Cement Kiln By-Pass Dust: An Effective Alkaline Activator for Pozzolanic Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Physical-Mechanical Measurements

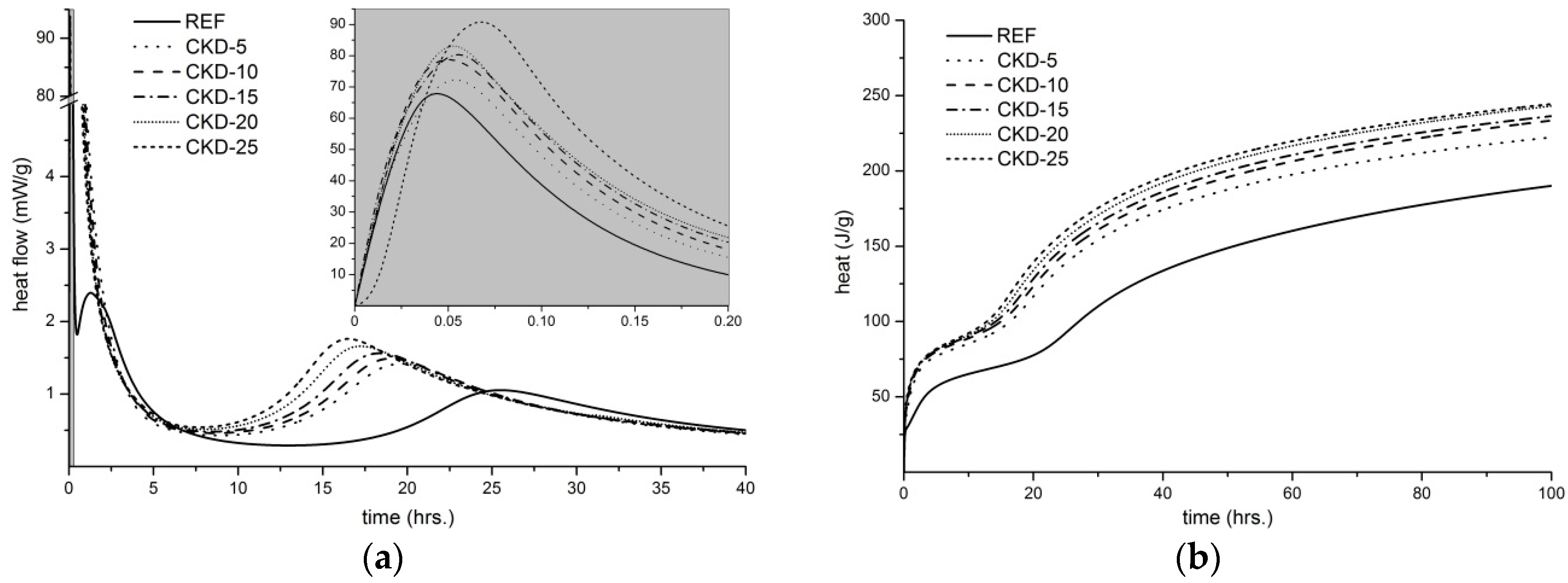

2.3. Isothermal Calorimetry

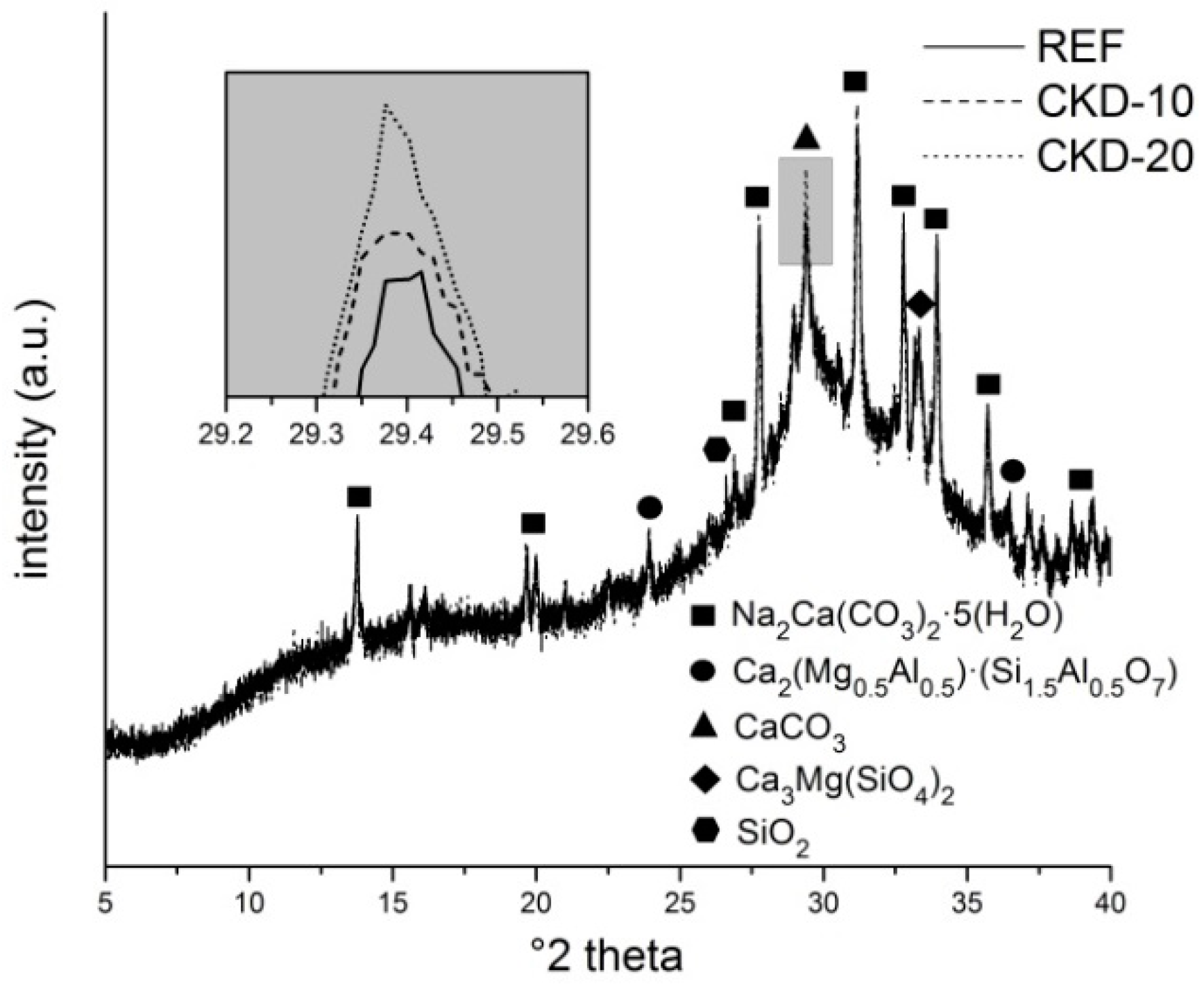

2.4. X-ray Diffraction Analysis (XRD)

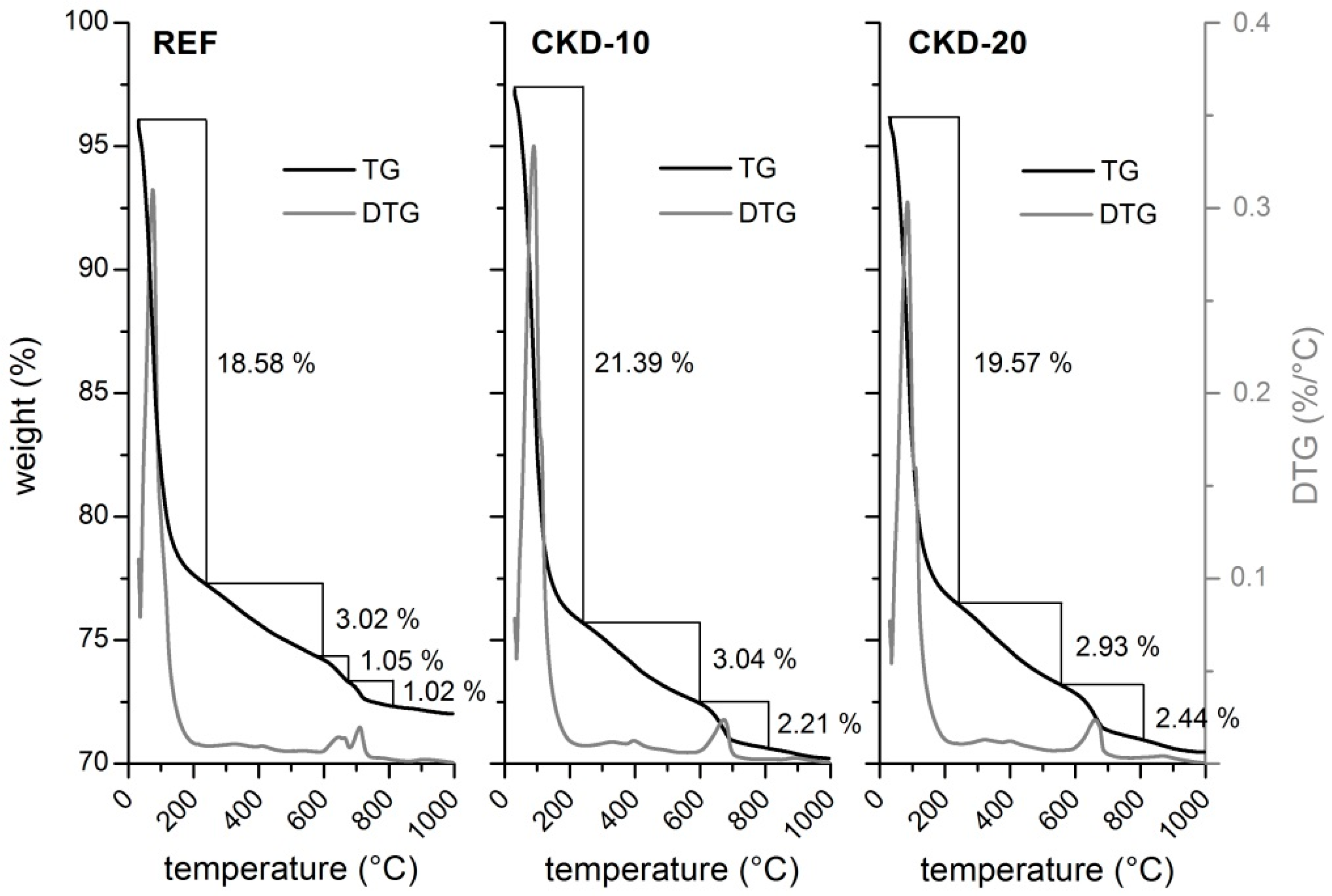

2.5. Thermogravimetry (TG)

3. Results and Discussion

4. Conclusions

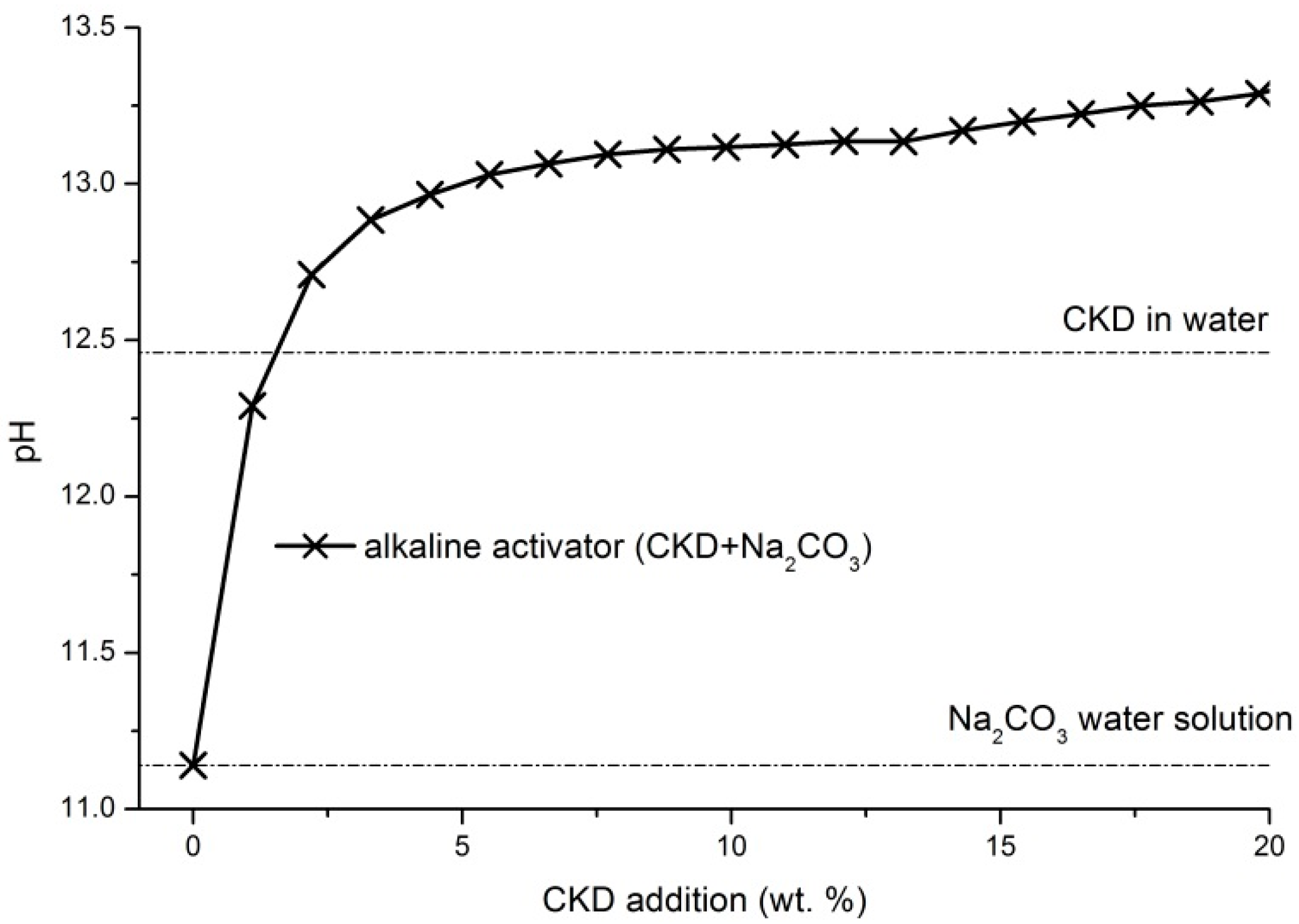

- The combination of CKD and sodium carbonate together with sodium water glass used as alkaline activators leads to the secondary formation of sodium hydroxide causing an increase in the pH of water solution in mixtures which promote the dissolution process of activated aluminosilicate.

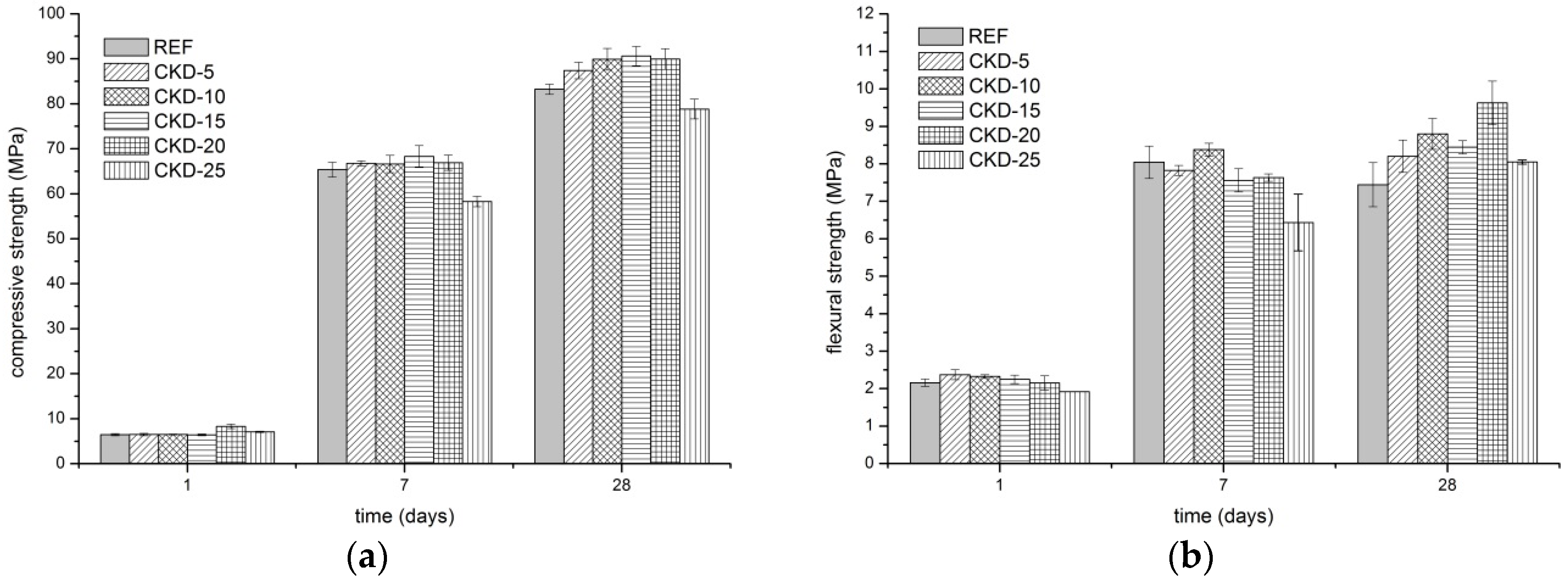

- Higher degree of BFS dissolution influences the hydration process in the sense of higher binder phase creation which positively affects the mechanical properties up to a certain limit.

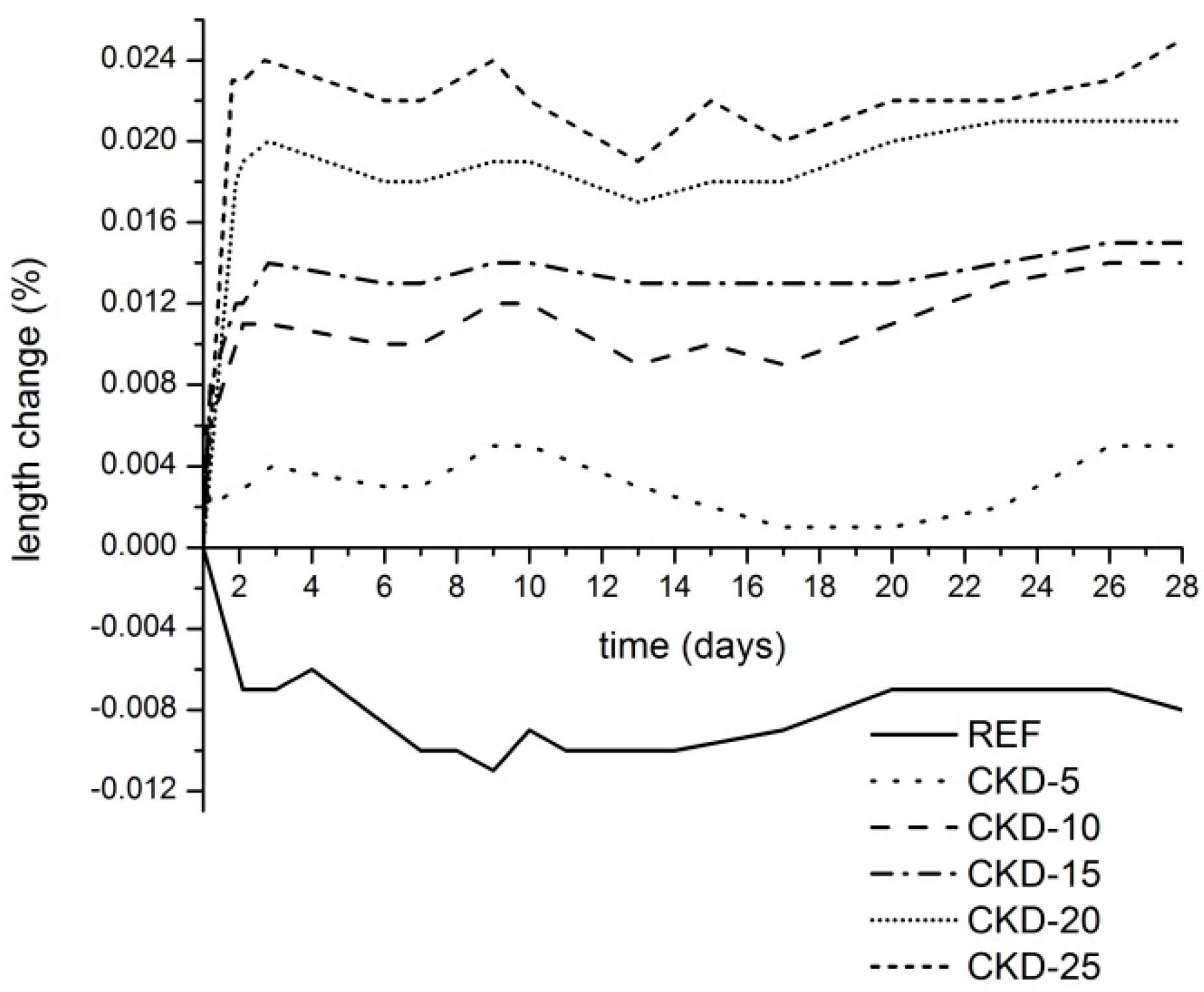

- The CKD content in alkali-activated BFS causes a small expansion of the whole system and thereafter the shrinkage cracking connected with the decrease of compressive as well as flexural strengths is reduced.

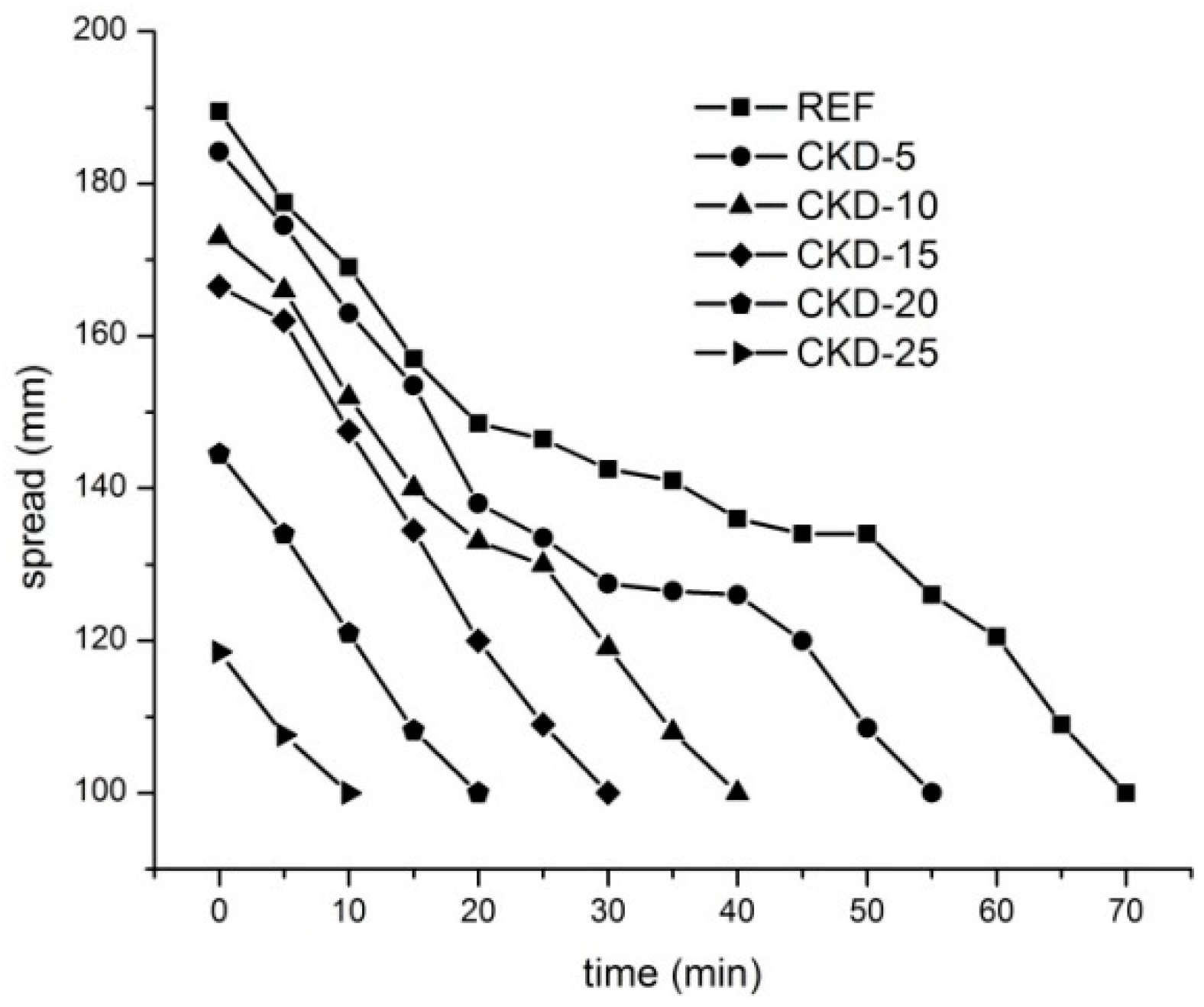

- The addition of CKD into the alkali-activated systems decreases the workability due to early hydration of lime resulting in the system inhomogeneity which can strongly influence the mechanical properties.

- The production of alkali-activated BFS binders with CKD addition depends on its optimum dosage into the system, moreover, the CKD chemical and phase composition must always be taken into account.

Author Contributions

Funding

Conflicts of Interest

References

- Blanchard, O. Energy-consumption and modes of industrialization—Four developing-countries. Energy Policy 1992, 20, 1174–1185. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2013. [Google Scholar]

- Siddique, R. Utilization of cement kiln dust (CKD) in cement mortar and concrete—An overview. Resour. Conserv. Recycl. 2006, 48, 315–338. [Google Scholar] [CrossRef]

- Eckert, J.O.; Guo, Q.H. Heavy metals in cement and cement kiln dust from kilns co-fired with hazardous waste-derived fuel: Application of EPA leaching and acid-digestion procedures. J. Hazard. Mater. 1998, 59, 55–93. [Google Scholar] [CrossRef]

- Duxson, P.; Fernandez-Jimenez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Palomo, A.; Kavalerova, E.; Fernandez-Jimeneza, A.; Krivenko, P.; Garcia-Lodeiro, I.; Maltseva, O. A Review on Alkaline Activation: New Analytical Perspectives. 2015. Available online: http://digital.csic.es/handle/10261/110274 (accessed on 18 September 2018).

- Konsta-Gdoutos, M.S.; Shah, S.P. Hydration and properties of novel blended cements based on cement kiln dust and blast furnace slag. Cem. Concr. Res. 2003, 33, 1269–1276. [Google Scholar] [CrossRef]

- Lachemi, M.; Sahmaran, M.; Hossain, K.M.A.; Lotfy, A.; Shehata, M. Properties of controlled low-strength materials incorporating cement kiln dust and slag. Cem. Concr. Compos. 2010, 32, 623–629. [Google Scholar] [CrossRef]

- Kalina, L.; Koplik, J.; Soukal, F.; Masilko, J.; Jaskowiecova, L. Potential uses of geopolymers to immobilize toxic metals from by-products materials. Environ. Eng. Manag. J. 2012, 11, 579–584. [Google Scholar] [CrossRef]

- Wang, K.; Shah, S.P.; Mishulovich, A. Effects of curing temperature and NaOH addition on hydration and strength development of clinker-free CKD-fly ash binders. Cem. Concr. Res. 2004, 34, 299–309. [Google Scholar] [CrossRef]

- Thomas, J.J.; Allen, A.J.; Jennings, H.M. Density and water content of nanoscale solid C-S-H formed in alkali-activated slag (AAS) paste and implications for chemical shrinkage. Cem. Concr. Res. 2012, 42, 377–383. [Google Scholar] [CrossRef]

- Chen, W.; Brouwers, H.J.H. The hydration of slag, part 1: Reaction models for alkali-activated slag. J. Mater. Sci. 2007, 42, 428–443. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson: London, UK, 2011. [Google Scholar]

- Troli, R.; Collepardi, M. Shrinkage-compensating concretes for special structures. In Proceedings of the 4th International Conference on Non-Traditional Cement and Concrete, Brno, Czech Republic, 27–30 June 2011; pp. 18–36. [Google Scholar]

- Collepardi, M.; Borsoi, A.; Collepardi, S.; Olagot, J.J.O.; Troli, R. Effects of shrinkage reducing admixture in shrinkage compensating concrete under non-wet curing conditions. Cem. Concr. Compos. 2005, 27, 704–708. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.H.; Li, L.T. A review: The comparison between alkali-activated slag (Si + Ca) and metakaolin (Si + Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.; Puertas, F.; Arteaga, A. Determination of kinetic equations of alkaline activation of blast furnace slag by means of calorimetric data. J. Therm. Anal. Calorim. 1998, 52, 945–955. [Google Scholar] [CrossRef]

- Shi, C.J.; Day, R.L. A calorimetric study of early hydration of alkali-slag cements. Cem. Concr. Res. 1995, 25, 1333–1346. [Google Scholar] [CrossRef]

- Ke, X.Y.; Bernal, S.A.; Provis, J.L. Controlling the reaction kinetics of sodium carbonate-activated slag cements using calcined layered double hydroxides. Cem. Concr. Res. 2016, 81, 24–37. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodriguez, E.D.; de Gutierrez, R.M.; Provis, J.L. Performance at High Temperature of Alkali-Activated Slag Pastes Produced with Silica Fume and Rice Husk Ash Based Activators. 2015. Available online: http://materconstrucc.revistas.csic.es/index.php/materconstrucc/article/view/1689/2071 (accessed on 18 September 2018).

- Johnson, D.R.; Robb, W.A. Gaylussite—Thermal properties by simultaneous thermal-analysis. Am. Mineral. J. Earth Planet. Mater. 1973, 58, 778–784. [Google Scholar]

- Alarcon-Ruiz, L.; Platret, G.; Massieu, E.; Ehrlacher, A. The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem. Concr. Res. 2005, 35, 609–613. [Google Scholar] [CrossRef]

| Raw Material | Chemical Composition/wt % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | CaO | Na2O | K2O | MgO | SO3 | Fe2O3 | TiO2 | MnO | Cl− | |

| BFS | 34.7 | 9.1 | 41.1 | 0.4 | 0.9 | 10.5 | 1.4 | 0.3 | 1.0 | 0.6 | – |

| CKD | 11.9 | 4.2 | 45.7 | 0.4 | 16.9 | 0.9 | 7.2 | 2.4 | 0.3 | – | 10.1 |

| Mixture Designation | REF | CKD-5 | CKD-10 | CKD-15 | CKD-20 | CKD-25 |

|---|---|---|---|---|---|---|

| BFS | 21.6 | 20.5 | 19.4 | 18.3 | 17.2 | 16.1 |

| CKD | – | 1.1 | 2.2 | 3.3 | 4.4 | 5.5 |

| Na2CO3 | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 |

| Na-water glass | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 |

| water | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 |

| standard sand | 64.8 | 64.8 | 64.8 | 64.8 | 64.8 | 64.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalina, L.; Bílek, V., Jr.; Kiripolský, T.; Novotný, R.; Másilko, J. Cement Kiln By-Pass Dust: An Effective Alkaline Activator for Pozzolanic Materials. Materials 2018, 11, 1770. https://doi.org/10.3390/ma11091770

Kalina L, Bílek V Jr., Kiripolský T, Novotný R, Másilko J. Cement Kiln By-Pass Dust: An Effective Alkaline Activator for Pozzolanic Materials. Materials. 2018; 11(9):1770. https://doi.org/10.3390/ma11091770

Chicago/Turabian StyleKalina, Lukáš, Vlastimil Bílek, Jr., Tomáš Kiripolský, Radoslav Novotný, and Jiří Másilko. 2018. "Cement Kiln By-Pass Dust: An Effective Alkaline Activator for Pozzolanic Materials" Materials 11, no. 9: 1770. https://doi.org/10.3390/ma11091770

APA StyleKalina, L., Bílek, V., Jr., Kiripolský, T., Novotný, R., & Másilko, J. (2018). Cement Kiln By-Pass Dust: An Effective Alkaline Activator for Pozzolanic Materials. Materials, 11(9), 1770. https://doi.org/10.3390/ma11091770