Evolution of Elevated-Temperature Strength and Creep Resistance during Multi-Step Heat Treatments in Al-Mn-Mg Alloy

Abstract

1. Introduction

2. Experimental

2.1. Alloy Preparation

2.2. Heat Treatment

2.3. Evolution of Alloy Properties

2.4. Microstructure Observation

3. Results and Discussion

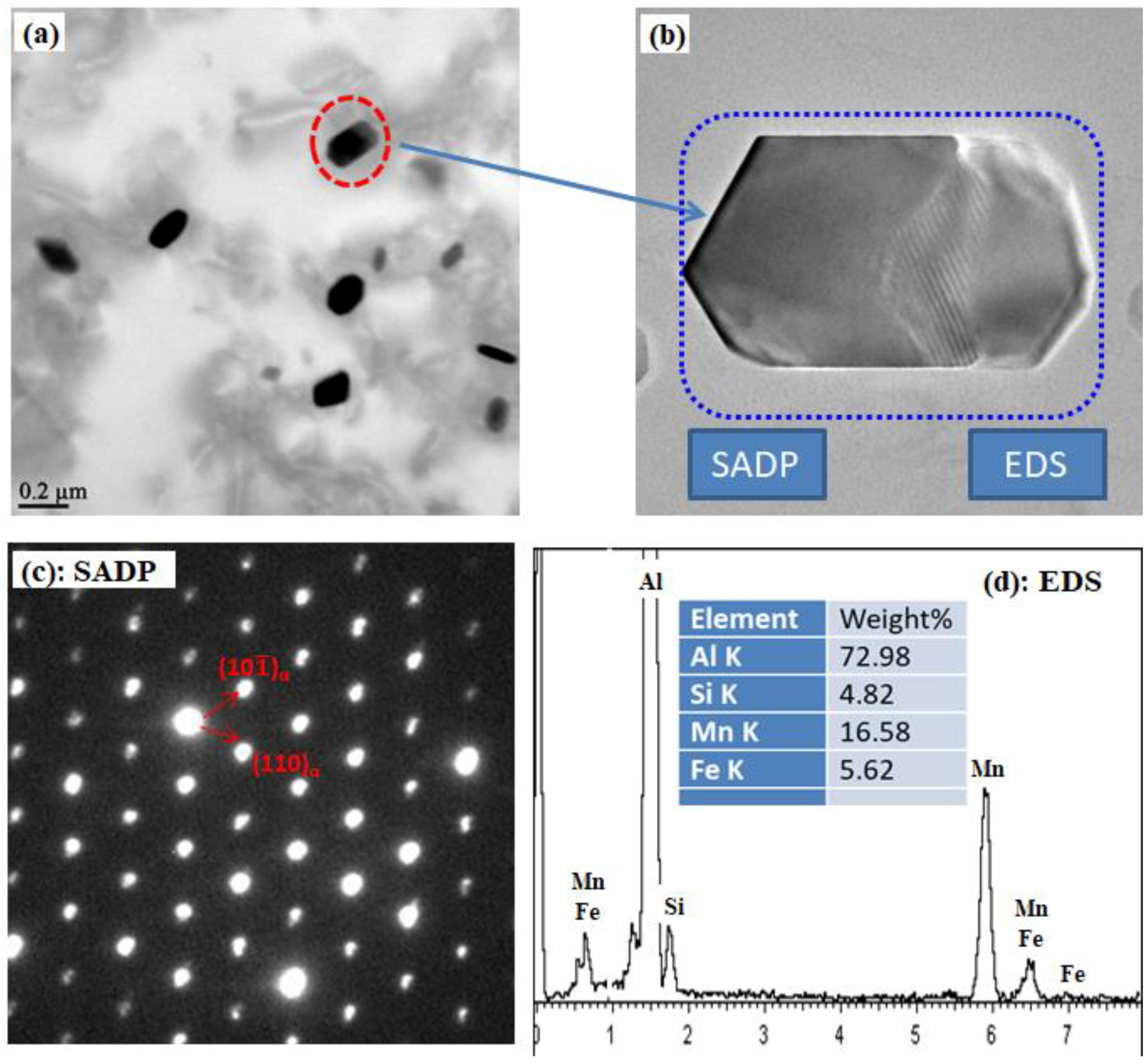

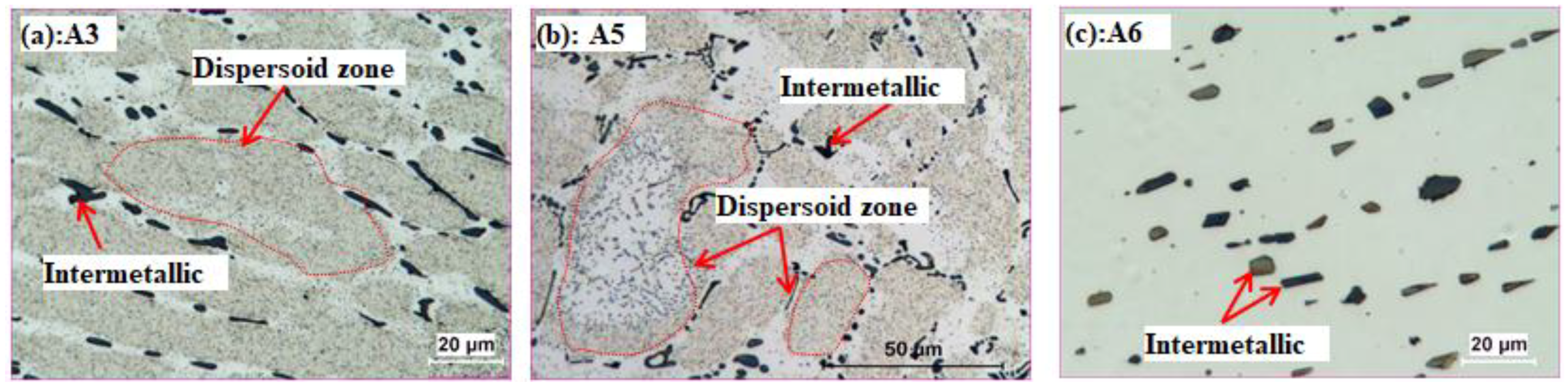

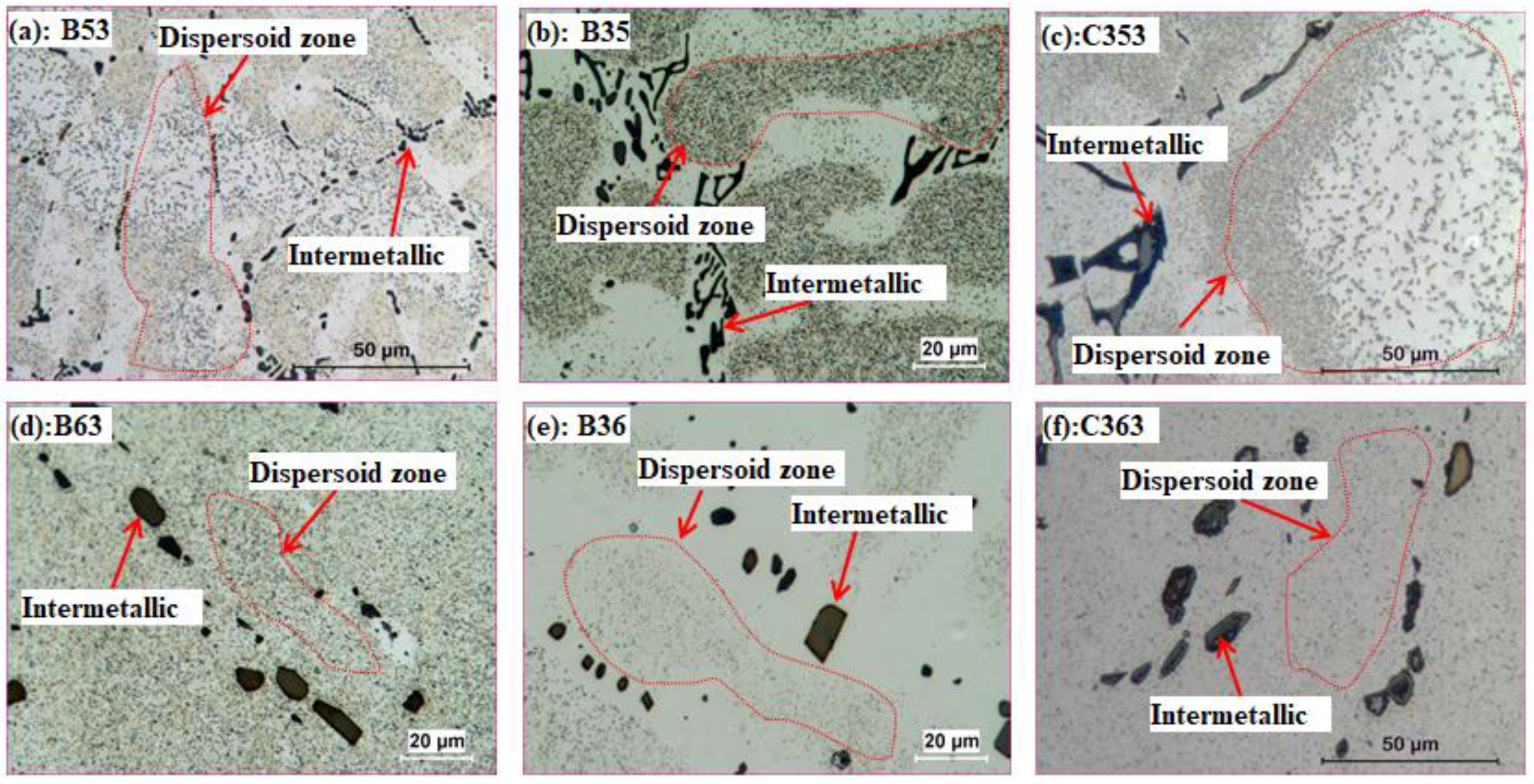

3.1. Precipitation of Dispersoids during the Heat Treatment

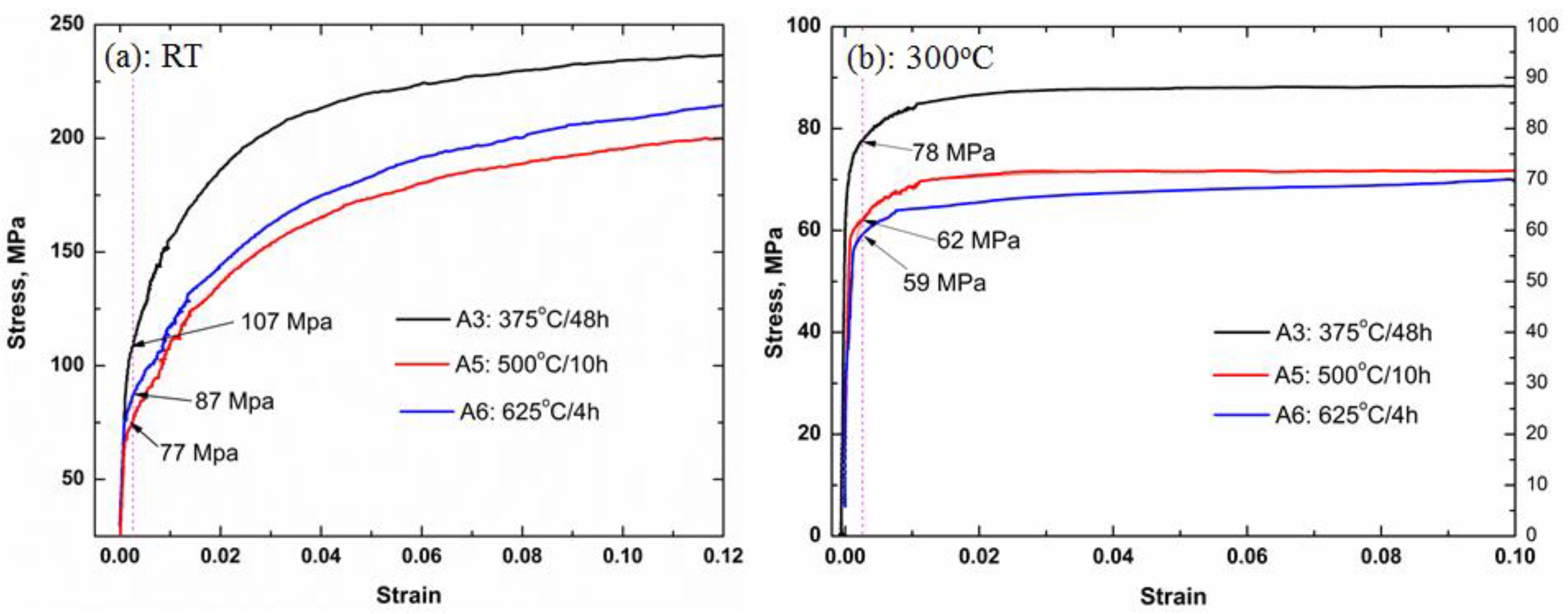

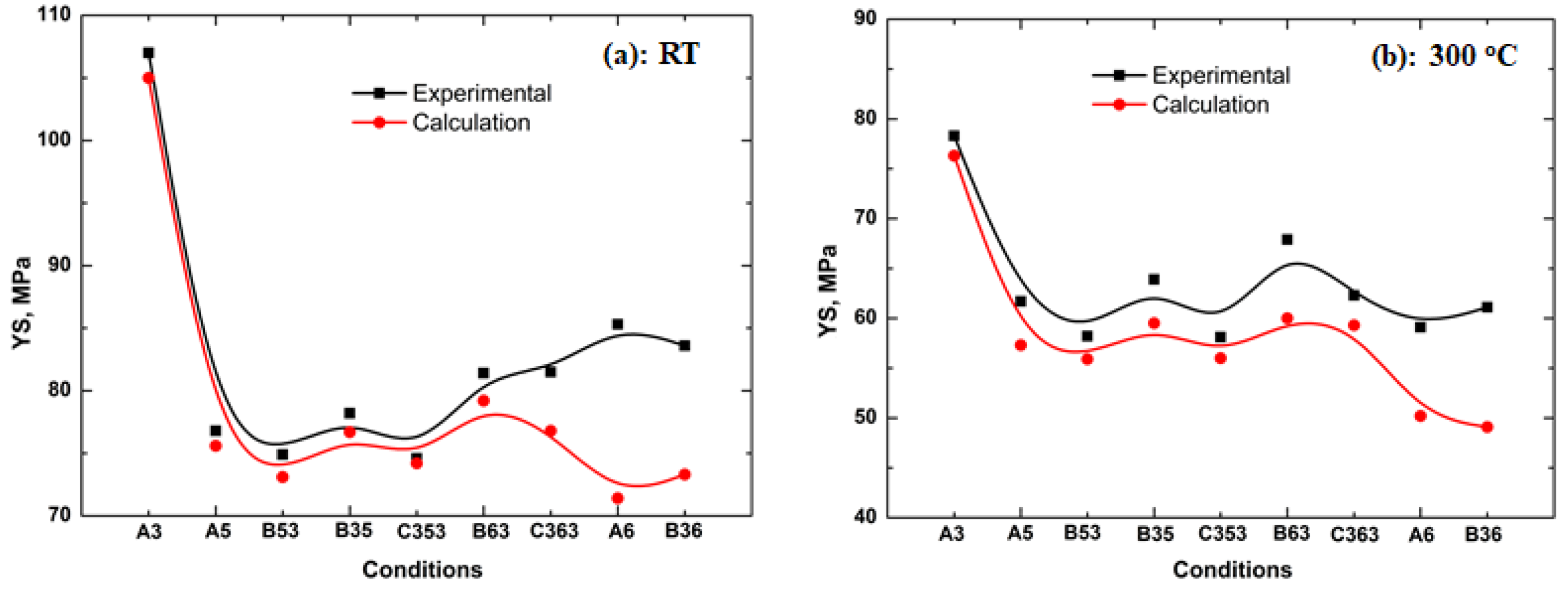

3.2. Compression Yield Strength

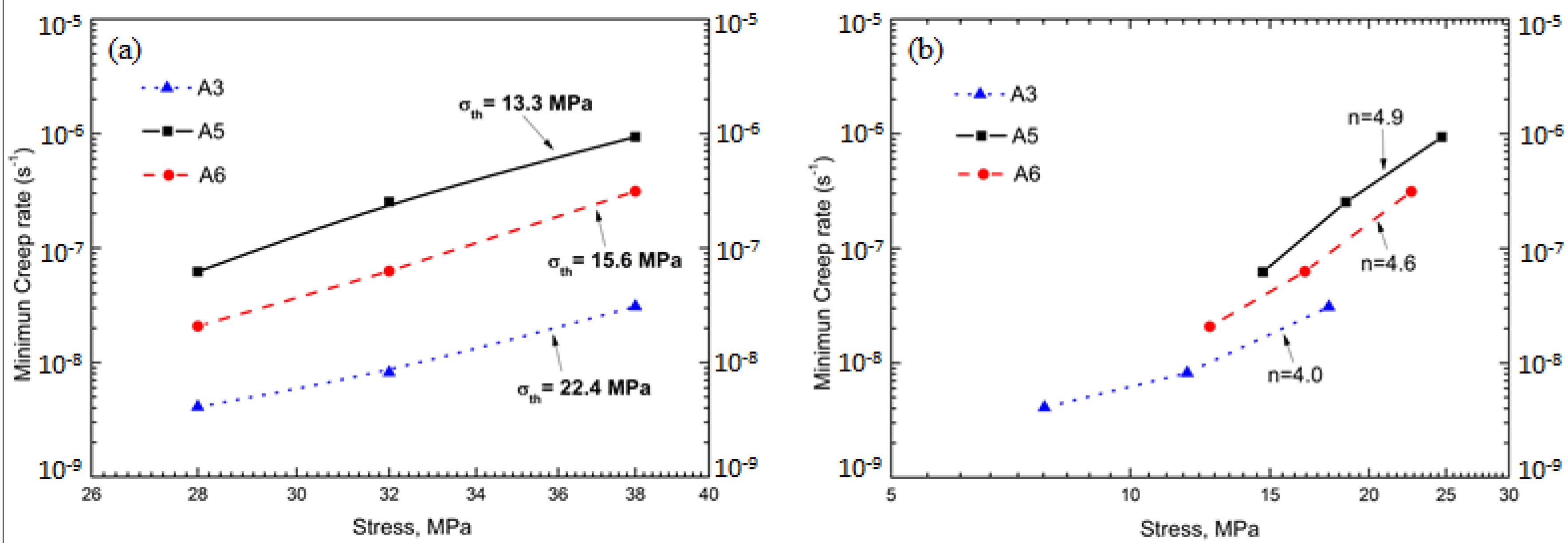

3.3. Creep Resistance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kaufman, J.G. Properties of Aluminum Alloys : Tensile, Creep, and Fatigue Data at High and Low Temperatures; ASM International: Geauga County, OH, USA, 1999. [Google Scholar]

- Polmear, I.J.; Couper, M.J. Design and development of an experimental wrought aluminum alloy for use at elevated temperatures. Metall. Trans. A 1988, 19, 1027–1035. [Google Scholar] [CrossRef]

- Van Dalen, M.E.; Gyger, T.; Dunand, D.C.; Seidman, D.N. Effects of Yb and Zr microalloying additions on the microstructure and mechanical properties of dilute Al-Sc alloys. Acta Mater. 2011, 59, 7615–7626. [Google Scholar] [CrossRef]

- Lai, J.; Zhang, Z.; Chen, X.G. The thermal stability of mechanical properties of Al-B4C composites alloyed with Sc and Zr at elevated temperatures. Mater. Sci. Eng. A 2012, 532, 462–470. [Google Scholar] [CrossRef]

- Farkoosh, A.R.; Grant Chen, X.; Pekguleryuz, M. Dispersoid strengthening of a high temperature Al-Si-Cu-Mg alloy Via Mo Addition. Mater. Sci. Eng. A 2015, 620, 181–189. [Google Scholar] [CrossRef]

- Liu, K.; Ma, H.; Chen, X.G. Enhanced elevated-temperature properties via mo addition in Al-Mn-Mg 3004 alloy. J. Alloys Compd. 2017, 694, 354–365. [Google Scholar] [CrossRef]

- Li, Y.J.; Muggerud, A.M.F.; Olsen, A.; Furu, T. Precipitation of partially coherent α-Al(Mn,Fe)Si dispersoids and their strengthening effect in AA 3003 alloy. Acta Mater. 2012, 60, 1004–1014. [Google Scholar] [CrossRef]

- Liu, K.; Chen, X.G. Evolution of Microstructure and Elevated-Temperature Properties with Mn Addition in Al-Mn-Mg Alloys. J. Mater. Res. 2017, 32, 2585–2593. [Google Scholar] [CrossRef]

- Liu, K.; Chen, X.G. Development of Al-Mn-Mg 3004 alloy for applications at elevated temperature via dispersoid strengthening. Mater. Des. 2015, 84, 340–350. [Google Scholar] [CrossRef]

- Liu, K.; Chen, X.G. Evolution of intermetallics dispersoids, and elevated temperature properties at various Fe contents in Al-Mn-Mg 3004 alloys. Metall. Mater. Trans. B 2015, 47B, 3291–3300. [Google Scholar] [CrossRef]

- Liu, K.; Chen, X.G. Influence of heat treatment and its sequence on elevated-temperature properties of Al-Mn-Mg 3004 alloy. Mater. Sci. Eng. A 2017, 697, 141–148. [Google Scholar] [CrossRef]

- Liu, K.; Nabawy, A.M.; Chen, X.G. Influence of TiB2 nanoparticles on the elevated-temperature properties of Al-Mn-Mg 3004 alloy. Trans. Nonferr. Met. Soc. China 2017, 27, 771–778. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Portnoy, V.K.; Mochugovskiy, A.G.; Zadorozhnyy, M.Y.; Tabachkova, N.Y.; Golovin, I.S. Effect of homogenisation treatment on precipitation, recrystallisation and properties of Al – 3% Mg – TM alloys (TM=Mn, Cr, Zr). Mater. Des. 2016, 109, 197–208. [Google Scholar] [CrossRef]

- Engler, O.; Liu, Z.; Kuhnke, K. Impact of homogenization on particles in the Al-Mg-Mn Alloy AA 5454—experimental and simulation. J. Alloys Compd. 2013, 560, 111–122. [Google Scholar] [CrossRef]

- Radetić, T.; Popović, M.; Romhanji, E. Microstructure evolution of a modified AA5083 aluminum alloy during a multistage homogenization treatment. Mater. Charact. 2012, 65, 16–27. [Google Scholar] [CrossRef]

- Engler, O.; Miller-Jupp, S. Control of second-phase particles in the Al-Mg-Mn alloy AA 5083. J. Alloys Compd. 2016, 689, 998–1010. [Google Scholar] [CrossRef]

- Engler, O.; Kuhnke, K.; Hasenclever, J. Development of intermetallic particles during solidification and homogenization of two AA 5xxx series Al-Mg alloys with different Mg contents. J. Alloys Compd. 2017, 728, 669–681. [Google Scholar] [CrossRef]

- Cadek, J. Creep in precipitation- and dispersion-strengthened alloys (a review). Kovove Mater. 1991, 29, 385–398. [Google Scholar]

- Knipling, K.E.; Dunand, D.C.; Seidman, D.N. Criteria for developing castable creep-resistant aluminum-based alloys—A review. Z METALLKD. 2006, 97, 246–265. [Google Scholar] [CrossRef]

- Zhu, A.W.; Gable, B.M.; Shiflet, G.J.; Starke, E.A., Jr. The intelligent design of high strength, creep-resistant aluminum alloys. In Proceedings of the 8th International Conference ICAA8, Cambridge, UK, 2–5 July 2002. [Google Scholar]

- Knipling, K.E.; Dunand, D.C. Creep resistance of cast and aged Al-0.1Zr and Al-0.1Zr-0.1Ti (at. %) alloys at 300–400 °C. Scr. Mater. 2008, 59, 387–390. [Google Scholar] [CrossRef]

- Krug, M.E.; Dunand, D.C. Modeling the creep threshold stress due to climb of a dislocation in the stress field of a misfitting precipitate. Acta Mater. 2011, 59, 5125–5134. [Google Scholar] [CrossRef]

- Marquis, E.A.; Dunand, D.C. Model for creep threshold stress in precipitation-strengthened alloys with coherent particles. Scr. Mater. 2002, 47, 503–508. [Google Scholar] [CrossRef]

- Seidman, D.N.; Marquis, E.A.; Dunand, D.C. Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys. Acta Mater. 2002, 50, 4021–4035. [Google Scholar] [CrossRef]

- Liu, P.X.; Liu, Y.; Xu, R. Microstructure quantitative analysis of directionally solidified Al-Ni-Y ternary eutectic alloy. Trans. Nonferr. Met. Soc. China 2014, 24, 2443–2451. [Google Scholar]

- Weibel, E.R.; Elias, H. Quantitative Methods in Morphology; Springer: Berlin, Germany, 1967. [Google Scholar]

- Li, Y.J.; Arnberg, L. Quantitative study on the precipitation behavior of dispersoids in DC-cast AA3003 alloy during heating and homogenization. Acta Mater. 2003, 51, 3415–3428. [Google Scholar] [CrossRef]

- Li, Y.; Arnberg, L. Precipitation of dispersoids in DC-Cast AA31O3 alloy during heat treatment. In Essential Readings in Light Metals; Grandfield, J.F., Eskin, D.G., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 1021–1027. [Google Scholar]

- Li, Y.J.; Zhang, W.Z.; Marthinsen, K. Precipitation crystallography of plate-shaped Al6(Mn,Fe) dispersoids in AA5182 alloy. Acta Mater. 2012, 60, 5963–5974. [Google Scholar] [CrossRef]

- Ping, Y.; Olaf, E.; Hans-Joachim, K. Orientation relationship between Al6Mn precipitates and the Al matrix during continuous recrystallization in Al-1.3%Mn. J. Appl. Crystallogr. 1999, 32, 1105–1118. [Google Scholar]

- Kamat, R. AA3104 can-body stock ingot: Characterization and Homogenization. JOM 1996, 48, 34–38. [Google Scholar] [CrossRef]

- Huang, H.W.; Ou, B.L. Evolution of precipitation during different homogenization treatments in a 3003 aluminum alloy. Mater. Des. 2009, 30, 2685–2692. [Google Scholar] [CrossRef]

- Li, Y.J.; Arnberg, L. Evolution of eutectic intermetallic particles in DC-cast AA3003 alloy during heating and homogenization. Mater. Sci. Eng. A 2003, 347, 130–135. [Google Scholar] [CrossRef]

- Muggerud, A.M.F.; Mørtsell, E.A.; Li, Y.; Holmestad, R. Dispersoid strengthening in AA3xxx alloys with varying mn and si content during annealing at low temperatures. Mater. Sci. Eng. A 2013, 567, 21–28. [Google Scholar] [CrossRef]

- Karnesky, R.A.; Meng, L.; Dunand, D.C. Strengthening mechanisms in aluminum containing coherent Al3Sc precipitates and incoherent Al2O3 dispersoids. Acta Mater. 2007, 55, 1299–1308. [Google Scholar] [CrossRef]

- Huskins, E.L.; Cao, B.; Ramesh, K.T. Strengthening mechanisms in An Al–Mg alloy. Mater. Sci. Eng. A 2010, 527, 1292–1298. [Google Scholar] [CrossRef]

- Kahl, S.; Ekström, H.E.; Mendoza, J. Tensile, Fatigue, and Creep properties of aluminum heat exchanger tube alloys for temperatures from 293 K to 573 K (20 °C to 300 °C). Metall. Mater. Trans. A 2014, 45, 663–681. [Google Scholar] [CrossRef]

- Zhao, Q. The Influence of Mn, Fe and Si on the Work Hardening of Aluminum Alloys. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2013. [Google Scholar]

- Kazantzis, A.V.; Chen, Z.G.; De Hosson, J.T.M. Deformation mechanism of aluminum–magnesium alloys at elevated temperatures. J. Mater. Sci. 2013, 48, 7399–7408. [Google Scholar] [CrossRef]

- Shi, C.; Chen, X.G. Effect of vanadium on hot deformation and microstructural evolution of 7150 aluminum alloy. Mater. Sci. Eng. A 2014, 613, 91–102. [Google Scholar] [CrossRef]

- Sherby, O.D.; Goldberg, A.; Ruano, O.A. Solute-diffusion-controlled dislocation creep in pure aluminium containing 0.026 at.% Fe. Philos. Mag. 2004, 84, 2417–2434. [Google Scholar] [CrossRef]

- Dieter, G.E. Mechanical Metallurgy; McGraw-Hill: New York, NY, USA, 1986. [Google Scholar]

- Deshmukh, S.P.; Mishra, R.S.; Kendig, K.L. Creep behavior and threshold stress of an extruded Al–6Mg–2Sc–1Zr alloy. Mater. Sci. Eng. A 2004, 381, 381–385. [Google Scholar] [CrossRef]

- Farkoosh, A.R.; Chen, X.G.; Pekguleryuz, M. Interaction between molybdenum and manganese to form effective dispersoids in an Al–Si–Cu–Mg alloy and their influence on creep resistance. Mater. Sci. Eng. A 2015, 627, 127–138. [Google Scholar] [CrossRef]

- Li, Y.; Nutt, S.R.; Mohamed, F.A. An investigation of creep and substructure formation in 2124 Al. Acta Mater. 1997, 45, 2607–2620. [Google Scholar] [CrossRef]

- Mohamed, F.A.; Park, K.-T.; Lavernia, E.J. Creep behavior of discontinuous SiCAl composites. Mater. Sci. Eng. A 1992, 150, 21–35. [Google Scholar] [CrossRef]

- Lin, Z.; Li, Y.; Mohamed, F.A. Creep and substructure in 5 vol.% SiC-2124Al composite. Mater. Sci. Eng. A 2002, 332, 330–342. [Google Scholar] [CrossRef]

- Watanabe, H.; Mukai, T.; Higashi, K. Influence of temperature and grain size on threshold stress for superplastic flow in a fine-grained magnesium alloy. Metall. Mater. Trans. A 2008, 39, 2351–2362. [Google Scholar] [CrossRef]

| Code | Parameter | Code | Parameter |

|---|---|---|---|

| A3 | 375 °C/48 h | - | - |

| A5 | 500 °C/10 h | A6 | 625 °C/4 h |

| B53 | 500 °C/10 h + 375 °C/48 h | B63 | 625 °C/4 h + 375 °C/48 h |

| B35 | 375 °C/48 h + 500 °C/10 h | B36 | 375 °C/48 h + 625 °C/4 h |

| C353 | 375 °C/48 h + 500 °C/10 h + 375 °C/48 h | C363 | 375 °C/48 h + 625 °C/4 h + 375 °C/48 h |

| Code | Dispersoids | PFZ | Code | Dispersoids | PFZ | ||

|---|---|---|---|---|---|---|---|

| Equivalent diameter nm | Volume fraction vol. % | Volume fraction vol. % | Equivalent diameter n | Volume fraction vol. % | Volume fraction vol. % | ||

| A3 | 67(11) * | 2.95(0.68) | 28(3) | ||||

| A5 | 107(14) | 1.58(0.52) | 32(4) | A6 | 102(12) | 0.27(0.13) | – |

| B53 | 112(15) | 1.36(0.62) | 55(8) | B63 | 82(15) | 0.87(0.15) | 10(5) |

| B35 | 105(12) | 1.67(0.54) | 37(6) | B36 | 106(14) | 0.51(0.21) | – |

| C353 | 111(21) | 1.61(0.48) | 45(7) | C363 | 83(12) | 1.21(0.15) | 8(6) |

| Code | EC (%IACS) | YS (RT) (MPa) | YS (300 °C) (MPa) | Code | EC (%IACS) | YS (RT) (MPa) | YS (300 °C) (MPa) |

|---|---|---|---|---|---|---|---|

| A3 | 37.8 (0.3) * | 107.9(3.5) | 78.3(0.6) | ||||

| A5 | 39.2(0.5) | 77.7(2.3) | 61.7(0.9) | A6 | 26.9 (0.8) | 86.2(1.8) | 59.3(1.6) |

| B53 | 38.1(0.6) | 75.8(1.8) | 58.2(0.5) | B63 | 38.3(0.5) | 82.3(2.5) | 60.9(1.4) |

| B35 | 38.9(0.5) | 79.1(2.1) | 63.9(1.1) | B36 | 27.9(0.5) | 84.5(2.1) | 61.9(1.9) |

| C353 | 37.9(0.2) | 76.4(2.6) | 58.6(0.5) | C363 | 38.1(0.6) | 82.4(1.9) | 62.3(1.5) |

| Code | B35 | B53 | C353 | B36 | B63 | C363 |

|---|---|---|---|---|---|---|

| σth (MPa) | 13.4 | 12.8 | 13.1 | 15.3 | 14.2 | 14.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.S.; Liu, K.; Wang, S.L. Evolution of Elevated-Temperature Strength and Creep Resistance during Multi-Step Heat Treatments in Al-Mn-Mg Alloy. Materials 2018, 11, 1158. https://doi.org/10.3390/ma11071158

Wang GS, Liu K, Wang SL. Evolution of Elevated-Temperature Strength and Creep Resistance during Multi-Step Heat Treatments in Al-Mn-Mg Alloy. Materials. 2018; 11(7):1158. https://doi.org/10.3390/ma11071158

Chicago/Turabian StyleWang, G. S., K. Liu, and S. L. Wang. 2018. "Evolution of Elevated-Temperature Strength and Creep Resistance during Multi-Step Heat Treatments in Al-Mn-Mg Alloy" Materials 11, no. 7: 1158. https://doi.org/10.3390/ma11071158

APA StyleWang, G. S., Liu, K., & Wang, S. L. (2018). Evolution of Elevated-Temperature Strength and Creep Resistance during Multi-Step Heat Treatments in Al-Mn-Mg Alloy. Materials, 11(7), 1158. https://doi.org/10.3390/ma11071158