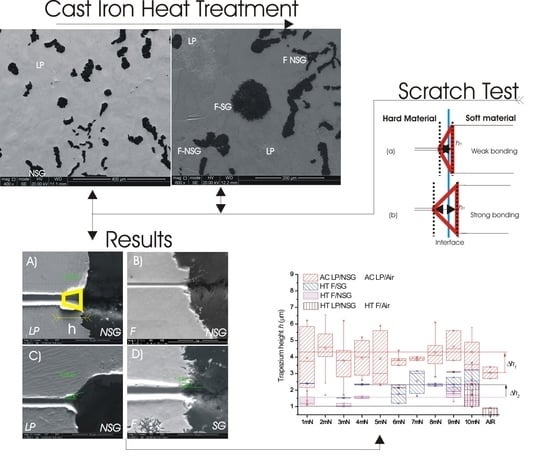

Proposal of Characterization Procedure of Metal–Graphite Interface Strength in Compacted Graphite Iron

Abstract

1. Introduction

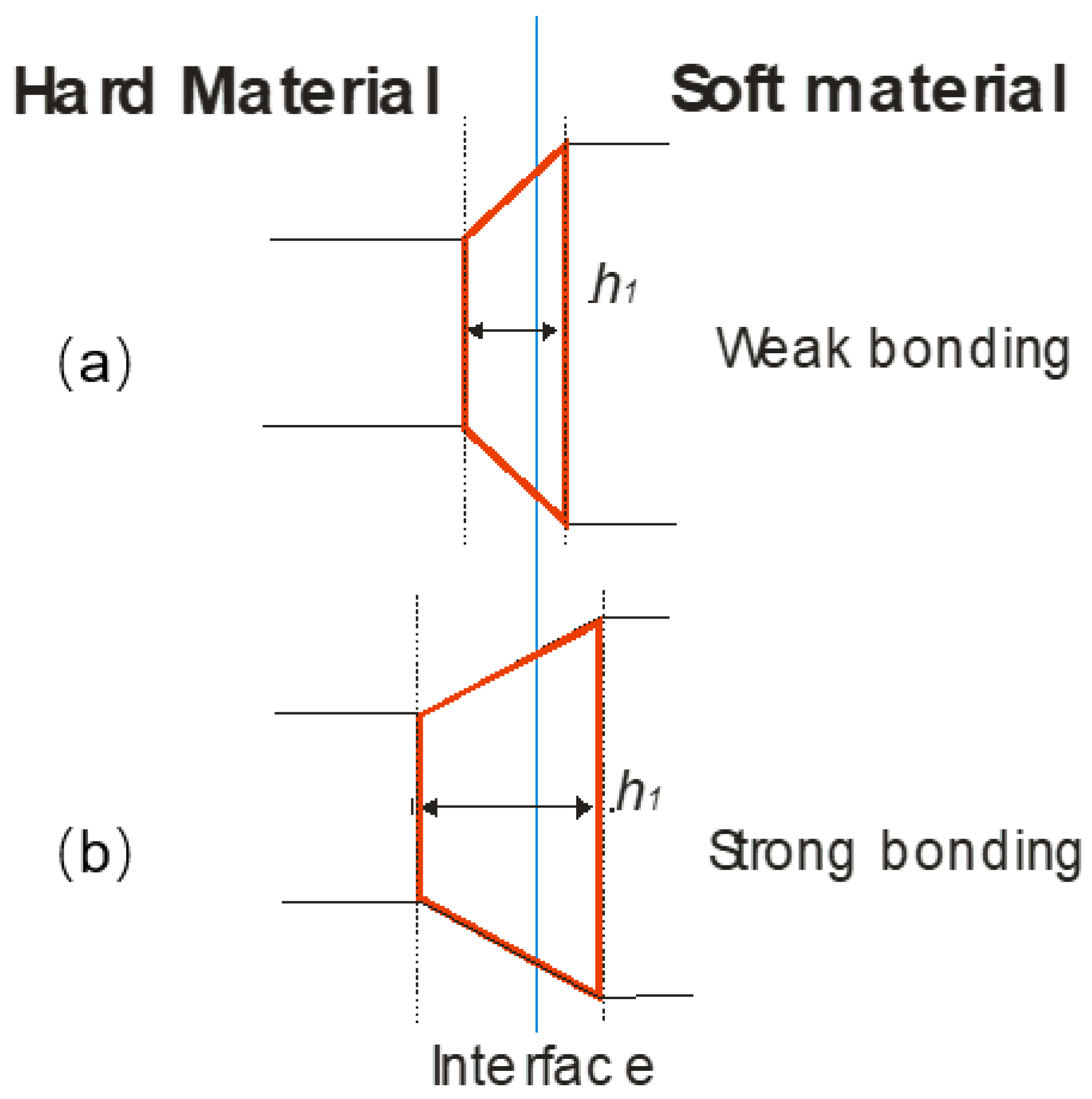

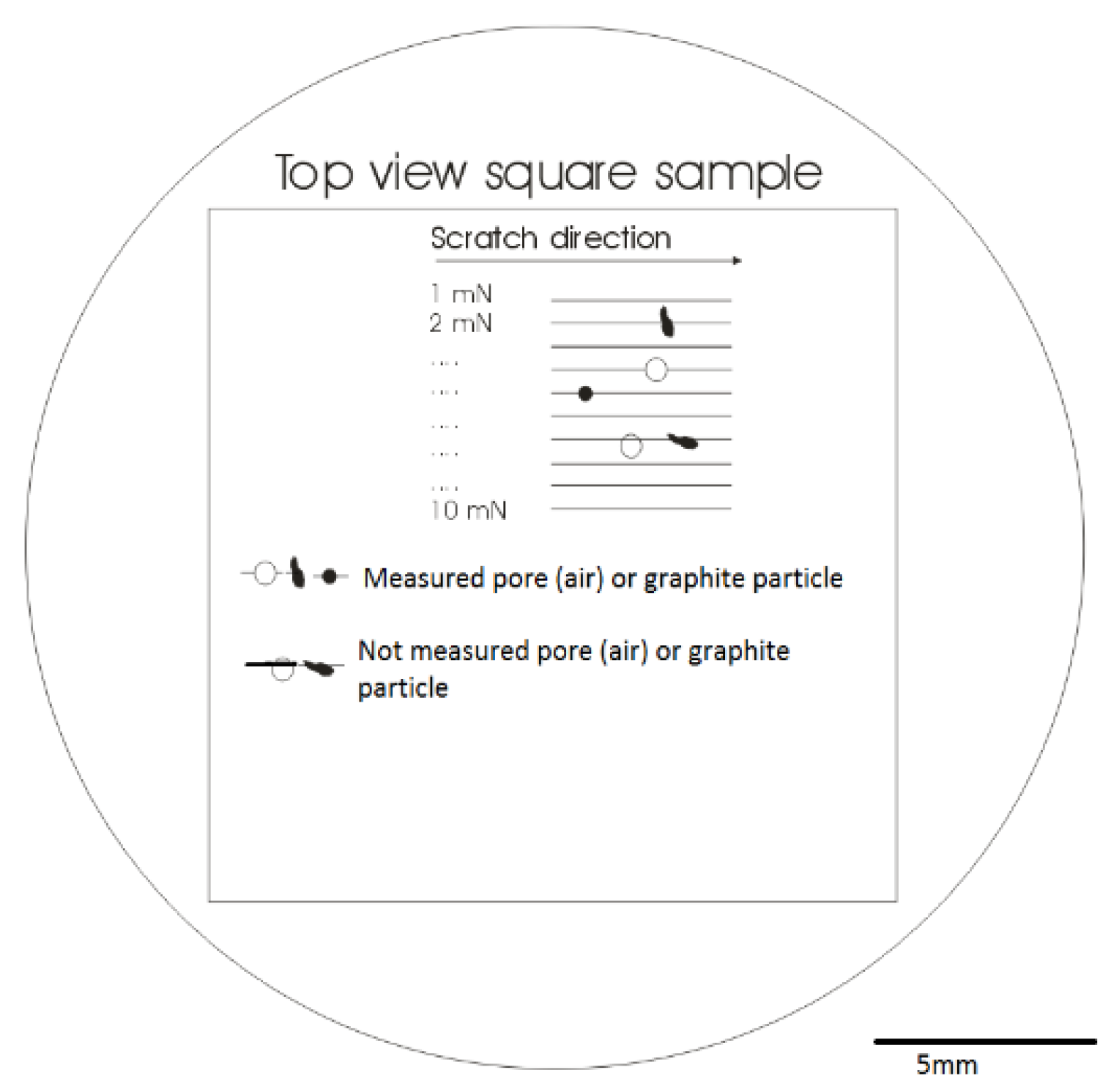

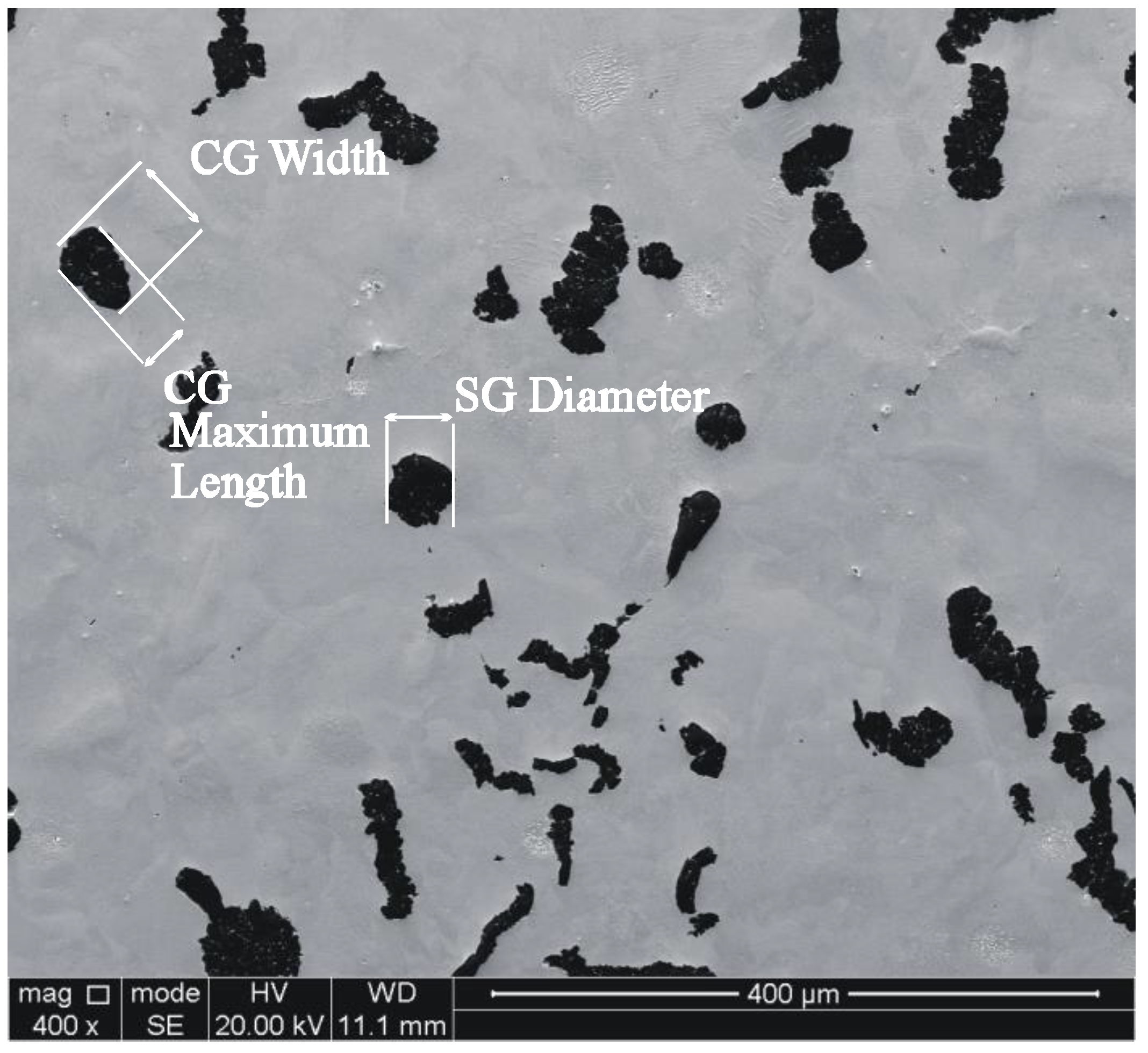

2. Materials and Methods

3. Results

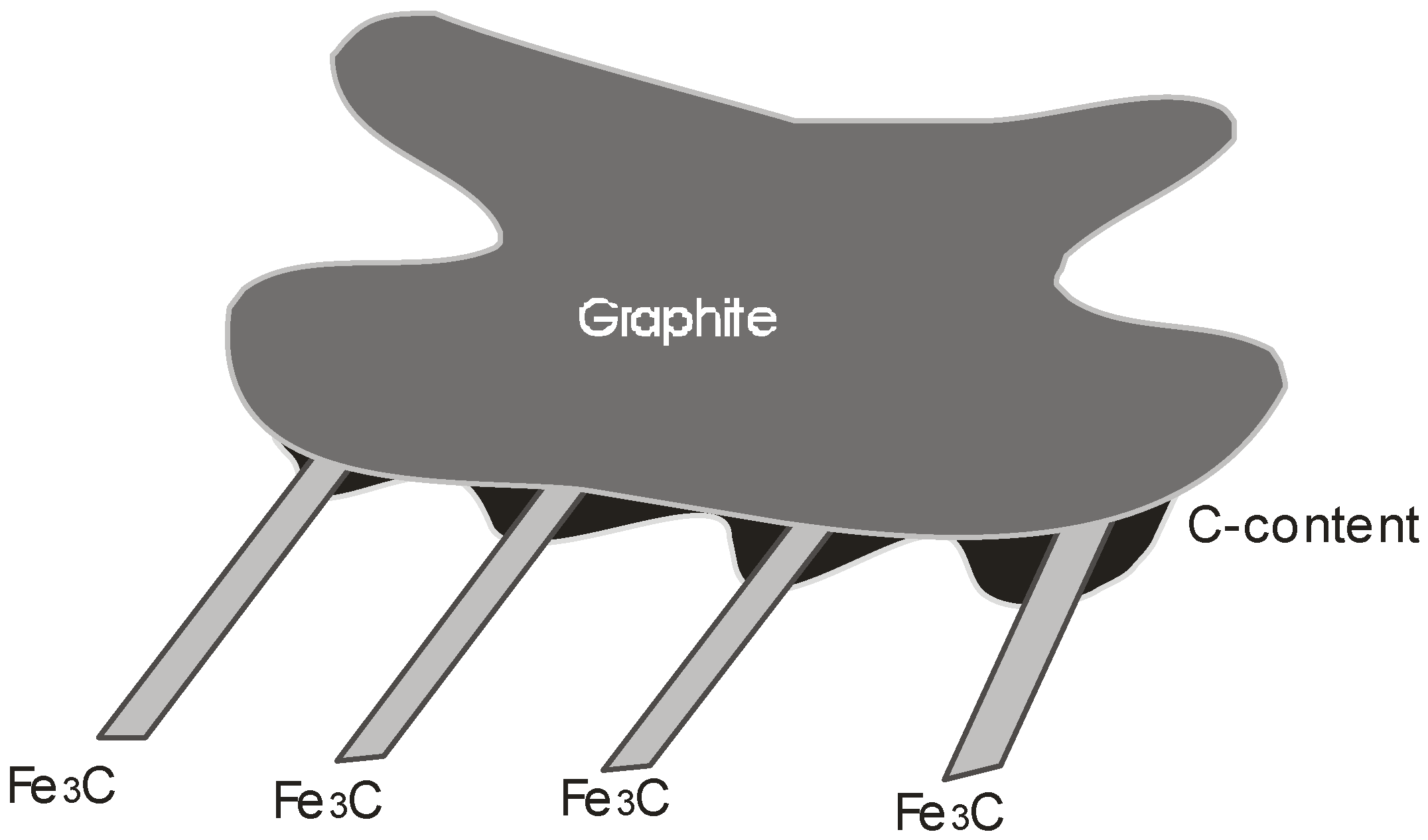

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CGI | compacted graphite iron |

| CG | compacted graphite |

| SI | spheroidal graphite |

| AC | as cast |

| HT | heat treated |

| TMF | thermomechanical fatigue |

| FE | finite element |

| M–G | metal–graphite |

| ε | strain |

| h | trapezium height |

| ΔH | difference in materials‘ hardness |

| σc | critical stress normal to the M–G interface |

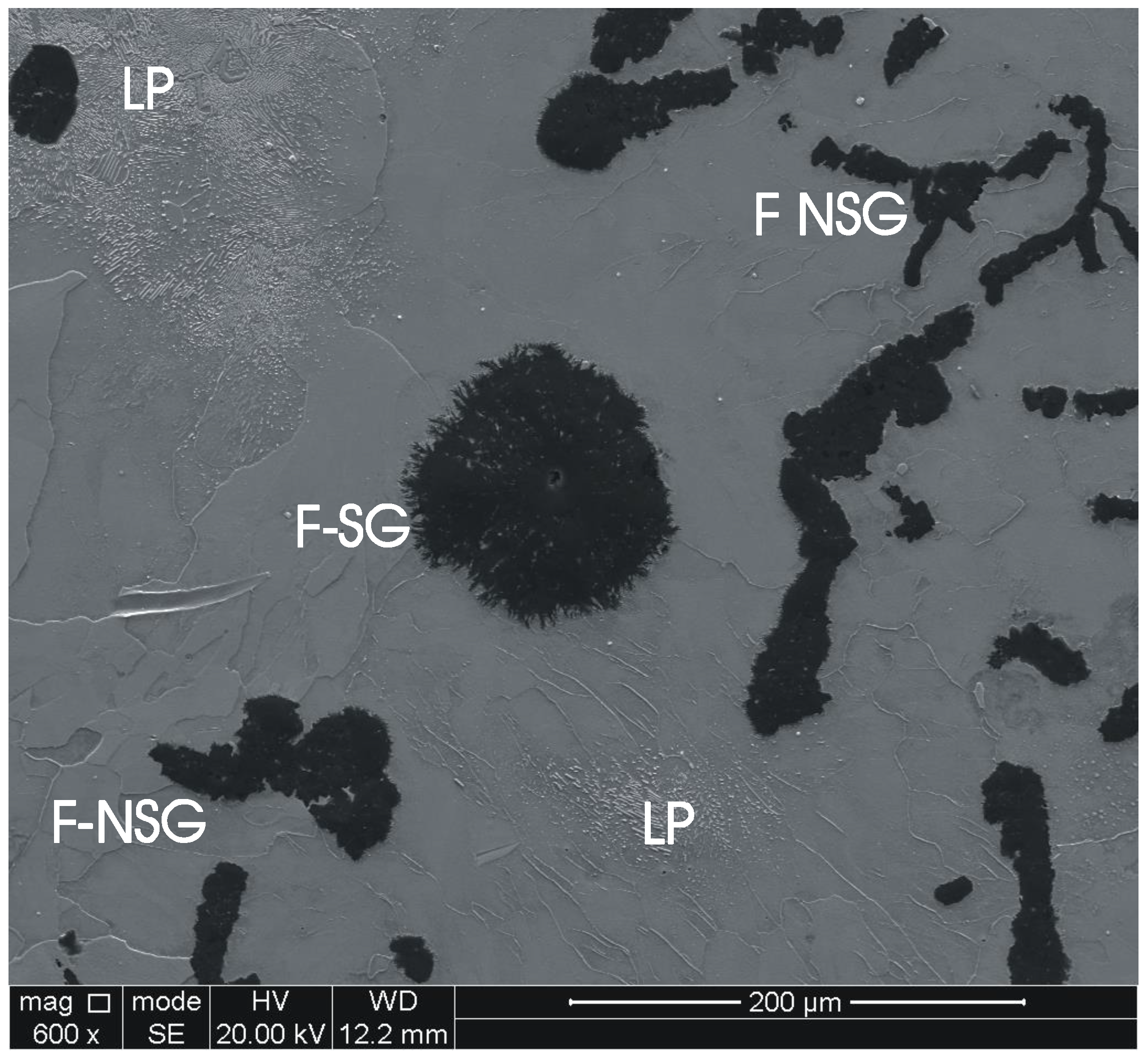

| LP | lamellar pearlite |

| SG | spiky graphite |

| NSG | non-spiky graphite |

| F | ferrite |

| STDEV | standard deviation |

References

- Ghodrat, S. Thermo-Mechanical Fatigue of Compacted Graphite Iron in Diesel Engine Components. Ph.D. Dissertation, Delft University of Technology, Delft, The Netherlands, 2013. [Google Scholar]

- Li, J.; Wang, P.; Cui, X.; Li, K.; Yi, R. Gray cast iron cylinder head thermal mechanical fatigue analysis. In Proceedings of the Fisita 2012 World Automotive Congress; Springer: Berlin, Germany, 2013; pp. 243–257. [Google Scholar]

- Metzger, M.; Nieweg, B.; Schweizer, C.; Seifert, T. Lifetime prediction of cast iron materials under combined thermomechanical fatigue and high cycle fatigue loading using a mechanism-based model. Int. J. Fatigue 2013, 53, 58–66. [Google Scholar] [CrossRef]

- Metzger, M.; Seifert, T. A mechanism-based model for LCF/HCF and TMF/HCF life prediction: Multiaxial formulation, finite-element implementation and application to cast iron. Tech. Mech. 2012, 32, 435–445. [Google Scholar]

- Gocmez, T.; Awarke, A.; Pischinger, S. A new low cycle fatigue criterion for isothermal and out-of-phase thermomechanical loading. Int. J. Fatigue 2010, 32, 769–779. [Google Scholar] [CrossRef]

- Zieher, F.; Langmayr, F.; Ennemoser, A.; Jelatancev, A.; Hager, G.; Wieser, K. Advanced thermal mechanical fatigue life simulation of cylinder heads. In Proceedings of the Abaqus User Conference, Boston, MA, USA, 25–27 May 2004; pp. 789–805. [Google Scholar]

- Mohammed, W.M.; Ng, E.; Elbestawi, M.A. Modeling the effect of compacted graphite iron microstructure on cutting forces and tool wear. CIRP J. Manuf. Sci. Technol. 2012, 5, 87–101. [Google Scholar] [CrossRef]

- Hellström, P.; Olander, K. Analysis and Modeling of Properties of Compacted Graphite Iron on a Microstructural Level. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2012. [Google Scholar]

- He, Z.R.; Lin, G.X.; Ji, S. A new understanding on the relation among microstructure micro interfacial mechanical behaviours and macro mechanical properties in cast iron. Mater. Sci. Eng. A 1997, 234, 161–164. [Google Scholar] [CrossRef]

- Lundberg, M.L.M.; Calmunger, M.; Peng, R.L. In-situ sem/ebsd study of deformation and fracture behaviour of flake cast iron. In Proceedings of the 13th International Conference on Fracture, Beijing, China, 16–21 June 2013. [Google Scholar]

- Ghodrat, S.; Kestens, L.A. Microstructural dependence of tensile and fatigue properties of compacted graphite iron in diesel engine components. Steel Res. Int. 2016, 86, 8. [Google Scholar] [CrossRef]

- Nakamura, R.; Iwabuchi, A. Role of graphite in cast iron on tribological behavior in nano-scratch test. J. Adv. Mech. Des. Syst. Manuf. 2012, 6, 10. [Google Scholar] [CrossRef]

- Waudby, R.; Andersson, P.; Holmberg, K. Low-Speed sliding tests with nodular cast iron in contact with steel wire and a diamond tip. Tribol. Int. 2013, 65, 171–176. [Google Scholar] [CrossRef]

- Li, J.; Beres, W. Three-Dimensional finite element modelling of the scratch test for a tin coated titanium alloy substrate. Wear 2006, 260, 1232–1242. [Google Scholar] [CrossRef]

- Leroch, S.; Varga, M.; Eder, S.J.; Vernes, A.; Ripoll, M.R.; Ganzenmüller, G. Smooth particle hydrodynamics simulation of damage induced by a spherical indenter scratching a viscoplastic material. Int. J. Solids Struct. 2016, 81, 188–202. [Google Scholar] [CrossRef]

- Elwasli, F.; Zemzemi, F.; Mkaddem, A.; Mzali, S.; Mezlini, S. A 3d multi-scratch test model for characterizing material removal regimes in 5083-al alloy. Mater. Des. 2015, 87, 352–362. [Google Scholar]

- Vencl, A.; Arostegui, S.; Favaro, G.; Zivic, F.; Mrdak, M.; Mitrović, S.; Popovic, V. Evaluation of adhesion/cohesion bond strength of the thick plasma spray coatings by scratch testing on coatings cross-sections. Tribol. Int. 2011, 44, 1281–1288. [Google Scholar] [CrossRef]

- Bianchi, L.; Leger, A.C.; Vardelle, M.; Vardelle, A.; Fauchais, P. Splat formation and cooling of plasma-sprayed zirconia. Thin Solid Films 1997, 305, 35–47. [Google Scholar] [CrossRef]

- Lin, J.-S.; Zhou, Y. Can scratch tests give fracture toughness? Eng. Fract. Mech. 2013, 109, 161–168. [Google Scholar] [CrossRef]

- Erickson, L.C.; Westergård, R.; Wiklund, U.; Axen, N.; Hawthorne, H.M.; Hogmark, S. Cohesion in plasma-sprayed coatings—A comparison between evaluation methods. Wear 1998, 214, 30–37. [Google Scholar] [CrossRef]

- Akono, A.-T.; Ulm, F.-J. Scratch test model for the determination of fracture toughness. Eng. Fract. Mech. 2011, 78, 334–342. [Google Scholar] [CrossRef]

- Hossain, M.M.; Xiao, S.; Sue, H.-J.; Kotaki, M. Scratch behavior of multilayer polymeric coating systems. Mater. Des. 2017, 128, 143–149. [Google Scholar] [CrossRef]

- Varga, M.; Leroch, S.; Rojacz, H.; Ripoll, M.R. Study of wear mechanisms at high temperature scratch testing. Wear 2017, 388–389, 112–118. [Google Scholar] [CrossRef]

- Hu, H.; Zhao, S.; Sun, G.; Zhong, Y.; You, B. Evaluation of scratch resistance of functionalized graphene oxide/polysiloxane nanocomposite coatings. Prog. Org. Coat. 2018, 117, 118–129. [Google Scholar] [CrossRef]

- Lin, J.-S.; Zhou, Y. Rebuttal: Shallow wide groove scratch tests do not give fracture toughness. Eng. Fract. Mech. 2015, 133, 211–222. [Google Scholar] [CrossRef]

- Nohava, J.; Bonferroni, B.; Bolelli, G.; Lusvarghi, L. Interesting aspects of indentation and scratch methods for characterization of thermally-sprayed coatings. Surf. Coat. Technol. 2010, 205, 1127–1131. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Li, C.J.; Ohmori, A. Influence of substrate roughness on the bonding mechanisms of high velocity oxy-fuel sprayed coatings. Thin Solid Films 2005, 485, 141–147. [Google Scholar] [CrossRef]

- Kim, W.-S.; Yun, I.-H.; Lee, J.-J.; Jung, H.-T. Evaluation of mechanical interlock effect on adhesion strength of polymer–Metal interfaces using micro-patterned surface topography. Int. J. Adhes. Adhes. 2010, 30, 408–417. [Google Scholar] [CrossRef]

- Mousa, S.; Kim, G.-Y. Experimental study on warm roll bonding of metal/polymer/metal multilayer composites. J. Mater. Process. Technol. 2015, 222, 84–90. [Google Scholar] [CrossRef]

- Ghodrat, S.; Janssen, M.; Kestens, L.A.; Sietsma, J. Volume expansion of compacted graphite iron induced by pearlite decomposition and the effect of oxidation at elevated temperature. Oxid. Met. 2013, 80, 161–176. [Google Scholar] [CrossRef]

- Smallman, R.E.; Bishop, R.J. Structural phases: Their formation and transitions. In Modern Physical Metallurgy and Materials Engineering, 6th ed.; Butterworth-Heinemann: Oxford, UK, 1999; Chapter 3; pp. 42–83. [Google Scholar]

- Monchoux, J.P.; Verdu, C.; Thollet, G.; Fougères, R.; Reynaud, A. Morphological changes of graphite spheroids during heat treatment of ductile cast irons. Acta Mater. 2001, 49, 4355–4362. [Google Scholar] [CrossRef]

- Theuwissen, K.; Lacaze, J.; Laffont, L. Structure of graphite precipitates in cast iron. Carbon 2016, 96, 1120–1128. [Google Scholar] [CrossRef]

- Theuwissen, K.; Lacaze, J.; Véron, M.; Laffont, L. Nano-Scale orientation mapping of graphite in cast irons. Mater. Charact. 2014, 95, 187–191. [Google Scholar] [CrossRef]

| Dimension | Size | |

|---|---|---|

| CG width | 4.14 μm (±2.01) | |

| CG maximum length | 45 μm (±25) | |

| CG aspect ratio | 3.01 μm (±2.1) | |

| SG diameter | 18 μm (±5) | |

| SG nodularity (area fraction of nodular graphite particles) | 15.6% | |

| wt % | Si | Cr | Mn | Ti | Cu | Mg | C |

|---|---|---|---|---|---|---|---|

| AC | 1.25 (0.33) | 0.09 (0.05) | 0.45 (0.13) | 0.07 (0.01) | 0.9 (0.22) | 0.08 (0.09) | - |

| HT LP | 0.95 (0.13) | 0.14 (0.18) | 0.73 (0.19) | 0.07 (0.05) | 0.39 (0.12) | 0.08 (0.05) | - |

| HT F | 1.65 (0.13) | 0.09 (0.01) | 0.35 (0.01) | 0.04 (0.008) | 1.2 (0.87) | 0.08 (0.06) | - |

| Ref [1] | 1.9–2.2 | <0.1 | 0.15–0.4 | <0.015 | 0.75–0.95 | 0.004–0.01 | 3.6–3.9 |

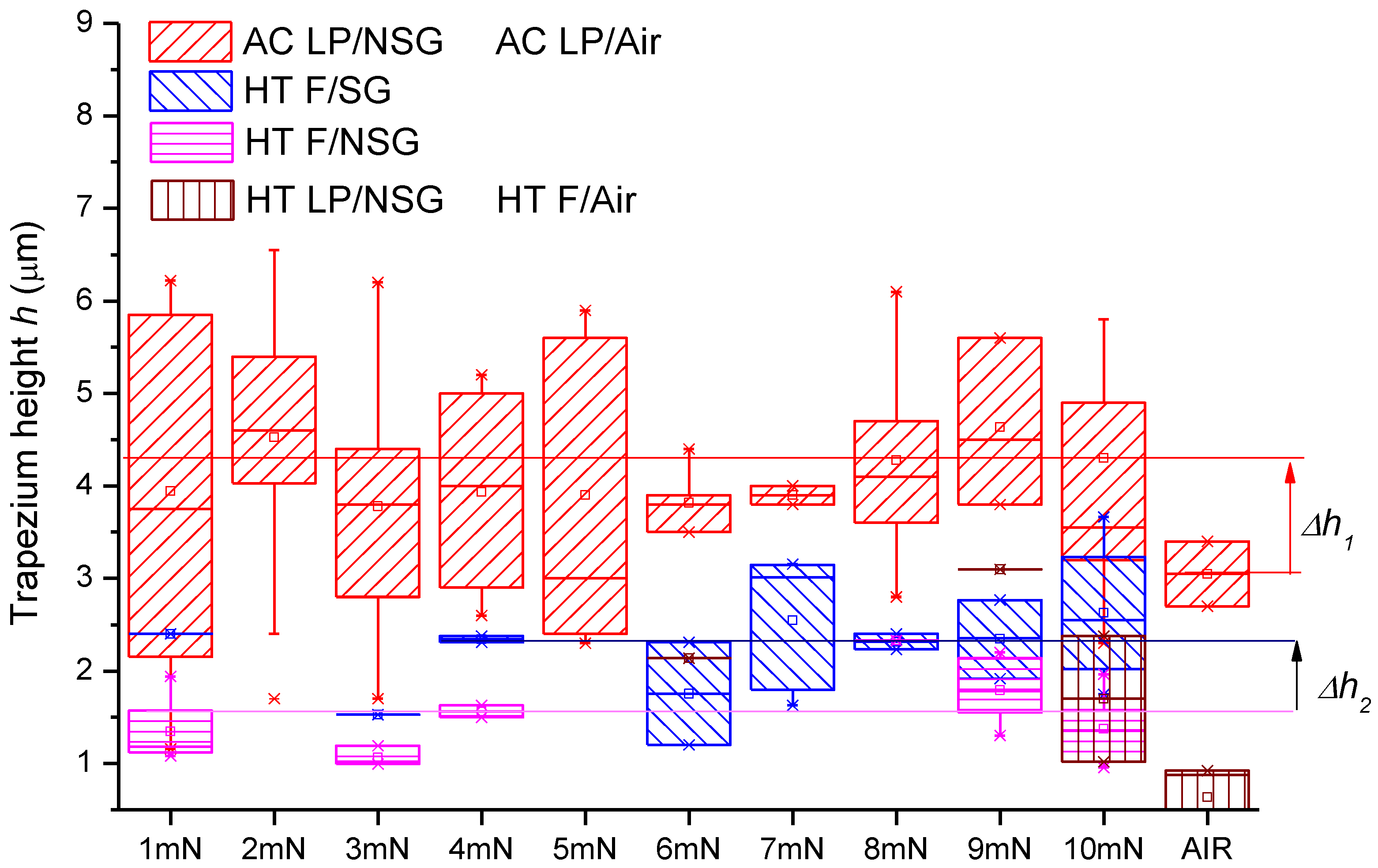

| Phase | HT | AC | |

|---|---|---|---|

| LP | F | LP | |

| h (μm) ΔH (HVN) | h (μm) ΔH (HVN) | h (μm) ΔH (HVN) | |

| SG | - | 2.13 (0.8) 103 (3.8) | - |

| NSG | 2.15 (0.7) 204 (4.5) | 1.5 (0.5) 103 (6.4) | 4.14 (1.4) 226 (7.2) |

| Air | - | 0.911 (0.01) 133 (2.7) | 3.05 (0.35) 256 (5.5) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopez-Covaleda, E.A.; Ghodrat, S.; Kestens, L.A.I.; Sacre, C.-H.; Pardoen, T. Proposal of Characterization Procedure of Metal–Graphite Interface Strength in Compacted Graphite Iron. Materials 2018, 11, 1159. https://doi.org/10.3390/ma11071159

Lopez-Covaleda EA, Ghodrat S, Kestens LAI, Sacre C-H, Pardoen T. Proposal of Characterization Procedure of Metal–Graphite Interface Strength in Compacted Graphite Iron. Materials. 2018; 11(7):1159. https://doi.org/10.3390/ma11071159

Chicago/Turabian StyleLopez-Covaleda, Edwin A., Sepideh Ghodrat, Leo A.I. Kestens, Charles-Henry Sacre, and Thomas Pardoen. 2018. "Proposal of Characterization Procedure of Metal–Graphite Interface Strength in Compacted Graphite Iron" Materials 11, no. 7: 1159. https://doi.org/10.3390/ma11071159

APA StyleLopez-Covaleda, E. A., Ghodrat, S., Kestens, L. A. I., Sacre, C.-H., & Pardoen, T. (2018). Proposal of Characterization Procedure of Metal–Graphite Interface Strength in Compacted Graphite Iron. Materials, 11(7), 1159. https://doi.org/10.3390/ma11071159