A Modified Back Propagation Artificial Neural Network Model Based on Genetic Algorithm to Predict the Flow Behavior of 5754 Aluminum Alloy

Abstract

1. Introduction

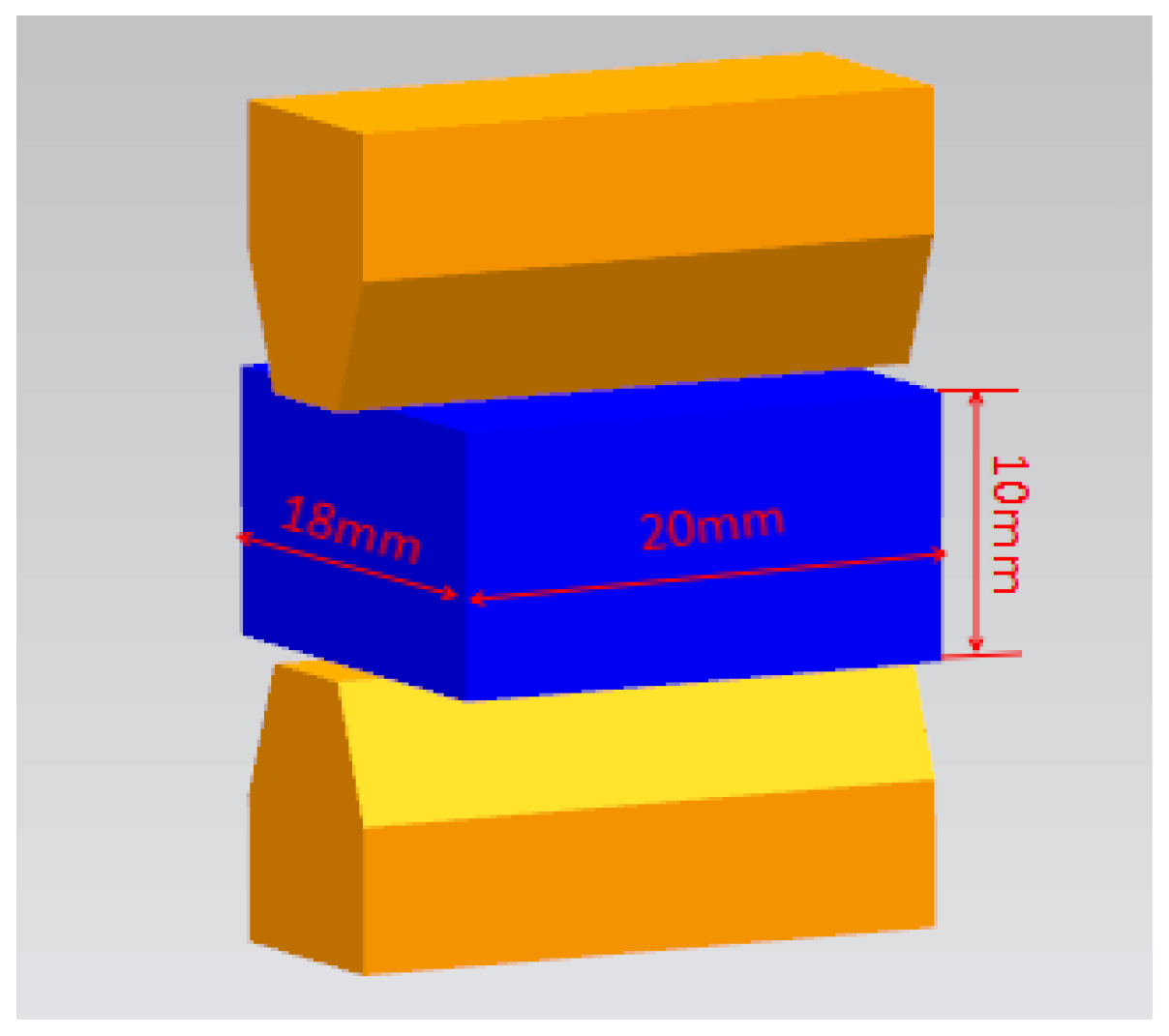

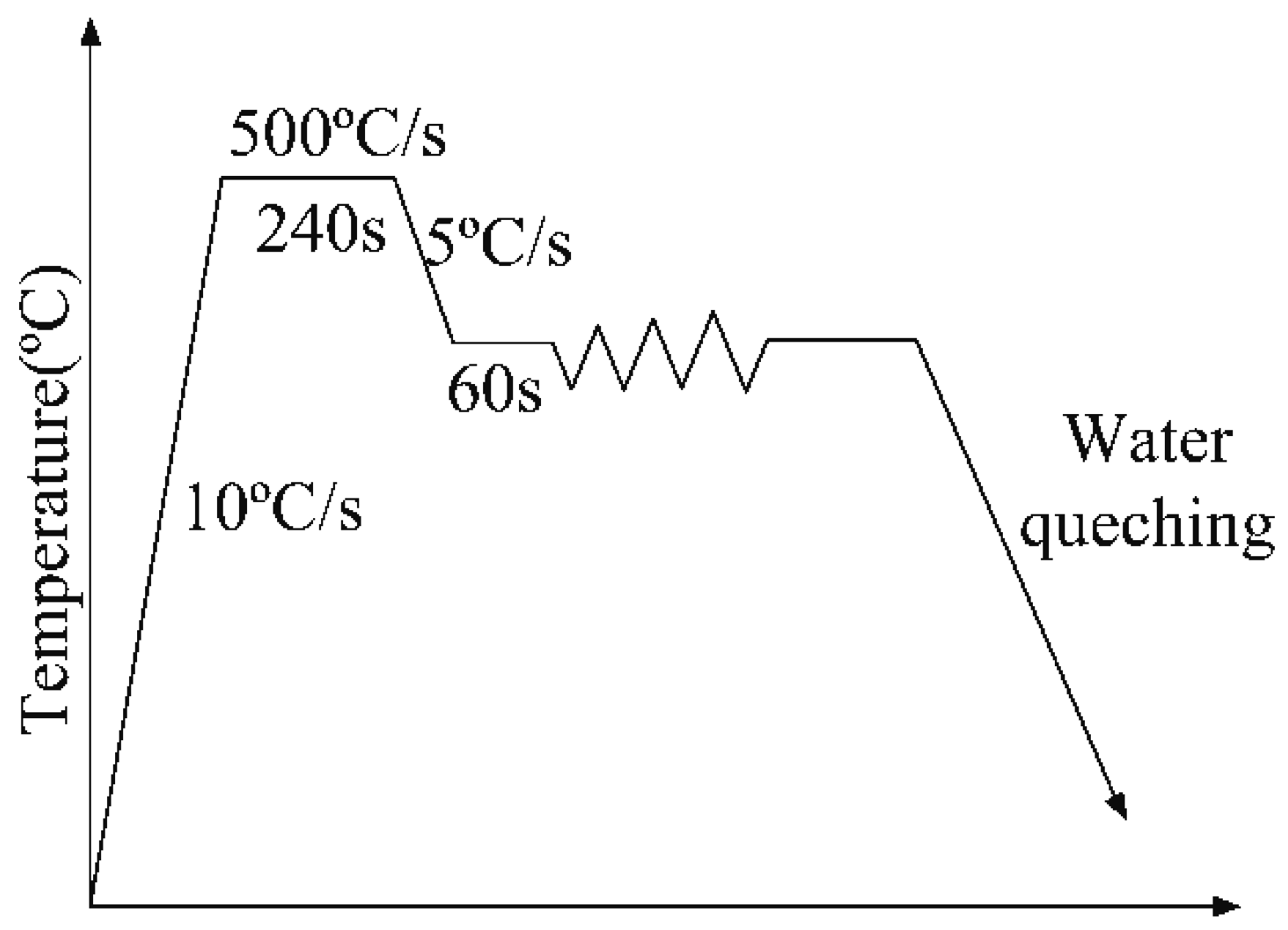

2. Experiment and Materials

3. Results and Discussion

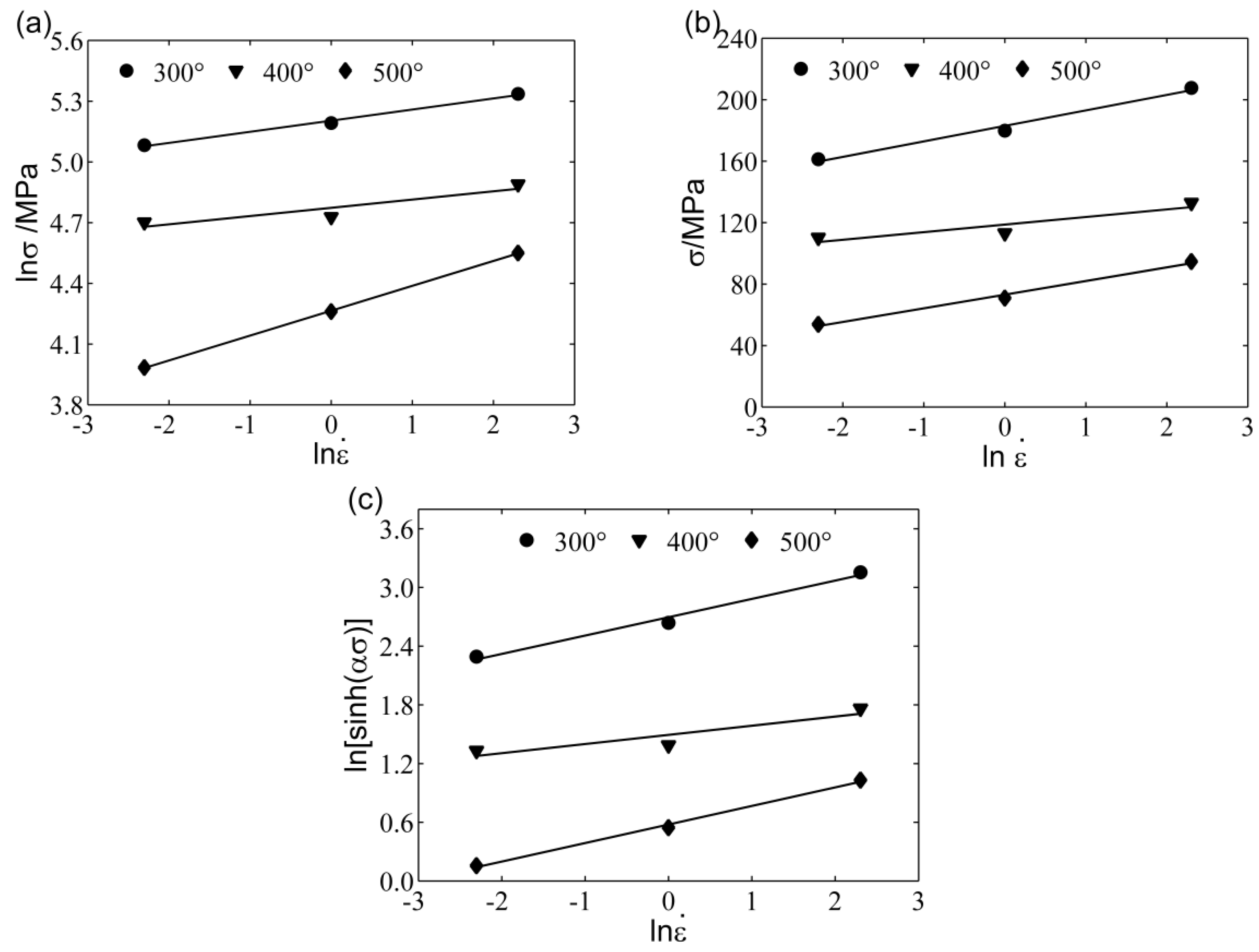

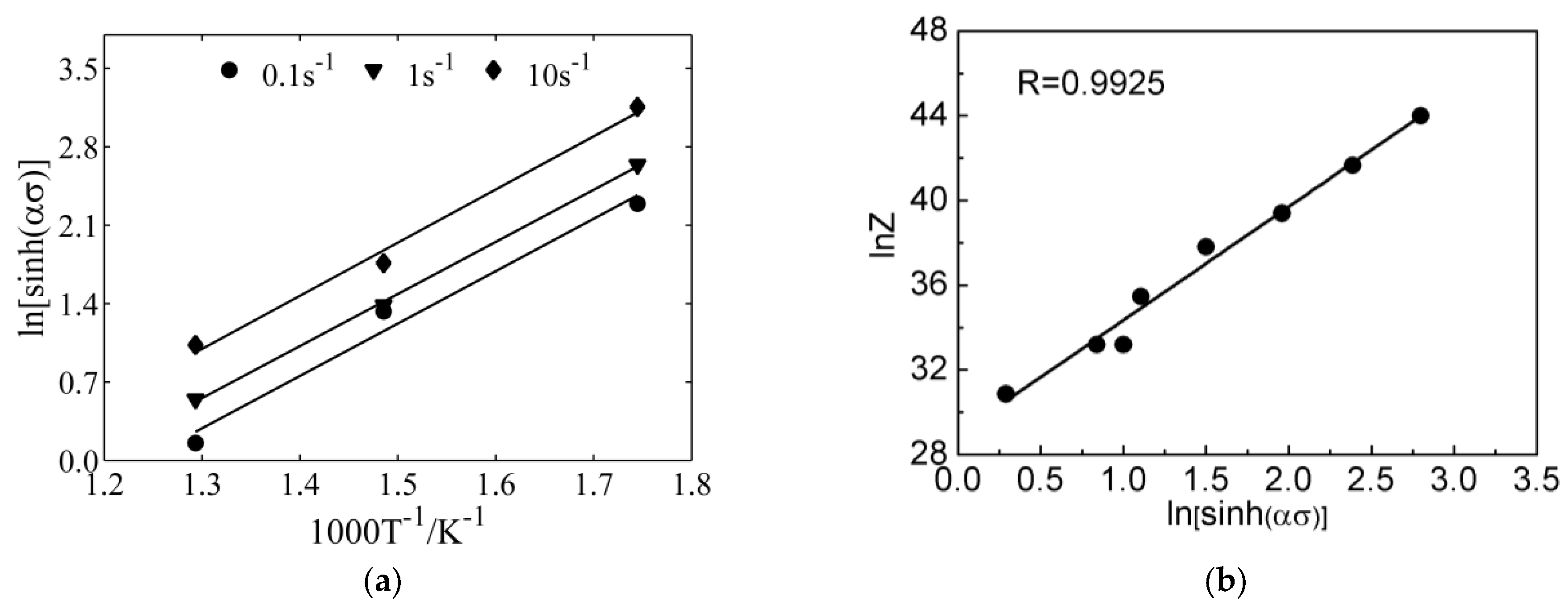

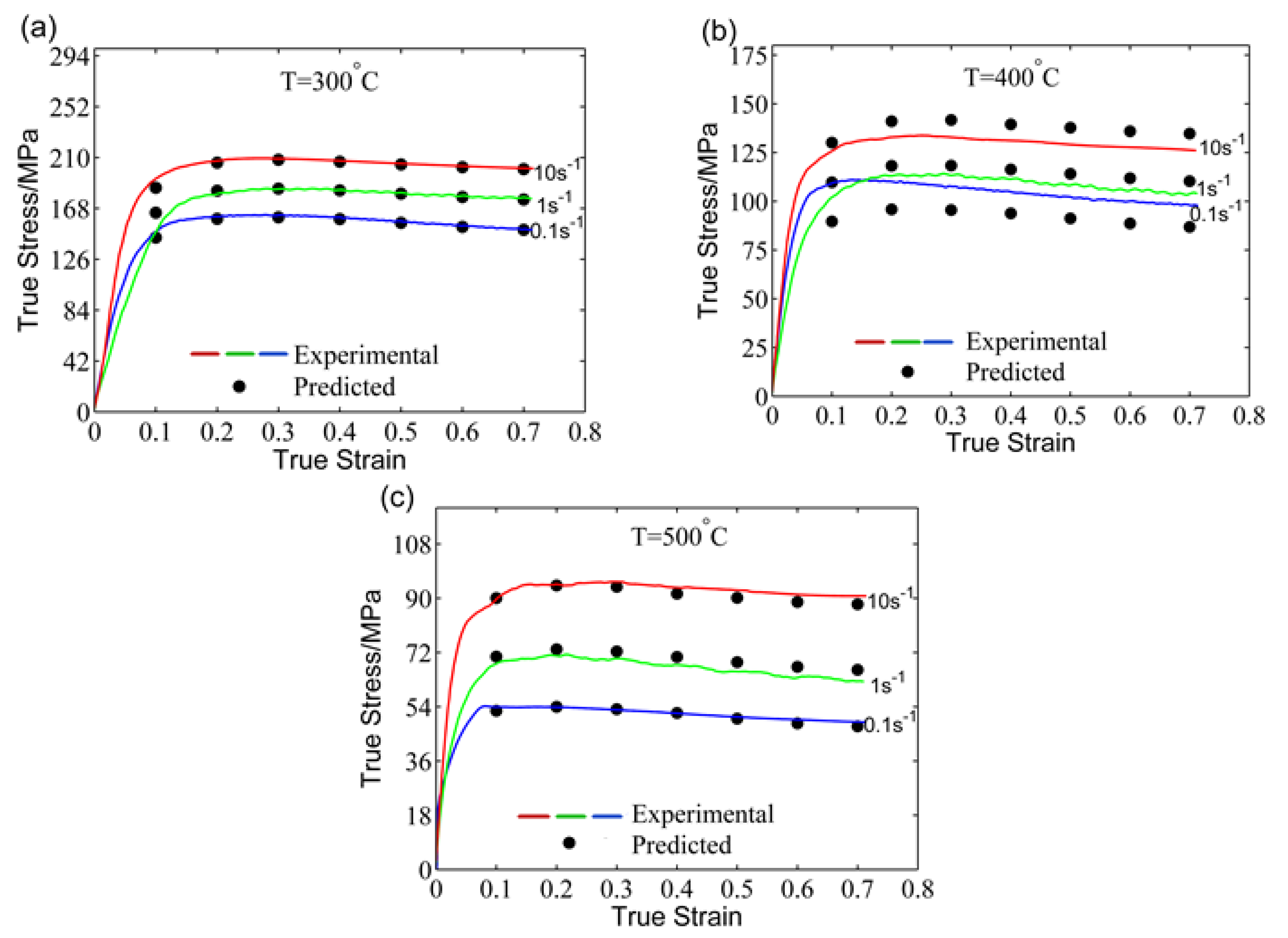

3.1. The SA Model

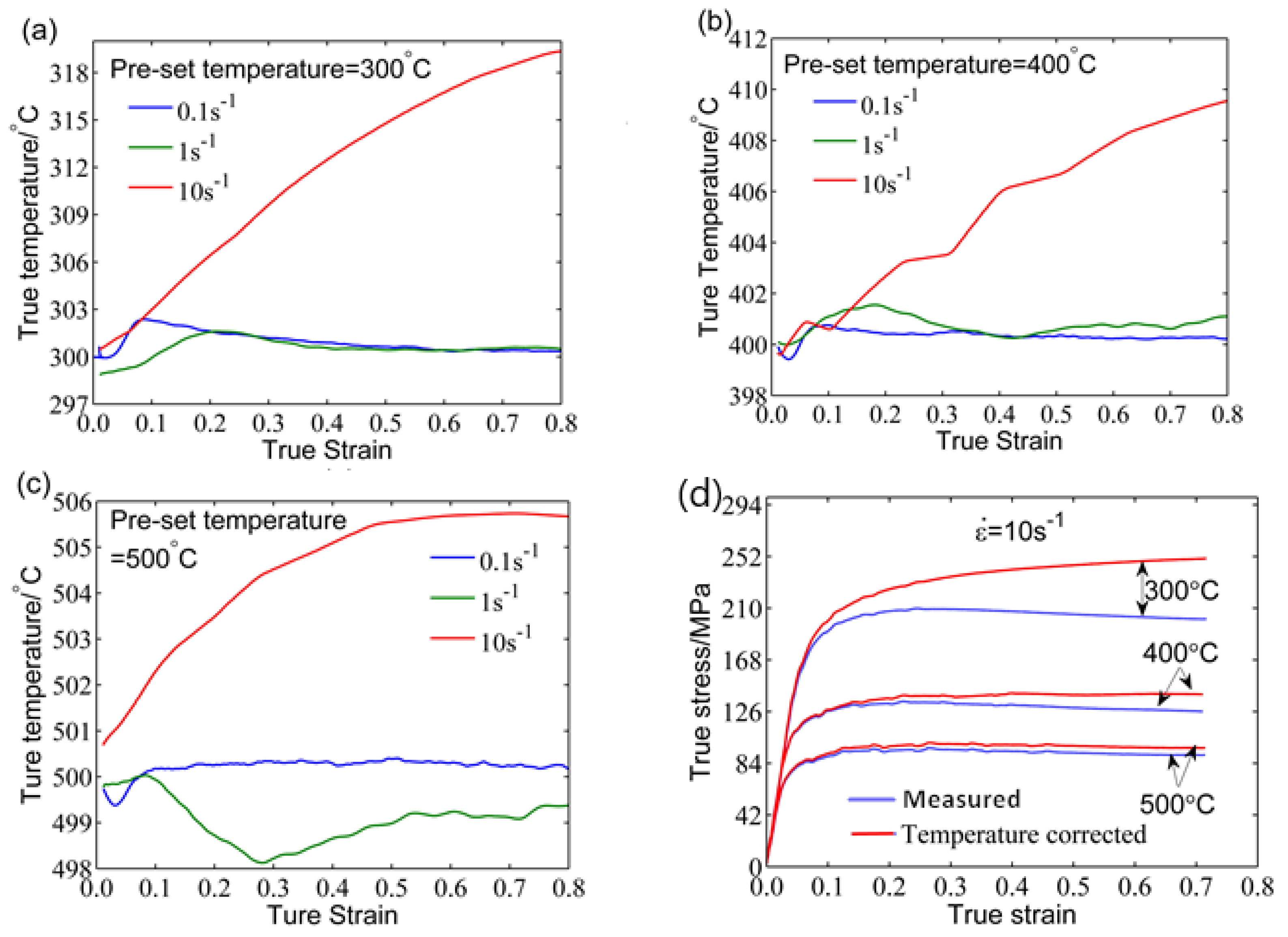

3.2. Correction of Temperature Rise Effect

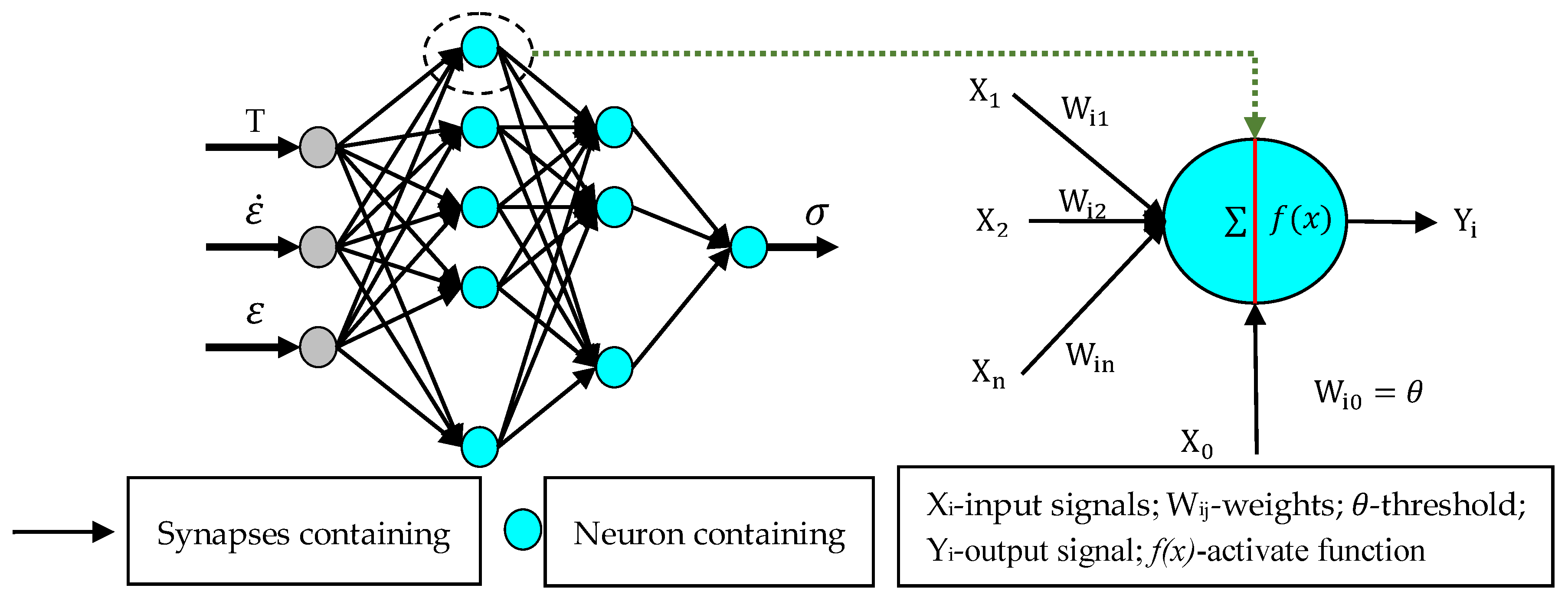

3.3. The BP–ANN Model

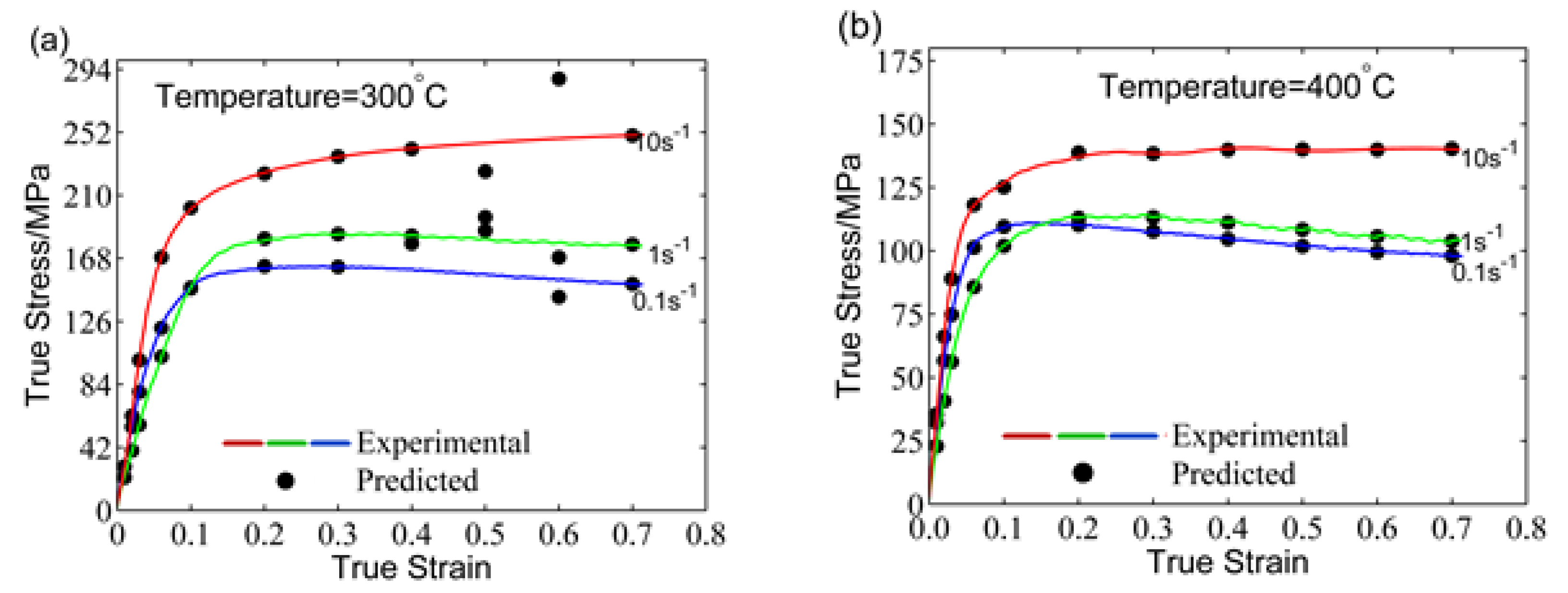

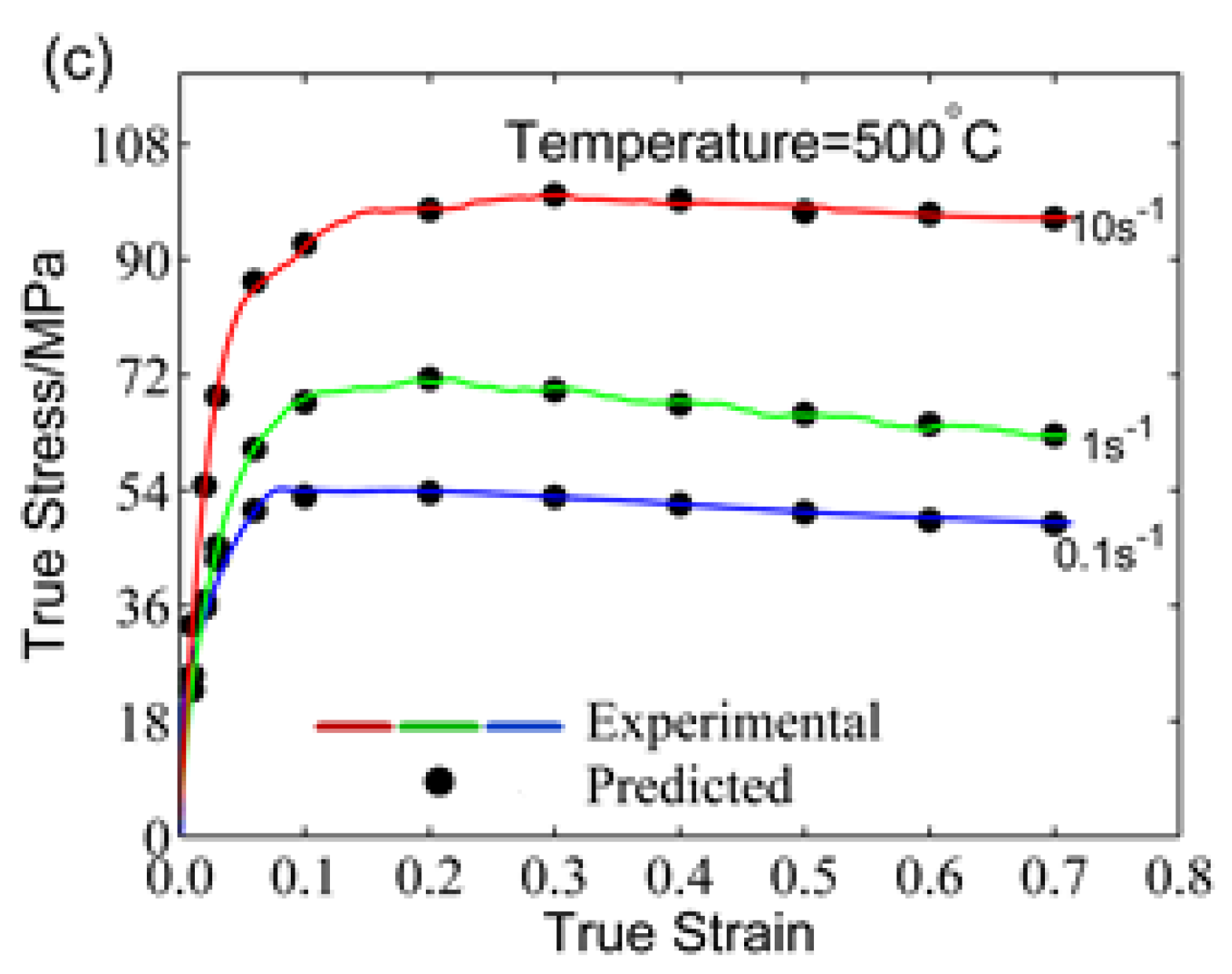

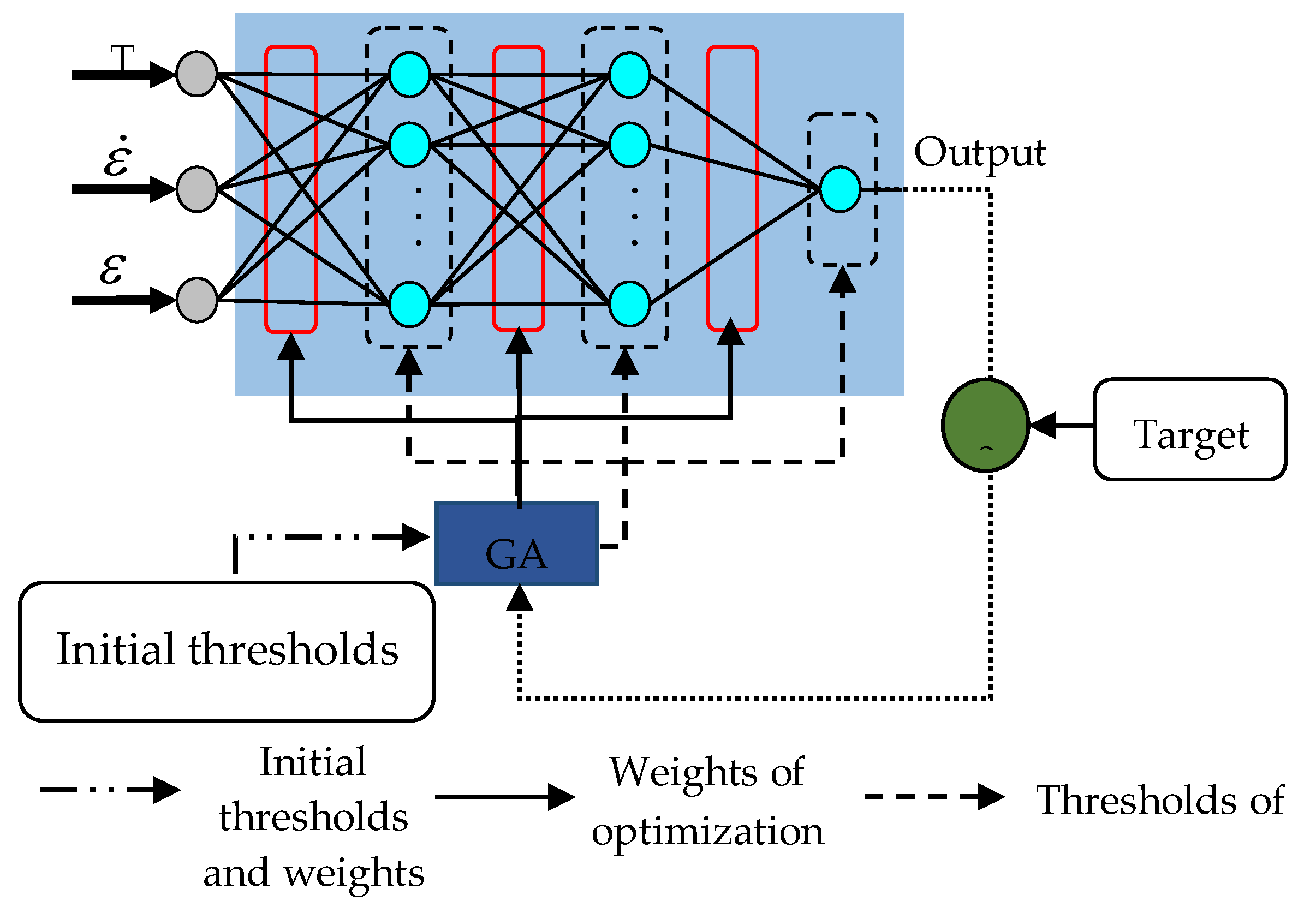

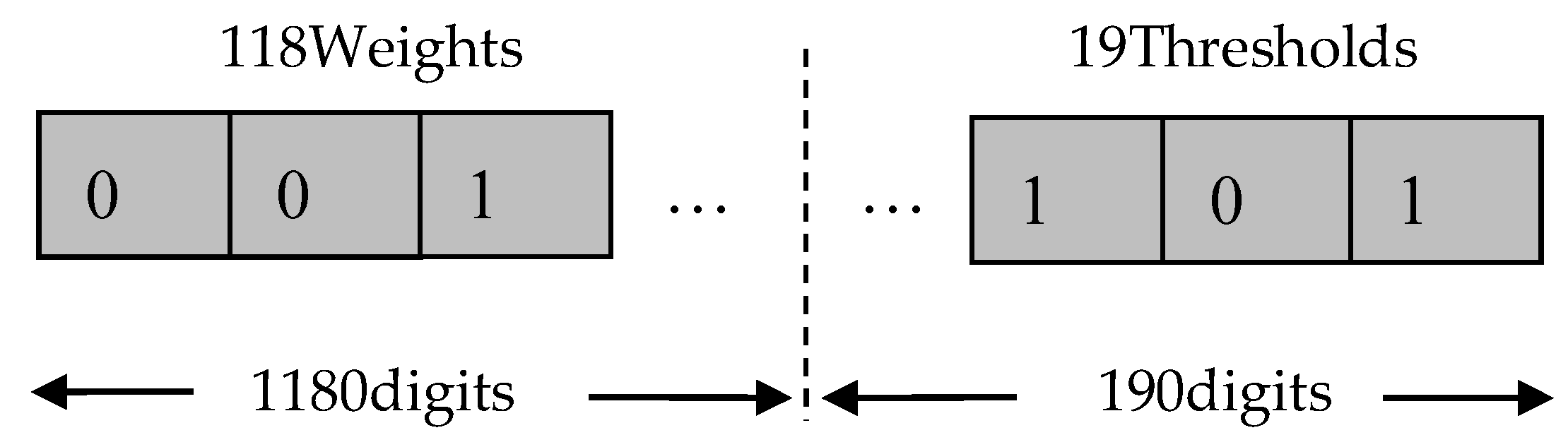

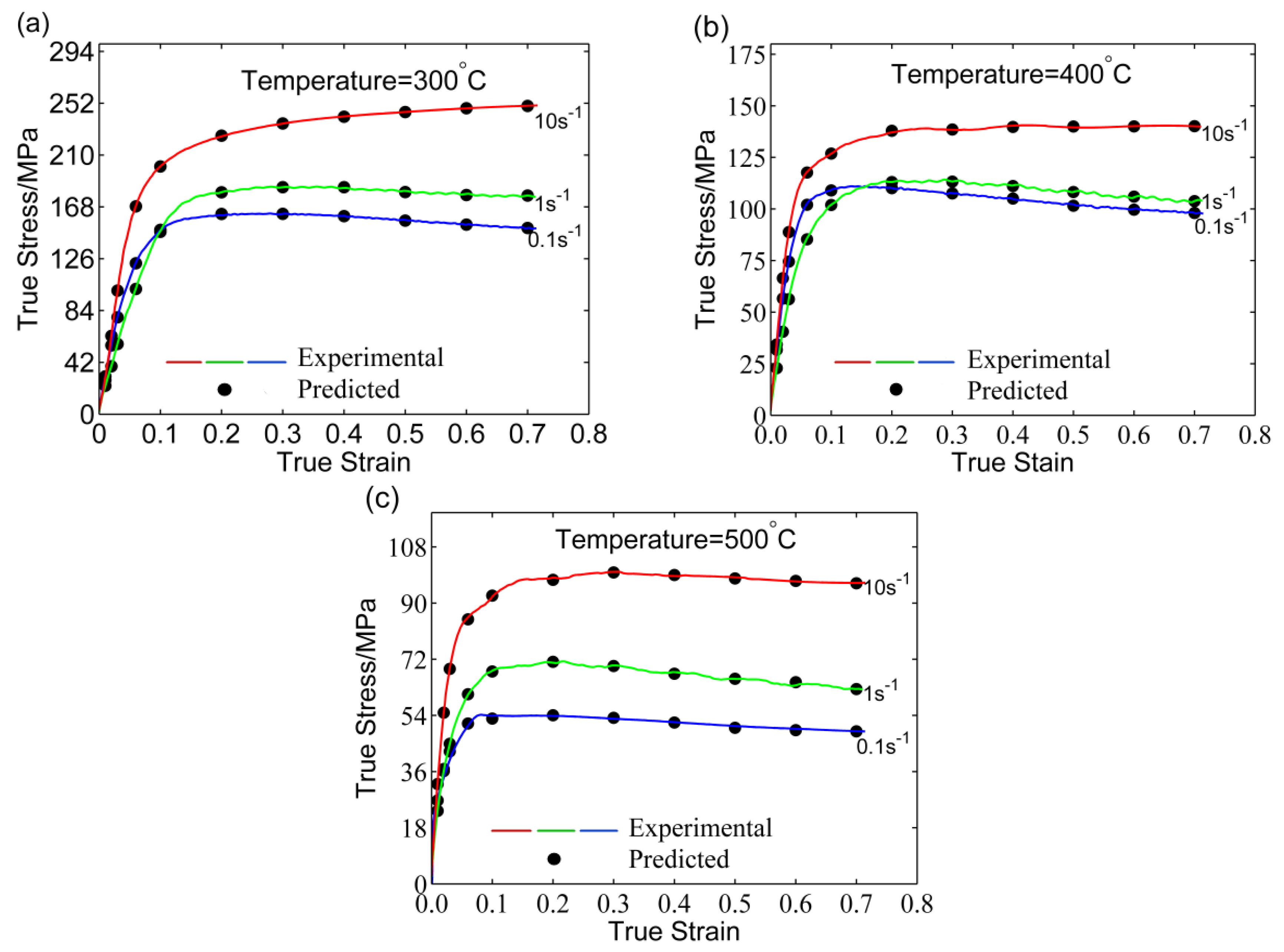

3.4. The ANN–GA Model

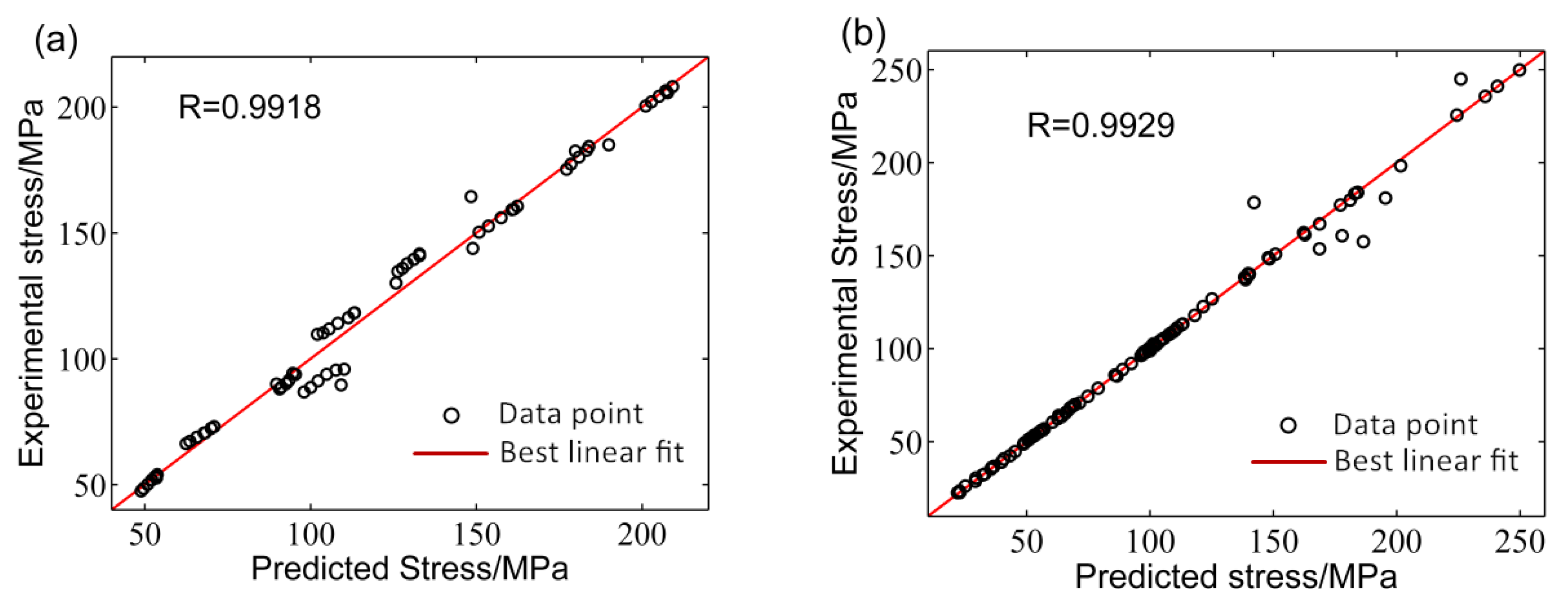

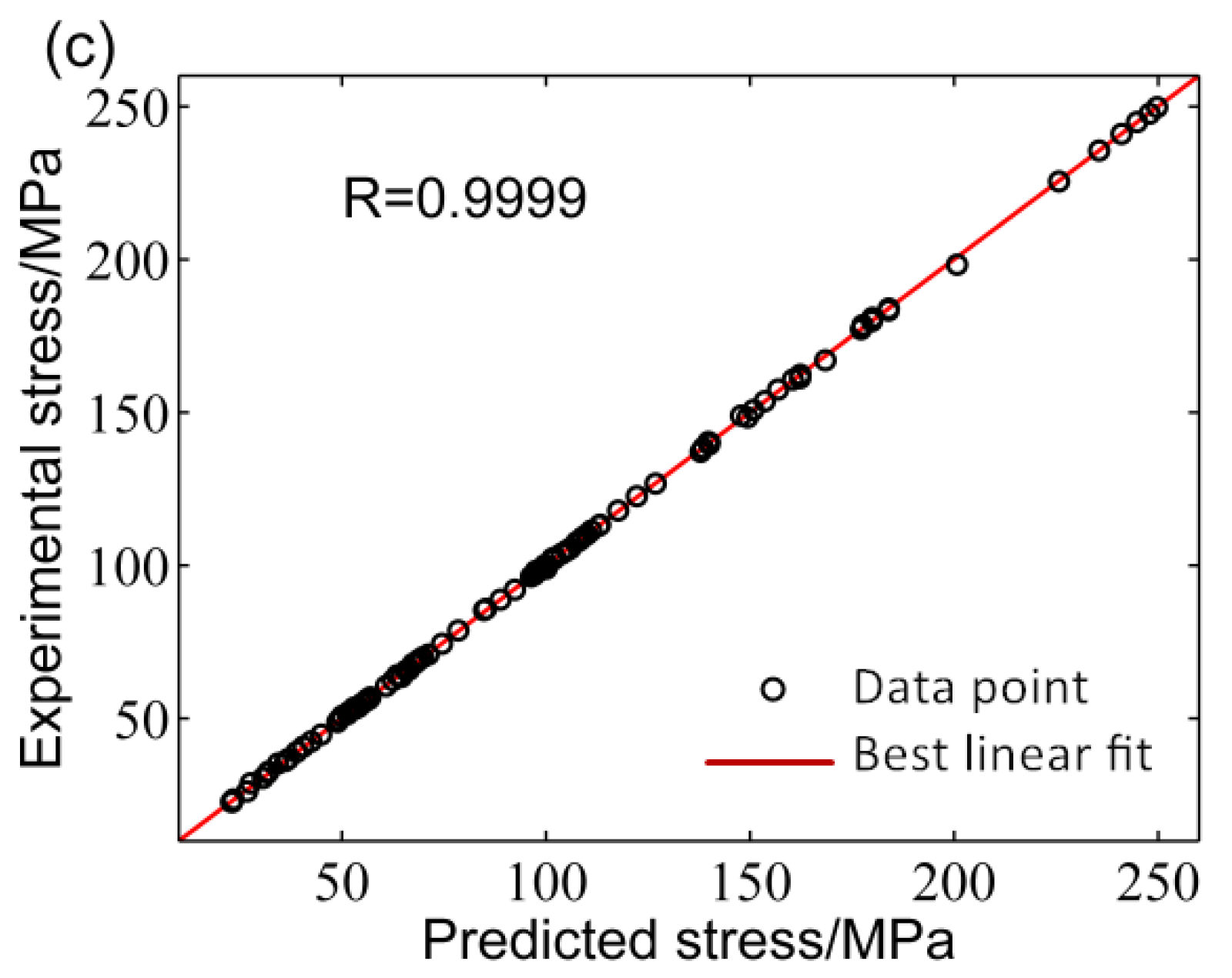

3.5. Performance of the SA, BP–ANN, and ANN-GA Models

3.6. The Dynamic Softening Mechanism of 5754 Aluminum Alloy

4. Conclusions

- Three models were established to predict the flow behavior of 5754 aluminum alloy during the hot compression tests. The SA model had a good prediction of flow stress in the steady state for the 5754 aluminum alloy. However, it resulted in a large predicted error at 400 °C. The BP–ANN model could predict the flow curves under different conditions, but the network training results could easily find the local optimum. Therefore, the prediction results fluctuated at 300 °C and true strains in the range of 0.4–0.6. The BP–ANN model optimized by GA had the best predictive ability of the flow behavior of 5754 aluminum alloy under hot compression tests.

- The R calculated from the SA, BP–ANN, and ANN–GA models were 0.9918, 0.9929, and 0.9999, respectively, while the AARE for these models were 3.2499–5.6774%, 0.0567–5.4436%, and 0.0232–1.0485%, respectively. Compared with the SA and BP–ANN models, the ANN–GA was a better predictor of the flow behavior of 5754 aluminum alloy. In addition, the ANN–GA model could find the optimal weight and threshold for ANN at the same time. Thus, the predicted values of the flow stress from the ANN–GA model were stable and the prediction accuracy was very high.

- The 5754 aluminum alloy experienced a steady flow softening phenomenon during the hot compression tests. The flow stress rose rapidly with increasing strain until it reached a peak, before remaining constant. Besides, the flow stress and the required strain to reach the steady state deformation increased with decreasing deformation temperature and increasing strain rate. Through the observation of the microstructure, no recrystallized grains were found even at high temperature and low strain rate. Therefore, the dynamic softening mechanism of 5754 aluminum alloy was mainly controlled by the DRV process during the single-pass hot compression.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Changizian, P.; Zarei-Hanzaki, A.; Roostaei, A.A. The high temperature flow behavior modeling of AZ81 magnesium alloy considering strain effects. Mater. Des. 2012, 39, 384–389. [Google Scholar] [CrossRef]

- Taleghani, M.A.J.; Navas, E.M.R.; Salehi, M.; Torralba, J.M. Hot deformation behaviour and flow stress prediction of 7075 aluminium alloy powder compacts during compression at elevated temperatures. Mater. Sci. Eng. A 2012, 534, 624–631. [Google Scholar] [CrossRef]

- Sellars, C.M.; Mctegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Abbasi, S.M.; Shokuhfar, A. Prediction of hot deformation behaviour of 10Cr–10Ni–5Mo–2Cu steel. Mater. Lett. 2007, 61, 2523–2526. [Google Scholar] [CrossRef]

- Krishnan, S.A.; Phaniraj, C.; Ravishankar, C.; Bhaduri, A.K.; Sivaprasad, P.V. Prediction of high temperature flow stress in 9Cr–1Mo ferritic steel during hot compression. Int. J. Press. Vessels Pip. 2011, 88, 501–506. [Google Scholar] [CrossRef]

- Phaniraj, C.; Samantaray, D.; Mandal, S.; Bhaduri, A.K. A new relationship between the stress multipliers of Garofalo equation for constitutive analysis of hot deformation in modified 9Cr–1Mo (P91) steel. Mater. Sci. Eng. A 2011, 528, 6066–6071. [Google Scholar] [CrossRef]

- Yang, X.; Li, W. Flow Behavior and Processing Maps of a Low-Carbon Steel During Hot Deformation. Metall. Mater. Trans. A 2015, 46, 6052–6064. [Google Scholar] [CrossRef]

- Asgharzadeh, A.; Aval, H.J.; Serajzadeh, S. A Study on Flow Behavior of AA5086 over a Wide Range of Temperatures. J. Mater. Eng. Perform. 2016, 25, 1076–1084. [Google Scholar] [CrossRef]

- Lin, Y.C.; Nong, F.Q.; Chen, X.M.; Chen, D.D.; Chen, M.S. Microstructural evolution and constitutive models to predict hot deformation behaviors of a nickel-based superalloy. Vacuum 2017, 137, 104–114. [Google Scholar] [CrossRef]

- Cai, J.; Zhang, X.; Wang, K.; Miao, C. Physics-Based Constitutive Model to Predict Dynamic Recovery Behavior of BFe10-1-2 Cupronickel Alloy during Hot Working. High Temp. Mater. Process. 2016, 35, 1037–1045. [Google Scholar] [CrossRef]

- Xiao, G.; Yang, Q.W.; Luo-Xing, L.I. Modeling constitutive relationship of 6013 aluminum alloy during hot plane strain compression based on Kriging method. Trans. Nonferrous Met. Soc. China 2016, 26, 1096–1104. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, Q.F.; Xia, Y.C.; Li, L.T. A phenomenological constitutive model for high temperature flow stress prediction of Al–Cu–Mg alloy. Mater. Sci. Eng. A 2012, 534, 654–662. [Google Scholar] [CrossRef]

- Quan, G.Z.; Wang, T.; Li, Y.L.; Zhan, Z.Y.; Xia, Y.F. Artificial Neural Network Modeling to Evaluate the Dynamic Flow Stress of 7050 Aluminum Alloy. J. Mater. Eng. Perform. 2016, 25, 1–12. [Google Scholar] [CrossRef]

- Han, Y.; Qiao, G.; Sun, J.P.; Zou, D. A comparative study on constitutive relationship of as-cast 904L austenitic stainless steel during hot deformation based on Arrhenius-type and artificial neural network models. Comput. Mater. Sci. 2013, 67, 93–103. [Google Scholar] [CrossRef]

- Lin, Y.C.; Xia, Y.C.; Chen, X.M.; Chen, M.S. Constitutive descriptions for hot compressed 2124-T851 aluminum alloy over a wide range of temperature and strain rate. Comput. Mater. Sci. 2010, 50, 227–233. [Google Scholar] [CrossRef]

- Jia, W.; Zeng, W.; Zhou, Y.; Liu, J.; Wang, Q. High-temperature deformation behavior of Ti60 titanium alloy. Mater. Sci. Eng. A 2011, 528, 4068–4074. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Zeng, W.D.; Feng, F.; Sun, Y.; Han, Y.F.; Zhou, Y.G. Characterization of hot deformation behavior of as-cast TC21 titanium alloy using processing map. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2011, 528, 1757–1763. [Google Scholar] [CrossRef]

- Guo-Fu, X.U.; Peng, X.Y.; Liang, X.P.; Xu, L.I.; Yin, Z.M. Constitutive relationship for high temperature deformation of Al-3Cu-0.5Sc alloy. Trans. Nonferrous Met. Soc. China 2013, 23, 1549–1555. [Google Scholar]

- Li, J.; Li, F.; Cai, J.; Wang, R.; Yuan, Z.; Xue, F. Flow behavior modeling of the 7050 aluminum alloy at elevated temperatures considering the compensation of strain. Mater. Des. 2012, 42, 369–377. [Google Scholar] [CrossRef]

- Mandal, S.; Sivaprasad, P.V.; Dube, R.K. Modeling Microstructural Evolution during Dynamic Recrystallization of Alloy D9 Using Artificial Neural Network. J. Mater. Eng. Perform. 2007, 16, 672–679. [Google Scholar] [CrossRef]

- Ramesh, R.; Gnanamoorthy, R. Artificial Neural Network Prediction of Fretting Wear Behavior of Structural Steel, En 24 Against Bearing Steel, En 31. J. Mater. Eng. Perform. 2007, 16, 703–709. [Google Scholar] [CrossRef]

- Ashtiani, H.R.R.; Shahsavari, P. A comparative study on the phenomenological and artificial neural network models to predict hot deformation behavior of AlCuMgPb alloy. J. Alloys Compd. 2016, 687, 263–273. [Google Scholar] [CrossRef]

- Devadas, C.; Baragar, D.; Ruddle, G.; Samarasekera, I.V.; Hawbolt, E.B. The thermal and metallurgical state of steel strip during hot rolling: Part II. Factors influencing rolling loads. Metall. Trans. A 1991, 22, 321. [Google Scholar] [CrossRef]

- Mosleh, A.; Mikhaylovskaya, A.; Kotov, A.; Pourcelot, T.; Aksenov, S.; Kwame, J.; Portnoy, V. Modelling of the Superplastic Deformation of the Near-alpha Titanium Alloy (Ti-2.5Al-1.8Mn) Using Arrhenius-Type Constitutive Model and Artificial Neural Network. Metals 2017, 7, 568. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, J.; Zhu, N. Constitutive Equations and ANN Approach to Predict the Flow Stress of Ti-6Al-4V Alloy Based on ABI Tests. J. Mater. Eng. Perform. 2016, 25, 4875–4884. [Google Scholar] [CrossRef]

- Mandal, S.; Sivaprasad, P.V.; Venugopal, S. Capability of a feed-forward artificial neural network to predict the constitutive flow behavior of as cast 304 stainless steel under hot deformation. J. Eng. Mater. Technol. 2007, 129, 242–247. [Google Scholar] [CrossRef]

- Sun, Y.; Zeng, W.D.; Zhao, Y.Q.; Zhang, X.M.; Shu, Y.; Zhou, Y.G. Modeling constitutive relationship of Ti40 alloy using artificial neural network. Mater. Des. 2011, 32, 1537–1541. [Google Scholar] [CrossRef]

- Shakiba, M.; Parson, N.; Chen, X.G. Modeling the Effects of Cu Content and Deformation Variables on the High-Temperature Flow Behavior of Dilute Al-Fe-Si Alloys Using an Artificial Neural Network. Materials 2016, 9, 536. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Feng, Y.; Ma, F.; Mao, Y.; Liu, X.; Zhang, P.; Kou, H.; Fu, H. Isothermal compression flow stress prediction of Ti-6Al-3Nb-2Zr-1Mo alloy based on BP-ANN. Rare Met. Mater. Eng. 2016, 45, 1549–1553. [Google Scholar]

- Yan, J.; Pan, Q.L.; An-De, L.I.; Song, W.B.; Yan, J.; Pan, Q.L.; An-De, L.I.; Song, W.B.; Yan, J.; Pan, Q.L. Flow behavior of Al–6.2Zn–0.70Mg–0.30Mn–0.17Zr alloy during hot compressive deformation based on Arrhenius and ANN models. Trans. Nonferrous Met. Soc. China 2017, 27, 638–647. [Google Scholar] [CrossRef]

- Ji, G.; Li, F.; Li, Q.; Li, H.; Li, Z. A comparative study on Arrhenius-type constitutive model and artificial neural network model to predict high-temperature deformation behaviour in Aermet100 steel. Mater. Sci. Eng. A 2011, 528, 4774–4782. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, Z.; Li, B.; Xue, Y. Modeling the constitutive relationship of powder metallurgy Al–W alloy at elevated temperature. Mater. Des. 2014, 64, 667–674. [Google Scholar] [CrossRef]

- Chamanfar, A.; Jahazi, M.; Gholipour, J.; Wanjara, P.; Yue, S. Evolution of flow stress and microstructure during isothermal compression of Waspaloy. Mater. Sci. Eng. A 2014, 615, 497–510. [Google Scholar] [CrossRef]

- Huang, C.; Liu, L. Application of the Constitutive Model in Finite Element Simulation: Predicting the Flow Behavior for 5754 Aluminum Alloy during Hot Working. Metals 2017, 7, 331. [Google Scholar] [CrossRef]

- Azamathulla, H.M.; Zakaria, N.A. Prediction of scour below submerged pipeline crossing a river using ANN. Water Sci. Technol. A J. Int. Assoc. Water Pollut. Res. 2011, 63, 2225–2230. [Google Scholar] [CrossRef]

- Raikar, R.V.; Wang, C.Y.; Shih, H.P.; Hong, J.H. Prediction of contraction scour using ANN and GA. Flow Meas. Instrum. 2016, 50, 26–34. [Google Scholar] [CrossRef]

- Phaniraj, M.P.; Lahiri, A.K. The applicability of neural network model to predict flow stress for carbon steels. J. Mater. Process. Technol. 2003, 141, 219–227. [Google Scholar] [CrossRef]

- Lucon, P.A.; Donovan, R.P. An artificial neural network approach to multiphase continua constitutive modeling. Compos. B Eng. 2007, 38, 817–823. [Google Scholar] [CrossRef]

- Sivanandam, S.N.; Deepa, S.N. Introduction to Genetic Algorithms; Springer: Berlin/Heidelberg, Germany, 2008; pp. 63–65. [Google Scholar]

- Wouters, P.; Verlinden, B.; Mcqueen, H.J.; Aernoudt, E.; Delaey, L.; Cauwenberg, S. Effect of homogenization and precipitation treatments on the hot workability of an aluminium alloy AA2024. Mat. Sci. Eng. A 1990, 123, 239–245. [Google Scholar] [CrossRef]

| Composition | Mg | Mn | Si | Fe | Cr | Zn | Ti | Cu | Impurity | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (wt %) | 2.6–3.6 | 0.5 | 0.4 | 0.4 | 0.3 | 0.2 | 0.15 | 0.1 | 0.15 | Balance |

| Total data | Training data | Verification data | Train epoch | Learning rate | Training target |

|---|---|---|---|---|---|

| 234 | 136 | 98 | 1000 | 0.2 | 10−7 |

| Encoding Length | Genetic Algebra | Population Size | Crossover Probability | Mutation Probability | Generation Gap |

|---|---|---|---|---|---|

| 1370 | 8 | 5 | 0.7 | 0.01 | 1 |

| Model | R | AARE (%) |

|---|---|---|

| Arrhenius | 0.9918 | 3.2499–5.6774 |

| ANN | 0.9929 | 0.0567–5.4436 |

| ANN–GA | 0.9999 | 0.0232–1.0485 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.; Jia, X.; Zhang, Z. A Modified Back Propagation Artificial Neural Network Model Based on Genetic Algorithm to Predict the Flow Behavior of 5754 Aluminum Alloy. Materials 2018, 11, 855. https://doi.org/10.3390/ma11050855

Huang C, Jia X, Zhang Z. A Modified Back Propagation Artificial Neural Network Model Based on Genetic Algorithm to Predict the Flow Behavior of 5754 Aluminum Alloy. Materials. 2018; 11(5):855. https://doi.org/10.3390/ma11050855

Chicago/Turabian StyleHuang, Changqing, Xiaodong Jia, and Zhiwu Zhang. 2018. "A Modified Back Propagation Artificial Neural Network Model Based on Genetic Algorithm to Predict the Flow Behavior of 5754 Aluminum Alloy" Materials 11, no. 5: 855. https://doi.org/10.3390/ma11050855

APA StyleHuang, C., Jia, X., & Zhang, Z. (2018). A Modified Back Propagation Artificial Neural Network Model Based on Genetic Algorithm to Predict the Flow Behavior of 5754 Aluminum Alloy. Materials, 11(5), 855. https://doi.org/10.3390/ma11050855