materials 12, no. 1: 79. https://doi.org/10.3390/ma12010079

APA StyleWang, L., Suo, Y., Wu, C., Wang, D., & Liang, Z. (2019). Effect of Pulse Frequency on Microstructure and Mechanical Properties of 2198 Al-Li Alloy Joints Obtained by Ultrahigh-Frequency Pulse AC CMT Welding. Materials, 12(1), 79. https://doi.org/10.3390/ma12010079