Effect of Resin Type on the Tribological Properties of a Three-Dimensional Self-Lubricating Composite Surface

Abstract

:1. Introduction

2. Materials and Methods

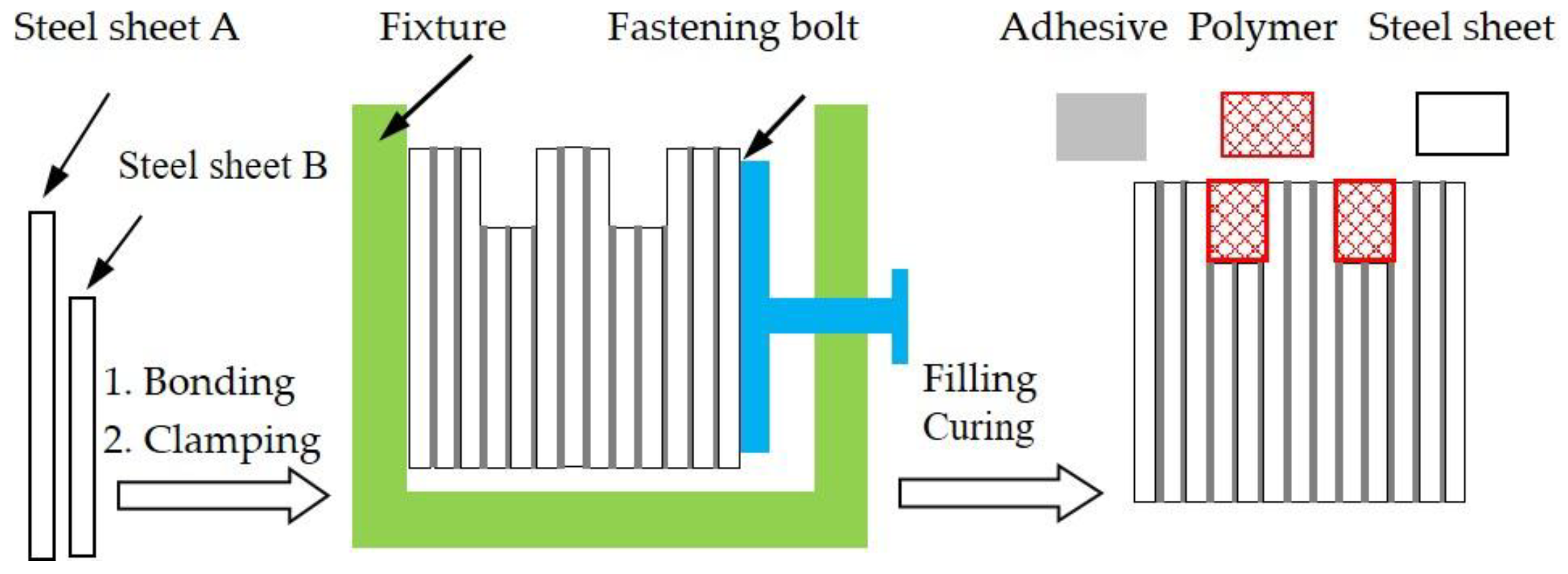

2.1. Preparation of Laminated Composite Surfaces

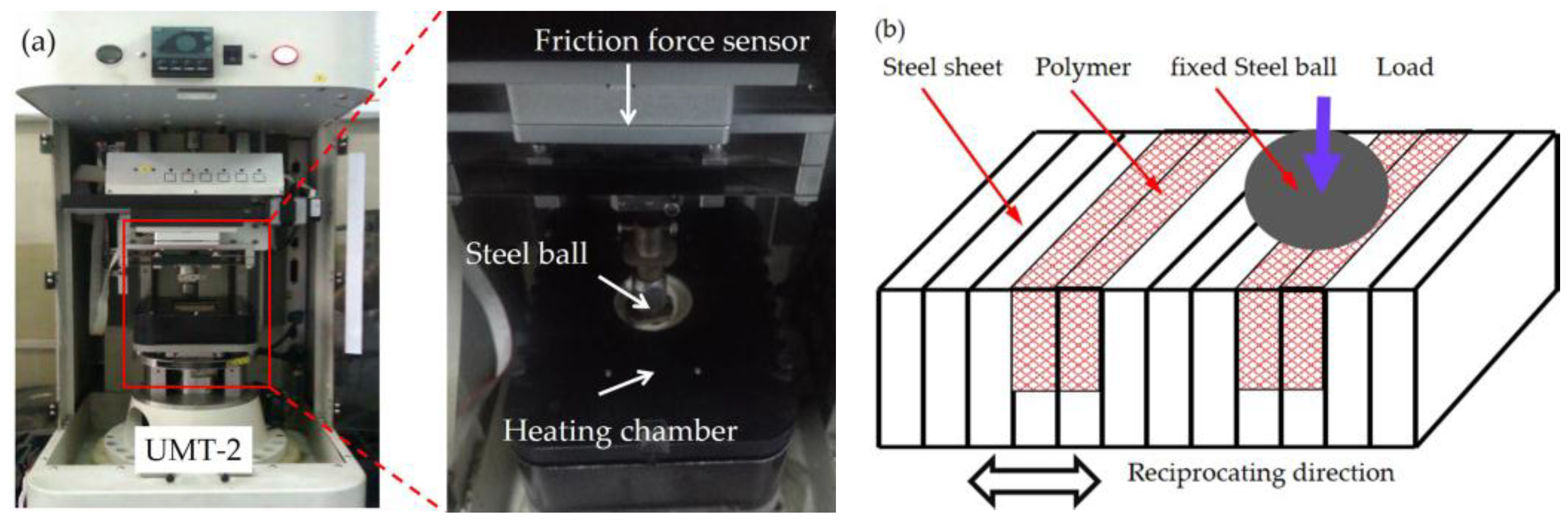

2.2. Performance Test

3. Results

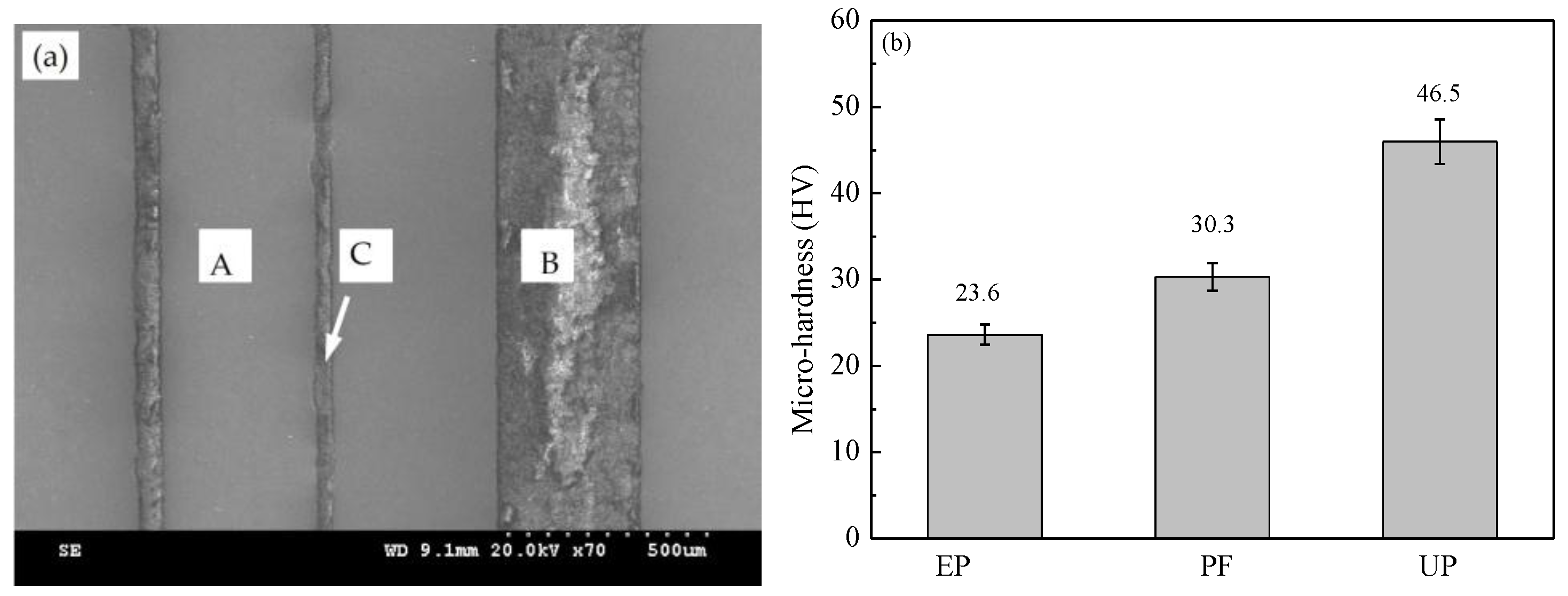

3.1. Characterization of Polymer Composites

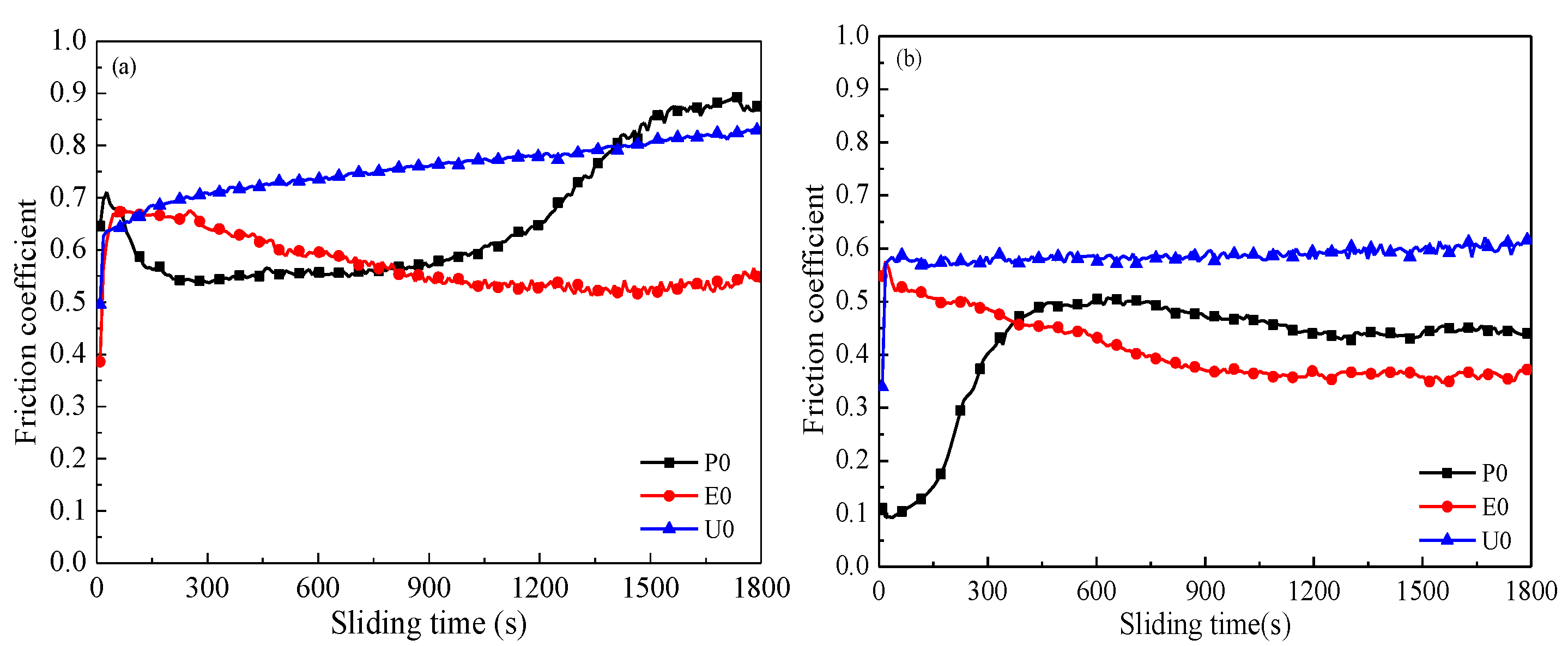

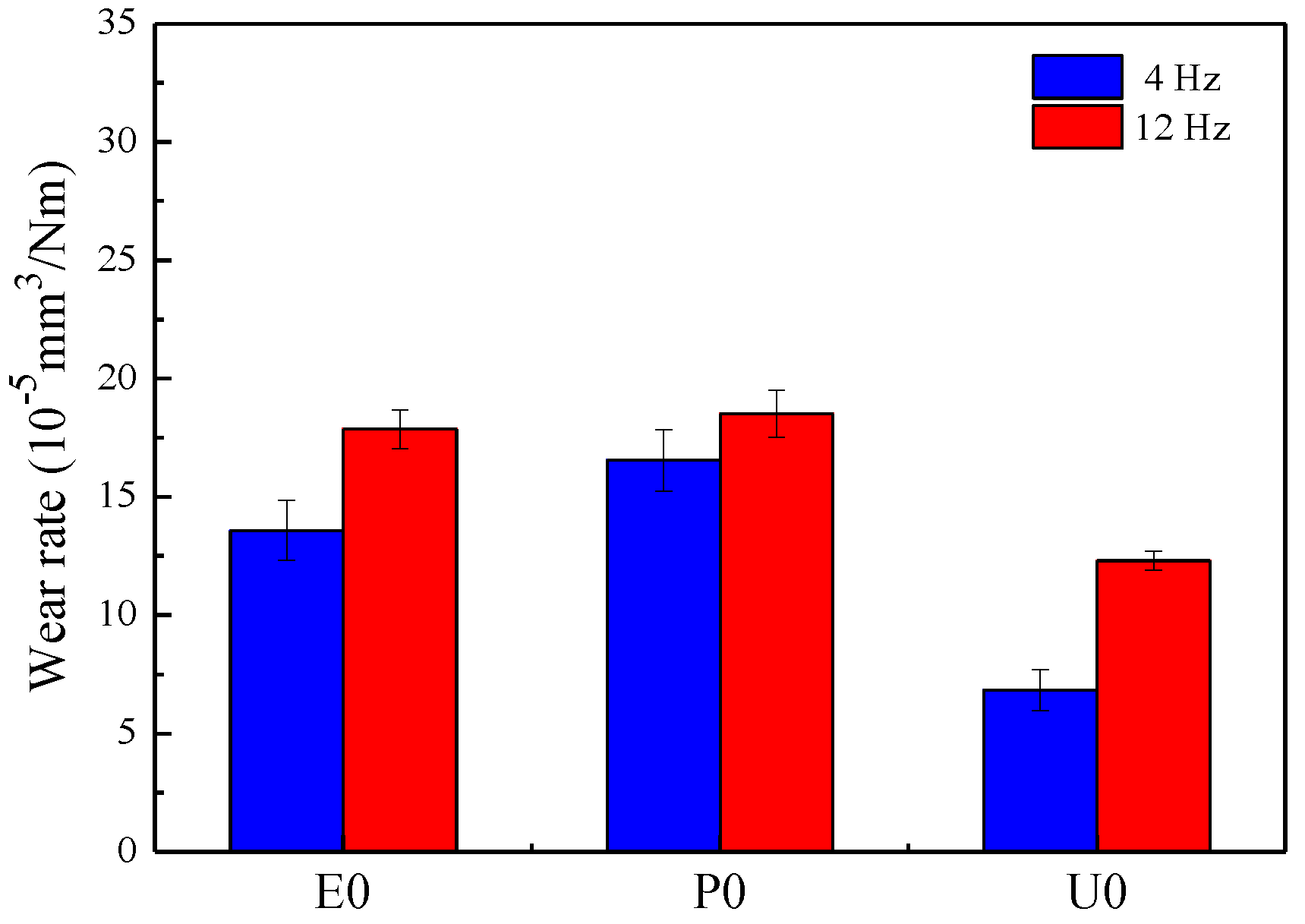

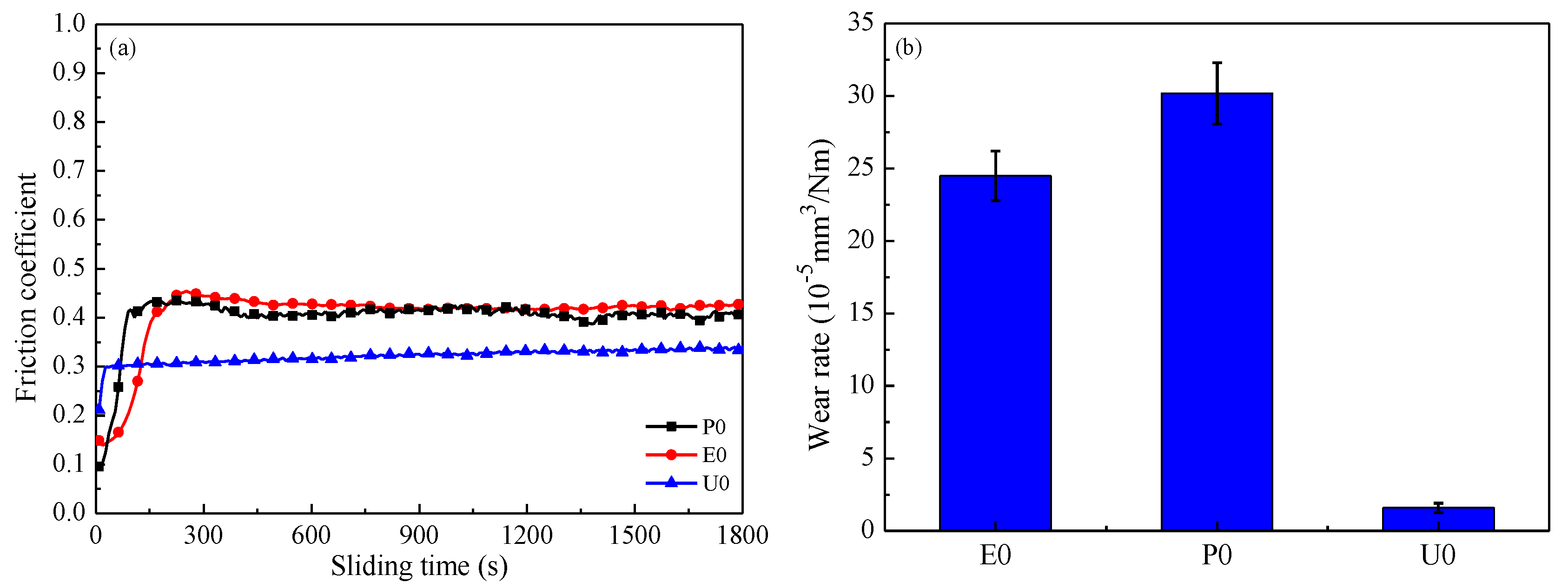

3.2. Tribological Properties of E0, P0, and E0 at Room Temperature

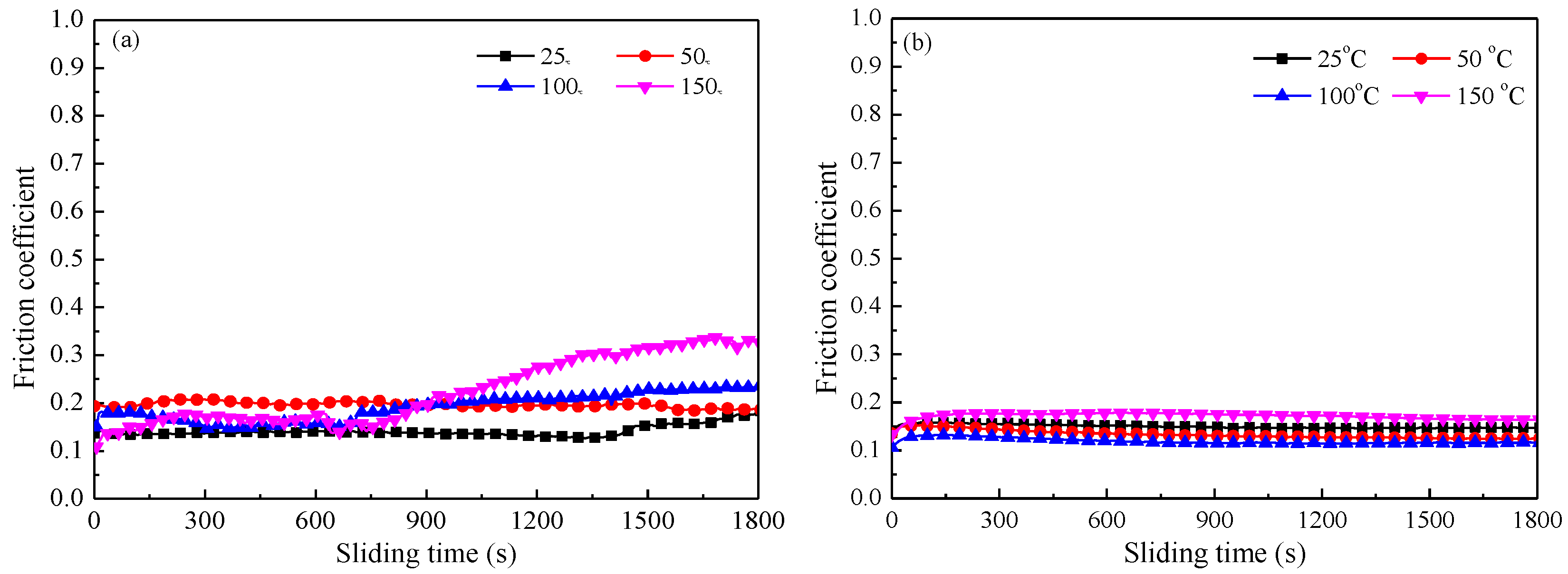

3.3. Tribological Properties at 100 °C

3.4. Effects of MoS2 on the Friction Coefficient of E1 and U1

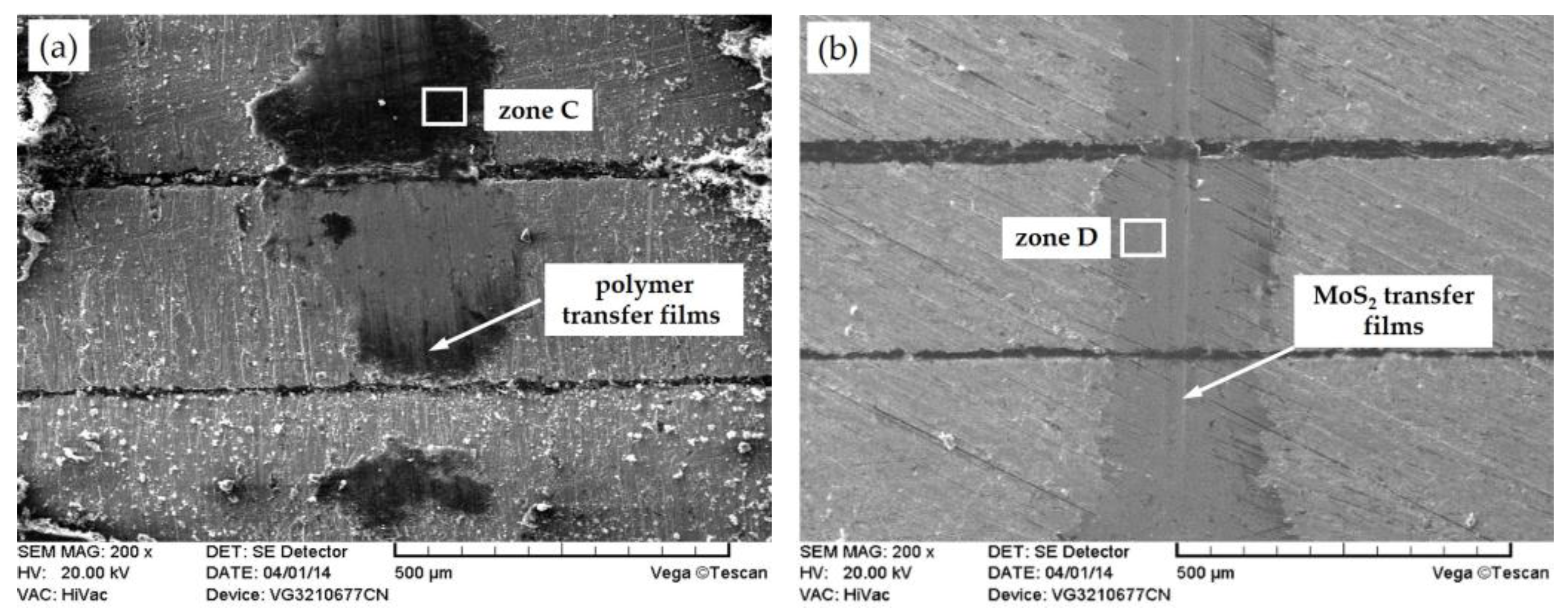

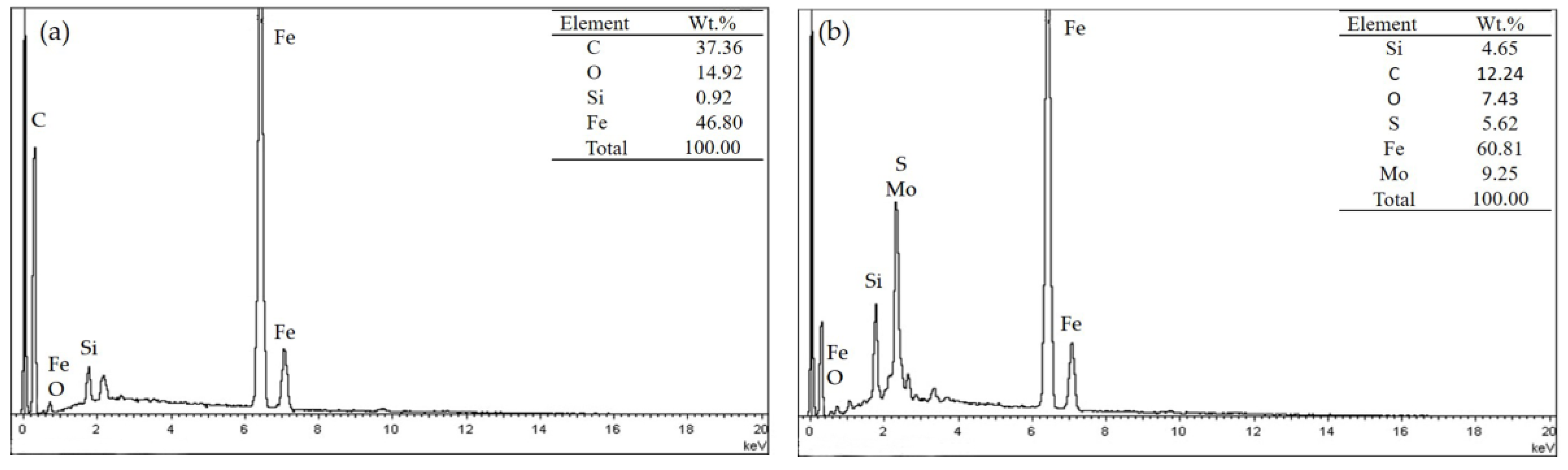

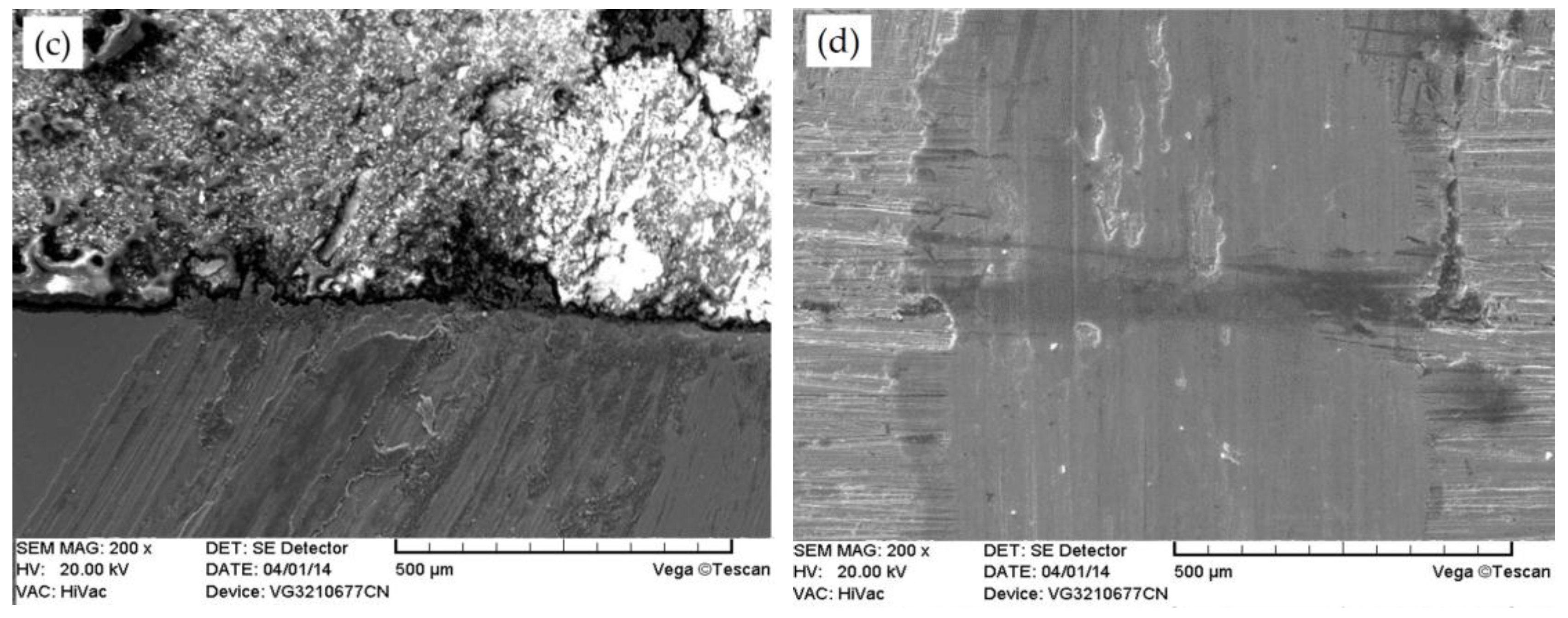

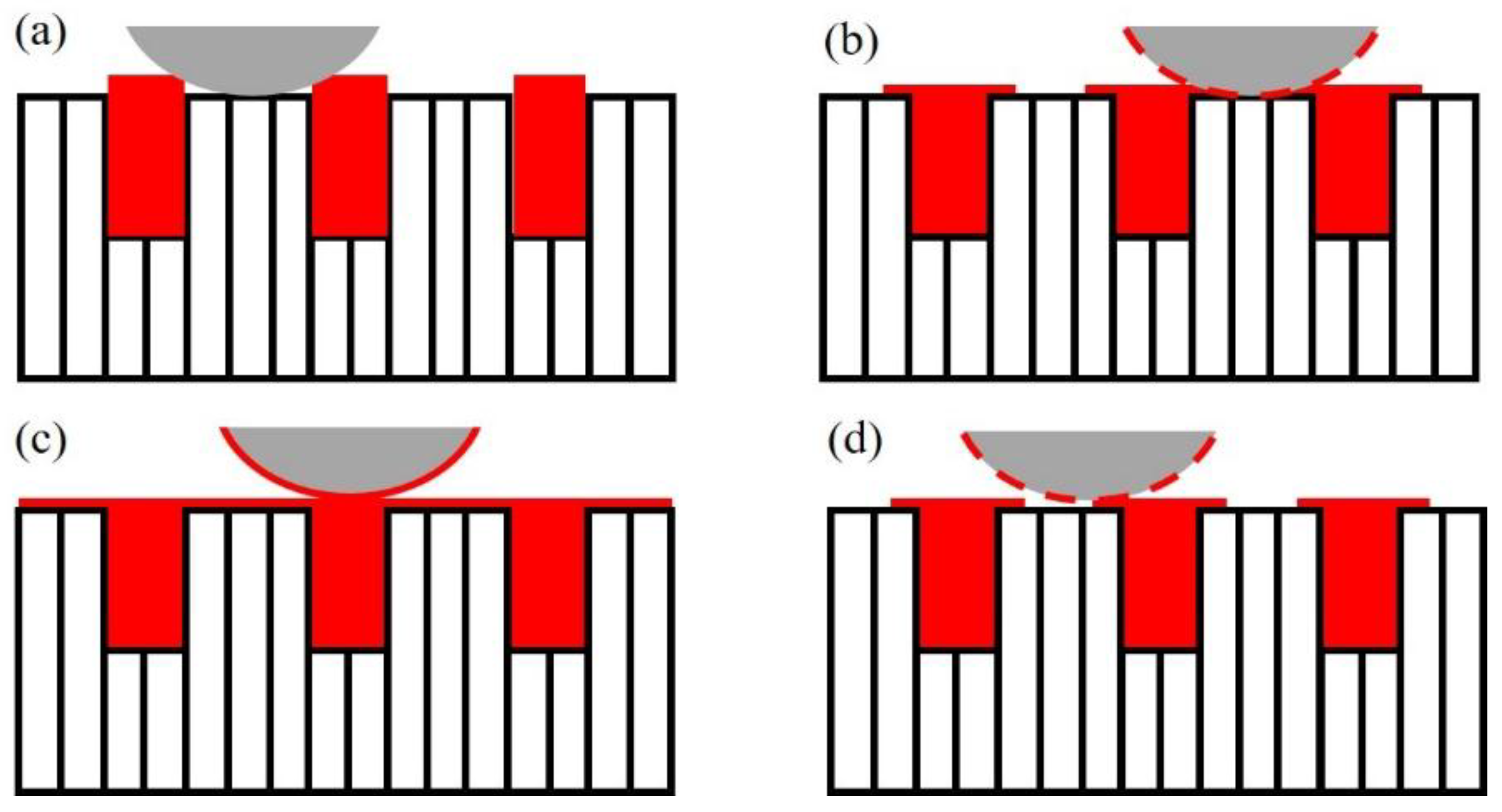

3.5. Wear Surface Analysis and Self-Lubricating Mechanism

4. Conclusions

- For the laminated composite surface without adding solid lubricant, the friction coefficient and wear rate of E0 and P0 are much higher than that of U0. Meanwhile, the friction coefficients of the laminated composite are obviously low at a high sliding speed of 12 Hz and high temperature of 100 °C, respectively.

- The friction coefficient of the laminated composite containing MoS2 is much lower than that without adding MoS2 as the temperature increases. However, at a temperature of 150 °C, the friction coefficient of E1 is increased to 0.35, while that of U1 is stable at 0.17.

- MoS2 polymer filled in the grooves thermally expand under a high temperature field and, thus, the MoS2 particles generate a transfer film on the sliding surface which endows the good tribological performance of the laminated composite under high temperature. However, the transfer film is consumed at an accelerated rate as temperature increases, which may induce the fatigue of the self-lubricating laminated composite.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pan, G.; Guo, Q.; Zhao, Z.; Wang, S.; Qin, Y.; Wang, L. Tribological properties of solid multilayer composite coatings in dry rolling contact. Tribol. Int. 2011, 44, 789–796. [Google Scholar] [CrossRef]

- Zhang, D.; Dong, G.; Chen, Y.; Zeng, Q. Electrophoretic deposition of PTFE particles on porous anodic aluminum oxide film and its tribological properties. Appl. Surf. Sci. 2014, 290, 466–474. [Google Scholar] [CrossRef]

- Ji, K.; Shan, W.; Xia, Y.; Dai, Z. The tribological behaviors of self-lubricating composites as filler in copper foam. Tribol. Trans. 2012, 55, 20–31. [Google Scholar] [CrossRef]

- Zhang, D.; Ho, J.K.L.; Dong, G.; Zhang, H.; Hua, M. Tribological properties of Tin-based Babbitt bearing alloy with polyurethane coating under dry and starved lubrication conditions. Tribol. Int. 2015, 90, 22–31. [Google Scholar] [CrossRef]

- Rapoport, L.; Moshkovich, A.; Perfilyev, V.; Gedanken, A.; Koltypin, Y.; Sominski, E.; Halperin, G.; Etsion, I. Wear life and adhesion of solid lubricant films on laser-textured steel surfaces. Wear 2009, 267, 1203–1207. [Google Scholar] [CrossRef]

- Rapoport, L.; Moshkovich, A.; Perfilyev, V.; Lapsker, I.; Halperin, G.; Itovich, Y.; Etsion, I. Friction and wear of MoS2 films on laser textured steel surfaces. Surf. Coat. Technol. 2008, 202, 3332–3340. [Google Scholar] [CrossRef]

- Hu, T.; Zhang, Y.; Hu, L. Tribological investigation of MoS2 coatings deposited on the laser textured surface. Wear 2012, 278, 77–82. [Google Scholar] [CrossRef]

- Moshkovith, A.; Perfiliev, V.; Gindin, D.; Parkansky, N.; Boxman, R.; Rapoport, L. Surface texturing using pulsed air arc treatment. Wear 2007, 263, 1467–1469. [Google Scholar] [CrossRef]

- Li, J.; He, Y.; Xiong, D.; Qin, Y.; Chen, J.; Zhu, H. Tribological properties of silver coatings with laser surface textured nickel as interlayer. Tribol. Int. 2016, 100, 178–185. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Wang, X.; Meng, R. Effect of laser surface textures combined with multi-solid lubricant coatings on the tribological properties of Al2O3/TiC ceramic. Wear 2015, 342, 1–12. [Google Scholar] [CrossRef]

- Kim, B.C.; Dong, C.P.; Kim, B.J.; Dai, G.L. Through-thickness compressive strength of a carbon/epoxy composite laminate. Compos. Struct. 2010, 92, 480–487. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, Y.; Song, J.; Fang, Y.; Hu, L. High-temperature self-Lubricated and fracture properties of Alumina/Molybdenum fibrous monolithic ceramic. Tribol. Lett. 2015, 61, 9. [Google Scholar] [CrossRef]

- Zhang, D.; Lin, P.; Dong, G.; Zeng, Q. Mechanical and tribological properties of self-lubricating laminated composites with flexible design. Mater. Des. 2013, 50, 830–838. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, P.; Lin, P.; Dong, G.; Zeng, Q. Tribological properties of Self-Lubricating polymer–steel laminated composites. Tribol. Trans. 2013, 56, 908–918. [Google Scholar] [CrossRef]

- Zhang, D.; Gao, F.; Wang, J.; Zhang, H.; Dong, G. Study on tribological performance of bionic oil containing-laminated composite under high temperature conditions. J. Xi’an Jiaotong Univ. 2017, 5, 69–74. [Google Scholar]

- Zhang, D.; Dong, G.; Gao, F.; Li, Y. Effect of magnetic field intensity on tribological properties of laminated composites. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2016, 6, 52–56. [Google Scholar]

- Hu, T.; Hu, L.; Ding, Q. Effective solution for the tribological problems of Ti-6Al-4V: Combination of laser surface texturing and solid lubricant film. Surf. Coat. Technol. 2012, 206, 5060–5066. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Wu, Z.; Cheng, H. Effect of regular surface textures generated by laser on tribological behavior of Si3N4/TiC ceramic. Appl. Surf. Sci. 2013, 265, 823–832. [Google Scholar] [CrossRef]

- Zalaznik, M.; Novak, S.; Huskić, M.; Kalin, M. Tribological behaviour of a PEEK polymer containing solid MoS2 lubricants. Lubr. Sci. 2016, 28, 27–42. [Google Scholar] [CrossRef]

| Sample | Resin (g) | Curing Agent (g) | MoS2 (g) |

|---|---|---|---|

| E0 (Epoxy resin) | 10.0 | 1 | 0 |

| P0 (Phenolic Resin) | 10.0 | 1 | 0 |

| U0 (Unsaturated polyester) | 10.0 | 0.5 | 0 |

| E1 (Epoxy resin) | 10.0 | 1 | 4 |

| U1 (Unsaturated polyester) | 10.0 | 0.5 | 4 |

| Item | Value |

|---|---|

| Applied load (N) | 6 |

| Sliding frequency (Hz) | 4 and12 |

| Stroke (mm) | 6 |

| Sliding distance (m) | 43.2 and 129.6 |

| Diameter of the steel ball (mm) | 9.5 |

| Lubrication type | Dry |

| Test time (min) | 30 |

| Temperature (°C) | 25–150 |

| Relative humid (%) | 40–45 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Sun, X.; Dang, K.; Gao, F.; Zhang, H.; Dong, G. Effect of Resin Type on the Tribological Properties of a Three-Dimensional Self-Lubricating Composite Surface. Materials 2018, 11, 643. https://doi.org/10.3390/ma11040643

Zhang D, Sun X, Dang K, Gao F, Zhang H, Dong G. Effect of Resin Type on the Tribological Properties of a Three-Dimensional Self-Lubricating Composite Surface. Materials. 2018; 11(4):643. https://doi.org/10.3390/ma11040643

Chicago/Turabian StyleZhang, Dongya, Xizhou Sun, Kai Dang, Fen Gao, Hui Zhang, and Guangneng Dong. 2018. "Effect of Resin Type on the Tribological Properties of a Three-Dimensional Self-Lubricating Composite Surface" Materials 11, no. 4: 643. https://doi.org/10.3390/ma11040643

APA StyleZhang, D., Sun, X., Dang, K., Gao, F., Zhang, H., & Dong, G. (2018). Effect of Resin Type on the Tribological Properties of a Three-Dimensional Self-Lubricating Composite Surface. Materials, 11(4), 643. https://doi.org/10.3390/ma11040643