Mechanical Behavior of Liquid Nitrile Rubber-Modified Epoxy Resin under Static and Dynamic Loadings: Experimental and Constitutive Analysis

Abstract

:1. Introduction

2. Specimen Fabrications

3. Experiments

3.1. Quasi-Static Compression Experiments

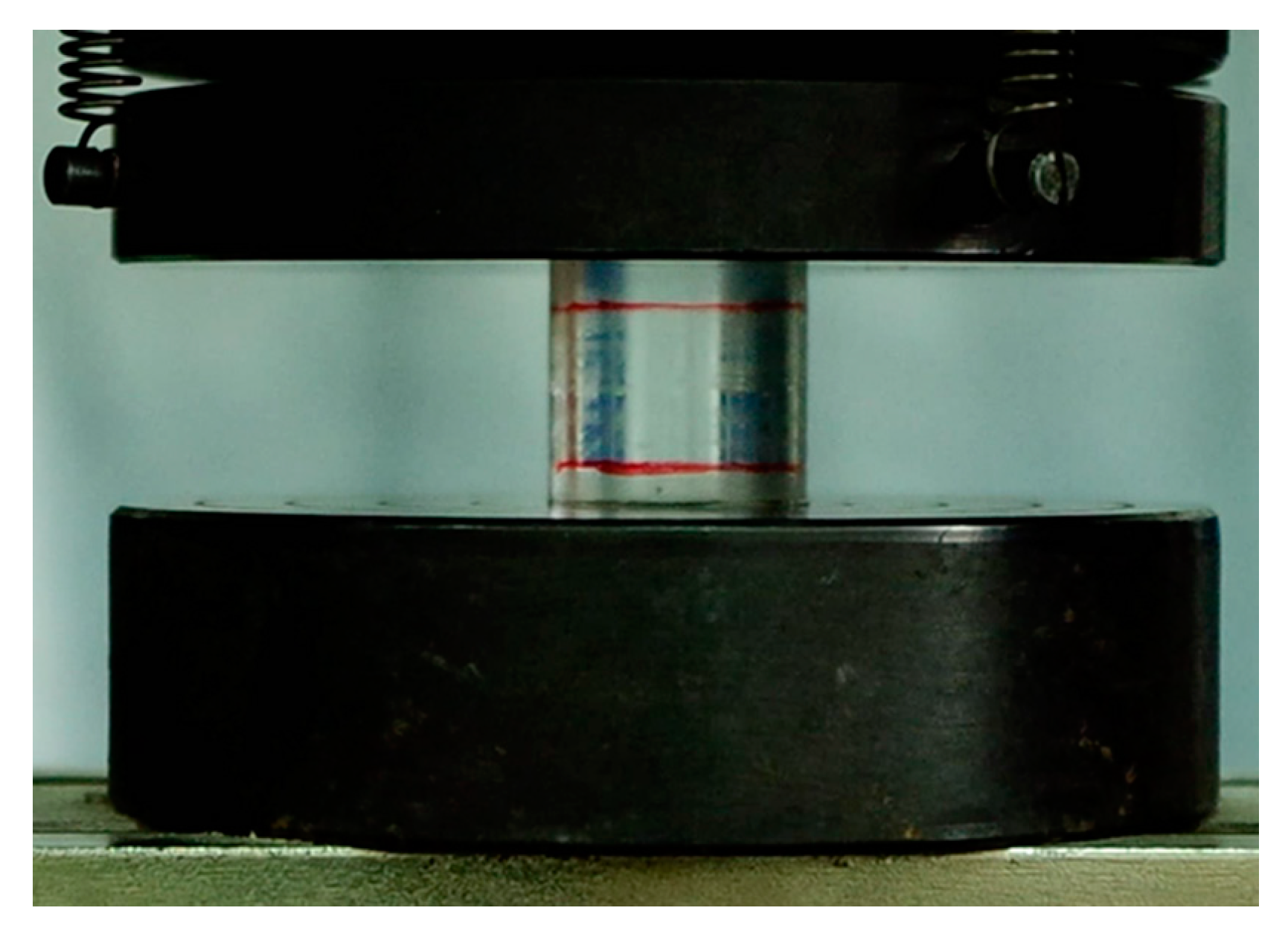

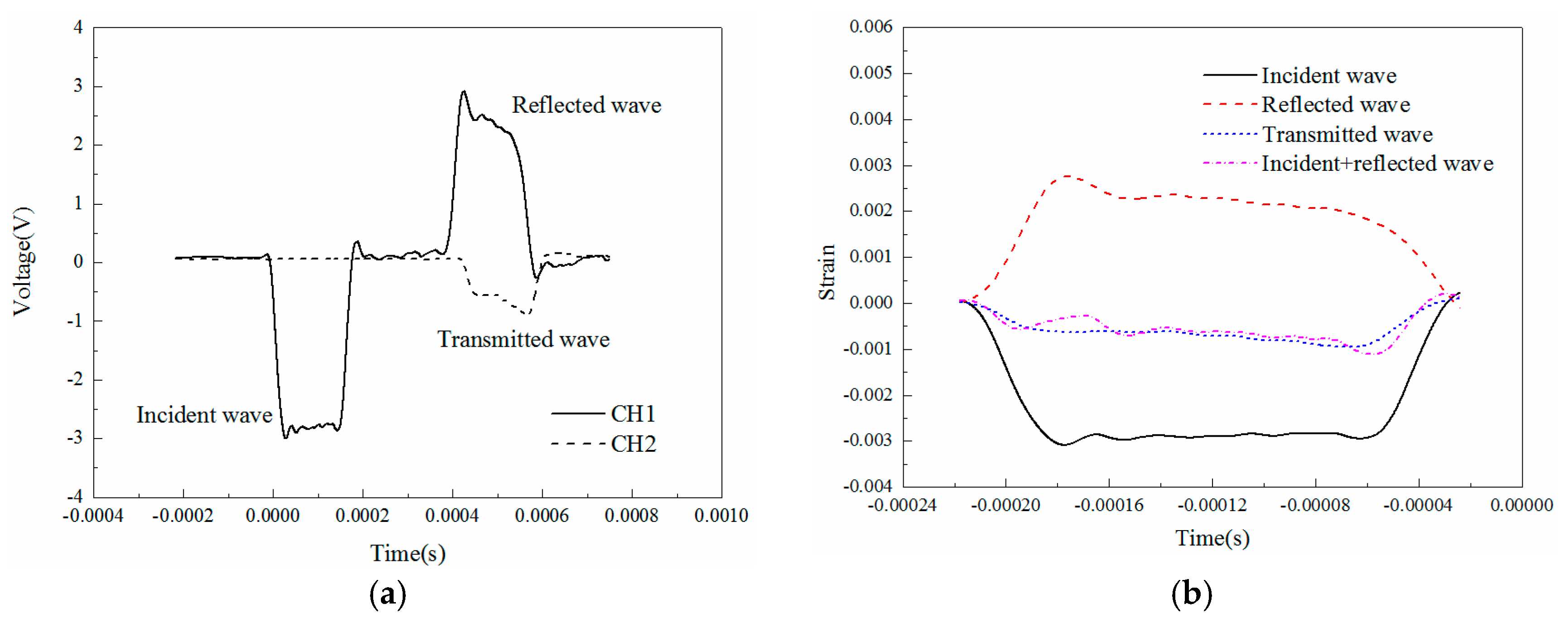

3.2. SHPB Compression Experiments

4. Experimental Results and Discussion

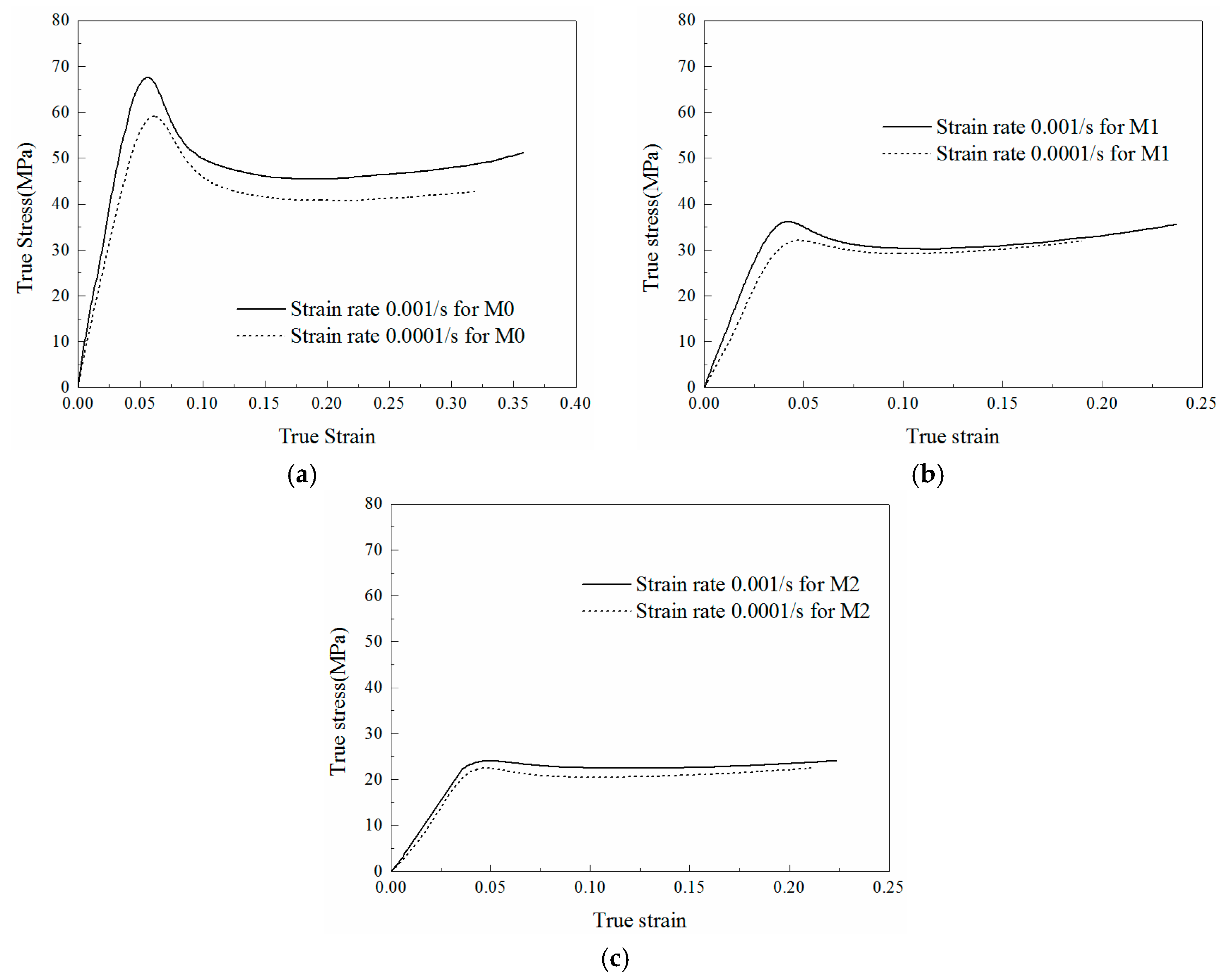

4.1. Quasi-Static Experimental Results

4.1.1. Stress-Strain Relationship

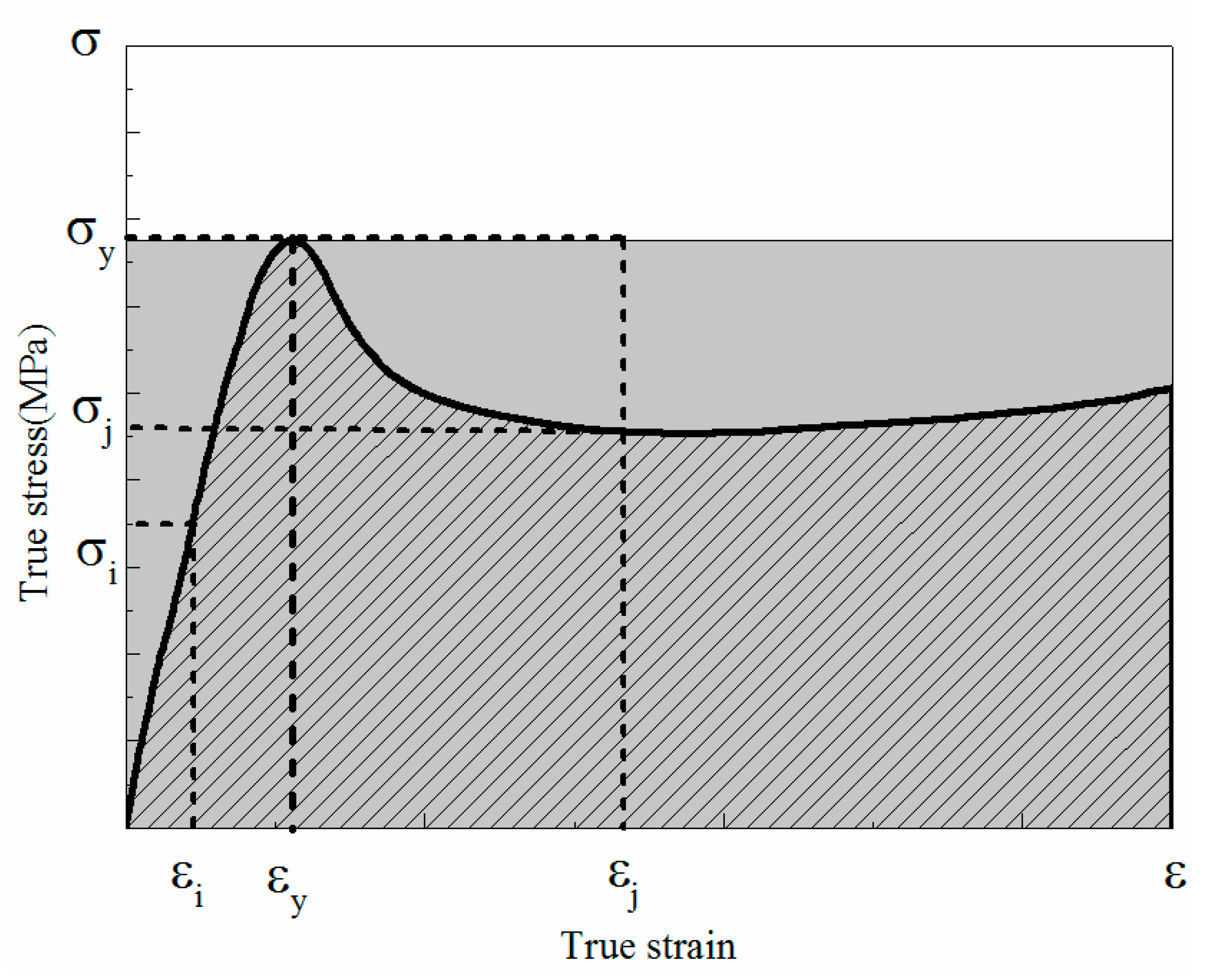

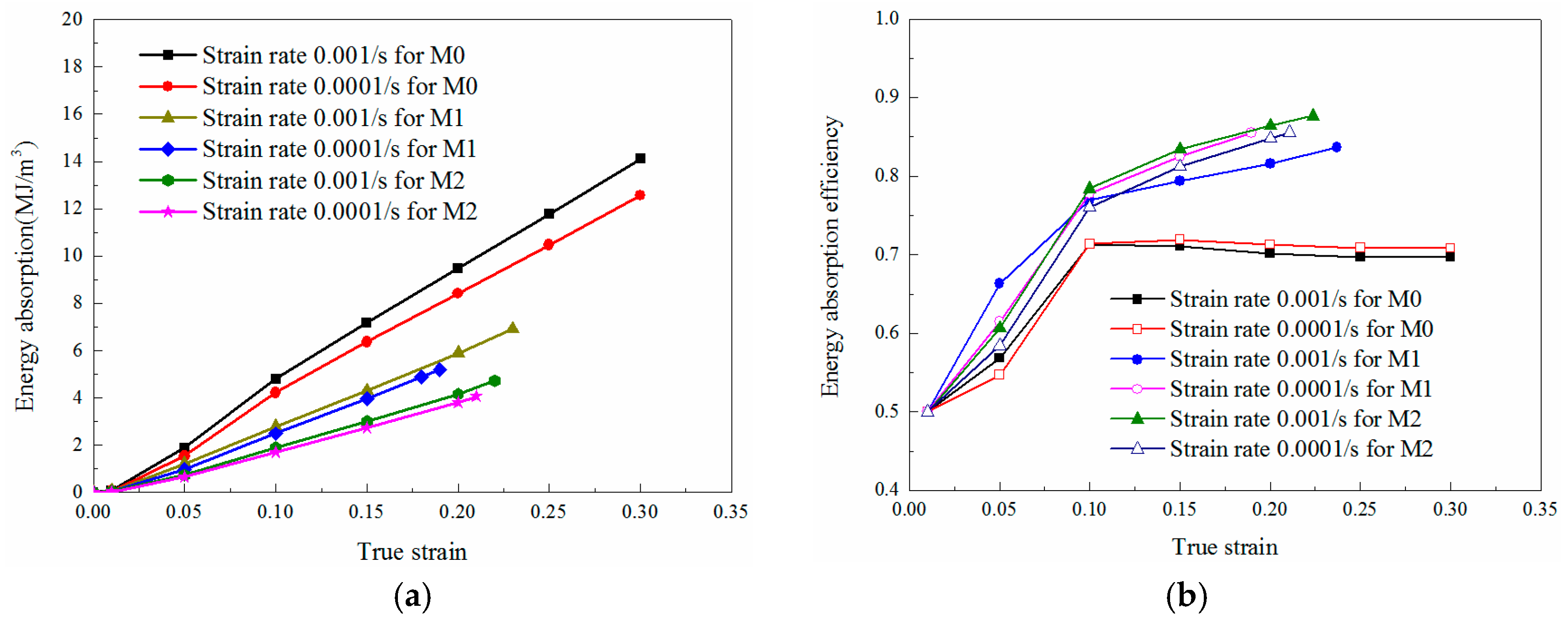

4.1.2. Energy Absorption Analysis

4.2. SHPB Experimental Results

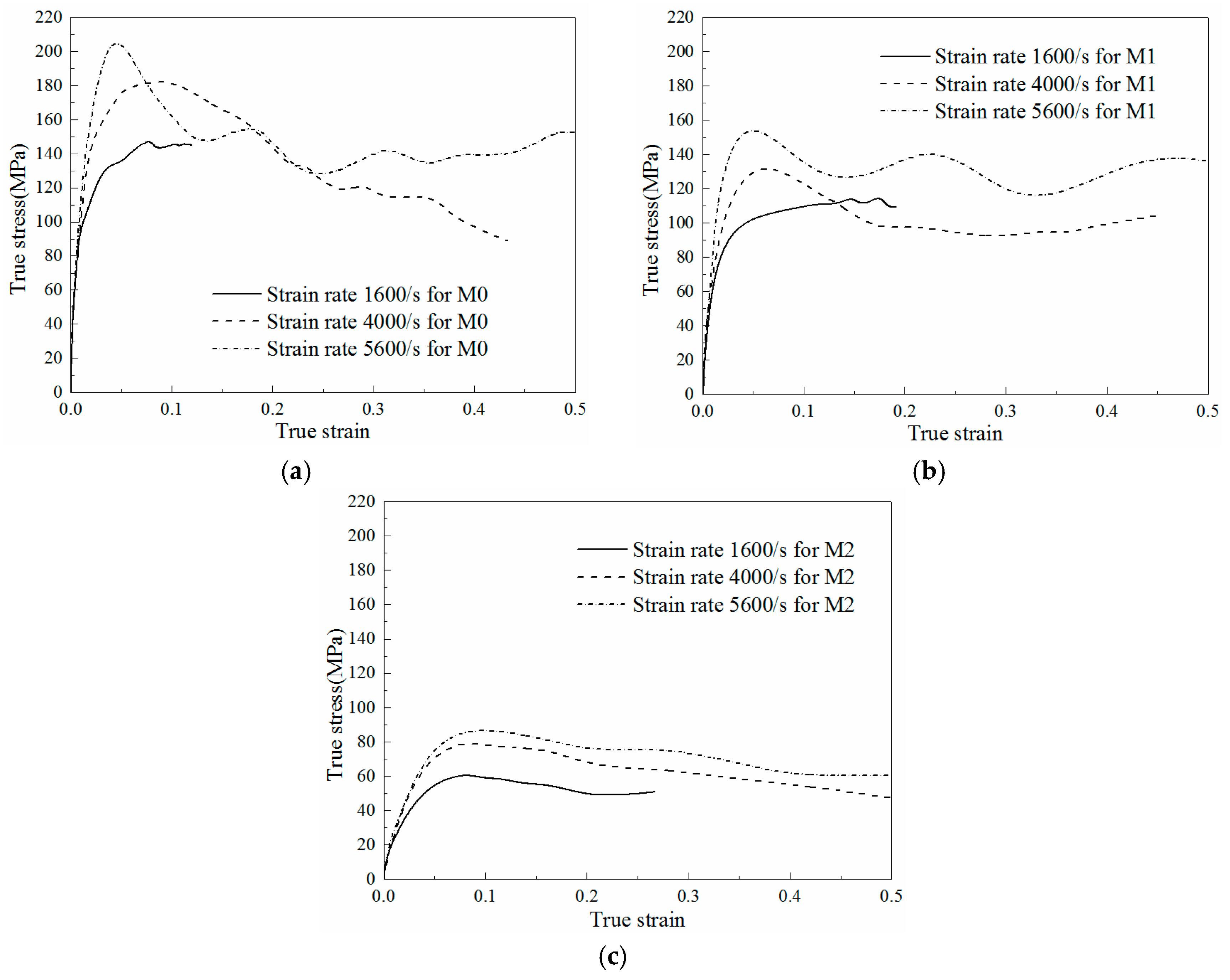

4.2.1. Dynamic Stress-Strain Relationship

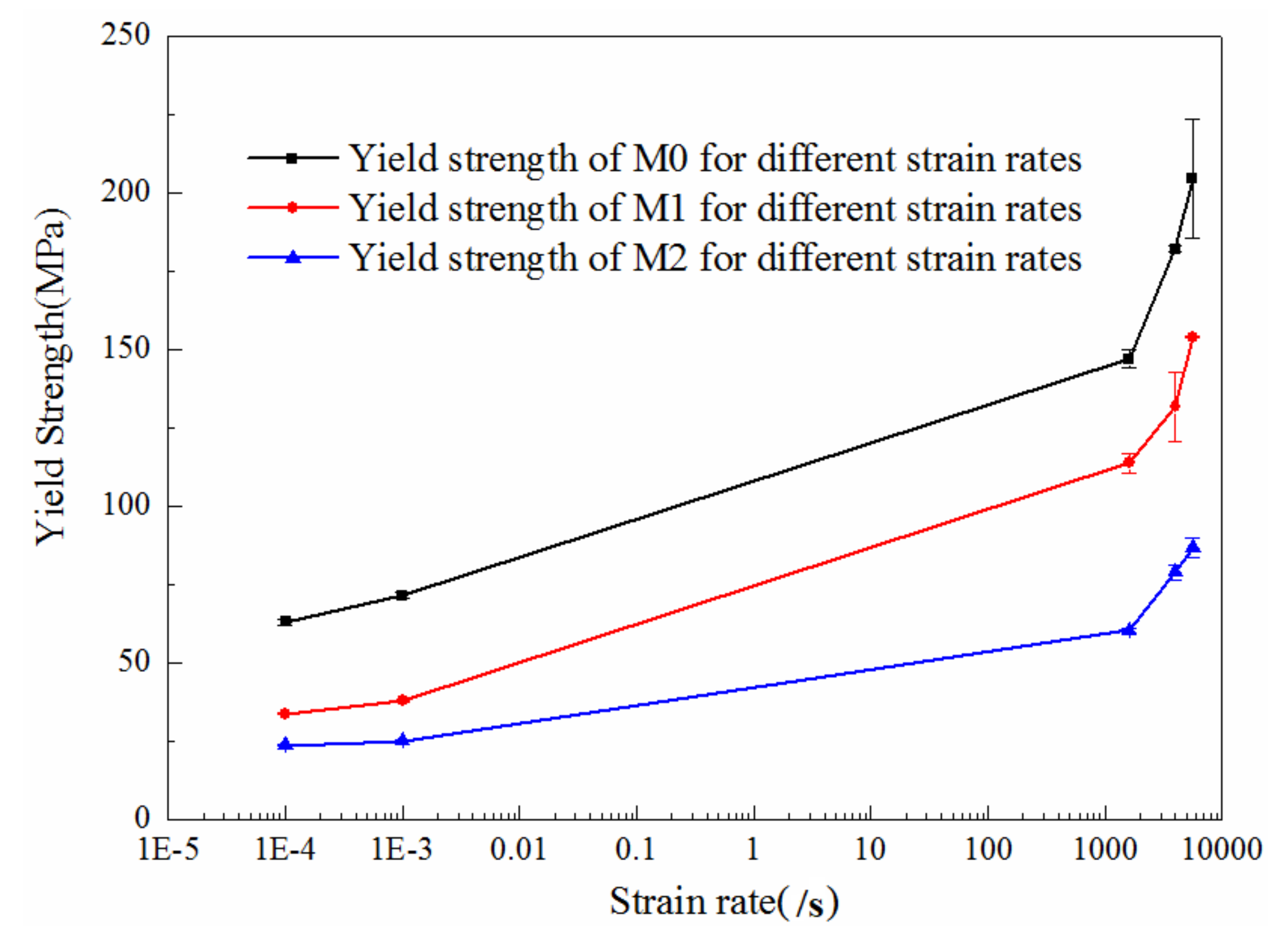

4.2.2. Strain Rate Effect

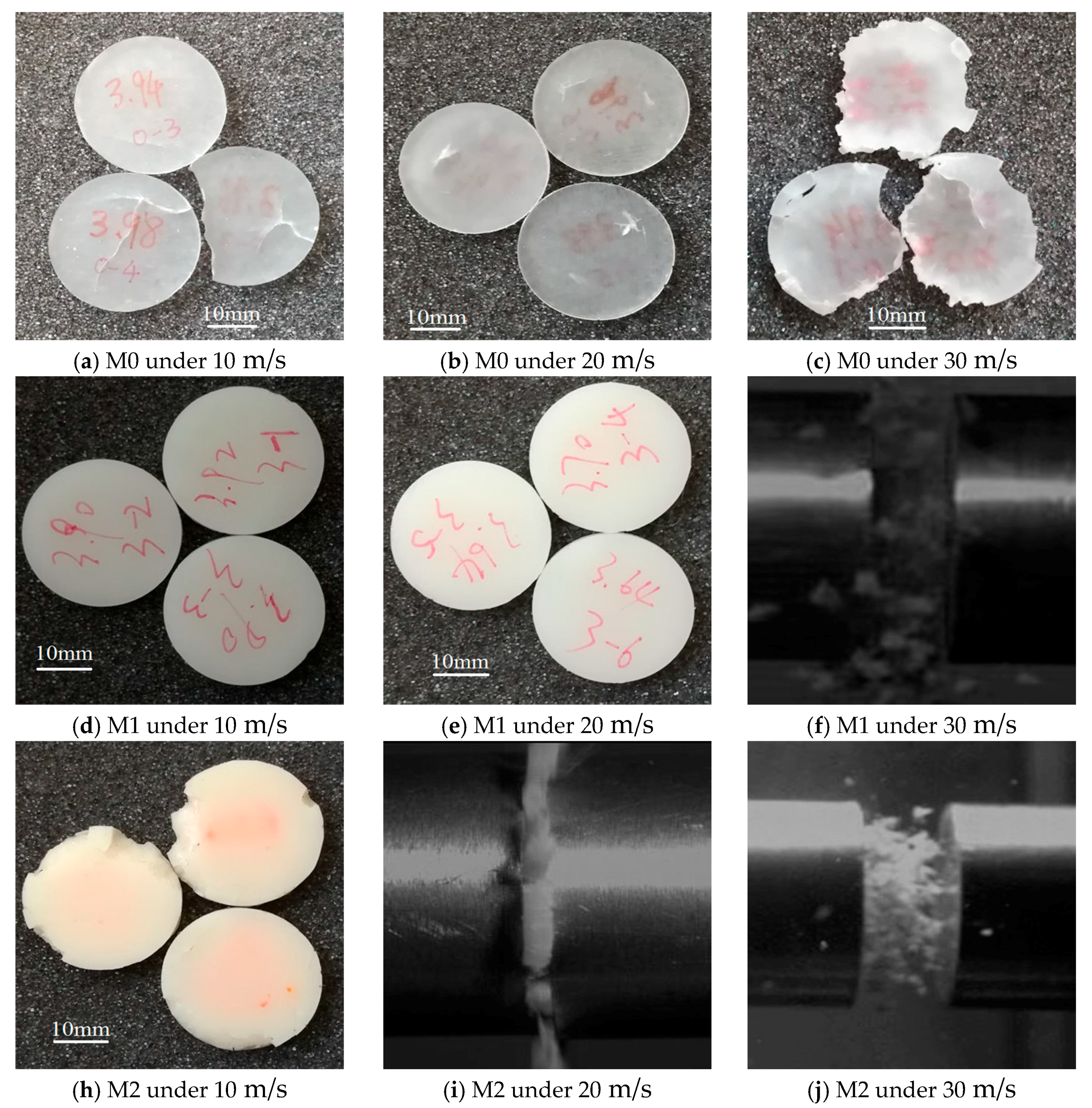

4.2.3. Dynamic Deformation Observation

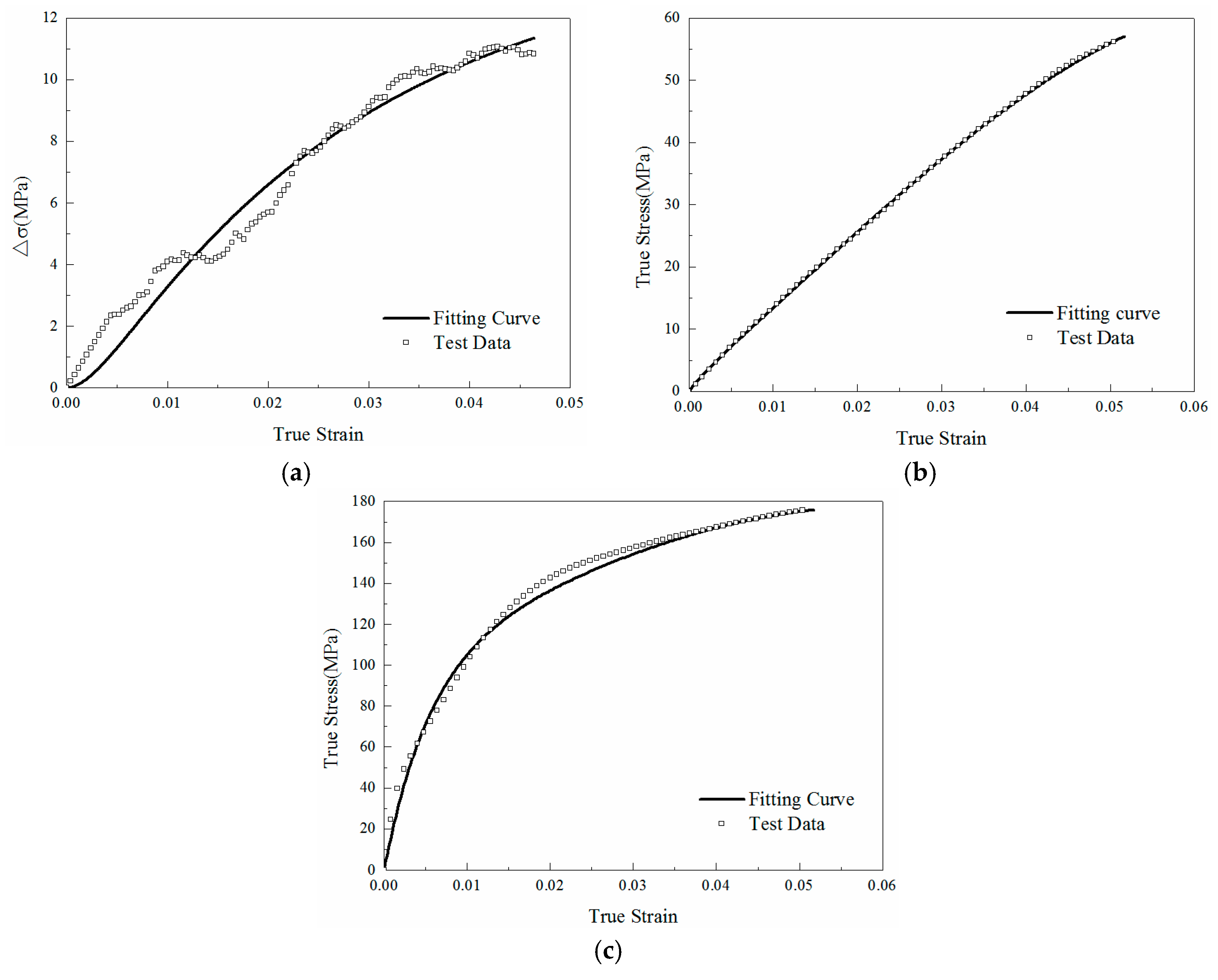

5. Model Calibration and Parameter Identification

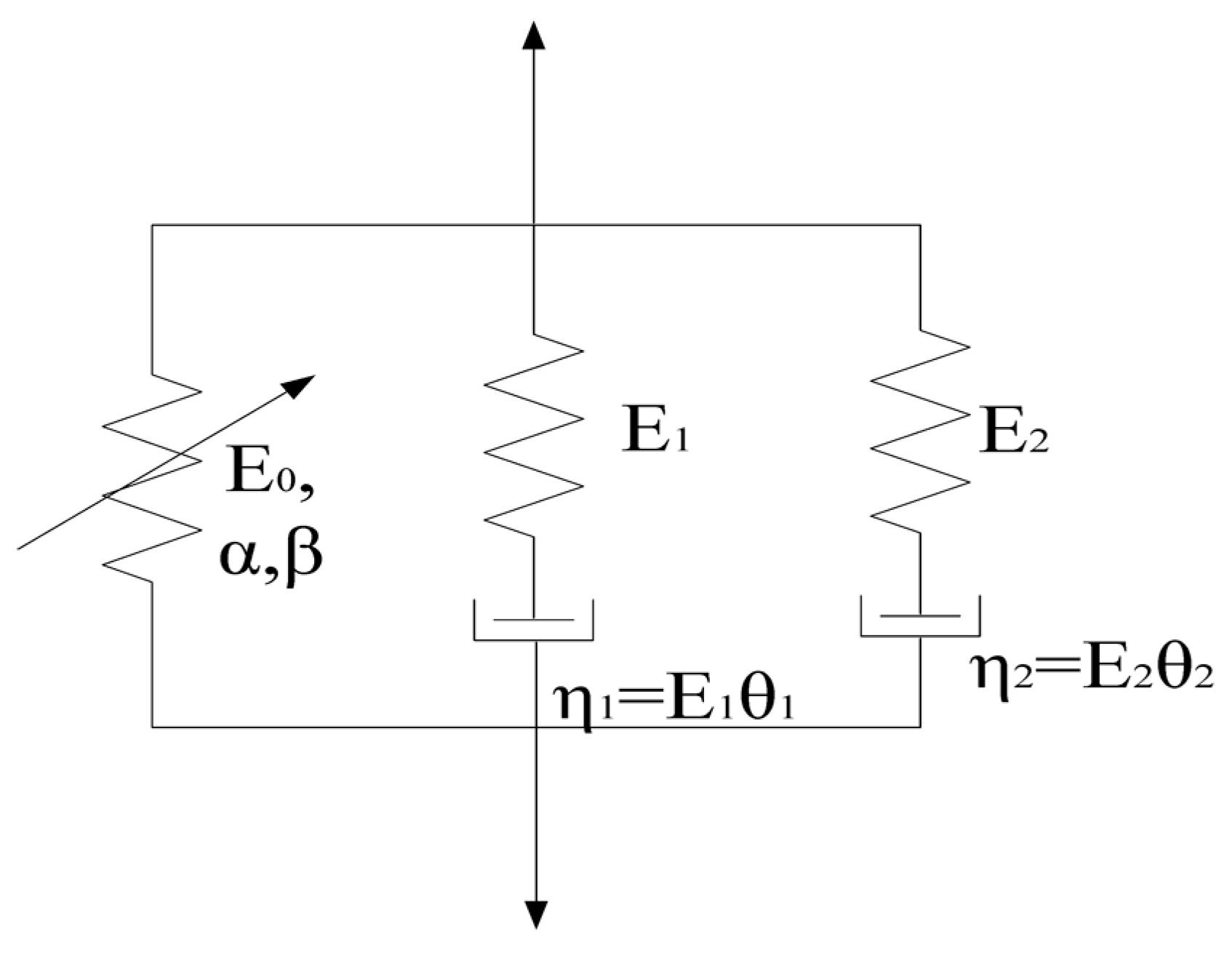

5.1. Viscoelastic Material Models

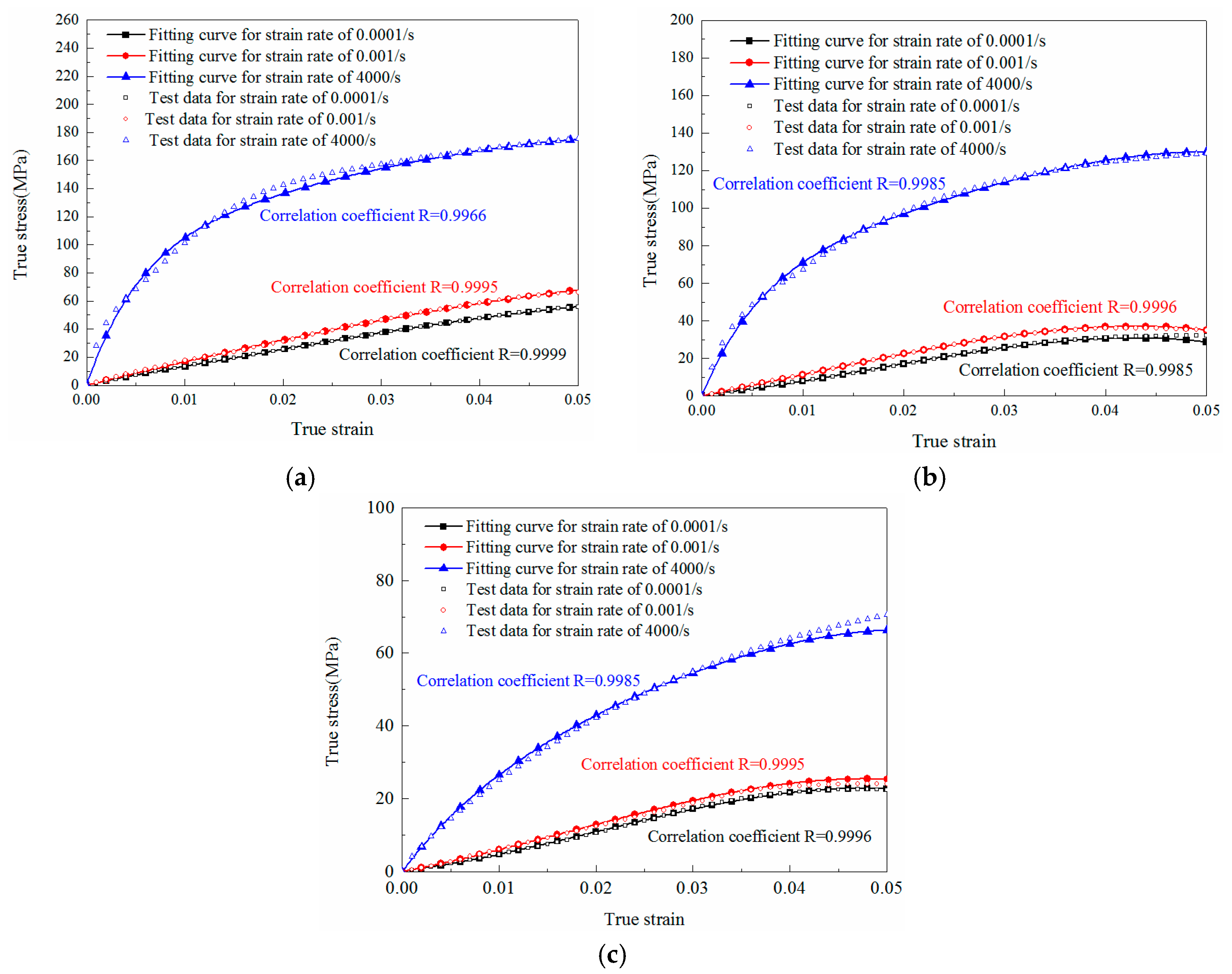

5.2. Parameter Identification

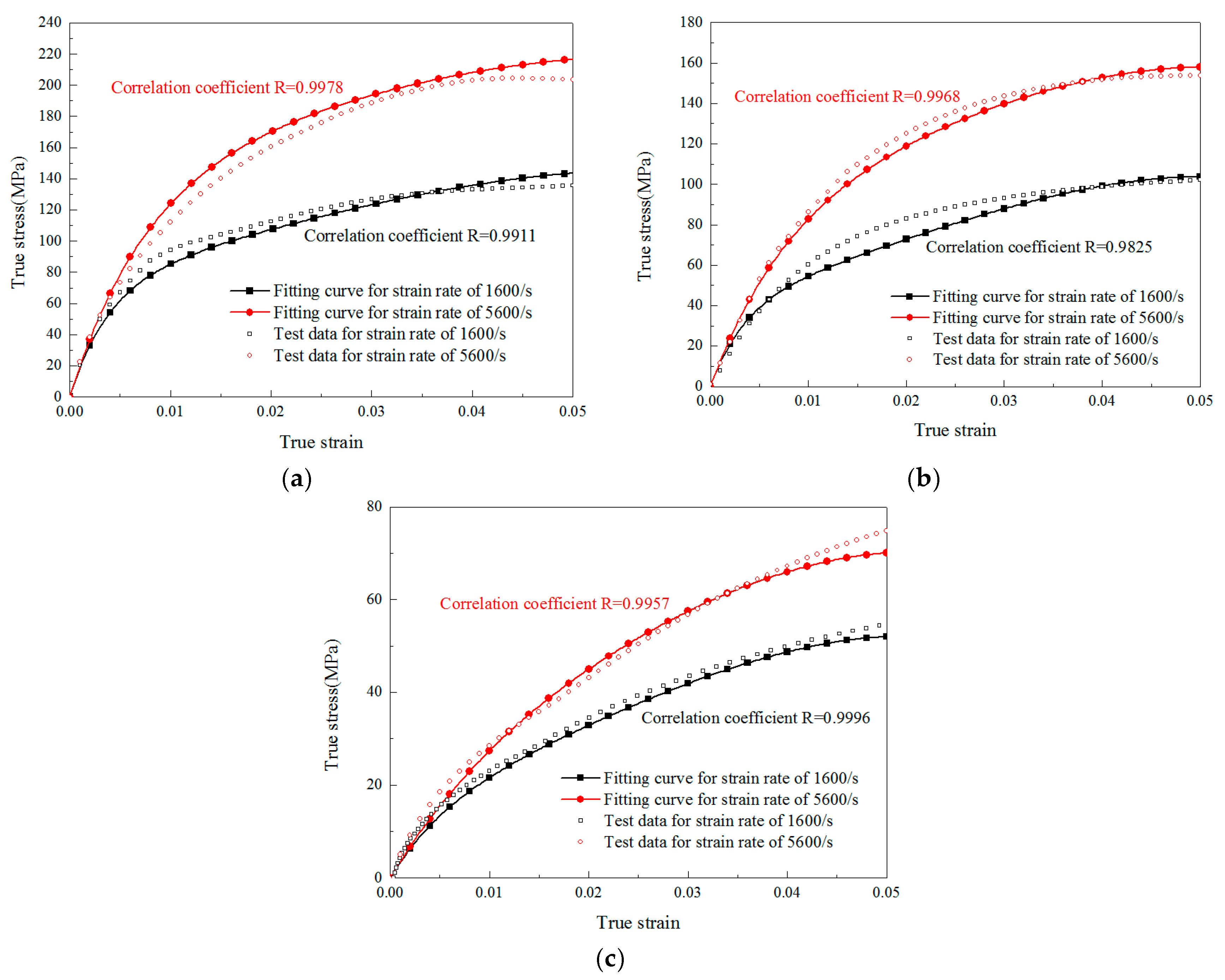

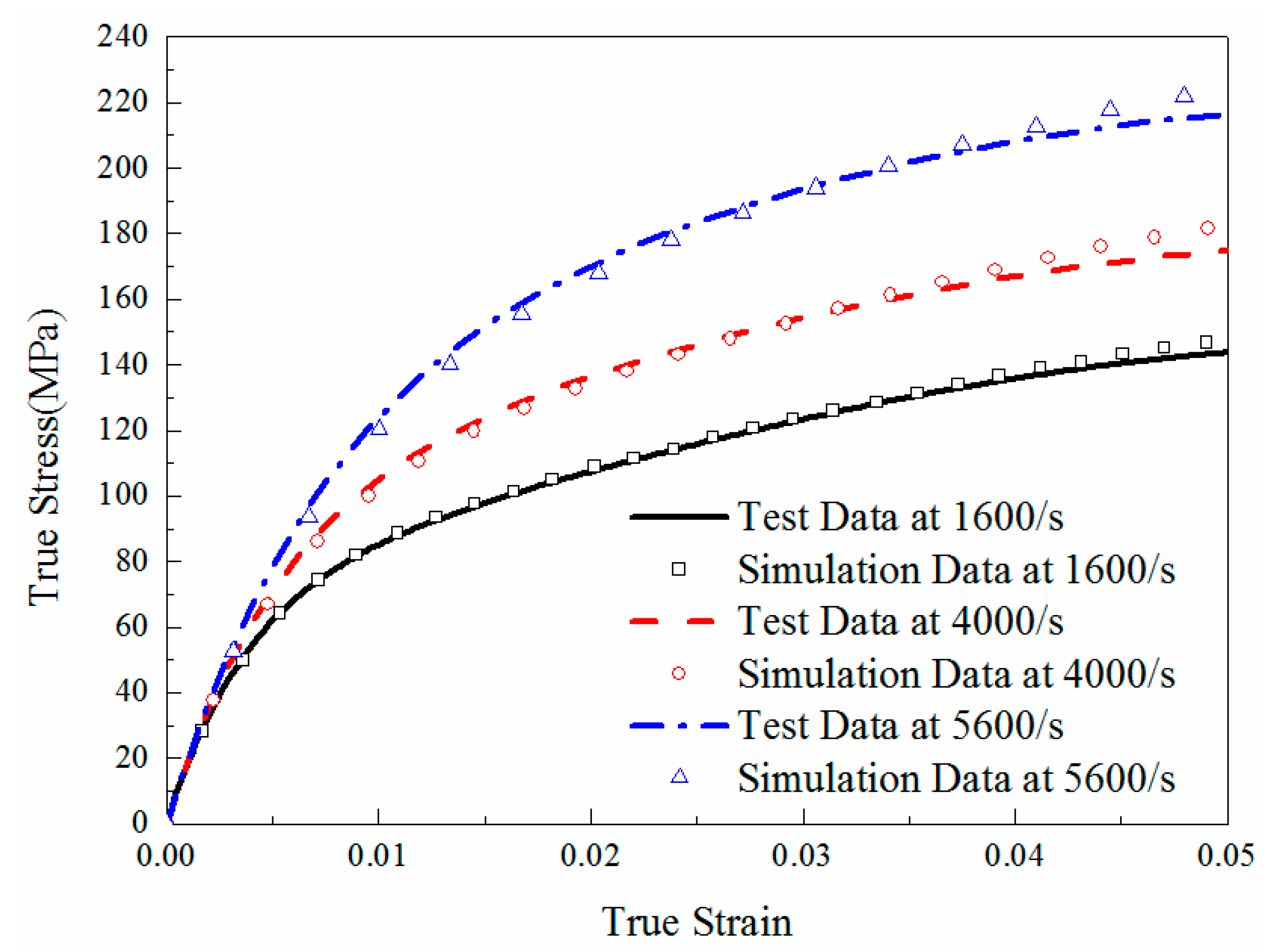

5.3. Prediction of Compression Behavior under Other Strain Rates

6. FE Simulations

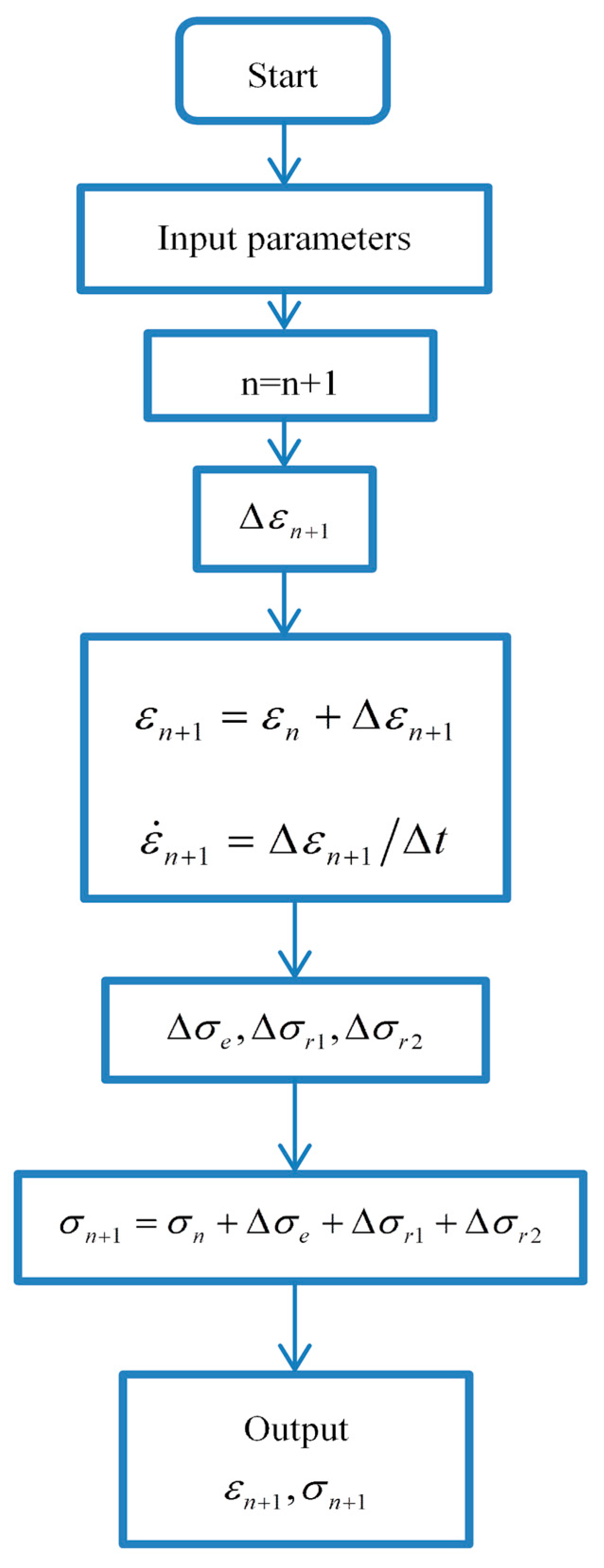

6.1. Incremented Algorithm of ZWT Constitutive Model in the Finite Element Analysis

6.2. Simulation Verification

7. Conclusions

- (1)

- The strain rate effect of epoxy resin has been observed. Not only the yield strength but also the elastic stiffness of epoxy resin enhances with the increasing of strain rate.

- (2)

- The LNBR modifier can effectively increase the energy absorption efficiency and the strain-softening effect of the material decreases with increasing LNBR mass fractions. Meanwhile, the specimens with 10% LNBR additive can enhance their integrity under 10 m/s projectile impact.

- (3)

- The yield strengths and elastic stiffness of the modified epoxy resins are reduced by the soft rubber additive, which are also embodied in the ZWT model parameters.

- (4)

- The algorithm mentioned in this study can embed the ZWT constitutive model into the LS-DYNA software successfully, which would have many applications in the engineering.

Author Contributions

Funding

Conflicts of Interest

References

- Mlyniec, A.; Korta, J.; Uhl, T. Structurally based constitutive model of epoxy adhesives incorporating the influence of post-curing and thermolysis. Compos. Part B Eng. 2016, 86, 160–167. [Google Scholar] [CrossRef]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Zhang, J.; Mouritz, A.P.; Wang, C.H. Improving the toughness and electrical conductivity of epoxy nanocomposites by using aligned carbon nanofibres. Compos. Sci. Technol. 2015, 117, 146–158. [Google Scholar] [CrossRef]

- Lee, S.K.; Kim, M.W.; Park, C.J.; Chol, M.J.; Kim, G.; Cho, J.M.; Choi, C.H. Effect of fiber orientation on acoustic and vibration response of a carbon fiber/epoxy composite plate: Natural vibration mode and sound radiation. Int. J. Mech. Sci. 2016, 117, 162–173. [Google Scholar] [CrossRef]

- Naik, N.K.; Pandya, K.S.; Kavala, V.R.; Zhang, W.; Koratkar, N.A. Alumina nanoparticle filled epoxy resin: High strain rate compressive behavior. Polym. Eng. Sci. 2014, 54, 2896–2901. [Google Scholar] [CrossRef]

- Rosso, P.; Ye, L.; Friedrich, K.; Sprenger, S. A toughened epoxy resin by silica nanoparticle reinforcement. J. Appl. Polym. Sci. 2006, 100, 1849–1855. [Google Scholar] [CrossRef]

- Makota, I.; Kishimoto, W.; Okita, K.; Nakayama, H. Improvement of impact fatigue strength of adhesive joint by CTBN modification. J. Appl. Polym. Sci. 1984, 29, 373–382. [Google Scholar] [CrossRef]

- Manzione, L.T.; Gillham, J.K.; McPherson, C.A. Rubber-modified epoxies. I. Transitions and morphology. J. Appl. Polym. Sci. 1981, 26, 889–905. [Google Scholar] [CrossRef]

- Fakhar, A.; Seyed Salehi, M.; Keivani, M.; Abadyan, M. Comprehensive Study on Using VTBN Reactive Oligomer for Rubber Toughening of Epoxy Resin and Composite. Polym. Plast. Technol. Eng. 2016, 55, 343–355. [Google Scholar] [CrossRef]

- Liu, H.Y.; Wang, G.T.; Mai, Y.W.; Zeng, Y. On fracture toughness of nano-particle modified epoxy. Compos. Part B Eng. 2011, 42, 2170–2175. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Masania, K.; Sohn Lee, J.; Taylor, A.C.; Sprenger, S. The toughness of epoxy polymers and fibre composites modified with rubber microparticles and silica nanoparticles. J. Mater. Sci. 2010, 45, 1193–1210. [Google Scholar] [CrossRef]

- Poulain, X.; Benzerga, A.A.; Goldberg, R.K. Finite-strain elasto-viscoplastic behavior of an epoxy resin: Experiments and modeling in the glassy regime. Int. J. Plast. 2014, 62, 138–161. [Google Scholar] [CrossRef]

- Bergstrom, J.S.; Boyce, M.C. Constitutive modeling of the large strain time-dependent behavior of elastomers. J. Mech. Phys. Solids 1998, 46, 931–954. [Google Scholar] [CrossRef]

- Mulliken, A.D.; Boyce, M.C. Mechanics of the rate-dependent elastic-plastic deformation of glassy polymers from low to high strain rates. Int. J. Solids Struct. 2006, 43, 1331–1356. [Google Scholar] [CrossRef]

- Sue, H.J. Study of rubber-modified brittle epoxy systems. Part II: Toughening mechanisms under mode-I fracture. Polym. Eng. Sci. 1991, 31, 275–288. [Google Scholar] [CrossRef]

- Sun, C.T.; Gates, T.S. Elastic/visoplastic constitutive model for fiber reinforced thermoplastic composites. AIAA J. 1990, 29, 457–463. [Google Scholar]

- Kontou, E. Viscoplastic deformation of an epoxy resin at elevated temperatures. J. Appl. Polym. Sci. 2006, 101, 2027–2033. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, J.S.; Zhang, Z.S.; Chen, X. Rate-dependent compressive behavior of EPDM insulation: Experimental and constitutive analysis. Mech. Mater. 2016, 96, 30–38. [Google Scholar] [CrossRef]

- Zhang, L.H.; Yao, X.H.; Zang, S.G.; Han, Q. Temperature and strain rate dependent tensile behavior of a transparent polyurethane interlayer. Mater. Des. 2015, 65, 1181–1188. [Google Scholar] [CrossRef]

- Fard, M.Y.; Chattopadhyay, A.; Liu, Y. Multi-linear stress-strain and closed-form moment curvature response of epoxy resin materials. Int. J. Mech. Sci. 2012, 57, 9–18. [Google Scholar] [CrossRef]

- Iwamoto, T.; Nagai, T.; Sawa, T. Experimental and computational investigations on strain rate sensitivity and deformation behavior of bulk materials made of epoxy resin structural adhesive. Int. J. Solids Struct. 2010, 47, 175–185. [Google Scholar] [CrossRef]

- Lee, C.S.; Lee, J.M. Anisotropic elasto-viscoplastic damage model for glass-fiber-reinforced polyurethane foam. J. Compos. Mater. 2014, 48, 3367–3380. [Google Scholar] [CrossRef]

- Wang, F.S.; Yue, Z.F. Numerical simulation of damage and failure in aircraft windshield structure against bird strike. Mater. Des. 2010, 31, 687–695. [Google Scholar] [CrossRef]

- Zhao, H.; Gary, G. On the use of SHPB techniques to determine the dynamic behavior of materials in the range of small strains. Int. J. Solids Struct. 1996, 33, 3363–3375. [Google Scholar] [CrossRef]

- Xiao, L.J.; Song, W.D.; Wang, C.; Liu, H.Y.; Tang, H.P.; Wang, J.Z. Mechanical behavior of open-cell rhombic dodecahedron Ti-6Al-4V lattice structure. Mater. Sci. Eng. A 2015, 640, 375–384. [Google Scholar] [CrossRef]

- Wang, L.L. Stress wave propagation for nonlinear viscoelastic polymeric materials at high strain rates. Chin. J. Mech. 2003, 19, 177–183. [Google Scholar] [CrossRef]

- Lakes, R. Viscoelastic Materials, 1st ed.; Cambridge University Press: New York, NY, USA, 2009; pp. 14–26. ISBN 978-0-521-88568-3. [Google Scholar]

| Material Number | Mass/g | wt % of LNBR | ||

|---|---|---|---|---|

| Epoxy 2002A | Hardener 2002B | LNBR | ||

| M0 | 80 | 40 | 0 | 0% |

| M1 | 80 | 40 | 12 | 10% |

| M2 | 80 | 40 | 30 | 25% |

| Material | 0.0001/s | 0.001/s | 1600/s | 4000/s | 5600/s |

|---|---|---|---|---|---|

| M0 | 62.83 (±1.15) | 71.45 (±0.8) | 146.92 (±3) | 181.97 (±1.1) | 204.33 (±19) |

| M1 | 33.58 (±0.25) | 37.65 (±0.4) | 113.58 (±3) | 131.46 (±11.1) | 153.76 (±0.2) |

| M2 | 23.58 (±0.3) | 25.04 (±0.3) | 60.24 (±0.6) | 78.84 (±2.5) | 86.52 (±3) |

| Material No. | E0 (GPa) | α (GPa) | β (GPa) | E1 (GPa) | θ1 (s) | E2 (GPa) | θ2 (μs) |

|---|---|---|---|---|---|---|---|

| M0 | 1.141 | 5.765 | −136.834 | 0.573 | 27.8 | 19 | 1.38 |

| M1 | 0.505 | 25.63 | −490.71 | 0.637 | 11.17 | 12.01 | 1.46 |

| M2 | 0.29 | 17.71 | −291.58 | 0.219 | 13.7 | 3.05 | 2.19 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Gao, S.; Ou, Z.; Ye, H. Mechanical Behavior of Liquid Nitrile Rubber-Modified Epoxy Resin under Static and Dynamic Loadings: Experimental and Constitutive Analysis. Materials 2018, 11, 1565. https://doi.org/10.3390/ma11091565

Xu X, Gao S, Ou Z, Ye H. Mechanical Behavior of Liquid Nitrile Rubber-Modified Epoxy Resin under Static and Dynamic Loadings: Experimental and Constitutive Analysis. Materials. 2018; 11(9):1565. https://doi.org/10.3390/ma11091565

Chicago/Turabian StyleXu, Xiao, Shiqiao Gao, Zhuocheng Ou, and Haifu Ye. 2018. "Mechanical Behavior of Liquid Nitrile Rubber-Modified Epoxy Resin under Static and Dynamic Loadings: Experimental and Constitutive Analysis" Materials 11, no. 9: 1565. https://doi.org/10.3390/ma11091565

APA StyleXu, X., Gao, S., Ou, Z., & Ye, H. (2018). Mechanical Behavior of Liquid Nitrile Rubber-Modified Epoxy Resin under Static and Dynamic Loadings: Experimental and Constitutive Analysis. Materials, 11(9), 1565. https://doi.org/10.3390/ma11091565