The failure mechanisms that arise in the surface of indefinite chill double-poured (ICDP) work rolls used in the finishing stands of hot strip mills involve phenomena of plastic deformation, abrasive wear, and cracking resulting from mechanical or thermal stresses [

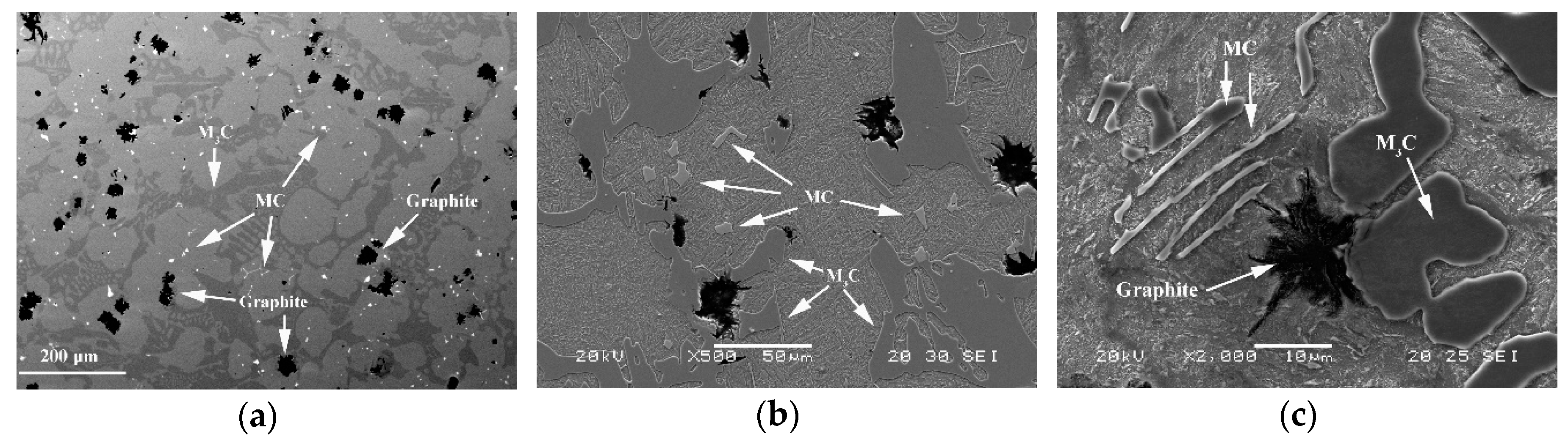

1]. These work rolls are manufactured by means of vertical centrifugal casting. The outer working layer is a martensitic white cast iron with the presence of graphite particles, while the core is a grey cast iron with a pearlitic matrix and dispersed spheroidal graphite. Its main alloying elements are Ni and Cr. The chemical composition may include Nb and Mo so as to improve the wear resistance of the working layer. The Nb forms carbides of the MC type with a hardness close to 2400 HV [

2], while the Cr forms carbides of the M

3C type [

3], with a hardness close to 1200 HV [

3], and the Ni and the Mo increase the hardenability of the material [

4]. Thus, its microstructure will mainly be made up of proeutectic austenite, eutectic austenite, MC and M

3C carbides, and graphite particles [

5]. The austenite will be partially converted to martensite during air cooling after quenching at 1000 °C. During the rolling process, the working layer is heated on entering into contact with the sheet steel to be rolled. This heating is counteracted by spraying with water as the materials enters and exits the rolling pass [

6]. During the initial stages in the finishing stands, the surface of the work rolls can reach over 500 °C, subsequently cooling down to 50 to 80 °C during water cooling [

7], thereby producing thermal fatigue cycles. During the rolling pass, the work roll, likewise, undergoes compression forces that oppose thermal expansion. Hence, the service life of these rolls depends not only on their wear resistance but also on their fatigue behavior versus cyclic thermal and mechanical stresses [

8]. In this context, in addition to the presence of carbides and their network distribution, the percentage of graphite and its morphology also play a very important role against said thermal cycling. Although crack nucleation is predominant in carbides, the subsequent progression of cracks may be favored by laminar graphite morphologies [

9,

10]. However, thermal conductivity is improved by this morphology compared to compact and spheroidal morphologies [

11]. Thus, the laminar morphology of graphite improves the evacuation of heat, but favors the progression of the possible cracks that are generated in the carbide network during the rolling process. In contrast, a spheroidal geometry reduces the evacuation of heat, but constitutes a barrier to the progression of said cracks. Furthermore, graphite performs dry lubrication functions [

12], reducing the coefficient of friction between the work roll and the sheet steel to be rolled [

13]. One of the quality indicators established for the working layer of these rolls is the volume fraction of graphite. Optimal quality is achieved when this percentage falls within the 2 to 5% range [

14]. Hence, one of the objectives of manufacturers and users of this type of work roll should be to control both the volume fraction of graphite and its geometry, in addition to knowing how the different variables of the manufacturing process affect these parameters. This paper presents a research methodology aimed at achieving these objectives in white cast irons alloyed with Ni, Cr, Mo, and Nb. To this end, a fractional Design of Experiments (DOE) is applied to identify those Factors in the manufacturing process that have a significant influence on the percentage of precipitated graphite and its geometry. The analyzed manufacturing Factors were: the use of inoculants based on FeSi alloys that include traces of lanthanum; inoculation with different percentages of Mg, FeB, and SiCaMn; the liquidus lemperature, and the percentage of Si. Both the volume fraction and the number of counts of graphite increase with increasing equivalent carbon (EC), while Mg favors the precipitation of graphite with a spheroidal morphology [

15,

16]. There are many theories that justify the possible spheroidal growth of the graphite. It should be noted that, one of them, which has been proven on iron–carbon–silicon alloys with no sulphur contamination, vacuum caste, and without any presence known of any spheroidizing element (Mg, Ce, RE, etc.). This theory is based on the fact that graphite–liquid surface energy is higher in spheroidal graphite than in flake graphite, so that the crystalline growth of graphite will “curve” to reduce the free surface energy [

17], or to decrease the energy–volume ratio [

18]. The carbon equivalent implicitly includes factors, such as the %Si and the liquidus temperature, both of which are analyzed in this paper. The composition of FeSi alloys includes elements such as Ca, Al, and Ba, which, due to their high affinity with O, precipitate forming small oxide particles that can act as agents for the nucleation of graphite [

19]. The use of inoculants with high percentages of Ca may promote a decrease in the grain size of the primary austenite and discontinuity of the carbide network [

20]. La could increase the number of counts of graphite [

21] and promote a finer structure of the carbide network [

22]. B may combine with the N dissolved in the molten metal forming particles of BN that can act as heterogeneous nucleating agents of graphite [

23]. B can also form carbides, thereby improving the wear resistance of the material [

24,

25]. Nb tends to reduce the eutectic cell, which could result in graphite of smaller size that is more uniformly distributed [

19,

26]. The formation of Nb carbides in the liquid phase could promote heterogeneous nucleation of graphite [

27]. These carbides can also increase the hardness of the resulting material and improve its wear resistance [

26]. The study was carried out on an industrial scale, casting eight work rolls with a diameter of 700 mm, a length of between 1800 and 2000 mm, and a thickness of the working layer of 50 mm.