Optimization of TiC Content during Fabrication and Mechanical Properties of Ni-Ti-Al/TiC Composites Using Mixture Designs

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

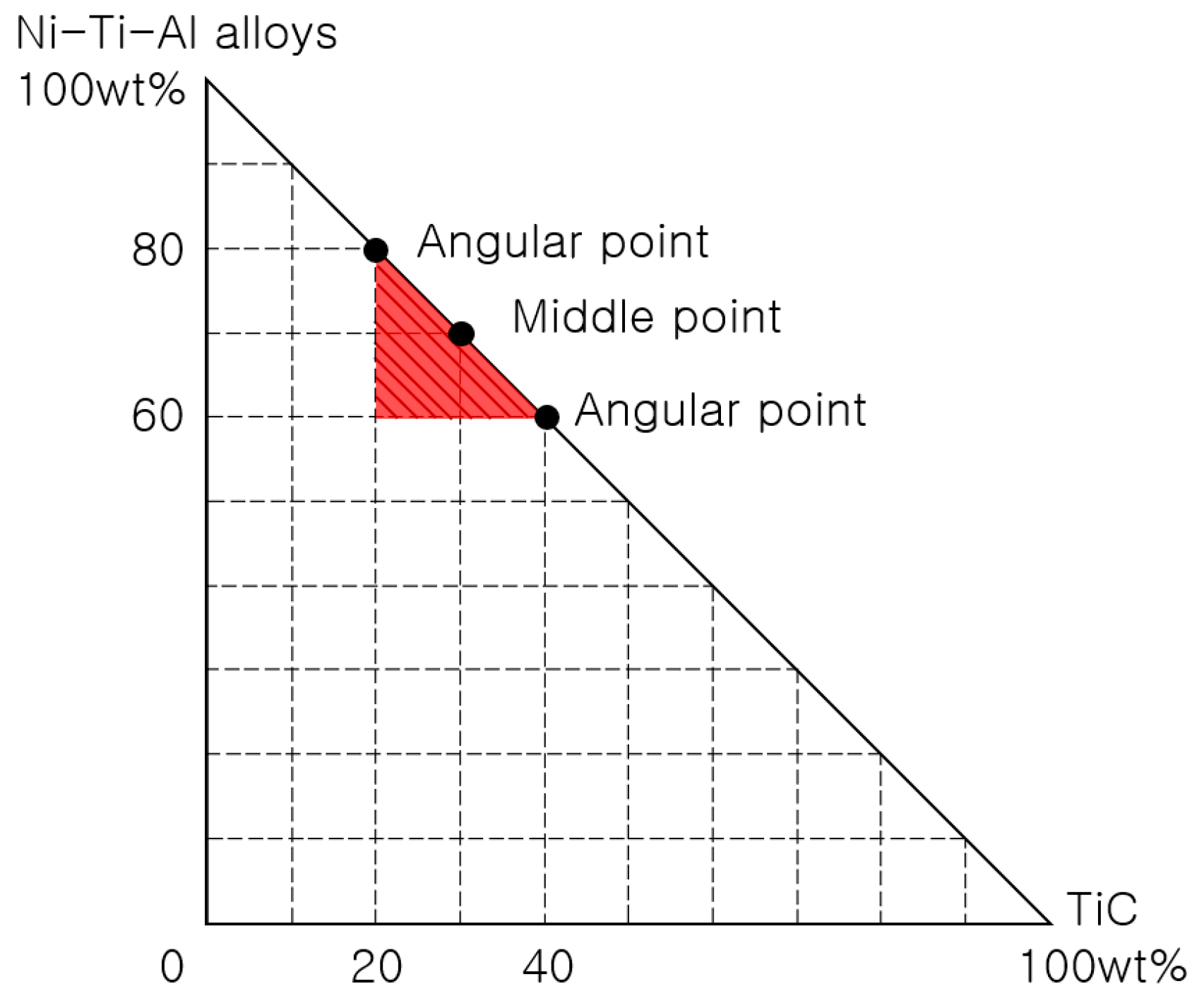

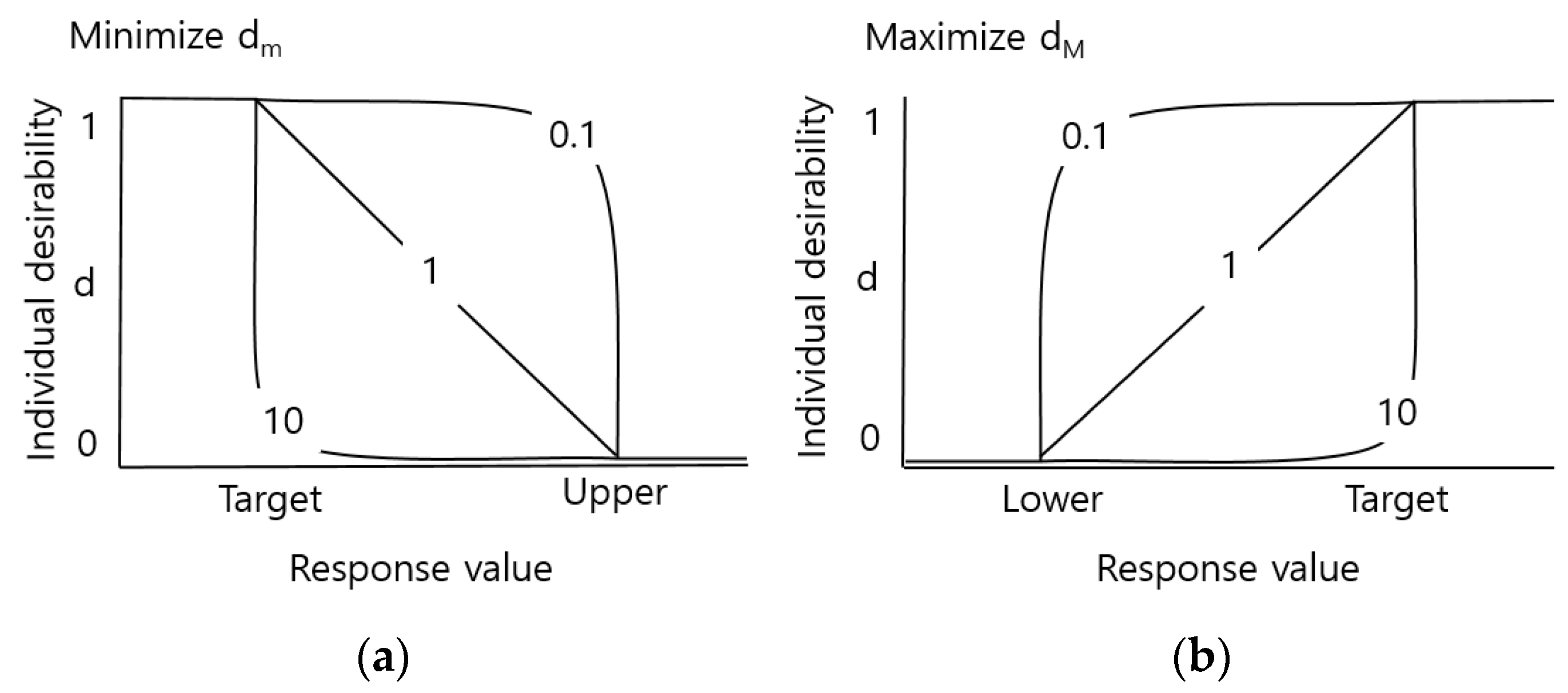

3.1. Optimization of TiC Contents through the Mixture Design

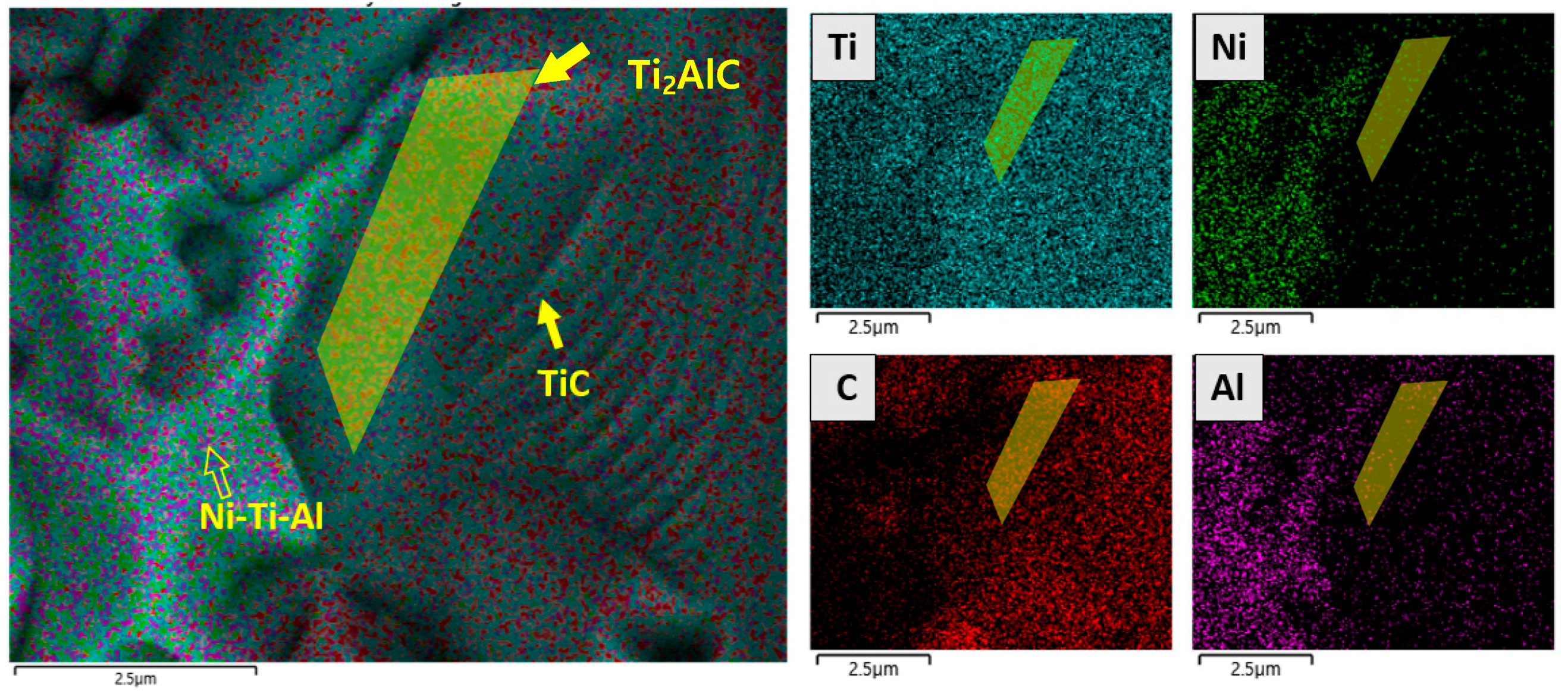

3.2. Effect of TiC Contents on Density and XRD Pattern Microstructure of Ni-Ti-Al/TiC Composites

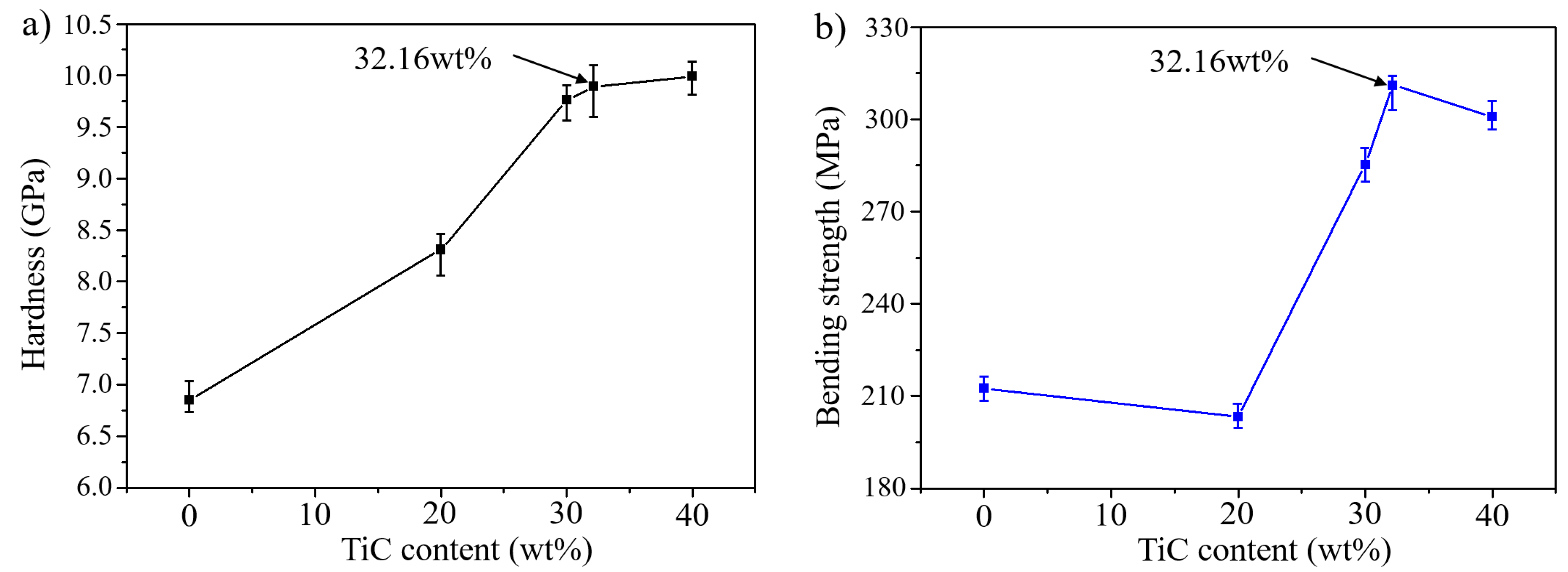

3.3. Mechanical Properties of Ni-Ti-Al/TiC Composites

4. Conclusions

- The Ti2AlC phase was increased with the addition of TiC, but the Ti2AlC phase was not formed sufficiently between the interfaces due to the failure of TiC particles to penetrate smoothly at 40 wt %. High densification was achieved using the spark plasma sintering method. However, density was reduced with an increase in the TiC content, and pores were generated at interfaces between TiC and Ni-Ti-Al.

- The hardness value increased with an increase in the TiC content, and the highest hardness value was measured at 40 wt %. In addition, TiC was saturated on the surface at 40 wt % and an increase range of hardness was decreased from 9.75 GPa to 9.98 GPa.

- The bending strength was increased due to the formation of Ti2AlC, and the formation of the NiTi phase was inhibited with an increase in the TiC particles. The interfacing bonding energy increased between the TiC and Ni-Ti-Al alloy during the Ti2AlC phase. The Ti2AlC peak at 32.16 wt % was superior to that of the other content materials and the bending strength was superior at 311 MPa.

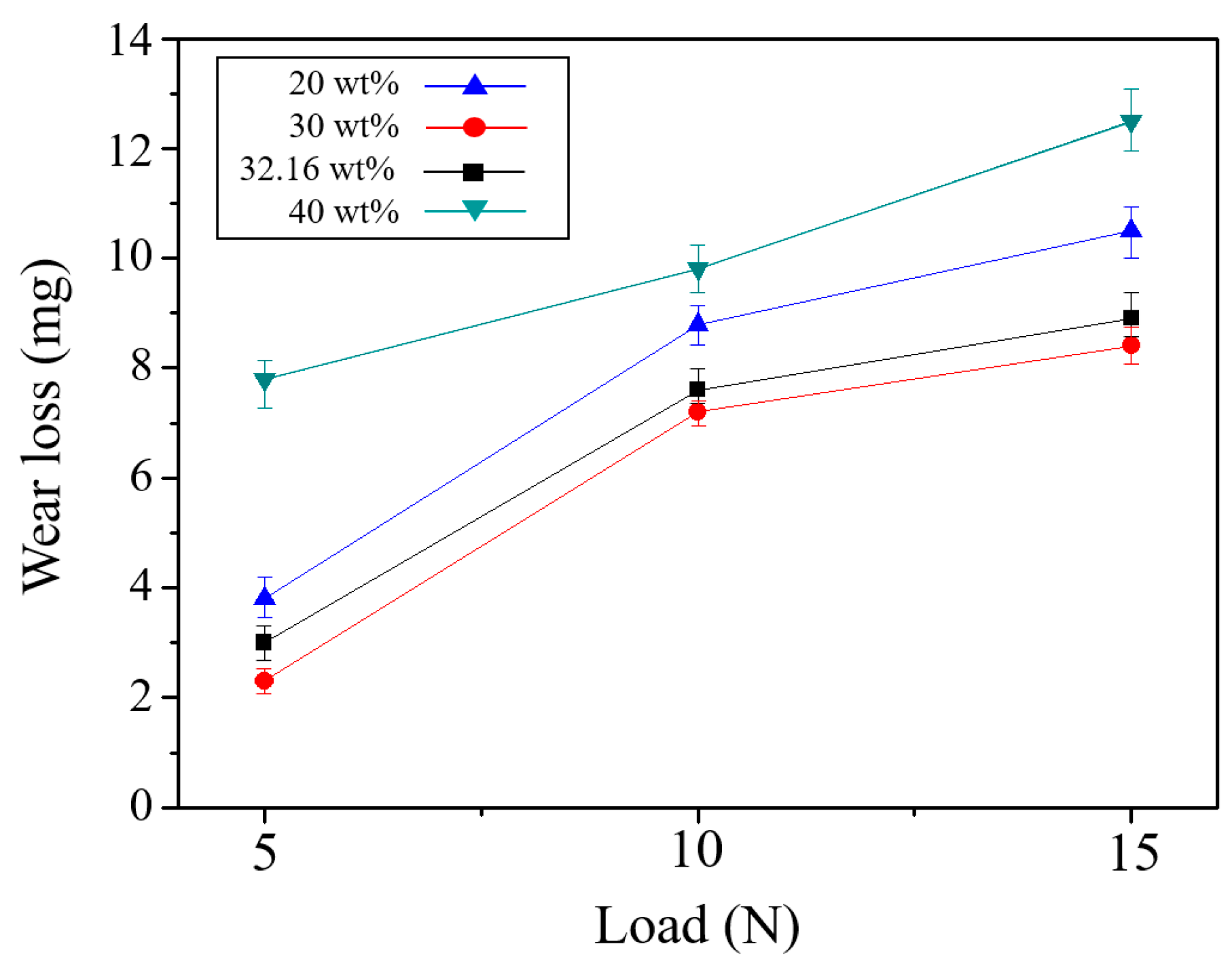

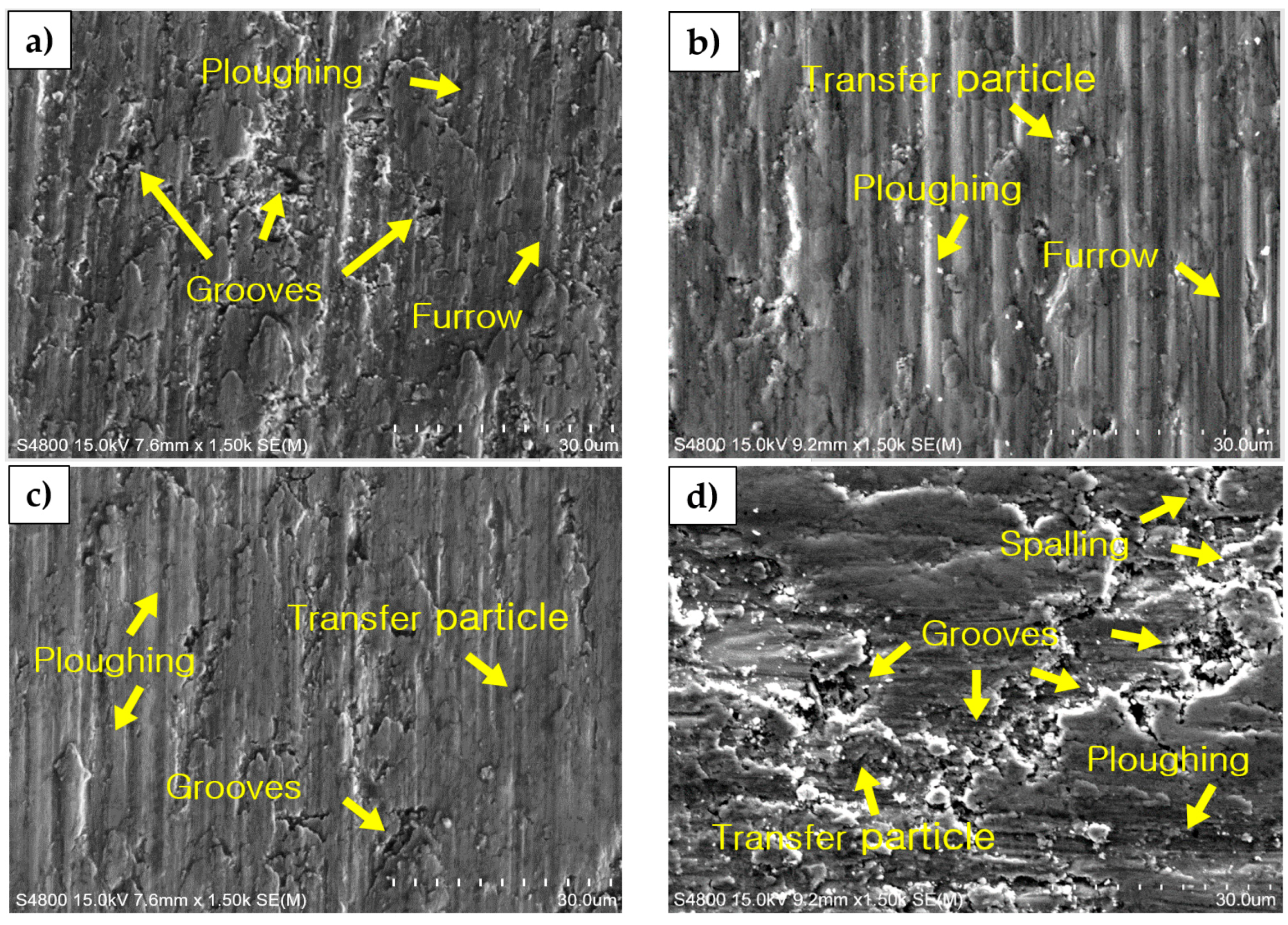

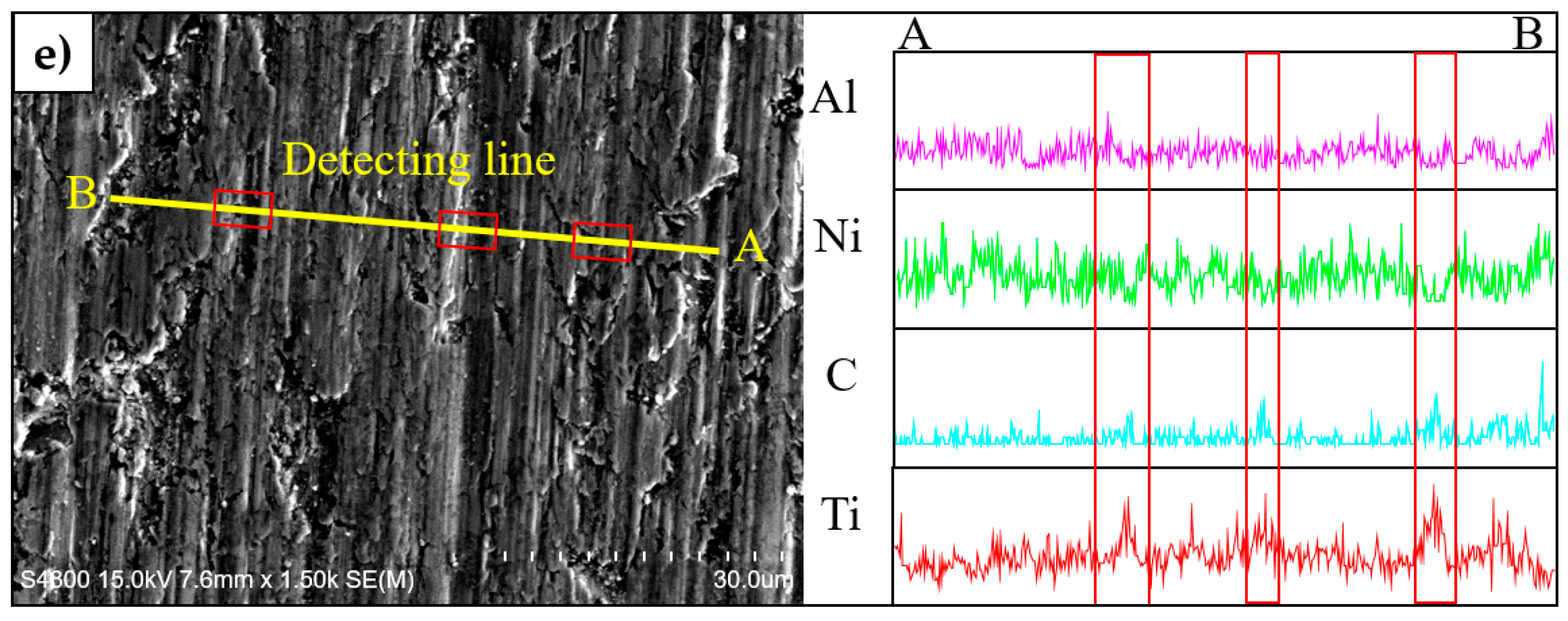

- The TiC content has a significant effect on the wear resistance of the composites. At a TiC content of 30 wt %, the weight loss of the composites reached a minimum value of 2.2 mg. Secondary wear occurred with the TiC particle by spalling at TiC 40 wt %.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Koizumi, Y.; Ro, Y.; Nakazawa, S.; Harada, H. NiTi-base intermetallic alloys strengthened by Al substitution. Mater. Sci. Eng. A 1997, 223, 36–41. [Google Scholar] [CrossRef]

- Meng, L.; Li, Y.; Zhao, X.; Xu, J.; Xu, H. The mechanical properties of intermetallic Ni50−xTi50Alx alloys (x = 6, 7, 8, 9). Intermetallics 2007, 15, 814–818. [Google Scholar] [CrossRef]

- Zhou, L.; Zheng, L.J.; Zhang, H. Effect of heating temperature on microstructure of directionally solidified Ni-43Ti-7Al alloy. Mater. Sci. Forum 2017, 898, 552–560. [Google Scholar] [CrossRef]

- Song, X.; Li, Y.; Zhang, F. Microstructure and tensile properties of isothermally forged Ni–43Ti–4Al–2Nb–2Hf alloy. Rare Met. 2013, 32, 475–479. [Google Scholar] [CrossRef]

- Song, X.; Li, Y.; Zhang, F. Microstructure and mechanical properties of Nb- and Mo-modified NiTi–Al-based intermetallics processed by isothermal forging. Mater. Sci. Eng. A 2014, 594, 229–234. [Google Scholar] [CrossRef]

- Song, X.; Li, Y.; Zhang, F.; Li, S. NiTiAl intermetallic alloys strengthened by Mo replacement. Chin. J. Aeronaut. 2010, 23, 715–719. [Google Scholar]

- Li, Y.; Yu, K.; Song, X.; Zhang, F. Effect of Zr addition on microstructures and mechanical properties of Ni-46Ti-4Al alloy. Rare Met. 2011, 30, 522–526. [Google Scholar] [CrossRef]

- Xu, H.; Meng, L.; Xu, J.; Li, Y.; Zhao, X. Mechanical properties and oxidation characteristics of TiNiAl (Nb) intermetallics. Intermetallics 2007, 15, 778–782. [Google Scholar] [CrossRef]

- Xiaoyun, S.; Wenjun, Y.; Songxiao, H.; Yan, L. Oxidation behavior of NiTi-Al based alloy with Nb and Mo additions. IOP Conf. Ser. Mater. Sci. Eng. 2017, 250, 1–5. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, Y.; Li, R.F.; Wang, J.Q.; Chen, L.L.; Li, S.B. Preparation and mechanical properties of TiC-Fe cermets and TiC-Fe/Fe bilayer composites. J. Mater. Eng. Perform. 2017, 26, 4933–4939. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, T.; He, X.B.; Shao, H.P.; Tang, B.; Qu, X.H. Fabrication and properties of the TiC reinforced high-strength steel matrix composite. Int. J. Refract. Met. Hard Mater. 2016, 58, 14–21. [Google Scholar] [CrossRef]

- Liu, N.; Chen, M.H.; Xu, Y.D.; Zhou, J.; Shi, M. Wettability and bonding between Ni and Ti(C, N) with multiple carbide additions. J. Mater. Sci. Technol. 2005, 21, 53–59. [Google Scholar]

- Korean Standards Association. Sintered Materials, Excluding Hard Metals—Determination of Transverse Rupture Strength; KS D ISO 3325; Korean Standards Association: Seoul, Korea, 2011. [Google Scholar]

- Gonzalez, J.J.; Llorente, J.; Bram, M.; Belmonte, M.; Guillon, O. Novel Cr2AlC MAX-phase/SiC fiber composites: Synthesis, processing and tribological response. J. Eur. Ceram. Soc. 2017, 37, 467–475. [Google Scholar] [CrossRef]

- Wang, Y.; Lei, K.; Ruan, Y.; Dong, W. Microstructure and wear resistance of c-BN/Ni–Cr–Ti composites prepared by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2016, 54, 98–103. [Google Scholar] [CrossRef]

- Bin, C.; Ye, F.T.; Long, H.E.; Hua, T.; Li, G. Tribological properties of TiC particles reinforced Ni-based alloy composite coatings. Trans. Nonferr. Met. Soc. China 2013, 23, 1681–1688. [Google Scholar]

| Sample | Ni | Ti | Al | TiC |

|---|---|---|---|---|

| Ni-Ti-Al/20 wt % TiC | 40 | 36.8 | 3.2 | 20 |

| Ni-Ti-Al/30 wt % TiC | 35 | 32.2 | 2.8 | 30 |

| Ni-Ti-Al/40 wt % TiC | 30 | 27.6 | 2.4 | 40 |

| Sample | Theoretical Density (g/cm3) | Measured Density (g/cm3) | Relative Density (g/cm3) |

|---|---|---|---|

| Ni-Ti-Al/20 wt % TiC | 5.59 | 5.52 | 98.8% |

| Ni-Ti-Al/30 wt % TiC | 5.50 | 5.41 | 98.4% |

| Ni-Ti-Al/40 wt % TiC | 5.41 | 5.25 | 97.1% |

| Ni-Ti-Al/32.16 wt % TiC | 5.48 | 5.37 | 98.1% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.-J.; Park, J.-H.; Kang, M.-C. Optimization of TiC Content during Fabrication and Mechanical Properties of Ni-Ti-Al/TiC Composites Using Mixture Designs. Materials 2018, 11, 1133. https://doi.org/10.3390/ma11071133

Lee D-J, Park J-H, Kang M-C. Optimization of TiC Content during Fabrication and Mechanical Properties of Ni-Ti-Al/TiC Composites Using Mixture Designs. Materials. 2018; 11(7):1133. https://doi.org/10.3390/ma11071133

Chicago/Turabian StyleLee, Dong-Jin, Jae-Ha Park, and Myung-Chang Kang. 2018. "Optimization of TiC Content during Fabrication and Mechanical Properties of Ni-Ti-Al/TiC Composites Using Mixture Designs" Materials 11, no. 7: 1133. https://doi.org/10.3390/ma11071133

APA StyleLee, D.-J., Park, J.-H., & Kang, M.-C. (2018). Optimization of TiC Content during Fabrication and Mechanical Properties of Ni-Ti-Al/TiC Composites Using Mixture Designs. Materials, 11(7), 1133. https://doi.org/10.3390/ma11071133