Friction Stir Processing of Copper-Coated SiC Particulate-Reinforced Aluminum Matrix Composite

Abstract

:1. Introduction

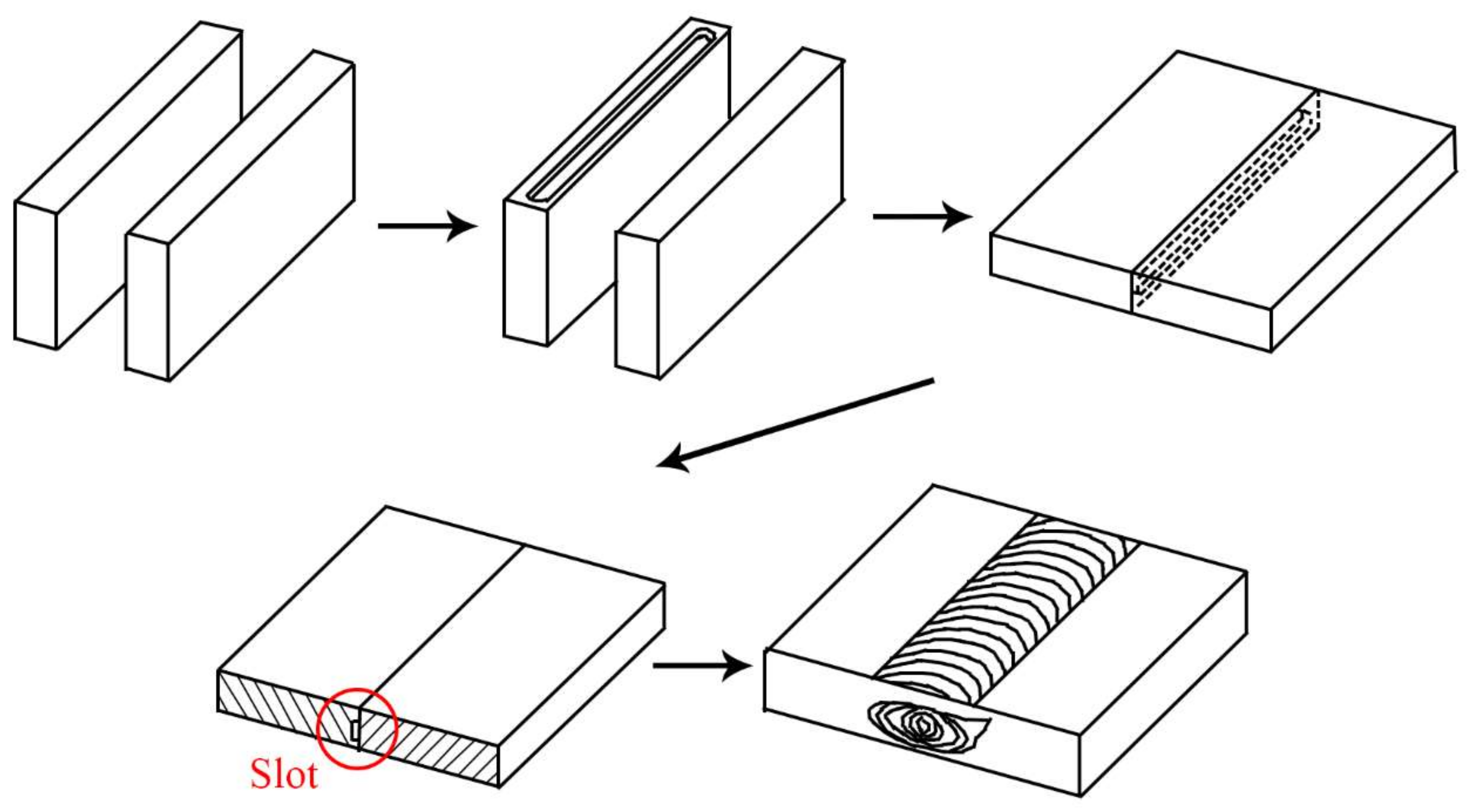

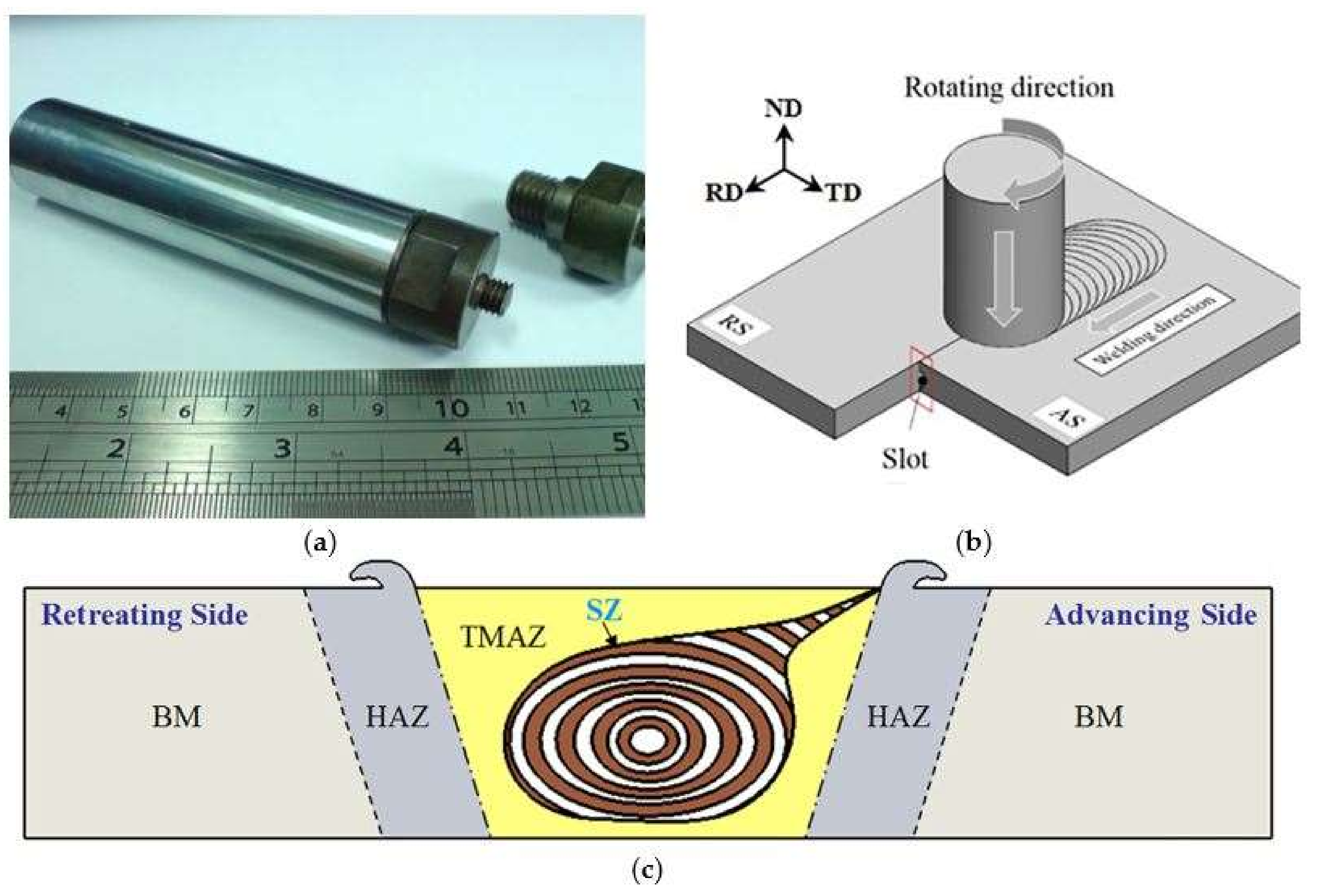

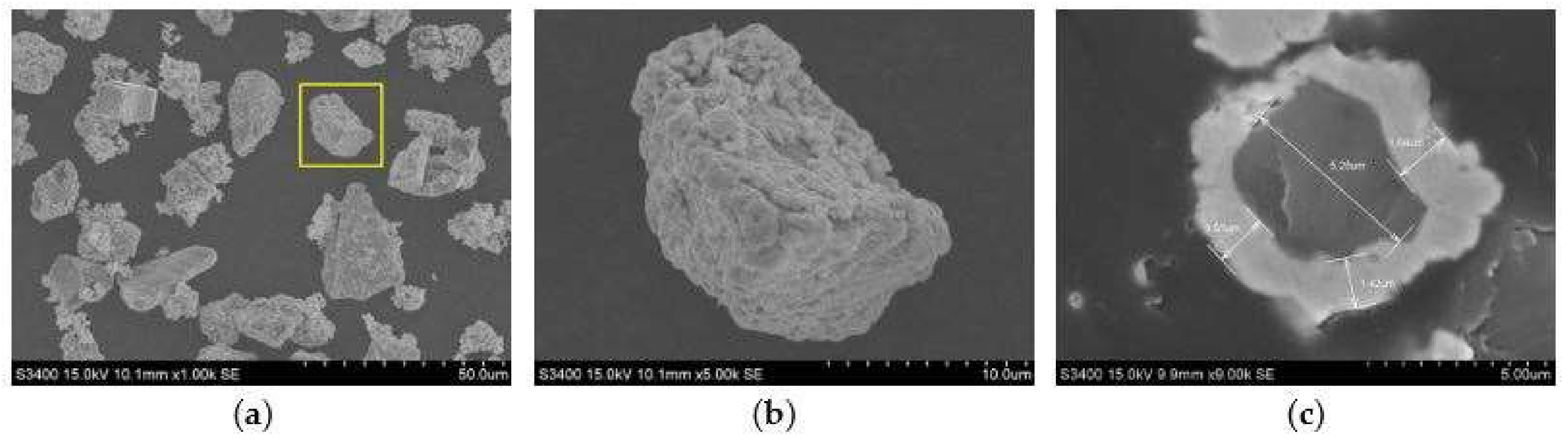

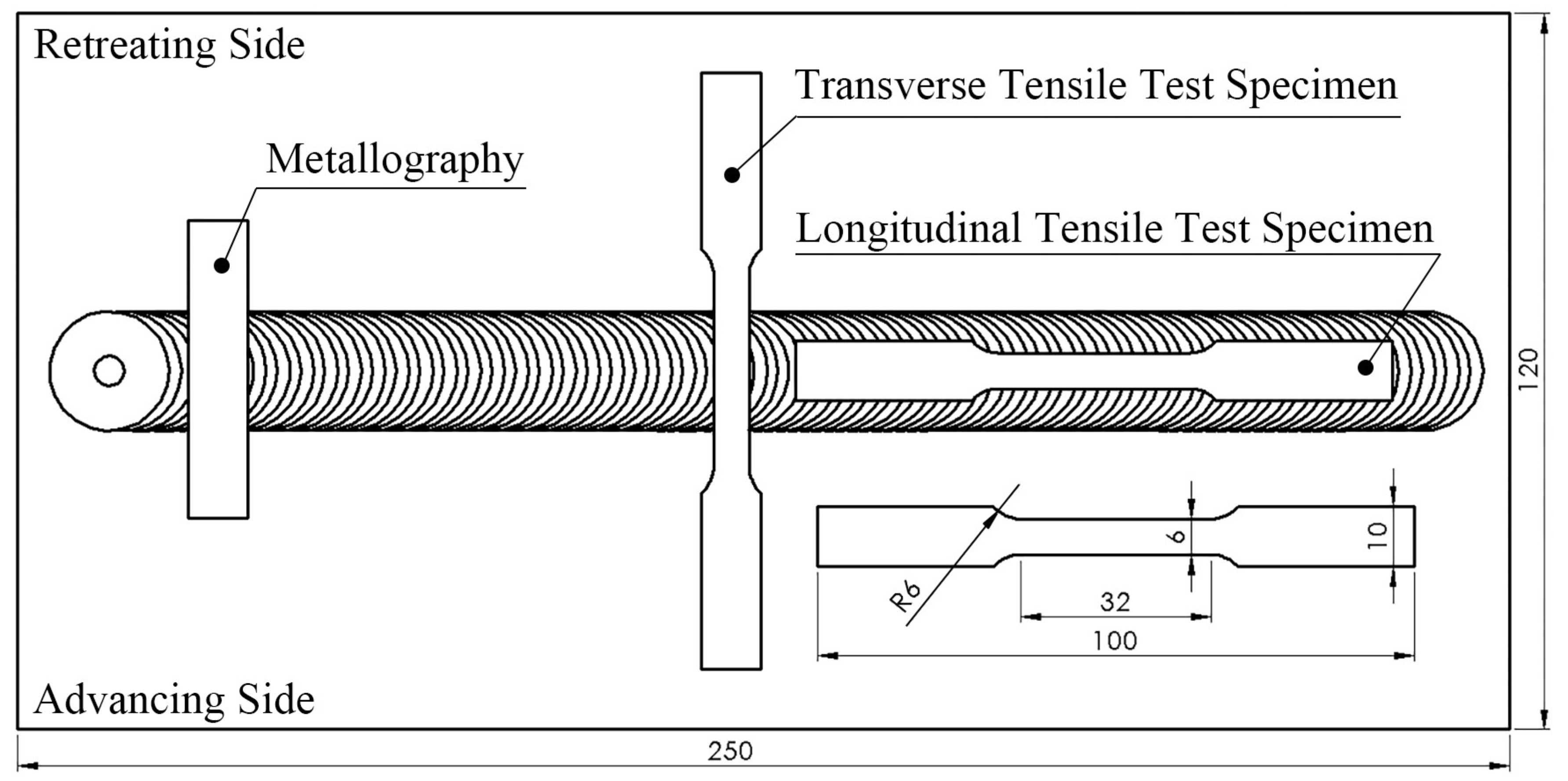

2. Materials and Methods

3. Results

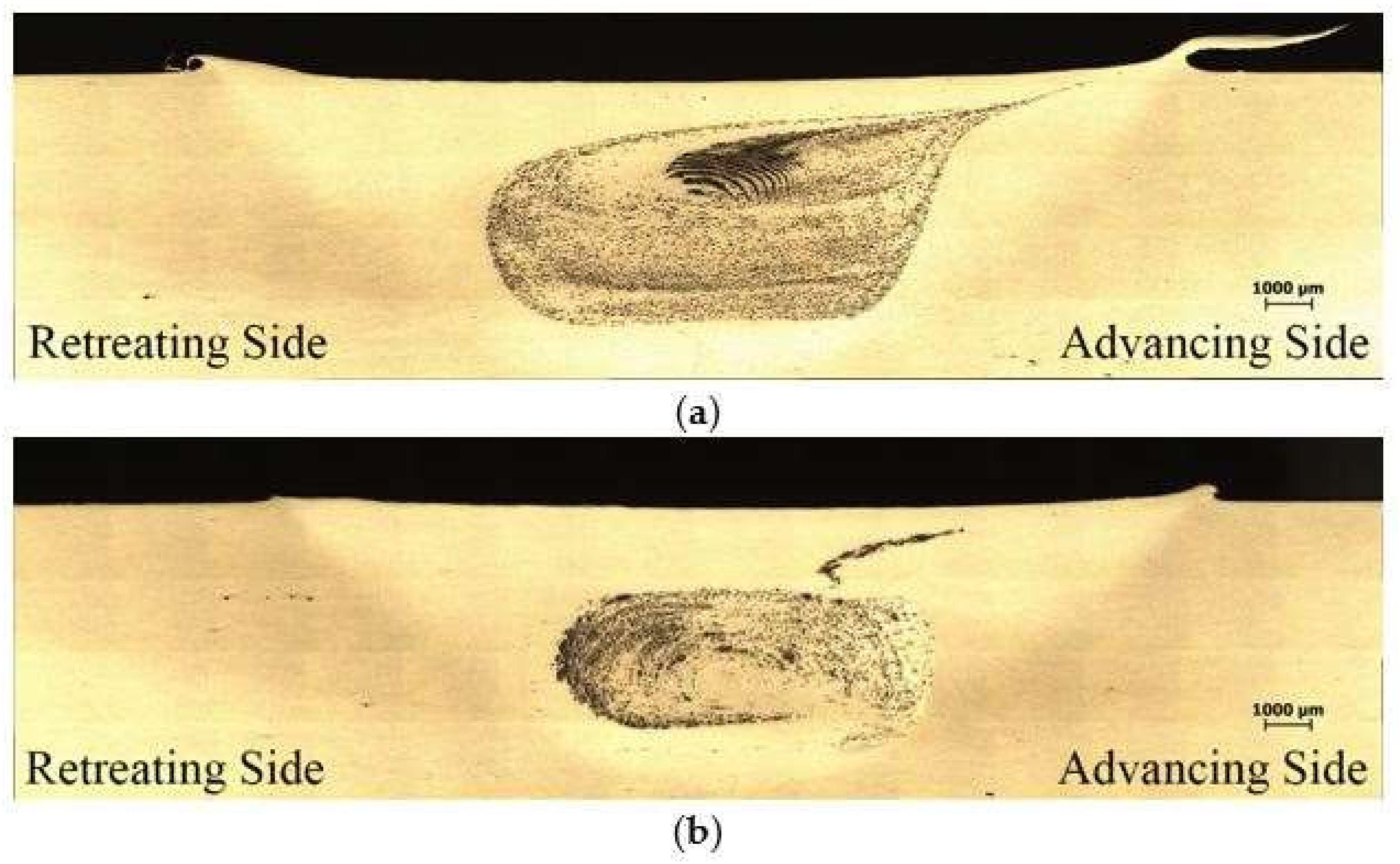

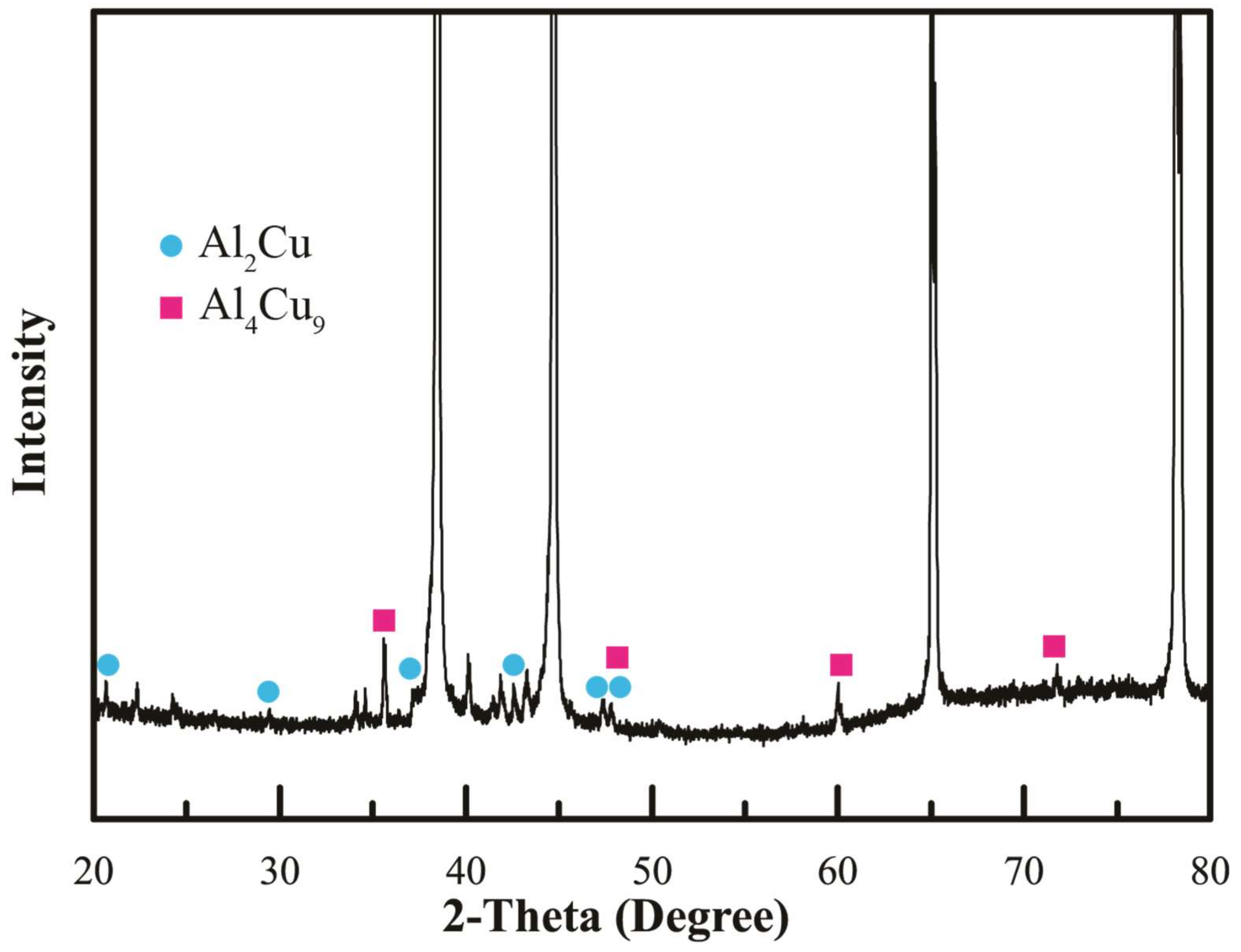

3.1. Microstructure and XRD Analysis

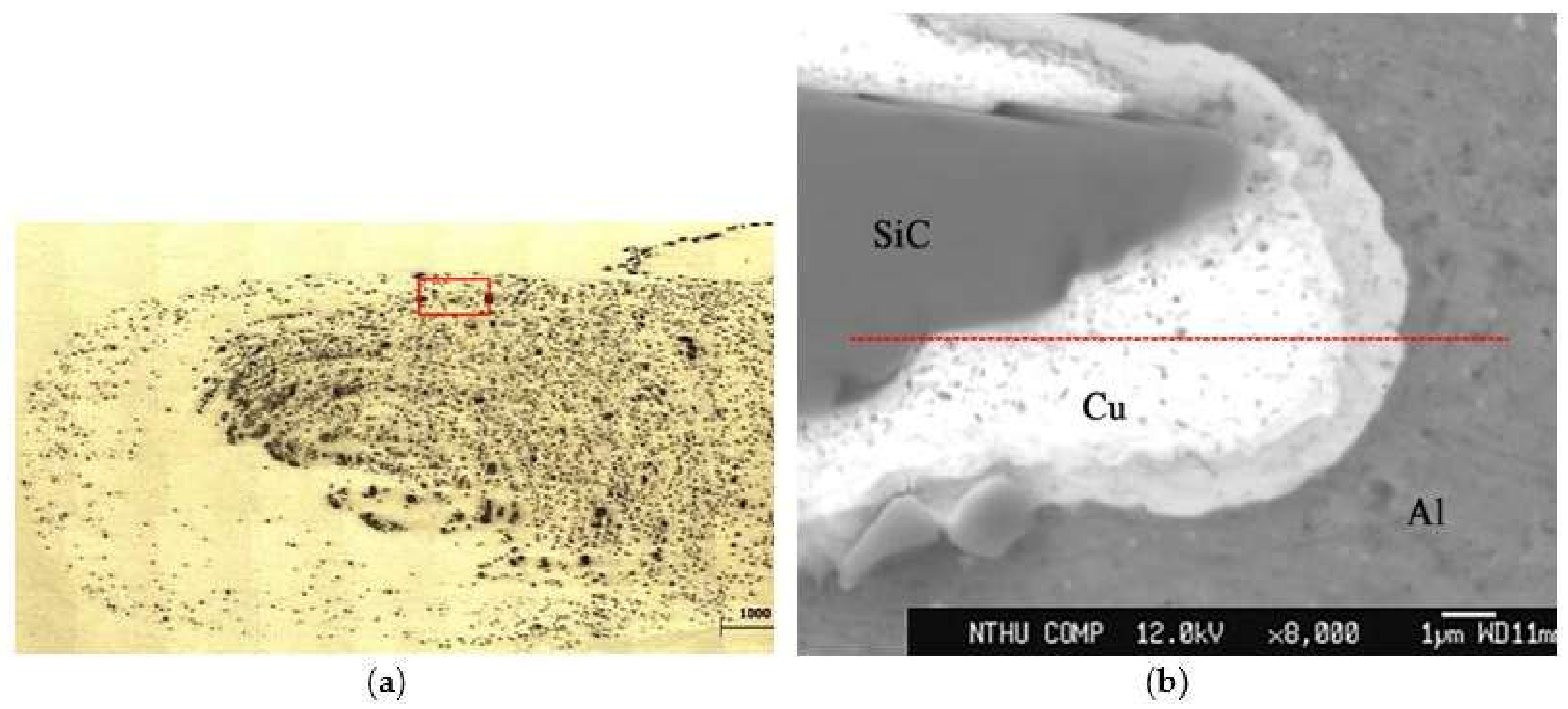

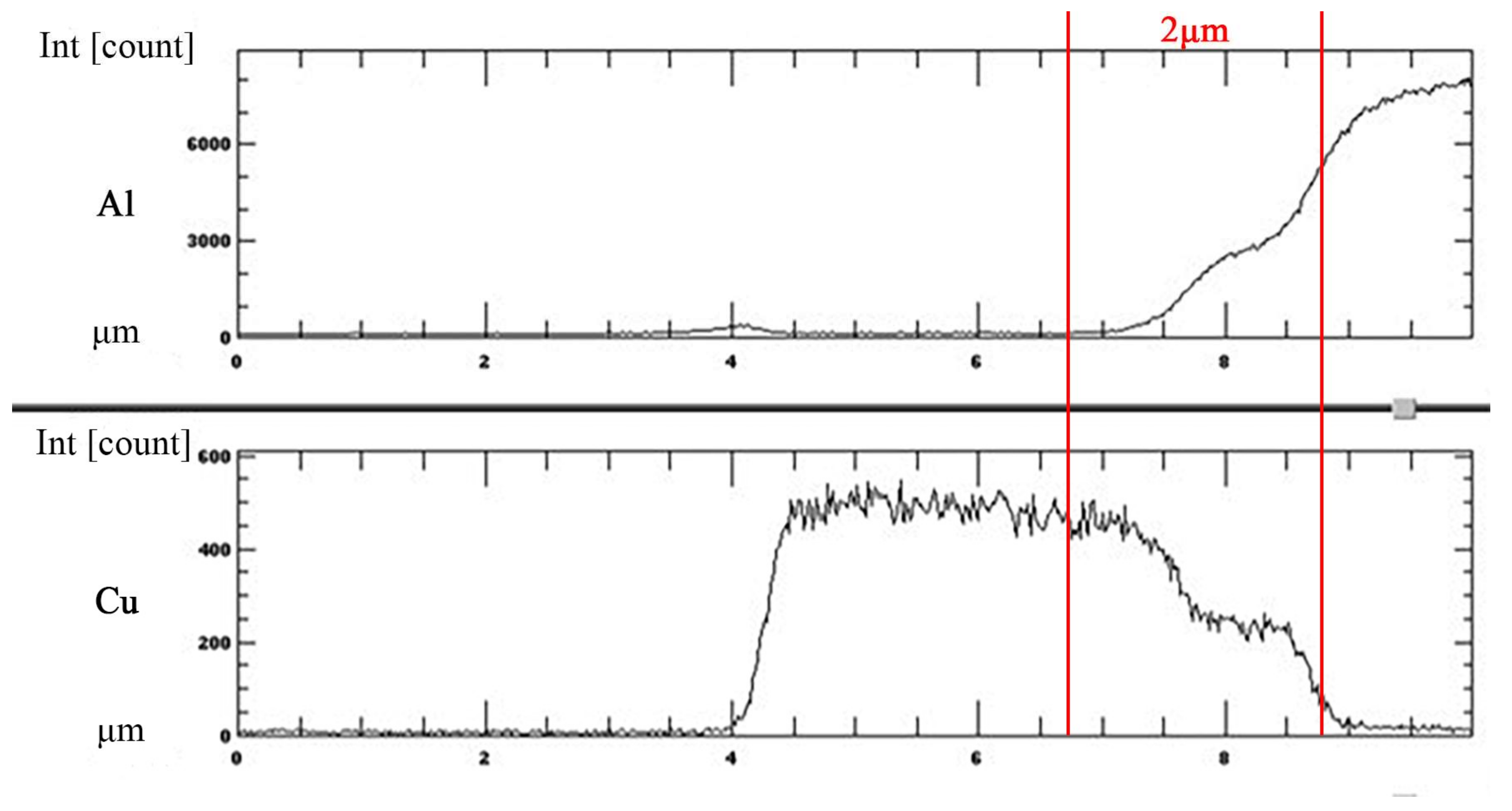

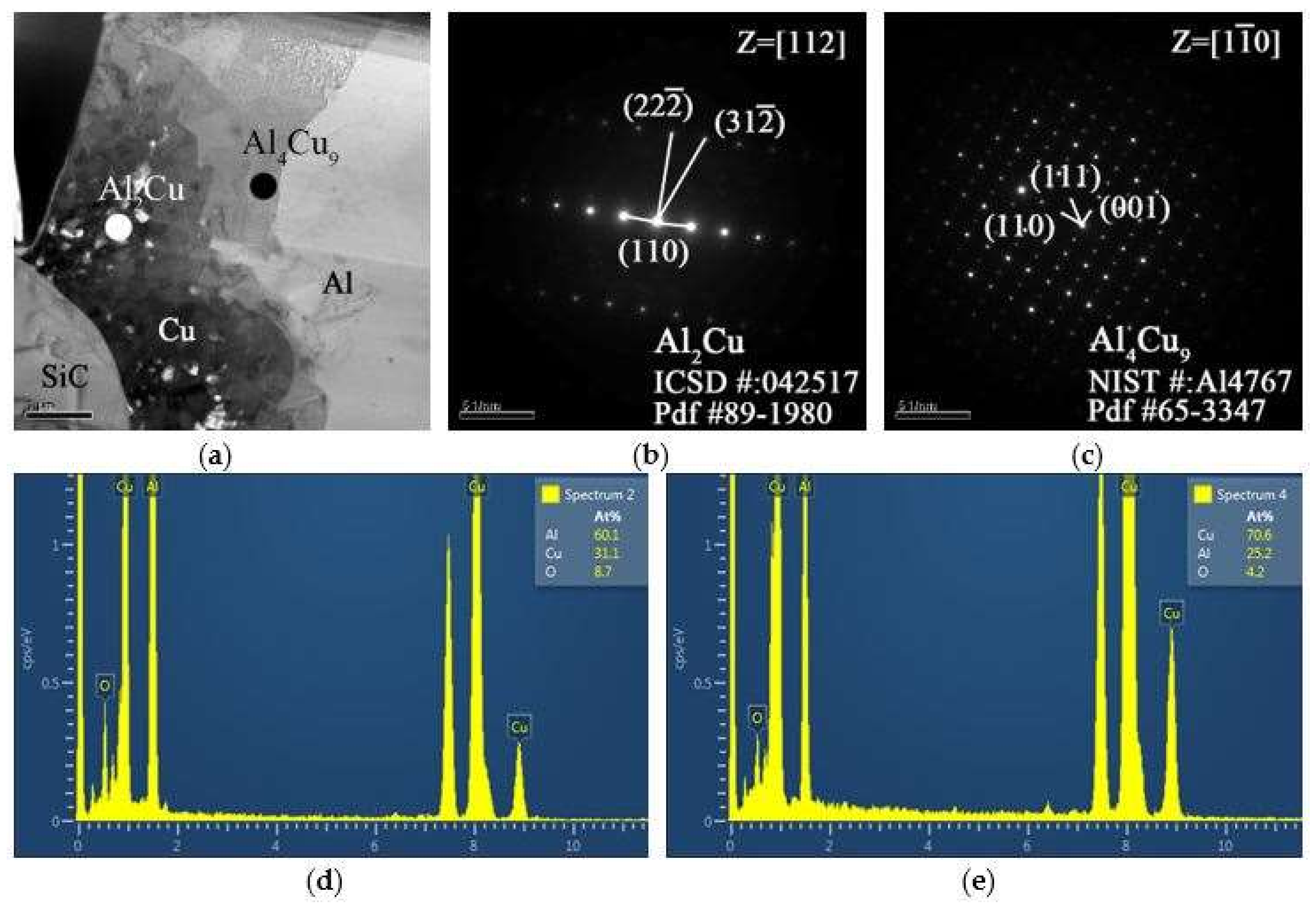

3.2. EPMA Analysis on Cu-Coated SiC Reinforcement in SZ

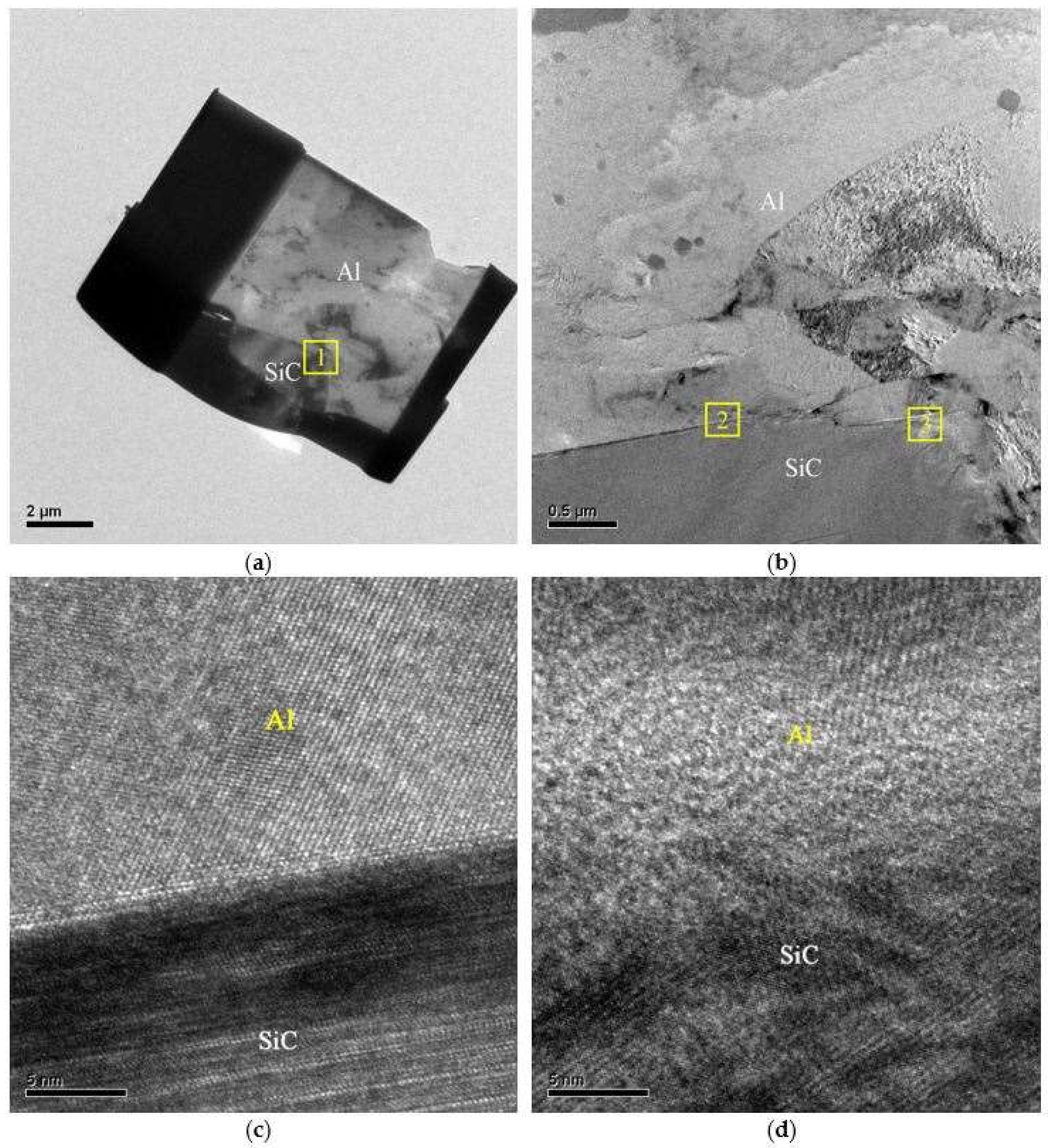

3.3. HRTEM Investigation on Interface between SiC Reinforcement and Al Matrix

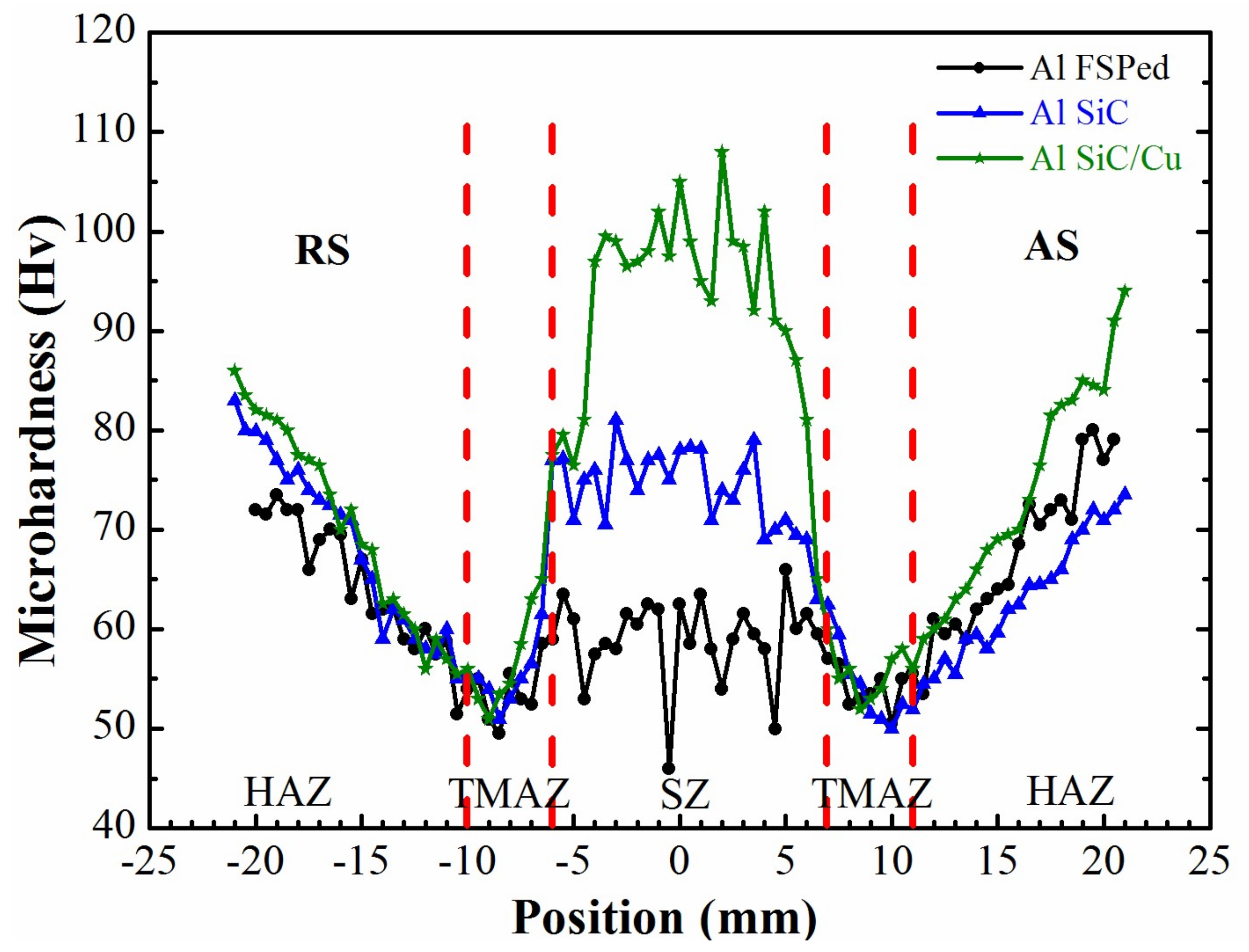

3.4. Hardness Test

- The intermediate inter-diffusion layer between Cu-coating and Al matrix provides better adhesion between the reinforced SiC particle and matrix.

- The very fine Cu debris, which is randomly distributed in the SZ provide a dispersive strengthening effect in impeding the plastic deformation.

- The diffusion of the copper atoms into the Al matrix rendered slightly elevated Cu content, which provides an additional solid solution strengthening effect.

3.5. Tensile Test

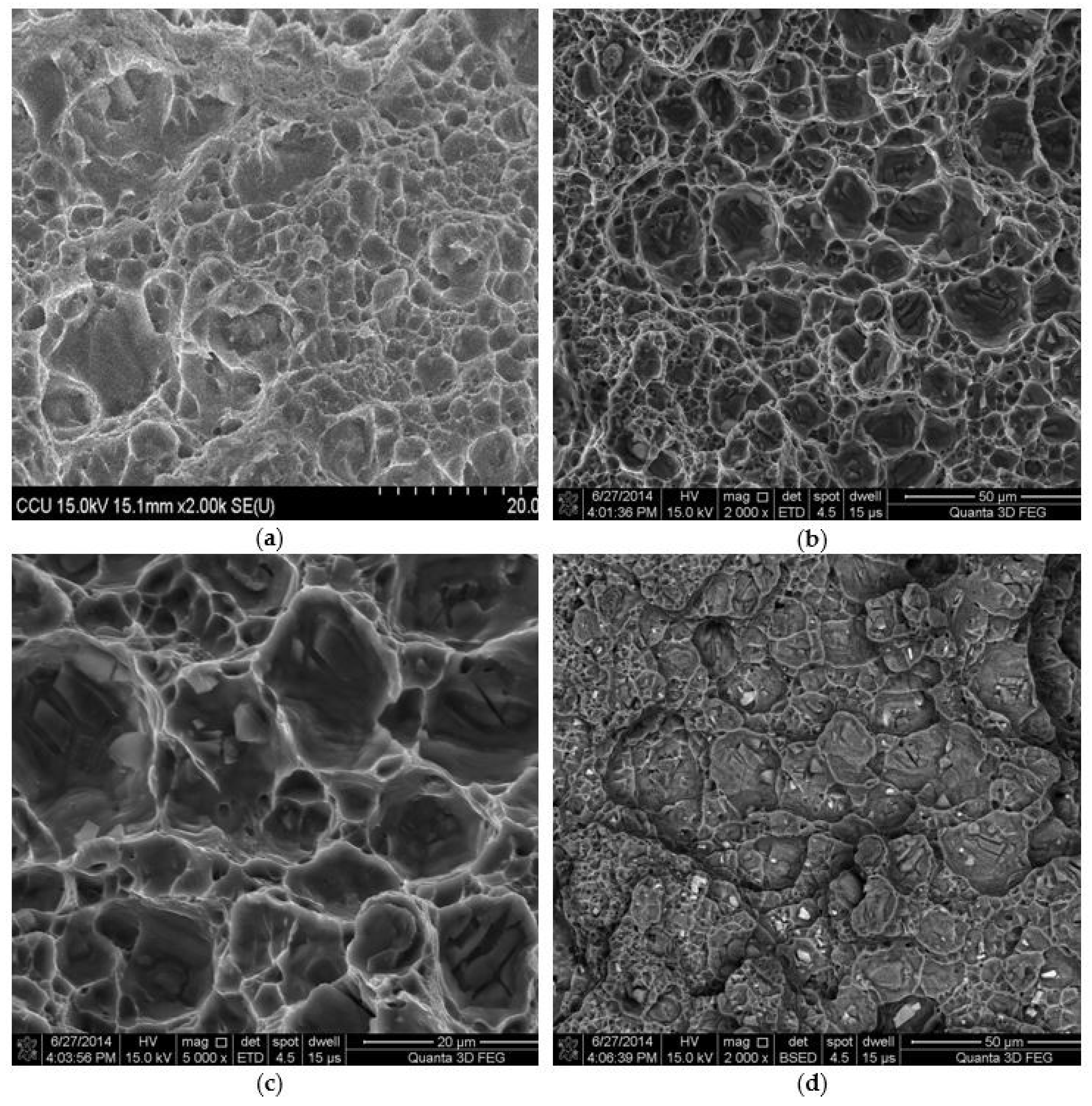

3.6. Fractography on Tensile Specimens

4. Conclusions

- The microstructure reveals a defect-free stir zone characterized by uniform distribution of SiC or Cu-coated SiC particulate reinforcement. Perfect cohesion between SiC particles and Al-matrix or between Cu-coated SiC particles and Al matrix has been achieved.

- During friction stir processing, the intermetallic compounds, such as Al2Cu and Al4Cu9, were in-situ formed at the inter-diffusion layer between the Cu layer around the SiC particles and the Al matrix. The formation of the IMCs may enhance the cohesion of the reinforced particles to the matrix and results in the effective improvement in micro-hardness and tensile strength.

- Peeling-off Cu-coating from the SiC particles during FSP could result in the dispersion of very fine Cu debris in the matrix and provide further dispersion strengthening and solid solution strengthening of Al6061.

- The concept that is realized in this work may open a new way of fabrication of particulate reinforced metal matrix composites.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rao, R.N.; Das, S. Effect of applied pressure on the tribological behaviour of SiCp reinforced AA2024 alloy. Tribol. Int. 2011, 44, 454–462. [Google Scholar] [CrossRef]

- Rao, R.N.; Das, S. Effect of sliding distance on the wear and friction behavior of as cast and heat-treated Al-SiCp composites. Mater. Des. 2011, 32, 3051–3058. [Google Scholar] [CrossRef]

- Rao, R.N.; Das, S. Effect of matrix alloy and influence of SiC particle on the sliding wear characteristics of aluminium alloy composites. Mater. Des. 2010, 31, 1200–1207. [Google Scholar] [CrossRef]

- Mousavi Abarghouie, S.M.R.; Seyed Reihani, S.M. Investigation of friction and wear behaviors of 2024 Al and 2024 Al/SiCp composite at elevated temperatures. J. Alloys Compd. 2010, 501, 326–332. [Google Scholar] [CrossRef]

- Rosso, M. Ceramic and metal matrix composites: Routes and properties. J. Mater. Process. Technol. 2006, 175, 364–375. [Google Scholar] [CrossRef]

- Chen, H.S.; Wang, W.X.; Nie, H.H.; Li, Y.L.; Wu, Q.C.; Zhang, P. Microstructure and dynamic compression properties of PM Al6061/B4C composite. Acta Metall. Sin. (Engl. Lett.) 2015, 28, 1214–1221. [Google Scholar] [CrossRef]

- Yigezu, B.S.; Jha, P.K.; Mahapatra, M.M. The key attributes of synthesizing ceramic particulate reinforced Al-based matrix composites through stir casting process: A review. Mater. Manuf. Process. 2013, 28, 969–979. [Google Scholar] [CrossRef]

- Kok, M. Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J. Mater. Process. Technol. 2005, 161, 381–387. [Google Scholar] [CrossRef]

- Rahimian, M.; Ehsani, N.; Parvin, N.; reza Baharvandi, H. The effect of particle size, sintering temperature and sintering time on the properties of Al-Al2O3 composites, made by powder metallurgy. J. Mater. Process. Technol. 2009, 209, 5387–5393. [Google Scholar] [CrossRef]

- Albiter, A.; León, C.A.; Drew, R.A.L.; Bedolla, E. Microstructure and heat-treatment response of Al-2024/TiC composites. Mater. Sci. Eng. A 2000, 289, 109–115. [Google Scholar] [CrossRef]

- Forcellese, A.; Simoncini, M.; Casalino, G. Influence of Process Parameters on the Vertical Forces Generated during Friction Stir Welding of AA6082-T6 and on the Mechanical Properties of the Joints. Metals 2017, 7, 350. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.; Mortello, M. Influence of shoulder geometry and coating of the tool on the friction stir welding of aluminium alloy plates. Procedia Eng. 2014, 69, 1541–1548. [Google Scholar] [CrossRef]

- Avettand-fènoël, M.; Simar, A. Materials Characterization Tutorial review A review about Friction Stir Welding of metal matrix composites. Mater. Charact. 2016, 120, 1–17. [Google Scholar] [CrossRef]

- Bahrami, M.; Dehghani, K.; Besharati Givi, M.K. A novel approach to develop aluminum matrix nano-composite employing friction stir welding technique. Mater. Des. 2014, 53, 217–225. [Google Scholar] [CrossRef]

- Bodaghi, M.; Dehghani, K. Friction stir welding of AA5052: The effects of SiC nano-particles addition. Int. J. Adv. Manuf. Technol. 2017, 88, 2651–2660. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G.; Casavola, C.; Moramarco, V. Analysis and comparison of friction stir welding and laser assisted friction stir welding of aluminum alloy. Materials 2013, 6, 5923–5941. [Google Scholar] [CrossRef] [PubMed]

- Davidson, A.M.; Regener, D. A comparison of aluminium-based metal-matrix composites reinforced with coated and uncoated particulate silicon carbide. Compos. Sci. Technol. 2000, 60, 865–869. [Google Scholar] [CrossRef]

- Moustafa, S.F.; Abdel-Hamid, Z.; Abd-Elhay, A.M. Copper matrix SiC and Al2O3 particulate composites by powder metallurgy technique. Mater. Lett. 2002, 53, 244–249. [Google Scholar] [CrossRef]

- Standard Test Methods for Tension Testing of Metallic Materials; ASTM E8/E8M-13; ASTM International: West Conshohocken, PA, USA, 2013.

- Abdollahi, S.H.; Karimzadeh, F.; Enayati, M.H. Development of surface composite based on Mg-Al-Ni system on AZ31 magnesium alloy and evaluation of formation mechanism. J. Alloys Compd. 2015, 623, 335–341. [Google Scholar] [CrossRef]

- Hsu, C.J.; Kao, P.W.; Ho, N.J. Ultrafine-grained Al-Al2 Cu composite produced in situ by friction stir processing. Scr. Mater. 2005, 53, 341–345. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. Enhanced mechanical properties of friction stir welded dissimilar Al-Cu joint by intermetallic compounds. Mater. Sci. Eng. A 2010, 527, 5723–5727. [Google Scholar] [CrossRef]

- Uzun, H. Friction stir welding of SiC particulate reinforced AA2124 aluminium alloy matrix composite. Mater. Des. 2007, 28, 1440–1446. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xiao, B.L.; Wang, W.G.; Ma, Z.Y. Developing high-performance aluminum matrix composites with directionally aligned carbon nanotubes by combining friction stir processing and subsequent rolling. Carbon 2013, 62, 35–42. [Google Scholar] [CrossRef]

- Sharma, V.; Prakash, U.; Kumar, B.V.M. Surface composites by friction stir processing: A review. J. Mater. Process. Technol. 2015, 224, 117–134. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kilmametov, A.R.; Ivanisenko, Y.; Gornakova, A.S.; Mazilkin, A.A.; Kriegel, M.J.; Fabrichnaya, O.B.; Baretzky, B.; Hahn, H. Phase Transformations in Ti-Fe Alloys Induced by High-Pressure Torsion. Adv. Eng. Mater. 2015, 17, 1835–1841. [Google Scholar] [CrossRef]

- Straumal, B.B.; Sauvage, X.; Baretzky, B.; Mazilkin, A.A.; Valiev, R.Z. Grain boundary films in Al-Zn alloys after high pressure torsion. Scr. Mater. 2014, 70, 59–62. [Google Scholar] [CrossRef]

- Barmouz, M.; Besharati Givi, M.K.; Seyfi, J. On the role of processing parameters in producing Cu/SiC metal matrix composites via friction stir processing: Investigating microstructure, microhardness, wear and tensile behavior. Mater. Charact. 2011, 62, 108–117. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enomoto, M.; Jogan, S. Microstructural evolution of 6063 aluminum during friction-stir welding. Metall. Mater. Trans. A 1999, 30, 2429–2437. [Google Scholar] [CrossRef]

- Hansen, N. Hall-petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Dolatkhah, A.; Golbabaei, P.; Besharati Givi, M.K.; Molaiekiya, F. Investigating effects of process parameters on microstructural and mechanical properties of Al5052/SiC metal matrix composite fabricated via friction stir processing. Mater. Des. 2012, 37, 458–464. [Google Scholar] [CrossRef]

- Zohoor, M.; Besharati Givi, M.K.; Salami, P. Effect of processing parameters on fabrication of Al-Mg/Cu composites via friction stir processing. Mater. Des. 2012, 39, 358–365. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Narendra, N.; Troxell, J.D. Tensile deformation and fracture behavior of an oxide dispersion strengthened copper alloy. Mater. Des. 2000, 21, 191–198. [Google Scholar] [CrossRef]

- Khorrami, M.S.; Kazeminezhad, M.; Kokabi, A.H. Mechanical properties of severely plastic deformed aluminum sheets joined by friction stir welding. Mater. Sci. Eng. A 2012, 543, 243–248. [Google Scholar] [CrossRef]

- Mohammadzadeh Jamalian, H.; Ramezani, H.; Ghobadi, H.; Ansari, M.; Yari, S.; Besharati Givi, M.K. Processing-structure-property correlation in nano-SiC-reinforced friction stir welded aluminum joints. J. Manuf. Process. 2016, 21, 180–189. [Google Scholar] [CrossRef]

- Lloyd, D.J. Particle reinforced aluminium and magnesium matrix composites. Int. Mater. Rev. 1994, 39, 1–23. [Google Scholar] [CrossRef]

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Al |

|---|---|---|---|---|---|---|---|

| Weight % | 0.478 | 0.800 | 0.284 | 0.148 | 0.968 | 0.277 | Balance |

| Base Material | UTS(MPa) | YS(MPa) | Elongation (%) |

|---|---|---|---|

| Al6061-T651 | 312 | 289 | 15.5 |

| Components | Concentration |

|---|---|

| CuSO4·5H2O | 0.03 mol/L |

| EDTA | 0.1 mol/L |

| 2,2′-bipyridyl | 5 × 10−4 mol/L |

| Potassium Ferrocyanide | 5 × 10−4 mol/L |

| Formaldehyde (35 wt %) | 13.5 mL/L |

| SiC particles | 2 g/L |

| HF | HCl | HNO3 | DI Water |

|---|---|---|---|

| 12 mL | 12 mL | 12 mL | 150 mL |

| Reinforcement Schemes of SZ | UTS (MPa) | (MPa) | (%) | Fracture Location |

|---|---|---|---|---|

| Al FSPed 1pass | 195 | 134 | 10.2 | TMAZ |

| Al-SiC 1pass | 199 | 134 | 8.9 | TMAZ |

| Al-SiC/Cu 1pass | 205 | 137 | 9.2 | TMAZ |

| Al FSPed 2pass | 192 | 123 | 10.7 | TMAZ |

| Al-SiC 2pass | 197 | 130 | 10.4 | TMAZ |

| Al-SiC/Cu 2pass | 243 | 175 | 9.6 | TMAZ |

| Reinforcement Schemes of SZ | UTS (MPa) | (MPa) | (%) |

|---|---|---|---|

| Al6061-T651 | 312 | 289 | 15.5 |

| Al FSPed 1pass | 246 | 128 | 35.5 |

| Al-SiC 1pass | 222 | 122 | 14.2 |

| Al-SiC/Cu 1pass | 235 | 126 | 18.4 |

| Al FSPed 2pass | 251 | 130 | 37.0 |

| Al-SiC 2pass | 240 | 125 | 24.7 |

| Al-SiC/Cu 2pass | 265 | 141 | 20.1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-W.; Aoh, J.-N. Friction Stir Processing of Copper-Coated SiC Particulate-Reinforced Aluminum Matrix Composite. Materials 2018, 11, 599. https://doi.org/10.3390/ma11040599

Huang C-W, Aoh J-N. Friction Stir Processing of Copper-Coated SiC Particulate-Reinforced Aluminum Matrix Composite. Materials. 2018; 11(4):599. https://doi.org/10.3390/ma11040599

Chicago/Turabian StyleHuang, Chih-Wei, and Jong-Ning Aoh. 2018. "Friction Stir Processing of Copper-Coated SiC Particulate-Reinforced Aluminum Matrix Composite" Materials 11, no. 4: 599. https://doi.org/10.3390/ma11040599

APA StyleHuang, C.-W., & Aoh, J.-N. (2018). Friction Stir Processing of Copper-Coated SiC Particulate-Reinforced Aluminum Matrix Composite. Materials, 11(4), 599. https://doi.org/10.3390/ma11040599