Numerical Simulation and Experimental Validation of Sheet Laser Forming Processes Using General Scanning Paths

Abstract

1. Introduction

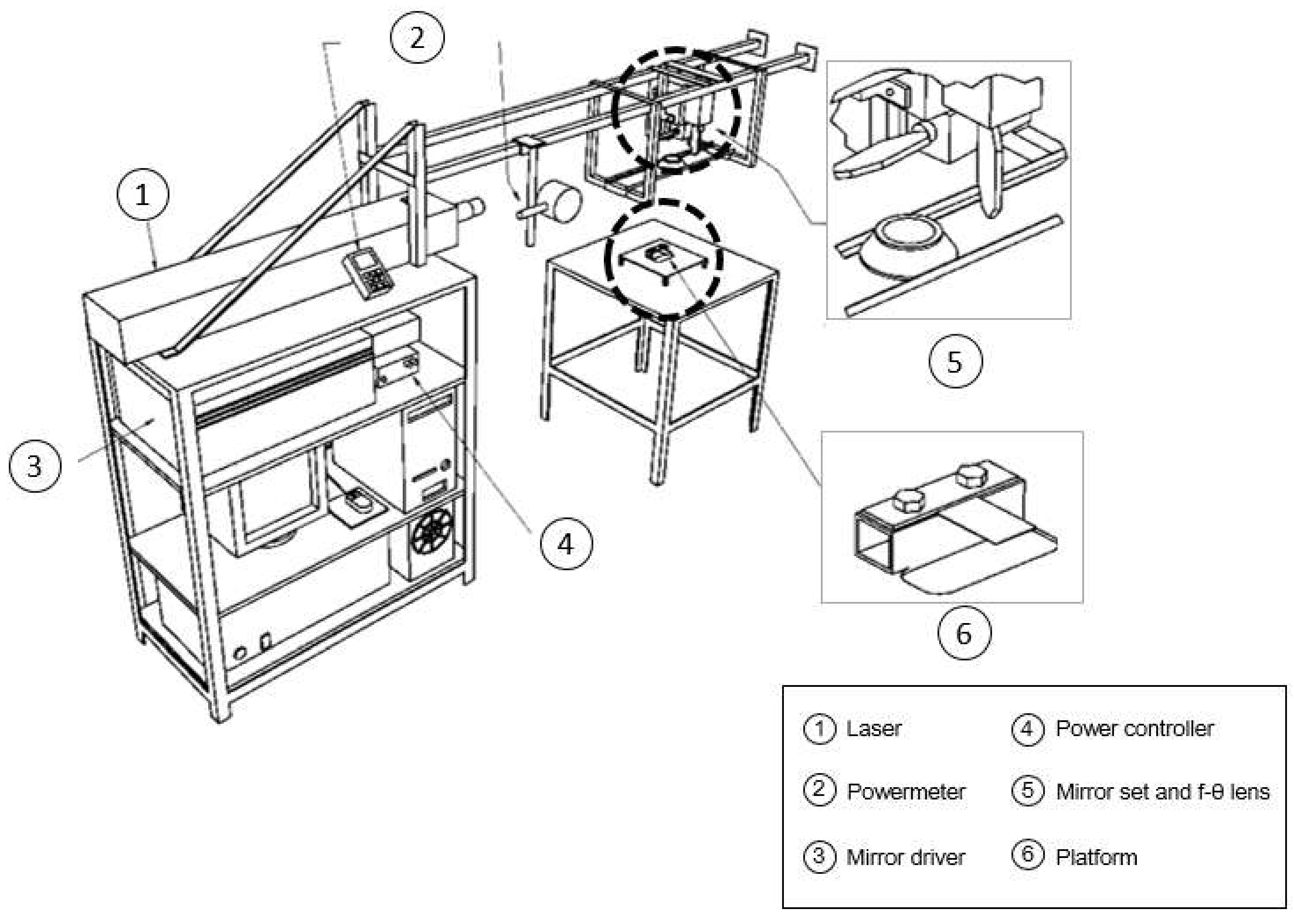

2. Materials and Methods

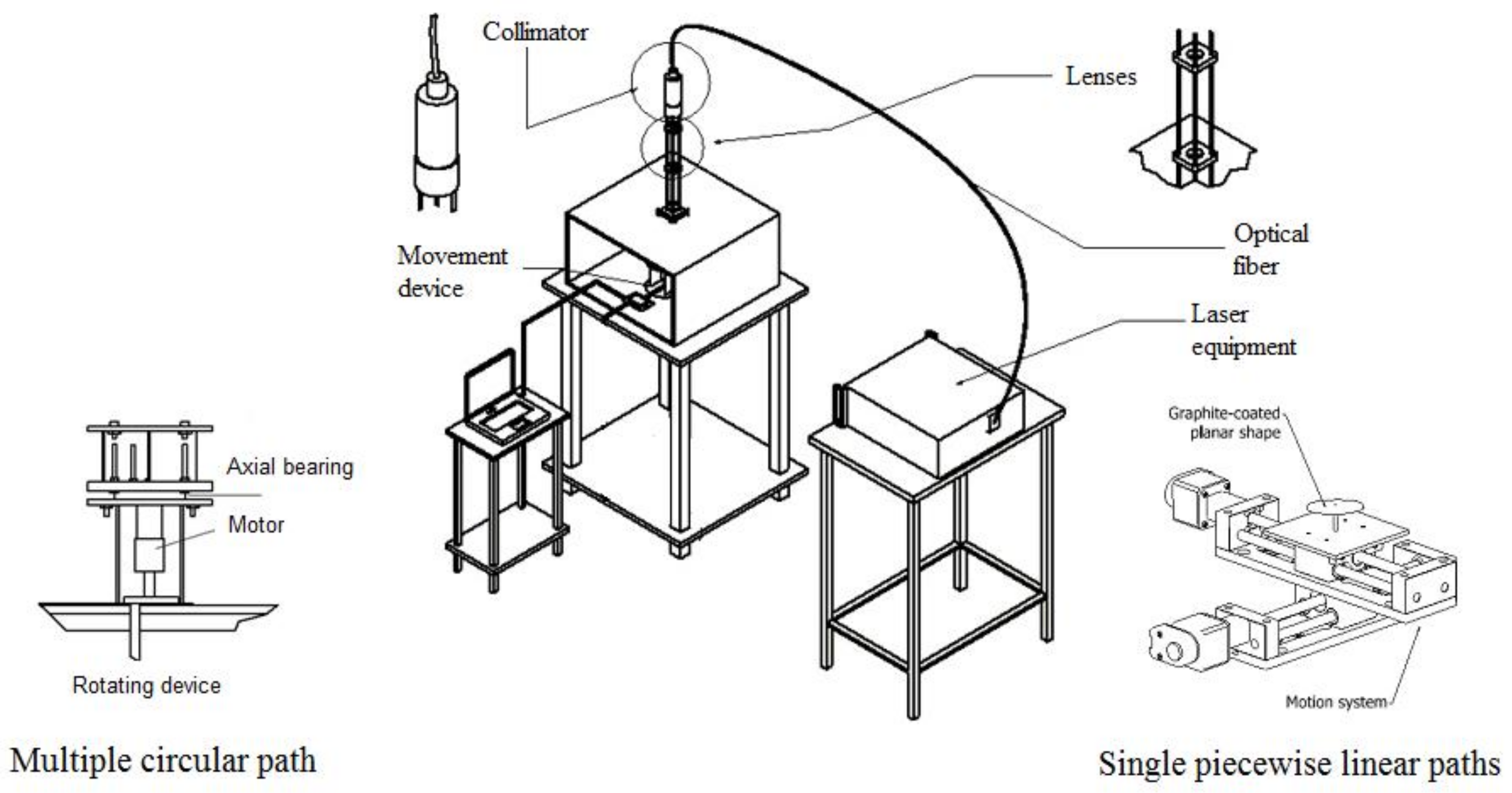

2.1. Experimental Procedure

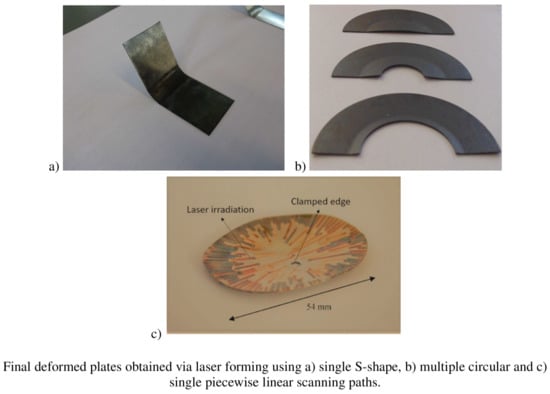

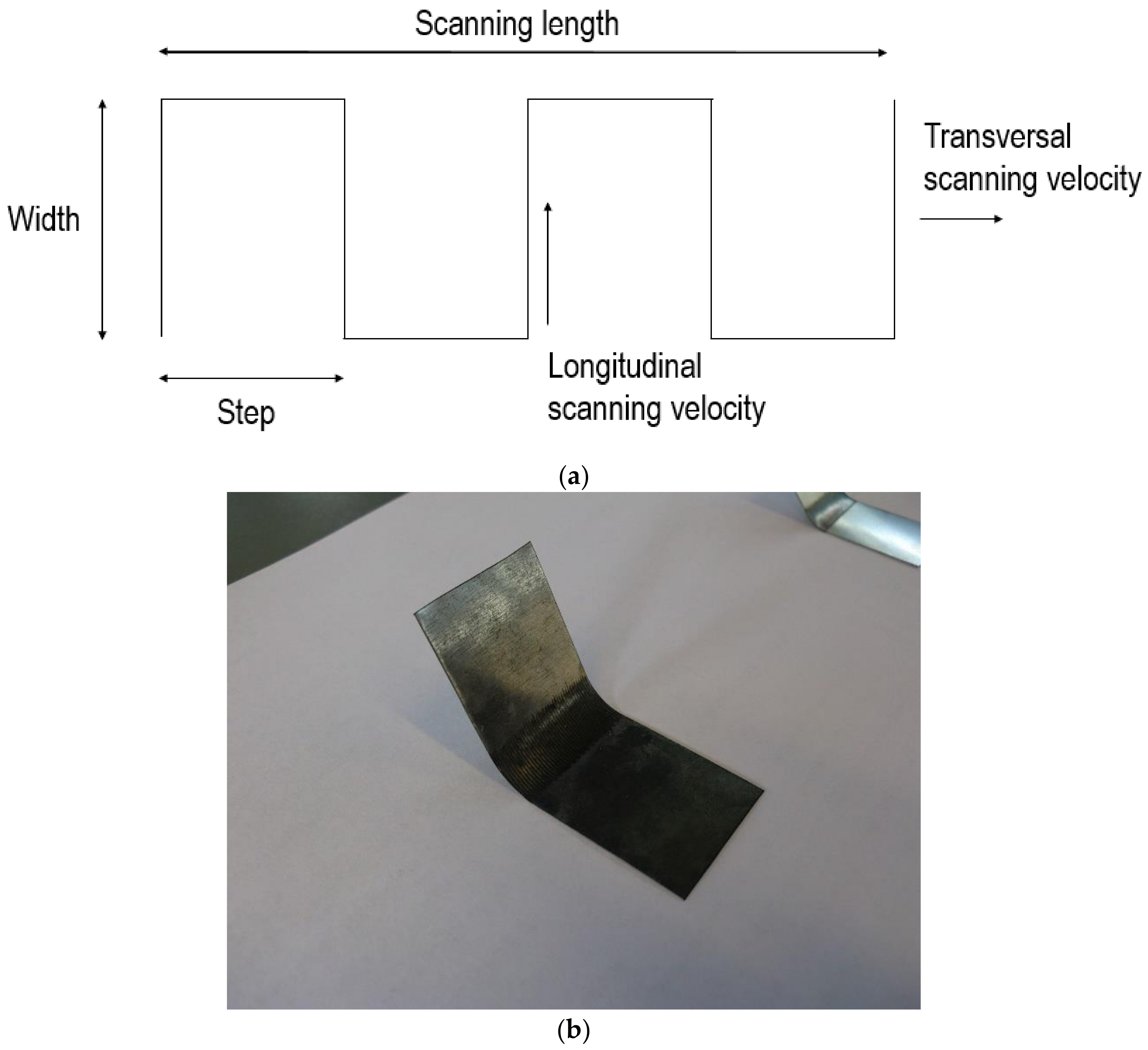

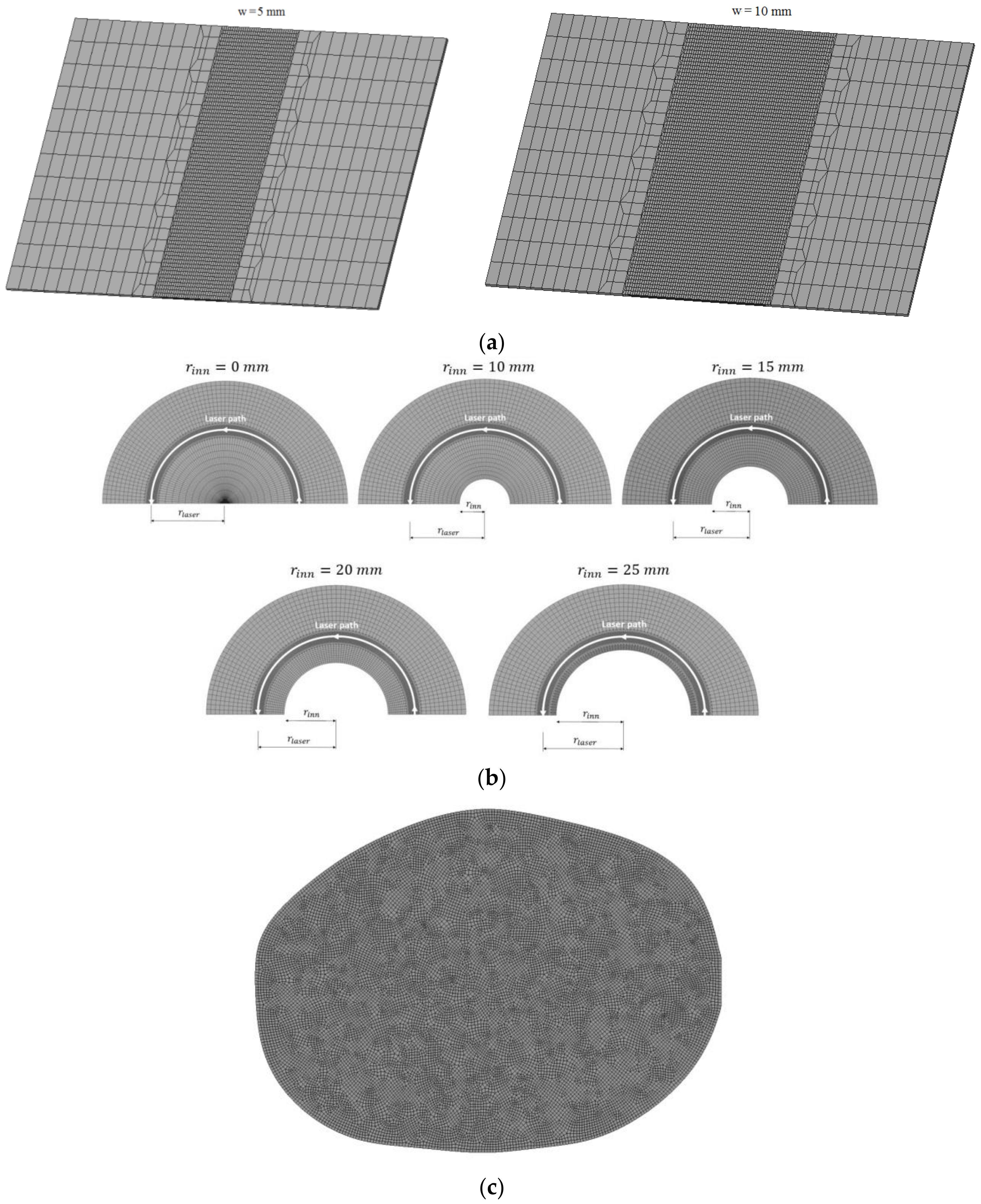

2.1.1. Single S-Shape Scanning Path

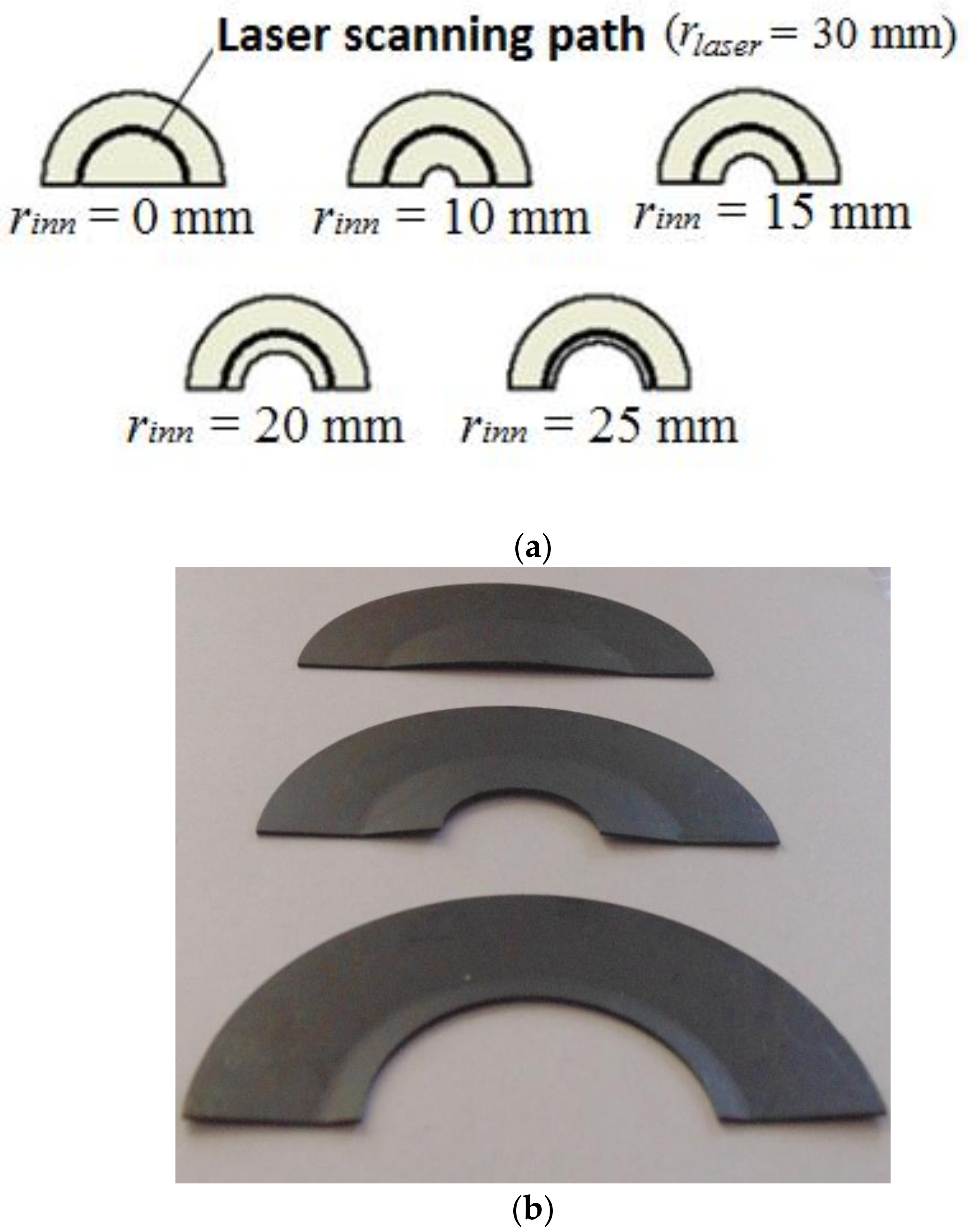

2.1.2. Multiple Circular Scanning Path

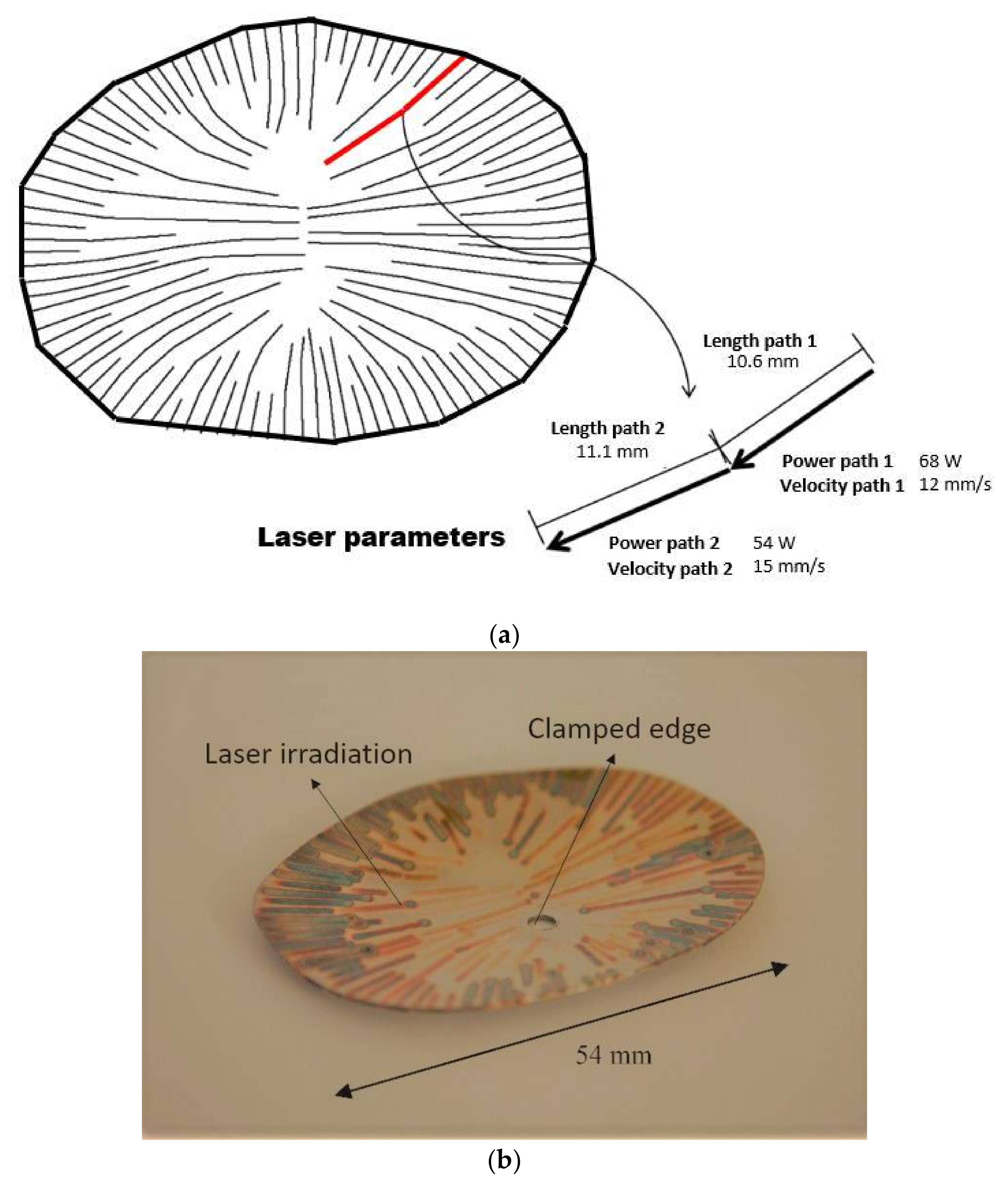

2.1.3. Single Piecewise Linear Scanning Paths

2.2. Modeling and Numerical Simulation

3. Results and Discussion

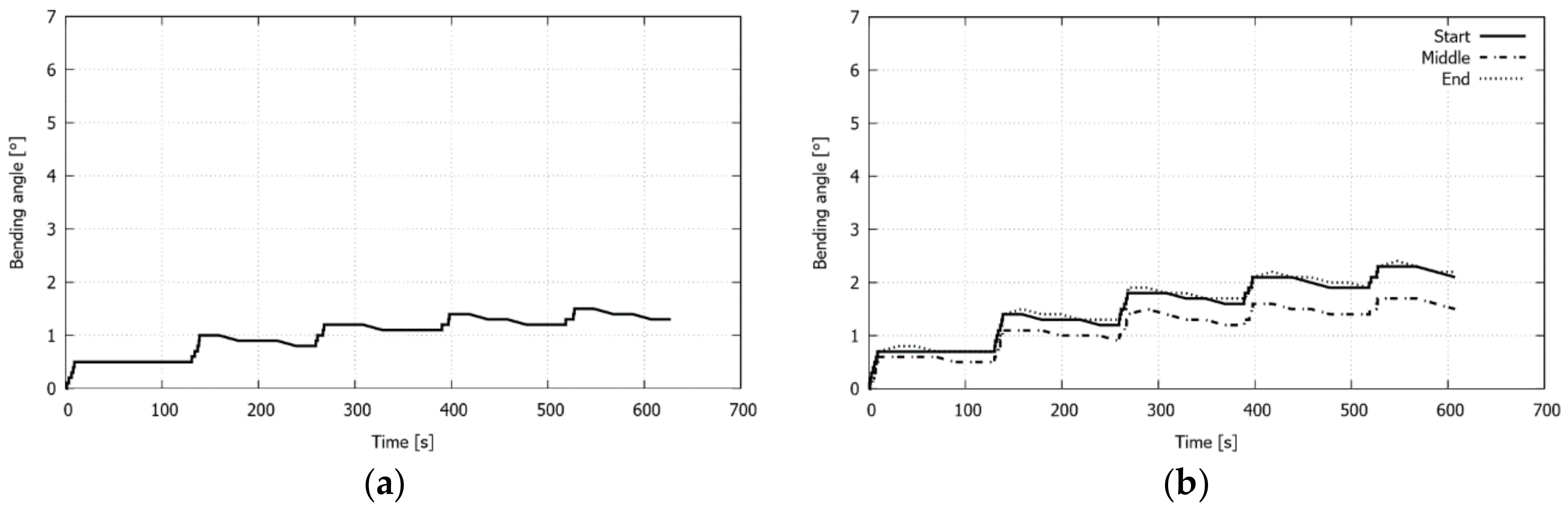

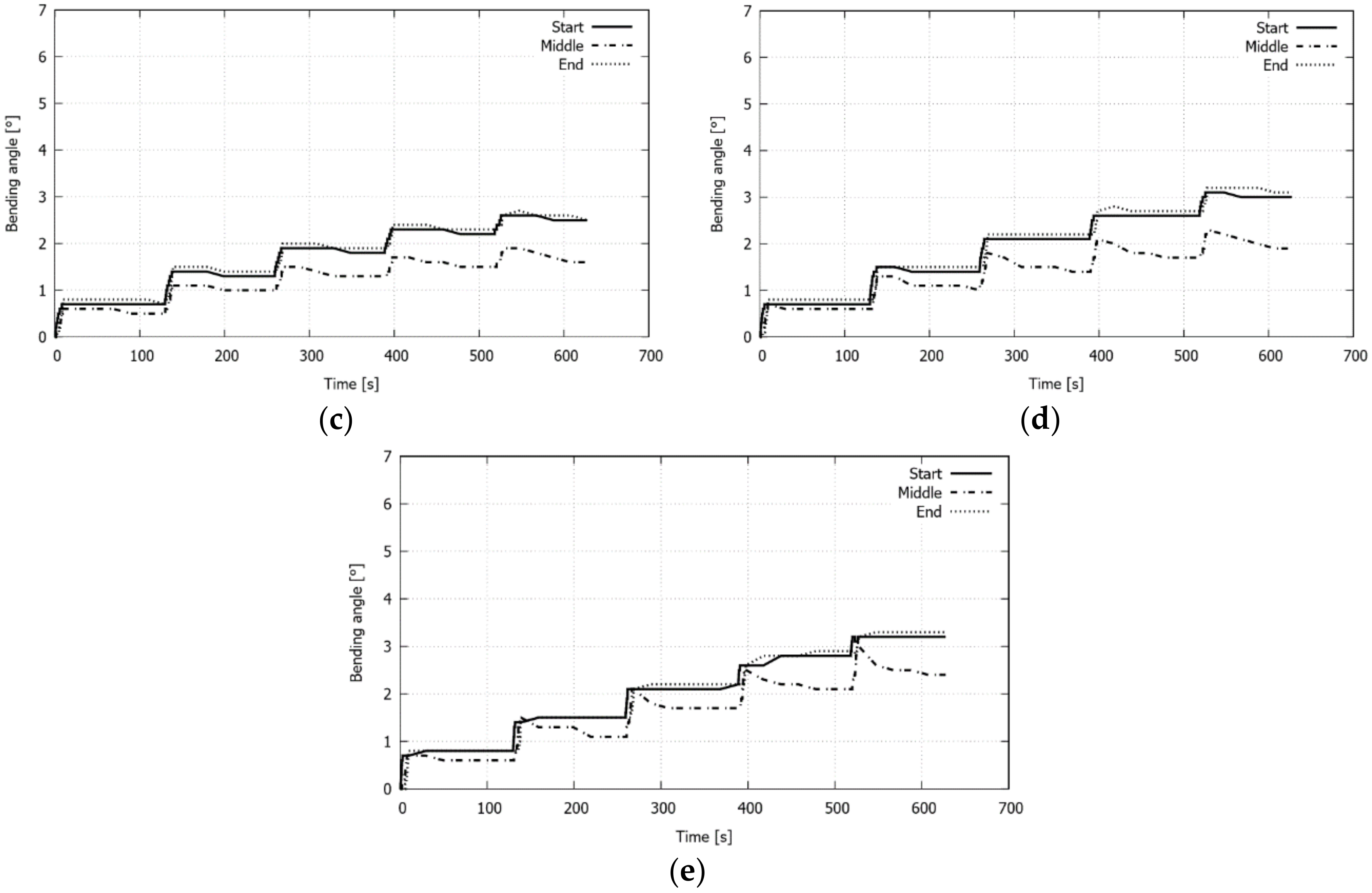

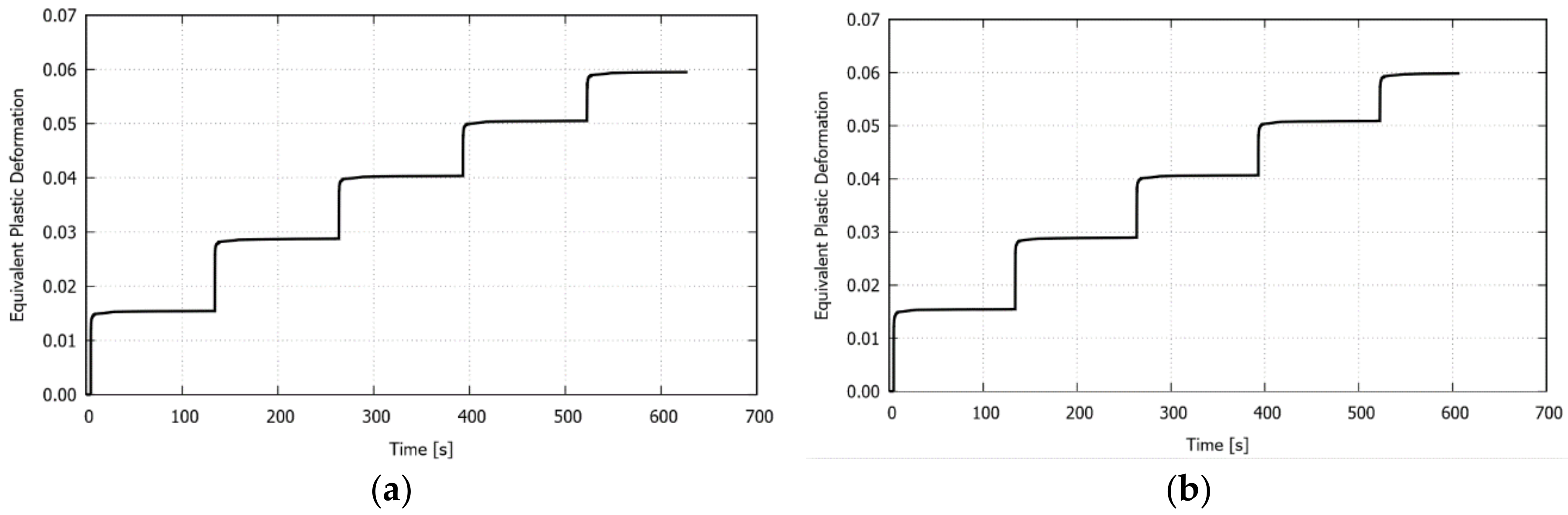

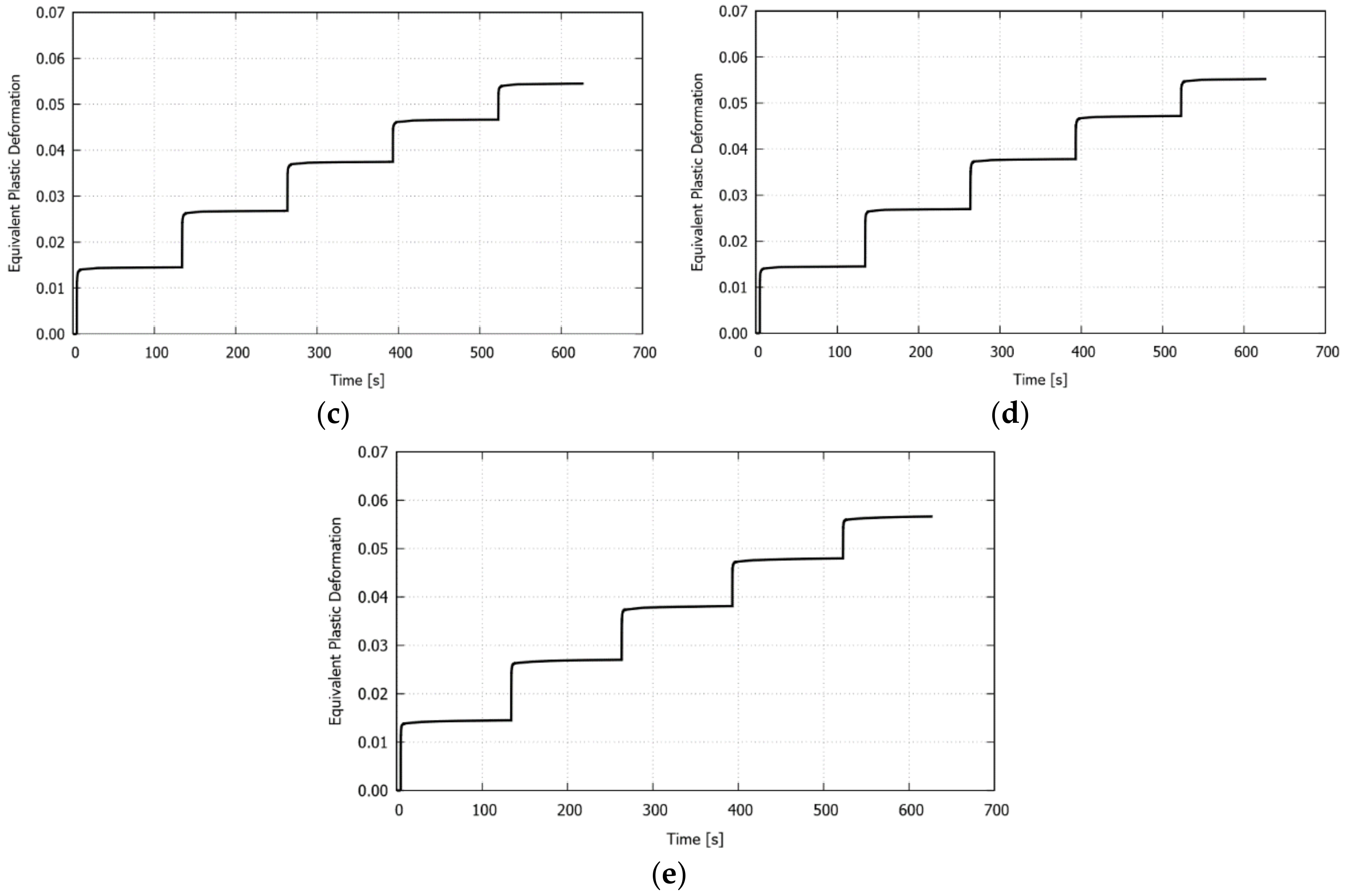

3.1. Single S-Shape Scanning Path

3.2. Multiple Circular Scanning Path

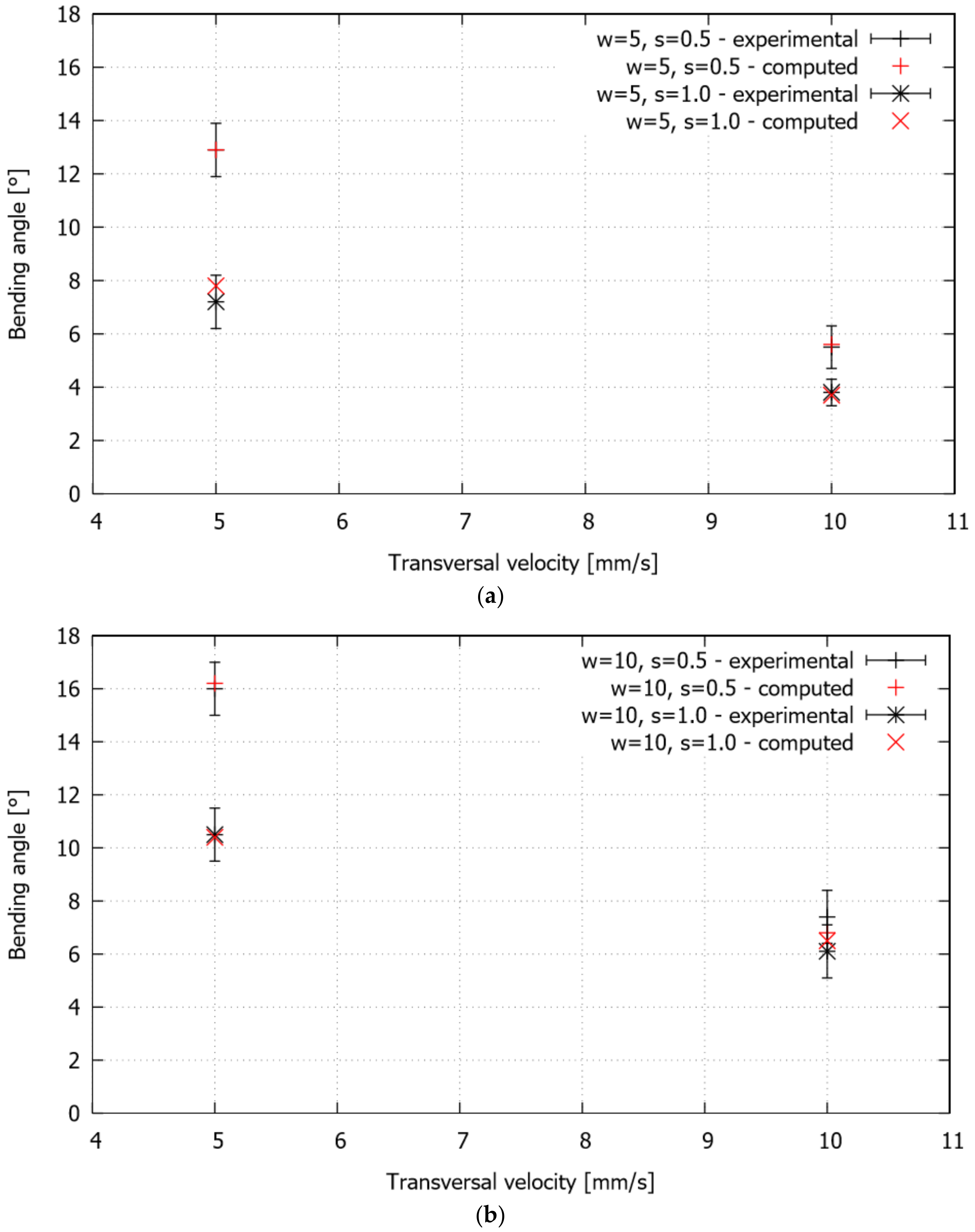

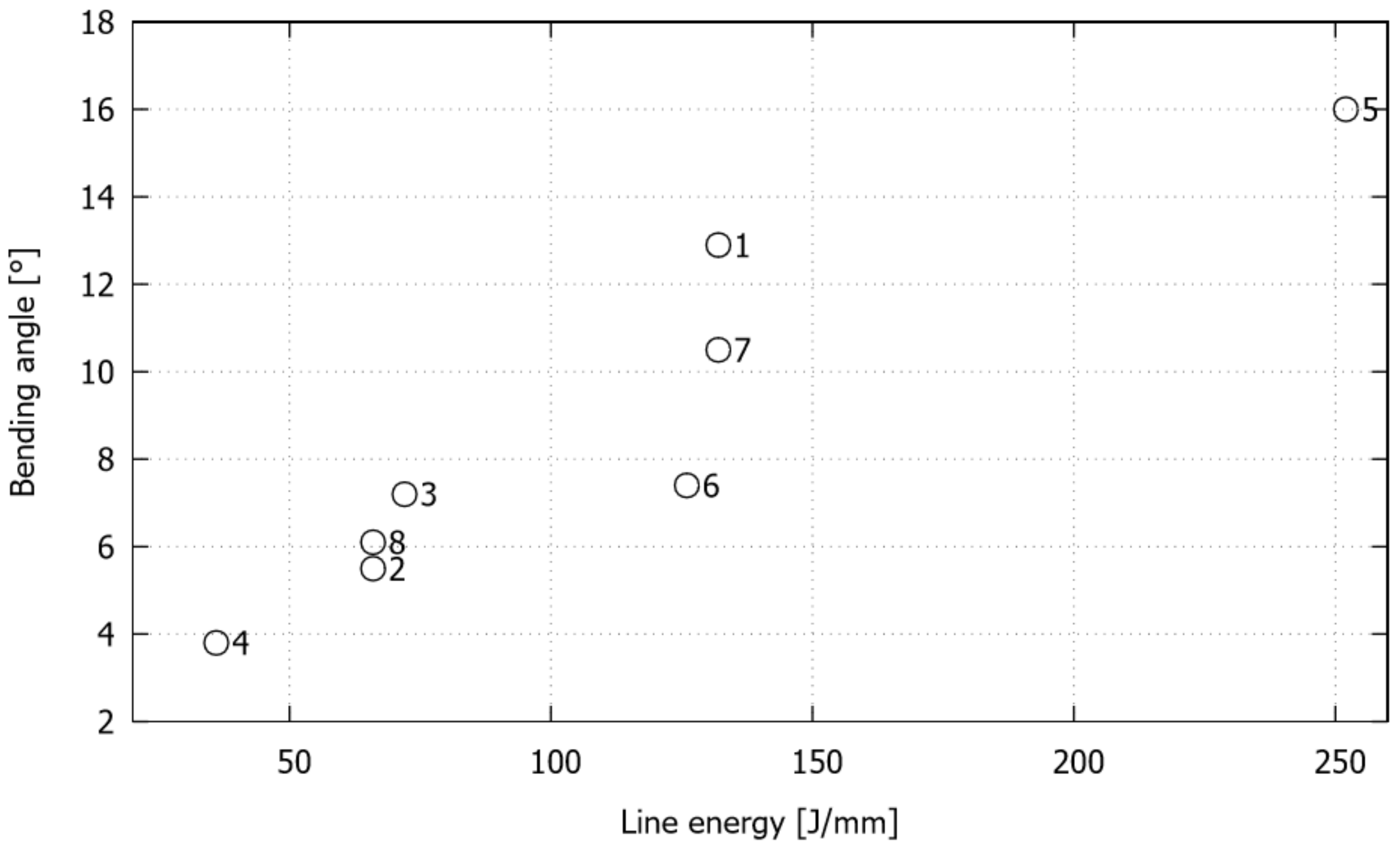

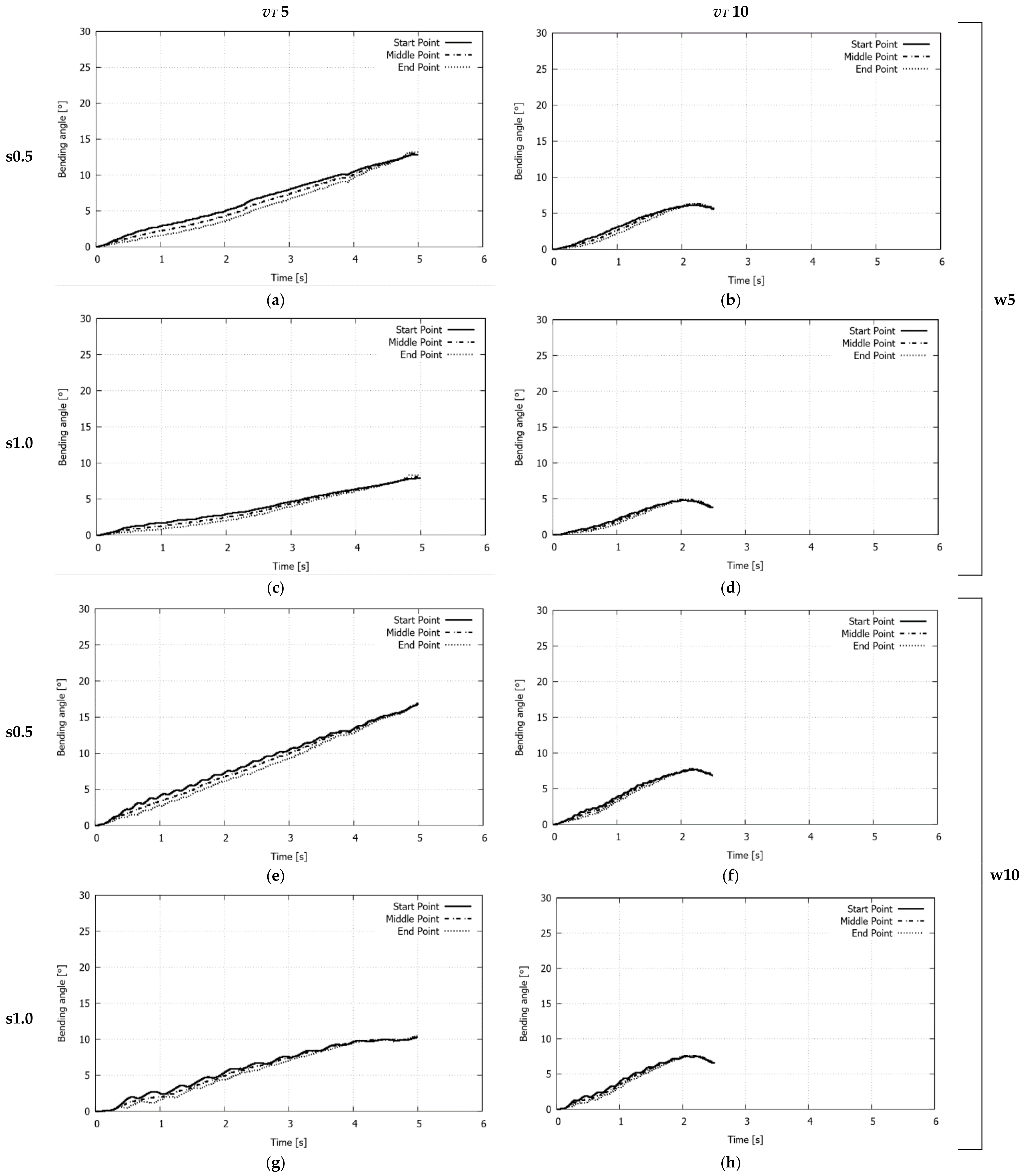

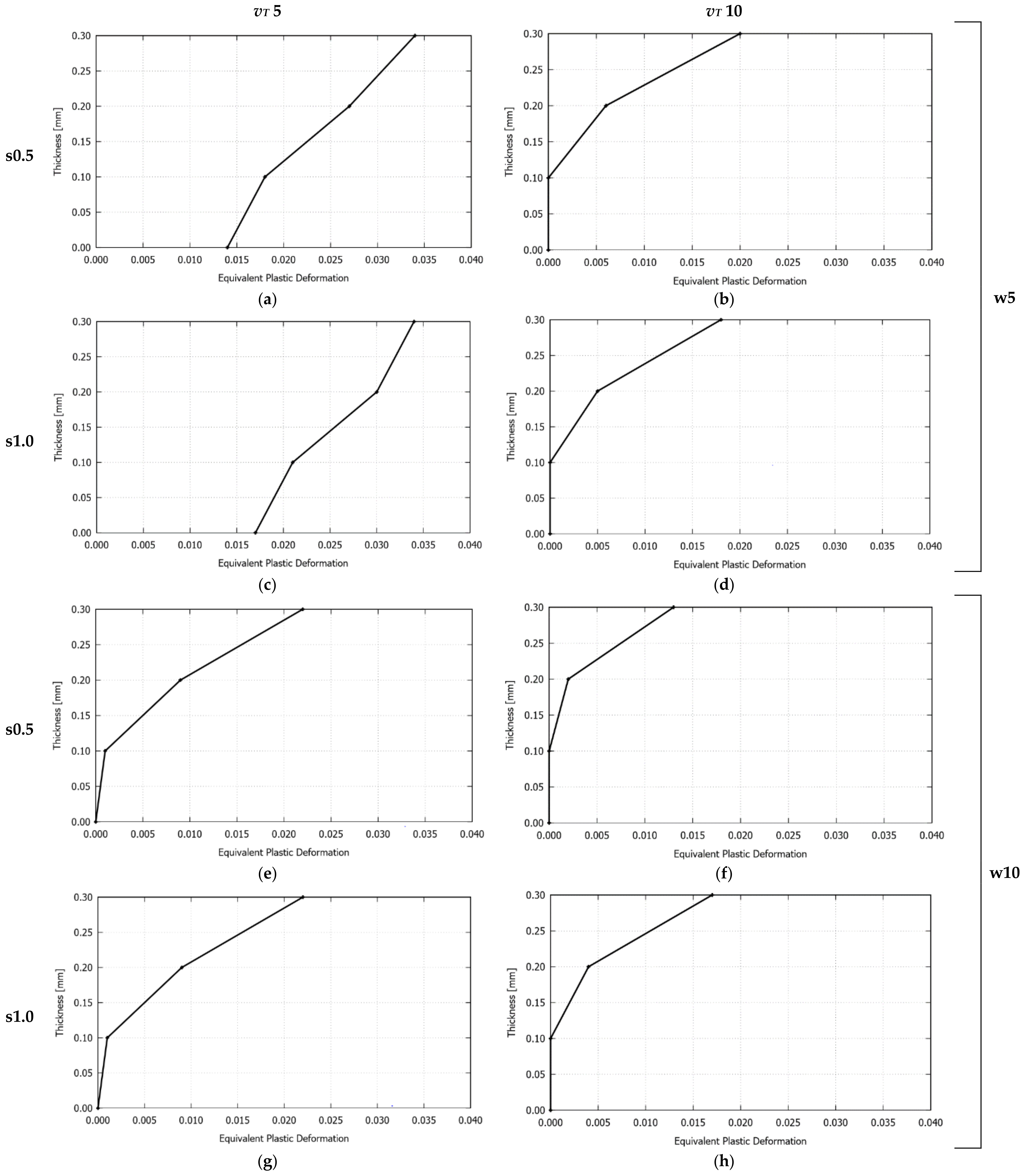

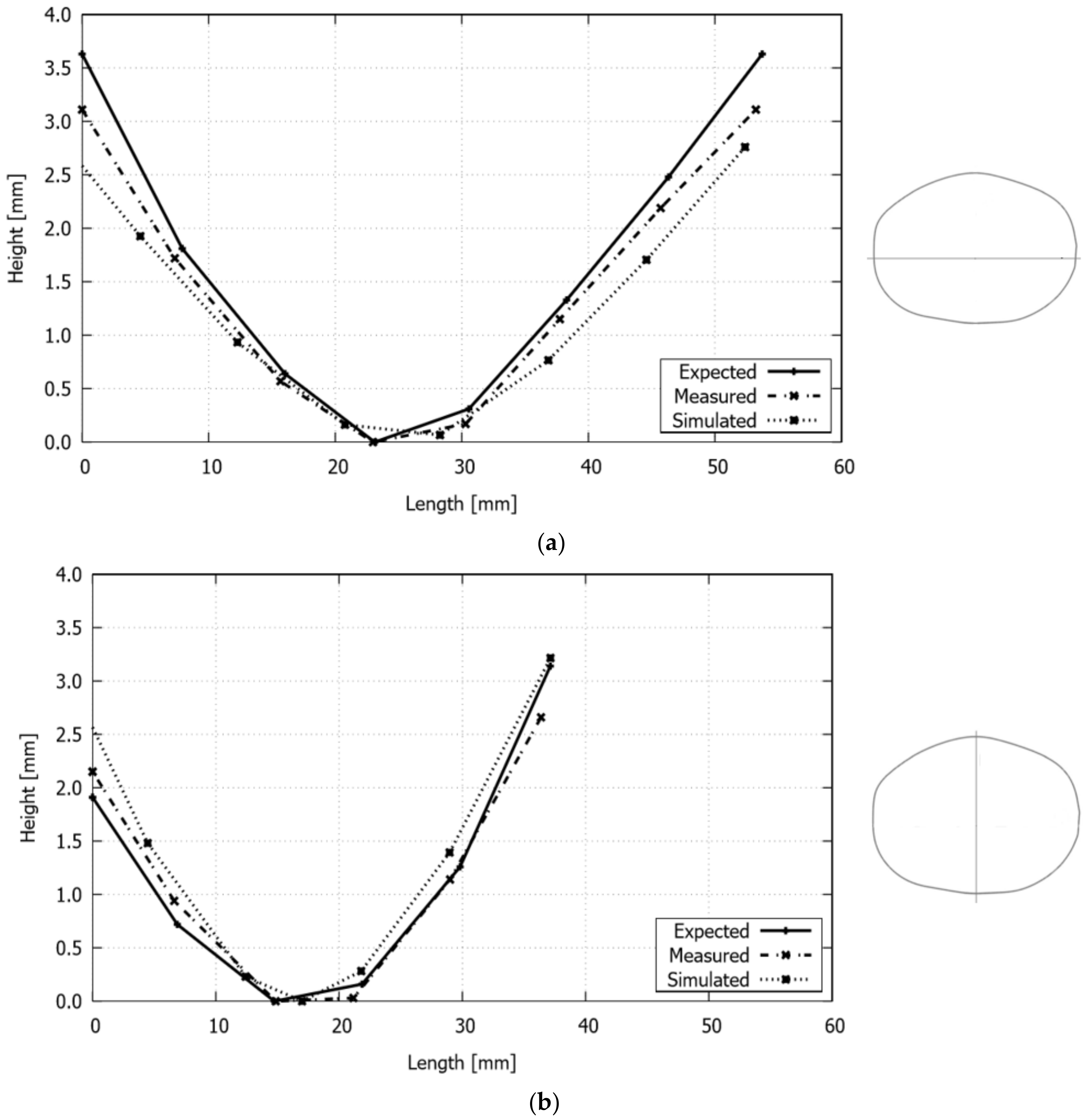

3.3. Single Piecewise Linear Scanning Paths

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Magee, J.; Watkins, K.G.; Steen, W.M.; Calder, N.J.; Sidhu, J.; Kirby, J. Laser forming of aerospace alloys. In Proceedings of the ICALEO’97, Section E, San Diego, CA, USA, 17–20 November 1997; pp. 156–165. [Google Scholar]

- Magee, J.; Watkins, K.G.; Steen, W.M. Advances in laser forming. J. Laser Appl. 1998, 10, 235–246. [Google Scholar] [CrossRef]

- Shen, H.; Vollertsen, F. Modelling of laser forming—A review. Comput. Mater. Sci. 2009, 46, 834–840. [Google Scholar] [CrossRef]

- Geiger, M.; Vollertsen, F. The mechanisms of laser forming. CIRP Ann. Manuf. Technol. 1993, 42, 301–304. [Google Scholar] [CrossRef]

- Safari, M. Numerical investigation of the effect of process and sheet parameters on bending angle in the laser bending process. World J. Mech. 2014, 4, 97–101. [Google Scholar] [CrossRef]

- Stevens, V.; Celentano, D.; Ramos-Grez, J.; Walczak, M. Experimental and Numerical Analysis of Low Output Power Laser Bending of Thin Steel Sheets. J. Manuf. Sci. Eng. 2012, 134, 031010. [Google Scholar] [CrossRef]

- Shen, H.; Yao, Z.Q. Analysis of varying velocity scanning schemes on bending angle in laser forming. In Proceedings of the International Workshop on Thermal Forming and Welding Distortion, Bremen, Germany, 22–23 April 2008; pp. 215–227. [Google Scholar]

- Hu, Z.; Labudovic, M.; Wang, H.; Kovacevic, R. Computer simulation and experimental investigation of sheet metal bending using laser beam scanning. Int. J. Mach. Tools Manuf. 2001, 41, 589–607. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, C.; Sun, G.; Li, C. Study on reducing edge effects using assistance force in laser forming. J. Mater. Process. Technol. 2016, 227, 169–177. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Akhtar, S.S. Laser bending of metal sheet and thermal stress analysis. Opt. Laser Technol. 2014, 61, 34–44. [Google Scholar] [CrossRef]

- Hu, J.; Xu, H.; Dang, D. Modelling and reducing edge effects in laser bending. J. Mater. Process. Technol. 2013, 213, 1989–1996. [Google Scholar] [CrossRef]

- Safari, M.; Mostaan, H. Experimental and numerical investigation of laser forming of cylindrical surfaces with arbitrary radius of curvature. Alex. Eng. J. 2016, 55, 1941–1949. [Google Scholar] [CrossRef]

- Navarrete, A.; Celentano, D. Effect of workpiece geometry using circular scan patterns in sheet laser forming processes. Int. J. Adv. Manuf. Technol. 2018, 96, 1835–1846. [Google Scholar] [CrossRef]

- Hoseinpour Gollo, M.; Mahdavian, S.M.; Moslemi Naeini, H. Statistical analysis of parameter effects on bending angle in laser forming process by pulsed Nd:YAG laser. Opt. Laser Technol. 2011, 43, 475–482. [Google Scholar] [CrossRef]

- Roohi, A.H.; Hoseinpour Gollo, M.; Moslemi Naeini, H. External force-assisted laser forming process for gaining high bending angles. J. Manuf. Process. 2012, 14, 269–276. [Google Scholar] [CrossRef]

- Shen, H.; Shi, Y.; Yao, Z. Numerical simulation of the laser forming of plates using two simultaneous scans. Comput. Mater. Sci. 2006, 37, 239–245. [Google Scholar] [CrossRef]

- Hennige, T. Development of irradiation strategies for 3-D laser forming. J. Mater. Process. Technol. 2000, 103, 102–108. [Google Scholar] [CrossRef]

- Venkadeshwaran, K.; Das, S.; Misra, D. Finite element simulation of 3-D laser forming by discrete section circle line heating. Int. J. Eng. Sci. Technol. 2010, 2, 163–175. [Google Scholar] [CrossRef]

- Safari, M.; Farzin, M. Experimental investigation of laser forming of a saddle shape with spiral irradiating scheme. Opt. Laser Technol. 2015, 66, 146–150. [Google Scholar] [CrossRef]

- Chakraborty, S.S.; More, H.; Nath, A.K. Laser forming of a bowl shaped surface with a stationary laser beam. Opt. Laser Eng. 2016, 77, 126–136. [Google Scholar] [CrossRef]

- Gao, H.; Sheikholeslami, G.; Dearden, G.; Edwardson, S.P. Development of scan strategies for controlled 3D laser forming of sheet metal components. Phys. Procedia 2016, 83, 286–295. [Google Scholar] [CrossRef]

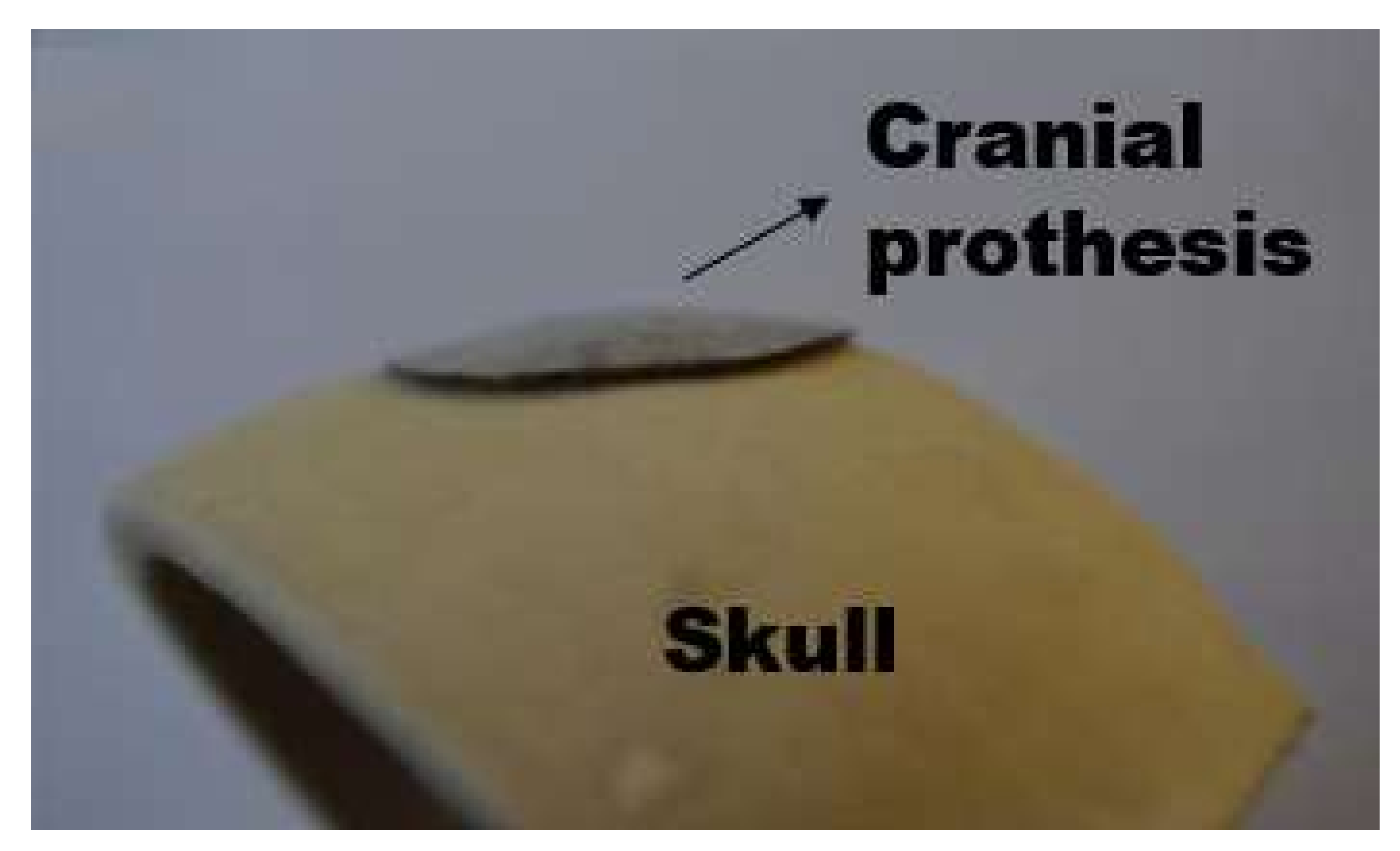

- Cook, F.; Celentano, D.; Ramos-Grez, J. Experimental-numerical methodology for the manufacturing of cranial prosthesis via laser forming. Int. J. Adv. Manuf. Technol. 2016, 86, 2187–2196. [Google Scholar] [CrossRef]

- Imani Shahabad, S.; Moslemi Naeini, H.; Roohi, A.H.; Tavakoli, A.; Nasrollahzade, M. Experimental investigation of laser forming process to produce dome-shaped products. Int. J. Adv. Manuf. Technol. 2017, 90, 1051–1057. [Google Scholar] [CrossRef]

- Tavakoli, A.; Moslemi Naeini, H.; Roohi, A.H.; Hoseinpour Gollo, M.; Imani Shahabad, S. Optimization of circular scan path to produce bowl shapes in 3D laser forming process. J. Laser Appl. 2017, 29, 042001. [Google Scholar] [CrossRef]

- Tavakoli, A.; Moslemi Naeini, H.; Roohi, A.H.; Hoseinpour Gollo, M.; Imani Shahabad, S. Determining optimized radial scan path in 3D laser forming of steel AISI 304 plates to produce bowl shapes. Int. J. Adv. Manuf. Technol. 2017, 91, 3457–3465. [Google Scholar] [CrossRef]

- Tavakoli, A.; Moslemi Naeini, H.; Roohi, A.H.; Hoseinpour Gollo, M.; Imani Shahabad, Sh. Codification of scan path parameters and development of perimeter scan strategies for 3D bowl-shaped laser forming. Opt. Laser Technol. 2018, 98, 121–133. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Ealo, J.A.; Campa, F.J.; Lamikiz, A.; López de Lacalle, L.N. Feed rate calculation algorithm for the homogeneous material deposition of blisk blades by 5-axis laser cladding. Int. J. Adv. Manuf. Technol. 2014, 74, 1219–1228. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Fernández, A.; Celaya, A.; Lamikiz, A.; de Lacalle, L.N.L. Improvement of strategies and parameters for multi-axis laser cladding operations. Opt. Lasers Eng. 2014, 56, 113–120. [Google Scholar] [CrossRef]

- Rahman Rashid, R.A.; Abaspour, S.; Palanisamy, S.; Matthews, N.; Dargusch, M.S. Metallurgical and geometrical characterisation of the 316L stainless steel clad deposited on a mild steel substrate. Surf. Coat. Technol. 2017, 327, 174–184. [Google Scholar] [CrossRef]

- Cook, F.; Jacobsen, V.; Celentano, D.; Ramos, J. Characterization of the absorptance of laser irradiated steel sheets. J. Laser Appl. 2015, 27, 032006. [Google Scholar] [CrossRef]

- Cook, F.; Miró, L.; Celentano, D.; Ramos-Grez, J. Effect of inclination angle on the absorptance of a graphite-coated cold-rolled steel sheet irradiated by laser. J. Laser Appl. 2016, 28, 022001. [Google Scholar] [CrossRef]

- Castillo, J.I.; Celentano, D.J.; Cruchaga, M.A.; García-Herrera, C.M. Characterization of strain rate effects in sheet laser forming. Comptes Rendus Mécanique 2018, in press. [Google Scholar] [CrossRef]

| Case | Width, w [mm] | Step, s [mm] | Transversal Velocity, vT [mm/s] | Longitudinal Velocity, vL [mm/s] vL = (w + s)/s vT |

|---|---|---|---|---|

| 1 | 5 | 0.5 | 5 | 55 |

| 2 | 5 | 0.5 | 10 | 110 |

| 3 | 5 | 1.0 | 5 | 30 |

| 4 | 5 | 1.0 | 10 | 60 |

| 5 | 10 | 0.5 | 5 | 105 |

| 6 | 10 | 0.5 | 10 | 210 |

| 7 | 10 | 1.0 | 5 | 55 |

| 8 | 10 | 1.0 | 10 | 110 |

| Geometric Configuration | Start | End | ||

|---|---|---|---|---|

| Internal Radius (mm) | Experimental (°) | Computed (°) | Experimental (°) | Computed (°) |

| 0 | 1.5 ± 0.1 | 1.5 | 1.7 ± 0.1 | 1.5 |

| 10 | 2.3 ± 0.2 | 2.4 | 2.5 ± 0.1 | 2.4 |

| 15 | 2.5 ± 0.1 | 2.4 | 2.5 ± 0.1 | 2.5 |

| 20 | 3.1 ± 0.1 | 2.8 | 2.5 ± 0.2 | 2.6 |

| 25 | 3.0 ± 0.3 | 3.1 | 3.2 ± 0.1 | 3.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navarrete, Á.; Cook, F.; Celentano, D.; Cruchaga, M.; García-Herrera, C. Numerical Simulation and Experimental Validation of Sheet Laser Forming Processes Using General Scanning Paths. Materials 2018, 11, 1262. https://doi.org/10.3390/ma11071262

Navarrete Á, Cook F, Celentano D, Cruchaga M, García-Herrera C. Numerical Simulation and Experimental Validation of Sheet Laser Forming Processes Using General Scanning Paths. Materials. 2018; 11(7):1262. https://doi.org/10.3390/ma11071262

Chicago/Turabian StyleNavarrete, Álvaro, Felipe Cook, Diego Celentano, Marcela Cruchaga, and Claudio García-Herrera. 2018. "Numerical Simulation and Experimental Validation of Sheet Laser Forming Processes Using General Scanning Paths" Materials 11, no. 7: 1262. https://doi.org/10.3390/ma11071262

APA StyleNavarrete, Á., Cook, F., Celentano, D., Cruchaga, M., & García-Herrera, C. (2018). Numerical Simulation and Experimental Validation of Sheet Laser Forming Processes Using General Scanning Paths. Materials, 11(7), 1262. https://doi.org/10.3390/ma11071262